Page 1

OPERATION

MANUAL

RTI

BRC35

ON-THE CAR

BRAKE ROTOR LATHE

RTI

TECHNOLOGIES, INC.

4075 East Market Street

York, PA 17402

Manual P/N 035-80253-00

Page 2

BRAKE LATHE

BRC 35

CONGRATULATIONS... You have purchased one of the fin est lathes for on-the-car

machining of brake rotors available at any price.

GREAT RESULTS WITH THE BRC 35 ARE AHEAD...

l Fast to set up and simple to operate.

l Professional, high quality on-t he-car brake rotor turning with "total alignment"

every time.

l Uses two reference points - hub axis and caliper mount geom etry. Brake pads

will now be perfectly aligned with the rotor.

l Components have maxim um flexibility of assembly to allow custom ization for

individual preferences during setup.

l Integral, high strength storage container keeps accessory items in one

convenient location; no more hunting for tools.

l Mobile stand features a broad range of adjustment; turn rotors while the car sits

on floor jacks or on a hydraulic lift.

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 1

Page 3

CONTENTS

Warranty ...................................... Page 3

Lathe & Accessories ............................. Page 4

Drive Stand & Motor............................. Page 6

Main Features .................................. Page 8

Mounting the Lathe .............................. Page 10

Attaching the Drive Motor ........................ Page 12

Control Devices................................. Page 13

Turning a Rotor ................................. Page 14

Slideway Adjustment ............................ Page 17

Summary ...................................... Page 18

WARNING

The Wheel Connection Shaft is connected to the Motor Shaft

with a Universal Coupling.

The Collar provided on t he Connecting Shaft mu st be slid

over the Universal Coupling when not in use.

Serious injury may result if power is applied to the Motor

while the Wheel Connection Shaft is hanging loose.

Page 2

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 4

WARRANTY

Fill out and return the Warranty Card within 90 days to activate warranty and free lifetime

technical support.

WARRANTY... The BRC 35 is warranted to be free of defects in workmanship and

materials for a period of one year from date of purchase by original

purchaser.

If the product fails within this period, it will be repaired or replaced at

the manufacturer's option, provided (1) factory authorization has been

issued and (2) the product is submitted with proof of purchase.

Liability under this warranty is expressly limited to repairing or

replacing the product or parts thereof.

This warranty does not apply to product or parts broken due to accident,

overload, abuse, tampering, or alteration.

If this warranty does not apply, the retail purchaser shall pay all costs for

labor, material, and transportation.

FOR SERVICE OR TECHNICAL ASSISTANCE

800-468-2321 (Extension 259)

FAX 717-755-8304

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 3

Page 5

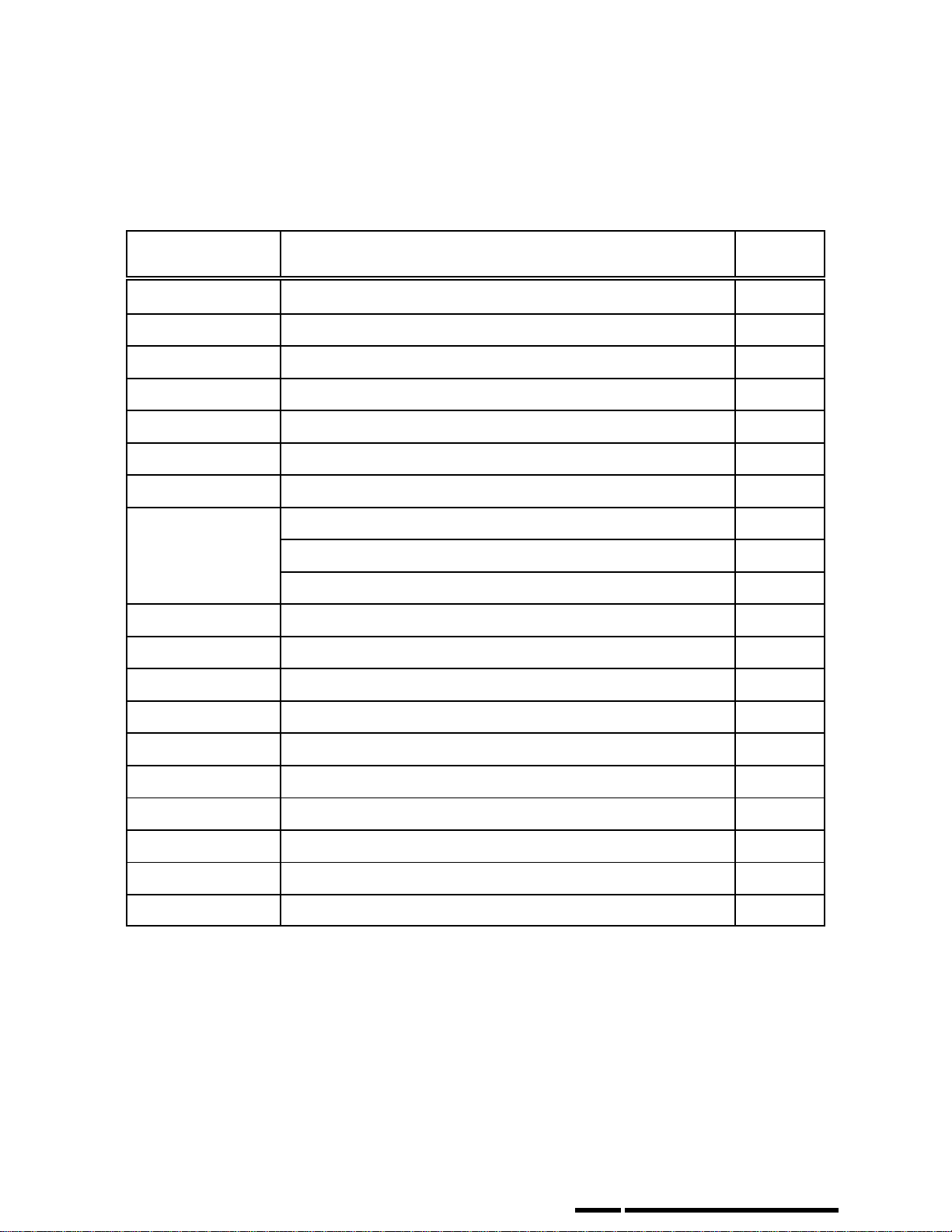

LATHE & ACCESSORIES

BRC 35

RTI

Part No.

080-80000-71 Bracket Twin Cylinder (80mm) 2

080-80000-04 Band Silencer 1

080-80000-05 Wrench Hex Key (6mm) 1

080-80000-06 Wrench Hex Key (8mm) 1

080-80000-07 Spacer Mounting 6

080-80000-08 Bar Threaded 2

080-80000-09 Hook “S” Shaped 2

Adapter Hollow (48mm lg.) 2

080-80000-10 Bolt 8mm x 1.25 (70mm lg.) 2

Bolt 10mm x 1.50 (70mm lg.) 2

080-80001-22 Bolt 10mm x 1.50 (90mm lg.) 2

080-80001-23 Bolt 10mm x 1.50 (80mm lg.) 2

080-80000-45 Threaded Adapter 03 (M10 x 1.25) 2

Description Qty

080-80000-46 Threaded Adapter 05 (M10 x 1.50) 2

080-80000-47 Threaded Adapter 09 (M12 x 1.50) 2

080-80000-48 Threaded Adapter 44 (M11 x 1.50) 2

080-80000-49 Threaded Adapter 48 (M9 x 1.25) 2

080-80000-79 Threaded Adapter 60 (M14 x 2.00) 2

080-80000-14 Cord 12 Volt Coiled 1

080-80000-02 Handle Lathe Carrying 1

Refer to next page for illustration of above components.

Page 4

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 6

LATHE & ACCESSORIES

BRC 35

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 5

Page 7

DRIVE STAND & MOTOR

BRC 35

RTI

Part No.

080-80000-83 Motor Gear Drive (Complete Assembly) Voltage: 110 or 220 VAC

110 volt unit has been tested and approved for 100 volt operation in

Japan

080-80002-00 Motor Mount 1

080-80002-01 Inner Column 1

080-80002-02 Outer Column 1

080-80003-03 Base 1

080-80003-01 Short Leg 2

080-80003-02 Long Leg 1

080-80000-21 Swivel Caster 3

080-80002-08 Locking Handle 1

080-80000-23 Accessory Box Support 1

080-80000-24 Bolt M6 x 1mm x 35mm Lg. 4

080-80000-25 Bolt M8 x 1.25mm x 60mm Lg. 3

Description Qty

1

080-80002-05 Bolt 2

080-80003-05 Bolt 1

080-80003-04 Bolt Allen Socket Head M10 x 1.50mm x 25mm Lg. 3

080-80003-06 Plastic Cap 3

080-80000-29 Washer M6 8

080-80000-30 Washer M8 6

080-80000-31 Washer M10 3

080-80000-32 Nut M6 x 1.00mm 4

080-80000-33 Nut M8 x 1.25mm 3

080-80002-07 Nut Square 6

Refer to next page for illustration of above components.

Page 6

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 8

DRIVE STAND & MOTOR

BRC 35

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 7

Page 9

MAIN FEATURES

BRC 35

Page 8

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 10

CAUTION

Check for any end-play in the wheel

bearing before mounting the BRC 35

Brake Lathe.

A loose wheel bearing may cause a poor

surface finish.

If bearing play is adjustable, tighten nuts

slightly before machining, and then readjust to factory specifications afterward.

If there is play in a non-adjustable bearing,

it should be replaced before machining the

rotor.

Most non-adjustable bearings are doublerow ball bearings that require pre-load.

Tapered roller bearings found on the front

of most rear wheel drive vehicles are

designed to operate with end-play.

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 9

Page 11

MOUNTING THE LATHE

1. Place automobile in NEUTRAL with

parking brake OFF and raise on lift.

Start on passenger side and remove

wheel nuts and wheel.

2. Place Spacers on wheel studs as

shown in Figure 1. Replace and

tighten nuts to manufacturer’s

specification using torque wrench.

3. Remove the brake caliper and hang

it out of the way using an S-Hook.

4. Remove all rust and dirt from the

brake caliper bolt area. Failure to

clean these surfaces will result in

unsatisfactory machining.

5. Select Threaded Adapters with

threads matching brake caliper

mounting bolts.

Insert and tighten Thr eaded Adapters

in the brake caliper bolt mounting

holes.

Some caliper mounting holes are not

threaded. In these cases, use Hollow

Adapters, Threaded Bars, and Bolts.

Refer to Figure 2.

Some caliper mountings m ay require

special adapters included in the

Deluxe Adapter Kit.

Figure 1 Mounting of Spacers & Wheel Nuts

Figure 2 Mounting of Threaded or Hollow Adapters

RTI

Page 10

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 12

MOUNTING THE LATHE

6. Place Twin Cylinder Mounting

Brackets on each of the Adapters

mounted in the preceding step.

Do not tighten the Allen Socket

Bolts in the Mounting Brackets.

7. Hang the Lathe on the lower

Twin Cylinder Mounting B racket

as shown in Figure 3.

Figure 3 Hang the Lathe

8. Swing the Lathe upwards and

insert the top Twin Cylinder

Mounting Bracket onto the Lathe

mounting bracket. See Figure 4.

9. Position the Lathe so that the

Lathe centerlin e is slig htly below

the center of the wheel hub and

the brake rotor is centered

between the side plates of the

Lathe. Refer to Figure 5.

10. Tighten Allen Socket Bolts in

both Twin Cylinder Mounting

Brackets.

Figure 4 Mounting the Lathe

Figure 5 Positioning the Lathe

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 11

Page 13

ATTACHING THE DRIVE MOTOR

1. Attach the Wheel Drive Brackets,

with Spacers, to the two vacant

wheel studs as shown in Figure 6.

Leave the wheel nuts slightly

loose.

2. Slide the sleeve on the connecting

shaft of the Drive Motor away

from the universal coupling so

the shaft is free to articulate.

3. Position the Drive Motor Stand

and connect the Wheel Drive

Brackets to the end of the Drive

Motor Shaft.

4. Tighten the wheel nuts so the

Wheel Drive Bracket s are on th e

centerline of the wheel hub.

Figure 6 Mounting the Wheel Drive Brackets

5. Carefully adjust the Drive Motor

Stand so the shaft aligns with the

axis of rotation of the wheel.

Refer to Figure 7 for proper setup

and alignment.

6. Set the locks on the Drive Motor

Stand casters. Check that

adjusting handles on the stand are

tight.

7. Slide the vinyl cover over the

Wheel Drive Brackets.

This cover must remain in

place during operation of the

Wheel Drive Motor.

8. Connect the coiled Power Cable

between the Wheel Drive Motor

and the Lathe.

Figure 7 Aligning the Wheel Drive Motor

RTI

Page 12

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 14

CONTROL DEVICES

FEED DIRECTION SWITCH

Direction of travel of the cutting tools is

controlled by a 3-position switch on the

Lathe Control Panel. Pressing the top

activates INFEED (towards the center of

the rotor) and pressing the bottom

activates OUTFEED (away from the

center of the rotor). Between these

positions is the OFF position.

INFEED STOP

This switch stops travel of the cutting

tools when moving towards the center of

the rotor during automatic operation.

POWER ON LIGHT

This light will be on when the lathe is

feeding in or out (Feed Direction Swit ch

pressed for INFEED or OUTFEED). Th e

brightness will vary depending on the

setting of the Feed Rate Switch (1 is

dim, 9 is brightest).

Figure 8 Lathe Controls

The light will be OFF if the Infeed Stop

is pushed in all the way.

EMERGENCY STOP

The Emergency Stop Button stops the

Drive Motor and Lathe. Turn and pull

(See arrows on knob) to reset. Some

switches do not require turning.

FEED RATE SWITCH

Rate of travel (feed) of the cutting tools

is controlled by the variable Feed Rate

Switch on the Drive Motor Control

Panel (1 is slow, 9 is fast).

DRIVE MOTOR SWITCH

The Drive Motor turns the rotor

clockwise or counter-clockwise in one of

two speeds (1 is slow, 2 is fast). This 5position switch is located on the Drive

Motor Control Panel. The middle

position is OFF.

Figure 9 Drive Motor Controls

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 13

Page 15

TURNING A ROTOR

1) Mount the Lathe and attach the

Drive Motor per the instructions

in the preceding section.

The Silencer Band can be

mounted around the outer edge of

the rotor to reduce noise during

machining if desired. This must

be done before mounting the

Lathe.

2) Set the Feed Direction Switch on

the Lathe Control to OFF (middle

position).

3) Set the Drive Motor Switch on

the Drive Motor Control to OFF

(Marked “0").

4) Check that the coiled Power

Cable is connected between the

Drive Motor and the Lathe.

5) Check that the Emergency Stop

Button is reset to ON (if n ot , turn

and release to reset).

6) Plug the power cord on the Drive

Motor into a 120 vac supply.

7) Turn the Drive Motor Switch

clockwise to number 1. The rotor

should be turning in the direction

shown in Figure 11.

If not, turn the Drive Motor

Switch counter-clockwise to

number 1.

8) Press the Safety Lock and move

the AUTO/MAN Shift to

MANUAL.

9) Using the Hand Wheel, move the

cutting tool tips to about ½ in.

inward from the outer edge of the

Rotor.

Figure 10 Lathe Controls

Figure 11 Direction of Rotor Rotation

TURNING A ROTOR

RTI

Page 14

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 16

10) Use the Cut Depth Micrometer to

move both cutting tool tips towards

the rotor until they just touch the

rotor surface.

11) Turn the hand wheel to manually feed

the cutting tools outward toward the

edge of the rotor to remove any rust

build-up on the outer edge.

12) Manually feed the cutting tools

inward towards the center o f the rotor

to a point slightly bey ond t he contact

surface of the brake pads. Use care as

the depth of cut may vary due to

runout in the surface of the rotor.

13) Push the Auto Infeed Stop button all

the way in. Twisting the knob while

pushing inward makes this step

easier. This sets the point where the

cutting tools will stop during

automatic feed towards the center of

the rotor in the following steps.

Figure 12 Lathe Controls

14) Press the Safety Lock and move the

AUTO/MAN Shift to AUTO.

15) Turn both Cut Depth Micro-meters

clockwise one large division to move

the cutting tool tips into the faces of

the rotor by 0.004 in. Figure 13

illustrates that 0.004 in. is the

distance between two numbers on the

micrometer.

16) Turn the Feed Rate Switch on the

Drive Motor Control to 9 (fast feed).

17) Press the top (OUTFEED) of the

Feed Direction Switch on the lathe.

The lathe cutting tools will

automatically feed outward, making

a rough cut on the rotor.

Figure 13 Cut Depth Micrometer

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 15

Page 17

TURNING A ROTOR

18) When the cutting tools have moved

outward beyond the edge of the rotor,

press the bottom (OUTFEED) of the

Feed Direction Switch on the lathe to

place the switch in the OFF position.

19) Momen tarily turn off the Drive Motor

and check the surface of the rotor. It

should have a rough cut surface across

the entire face on both sides. If not,

make another rough cut, otherwise

proceed to the next step for a finish

cut.

20) Turn both Cut Depth Micro-meters

clockwise one small division to move

the cutting tool tips towards the face

of the rotor by 0.002 in. Figure 14

illustrates that 0.002 in. is the distance

between two of the closest marks.

21) Turn the Feed Rate Switch on the

Drive Motor Control to 2 (slow feed).

22) Press the top (INFEED) of the Feed

Direction Switch on the lathe. The

lathe cutting tools will automatically

feed inward making a finish cut on the

rotor. The cutting tools will

automatically stop at the setting

determined in Step 13 by setting the

Auto Infeed Stop button.

Figure 14 Cut Depth Micrometer

When a satisfactory surface finish has been obtained, press the

Safety Lock and move the AUTO/MAN Shift to MANUAL.

Back the cutting tool tips away from the rotor by turning the Cut

Depth Micrometers counter-clockwise.

Use the handwheel to back the cutting tools to a position bey ond the

outer edge of the rotor.

Remove the Lathe and repeat the operation on the other side of the

vehicle.

One rough cut and one finish cut are

normally sufficie nt for most applications. If

not, repeat rough and/or finish cuts as

required.

Page 16

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 18

SLIDEWAY ADJUSTMENT

Figure 15 Slideway Adjustment

Periodically check the “snugness” of the Tool Holders in the Slideways. When fully extended from the Lathe, there

should be no movement of the Tool Holders when pulled up or pushed down. Unsatisfactory surface fin ish on rotors

is often an indication that the Slideways need adjustment.

Carefully study Figure 15 to understand the dynamics of adjusting the tension of the Slideways on the Tool Holders.

1) Loosen the eight smaller “B” screws by approximately 1/16 turn.

2) Loosen the four larger “A” screws by approximately 1/16 turn.

3) Tighten the eight “B” s crews evenly to obtain the “snug” feel of the Tool Holders. Check the operation and

feel by manually moving the Tool Holders in and out with the handwheel.

4) Tighten the four “A” screws to lock the setting of the slideways.

NOTE: Only the screws in the Top Plate are adjusted. Do not loosen screws in the Bottom Plate

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Page 17

Page 19

SUMMARY

The BRC 35 will provide many years of dependable brake rotor machining

with proper care and use.

This manual describes basic operating procedures for quick and easy use of the

BRC 35.

As with any fine piece of machinery, experienced operators will quickly

discover new and more versatile me thods of operation.

The BRC 35 can be set up in various configurations for optimum access to

control devices and tool adjustments. No one wa y is necessarily the be st for all

vehicles.

Cutting tool heads can easily be removed and re-mounted for reverse cutting

applications.

The BRC 35 operates up-side-down just as well as right-side-up. Just

remember to set the cutting tools slightly below the centerline of the hub so the

rotor turns downward to the cutting tips.

Adaption to special vehicles may require special accessories.

Page 18

RTI

RTI

RTIRTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.TECHNOLOGIES, INC.

Loading...

Loading...