Operation Manual

Wheel lift system

MAHLE CWL-20

EN

U.S. Patent No. D357,106 & 5,484,134

en | 2 |

CWL

-20

EVERY P

ERSON WHO OPERATES THIS

READ THIS MANUAL

EQUIPMENT NEEDS TO KNOW AND

UNDERSTAND ALL OF THE INFORMATION IN

THIS MANUAL – FAILURE TO DO SO COULD

RESULT IN SERIOUS INJURY OR DEATH.

RETAIN FOR YOUR

CAREFULLY AND

RECORDS

CWL

-20 | 3 |

en

Contents

Contents

1. Safety Regulations ................................................ 4

1.1 Warnings ....................................................... 4

2. Foreword ................................................................ 5

2.1 From the manufacturer ................................. 5

3. Symbols Use .......................................................... 5

3.1 Signal words ................................................. 5

4. Responsibilities ..................................................... 6

4.1 Receiving inspection ..................................... 6

4.2 Owner and/or operator responsibilities ......... 6

5. Specifications ........................................................ 6

5.1 CWL-20......................................................... 6

6. Product Description .............................................. 7

6.1 Component identification .............................. 7

7. Operation ............................................................... 8

7.1 Preparing the lifts and vehicle ....................... 8

7.2 Raising a vehicle ........................................... 8

7.3 Pinning the lifts as stands ............................. 9

7.4 Lowering a vehicle to the ground .................. 9

7.5 Using the lifts with support stands .............. 10

Transferring a load to support stands ................... 10

Removing support stands ..................................... 10

8. Maintenance and Inspection .............................. 11

8.1 Structural inspection ................................... 11

8.2 Air hose inspection ..................................... 11

8.3 Maintenance instructions ............................ 11

8.4 Air control unit cleaning instructions ........... 12

8.5 Lift table adjustment ................................... 12

9. Troubleshooting .................................................. 13

10. Optional adapters ................................................ 13

Installing the adapters ........................................... 13

Using the adapters ................................................ 13

11. Maintenance Chart .............................................. 14

12. Notes .................................................................... 16

en | 4 |

CWL

-20

Safety Regulations

1. Safety Regulations

Use the lifts only in pairs, on the opposite ends of

the same axle.

1.1 Warnings

Failure to follow all of these safety instructions can

lead to severe injury or death from a sudden loss of

the load. Contact the manufacturer at the numbers or

address printed on the back cover of this manual if

you have any questions.

Anyone who operates this jack must read and

understand all the instructions and warnings

provided with this jack before being allowed to use

it. All operators must be careful, competent, trained,

and qualified in the safe operation of the jack. The

owner (or other responsible individual) must ensure

that any operator observes the proper safety

procedures for using this jack at all times. If the

operator does not read well or is not fluent in English,

the owner / manager must read and review the

instructions and warnings in the manual with the

operator in the operator's native language to be sure

that the operator will use the jack properly.

The owner / manager must keep this manual for

future reference, and make sure the warning labels

on the jack are legible and intact at all times.

Replacement labels and manuals are available from

the manufacturer. Call the manufacturer using the

contact information on the back cover of this manual

if you have any questions.

Make sure the load does not exceed the maximum

capacity of the lift. Maximum capacity is 20,000 lbs.

/ 9,070 kg. per lift. Never use the lift system to raise or

support more than maximum capacity per lift. Never

use a lift as a stand to support more than maximum

capacity per lift.

NEVER modify the product in any way.

Modifications may cause the lift to perform

improperly, resulting in injury or death.

Always use lift on a hard level surface, capable of

sustaining the load. Be sure surface is clean and free

of debris, cracks, and chips.

The lift system is designed to lift over-the-road

vehicles with rims of at least 21 inches in diameter

(14 inches in diameter if the manufacturer supplied

optional adapters are used). NEVER use the lift

system on vehicles with rims

diameter (14 inches if adapters are used).

less

than 21 inches in

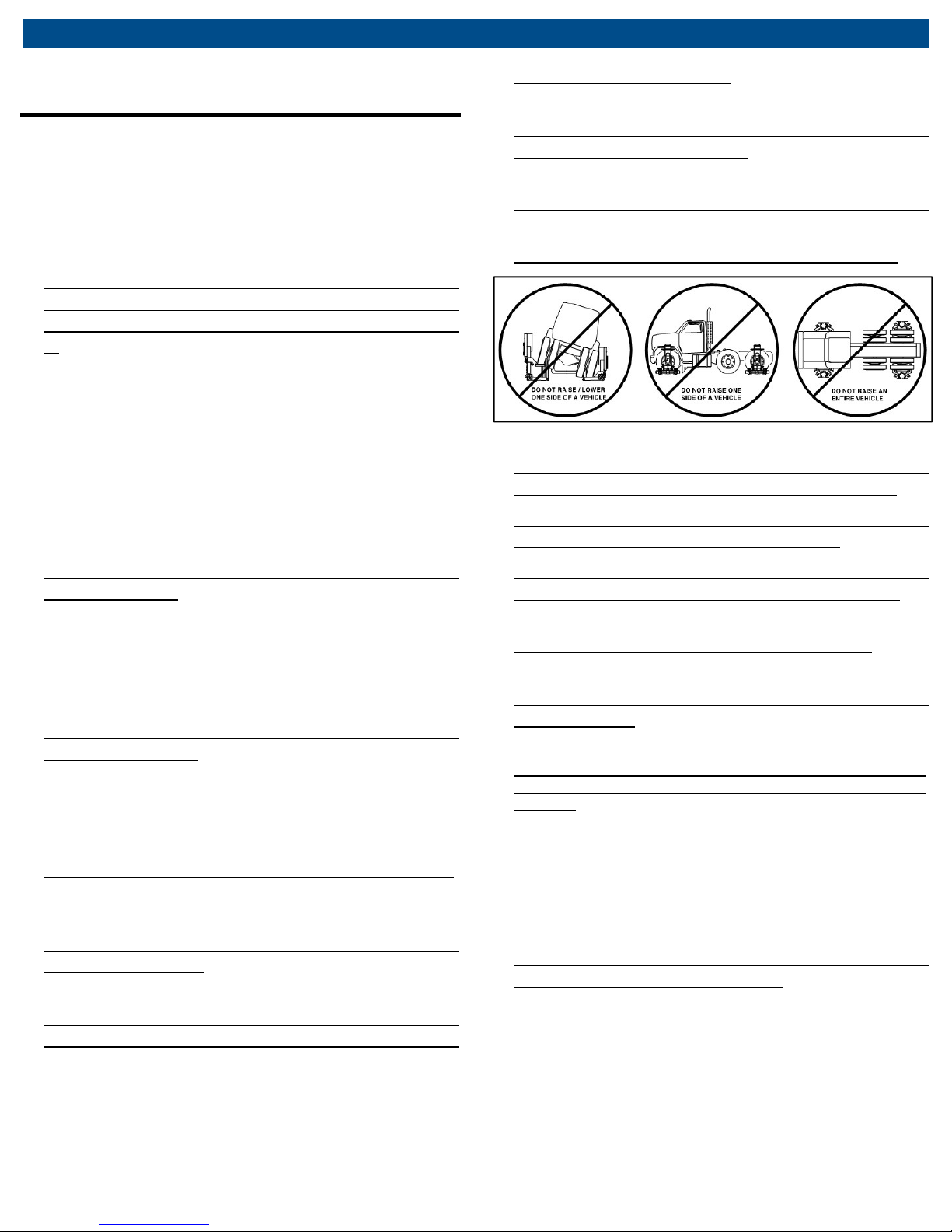

NEVER use the lift system to raise a vehicle by the

frame or structural member. The lift is designed to

be used only beneath the vehicle tires.

To prevent tipping, never raise or lower just one

side of a vehicle.

NEVER lift an entire vehicle with the lift system.

Fig. 1: Warnings

Do not allow any part of your body under the

vehicle until both the lifts are pinned as stands.

NEVER use the lift system in conjunction with any

other equipment used to raise a vehicle.

Never use blocks, adapters, or accessories that

have not been provided by the manufacturer, or

cribbing devices of any kind with this lift system.

NEVER use the lift system as a wheel dolly for the

removal of tires.

NEVER allow the lift system to be used unless all

warning labels and instructional decals are in place

and legible.

NEVER use this jack to lower a vehicle if the

vehicle was raised using another lifting device or

devices. The vehicle should be lowered with the

same equipment that was used to properly raise it

(read and follow the warnings and instructions for this

other equipment).

Always use caution while operating this device and

remain mindful of how the device and load will react

during operation of this device.

Failure to understand and obey this warning may

result in personal injury or death.

CWL

-20 | 5 |

en

Foreword

Immediate

or

injury.

impending

or

injury

Possible

injury

Possible

Possible property

2. Foreword

2.1 From the manufacturer

Thank you for your purchase. To complement the

offering of A/C, fluid and nitrogen service equipment,

MAHLE Service Solutions has partnered with Gray

Manufacturing to provide the highest quality hydraulic

and pneumatic equipment available for the professional

service technician. This equipment adheres to high

standards promised in the MAHLE guarantee including

the assurance of innovation and reliability that comes

with the Gray Manufacturing name. Please contact

MAHLE Service Solutions’ customer service at (800)

468-2321 or tech.mss@us.mahle.com with any

comments or questions.

3. Symbols Use

3.1 Signal words

Signal words call attention to a safety message or

messages, or a property damage message or messages,

and designate a degree or level of hazard seriousness.

Signal words used in this manual include:

Keyword

DANGER

WARNING

CAUTION

NOTICE

Probability of

occurrence

impending danger

Possible

danger

dangerous

situation

damage to

property

instructions not observed

Death

Death

Minor

damage

Severity of danger if

severe

severe

en | 6 |

CWL

-20

Responsibilities

4. Responsibilities

4.1 Receiving inspection

Before attempting to operate this equipment, thoroughly

read and understand this manual. Completely remove all

tape and packaging. Inspect the equipment immediately

upon delivery. If shipping damage is evident, inform the

delivering carrier immediately and contact the

manufacturer using the contact information on the back

cover of this manual.

4.2 Owner and/or operator responsibilities

The owner and / or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this system. The use of portable lifting

devices is subject to certain hazards that cannot be

avoided by mechanical means, but only by the exercise

of intelligence, care, and common sense. Personnel

involved in the use and operation of equipment shall be

careful, competent, trained, and qualified in the safe

operation of the equipment and its proper use when

servicing motor vehicles and their components.

Examples of hazards are dropping, tipping, or slipping of

vehicles or their components caused primarily by

improperly securing loads, overloading, off-centered

loads, use on other than hard level surfaces, and using

equipment for a purpose for which it was not designed.

Warning information should be emphasized and

understood.

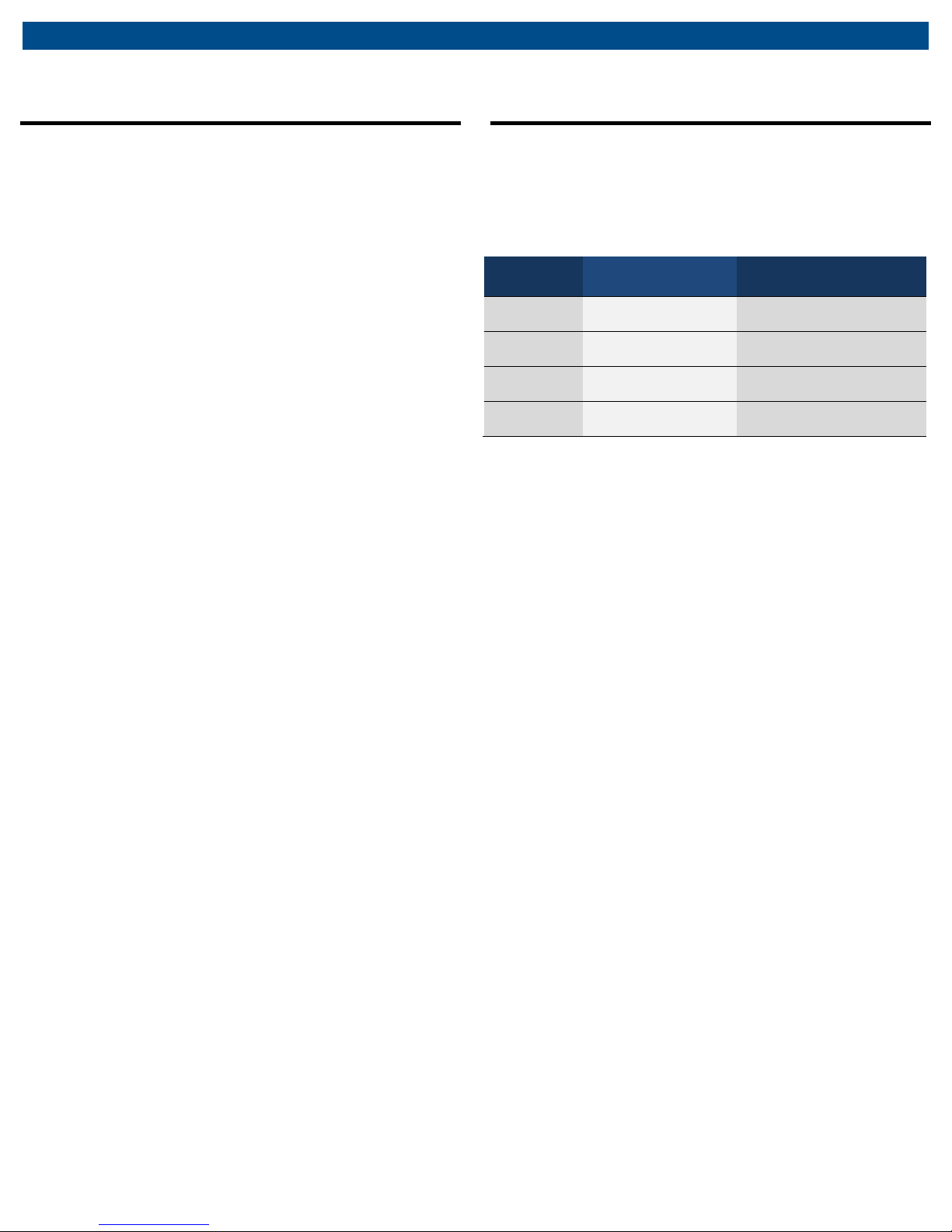

5. Specifications

5.1 CWL-20

Model CWL-20 US units Metric units

Maximum capacity (each lift) 20,000 lb 9,070 kg

Maximum capacity (system) 40,000 lb 18,140 kg

Maximum air pressure 155 psi 10.7 bar

Minimum wheel diameter (w/o

adapters)

Minimum wheel diameter (w.

adapters)

Maximum tire to fender

clearance

System weight 1964 lb 890.9 kg

Weight per lift 982 lb 445.4 kg

Adapter weight 22 lb 10 lb

Width 45 in 114.3 cm

Depth 44 in 111.8 cm

Height (lowered) 63 in 160.0 cm

Height (raised) 93 in 236.2 cm

21 in 53.3 cm

14 in 35.6 cm

8 in 20.3 cm

Air pressure requirements (used in pairs)

The owner / manager must make this manual available to

all personnel using this jack at your direction. They must

read and understand the contents of this manual. If the

operator is not fluent in English, the manufacturer’s

instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the purchaser / owner, making sure that the operator

comprehends its contents and observes the proper

procedures for use of this jack.

Owner and / or user must study and maintain for future

reference the manufacturer’s instructions. Owner and /

or user are responsible for keeping all warning labels and

instruction manuals legible and intact. Replacement

labels and literature are available from the manufacturer.

Weight Air pressure

10,000 lbs.

15,000 lbs.

20,000 lbs.

25,000 lbs.

30,000 lbs.

35,000 lbs.

40,000 lbs.

40 psi

59 psi

78 psi

97 psi

116 psi

134 psi

152 psi

CWL

-20 | 7 |

en

Product Description

6. Product Description

6.1 Component identification

Fig. 2: CWL-20 front view

1 Cylinder head plate

2 Handle grips

3 Load retention pin

4 Base post

5 Lift table tube

6 Lift pad

7 Front wheels

Fig. 3: Air control unit components

1 Air control unit

2 Air control levers

Fig. 4: CWL-20 side view

1 Front wheels

2 Roller wheel

3 Downstop lug

4 Downstop pawl

5 Downstop release handle

6 Air hose

7 Air hose holder

8 Swivel caster

en | 8 |

CWL

-20

Operation

7. Operation

WARNING -

To prevent serious injury or death from

a falling vehicle, make sure the vehicle’s rims are at

least 21 inches in diameter (or 14" if adapters are

used). Make sure the tires are properly inflated, to

maintain necessary tire diameter. Make sure weight

on the vehicle axle does not exceed 40,000 lbs.

WARNING -

To prevent serious injury or death from

a falling vehicle, make sure that the hoses avoid all

pinch points and that they do not pass under the

base of a lift. The base lowers slightly as the vehicle

is raised.

7.1 Preparing the lifts and vehicle

1. Before proceeding, review the Safety Instructions

section of this manual.

2. Position the vehicle on a hard, level surface and set

the parking brake.

3. Check that the tires on the vehicle are properly

inflated, to maintain necessary tire diameter.

4. Position the Wheel Lifts so the lift pads are cradling

the tires at opposite ends of the same axle.

Fig. 6: Air control lever

9.

Connect the air hose from the lift on your right to the

right side of the air control unit. Connect the air hose

from the lift on your left to the left side of the air

control unit (see Fig. 6 for connections).

10. Connect the air supply (145 psi max) to the air inlet

port of the air control unit (see Fig. 3 for connection).

7.2 Raising a vehicle

To prevent serious injury or death from a falling vehicle,

operate both air control levers at the same time and

keep the vehicle level as it is raised or lowered.

5. Push the lift pad under the tire until the lift table tube

contacts the tire (see Fig. 5 for identification).

Fig. 5: Lift table tube and pads

6. Release the vehicle’s parking or air brake and place

the transmission in neutral.

7. Uncoil the air hoses from both lifts and route them for

connecting to the air control unit, at either the front or

the rear of the vehicle.

8. Position yourself at the front or rear of the vehicle so

both lifts are visible. Face the vehicle and hold the air

control unit with the air control levers pointing toward

the vehicle and the quick couplers on the underside of

the air control unit. (See Fig. 6 for orientation).

1. Position one unit on each end of the same axle. Make

sure the lift arms fully engage each wheel.

2.

Raise the vehicle by lifting up on both the air control

levers at the same time. Be sure to operate the air

control levers so the vehicle stays level at all times as

it is raised or lowered.

3.

Raise the vehicle until it is 2"- 4" above the desired

working height (the vehicle will lower by that amount

as the downstop lugs engage). Visually confirm that

the downstop pawls will engage downstop lugs at the

same height on each lift. If they will not engage

downstop lugs at the same height, carefully adjust

vehicle level until the lifts are at the same height. See

Fig. 7 and 8 for downstop pawl and lug identification.

Fig. 7: Downstop lug identification

CWL

-20 | 9 |

en

Operation

7.3 Pinning the lifts as stands

1. With the vehicle 2"-4" above the final working height,

carefully lower the lifts by pushing both the air control

levers down at the same time until the downstop

pawls engage the closest downstop lugs.

2. Visually confirm that the downstop pawls are securely

engaged on the downstop lugs of each lift and the

raised axle is level (see Fig. 8).

Downstop

Pawl

Downstop

Lug

Fig. 8: Downstop pawl and lug identification

3. On both lifts, remove the load retention pin from its

holder and insert it through the oblong hole in the lift

stop bar and fully into the corresponding hole in the

downstop lug (see Fig. 9) to pin the lifts as stands.

Load

retention

pin in

holder.

Lift Stop

Bar.

Insert load

retention

pin here to

pin lift as

stand.

Fig. 9: Load retention pin

4. Exhaust all air from both cylinders by pushing both air

control levers down at the same time.

5. Disconnect the air hoses and coil them on the hose

holders on the back of each lift.

7.4 Lowering a vehicle to the ground

To prevent serious injury or death from a falling

vehicle, operate both air control levers at the same

time and keep the vehicle level as it is raised or

lowered.

To prevent serious injury or death, clear the work area

of all tools and equipment. Make sure all personnel

are clear before lowering a vehicle.

1. Use this lift to lower the vehicle only if you used it to lift

the vehicle. Using this lift to lower a vehicle that was

raised with another device (or multiple devices) could

overload the lift to the point of catastrophic failure.

2. Remove the load retention pins and insert them into

their holders.

3. Uncoil the air hoses from both lifts. Be sure the air

hoses are free from all pinch points.

4. Position yourself at the front or rear of the vehicle so

both lifts are visible. Face the vehicle and hold the air

control unit with the air control levers pointing toward

the vehicle and the quick couplers at the bottom of

the air control unit.

5. Connect the air hose from the lift on your right to the

right side of the air control unit and the air hose from

the lift on your left to the left side of the air control unit

(see Fig. 6).

6. Connect the air supply to the air inlet port of the air

control unit (see Fig. 6).

7. Raise both lifts slightly (about 1/2") so the downstop

pawls are raised above the downstop lugs.

8. At each lift, release the downstop pawl by pushing the

downstop release handle toward the lift (see Fig. 10.)

Downstop

Release

Handle

(controls

downstop

pawl).

Push

handle

toward lift

to release

downstop

pawl.

Fig. 10: Push downstop release handle torward lift

9. Lower the lifts by pushing both the air control levers

down at the same time. Be sure to operate the air

control levers so the vehicle stays level. Lower the lifts

to their lowest position do the downstop pawls will

automatically reset.

If you decide to raise the vehicle again before it has

been fully lowered, you must reset the downstop

pawls. To manually reset the downstop pawls, pull

the downstop release handle toward you on each of

the lifts. (See Fig. 7).

10. Place the vehicle transmission in gear (or park) and

engage the brakes.

11. Disconnect the air hoses and coil them on each lift.

12. Move the lifts away from the work area.

en | 10 |

CWL

-20

Operation

7.5 Using the lifts with support stands

To prevent serious injury or death from a falling

vehicle, never put any part of your body under a

vehicle supported by lift system unless the lifts have

the load retention pins properly inserted to pin the lifts

as stands.

Removing support stands

1. Move the lifts into place at opposite ends of the axle

to be lowered and position them so the lift pads will

cradle the tires when contact is made.

2. Carefully follow steps 7-10 under “Preparing the lifts

and vehicle,” section.

To prevent serious injury or death from a falling

vehicle, operate both air control levers at the same

time and keep the vehicle level as it is lowered.

Vehicles that are not supported evenly may shift and

fall. To avoid serious injury or death by crushing,

make sure that the stands used are the same height,

and that they are positioned at the manufacturer’s

recommended locations the same distance from the

lifts on each side of the vehicle.

Transferring a load to support stands

After the vehicle has been raised (following instructions

under the “Raising a vehicle” section) and the wheel lifts

have been pinned as stands (“Pinning the lifts as stands”

section) you can transfer the vehicle to support stands

and remove the wheel lifts, if you choose.

1. Select stands of the same height for each side of the

vehicle. Make sure the stands are capable of

supporting the weight of the vehicle.

2. Identify appropriate manufacturer recommended

locations, suitable for supporting the vehicle on stands,

an equal distance from the lifts on each side of the

vehicle.

3. Clear the work area under the vehicle of all personnel,

then place the stands at the appropriate locations on

each side of the vehicle.

4. Remove the load retention pins and lower the vehicle

down onto the support stands (if the load retention

pins will not pull out easily, raise the vehicle just

enough to free the load retention pins). Make sure the

vehicle comes down evenly on the stands.

5.

When the vehicle is securely supported by the

support stands, lower the lifts to their lowest position

so the downstop pawls are automatically reset.

CAUTION - The downstop pawls will not automatically

reset until lift has been fully lowered. If lift is used

without being lowered completely first, you must

manually reset downstop pawls by pulling the downstop

release handle toward you on each of the lifts.

6.

Disconnect the air hoses and coil them on the air

hose holders on the back of each lift. Pull the lifts

away from the work area

.

3. To raise the lifts, pull up on both air control levers at

the same time. Operate the air control levers so both

of the lift pads contact the tires at the same time.

4. Visually confirm that both lift pads have securely

engaged the tires, and that the lift table tube of each

lift contacts the side of the tire.

5. Raise the vehicle off the support stands by lifting up

on both the air control levers at the same time. Be

sure to operate the air control levers so the vehicle

stays level.

6. Pin the lifts as stands, carefully following the

instructions in “Pinning the lifts as stands,” section.

7. Once the lifts have been pinned as stands, remove

the support stands from under the vehicle; then lower

the vehicle, following the instructions under “Lowering

a vehicle to the ground” section.

CWL

-20 | 11 |

en

Maintenance and Inspection

8. Maintenance and Inspection

WARNING -

knowledgeable person to inspect the jack for signs of

corrosion and / or excessive wear. Visual inspection

should be made before each use of jack, checking for

abnormal conditions. Regular inspections should be

made weekly for daily use and monthly for intermittent

use. Each jack must be inspected immediately if

subjected to an abnormal load or shock. Any jack

which appears to be damaged in any way, is found to

be badly worn, or operates abnormally shall be

removed from service until necessary repairs are

made. Contact the manufacturer using the contact

information printed on the back cover of this manual.

The owner must inspect, or appoint a

If any irregularities or problems are detected during an

inspection, the stand must be removed from service

immediately and repaired. Contact the manufacturer

using the contact information on the back cover of

this manual.

8.2 Air hose inspection

To prevent serious injury or death from a falling vehicle,

or possible serious injury due to bursting air hoses,

replace air hoses only with single-wire reinforced air

hoses from manufacturer, part number 1-271-02002.

The use of any other air hose increases the risk that the

air hose may become pinched or damaged, resulting in

failure of the air hose or of the lift during operation.

Contact the manufacturer.

8.1 Structural inspection

The jack must be removed from service and inspected

for damage immediately if the jack is subjected to an

abnormal shock or load. Never return the Lift system to

service until all damaged components have been

properly repaired or replaced. Always test the lift and

verify proper operation before returning the Lift system

to service. Failure to heed this warning may result in

personal and / or property damage.

To prevent serious injury or death from a falling vehicle,

all inspection and maintenance procedures must be

performed after the jack has been removed from

service. Position the lifts so you have clear access to all

sides of the lift for inspection and service.

Inspect the lifts for any cracks, chips, or signs of

excessive wear. Visually inspect the welds.

Inspect the load retention pins for deformities or

excessive wear — if the deformities or wearing away

of material are easily noticeable without close

inspection, it is excessive. Test the load retention

pins by inserting them through the lift stop bar and

into each downstop lug. If the load retention pin

cannot be inserted fully through the lift stop bar and

into each of the holes in the downstop lugs in all

positions, it is excessively damaged and must be

replaced before the lift can be used again.

Inspect the holes for the load retention pins in the

base post. If these holes show excessive elongation

or wear on the top or bottom surfaces, they must be

repaired before the lift can be placed back into

service. Contact the manufacturer using the contact

information on the back cover of this manual for

repair recommendations.

Inspect the air hoses daily for any signs of cuts,

abrasions, or excessive wear. If any air hose appears

to be damaged, replace it immediately with

manufacturer authorized reinforced steel air hose,

part number 1-271-02002.

Inspect the air fittings daily for cracks and/or

damaged parts. If any show damage, replace them

before putting the Lift system back into service.

8.3 Maintenance instructions

WARNING - All inspection and maintenance procedures

must be performed after the jack has been removed from

service. Failure to do this may result in personal injury

and/or property damage.

All warning and capacity labels should be readable

and complete. Wash external surfaces of jack, labels,

and decals with a mild soap solution.

Lubricate all rotating and sliding portions of the jack

monthly (Fig. 11).

Oil downstop

pivot shaft

and release

springs

monthly

Grease roller wheel monthly.

Grease base post monthly with EP-1 yellow grease.

Grease swivel

casters monthly

Fig. 11: Lubrication points

Oil front wheels

monthly.

en | 12 |

CWL

-20

Maintenance and Inspection

8.4 Air control unit cleaning instructions

Occasionally, pieces of rust, scale or dirt from the airlines

may become lodged under the rubber seals of the air

control unit. This may cause minor air leakage and the lift

system units may slowly raise or lower even though the air

control levers have not been actuated. This minor air

leakage is easily corrected by following the steps below

(refer to Fig. 12 for component identification):

Fig. 12: Air control unit component identification

1. Disconnect the three air hoses attached to the air

control unit.

8.5 Lift table adjustment

The lift system has a 1/2-13 hex head cap screw

mounted inside the top weldment to allow the lift table to

be raised or lowered slightly. The cap screw has been

adjusted at the factory to provide 1/4" to 5/16" of

clearance between the bottom of the lift pads and the

floor.

To raise or lower the lift table, follow the lift table

adjustment steps below:

1. Place the lifts on a level floor in a suitable open area.

2. Raise both lifts onto their lowest downstop.

3. Loosen the jam nut and turn the cap screw a few

turns in the required direction. Clockwise raises the lift

table, counterclockwise lowers it. (See Fig. 13 for

identification.)

Capscrew

Jam Nut

Lift Table

2. Remove the valve bracket.

3. Remove the plug or plugs.

4. Use a stiff wire or pin punch to push the spool out of

the valve body.

5. Carefully examine the rubber seal for any dirt or

foreign material. If foreign material is embedded in the

rubber seal, remove the screw and cup from the end

of the spool, then remove and clean the rubber seal.

Turn the seal over and reassemble it into the cup.

Secure the cup back onto the end of the spool with

the screw.

6. Lubricate the spool with a light chassis grease.

7. Insert the spool with O-ring into the air inlet spool

port.

8. Insert the spool without O-ring into the air exhaust

spool port.

9. Insert the spring(s).

10. Apply thread sealant to the plug(s) and install the

plugs into the valve body. Do not over tighten the

plug(s), as the threads can very easily be damaged.

Fig. 13: Lift table clearance adjustment

4. Tighten the jam nut.

5. Lower the lift to its lowest position and check the lift

table height above the floor.

Repeat the adjustment as needed until each lift has a

minimum of 1/8" clearance between the lift table bottom

and the floor. With the lift table resting on the floor, the

lifts may not easily move around the shop floor.

CWL

-20 | 13 |

en

Tro

ubleshooting

9. Troubleshooting

This section is a list, in which may be encountered and

their solutions. If the solution listed fails to correct the

problem, contact the manufacturer using the contact

information on the back cover of this manual. Please

have the model number, and serial number of your jack

available. The serial number is printed on a tag located

on the right caster brake.

Problem Cause/Solution

•

Fails to lift load

Only one lift raises

Will not cradle tire

Inadequate air pressure; requires 155 psi.

• Lifts are overloaded. Rated capacity is

20,000 lbs. per lift. Use larger-capacity lift.

•

Air hoses are not connected properly,

damaged or pinched.

•

Air control unit is dirty or damaged. See

the “Air control unit cleaning instructions”

section of manual.

•

Air hoses are not connected properly,

damaged or pinched.

• Air control unit is dirty or damaged. See

the “Air control unit cleaning instructions”

section of manual.

• Tire is underinflated or tire diameter is too

large.

• Lift is not fully lowered.

• Vehicle is overloaded. Use other lifting

means.

10. Optional adapters

To prevent serious injury or death from a falling

vehicle, use WL-Adapters only for vehicles with rims

between 14" and 21" in diameter.

Install the WL-Adapters with both hooks in the holes

of the lift pad. Proper installation is shown in Fig. 14.

Installing the adapters

Make sure the wheel rims on the vehicle to be raised are

a minimum of 21" in diameter, unless you are using the

manufacturer supplied adapters with the lift system. With

the adapters, properly positioned on the lift pads,

vehicles with wheel rims of 14" can be safely raised. For

rims of 14-21 inches in diameter, install the adapters as

follows:

Lift will not lower or

lowers erratically

Lift table hits floor

Lift raises slowly

• Vehicle parking brake is set and/or

transmission is in gear.

• Air hoses are not connected properly.

• Air hoses are pinched. Remove load from

lifts using other lifting means; remove air

hoses from pinch point.

• Floor is uneven and/or rough. Raise lift to

lowest downstop.

• Lift table height needs adjustment for

minimum clearance. See the “Lift table

adjustment: section of this manual.

• Low air pressure. Raise air pressure to 145

psi.

• Air control unit is dirty or damaged. See

the “Air control unit cleaning instructions”

section of manual.

• Lifts overloaded. Rated capacity is 20,000

lbs. per lift. Use other lifting means.

Fig. 14: Installing the WL-adapters

Using the adapters

Use the adapters only on vehicles with rims of 14 inches

- 21 inches in diameter. Follow normal operating

instructions to use the lift system with adapters installed.

Fig. 15: Lift table tube identification

en | 14 |

CWL

-20

Maintenance Chart

11. Maintenance Chart

Action Date Details

Receiving inspection

Person

responsible

CWL

-20 | 15 |

en

Maintenance Chart

Action Date Details

Person

responsible

en | 16 |

CWL

-20

Notes

12. Notes

CWL

-20 | 17 | en

Notes

en | 18 |

CWL

-20

Notes

CWL

-20 | 19 | en

Notes

670

-

907

52

MAHLE Aftermarket Inc.

10 Innovation Drive

York, PA 17402 U.S.A.

Phone: (800) 468-2321

Fax: (717) 755-8304

E-mail: tech.mss@us.mahle.com

www.servicesolutions.mahle.com

Loading...

Loading...