Page 1

Bench Mounted Lathe

RTI TECHNOLOGIES, INC.

Division of A’Gramkow

York, PA 17402

800-468-2321 (ext. 259)

Manual P/N 035-80470-00

Page 2

Table of Contents

I Introduction ........................................... 1

II Safety............................................... 2

III Checking out the Parts .................................. 3

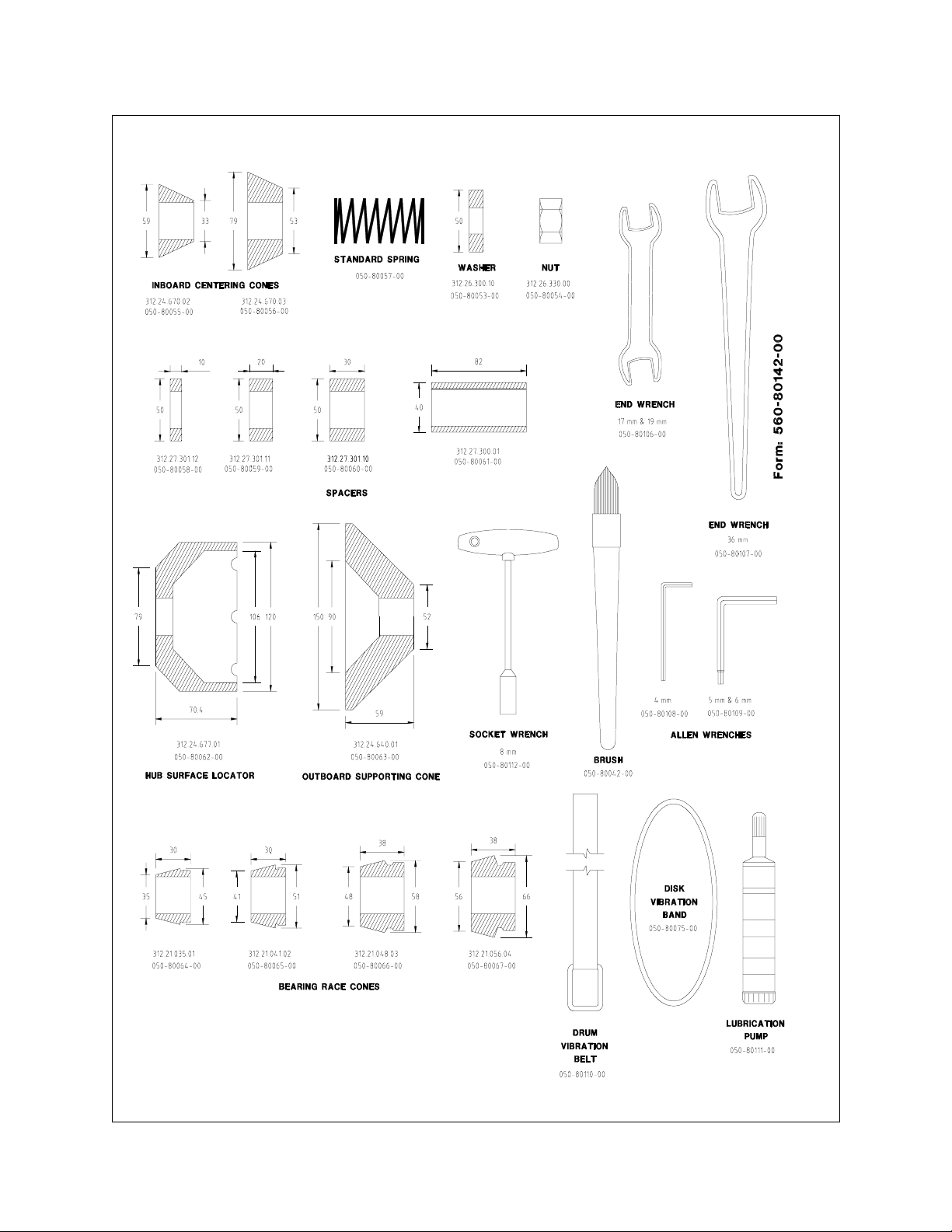

Figure 1 Standard Accessories .......................... 4

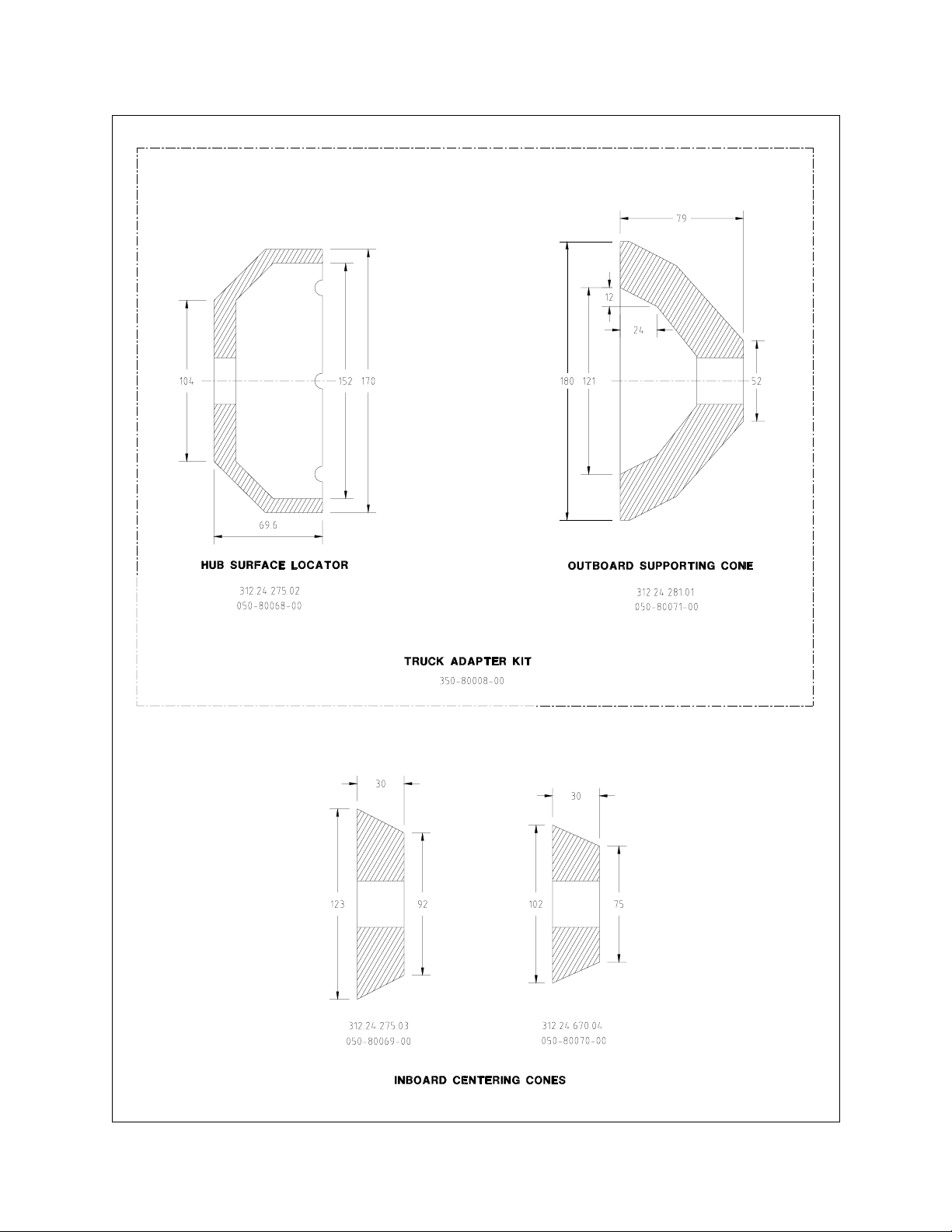

Figure 2 Optional Accessories .......................... 5

IV Initial Set-up .......................................... 6

Figure 3a Tip Holder and Cutting Tip Setup ................ 7

Figure 3b Mounting the Tool Holder ...................... 8

Figure 4 Drive Belt Position and Adjustment ................ 9

V Cutting Brake Rotors .................................. 10

Figure 5 Mounting a Hubless or Composite Rotor with

less than 6.95" inside hat diameter .............. 12

Figure 6 Mounting a Hubless or Composite Rotor with

Larger than 6.95" inside hat diamet er ............ 13

Figure 7 Mounting a Rotor with hub ..................... 14

VI Cutting Drums........................................ 15

VII Locking the Tool Slide ................................. 15

Figure 8 Mounting Hubless Drums ...................... 16

Figure 9 Mounting Drums with Hubs ..................... 17

Figure 10 Setup of Drum Cutting Tool ................... 18

Figure 11 Tool Slide Lock............................. 19

VIII Changing Spindle Speed ............................... 20

IX Adjusting Chain....................................... 20

X Changing Cutting Tips ................................. 20

XI General Maintenance .................................. 20

XII Technical Support ..................................... 20

Page 3

I. Introduction

Thank you for your purchase of a BRC500/550 brake lathe. Congratulations on your choice! The

BRC500/550 is designed to outperfor m every other com par able brake lathe in all respects.

The BRC550 is just like the BRC500 except that the BRC 550 comes with an exclusive RTI feature

that we call “offset step feed”. The offset step feed can be turne d on or off. When off, the BRC550

operates in the same way as the BRC500. When the offset step feed is on, the feed for the brake

disc cutting tools is turned on and off intermittently so as to create a non-directional finish

automatically. Non-directional finish is normal ly only an issue when cutting at high feed rates. The

BRC500 when set at low feed rates for a finish cut will produce a surface finish so good, that no

directional pattern is noticed.

The BRC500 was designed as a completely new product, with the new re quirements for brake disc

turning for moder n late m odel automobiles and lig ht truck s in m ind. T he BR C 500 is designed to

minimi ze run out. In fact “near zero” run out can be easily achieved. Minimizing brake disc run o ut

is an important aspect of modern brake service. Additionally, the BRC500 is designed to allow you

to produce a surface finish that is superior to that on most new rotors. The BRC500 can

consist ently produce bett er than 35 m icro inches where most ot her lathes can do no bet ter than

40 or 50 micro inches. This smoot h surface finish is required for fast br eak in and maximum

stopping power. Brake lathes designed in the past (even many that are sold today) cannot in most

cases match the results of the BRC500.

Another major design innovation with the BRC500 is the simplicit y of the set-up using a new

concept in adaptor and arbor design. You will note that t he BRC500 uses a special “hub surface

locator” along with a special high mass “outboard supporting cone” and a special 1 3/16" (30 mm)

“big arbor” . With this one basic standard set-up, composite and hubless rotors with a hat diameter

of less than 6.95 inches (176 mm) can be turned--this set-up and the big arbor with 40% more

strength than competitor’s arbors is one of the secrets to achieving near zero run out and a

superior finish. For larger rotors on HD trucks, a larger set of adaptors is required as an option--the

set-up being similar. For hub-type rot ors, a set of bear ing ra ce co nes are supplied as st andard.

Drums are set-up in a manner almost the sam e as with rotors. Chang eover t ime from dr ums to

rotors or from rot or s t o dr um s is less than one minute.

Running the BRC500 is simple. It can be set for one of two spindle speeds. In most cases you will

use the 110 RPM slow speed, but by making a fast belt change, the speed can be increased to 220

RPM to allow an extra superior finish on small passenger car rotors. The BRC500 can be used as

a “single pass-one cut” machine by selecting a feed rate setting of 2.5-3. This is the recommended

technique for drums. However, RTI recommends a “two pass” machining process for rotors, with

a setting of 5-6 f or a r ough “foundation” cut j ust deep enough to clean up the r ot or, and an extra

fine finish cut, with a depth of only 0.001-0.002" (0.025-0.05 mm) per side and a setting for the feed

of 1, taking f ull advantage of the special elect ronics and cutting tool design of the BRC500/550.

This two pass technique will not remove any more material than necessary, and even though it may

take a few minutes longer, it will result in a more perfect rotor in every respect.

The precision machined components of the BRC500/550 are produced by our affiliate, Hunger in

Germany, using the most modern and sophisticated machine tools in the world. For more than 30

years, Hunger has been the leading automotive brake lathe manufacturer in Germany. The

electrical controls are made in the USA, with f inal assembly of the electr ical control component s

and assembly/testing of the com plete lathe done by RTI in the USA.

Page 1

Page 4

II. Safety

Before we go to the next step, some reminders about safety

A. Avoid a major injury because of an unexpected start-up!

The BRC500 comes with a special mushroom type r ed “off/stop” switch. Be sure tha t

this switch is always pushed in when the lathe in not operating. This is particularly

important when mounting rotors or drums on the lathe or when changing the belt/s.

When pushed in, even if someone pushes the green “on/start” button, the lathe will not

start. The “off/stop” switch must be pulled out before the lathe can start.

B. Avoid a major injury from rotating machinery!

The BRC500 has a 1 HP spindle motor with a g reat deal of power and tor q ue. Do not

wear loose c lothi ng that could be entangled in the rotating par ts. Be sure that long hair

is properly secured so that it can not be entangl ed in the r otating parts. Do not place

any part of your body near the r otating part s of the B RC500 when in operation. Alw ays

be aware of the location of the red emergency stop switch so that the lathe can be

stopped immediately.

C. Protect your eyes!

Small metal chips will fly off from the rotor or drum during machining. Be sure to wear

your safety glasses at all times when the BRC500 i s in operation. Use the same safety

glasses that you are required to use when grinding metal.

D. Avoid possible electrical shock or unsafe operation!

Like any elec t rical appliance, nev er operate the BR C 500 when it is wet, or w hen y ou

are standing in water. Always unplug the BRC500 when servicing t h e electrical parts

of the BRC500. Be sure the receptacle for t he electrical plug is a three prong grounded

type, that it is the correct voltage for the BRC500/550 (110V, 60Hz in the North

America), that it is protected by a fuse or circui t breaker with the correct rating (15 Amp

maximum in North America), and that it is protected with a Ground Fault Interrupter

(GFI) dev ice. The BRC500/550 is protected by a fuse. Replace this fuse only with one

that is the same rated capacity.

E. Avoid all fire hazards!

The BRC500 is equipped with a special thermal overload device for your safety.

However, if for any reason the lathe spindle is jammed or locked up and stops

suddenly, be sure to turn the power off and unplug the l athe immediately, before fix ing

the cause of the problem.

Page 2

Page 5

III. Checking out the parts

A. The BRC500/550 lathe comes standard with:

Main lathe housing assembly

Foundation mounting bolts (Qty=4)

30 mm diameter Arbor with four Allen head cap scr ews

Standard Adaptors (See Figure 1)

Large open end wrench for Arbor nut

T-Handle wrench for square locking screws on cutting tip holders and bars

Small Allen Wr ench for locking belt pulley

Hand-held mini-lubrication pump for slideway nipples

15 mm (1/2") Positive Rake disc cutting tip holders (Qty=2, one right & one left )

Positive Rake Cutting Tips (Qty=10)

Drum cutter bar with Tip Holder

Vibration dampening rubber ring for discs

Vibration dampening belt for dr ums

Cleaning brush

B. The optional bench comes with:

Top Panel

End Panels (Qty=2)

Mid Panels (Qty=2)

Nuts and bolts for assembly

Assortment of studs f or st or age of accessories

C. The optional merchandising and lig ht kit comes with:

Uprights (Qty=2)

Peg type back board

Sign

Flourescent light

Chains for hanging light (Qty=2)

Nuts and bolts for assembly

D. The optional HD truck adaptor kit includes (See Figure 2):

Hub Surface Locator for rotors with inside hat diameter greater t han 6.95" (176 mm)

Outboard Supporting Cone to mat ch t he large Hub Surface Locator

The 3-5/8" to 4-7/8" ( 92- 123m m ) Inboard Centering Cone should be ordered separately.

Call RTI or your distributor for other accessories that are available.

Page 3

Page 6

Figure 1 Standard Accessories

Page 4

Page 7

Figure 2 Optional Accessories

Page 5

Page 8

IV. Initial Set-Up

A. Cleaning. The BRC500/550 is shipped with a rust preventative material on the unpainted

surfaces. Clean these surfaces, removing the rust preventative with a cleaning solvent. Do not use

a solvent that will dissolve the paint. Do not remove grease from the Feed Screws. After cleaning,

apply a light machine tool oil to lubricate the cleaned surfaces. You will need to move the tool slide

outward to its maximum extension and move it side to side with the two hand wheels. (Be sure the

black feed engagemen t k nobs in t he hand wheel hubs are pulled out.) Then, using the supplied

hand-held mini-lubrication pump, inject a small amount of oil in the slideway nipples. (This cleaning

and lubrication should be done periodically as part of normal ma int enance. )

B. Mounting. The BRC500/550 can be lifted using the eyebolt supplied, installed in the front of the

main lathe casting. (Caution, the tool slide should be as close to the main lathe housing as

possible. If not the unit may tend t o tip over when lifting or moving be for e it is mounted on t he

bench.) The BRC500/550 can be mounted to a heavy duty work bench. The (4) special bolts are

suppli ed with the lathe and are mounted through the bench to the bottom surface of the main lathe

casting. An optional heavy duty steel bench designed for t he BRC500/ 550 is available from RTI .

In addition, an optional merchandising kit, with a backboard and 46" flourescent light is also

available from RTI.

C. Installing the Arbor. T he precision arbor flange is mounted to the spindle flange using (4)

special Allen head cap screws. Be sure the arbor flange and t he spindle flange are clean. The

arbor flange mounting screws must be tightened securely to 30-35 lb-feet of torque in a cross

sequence using a 6 mm Allen W rench. A t orque wrenc h i s r ecommended. T he threads for the

arbor flange bolts are right hand and those on the end of the arbor are left hand, so you can use

the arbor nut to hold the arbor with the arbor nut wrench supplied when tightening ar bor flange

mounting screws. Clean the threads of the bolts and the spindle flange, then use blue Loctite on

the threads of the screws to insure they remain tight. They should be checked periodically as part

of normal maintenance. If t he cap screws are not tig ht, vibr a t i on an d a poor sur f ace f inish when

turning drums and r ot ors will result. O ne important aspect of the BRC500/550' s precision is the

correct torque of t he ar bor flange mounting screws.

D. Installing t he Cutting Tool Holders. The BRC500/550 comes with an extra str ong and rigid

cutting tool holder assembly. The cylindrical bar, with the flat machined por tion on top, is to be

inserted into one of the large cylinder bores of the cross slide. The inner bore, closest to the main

housing is for extra small rotors. The ou ter bore is for medium and large rotors. Use the outer bore

for most rotors. Clean all unpainted surfaces on t he bar, inside the bores, and on t he tool holder

arms as well as th e tip hol ders and tips to be installed, removing the rust preventative with a

cleaning solvent. Do not use a solvent that will dissolve t he paint on t he painted surfaces. After

cleaning, apply a light machine tool oil to lubricate the cleaned surfaces. After inserting the bar into

the bore so that the bar is approximately flush with the right side of the bore, and the tool holders

are horizontal or pointing slightly down, tight en the small square lock nuts using the T- Handle

wrench (See Figure 3a). Then, install the t ips on the tip holders with the screws provided. (With

positive rake tips, be s ure the tips are right side up and the back face is flat against the tip holder

machined back surface.) Then install the tip holders o n the tool holder arms, tightening the square

lock nuts with the T-Handle wrench. (See Figure 3b)T his set up is now alm ost ready for cutting

brake rotors/discs. The drum set up will be discussed later. Clean all other accessories, including

the drum cutting tool holder and apply a light oil.

E. Remove the black plastic transmission cover and position the belt on the slow speed (110 RPM)

setting. (See Figure 4) Re- inst all t he transmission cover.

Page 6

Page 9

Figure 3a Tip holder and cutting t ip set - up for rotors (positive rake)

Page 7

Page 10

Figure 3b Mounting the Tool Holder

Page 8

Page 11

Figure 4 Drive Belt position and adjustment .

Page 9

Page 12

V. Cutting Brake Rotors/Discs

A. Hubless Rotors. Figure 5 shows the most common adaptor set-up. Inst all the Hub Surface

Locator onto the arbor with the smallest diameter flat surface against the arbor flange. The largest

diamete r flat surface with the slots now simulates the flat surface of the hub of the vehicle. (Unlike

other lathes, on the BRC500/550, special care has been taken to grind both surfaces of the Hub

Surface Locator so that there is near zero run out of the larg e diam eter f lat surf ace. ) Now install

the Spring, Inboard Supporting Cone and brake rotor/disc as shown. The Inboard Supporting Cone

will be pushed toward the rotor by the spring and will keep the rotor centered. Install the Outboard

Supporting Cone and clamp the total assembly by installing spacers as needed and tightening the

left hand thread of t he arbor nut. Be sur e to spacers extend slightly past the arbor shoulder, use

the special washer, and do not over-tighten the nut. Figure 5 shows the set up using the standard

adaptors for brake rotors with an inside hat diameter less than 6.95" (176 mm). Figure 6 shows

the same set up using the optional HD truck adaptors for larger rotors. The standard adaptors can

be used for larger rotor s, but in some rare cases the opt ional adaptors are needed to minimize

vibration on extra large rotors with extra thin hat web sections.

B. Composite Rotors. One revolutionary aspect of the special adaptors designed for the

BRC500/550 is that these adaptors work very well for composite type rotors as well. No special

care or set up for composite rotors is required. The secret is the fact th at the rotor hat web section

is clamped tightly with full metal to metal contact between the Hub Surface Locator, rotors hat web,

and the Outboard Supporting Cone.

C. Vibration Dampening. The B RC500/550 comes with a Vibration Dampener rubber ring. This

should be installed onto the largest outside diameter of the rotor. Ther e are m any other types of

vibrat ion dampener types, including a device using two (2) rubbing blocks. On any rotor larger than

10" (255 mm) some type of vibration dampening devi c e is recommended to av oid ex cessive hi gh

pitched noise or vibration when machining the rotor.

D. Rotor and Hub Assembly. See Figure 7 f or the set up fo r ro tor s with the hub installed. Here

instead of clamping to the ro t or hat web section, the clamping is to the bearing races in the hub.

To insure that there is no abnormal run out, first be sure that the bearing races are in good

condition with no pitting and then after first tightening the arbor nut, loosen it very slightly and retighten.

E. Check Spindle/Arbor/Rotor Rot ation. Plug the power cord into a receptacle with the correct

power rating and safety features as descr ibed in t he Safety section of this manual.

Be sure all items are clear of the spindle/ arbor/rotor assembly, and be sure that t he black knobs

in the center of both

the green start button. Check for proper rotation. Stop the spindle/arbor/rotor’s rotation by pushing

the red mushroom stop switch.

F. Setting up for cutting. With the black knob inside the hand wheel pulled out, manually turn the

wheel, moving the cutting tool slide and th e cu tt in g tips t o a position almost t ouching the r otor’s

largest diameter. Note that there are two locking levers, one on the top of each cutting tool holder

along with a graduated adjusting knob to the left. By locking down one lever, with the other

loosened, turning the adjusting knob will move the tool holder with the lever loosened. Move each

tool holder so that the cutting tips are ve ry close, but not touching each side of the rotor--then move

the tool slide and cutting tips so that they are approx imately 1/4" (6 mm) inside the rotor’s largest

diameter braking surface.

hand wheels are pulled outward. The start the lathe momentarily by pushing

Page 10

Page 13

G. Initial surface cut. W ith the cutting tips appr oximately 1/4" (6 mm) in side th e rotor’s largest

diameter braking surface, with each tip close but not touching the rotor’s surfaces, start the lathe

by pushing the green start switch. With the rotor now rotating, by loc king down one lever of the two

tool holder locking levers, with the other loosened, turn the adjusting knob to move the tool holder

with the lever loosened until the cutting tip just “kisses” the rotor surface. This can be determined

by sound and sight. Lock down the lever and loosen the other tool holder lever, moving the cutting

tip with the adjusting knob similarly until the second cutting tip also just “kisses” the rotor surface.

Now, manually move the tool slide outward by turning the hand wheel very slowly . This will remove

any “ridge” on the outside edge of the rotor. (If the ridge is particularly large, this may require that

the cutting tips be moved outward and then inward with several passes. In this case, after removing

the ridge, stop the lathe rot at ion and r epeat the initial surface cut set up.)

H. Checking rotor surface. Once the in itial surface cut set-up is complete and the ridge is removed,

manually move the tool slide inward by turning the hand wheel very slowly. (If the depth of cut

increases significantly as the cutting tip moves inward, the rotor is warped or tapered. In this case,

stop and move the cutting tool outward away from the rotor surface to compensate.) When both

cuttings tips reach past the smallest diameter of the braking surfaces, stop the manual rotation of

the hand wheel. (Note that it is common for one cutting tip to reach this point before the other. As

long as one tip does not touch the rotor hat, continue until the manual rotation of the hand wheel

until both tools are inside the edge of the braking surfaces on both sides of the rotor. If one tip hits

the rotor hat b ef ore this is accom plished, it will be necessary to slide that cutting tip’s tip holder

back by loosening the two square locking nuts.)

I. Setting Depth of Cut and Speed. Note that the adjusting knob is calibrated with numbered “large”

graduations. These long lines denote 0.004" (0.10 mm) of tool holder and tip movement. The

shorter lines half way in b etween theref or e denote 0. 002" (0. 05 mm ). At this point , t he operator

has the choice of a “one pass” or a “multi- pass” t echnique. In order to per f orm a “one pass” cut ,

the operator must estimate t he depth of cut that will remove run out , taper, and grooves noted

during the rotor surface checked during manual hand wheel rotation, and to determine if that cut

will or will not res ult in the rotor being too thin (Less than manufacturer’s discard thickness.) Since

this is a complex procedure to estimate the exact depth, without cutting more than is needed and

wasting valuable rotor thickness, it is recommended that the a “multi-pass” technique be used. To

perform the first pass of a “multi-pass” technique, move each cutting tip inward 0.004" (0.10 mm)

or one large graduation by unlocking one lever, rotating the adjusting knob, locking that lever and

repeating the procedure for the other tool holder. (Note the total movement of the knob should be

0.008" (0.20 mm) after both tools are moved.) Now rotate the feed control knob to the setting of

“6 = Rough”, set the feed sele ction to “disc=out”, and push the black k nob in the center of the

handwheel inward. The tools will move outward rapidly while cutting. (For a “one-pass” technique

the depth set is as required and the feed control setting is “2-3=medium ”.) If this firs t “ rough cut”

does not cut the entire surface of the rotor and remove all grooves, then move the tool slide inwa rd

manually and repeat the procedure as required. Don’t forget to pull out and then push in the black

knob. Once there is a rough cut surface over the entire rotor surface and all grooves are removed,

now check to see if the rotor is too thin. If another at least another 0.008" (0.20 mm) could be

removed without the rotor being thinner than the discard thickness, then up to 0.004" (0.10 m m)

can be removed (0.002" = 0.05 mm each side) leaving some material for future wear of the rotor.

If so, move the tool slide inward manually and set each tool for a 0.002" (0.05 mm) “finish cut”. Set

the feed control at “1 = Fine”. (For the BRC550 also engage the Offset Step Feed.) This will result

in an extremely smooth surface finish.

Page 11

Page 14

Figure 5 Mounting a Hubless or Composite Rotor with less than 6.95" (176 mm) inside hat diamete r

Page 12

Page 15

Figure 6 Mounting a Hubless or Composite Rotor with larger than 6.95" (176 mm) insid e ha t dia mete r

Page 13

Page 16

Figure 7 Mounting a Brake Rotor with Hub

Page 14

Page 17

VI. Cutting Drums

A. Mounting. Mounting a brake drum on the arbor is similar to mounting a br ake rot or/disc. Se e

Figures 8 and 9. In order to have clearance for the drum, you will first need to loosen the (2) square

locking screws holding the rotor cutting tool holder assembly and either: 1) Remove the entire rotor

cutting tool holder assembly from the tool slide, or 2) Rotate the assembly 180 degrees so the tool

holders point away from the arbor and re-tig hten the locking scr ews. Rotating the assembly is

recommended and will give enough clearance for all but lar ger drums.

B. Install and Position Cutting T ool. Move the tool slide inward manually. Install t he drum cutting

tool bar in the slot of the tool slide. Position the bar so that the cutting tip extends toward the drum,

past the edge of the tool slide as necessar y to cut the ent ire drum surf ace. T hen lock t he bar in

place with the square locking screws. Normal operation is with the large drum cutting tool toward

the drum. (See Fig ur e 10 ) Fo r larg er drums, it may be necessary to reverse the posit ion of the

cutting tool bar, using one of the rotor cutting tool holders installed on the bar as shown.

C. Vibration Dampener. Install t he vibrat ion dam pening belt to minimize noise and vibration.

D. Setting Depth of Cut and Speed. Using the hand wheel on the right side of the lathe, move the

cutting tip inside the drum and position the cut ting tip 1/4" (6 mm) inside the lip of the drum.

Manually remove the rid ge and move the tool manually inward using the same general procedure

as with rotors/discs so as to establish the initial cutting position. The manual “feed” movement of

the cutting tool is with the side handwheel that moves the tool slide side to side. Depth of cut of the

cutting tool is set manually using the handwheel in the front of the lathe that moves the tool slide

in and out. The graduated hub on this handwheel will indicate the precision movement to set the

depth of cut. Once the depth of cut is set as desired, set the feed at “2-2.5=medium”. Set the feed

selector switch to “left to right” and push the black knob in the center of the side handwheel inward

so that the tool slide mov es to the right automatically. The same general procedures as to checking

for discard thick ness of a rotor/ disc apply to the discard diameter of a drum. T he same general

issues of “one-pass” and “multi-pass” cutting also apply. The major difference of operation is simply

that the au to feed for drums is from left to right instead of in to out and the depth of cut is set using

the outer handwheel.

VII. Locking the Tool Slide

In order to ensure the very best precision, the BRC500/550 has the provision to allow the operator

to lock the tool slide during cutting. (See Figure 11) This is more important for cutting rotors where

near zero run out is desired. Therefore the locking provision for the side to side movement of the

tool slide durin g rotor/disc machining is accomplished by tightening the black plastic knob. To lock

the in/out movement of the t ool slide when cutting drums, an Allen type wrench is required. The

tool slide locks push a small aluminum pad against the tool slide guide. D o not over tighten the lock

or the pad may be damaged. Be sure the tool slide lock is only engag ed during t he f inal cut and

is disengaged when the cut is complete!

Page 15

Page 18

Figure 8 Mounting Hubless Drums

Page 16

Page 19

Figure 9 Mounting Drums with Hubs

Page 17

Page 20

Figure 10 Set Up of Drum Cutting Tool

Page 18

Page 21

Figure 11 Tool Slide Lock

Page 19

Page 22

VIII. Changing Spindle Speed

All drum cutting and most rotor cutt ing should be done at 110 RPM or the slow speed setting as

shown in Figure 4. (This 110 RPM is faster than the slow and medium setting of most competitor’s

lathes.) For advanced level operation, cutting rotors with less than 10" (255 mm) the BRC500/550

is designed to allow for an extra fast 220 RPM fast setting. The faster speed will produce a better

surface finish, but tool life will be reduced. To change the belt position and spindle speed, first

loosen the Allen type l oc k sc rew on the pulley arm and then loosen and move the pulley arm stop

adjustment screw to the right. Chang e the belt position, tighten and m ove the pulley arm stop

adjustment screw to the left, locking the pulley arm by finally re-tightening the A llen type lock screw

on the pulley arm. Be sure both the narrow primary belt and the wider se condar y belts are both

tight and do not slip. There should be about 1/16 “ (1 mm) of movement in the belt when

approximately 10 pounds (5 Kg) of force is applied in the middl e of the belt. The belt should not be

too tight. This is evident if more than 20 pounds (10 Kg) of force is required t o deflect the belt or

chain 1/16" (1 mm)

IX. Adjusting Chain

The BRC500/550 uses a special roller chain for the final drive of t he spindle so that the full 1 HP

of the spindle motor can be used, with no vibration and no slippage. This chain may require

adjustment during the life of the lathe. The correct t ension will result in the chain deflecting from

at least 1/16" (1 mm) to a maximum of 1/4" (6 mm) when approximately 10 pounds (5 Kg) of force

is applied to the middle of the chain. Too much play may result in vibration and excess noise. To

adjust the chain, the top center pulley has an eccentric cam. To make the adjustment, the control

box must be removed to gain access to the lock nut for the eccentric cam. Re-check the t ension

of the middle belt.

X. Changing Cutting Tips

RTI’s Positive Rake Cutting Tips have three corners. There is a top and bottom. The tips will only

work when the top is up. When viewed from the side, the top is evident based on the fact that the

taper should from the top edge to the bottom with the top edge protruding more. The cutting tip

edge on each corner is worn and should b e changed when the surface finish no longer meets

requirements or when the corner is chipped or damaged. When one corner is worn, simply loosen

the tip, turn it 120 degress and r e- inst all ( See Figure 3).

XI. General Maintenance

There is no sug gested m aintenance to the BRC500/550 other than: 1) Keep the entire lathe,

especially the slideways, clean, removing cutting chips with the cleaning brus h supplied after each

use; 2) Clean and lube the slideways as noted in the Initial Set Up Section at least once per week;

3) Check belt and chain tension at least once per week; and 4) Lube the two feed screws and drive

chain with a moly based grease, as needed.

XII. Technical Support

For the life of the BRC500/ BRC550, you are entitled to free over the phone t echnical support.

Please call if you have any questions. Our number is 800-486-2321 or 717-840-0678 (Extension

259). If we are not immediately available due to extra heavy phone traffic, we will call you back the

same day . (8 AM to 6 PM ET). We look forward to speaking to you. We are happy to hear from our

customers.

Page 20

Loading...

Loading...