MAHLE NTF-515B

Operation Manual

EN

Nitrogen Tire Filling Unit

2 | NTF-515B | en

Contents

1. Information 4

1.1 Document warnings 4

1.2 Important notes 4

1.2.1 User group 4

1.2.2 Agreement 4

1.3 Warranty 5

1.4 Safety regulations 7

1.4.1 NTF-515B 7

1.5 Technical data 7

2. Product description 8

2.1 Application 8

2.2 Scope of delivery 8

2.3 Description of unit 9

2.4 User interface 10

2.4.1 Selection and function keys 10

2.4.2 Input selection 10

2.4.3 Value adjustment 10

2.5 Unit features 10

2.5.1 Nitrogen purity selection 10

2.5.2 Air chucks 10

2.5.3 Nitrogen purity tester 11

2.5.4 Locking caster brakes 11

2.5.5 Battery and battery charger 11

2.5.6 Dually hose connection 11

2.5.7 Single tire fill accessory connection port 11

2.6 Functional description 12

2.6.1 Unit function 12

2.6.2 Nitrogen generation 12

2.7 Commissioning 13

2.7.1 Removing transportation packaging 13

2.7.2 Verify air source 13

2.7.3 NTF-515B 13

2.7.4 Generating nitrogen 13

3. Nitrogen service 14

3.1 Preparation 14

3.1.1 Over pressure setting (OPS) and

nitrogen purge cycles (N2P) 14

3.2 Battery charging 14

3.3 Service phases 15

3.3.1 Nitrogen purge cycle 15

3.3.2 Nitrogen top-o 15

3.4 Nitrogen purge cycle 15

3.5 Nitrogen purge cycle 15

3.6 Top-o and nitrogen purge cycle counter 15

4. Maintenance 16

4.1 Maintenance interval 16

4.2 Automatic water/oil drain 16

4.2.1 Checking functionality 16

4.2.2 Cleaning automatic drain 16

4.3 Filter element maintenance 17

4.4 Troubleshooting 17

4.5 Spare and wearing parts 18

4.5.1 NTF-515B 18

5. Notes 19

© MAHLE

| NTF-515B | 3NTF-515B | 3 | 3

en

© MAHLE

4 | NTF-515B | Informationen

1. Information

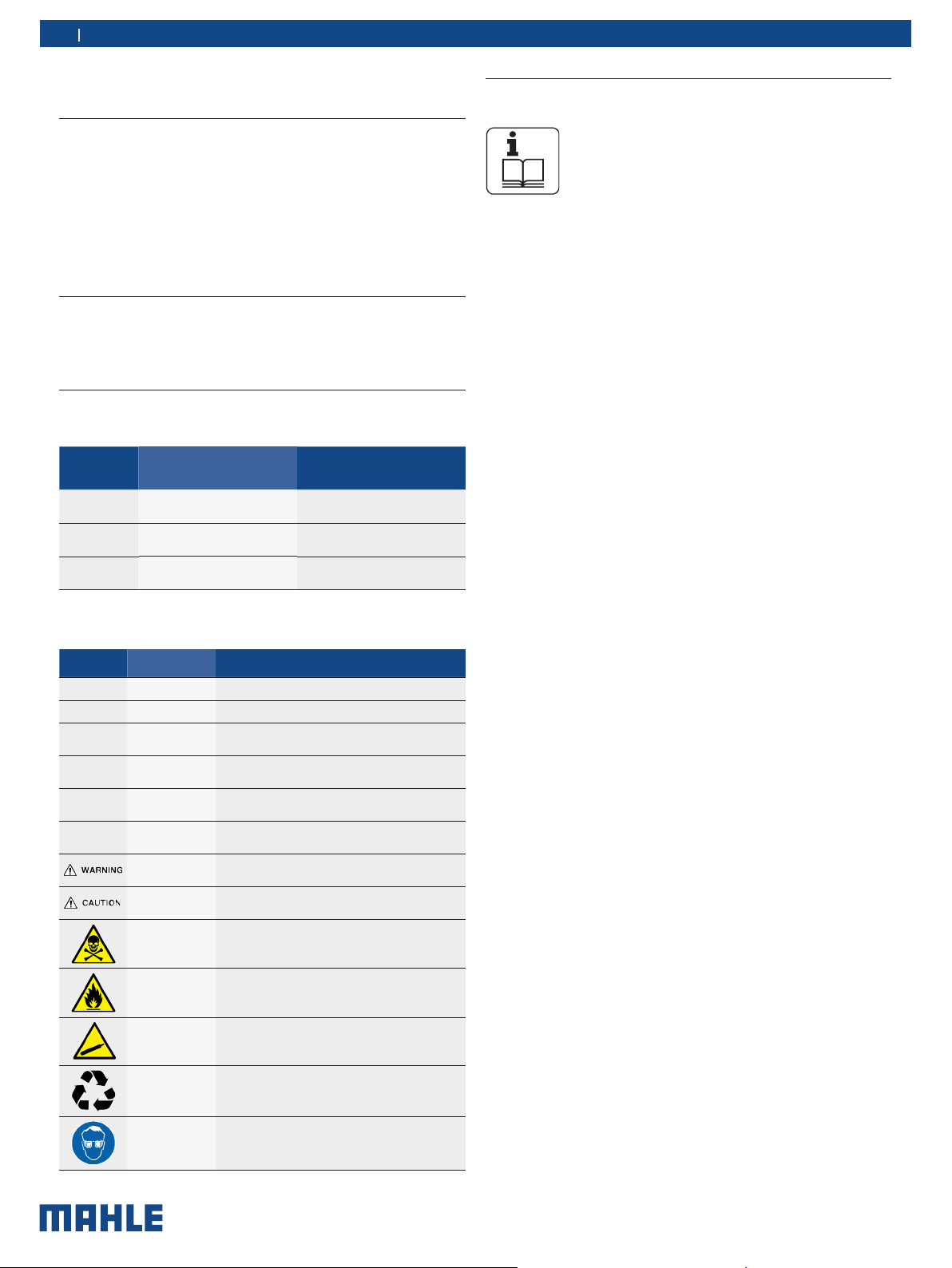

1.1 Document warnings

Warning notices—Structure and meaning

Warning notices warn of dangers to the user or people in the

vicinity. Warning notices also indicate the consequences of the

hazard as well as preventive action. Warning notices have the

following structure:

Warning

symbol

The key word indicates the likelihood of occurrence and the

severity of the hazard in the event of non-observance:

Key word Probability of

DANGER Immediate impending

WARNING Possible impending

CAUTION Possible dangerous

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of failure

to observe action and information given.

h Hazard prevention action and information.

occurrence

danger

danger

situation

Severity of danger if instructions not observed

Death or severe injury

Death or severe injury

Minor injury

1.2 Important notes

Before start up, connecting and operating MAHLE

products it is absolutely essential that the Original

instructions/owner’s manual and, in particular, the

safety instructions are studied carefully. By doing so

you can eliminate any uncertainties in handling MAHLE products

and thus associated safety risks upfront; something which is in

the interests of your own safety and will ultimately help avoid

damage to the device. When a MAHLE product is handed over

to another person, all documentation and and information on

its designated use must be handed over to the person. Contact

MAHLE if you detect a problem that you cannot solve with this

manual.

1.2.1 User group

The product may be used by skilled and instructed personnel

only. Personnel scheduled to be trained, familiarized, instructed

or to take part in a general training course may only work with

the product under the supervision of an experienced person.

All work conducted on pressurized equipment may be performed

by persons with sufficient knowledge and experience in the field

of refrigeration, cooling systems and coolants and, also be aware

of the risks involved in the use of pressurized devices.

Symbols in this documentation

Symbol Designation Explanation

m

t

1.

2.

h

Attention Warns about possible property damage.

Information Practical hints and other useful information.

Multi-step

operation

One-step

operation

Intermediate

result

Final result

Warning

Caution

Warning Risk of death due to suffocation.

Risk of fire

High pressure

Environmental

Instruction consisting of several steps.

Instruction consisting of one step.

An instruction produces a visible intermediate result.

There is a visible final result on completion

of the instruction.

Hazard that can cause death or serious injury. Follow the instructions.

Danger that can cause damage to the

equipment. Follow the instructions.

Oxygen-enriched air leads to an increased

risk of fire in the event of contact with flammable products.

Follow the instructions with respect to compressed gasses.

Dispose of components in manner consistent with local regulations.

1.2.2 Agreement

By using the product you agree to the following regulations:

Copyright

Software and data are the property of MAHLE or its suppliers

and protected against copying by copyright laws, international

agreements and other national legal regulations. Copying or selling of data and software or any part thereof is impermissible and

punishable; in the event of any infringements MAHLE reserves

the right to proceed with criminal prosecution and to claim for

damages.

Liability

All data in this program is based—where possible—on manufacturer and importer details. MAHLE does not accept liability for the

correctness and completeness of software and data; liability for

damage caused by faulty software and data is ruled out. Whatever

the event, MAHLE liability is restricted to the amount for which

the customer actually pays for this product. This disclaimer of

liability does not apply to damages caused by intent or gross

negligence on the part of MAHLE.

© MAHLE

Personal

protection

Wear protective glasses.

Information | NTF-515B | 5NTF-515B | 5 | 5

en

1.3 Warranty

MSS Five-Year NitroPRO Limited Warranty

(Applies only to NitroPRO Equipment owned and operated in

North America)

MAHLE (MSS) warrants to the original Purchaser of the NitroPRO

to be free from defects in materials and workmanship as follows:

Year One - MSS is responsible for costs associated with parts

and labor for repairs needed because of defects in material and/

or workmanship. MSS is not responsible for costs associated

with repairs needed because of improper use or a lack of normal

maintenance. The goal of MSS is to provide a timely turn-around

of the covered product requiring warranty repair.

The Purchaser must ASSIST AND PARTICIPATE with MSS

Technical Support during an over-the-phone diagnosis process of:

A) Determining that a legitimate failure has occurred and that the

complaint is not just the result of inadequate training and/or

improper use that could be easily remedied by over-the-phone

instructions.

B) Determining the nature of the failure and that it is reasonable

for MSS Technical Support to judge over the phone that the

failure is warrantable.

It is the responsibility of the Purchaser to operate and maintain

MSS equipment according to instructions in the MSS Operation

Manual for the covered product. MSS provides free technical

support over toll-free telephone lines in the USA to assist the

Purchaser in this regard for the life of the covered product.

The Purchaser should review the legal Warranty Disclaimer

(Page 2) for more details of coverage and limitations.

Warranty of Nitrogen Membrane

Year Two through Year Five - MSS specifically warrants to the

original Purchaser the Nitrogen Membrane in the NitroPRO to be

free from defects in materials and workmanship for a period of

five years. To maintain this warranty, filters must be replaced annually or sooner if indicator on water filter moves into the red area.

Failure to change filters as indicated will void the warranty and

may destroy the Nitrogen Membrane. Proof of filter replacement

according to MSS’s recommendations is required; replacement

filter kits provided by MSS will contain a serialized label which

should be applied to the maintenance log on the unit as proof

of proper filter maintenance. Purchaser is responsible for the

purchase and installation of any replacement membrane, as well

as return of the original membrane to MSS for evaluation. Upon

inspection, if it is confirmed that the failure is due to a defect in

materials or workmanship and not improper use or lack of proper

maintenance, MSS will reimburse Purchaser for the price paid for

the replacement membrane.

C) Determining the parts necessary to make the repairs so that

those parts can be shipped via the appropriate expedited

method at the expense of MSS if the failure is warrantable.

During the One Year Warranty period, MSS is solely responsible for

providing Field Repair Service when appropriate within a reasonable period of time after a warrantable failure is determined. Field

Repair Service is generally available in all areas within 150 miles of

major metropolitan areas in the USA. A reasonable period of time

will depend on the location of the Purchaser and the time of the

year. MSS maintains a large network of Service Providers in the

USA. When Field Repair Service is needed, in most locations near

a major USA metropolitan area, and during most times of the year,

a reasonable period of time for Field Service is 24 to 48 hours after

parts are received by the Purchaser.

Since repair parts from MSS will normally arrive 24 to 48 hours after

the Purchaser reports a failure, the Purchaser may at his sole option

and discretion, choose to make the necessary repairs, with overthe-phone support from MSS Technical Support so as to minimize

downtime. In such case, MSS will compensate the Purchaser, as

appropriate, for the time necessary to make repairs if the failure is

covered by warranty.

Warranty of Nitrogen Purity Analyzer

The NitroPRO Purity Tester is warranted for one year only. A defective unit must be returned to MSS for repair or replacement. During

the first 30 days, a new Purity Tester will be sent to the Purchaser in

exchange for the return of the defective unit to MSS.

After 30 days and up to one year, a defective Purity Tester must be

returned to MSS for repair or replacement with a new or refurbished

unit, at MSS’s sole discretion, in case of a warrantable defect.

WARRANTY DISCLAIMER FOR PRODUCTS OF MAHLE

AFTERMARKET INC., SERVICE SOLUTIONS (MSS)

1. MSS'S WARRANTY

This is to certify that MAHLE Aftermarket Inc., Service Solutions

(MSS) warrants to the first retail Purchaser only, the described

new product manufactured by it to be free from defects in materials and workmanship, when properly maintained, under normal

use and service for a period of FIVE YEARS (See paragraph

3 below and Limited NitroPRO Warranty on Page 1). All spare

parts supplied by MSS will have a 90 day warranty. This warranty includes the reasonable cost of parts and materials as well

as non-overtime labor. MSS shall be the sole judge of whether

failure is warrantable.

© MAHLE

6 | NTF-515B | Informationen

2. PURCHASER'S REMEDY

Purchaser's sole and exclusive remedy under this warranty

shall be limited to the repair or replacement, at MSS’s option,

of any defective part of the product. Purchaser shall call MSS

Technical Support who will assist Purchaser in diagnosing

the problem and, if deemed necessary, will immediately ship

replacement parts for installation by Purchaser if so requested. If Purchaser requests factory service, repairs under this

warranty shall only be made at a location designated by MSS.

3. DURATION

This warranty will expire five years from date of delivery to the

first retail purchaser.

4. PURCHASER'S DUTIES

(a) Register product with MSS by returning completed Warranty

Registration within 90 days of delivery of unit.

(b) Transportation Expense: Transportation expenses to and

from MSS are to be borne by the Purchaser.

(c) Notice of breach: Purchaser shall give written notice to MSS

of any alleged refusal or failure of the MSS to repair or replace

as promised by this warranty no later than fifteen days after

the Purchaser learns of such alleged failure or refusal.

5. DISCLAIMER

THE EXPRESS WARRANTY HEREIN IS IN LIEU OF ANY AND ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED. NO IMPLIED

WARRANTY OF MERCHANTABILITY IS MADE AND THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF.

6. EXCLUSIONS

The warranty and obligations stated here shall not apply to:

(a) Any product not registered within 90 days of delivery.

(b) Any product repaired or altered without prior approval of MSS

so as to affect adversely its stability or reliability.

(f) Parts, accessories or other items manufactured by others

which are used or installed on the product as a result of

Purchaser's specifications.

(g) Used items furnished by the Purchaser for installation on

the product.

(h) Items which are not defective, but must be replaced dur-

ing the warranty period as a result of fair wear and tear or

scheduled maintenance.

(i) Hoses, couplings, gaskets and O-rings carry a 90 day war-

ranty.

(j) Filters are considered consumables and are not covered by

any warranty.

7. EXCLUSION OF LOST PROFITS AND OTHER-

CONSEQUENTIAL DAMAGES

MSS will have no liability for any lost profit, cargo loss, usage loss

or other consequential damages alleged to have been caused

by any defect in the product or any failure of MSS to meet any

obligation under this agreement including the obligation to repair

and replace set forth in Paragraph 2.

8. LIMITATIONS OF ACTIONS

No action for breach of this warranty shall commence more than

one year after the accrual of the cause of action.

9. MERGER

This written warranty is the complete, final and exclusive agreement of the parties with respect to the quality or performance of

the goods and any and all warranties and representations, except

warranty extensions, if any, in writing as applicable.

10. NO ORAL MODIFICATIONS OR WAIVERS

No modification of this warranty or waiver of its terms shall be

binding on either party unless approved in writing by an authorized official of each party.

(c) Any product subjected to misuse, abuse or accident as well

as products used in a manner contrary to written instructions

or normal operating procedure.

(d) Any damage to product during original shipment or subse-

quent shipments to MSS's facility for service.

(e) Portions of products which are subject to warranties, if any,

given by their manufacturers. MSS does not adopt these

warranties.

© MAHLE

11. GOVERNING LAW

This warranty and the rights and duties of the parties under this

warranty shall be governed by the laws of Pennsylvania, the state

of MSS's principle place of business.

Information | NTF-515B | 7NTF-515B | 7 | 7 en

1.4 Safety regulations

1.4.1 NTF-515B

Always carefully study and follow all the safety regulationsbefore

using the MAHLE product. Correct use of the NTF-515B is important for your personal saftey and for trouble-free functionality.

Incorrect use can cause damage to the unit or lead to incorrect

functionality.

Nitrogen can cause suffocation. Make sure there is

adequate ventilation at all times!

y Regular maintenance should be performed on the NTF-515B

to ensure proper and safe operation. Ensure that instructions concerning health and safety are compliant with local

regulations.

y Some shop air supplies have an oiler installed to provide

lubrication to air tools. The life of the NTF-515B filters will be

increased if the air supply is free of moisture and oil.

y Only supply the NTF-515B with compressed air.

Oxygen enriched air leads to increased risk of fire in

the event of contact with flammable products.

y Do not block the flow of air from the membrane vent. Dam-

age may occur.

y Always follow vehicle manufacturer's suggested tire inflation

pressure.

y Incorrect settings on the NTF-515B can allow overinflation of

tires leading to a possible bursting of the tire.

y Do not install the NTF-515B in an area where explosive sub-

stances may be present.

Ensure the feed air pressure cannot exceed 150PSI.

y Oil content of the compressed air should be less than 0.01mg/

m3.

y Ensure that the compressed air pressure and quality is always

as prescribed.

y Ensure air supply is rated for 100-150PSI and minimum

13.3CFM.

y The NTF-515B unit should not be exposed to excess moisture

or be operated in wet areas.

In the case of an emergency, turn off power switch

and disconnect the compressed air supply line quick

coupling.

y The NTF-515B can be secured in position by locking the

caster brake.

y There are no additional safety systems for protecting the

NTF-515B against damage resulting from natural catastrophes.

y Never remove any components from inside the NTF-515B

except for maintenance or repair purposes.

y Follow the pertinent legal regulations or directives to ensure

safe handling of pressurized devices.

y The NTF-515B must be subjected to regular maintenance by

service personnel or authorized agents to ensure the safety

of the unit.

y Never perform any maintenance work which is not expressly

recommended in this manual. Contact customer service if

components have to be replaced other than in the course of

maintenance work.

y If there is damage to the NTF-515B, terminate usage imme-

diately and contact customer service.

y The service hoses and service quick-release couplings must

be regularly checked for wear and replaced if damaged.

y Observe local laws or directives as to ensure the safety of the

pressurized device.

1.5 Technical data

y Keep ambient air temperature between 40˚F - 110˚F (5˚C -

43˚C). Do not connect hot compressed air directly from a

compressor to inlet of the NTF-515B.

y Keep air feed to the NTF-515B clean and free of vapors of

organic solvents and other contaminants. Do not place the

NTF-515B in a room where organic solvent vapors may be

present.

Feature Value/Range

Dimensions H x W x D 1250 x 510 x 560mm

Weight 108kg

Unit operating voltage 12VDC

Battery charger voltage 110/220VAC

Air supply 100-150PSI, 13.3 CFM

Storage tank capacity 15gal

© MAHLE

8 | NTF-515B | Product descriptionen

2. Product description

2.1 Application

NTF-515B is suitable for all passenger cars, SUV, and small trucks

(pick-ups).

The following functions can be implemented:

y Nitrogen top-off.

y Nitrogen purge cycle.

y Single or multiple tire service.

m The NTF-515B can only be operated with compressed air not

exceeding 150 PSI. Excess pressure could damage membrane and other internal components.

m Check filters daily prior to use to ensure clean dry air is being

fed to the membrane. Damage may occur if contamination

reaches membrane.

2.2 Scope of delivery

Description

NTF-515B unit

Battery charger

Battery (installed in unit)

Nitrogen purity analyzer

Connection port for digital tire fill gun (fill gun sold as accessory)

Connection port for dually tire hose connection (additional hoses sold

as accessory

Operation manual

© MAHLE

2.3 Description of unit

Product description | NTF-515B | 9NTF-515B | 9 | 9 en

Fig. 3: Front control panel

1 Air inlet pressure gauge

2 Power switch

3 Main display LCD

4 Tank pressure LCD

5 "+" button

6 "-" button

7 "START" button

8 "N2" button

Fig. 1: Front view

1 Top tool tray and storage

2 Front control panel

3 Front tool tray and storage

4 NTF-515B front housing

5 Locking caster

6 Handle grip

7 Purity test port

8 Hose hook

9 Rear wheel

The pressure gauge (Fig. 3, Pos. 1) of the front control panel is

used to monitor the air inlet pressure. The N2 pressure inside the

tank is displayed on the lower LCD screen (Fig. 3, Pos. 4). The

status of the phases during service is displayed on the upper

LCD screen (Fig. 3, Pos. 3). The necessary entries are made by

way of the touch sensitive keys (Fig. 3, Pos. 5-8) .

The power switch (Fig. 3, Pos. 2) shuts the power off to conserve

the battery. It also functions as the main power to the air inlet

solenoid.

Fig. 2: Rear view

1 Dually tire hose accessory quick connect

2 Air inlet connection

3 Water filter with automatic drain

4 Single tire digital fill gun accessory quick connect

5 Automatic drain (oil and water)

6 Carbon filter

7 Purity selector valve (95% or 98%)

8 Oil filter with automatic drain

9 Nitrogen membrane

© MAHLE

10 | NTF-515B | Product descriptionen

2.4 User interface

2.4.1 Selection and function keys

Keys Function

Use this button to adjust the desired value higher.

+

Use this button to adjust the desired value lower.

-

START

2.4.2 Input selection

Press and hold button to begin a Nitrogen purge cycle or

just press once for a Top-Off cycle.

Press this button from the startup screen to adjust the OPS

setting and the number of purge cycles prior to starting

N

2

service.

t The buttons on the NTF-515B are touch sensitive. Touch black

dot on the control panel under the text of the desired selection.

2.5 Unit features

2.5.1 Nitrogen purity selection

t The NTF-515B allows the operator to select the desirable

purity of generated Nitrogen. Purity selector is located in the

lower left corner of the unit's rear panel.

To adjust the purity setting:

1. Turn knob to desired purity setting.

2. If switching from 95% to 98% purity, drain tank of all pressure

and allow tank to generate fresh Nitrogen.

m Nitrogen tank regeneration time will be about twice as long

if 98% purity is selected.

Fig. 4: Selecting button on control panel

2.4.3 Value adjustment

To adjust the target inflation value, simply press the + or - buttons. The value in the upper screen will adjust accordingly.

Fig. 5: Purity selector valve

2.5.2 Air chucks

t To connect air chuck to valve stem, press down on the silver

clip, push air chuck onto valve stem until tight, and release

silver clip.

t To remove the air chuck from the valve stem, press down on

the silver clip and pull off of valve stem.

Fig. 6: Air chuck

© MAHLE

Product description | NTF-515B | 11NTF-515B | 11 | 11 en

2.5.3 Nitrogen purity tester

The Nitrogen purity tester can be used to determine the percent

of nitrogen produced by the NTF-515B by connecting to the test

port on the right side of the unit. It can also be used to measure

the percent of nitrogen in the tires after performing a service.

t Refer to the operation manual for the purity tester (035-81169-

00) for further details.

Fig. 7: N2 purity analyzer

2.5.5 Battery and battery charger

The NTF-515B is powered by a 12V, 7AH battery mounted inside

the cabinet. There is a battery charger connection port located

on the left hand side of the unit.

The NTF-515B is switched on by toggling the rocker switch to

the On position.

m Do not leave NTF-515B unit powered on overnight as draining

the battery below 9V could cause damage to the battery cells.

t When using the purity tester to measure nitrogen purity in a

tire, you can minimze the pressure loss, and corresponding

refill requirements, by removing the tester from the valve stem

after a sample has been obtained. The reading continues to

climb after the tester has been removed - this is due to the

response time of the internal sensor. Once the rate of change

of the reading slows down or stabilizes, reapply the tester to

the valve stem to obtain another sample.

m Always recheck the tire pressure when purity testing is com-

plete and replenish nitrogen as necessary.

2.5.4 Locking caster brakes

Rolling of the NTF-515B can be prevented by locking the caster

brakes (Fig. 1, Pos. 5) at the rear wheels.

Fig. 8: Battery charger

2.5.6 Dually hose connection

The NTF-515B includes an additional connection port at the top

of the unit on the back (Fig. 2, Pos. 1). This port is utilized if the

Dually tire fill accessory kit is purchased and allows the filling of

6 tires simultaneously. MSS P/N 355 80123 00.

Fig. 9: Dually hose connection kit

2.5.7 Single tire fill accessory connection port

The NTF-515B includes an extra connection port on the back of

the unit (Fig. 2, Pos. 3). Some technicians prefer to use a digital

tire fill gauge to top off a tire instead of allowing the unit to fill the

tire. Technicians can connect their own coiled hose and digital

tire fill gun to the unit if they own one. In the instance that one is

not available, MSS has P/N 355 80258 00 available for purchase.

© MAHLE

12 | NTF-515B | Product descriptionen

2.6 Functional description

2.6.1 Unit function

The NTF-515B can be used to perform a fully automatic nitrogen

tire filling process. The technician simply needs to connect the air

supply, connect the 4 hoses to the valve stems, set the desired

pressure on the screen, and hold down the start button until the

unit beeps. The NTF-515B will automatically complete the service

and alert the technician for interaction when complete.

The NTF-515B can also be used to perform a nitrogen top off

in the instance a tire is underfilled, but was previously filled with

nitrogen.

2.6.2 Nitrogen generation

The nitrogen production depends on these parameters:

Parameter Description

Flow rate The lower the flow rate of compressed air through the hollow

Temperature The NTF-515B operates at a temperature between 40 -

Membrane

pressure

External

pressure

fiber membrane, the more oxygen can permeate through

the membrane wall. As a reuslt, the nitrogen produced at

the outlet will have a higher purity. Nitrogen purity can be

adjusted with the flow control valve.

110F (70-80F optimally). If the temperature increases, the

pressurized air consumption will also increase. Do not place

the system in a room where the temperature may rise unnecessarily high.

Allow enough piping between the compressor exit and the

NTF-515B inlet so that the hot compressed gas has time to

cool within the specifications listed in this manual. A higher

membrane pressure will increase the capacity (i.e. nitrogen

output) of the NTF-515B.

There must be atmospheric pressure at the outlet. The capacity and purity of the nitrogen gas decreases strongly if

the vent pressure exceeds atmospheric pressure.

Membrane function

The NTF-515B separates compressed air into nitrogen and an

oxygen enriched air stream. The separation system is based on

membrane technology. The compressed air comes from a central

system or from a dedicated compressor.

The nitrogen produced is stored in the nitrogen storage vessel. The NTF-515B then switches on and off depending on the

nitrogen demand.

Fig. 10: Nitrogen separation principle

1 Air inlet - pressurized air

2 Membrane fiber support layer

3 Membrane fiber separation layer

4 Nitrogen outlet

Ambient air contains nitrogen (78.1%), oxygen (20.9%), argon

(1%), carbon dioxide, water vapor, and traces of other inert gases.

Pressurized air (Fig. 10, Pos. 1) is fed through the hollow fiber

membrane (Fig. 10). The various air components diffuse through

the wall of the membrane.

© MAHLE

The diffusion rate differs for the various gases:

— Oxygen and water vapor have a high diffusion rate and

pewrmeate rapidly through the membrane wall.

— Nitrogen has a low diffusion rate and permeates slowly

through the membrane wall.

At the exit of the membrane (Fig.10, Pos. 4), pressurized nitrogen

is released.

Product description | NTF-515B | 13NTF-515B | 13 | 13 en

2.7 Commissioning

t All the operations described in this section must be

performed prior to first use.

2.7.1 Removing transportation packaging

m When removing the packaging, use care to ensure there is no

damage caused to the NTF-515B unit or any of the included

accessories.

t Do not unplug any electrical connections and only have in-

ternal components opened and repaired by trained customer

service personnel.

t Contact customer service in the event of any transportation

damage.

m Charge battery for at least 5 hours prior to first use.

2.7.2 Verify air source

m Ensure the compressed air source meets the specifications:

— Oil content is below 0.01mg/m

3

— Minimum air inlet pressure of 120PSI

— Maximum air inlet pressure of 150PSI

— Air flow is 13.3CFM minimum

— Air temperature is below 110F

2.7.3 NTF-515B

m The NTF-515B is designed for 12VDC operation. The charger

is designed for 110-240V, 50/60Hz. Follow the information on

NTF-515B rating plate.

2.7.4 Generating nitrogen

t Before the NTF-515B can be used to service tires, the unit

must generate nitrogen to fill the internal tank.

t An inadequate inlet pressure may make efficient filling of the

internal tank impossible.

m Generally speaking, the inlet pressure should be at least 5PSI

higher than the tank set pressure (120PSI).

1. To fill internal bottle, connect air supply to inlet connection on

back of unit (Fig. 2, Pos. 9).

2. Turn purity selector valve (Fig. 2, Pos. 6) to desired setting.

3. Turn power switch to the On position.

t The current pressure inside the nitrogen tank is indicated on

the lower LCD screen.

m If your application requires an inlet pressure of 100-119PSI,

the pressure value can be adjusted to accomodate the lower

system pressure. Contact MSS Technical Support at 1-800468-2321 for details.

© MAHLE

14 | NTF-515B | Nitrogen serviceen

3. Nitrogen service

3.1 Preparation

Perform the following preparatory work prior to vehicle nitrogen

service:

m Inspect hoses for signs of damage prior to performing service.

Use of damaged hoses will result in a loss of pressure during

service. This could cause uneven tire pressure or an error to

display.

t Follow the vehicle manufacturer's recommendations for tire

pressure.

1. To fill internal storage tank, connect air supply to inlet connection on back of unit (Fig. 2, Pos. 9).

2. Turn purity selector valve (Fig. 2, Pos. 6) to desired setting.

3. Turn power switch to the On position.

m Tires which have been in service may contain foreign sub-

stances such as leak sealers. It is important that these

substances are not pulled into the NTF-515B unit during the

procedure resulting in possible performance issues and costly

repairs not covered by MAHLE's warranty.

m When servicing a vehicle, first check the valve stems and valve

stem caps for any type of fluid or foreign substance. Install

deflators and allow tires to deflate to 0PSI if there is evidence

of any foreign substance, then connect hoses and reinflate

tires with nitrogen.

m While using the NTF-515B, the automatic drain function of

the filters may activate to remove excess water and oil. This

is normal with the standard operation of the unit.

3.1.1 Over pressure setting (OPS) and nitrogen

purge cycles (N2P)

The Over Pressure Setting can be used to improve the nitrogen

purity in the tire(s). The Over Pressure Setting over inflates the

target pressure on the first inflation by the OPS amount. For example, if the OPS is set at 5PSI and the initial target pressure is

set to 30PSI, the N2P will deflate to 3PSI, inflate to 35PSI, deflate

to 15PSI, and then inflate to 30PSI. Inflating to 35PSI during the

first inflation instead of 30PSI will result in higher nitrogen purity

in the tires.

The number of Nitrogen Purge Cycles can be adjusted. One

Nitrogen Purge Cycle consists of deflating, inflating to target

pressure (+OPS if adjusted), deflating to 50% of target pressure,

and inflating to the target pressure. This entire process can be

automatically repeated by changing the number of Nitrogen

Purge Cycles. This will result in a higher nitrogen purity in the tires.

1. Turn power switch on.

2. Press N2 button once.

3. Press + or - buttons to change the Over Pressure Setting

(OPS).

4. Press START button to save the Over Pressure Setting (OPS).

5. Press N2 button.

6. Press + or - buttons to select desired number of Nitrogen

Purge Cycles (N2P).

7. Press START button to save the number of Nitrogen Purge

Cycles (N2P).

3.2 Battery charging

t The NTF-515B is powered by an internal 12VDC battery.

Charge the battery for at least 5 hours prior to first use.

Battery charge level is displayed on the top screen during

power up of unit.

m When verifying pressure accuracy of the NTF-515B, make sure

the gauges being used are good quality, calibrated gauges.

Low quality pressure gauges, such as "stick" gauges, have

an accuracy of ±2 or 3PSI. This could allow for as much as

3-4PSI difference between the gauge reading and the display.

© MAHLE

t HI indicates the battery is charged. LO indicates low charge

and battery needs to be recharged.

Plug battery charger in wall outlet and insert plug into battery

charging port. Unit can be operated during recharging process. Typical recharge time is 3-5 hours, depending on battery

condition.

Nitrogen service | NTF-515B | 15NTF-515B | 15 | 15 en

3.3 Service phases

3.3.1 Nitrogen purge cycle

y Deflate: Tires are deflated to 10% of the target pressure.

y Inflate: Tires are inflated to target pressure plus the over

pressure setting.

y 50% Deflate:Tires are deflated to 50% of the target pres-

sure.

y Inflate: Tires are inflated to target pressure.

3.3.2 Nitrogen top-off

Deflate/Inflate: Tires are either inflated or deflated to the set

target pressure.

3.4 Nitrogen purge cycle

t Process can be used for single or multiple tires.

1. Attach air supply (150PSI max.) to the NTF-515B.

2. Turn on POWER switch. PCB will display battery charge status

(HI or LO). Ensure the 12VDC battery is charged. See battery

charging section for more information.

3. Verify pressure indicated on AIR PRESSURE gauge is between

120 - 150PSI.

4. Allow unit to build pressure in nitrogen storage tank as shown

on the lower screen (120PSI).

5. Connect hoses to tire(s). NTF-515B unit is equipped with

four service hoses, coiled on both sides. Short (12ft) hoses

should be connected to the tire(s) closest to unit. Long (24ft)

hoses should be connected to tire(s) farthest from unit. Ensure

air chuck(s) are fully engages with valve stem(s) for proper

service.

6. Set the final target pressure by pressing + or - buttons.

7. Check that OPS and N2P are set to desired values.

8. Press and hold START button for 2 seconds (until long beep).

This will start the Nitrogen Purge Cycle.

9. Unit screen will display the pressure in the tire(s) throughout

the service.

10. The unit will beep at the end of service and the word END

will appear on the top LCD.

11. Disconnect hose(s).

t It is recommended to wait 10-15 seconds after the end of

service prior to disconnecting hoses. This allows the tires to

fully balance pressures.

12. Press any key to stop process.

13. Install valve caps on the tire valve stems.

t Nitrogen (N

MAHLE. See Spare and Wearing parts section of manual or call

MAHLE Technical Support/Sales to order at 1-800-468-2321

) Valve cap kits are available for purchase through

2

3.5 Nitrogen purge cycle

t Process can be used for single or multiple tires.

1. Attach air supply (150PSI max.) to the NTF-515B.

2. Turn on POWER switch. PCB will display battery charge status

(HI or LO). Ensure the 12VDC battery is charged. See battery

charging section for more information.

3. Verify pressure indicated on AIR PRESSURE gauge is between

120 - 150PSI.

4. Allow unit to build pressure in nitrogen storage tank as shown

on the lower screen (120PSI).

5. Connect hoses to tire(s). NTF-515B unit is equipped with

four service hoses, coiled on both sides. Short (12ft) hoses

should be connected to the tire(s) closest to unit. Long (24ft)

hoses should be connected to tire(s) farthest from unit. Ensure

air chuck(s) are fully engages with valve stem(s) for proper

service.

6. Set the final target pressure by pressing + or - buttons.

7. Check that OPS and N2P are set to desired values.

8. Press and release START button (a short beep will sound).

This will start the Nitrogen Top-off routine.

9. Unit screen will display the pressure in the tire(s) throughout

the service.

10. The unit will beep at the end of service and the word END

will appear on the top LCD.

11. Disconnect hose(s).

t It is recommended to wait 10-15 seconds after the end of

service prior to disconnecting hoses. This allows the tires to

fully balance pressures.

12. Press any key to stop process.

13. Install valve caps on the tire valve stems.

3.6 Top-off and nitrogen purge cycle

counter

The NTF-515B will keep track of the total number of Top-offs and

Nitrogen purge cycles performed over the life of the unit.

To access this information:

1. Press and hold + and - buttons simultaneously until unit

beeps.

2. Screen should display Cnt (top off count) and then a number

on one screen if less than 1000 cycles. If more than a 1000

cycles, one number will be displayed (the thousands count),

followed by a screen showing the hundreds, tens, and ones

digits.

3. Press + button.

4. Screen should display CNP (Nitrogen purge count) and then

a number on one screen if less than 1000 cycles. If more than

a 1000 cycles, one number will be displayed (the thousands

count), followed by a screen showing the hundreds, tens, and

ones digits.

5. Press START button to exit counter mode.

© MAHLE

16 | NTF-515B | Maintenanceen

4. Maintenance

4.1 Maintenance interval

Description Action Frequency

Filter elements

(Water, oil, carbon)

Automatic drain Clean When required.

Replace Yearly or when indicator on the filter

head moves to the CHANGE area as

shown in Fig. 11.

4.2 Automatic water/oil drain

4.2.1 Checking functionality

t A periodic check of the automatic drains is necessary to en-

sure maximum membrane life.

To verify float is functioning correctly:

1. Open the filter bowl by turnign one-quarter turn counterclockwise.

2. Inspect inside of filter housing for water or oil.

3. If a float is not functioning, it may be submerged in water/oil.

t If a float is found to be inactive, follow the cleaning procedure.

t If necessary, a replacement drain is available for purchase.

MSS P/N 026 80386 00.

4.2.2 Cleaning automatic drain

Fig. 11: Filter life indicator

m Never perform any maintenance work which is not expressly

recommended in this section.

m Contact customer service if components have to be replaced

other than in the course of maintenance work.

Fig. 12: Automatic drain disassembly

1 Filter bowl

2 Float housing

3 Needle

4 Float seat

5 O-ring

6 Retention nut

To clean the automatic drains:

1. Turn the filter bowl (Fig. 12, Pos. 1) counter clockwise oneeighth turn and pull the filter bowl down from the filter housing.

2. Unscrew the nut (Fig. 12, Pos. 6).

3. Remove the drain unit (Fig. 12, Pos. 2-5) from the filter bowl

(Fig. 12, Pos. 1).

4. Remove the o-ring (Fig. 12, Pos. 5).

5. Carefully pull the float housing (Fig. 12, Pos. 2) from the seat

(Fig. 12, Pos. 4). Do not bend the needle (Fig. 12, Pos. 3).

6. Clean the parts with soap and water. Make sure the needle

bore is open and clean.

7. Assemble the parts in the reverse order. Make sure the parts

are dry before reassembly.

© MAHLE

Maintenance | NTF-515B | 17NTF-515B | 17 | 17 en

4.3 Filter element maintenance

m The condition of the filter element (mounted on rear of unit)

can only be checked when shop air is connected to the unit

and it is filling the tank with nitrogen. It may be necessary to

relieve some tank pressure to cause the tank to fall below the

set pressure and cause the tank to begin filling.

m The filter elements must be chaged when the indicator moves

into the CHANGE area and at least once annually to protect

the membrane warranty.

4.4 Troubleshooting

Problem Possible Cause Solution

Display does not light Dead battery Recharge battery

Inflat i o n proce s s

starts, but does not

complete

Air chucks will not

seal to the tire valve

stem(s)

Air chucks leak while

not conn ected to

tires

E4 on display

E6/E16 on display

E5/E8/E9 on display PCB or sensor error Contact MSS support

E10 on display Low battery charge

E11/E12 on display PCB fault Contact MSS support

Low supply pressure or

leaks exist

Air chucks work or not

completely pushed on

tire(s)

Air chucks worn Replace air chucks

Over inflation due to

blocked hose

Unit powered ON while

connected to tires

Check supply pressure

and confirm no leaks are

detected

Make sure air chucks are

pushed on tires or replace air chucks

Remove blockage or replace hose

Remove hoses from tires

and turn power OFF/ON

again

Charge battery for at

least 5 hours

Fig. 13: Filter disassembly

1 Filter housing

2 Sieve

3 Filter element

4 Knob

5 Filter bowl

6 Bleeder screw

To replace filter element:

1. Disconnect the air supply.

2. Allow system to depressurize (air pressure gauge should read

0 PSI).

3. Unscrew the bleed screw (Fig. 13, Pos. 6) slowly to ensure

that the filter is depressurized.

4. Turn the filter bowl (Fig. 13, Pos. 5) one-eighth of a turn

counter-clockwise and pull the filter bowl down from the filter

housing (Fig. 13, Pos. 1).

5. Unscrew the blue knob (Fig. 13, Pos. 4).

6. Remove the old filter element (Fig. 13, Pos. 3).

7. Clean the sieve (Fig. 13, Pos. 2), filter bowl, and the filter

housing, if necessary.

8. Install the new filter element.

9. Assemble the parts in the reverse order.

© MAHLE

18 | NTF-515B | Maintenanceen

4.5 Spare and wearing parts

4.5.1 NTF-515B

Description Order number

2 inch gauge, 0-160PSIg/bar 026 80452 00

Power switch 024 80066 00

Circuit board and sensors 024 80196 00

Hose clamp (to clamp hose to hose manifold) 021 80169 01

Air chuck 023 80390 00

Service hose (short) - 12ft 060 81638 12

Service hose (long) - 24ft 060 81638 24

Replacement air chuck (1) (w. barb & clamp) 355 80101 00

Replacement air chucks (5) (w. barbs & clamps) 355 80106 00

Service hose assembly (12ft) 355 80094 00

Service hose assembly (24ft) 355 80095 00

Battery charger power cord 025 80436 00

Battery charger 026 80636 00

Battery charger and cord 355 80204 00

Battery - 12VDC 040 80220 00

Automatic drain float assembly 026 80386 00

Filter element replacement kit 355 80267 00

N2valve cap kit (200 caps) 355 80026 00

N2valve cap kit (1000 caps) 355 80157 00

N2valve cap kit (100 packs of 5 caps) 355 80191 00

N2valve cap kit (500 packs of 5 caps) 355 80231 00

Replacement purity tester 355 80022 00

Operation manual 035 82548 00

Dually hose adapter connection kit (accessory) 355 80123 00

Digital tire gauge and coiled hose (accessory) 355 80258 00

Sealant detection kit (accessory item) 360 81733 00

© MAHLE

5. Notes

Notes | NTF-515B | 19NTF-515B | 19 | 19 en

© MAHLE

MAHLE Aftermarket Inc.

10 Innovation Drive

York, PA 17402

USA

717-840-0678

www.servicesolutions.mahle.com

2017-09-21

035 82548 00

Loading...

Loading...