Page 1

OPERATION MANUAL

Brake Fluid Exchanger

IMPORTANT:

Test drive

vehicle after

BFX-1

service to verify

proper brake

system

performance.

Manual P/N 035-80997-00 (Rev A)

RTI Technologies, Inc

4075 East Market St.

York, PA 17402

800-468-2321

www.rtitech.com

Page 2

Table of Contents

Component Description .................. 2

Safety Precautions ...................... 3

System Priming ........................ 4

Exchange ............................ 5-8

Empty Used Tank....................... 9

Fill New Tank .......................... 9

Parts Identification ......................10

Flow Diagram & Electrical Schematic........11

EC Declaration of Conformity for Machinery . . 12

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance

Page 1

Page 3

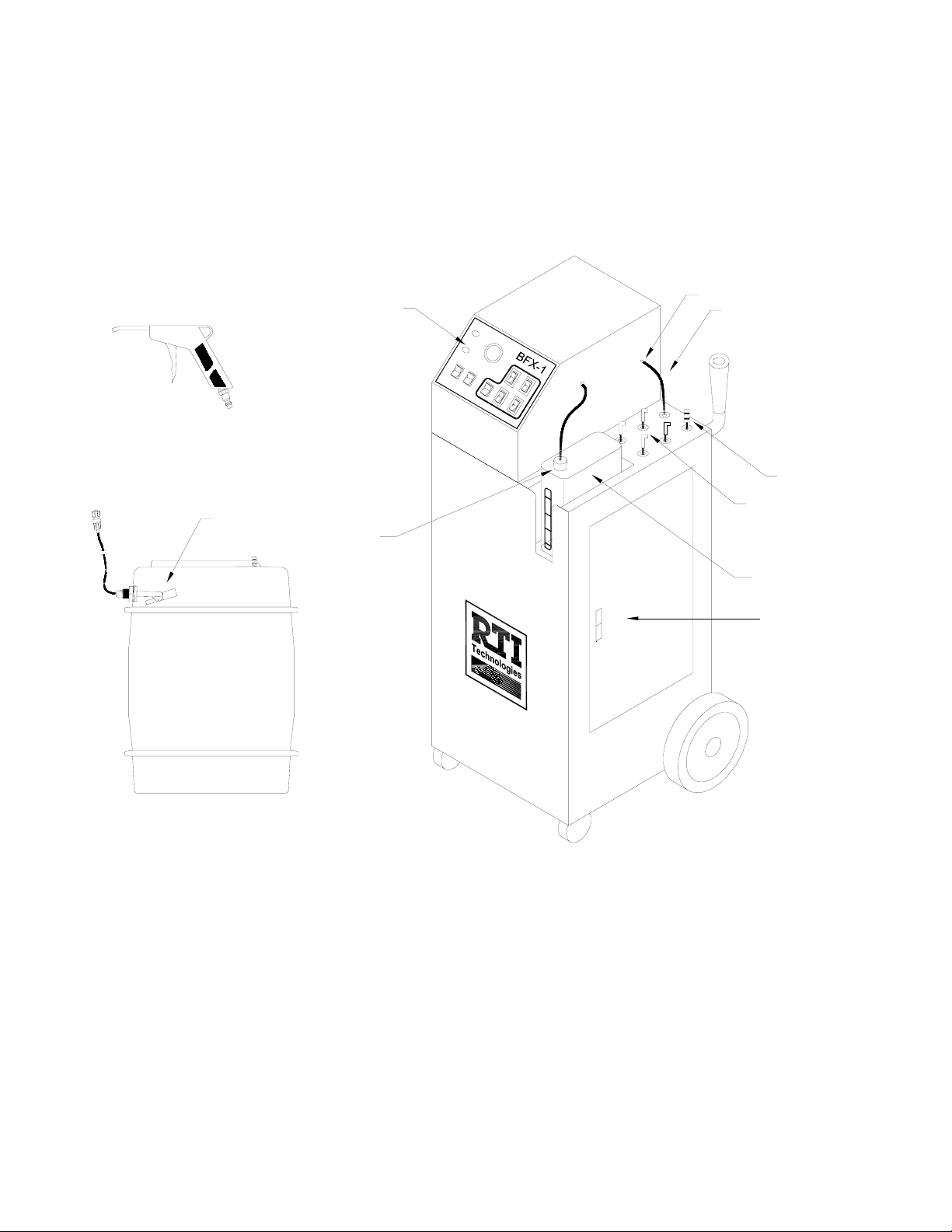

Component Description

Unpack all components and verify quantities per this illustration and adapter list on page 6.

Contact RTI if any items are missing.

Fill Gun

UsedTank

Float

Control Panel

New Tank

Float

Parking Stud

Vacuum Hose

Fill Hose

(4) Bleeder Hoses

New Tank

Hose Storage

Access Door

Used Tank

(Accessed through rear)

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 2

Page 4

Safety Precautions

WARNING: Failure to follow these precautions can result in

serious injury or death.

• Read and understand the Operation Manual completely before operating this unit.

• Always wear proper eye and skin protection when operating and maintaining this

equipment.

• Only disassemble or reassemble unit parts when directed by an RTI representative.

• Clean any spills that may occur immediately. Brake fluid is corrosive and is a high slip

hazard.

• Avoid exposure with painted surfaces. Brake fluid is corrosive and will damage the

finish on most painted surfaces. Use of fender covers is recommended.

• Always use vehicle specified brake fluid. Failure to do so may cause brake system

damage. The BFX is designed to use DOT 3 or 4 brake fluid. Use of any other fluid type is

not recommended and may void warranty.

• Comply with local, state and federal regulations for fluid disposal.

• Material Safety Data Sheets (MSDS) must be obtained on all chemicals and placed in a

shop file for reference. Note: MSDS can be found on the RTI web site www.rtitech.com.

• It is important to test drive every vehicle after the service to verify proper brake system

operation. Failure to do so could result in undetected brake system failure.

CAUTION: Failure to follow the precautions as outlined in the Operation Manual can

result in damage to the engine, vehicle or equipment which will not be

supported or covered under warranty.

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 3

Page 5

System Priming

Note: The System Priming Procedure is only necessary before the first time use of the

BFX or when changing brake fluid types. Between normal operation cycles, this

procedure will not be necessary.

1. Connect red (positive) clamp on power cable to red (positive) terminal on vehicle battery.

Connect the black (negative) clamp to a good ground. A good ground can be located by

following the negative cable from the battery to where it is connected to the chassis.

Warning: Handle battery connection cable with extreme caution. Batteries generate

explosive gases during normal operation. Working in the vicinity of a leadacid or other automotive battery is dangerous. Wear eye protection. Never

smoke or allow a spark or flame in the vicinity of the battery. Do not connect

the black power clip to the negative post of the battery to avoid a spark.

2. Fill New Tank with desired brake fluid.

3. Connect Fill Gun to Fill Hose.

4. Disconnect coupler on Used Fluid Tank Line and remove the cap.

5. Turn on FILL MASTER CYLINDER switch.

6. Place outlet tip of Fill Gun into the Used Fluid Tank opening and squeeze Fill Gun

trigger.

7. Continue until fluid is moving smoothly through the Fill Gun tip and into the Used Tank

without turbulence (air bubbles) visible in the Fill Hose.

8. Turn off FILL MASTER CYLINDER switch.

9. Disconnect Fill Gun from the Fill Hose.

10. Replace Used Tank cap and connect coupler.

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 4

Page 6

Exchange

BEFORE SERVICE: Verify that the Brake System does not have any malfunctions. If the

system is found to be malfunctioning verify that the malfunction will not

interfere with the exchange process. Perform all necessary repairs prior

to exchanging.

1. Verify that the vehicle engine is off.

2. Verify new and used fluid tank levels. Add new fluid or empty used as required.

3. Verify that all Switches and Attention Lights on the BFX control panel are OFF.

4. Connect red (positive) clamp on power cable to red (positive) terminal on vehicle

battery. Connect the black (negative) clamp to a good ground. A good ground can be

located by following the negative cable from the battery to where it is connected to the

chassis.

Warning: Handle battery connection cable with extreme caution. Batteries generate

explosive gases during normal operation. Working in the vicinity of a leadacid or other automotive battery is dangerous. Wear eye protection. Never

smoke or allow a spark or flame in the vicinity of the battery. Do not connect

the black power clip to the negative post of the battery to avoid a spark.

5. Remove master cylinder cover and inspect the master cylinder for damage. Repair any

damage found before continuing.

6. Turn on EMPTY MASTER CYLINDER switch and use the Vacuum Hose to remove all

of the fluid from the master cylinder.

7. Turn off EMPTY MASTER CYLINDER switch when master cylinder is empty and return

Vacuum Hose to Parking Stud.

Note: Failure to park Vacuum Hose on Parking Stud will result in minimum to no

vacuum at bleeder hoses.

8. Connect Fill Gun to Fill Hose. Turn on FILL MASTER CYLINDER switch and squeeze

trigger on Fill Gun to dispense fluid until master cylinder level is at the fill/max mark.

Turn off FILL MASTER CYLINDER and disconnect Fill Gun from the Fill Hose.

Note: To avoid fluid discharge from Fill Gun do not squeeze trigger after disconnecting

from Fill Hose.

9. Connect Master Cylinder Adapter.

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 5

Page 7

Exchange continued

A. Identify appropriate adapter for the Master Cylinder being serviced from list below.

B. Seat adapter on the Master Cylinder and tighten snugly.

C. Connect Fill Hose Coupler to the adapter coupler .

BA01 Chrysler & Others

025-88001-00

3 tab, twist on with expandable

O-ring fits most Chrysler

models. 2001+ PT Cruiser,

2002+ Grand Voyager, 1996+

Voyager LE, 1994+ Voyager

SE, Dodge: Power Ram,

Caravan, 2003+ Viper, 2001

Neon Jeep 1996+ Wrangler, 1996+ Grand Cherokee, 1999+

Wrangler Sport and others.

BA02 Ford

025-88002-00

2 tab, twist on with expandable O-ring fits all

Ford models with a two tab plastic twist on

cap.

BA03 Ford & Others

025-88003-00

Ford with 3 tab plastic twist cap. Chrysler

New Yorker, 1999-2002 Crossfire, 1999+

300 M, 1999+ Grand Voyager, 2001+

Sebring.Dodge 2001 Neon, 1999+

Stratus, Jeep Cherokee 1995 Hyundai

1995+ Sonata, 1995+ Accent, 2001+

Elantra Mazda 1999+ MPV, 1995+

121Mitsubishi 2003 Lancer, Outlander, 1999+ Wagons Nissan

1995+ 100SX, 200 SX, 1995+ Maxima Subaru 1989+ Outback,

1998+ Impreza, 1999+ Forrester

BA05 European

025-88005-00

European Vehicles with the threaded master

cylinder reservoir. Chrysler 2003+ Crossfire

Ford 1995 Cougar, Escort, Focus, Probe,

Galaxy, Festiva Suzuki Samarai Toyota 2003

Corolla

BA07 Universal

025-88006-00

All Vehicles with a round master cylinder.

BA08 Honda & Others

025-88007-00

Honda, Acura reservoirs with round

opening. Honda 1992+ Prelude,

1991+ Legend, All Civics. Isuzu

1989+ Trooper, 1989+ Monterey,

1989+ Frontera

BA10 Toyota & Others

025-88009-00

Toyota reservoirs with round opening.

BA11 Toyota & Others

025-88010-00

Toyota reservoirs with round opening.

BA12 Universal Cast

025-88011-00

For rectangular cast iron master

cylinders. Inside Dimensions: 7 in. x

4.5 in.

BA04 GM

025-88004-00

General Motors with 3 tab plastic twist cap.

Cadillac 1996+ Northstar, Eldorado, Seville SLE,

STS, 2001+ CTS, 2003+ SRX, XLR. Chevrolet

1996+ Corvette, 1999+ Blazer, Camaro, 1999+

Transport, 2003+ Tahoe. Mazda 2001+ MPV,

2001+ Tribute Pontiac Firebird all models,

Transport.

BA09 Honda

025-88008-00

Honda reservoirs with round opening. Honda

1985+ Accord, 1991 Prelude, 1999 + NSX-T

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

ST100 GM & Chrysler

025-88012-00

GM and Chrysler

Page 6

Page 8

Exchange continued

10. Turn on FILL MASTER CYLINDER switch. Verify that fluid is flowing through the Fill

Hose into the Master Cylinder and that the pressure stops and holds at approximately

12 psi as shown on the BFX Pressure Gauge.

Note: If pressure does not remain constant as indicated on Pressure Gauge, check

master cylinder adapter for leaks and tighten.

11. Verify hose and

battery cable

clearance, then raise

vehicle.

NEW TANK

EMPTY

PRESSURE

VACUUM BLEEDER

12. Connect Bleeder

Hoses to the bleeder

USED TANK

FULL

ON

ON

valves located on

each wheel cylinder.

Match color code on

each bleeder line to

the graphic located

on the BFX Control

Panel.

EMPTY

MASTER

CYLINDER

ON ON

FILL

MASTER

CYLINDER

EXCHANGE

BRAKE

FLUID

ON

OFF

ON

OFF

ON

13. Turn off FILL

MASTER

OFF OFF OFF

OFF

OFF

CYLINDER switch.

BFX 1

14. Turn on EXCHANGE

BRAKE FLUID switch.

15. Using the four VACUUM BLEEDER switches, vacuum each wheel bleeder. Always

follow the OEM recommend service for the correct sequence. Select appropriate

switch and turn on. Loosen corresponding bleeder until adequate flow is observed.

16. Monitor flow and color of fluid in Bleeder Hose and turn off VACUUM BLEEDER switch

when fluid becomes clear or the desired amount of fluid has been exchanged.

Warning: Monitor both the NEW TANK EMPTY and USED TANK FULL Indicator Lights.

If either illuminates during service, immediately turn all switches off, add new

or remove used fluid as needed and continue with procedure.

Note: The appearance of air bubbles in the Bleeder Hoses is due to air being pulled

around the thread of the bleeders. This is a common occurrence and does not

indicate a malfunction with the process.

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 7

Page 9

Exchange continued

17. When the fluid in all 4 Bleeder Hoses has been adequately exchanged turn all four

VACUUM BLEEDER switches on, close the bleeder valves and turn off the EXCHANGE

BRAKE FLUID and VACUUM BLEEDER switches.

18. Remove Bleeder Hoses from bleeders, return to unit and lower vehicle.

19. Remove Master Cylinder Adapter from the master cylinder

20. Disconnect Fill Hose from the Master Cylinder Adapter.

21. Adjust level in the master cylinder by using the Vacuum Hose and the EMPTY MASTER

CYLINDER switch to lower or the FILL MASTER CYLINDER switch and the Fill Gun on

the New Fluid Hose to raise.

22. Remove battery connections and install the master cylinder cover.

23. Test the brake system for proper pedal pressure. Press pedal to

floor, hold for 5 seconds, release and inspect bleeders for leaks.

Tighten bleeder if needed and retest. Take vehicle on test drive.

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 8

Page 10

Empty Used Tank

1. On the Used Fluid Tank, disconnect the fluid line coupler as well as the electrical float

switch connection.

2. Twist the cap counterclockwise to remove.

3. Empty into an appropriate bulk waste container.

4. Replace cap on Used Fluid Container (turn clockwise).

5. Connect fluid line coupler as well as the electrical float switch connection and place tank

in rear of BFX.

Note: Follow all federal and local laws and regulations when disposing of hazardous

material.

Warning: Not removing the electrical connection can cause serious damage that may

make the BFX nonoperational.

Fill New Tank

1. On the New Tank, remove the New Tank Float Stopper and pour new brake fluid into

the opening.

2. Replace Stopper into New Fluid Tank securely.

Note: For varying new tank heights slide the New Tank Float Stopper up or down the

New Tank Float until the appropriate height is obtained.

Warning: Failure to properly set the height of the New Tank Float Stopper can result in

a New Tank Float malfunction which could allow air into the brake system.

Warning: Brake fluid is Hygroscopic (absorbs moisture). It is recommended that the

new fluid container is emptied if unit will not be operated for an extended

period of time.

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 9

Page 11

Parts Identification

7

2

1

BFX 1

3

PRESSURE

NEW TANK

EMPTY

USED TANK

FULL

EMPTY

FILL

MASTER

MASTER

CYLINDER

CYLINDER

ON ON

OFF OFF OFF

EXCHANGE

BRAKE

FLUID

VACUUM BLEEDER

ON

ON

OFF

OFF

ON

ON

OFFONOFF

5 (x4)

4

9

6

8

10

X 4

15

16

11

12

13

14

Part No. Description

1 025-80358-00 Indicator Light Red 12VDC

2 325-80016-00 Pressure Gauge Assy (BFX-1)

3 024-80076-00 Switch Rocker SPDT (On-On)

17

4 024-80075-00 Switch Rocker DPDT (On-On)

5 024-80066-00 Rocker Switch SPDT

(On-On)Visi-Red

6 325-80027-00 Wand/Gun Assy (BFX)

7 026-80358-00 Sight Glass 1/4 FPT (Nylon)

8 325-80030-00 Vacuum Pump w/terminals Assy

18

9 325-80029-00 Supply Pump w/terminals Assy

10 023-80344-00 Adapter Brake Nipple x 3/16 Barb

11 325-80031-00 Press Switch 9-12 psi SPST

19

EPDM 1/4 MPT w/Terminals

12 024-80091-00 Relay 40 Amp SPDT 12VDC

13 025-80361-00 Manifold 4 Valve 12VDC 1/4FPT

14 325-80005-00 New Tank Assy (BFX-1)

15 024-80099-00 Float Switch Assy (New Tank)

16 360-81763-00

025-80342-10

Fuse Holder ATO Panel Mount

Fuse 10 Amp ATO Fast Blow

17 320-80005-00 Cord Power 14/2 SPT3 Battery

Clamps 12FT

18 325-80022-00 Float Switch Assy (Used Tank)

19 325-80004-00 Used Tank Assy (BFX-1)

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 10

Page 12

Flow Diagram & Electrical Schematic

USED

FLUID

#1

#2

#3

#4

S1

S3

S2

S4

M2

USED BRAKE

FLUID

TANK

INLINE

FILTER

FS1

NEW BRAKE

FS2

M1

FLUID

TANK

FIXED

ORIFICE

PRESSURE

SWITCH

(12 PSI)

PS1

PRESSURE

GAUGE

(0-30PSI)

NEW

FLUID

SUPPLY

CR2

FS1

FS2

CR1

FILL

MASTER

CYLINDER

SW1

EXCHANGE

SYSTEM

SW2

F1

CR1

CR2

NEW TANK

EMPTY

L2

ONOFF

ONOFF

ONOFF

EMPTY

MASTER

CYLINDER

SW3

PS1

HOSE #1

SW4

ONOFF

HOSE #2

SW5

ONOFF

HOSE #3

ONOFF

SW6

HOSE #4

SW7

ONOFF

ONOFF

M1

M2

S1

S2

S3

S4

USED TANK

FULL

L1

USED FLUID L EVEL RELAY

NEW FLUID L EVEL RELAY

NEW TANK EMPTY LIGHT

NEW FL UID SUPP L Y PUM P

USED FLUID PUMP

SOLENOID S1

SOLENOID S2

SOLENOID S3

SOLENOID S4

USED TAN K F ULL LIG HT

IMPORTANT: Test drive vehicle after service to verify proper

brake system performance.

Page 11

Page 13

EC Declaration of Conformity for Machinery

Herewith declares that:

- BFX-1 Brake Fluid Exchanger

- is in conformity with the provisions of the Machinery Directive (directive

98/37/EC) and with the national implementing legislation

Directive 98/37/EC

RTI Technologies, Inc.

4075 East Market Street

York, Pennsylvania 17402 USA

Phone: 717-840-0678

- is in conformity with the provisions of the following other EC directives:

Electromagnetic Compatibility (EMC) Directive 89/336/EEC

Electromagnetic Emissions EN 61000-6-4: 2001

Electromagnetic Immunity EN 61000-6-2: 1999

The BFX-1 is certified to the EMC Directive like the ATX-2 tested by:

TÜV America Inc.

1775 Old Highway 8 NW Ste. #104

New Brighton, MN 55112

Phone: 651-638-0262

Thomas L. Crandall

Vice President - Technology

Dated: January 10, 2005

Page 12

Loading...

Loading...