MAHLE CWL-20E Operation Manual

Operation Manual

Wireless w

heel lift system

MAHLE CWL-20E

EN

Patents pending

en | 2 |

CWL

-

20E

EVERY PERSON WHO OPERATES THIS

READ THIS MANUAL

EQUIPMENT NEEDS TO KNOW AND

UNDERSTAND ALL OF THE INFORMATION IN

THIS MANUAL – FAILURE TO DO SO COULD

RESULT IN SERIOUS INJURY OR DEATH.

CAREFULLY AND

RETAIN FOR YOUR

RECORDS

CWL-

20E

| 3 |

en

Contents

Contents

1. Safety Regulations ................................................ 4

1.1 Warnings ....................................................... 4

2. Foreword ................................................................ 6

2.1 From the manufacturer ................................. 6

3. Symbols Use .......................................................... 6

3.1 Signal words ................................................. 6

4. FCC Part 15 Statement for User’s Manual ........... 6

4.1 Operation of equipment ................................ 6

5. Responsibilities ..................................................... 7

5.1 Receiving inspection ..................................... 7

5.2 Owner and/or operator responsibilities ......... 7

6. Specifications ........................................................ 7

6.1 CWL-20E ...................................................... 7

7. Product Description .............................................. 8

7.1 Component identification .............................. 8

9. Battery information ............................................. 17

9.1 Battery type (lift unit) ................................... 17

9.2 Battery type (touch screen controller) ......... 17

9.3 Charging the batteries ................................. 17

9.4 Battery life ................................................... 18

10. Emergency procedures ....................................... 19

10.1 Emergency stop .......................................... 19

10.2 Manual lowering .......................................... 19

11. Using Multiple Lifts in the Same Work Area ...... 20

11.1 Adjusting lift communication frequency ...... 20

12. Maintenance and Inspection .............................. 21

12.1 Structural inspection ................................... 21

12.2 Maintenance instructions ............................ 22

12.3 Periodic lubrication ..................................... 22

12.4 Valve cleaning and inspection ..................... 22

8. Operation ............................................................... 9

8.1 Preparing the work area ................................ 9

8.2 Prepare the vehicle ....................................... 9

8.3 Prepare the lift units .................................... 10

8.4 Lift system initialization ............................... 11

8.5 Touch screen controller to lift

communication ........................................... 12

8.6 Main operation screen ................................ 13

8.7 Raising/lowering the vehicle ........................ 14

8.8 Lowering a vehicle to the ground ................ 14

8.9 Single/paired operation ............................... 15

8.10 Park mode .................................................. 16

8.11 Options ....................................................... 16

8.12 Status indicators ......................................... 16

8.13 Changing the touch screen frequency

on the lift units ............................................ 16

12.5 Lift table adjustment ................................... 23

12.6 Sensor adjustment ...................................... 23

12.7 Electronic components ............................... 23

12.8 Control box removal .................................... 24

13. Optional Adapters ............................................... 25

Installing the adapters ........................................... 25

14. Troubleshooting .................................................. 26

15. Maintenance Chart .............................................. 28

16. Notes .................................................................... 30

en | 4 |

CWL

-

20E

Safety Regulations

1. Safety Regulations

1.1 Warnings

Failure to follow all of these safety instructions can

lead to severe injury or death from a sudden loss of

the load. Contact the manufacturer at the numbers or

address printed on the back cover of this manual if

you have any questions.

Anyone who operates this jack must read and

understand all the instructions and warnings

provided with this jack before being allowed to use

it. All operators must be careful, competent, trained,

and qualified in the safe operation of the jack. The

owner (or other responsible individual) must ensure

that any operator observes the proper safety

procedures for using this jack at all times. If the

operator does not read well or is not fluent in English,

the owner / manager must read and review the

instructions and warnings in the manual with the

operator in the operator's native language to be sure

that the operator will use the jack properly.

The owner / manager must keep this manual for

future reference, and make sure the warning labels

on the jack are legible and intact at all times.

Replacement labels and manuals are available from

the manufacturer. Call the manufacturer using the

contact information on the back cover of this manual

if you have any questions.

Make sure the load does not exceed the maximum

capacity of the lift. Maximum capacity is 10,000 lbs.

/ 4,540 kg. per lift. Never use the lift system to raise or

support more than maximum capacity per lift. Never

use a lift as a stand to support more than maximum

capacity per lift.

NEVER modify the product in any way.

Modifications (other than those explicitly discussed in

this manual – e.g., use of optional small wheel

adapters) may cause the lift to perform improperly,

resulting in injury or death.

Always use lift on a hard level surface, capable of

sustaining the load. Be sure surface is clean and free

of debris, cracks, and chips.

The lift system is designed to lift over-the-road

vehicles with rims of at least 21 inches in diameter

(14 inches in diameter if the manufacturer supplied

optional adapters are used). NEVER use the lift

system on vehicles with rims

diameter (14 inches if adapters are used).

less

than 21 inches in

Use the lifts only in pairs of 2 or 4 lift units, on the

opposite ends of the same axle. Never lift using a

single unit.

NEVER use the lift system to raise a vehicle by the

frame or structural member. The lift is designed to

be used only beneath the vehicle tires.

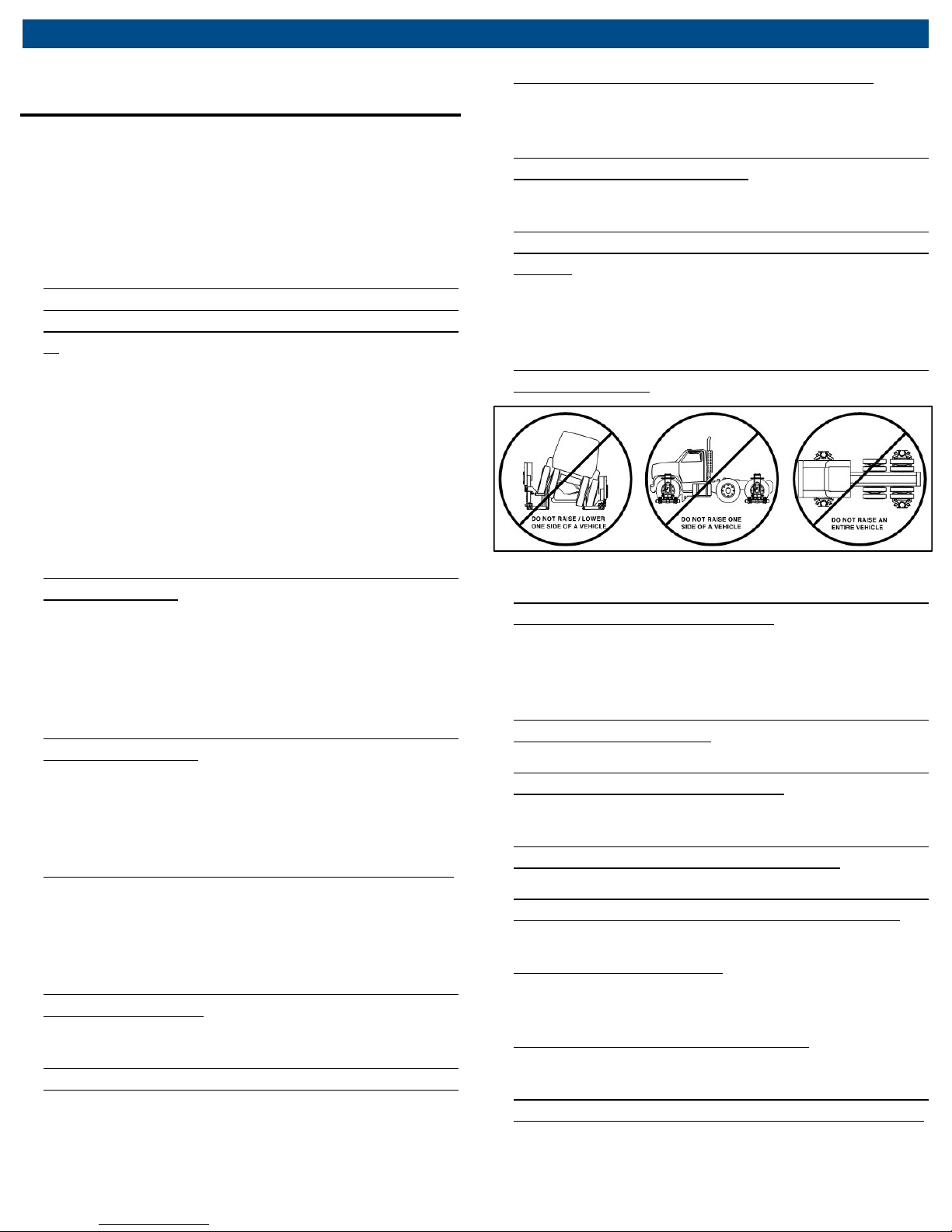

DO NOT raise one end of a vehicle if the opposite

end is supported by stands or another lifting

device. When using two lift units to raise one end of a

vehicle, the opposite end of the vehicle must be in

contact with the ground, transmission in neutral and

parking brake released.

To prevent tipping, never raise or lower just one

side of a vehicle.

Fig. 1: Warnings

DO NOT place hands, feet, other body parts, or

clothing on or near the lift table. There are potential

pinch points that can injure hands and fingers or

possibly grab clothing and pull body parts into pinch

points.

NEVER stand under the lift or vehicle when it is

being raised or lowered.

NEVER operate lift system from a distance that the

work area is not plainly visible, another room, or

from under the vehicle.

NEVER use the lift system in conjunction with any

other equipment used to raise a vehicle.

Never use blocks, adapters, or accessories that

have not been provided by the manufacturer, or

cribbing devices of any kind with this lift system.

To reduce the risk of fire, do not operate equipment

in the vicinity of open containers of flammable liquids

(gasoline).

To reduce the risk of electric shock, do not use on

wet surfaces or expose to rain.

NEVER raise the lift system or an individual lift

when an automatic pin is partially or fully inserted.

If a lift raises against an inserted pin, stop raising

immediately.

CWL-

20E

| 5 |

en

Contents

NEVER use the manual operation procedure as a

normal operation to raise or lower a vehicle. The

manual operation procedure is intended for use only

when the normal controls are not functioning.

NEVER use the lift system as a wheel dolly for the

removal of tires.

Always keep the covers closed on the lift units.

Do not operate equipment with a damaged cord or

if the equipment has been dropped or damaged –

until it has been examined by a qualified serviceman.

If an extension cord is necessary, a cord with a

current rating equal to or more than that of the

equipment should be used. Cords rated for less

current than the equipment may overheat. Care

should be taken to arrange the cord so that it will not

be tripped over or pulled.

Do not operate the lift system with air containing

excess moisture or particulate matter.

NEVER allow the lift system to be used unless all

warning labels and instructional decals are in place

and legible.

NEVER use this jack to lower a vehicle if the

vehicle was raised using another lifting device or

devices. The vehicle should be lowered with the

same equipment that was used to properly raise it

(read and follow the warnings and instructions for this

other equipment).

Always use caution while operating this device and

remain mindful of how the device and load will react

during operation of this device.

Do not let cord or hose hang over edge of table,

bench, or counter or come in contact with hot

manifolds or moving fan blades.

Adequate ventilation should be provided in the work

area.

Keep hair, loose clothing, fingers, and all parts of

body away from moving parts.

Use only as described in this manual. Use only

manufacturer’s recommended attachments.

ALWAYS WEAR SAFETY GLASSES. Everyday

eyeglasses only have impact resistant lenses, they are

NOT safety glasses.

Never use the cord to pull the plug from the outlet.

Grasp plug and pull to disconnect.

Failure to understand and obey this warning may

result in personal injury or death.

en | 6 |

CWL

-

20E

Foreword

Immediate

or

injury.

impending

or

injury

Possible

injury

Possible

Possible property

2. Foreword

2.1 From the manufacturer

Thank you for your purchase. To complement the

offering of A/C, fluid and nitrogen service equipment,

MAHLE Service Solutions has partnered with Gray

Manufacturing to provide the highest quality hydraulic

and pneumatic equipment available for the professional

service technician. This equipment adheres to high

standards promised in the MAHLE guarantee including

the assurance of innovation and reliability that comes

with the Gray Manufacturing name. Please contact

MAHLE Service Solutions’ customer service at (800)

468-2321 or tech.mss@us.mahle.com with any

comments or questions.

3. Symbols Use

3.1 Signal words

Signal words call attention to a safety message or

messages, or a property damage message or messages,

and designate a degree or level of hazard seriousness.

Signal words used in this manual include:

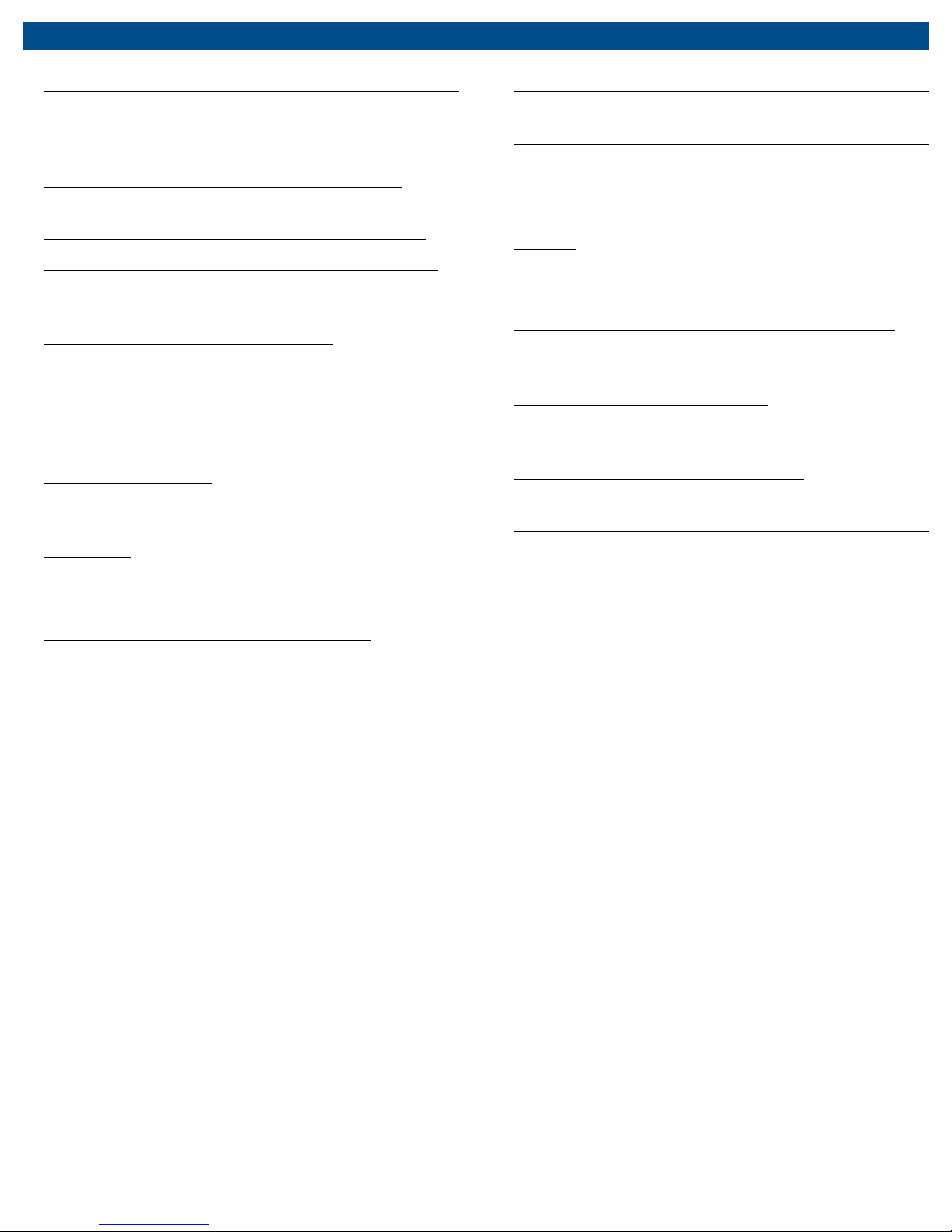

Keyword

DANGER

WARNING

CAUTION

NOTICE

Probability of

occurrence

impending danger

Possible

danger

dangerous

situation

damage to

property

instructions not observed

Death

Death

Minor

damage

Severity of danger if

severe

severe

4. FCC Part 15 Statement for

User’s Manual

4.1 Operation of equipment

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired

operation.

WARNING!

approved by the party responsible for compliance could

void the user’s authority to operate this equipment.

NOTE: This equipment has been tested and found to

comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there is

no guarantee that interference will not occur in a

particular installation. If this equipment does cause

harmful interference to radio or television reception,

which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment

Connect the equipment into an outlet on a

Consult the dealer or an experienced radio/TV

Changes or modifications not expressly

and receiver.

circuit different from that to which the receiver

is connected.

technician for help.

CWL

-

20E

7 |

en

Responsibilities

5. Responsibilities

5.1 Receiving inspection

Before attempting to operate this equipment, thoroughly

read and understand this manual. Completely remove all

tape and packaging. Inspect the equipment immediately

upon delivery. If shipping damage is evident, inform the

delivering carrier immediately and contact the

manufacturer using the contact information on the back

cover of this manual.

5.2 Owner and/or operator responsibilities

All personnel involved in the use and operation of this lift

system must be careful, competent, trained, and qualified

in the safe operation of this equipment and its proper use

when servicing motor vehicles and their components. It is

the responsibility of the employer, owner, and/or manager

to ensure that all personnel working with and around the lift

system know what they are doing, both during normal

operation and in emergency situations. To ensure all

personnel are properly trained and qualified, the following

items must be done prior to using the lift system:

All personnel must know and understand all

instructions and warnings before working with or

around these lifts. “All personnel” includes operators

as well as people working on or in the vicinity of

vehicles raised by the lift system.

All personnel must read and understand the contents

of the owner’s manual. If any personnel are illiterate or

not fluent in English, the employer, owner, and/or

manager must read and discuss the instructions and

warnings with them in a language they understand,

making sure that all personnel know this information

and observe the proper procedures for use of these

lift units.

The employer, owner, and manager are responsible

for maintaining the manual and all on-product

labeling. Labeling should be legible and intact at all

times. The manual must be readily available to all

personnel. Contact the manufacturer to receive

replacement labeling. Replacement (or extra) copies

of the manual are available from the manufacturer.

The employer, owner, and/or manager must enforce

safe work practices with the lift system in order to

ensure that personnel not only know how to use the

lifts safely, but also that they actually do what they

should.

As part of training, the employer, owner, and/or

manager should have all personnel practice normal

and emergency operating procedures without loads

prior to using the lift system to raise loads.

|

This lift system is not a product that personnel can just

“figure out” on their own. This lift system has been

designed to be easy to use, but it requires thoroughly

trained and knowledgeable personnel to use it safely.

Failure to operate this lift system according to the warnings

and instructions can result in severe injury or death.

It is highly recommended that the lift system be operated

using only clean and dry air. Any particulate matter or

moisture in the air can cause poor performance of the

pneumatic valves and/or lead to premature failure of the

valves. If the air system supplying air to the lift system

delivers air with particulate matter or moisture, a

compressed air dryer and filter should be added.

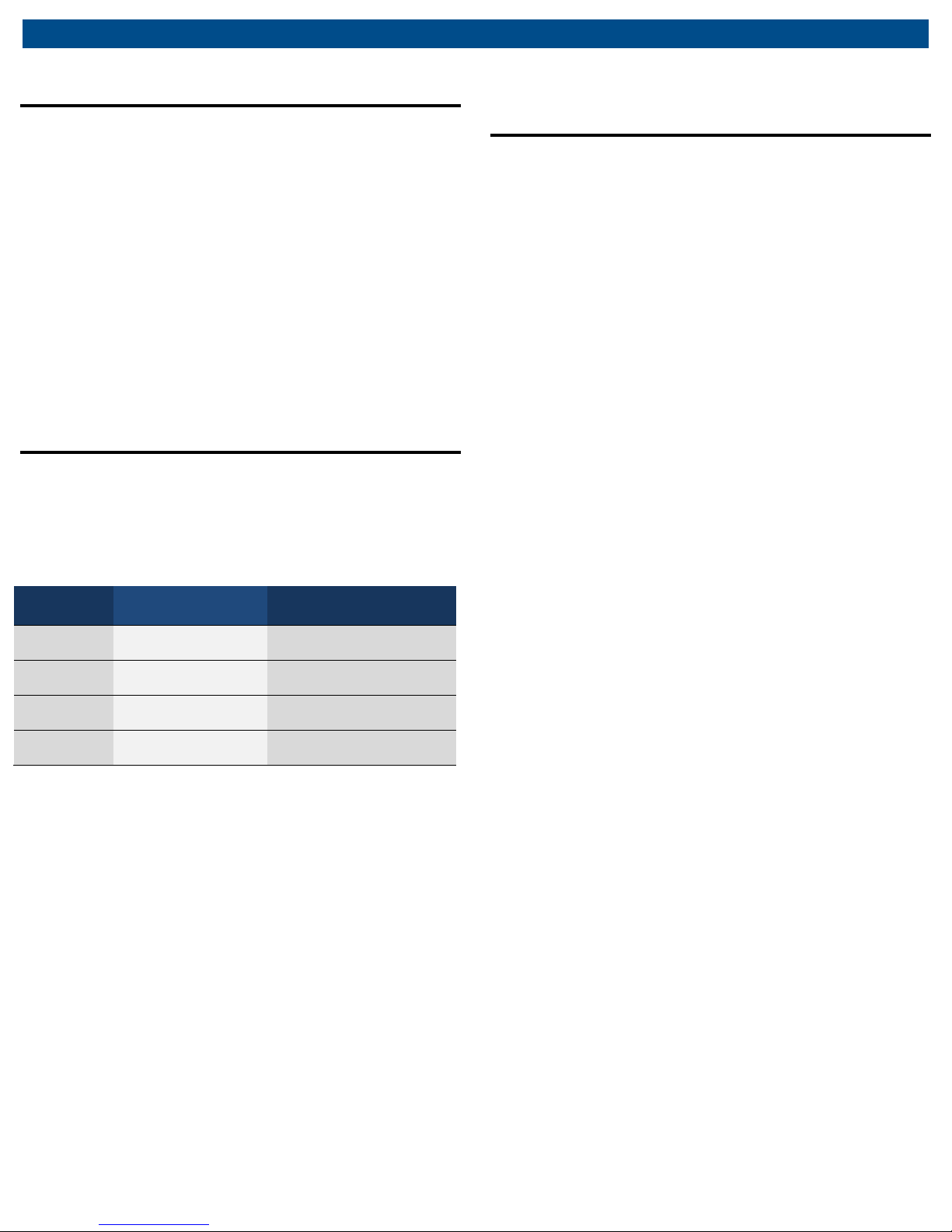

6. Specifications

6.1 CWL-20E

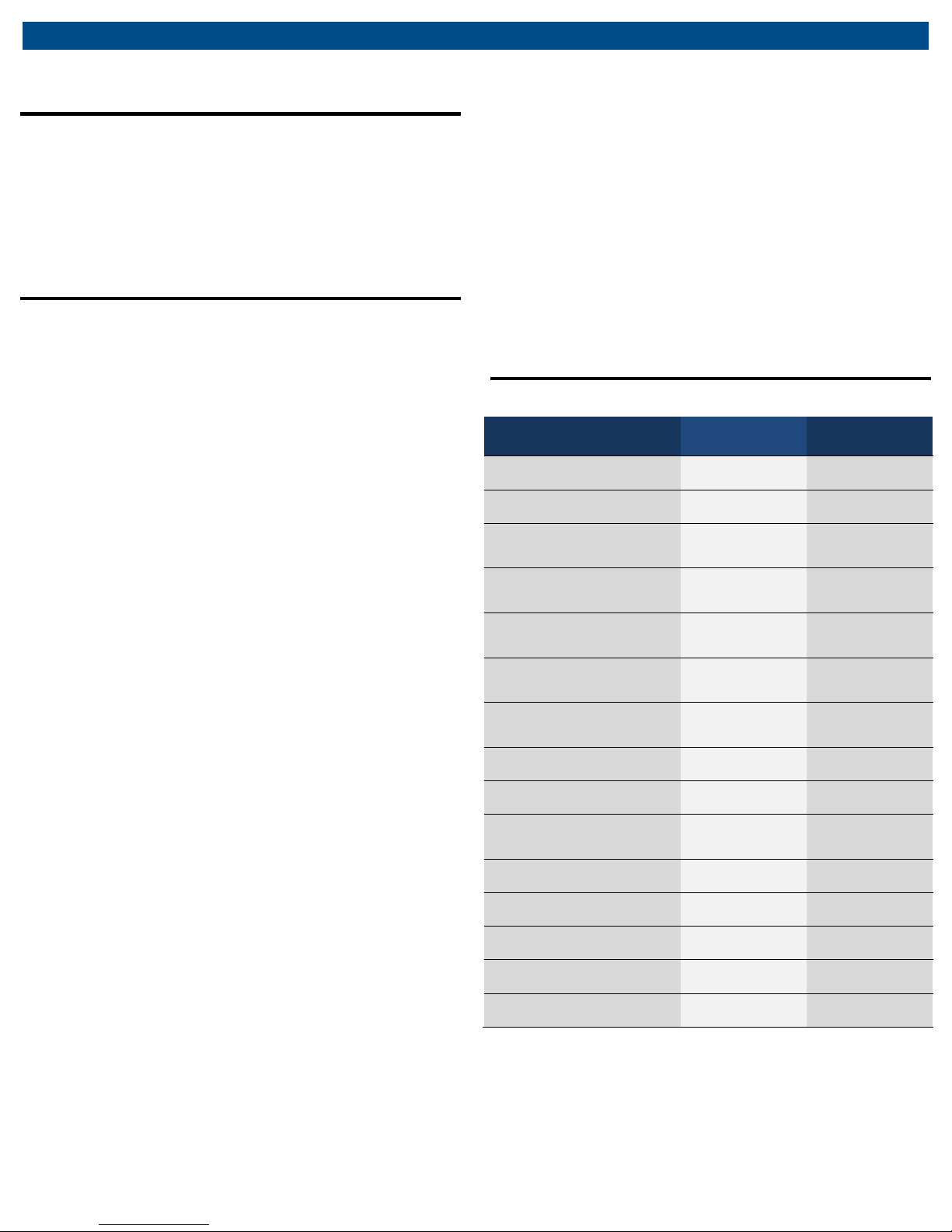

Model CWL-20E US units Metric units

Maximum capacity (each lift) 10,000 lb 4,540 kg

Maximum air pressure 160 psi 11.0 bar

Minimum air pressure for

rated capacity

Minimum air pressure 85 psi 5.9 bar

Minimum wheel diameter

(w/o adapters)

Minimum wheel diameter (w.

adapters)

Maximum tire to fender

clearance

Weight per lift 610 lb 445.4 kg

Adapter weight 22 lb 10 lb

Ground pressure for each lift

(max. load)

Width 41.6 in 105.7 cm

Depth 45.25 in 115.0 cm

Height (lowered) 53.25 in 135.3 cm

Height (raised) 77.25 in 196.2 cm

Charger voltage required 120VAC / 60Hz 120VAC / 60Hz

150 psi 10.3 bar

19 in 48.3 cm

16 in 40.6 cm

8 in 20.3 cm

275 psi 19.3 kg/cm

2

en | 8 |

CWL

-

20E

Product Description

7. Product Description

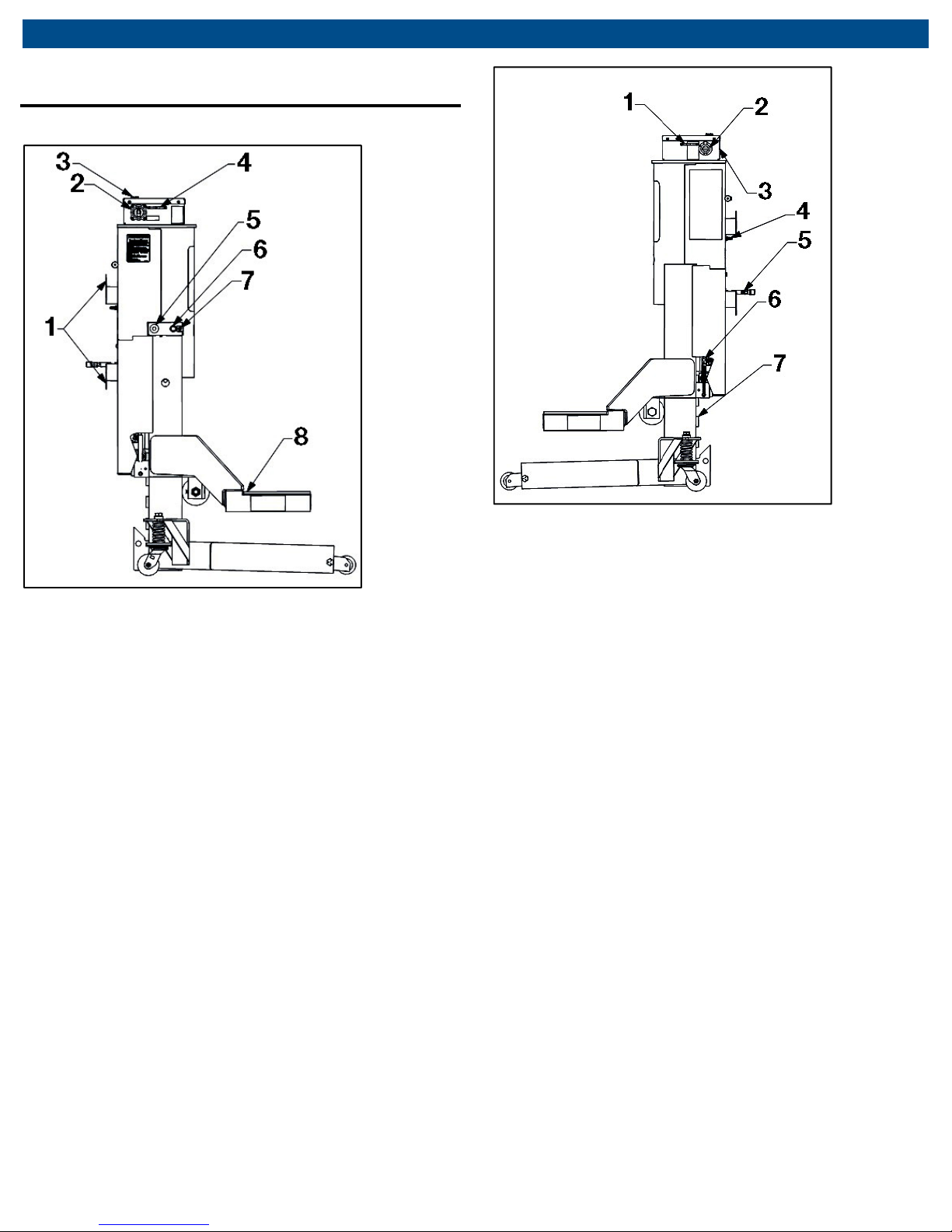

7.1 Component identification

Fig. 2: CWL-20E side view

1 Hose brackets

2 Master on/off switch

3 Status indicators

4 Screen communication antenna

5 Emergency stop button

6 Communication button

7 Manual raise/lower toggle switch

8 Lift table

Fig. 3: CWL-20E side view 2

1 Lift communication antenna

2 Charger inlet

3 Electronics enclosure

4 Air inlet

5 Air hose

6 Down stop handle

7 Down stop lug

CWL

-

20E

| 9 |

en

Operation

8. Operation

8.1 Preparing the work area

It is important that the surrounding area be properly

chosen and prepared before raising a load.

1. Use the lift system only on hard surfaces capable of

safely supporting the load. The surface must be

strong enough to support the weight of the lift units

and the vehicle being raised. The ground pressure for

each lift unit (at maximum load) is 275 psi (19.3

kg/cm2). The ground pressure listed is an

approximation and may be higher under some

conditions. Hot asphalt can become soft and should

be avoided to prevent property damage or an unsafe

situation.

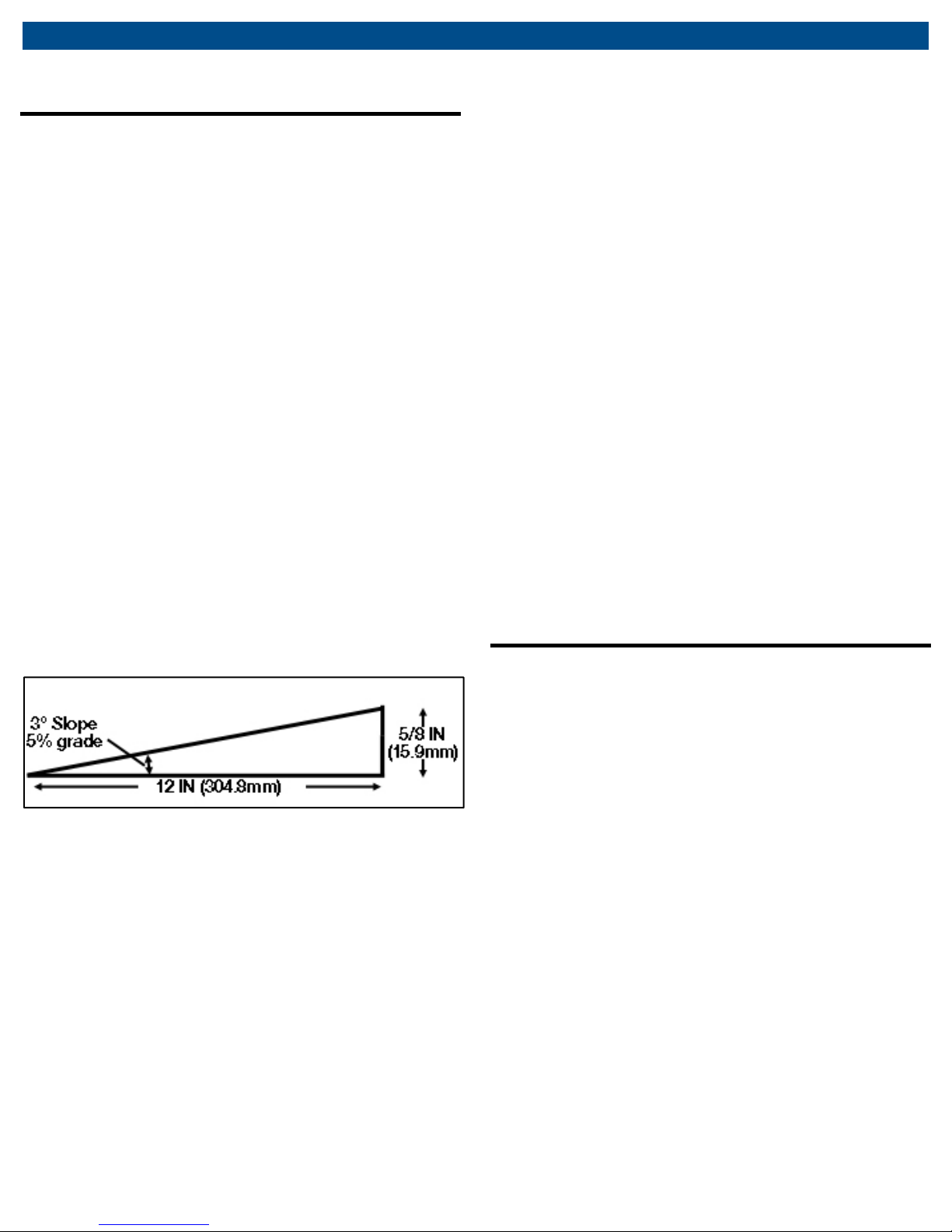

2. Use the lift system only on level, even surfaces. A

level surface is considered to be 3° slope or less. A

surface with 3° slope is equivalent to a 5% grade or

5/8 in. (15.9 mm) rise or drop per horizontal foot

(304.8 mm) (See Fig. 4 below. Note also that for each

degree of slope a surface rises or drops 0.210 in.

(5.33 mm) per horizontal foot (304.8 mm)). The surface

must also be free of ripples, ridges, depressions,

holes, or any undulation (e.g., a seam in a concrete

floor) that would cause only part of the lift unit’s

footprint to be in contact with the floor.

5. If the lift system is used outdoors the operator

assumes all risk. Understanding that these are

portable lifts, it is foreseeable that they can and will be

used outdoors.

WARNING! If lift units are used outdoors the following

conditions must be met:

Do NOT use lift units when wind speeds or gusts

exceed 20 mph to avoid tipping or loss of load.

Do NOT leave lift units unattended when used

outdoors to avoid inadvertent operation by untrained

operators and unforeseen changes in weather

conditions.

Do NOT use lift units outdoors when precipitation of

any type is falling or expected during the time the

units will be used. There is a risk of electric shock if lift

units are used while precipitation is falling.

Do NOT charge lift units while outdoors. Only charge

lift units while indoors to avoid risk of electric shock.

If these conditions cannot be met, move the vehicle

and lift units (separately) to an indoor area where the

lifting operation can be performed safely.

WARNING! NEVER attempt to move or reposition a

lift unit when a vehicle is raised on the lift unit.

8.2 Prepare the vehicle

Fig. 4: Slope of ground under lift

3. Make sure there is adequate clearance above the

highest point of the vehicle (including things like

vehicle exhaust pipes, air dams, etc.) so the vehicle

does not contact any overhead objects when raised

(e.g. ceiling/roof structural components, duct work,

hanging lights, heating/AC units, etc.). The lift system

can raise a vehicle as much as 24” (610 mm, but the

vehicle will extend vertically above this. The height of

the lift unit alone (at maximum lift height) is 77 1/4”

(1,962 mm).

4. Clear the work area (especially the area underneath

the lift unit) of any unnecessary personnel, tools,

equipment and other materials. No unauthorized

personnel should be allowed in the work area where

the lifts are being used.

1. The vehicle’s wheels (or rims; not the tires) should be

at least 19 inches in diameter or else they could fall

through the cradle of the lift table (for example, if the

tires deflate). For wheels 16 to 19 inches in diameter

refer to the “Optional adapters” section on page 25.

2. Check that the tires on the vehicle are properly

inflated and are in road-worthy condition. Make sure

the weight on any single tire does not exceed the

rated capacity of its lift unit, as the total weight of the

vehicle may not be evenly distributed across all lifted

tires. Also, be sure to consider the weight carried by

unsupported axles (i.e. a set of 4 lift units used to

raise a vehicle with three axles).

en | 10 |

CWL

-

20E

Operation

8.3 Prepare the lift units

It is important to prepare the lift units so they can be

used safely together.

1. Make sure the lift system is appropriate for the type

and weight of the vehicle to be lifted. Determine that it

is safe to raise the vehicle by calculating the weight of

the vehicle and the load applied to each lift unit when

the vehicle is raised. NEVER exceed the rated

capacity of an individual lift unit. Also, the lift system

is to be only used in sets where lift units are

positioned on opposite ends of the same axle–

NEVER as a single lift unit or on only one side of a

vehicle.

2. Before each use, you should inspect each lift unit for

any visible signs of wear or damage. See the

“Structural Inspection” section on page 21 for details

about how to inspect the lift unit.

WARNING!

WARNING! If you see any signs of wear or damage,

WARNING!WARNING!

or if there is any indication that the lift unit is not

performing normally, immediately take it out of service

and contact the manufacturer. NEVER use a lift unit

that appears damaged in any way.

3. Before each use, make sure the battery is fully

charged (see the “Charging the batteries” section on

page 17 of this manual). If the battery has not been

given time to fully charge, charge the battery before

use. Failure to fully charge the battery before use can

reduce the life of the battery.

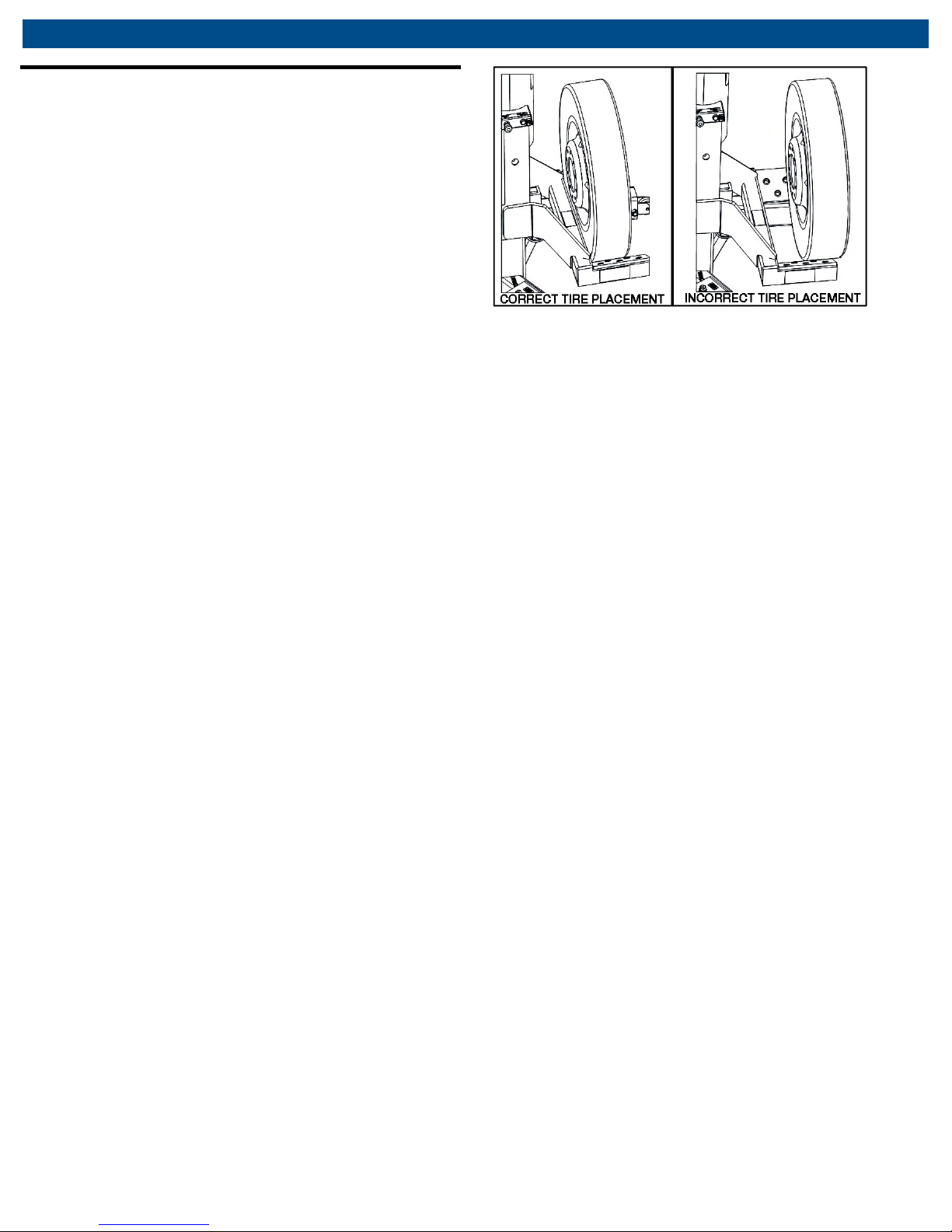

Fig. 5: Position lift table tube against tire

6. Connect an air hose from a compressed air source to

one of the lifts. The air hose from that lift can be

connected to the next lift and so on to daisy chain

them all together. The air hose on the last lift can stay

wrapped on its hose brackets. If desired, separate air

hoses from a compressed air source can be brought

in for multiple lifts. In general, performance will

increase with the number of air hoses brought in.

7. Place the vehicle transmission in neutral and release

the parking brake.

4. Transport the lift units to the work area by wheeling

them manually. A lift unit should be wheeled to the

work area over smooth, level surfaces avoiding any

obstacles or unsafe situations.

WARNING!

WARNING! Jolting caused by the lift unit’s wheels

WARNING!WARNING!

catching on uneven surfaces can cause physical

strain and personal injury.

5. Position the lift units so the lift pads cradle the tires at

opposite ends of the same axle. Make sure the lift

pads cradle the tires evenly and are parallel with the

wheel and tire. Position the lift pads under the tire so

the lift table tube contacts the tire (see Fig. 5).

Loading...

Loading...