Page 1

OPERATION MANUAL

BFX-2V

Brake Fluid Exchanger

IMPORTANT

Test drive vehicle after service to verify proper

brake system performance.

RTI Technologies, Inc.

10 Innovation Drive

York, Pennsylvania 17402 USA

Phone: 800-468-2321

Web-site: www.rtitech.com

035-81260-00

Page 2

Table of Contents

Safety Precautions .............................. 1

Components ................................... 2

System Priming ................................ 3

Exchange Brake Fluid ........................... 4

Displays Indicating Action Required ................. 7

Empty Used Fluid Tank .......................... 8

Filter Maintenance .............................. 8

Parts Identification .............................. 9

Flow Diagram & Electrical Schematic............... 10

EC Declaration of Conformity for Machinery ......... 11

Safety Precautions

WARNING: Failure to follow these precautions can result in serious injury or death.

• Read and understand the Operation Manual completely before operating this unit.

• Always wear proper eye and skin protection when operating and maintaining this

equipment.

• Only disassemble or reassemble unit parts when directed by an RTI representative.

• Clean any spills that may occur immediately. Brake fluid is corrosive and is a high slip

hazard.

• Avoid exposure with painted surfaces. Brake fluid is corrosive and will damage the

finish on most painted surfaces. Use of fender covers is recommended.

• Always use vehicle specified brake fluid. Failure to do so may cause brake system damage. The

BFX is designed to use DOT 3 or 4 brake fluid. Use of any other fluid type is not recommended

and may void warranty.

• Comply with local, state and federal regulations for fluid disposal.

• Material Safety Data Sheets (MSDS) must be obtained on all chemicals and placed in a shop

file for reference. Note: MSDS can be found on the RTI web site www.rtitech.com.

• It is important to test drive every vehicle after the service to verify proper brake system

operation. Failure to do so could result in undetected brake system failure.

CAUTION: Failure to follow the precautions as outlined in the Operation Manual can result in

damage to the engine, vehicle or equipment which will not be supported or covered

under warranty.

Page 1

Page 3

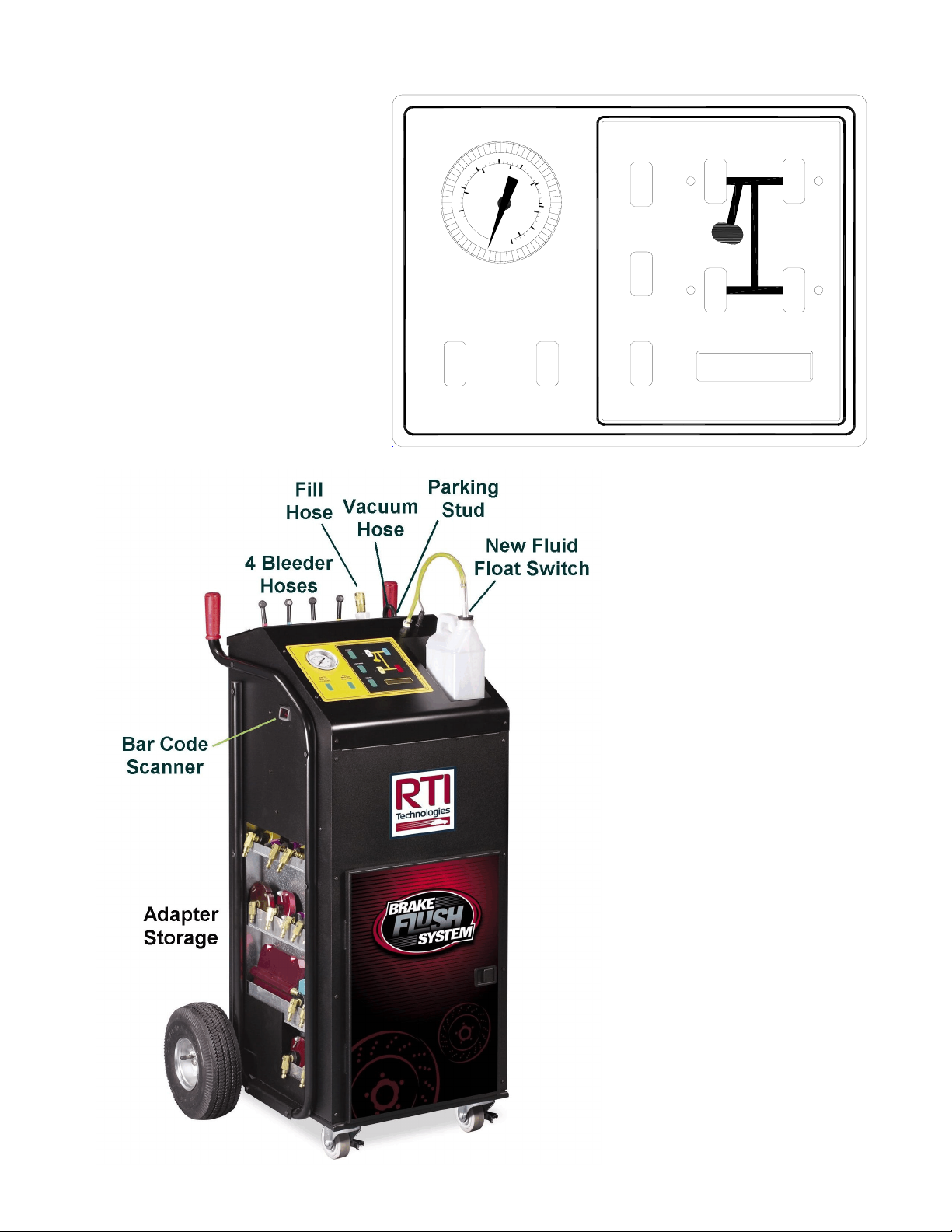

Components

FLUSH

LF RF

CONTINUE

EMPTY

MASTER

CYLINDER

FILL

MASTER

CYLINDER

RRLR

PAUSE

560-80379-00

Page 2

Page 4

System Priming (First Time Use Only)

Note: System Priming is only necessary before the first time use of the BFX.

Connect red (positive) clamp on power cable to red (positive) terminal on vehicle battery. Connect

the black (negative) clamp to a good ground. A good ground can be located by following the negative

cable from the battery to where it is connected to the chassis.

Warning: Handle battery connection cable with extreme caution. Batteries generate

explosive gases during normal operation. Working in the vicinity of a lead-acid or

other automotive battery is dangerous. Wear eye protection. Never smoke or allow

a spark or flame in the vicinity of the battery. Do not connect the black power clip

to the negative post of the battery to avoid a spark.

RT I TECHNOLOG I ES

BFX - 2V

NEW TANK =# # OZ

SELECT PROCESS

NEW TANK EMPTY

SCAN NEW BOTT LE

³ This will display for five seconds.

Buzzer will beep once. All LED’s will blink on

briefly.

³ This will display.

Connect Fill Gun to Fill Hose.

Disconnect coupler on Used Fluid Tank and

remove cap.

Press FILL MASTER CYLINDER.

Buzzer will beep three times.

³ This will display.

Swipe bar code on new bottle of Valvoline

Brake Fluid. Each bottle can only be scanned

once (the BFX records the bar code number

and will prevent a second scan). Buzzer will

beep once when valid bar code is read by

scanner.

INSTALL BOTTLE

PRESS >CONT I NUE<

³ This will display.

Install New Fluid Float Switch in bottle of brake

fluid.

Press CONTINUE.

Page 3

Page 5

REMAINING =## OZ

FILLING MC

³ This will display.

Place nozzle of Fill Gun into the Used Fluid

tank and squeeze trigger.

Remaining ounces will be displayed and when

zero will stop the process.

Press FILL MASTER CYLINDER to stop the

process.

Release trigger. Replace cap on Used Fluid

Tank and connect coupler.

NEW TANK =# # OZ

SELECT PROCESS

³ This will display.

Exchange Brake Fluid

BEFORE SERVICE: Verify that the brake system does not have any malfunctions. If the system is

found to be malfunctioning verify that the malfunction will not interfere with the

exchange process. Perform all necessary repairs prior to fluid exchange.

Connect red (positive) clamp on power cable to red (positive) terminal on vehicle battery. Connect

the black (negative) clamp to a good ground. A good ground can be located by following the negative

cable from the battery to where it is connected to the chassis.

Warning: Handle battery connection cable with extreme caution. Batteries generate

explosive gases during normal operation. Working in the vicinity of a lead-acid or

other automotive battery is dangerous. Wear eye protection. Never smoke or allow

a spark or flame in the vicinity of the battery. Do not connect the black power clip

to the negative post of the battery to avoid a spark.

RT I TECHNOLOG I ES

BFX - 2V

³ This will display for five seconds.

Buzzer will beep once. All LED’s will blink on

briefly.

Page 4

Page 6

NEW TANK =# # OZ

SELECT PROCESS

³ This will display.

Press EMPTY MASTER CYLINDER.

NEW TANK =# # OZ

EMPT Y I NG MC

NEW TANK =# # OZ

SELECT PROCESS

NEW TANK EMPTY

SCAN NEW BOTT LE

³ This will display.

Use Vacuum Hose to remove all fluid from the

master cylinder.

Press EMPTY MASTER CYLINDER to end the

process.

IMPORTANT: Place end of Vacuum Hose on

Parking Stud before proceeding to next step.

³ This will display.

Connect Fill Gun to Fill Hose.

Press FILL MASTER CYLINDER.

Buzzer will beep three times.

³ This will display.

Swipe bar code on new bottle of Valvoline

Brake Fluid. Each bottle can only be scanned

once (the BFX records the bar code number

and will prevent a second scan). Buzzer will

beep once when valid bar code is read by

scanner.

INSTALL BOTTLE

PRESS >CONT I NUE<

REMAINING =## OZ

FILLING MC

³ This will display.

Install New Fluid Float Switch in bottle of brake

fluid.

Press CONTINUE.

³ This will display.

Place nozzle of Fill Gun into the Master

Cylinder and squeeze trigger. Remaining

ounces will be displayed.

Release trigger when master cylinder is filled to

proper level.

Press FILL MASTER CYLINDER to stop the

process.

Hold Fill Gun over Master Cylinder and

squeeze trigger to relieve pressure.

Replace Master Cylinder cap and disconnect

Fill Gun.

Page 5

Page 7

NEW TANK =# # OZ

SELECT PROCESS

³ This will display.

Select correct Master Cylinder Adapter and

install on the Master Cylinder.

Connect Fill Hose to Master Cylinder Adapter.

Press Fill Master Cylinder and check that

adapter is sealed and there are no leaks.

Press Fill Master Cylinder to stop the process.

Raise vehicle to comfortable level to access

the brake bleeder valves. Use caution to not

disconnect power cable from battery or put

strain on the Fill Hose connected to the Master

Cylinder.

Connect a Bleeder Hose to each brake bleeder

valve. Match colors on Bleeder Hoses to the

control panel graphic.

Press FLUSH.

ENTER SEQUENCE

XX - XX - XX - XX

OPEN BLEEDERS

PRESS >CONT I NUE<

REMAINING =## OZ

BLEED I NG XX

³ This will display.

Press LF, RF, LR and RR in sequence desired

during the sequential brake fluid exchange.

The order pressed should be according to the

recommended sequence as specified by the

manufacturer for the particular vehicle.

The order entered will be displayed.

Press CONTINUE.

³ This will display.

Open all bleeder valves.

Press CONTINUE.

³ This will display.

This display will show each bleeder as fluid is

exchanged.

PRESS >CONT I NUE<

CLOSE BLEEDERS

³ This will display.

Buzzer will beep every 20 seconds to indicate

procedure is complete.

Press CONTINUE and then close bleeders.

Page 6

Page 8

PRESS >FLUSH<

WHEN F I N I SHED

³ This will display.

When all bleeders have been closed press

FLUSH.

CLEAR I NG PROCESS

RUNN I NG , WA I T

NEW TANK =# # OZ

SELECT PROCESS

Displays Indicating Action Required

USED TANK FUL L

MUST BE EMPT I ED

³ This will display.

When the clearing process is complete the

next screen will be displayed.

³ This will display.

Remove Master Cylinder Adapter and check

fluid level.

Press EMPTY MASTER CYLINDER to remove

fluid if required.

Pour in fluid from new fluid bottle if required.

³ This will display if the tank which holds used

fluid fills to capacity.

Refer to instructions for emptying the Used

Fluid Tank on the next page.

NEW TANK EMPTY

SCAN NEW BOTT LE

³ This will display if the level of fluid is too low

in the bottle of new fluid.

A new bottle must be scanned and connected.

Page 7

Page 9

Empty Used Fluid Tank

1. Disconnect the fluid line coupler and the electrical float switch cable on the Used Fluid Tank.

2. Remove cap on Used Fluid Tank (turn counterclockwise).

3. Empty used fluid into an appropriate bulk waste container.

4. Replace cap on Used Fluid Tank (turn clockwise).

5. Connect fluid line coupler and the electrical float switch cable.

Follow all federal and local laws and regulations when disposing of hazardous material.

Filter Maintenance

The BFX-2V has six filters to prevent debris from entering internal components.

New Fluid Filter: Filters fluid from the New Fluid Bottle. If the

fluid flow seems slow while trying to fill the

master cylinder - check and clean this filter.

This filter can be accessed through the front

door on the top of the BFX-2V. Remove

screws and gently raise the door to access

the filter.

Unscrew the filter cover and clean the

screen as required.

Vacuum Filter: Filters fluid in the five vacuum hoses. A filter

is mounted in-line on each of the hoses. If

the fluid flow seems slow from the bleeders check and clean these filters.

These filters can be accessed through the

rear door on the top of the BFX-2V. Remove

the two thumb screws and lift the door. The

filters will be seen about 12 inches below

where the hoses go through the panel

inside. Remove hoses from both ends of the

filter and try clearing the filter with

compressed air.

New Fluid Filter

Hose

Vacuum Filter

560-80379-00

Page 8

Page 10

Parts Identification

16

1

EMPTY

FILL

MASTER

MASTER

CYLINDER

CYLINDER

2

CONTINUE

3

FLUSH

LF RF

RRLR

PAUSE

5

6

14

7

560-80379-00

X 4

X 4

13

12

4

5

8

9

10

11

Part Number Description

1 024-80106-00 Keypad Overlay

2 024-80107-00 Circuit Board

17

18

3 325-80048-00 Pressure Gauge Assy

4 325-80002-00 Wand Assembly

5 025-80361-00 Manifold 4 Valve 12 VDC 1/4FPT

20

6 325-80057-00 Pressure Switch 14-17 psi SPST

7 325-80029-00 Supply Pump (with terminals)

8 325-80034-00 Vacuum Pump (with terminals)

X 4

9 325-80044-00 Solenoid S5 Assembly

10 026-80389-00 Sight Glass FPT (Nylon)

19

11 325-80042-00 Flow Sensor Assy (with terminals)

12 026-80325-00 Filter Inline 1/4 Barb 150 Micron

13 022-80133-00 Check Valve 3/16 Barb Nylon

14 023-80344-00 Adapter Brake Nipple x 3/16 Barb

15 024-80099-00 Float Switch Assy for New Bottle

16 025-80364-00 EMI Filter 16A

17 026-80372-00 Filter Inline 3/16 Barb 150 Micron

560-80379-00

18 320-80005-00 Cord Power 14/2 Clamps 12 ft

19 325-80004-00 Used Tank Assembly

20 025-80370-00 Barcode Scanner

Page 9

Page 11

Flow Diagram & Electrical Schematic

USED

FLUID

BLU

WHT

RED

YEL

FILTER

FILTER

FILTER

FILTER

FILTER

PRESSURE

PRESSURE

FIXED

ORIFICE

SWITCH

(17 PSI)

PS1

S5

S1

S2

FLOW

S3

INLINE

FILTER

SENSOR

M1

GAUGE

(0-30PSI)

NEW

FLUID

S4

M2

USED BRAKE

FLUID

TANK

FS1

NEW BRAKE

FS2

FLUID

TANK

FS1

FS2

PS1

FLOW SENSOR

BARCODE SCANNER

M1

M2

S1

S2

S3

S4

S5

NEW FLUID PUMP

USED FLUID PUMP

SOLENOID S1

SOLENOID S2

SOLENOID S3

SOLENOID S4

SOLENOID S5

570-80312-00

DATE: 10-27-05

Page 10

Page 12

EC Declaration of Conformity for Machinery

Herewith declares that:

- BFX-2V Brake Fluid Exchanger

- is in conformity with the provisions of the Machinery Directive (directive 98/37/EC) and with

the national implementing legislation

Directive 98/37/EC

RTI Technologies, Inc.

10 Innovation Drive

York, Pennsylvania 17402 USA

Phone: 717-840-0678

- is in conformity with the provisions of the following other EC directives:

Electromagnetic Compatibility (EMC) Directive 89/336/EEC

Electromagnetic Emissions EN 61000-6-4: 2001

Electromagnetic Immunity EN 61000-6-2: 1999

The BFX-2V is certified to the EMC Directive like the ATX-2 tested by:

TÜV America Inc.

1775 Old Highway 8 NW Ste. #104

New Brighton, MN 55112

Phone: 651-638-0262

Thomas L. Crandall

Vice President - Technology

Dated: November 11, 2005

Page 11

Loading...

Loading...