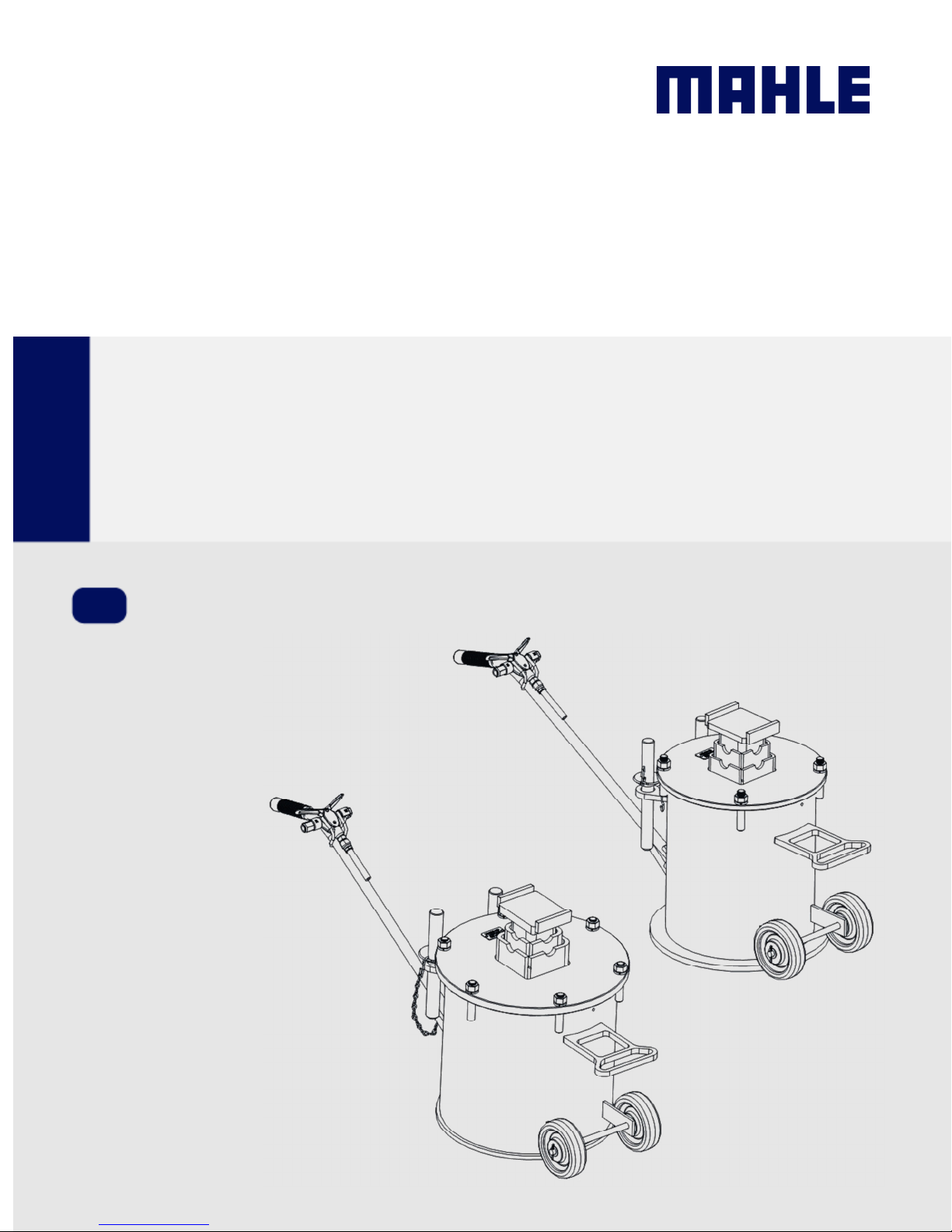

Operation Manual

Truck

Air Jack Stand

MAHLE CLS-10 &

EN

CLS-15

en | 2 |

CLS-10/CLS

-15

EVERY PERSON WHO OPERATES THIS

READ THIS MANUAL

EQUIPMENT NEEDS TO KNOW AND

UNDERSTAND ALL OF THE INFORMATION IN

THIS MANUAL – FAILURE TO DO SO COULD

RESULT IN SERIOUS INJURY OR DEATH.

CAREFULLY AND

RETAIN FOR YOUR

RECORDS

CLS-10/CLS

-

15 | 3 |

en

Contents

Contents

1. Safety Regulations ................................................ 4

1.1 Warnings ....................................................... 4

2. Foreword ................................................................ 5

2.1 From the manufacturer ................................. 5

3. Symbols Use .......................................................... 5

3.1 Signal words ................................................. 5

4. Responsibilities ..................................................... 6

4.1 Receiving inspection ..................................... 6

4.2 Owner and/or operator responsibilities ......... 6

5. Specifications ........................................................ 6

5.1 CLS-10.......................................................... 6

5.2 CLS-15.......................................................... 6

6. Product Description .............................................. 7

6.1 Component identification .............................. 7

7. Operation ............................................................... 8

7.1 Compressed air supply ................................. 8

To Operate a Single Jack ........................ 8

To Operate a Pair of Jacks ...................... 8

7.2 Preparation before operation ........................ 8

7.3 Identify a lift point on the vehicle and position

the jack ......................................................... 9

7.4 Raise the vehicle ........................................... 9

7.5 Support the vehicle. ...................................... 9

8. Maintenance and Inspection .............................. 10

8.1 Inspection – before each use ...................... 10

8.2 Maintenance instructions ............................ 10

9. Troubleshooting .................................................. 11

10. Maintenance Chart .............................................. 12

11. Notes .................................................................... 14

en | 4 |

CLS-10/CLS

-15

Safety Regulations

1. Safety Regulations

1.1 Warnings

Failure to follow all of these safety instructions can

lead to severe injury or death from a sudden loss of

the load. Contact the manufacturer at the numbers or

address printed on the back cover of this manual if

you have any questions.

Before using this jack, be sure you have read and

understood all of the instructions and warnings on the

on product labeling and in this owner’s manual. See

the section entitled “OWNER AND/OR OPERATOR

RESPONSIBILITIES” on page 6 of this manual for

more information.

Inspect the jack before each use. The jack must be

removed from service if damage is detected or if the

jack is subjected to an abnormal shock or load. See

page 10 of this manual for proper “INSPECTION –

BEFORE EACH USE.”

Inspect the work area before each use. Make sure

the jack and vehicle are located on a hard, level

surface capable of supporting the load.

Identify appropriate vehicle lift points before using

the jack. Lift only on areas of the vehicle specified by

the vehicle manufacturer. The lift point must be strong

enough to sustain the lifting force without damage to

the vehicle. The jack must remain in direct contact

with the floor and the lifting pad must be in direct

contact with the vehicle.

Make sure the lift point is securely cradled in the

center (i.e., between the “saddle ears”) of the lift post

saddle— Never lift a load with it resting on top of a

saddle ear of the lift post saddle. Always use the

factory-supplied lift post saddle to raise a load and

never use blocks or cribbing devices in conjunction

with this jack (only adapters and/or attachments

supplied by the manufacturer for this particular jack

can be used). Never place a hand or any other body

part between lift post saddle and vehicle.

Do not exceed the maximum lift height. Never use

more than one optional extension adapter with this

jack.

After lifting the vehicle, never allow any part of your

body to pass under it (and never begin work) until the

ram of the jack is properly pinned and the air is

exhausted. If the air is not exhausted and the jack is

not properly pinned, the jack may rise or drop

suddenly when a heavy object is removed from or

placed on the vehicle, which could cause dangerous

tilting or toppling of the vehicle.

Always use the jack as intended. Never modify or

alter the jack. If this jack does not have sufficient

capacity to lift a load, use a different jack with

adequate capacity. Never attempt to reposition or

rotate the jack or move, dolly, or drive the vehicle

while it is raised. Never use this jack to lower or

support a vehicle if the vehicle was raised using

another lifting device or devices. Do not attempt to

raise a partially-filled tanker or transport containing an

unrestrained load as a sudden load shift could cause

a dangerous tilting or toppling of the vehicle. Never

throw the jack or allow it to fall from an elevated

position, such as from a truck bed.

CAUTION - Use of this jack around corrosive

materials, such as chlorides, will damage inside the

cylinder, causing leakage. SUCH USE INVALIDATES

WARRANTY.

Make sure the load does not exceed the rated

capacity of the jack. The maximum capacity of the

jack is printed on the capacity tag located on the

head plate of the jack.

CLS-10/CLS

-

15 | 5 |

en

Foreword

Immediate

or

injury.

impending

or

injury

Possible

injury

Possible

Possible property

2. Foreword

2.1 From the manufacturer

Thank you for your purchase. To complement the

offering of A/C, fluid and nitrogen service equipment,

MAHLE Service Solutions has partnered with Gray

Manufacturing to provide the highest quality hydraulic

and pneumatic equipment available for the professional

service technician. This equipment adheres to high

standards promised in the MAHLE guarantee including

the assurance of innovation and reliability that comes

with the Gray Manufacturing name. Please contact

MAHLE Service Solutions’ customer service at (800)

468-2321 or tech.mss@us.mahle.com with any

comments or questions.

3. Symbols Use

3.1 Signal words

Signal words call attention to a safety message or

messages, or a property damage message or messages,

and designate a degree or level of hazard seriousness.

Signal words used in this manual include:

Keyword

DANGER

WARNING

CAUTION

NOTICE

Probability of

occurrence

impending danger

Possible

danger

dangerous

situation

damage to

property

Severity of danger if

instructions not observed

Death

Death

Minor

damage

severe

severe

en | 6 |

CLS-10/CLS

-15

Responsibilities

Maximum Lift Height with

Maximum Lift Height with

4. Responsibilities

4.1 Receiving inspection

Before attempting to operate this equipment, thoroughly

read and understand this manual. Completely remove all

tape and packaging. Inspect the equipment immediately

upon delivery. If shipping damage is evident, inform the

delivering carrier immediately and contact the

manufacturer using the contact information on the back

cover of this manual.

4.2 Owner and/or operator responsibilities

The owner of this equipment must read these

instructions and maintain them for future reference and

for instructing any other users of the equipment. The

owner is responsible for keeping all warning labels and

instruction manuals legible and intact. Replacement

labels and literature are available from the manufacturer.

The owner must never authorize or allow anyone to use

this equipment until the operator has read and

understood the information in this manual and on the

accompanying labeling on the equipment itself.

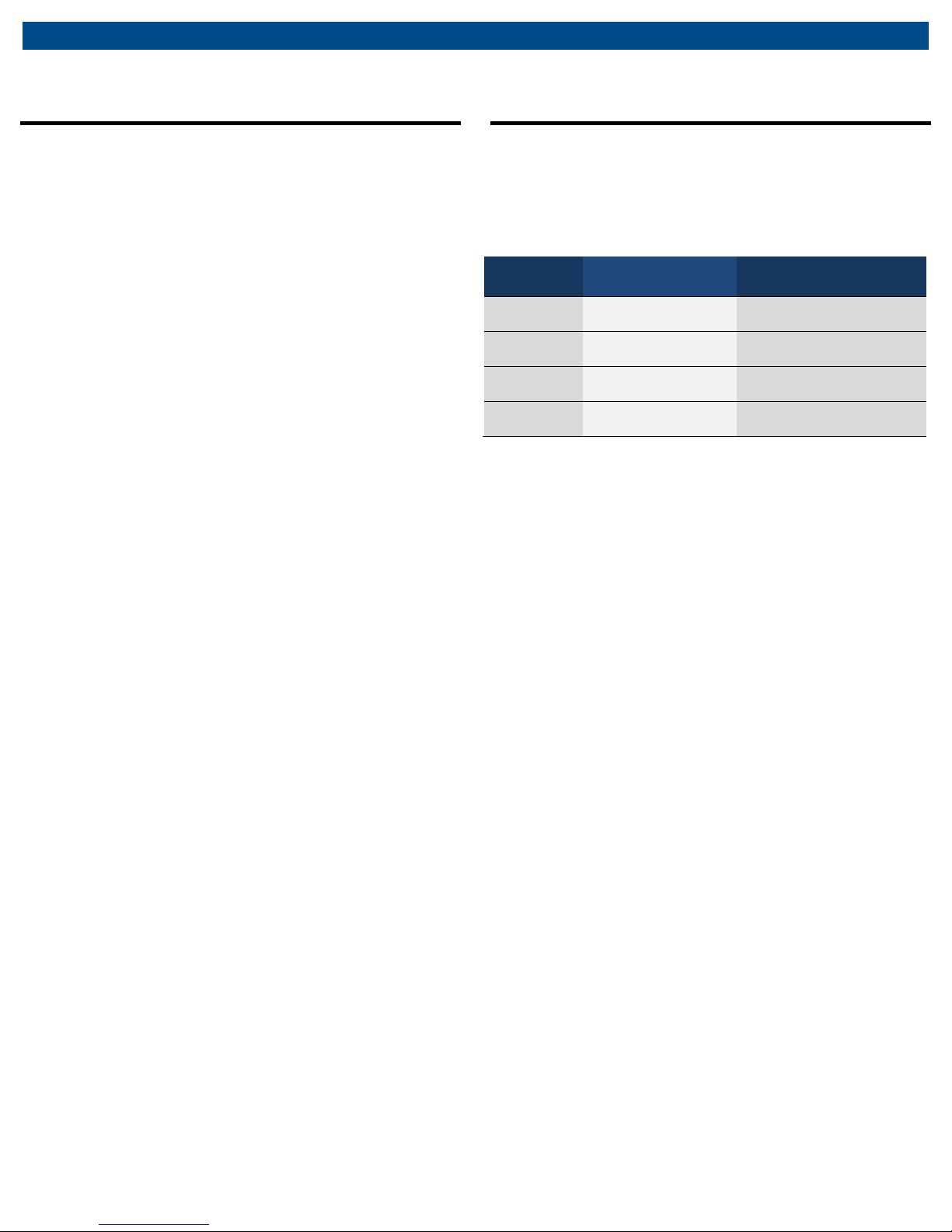

5. Specifications

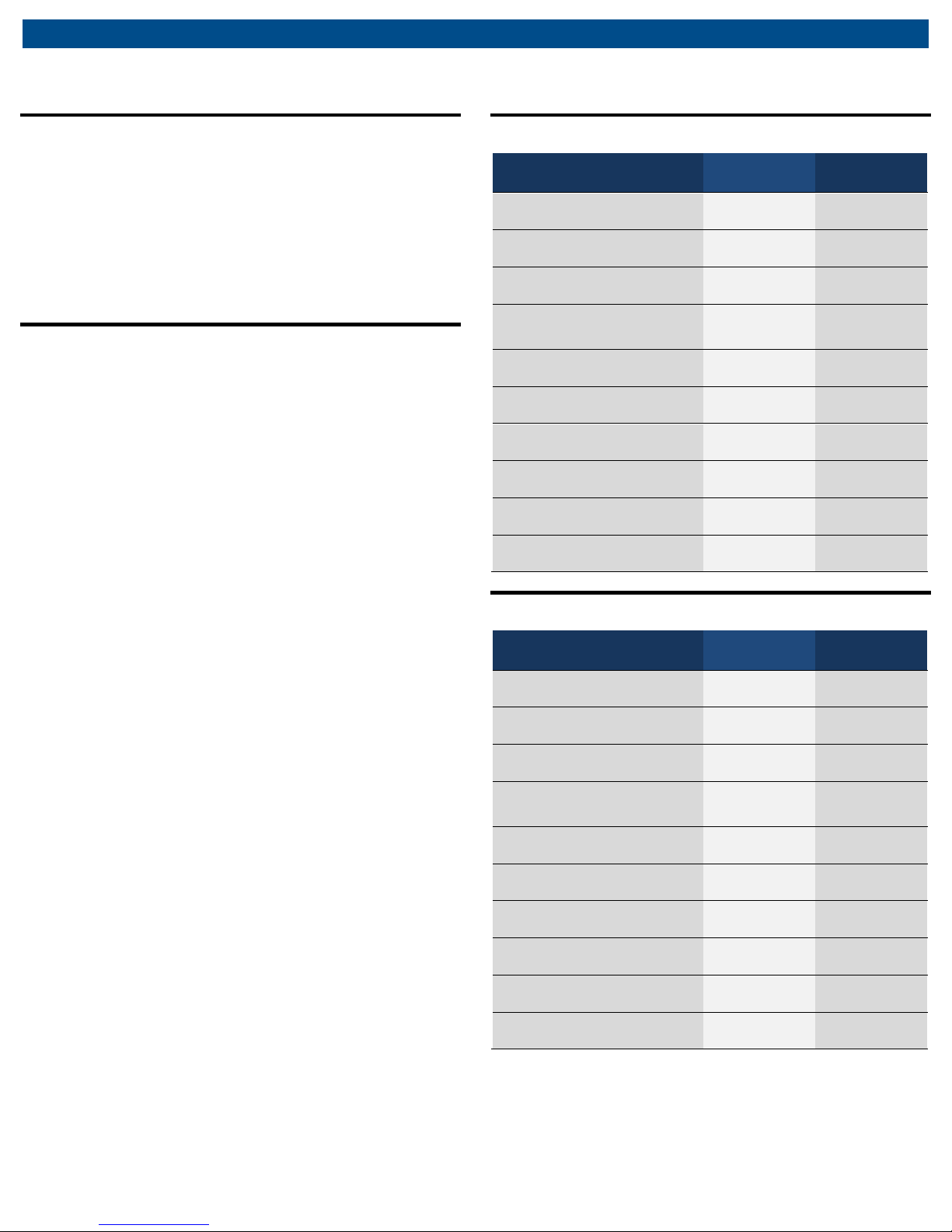

5.1 CLS-10

Model CLS-10 US units Metric units

Capacity (at 150 psi) 15,000 lb each 6,804 kg each

Capacity (at 200 psi) 20,000 lb each 9,072 kg each

Maximum Lift Height 37.38 in 94.9 cm

Optional Extension Adapter

Minimum Starting Height 17.88 in 45.4 cm

Pin Increment Positions 2.50 in 6.4 cm

Stroke 10 in 25.4 cm

Width 15 in 38.1 cm

Length 22 in 55.9 cm

Weight 139 lb 63 kg

52.38 in 133.0 cm

If this equipment is being used in an occupational setting

(or workplace), the employer should ensure that all

personnel working with and around the equipment know

of the risks associated with its use. Personnel involved in

the use and operation of this equipment shall be careful,

competent, trained, and qualified in the safe operation of

the equipment and its proper use when servicing motor

vehicles and their components. Safety information

provided with this equipment should be emphasized by

the employer and understood by each employee. The

employer must make this manual available to all

personnel using this equipment and all personnel must

read and understand the contents of this manual. If the

operator is not fluent in English, the manufacturer’s

instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the employer, making sure that the operator

comprehends its contents and observes the proper

procedures for use of this equipment.

5.2 CLS-15

Model CLS-15 US units Metric units

Capacity (at 150 psi) 20,000 lb each 9,072 kg each

Capacity (at 200 psi) 30,000 lb each 13,608 kg each

Maximum Lift Height 38.25 in 97.2 cm

Optional Extension Adapter

Minimum Starting Height 18.75 in 47.6 cm

Pin Increment Positions 2.50 in 6.4 cm

Stroke 10 in 25.4 cm

Width 16.25 in 41.2 cm

Length 23.75 in 60.3 cm

Weight 194 lb 88 kg

53.38 in 135.6 cm

CLS-10/CLS

-

15 | 7 |

en

Product Description

6. Product Description

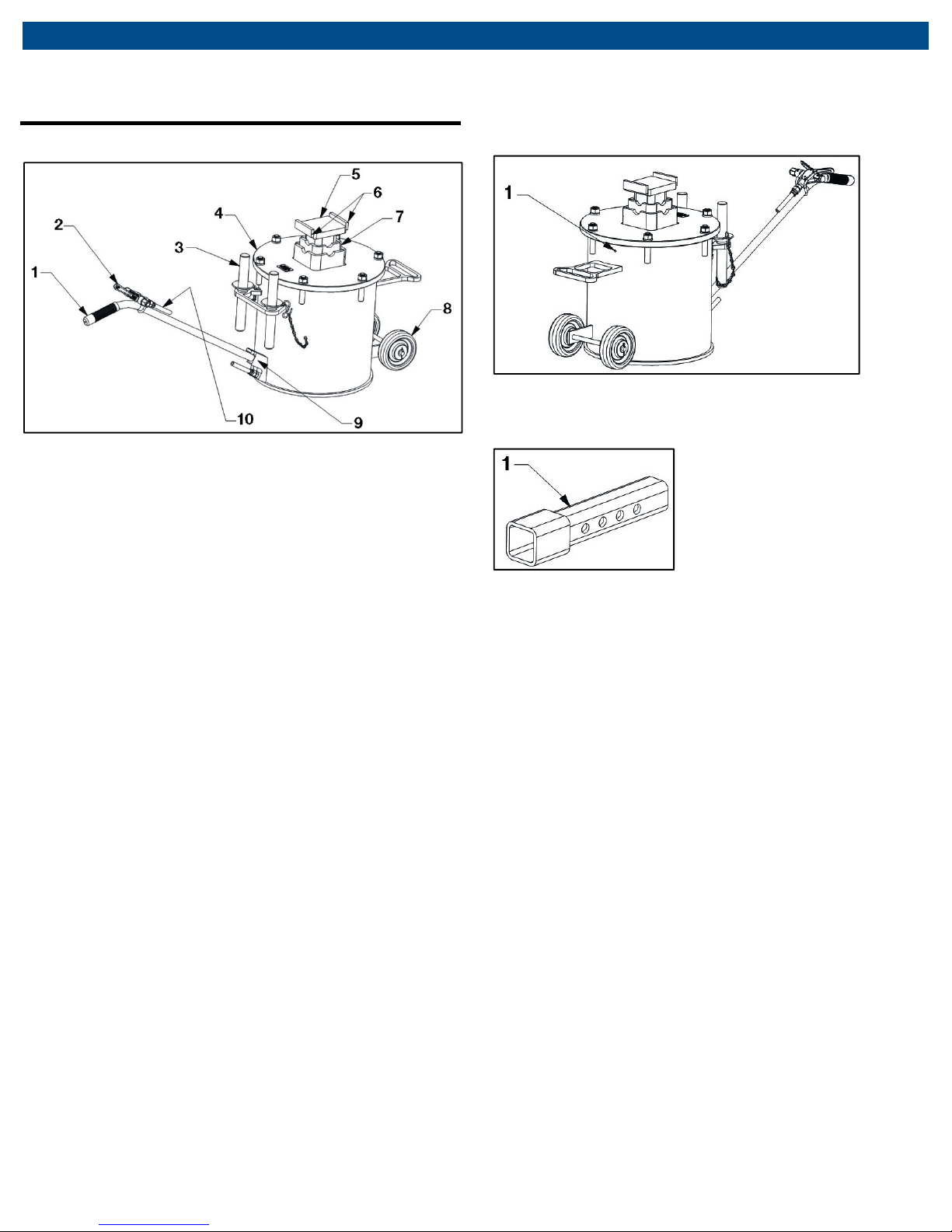

6.1 Component identification

Fig. 1: Top view

1 Handle

2 Air control valve

3 Stand pin

4 Head plate

5 Lift post saddle

6 Saddle ears

7 Piston rod

8 Wheel

9 Handle catch

10 Air line

Fig. 2: Drain hole location

1 Drain hole

Fig. 3: Extension adapter

1 Extension adapter

en | 8 |

CLS-10/CLS

-15

Operation

7. Operation

WARNING - This section discusses the appropriate and

safe methods for using the jack to raise and lower a

vehicle. Safe operation is not limited to simply raising

and lowering a vehicle - it also includes adequate

preparation before the vehicle is lifted. Failure to follow

all of the steps outlined in this section could result in

serious injury or death.

7.1 Compressed air supply

The jack requires a supply of compressed air to

operate.

To Operate a Single Jack

If the jack is being used as a single jack, the following

steps need to be completed prior to use:

1. Connect a quick coupler to the air control valve.

2. Attach an air hose with 200 psi maximum to the quick

coupler. The unit is now ready for use.

7.2 Preparation before operation

1. Make sure the vehicle load does not exceed the rated

capacity of the jack (see Specifications for the jack

model purchased).

2. Inspect the jack for signs of wear or damage (see

“Inspection Instructions” in Section 8). The jack should

be immediately removed from service if you detect any

abnormal conditions or signs of damage that suggest

the jack will not work properly or safely — When in

doubt, don’t use the jack!

If you see any signs of wear or damage, or if there is any

indication that the jack is not performing normally,

immediately take it out of service and contact customer

service at the address and number shown on the back

cover of this manual. NEVER use a jack that appears

damaged in any way.

3. Transport the jack to the work area by wheeling it. You

can push or pull the jack. Wheel the jack across smooth

surfaces only.

3. Actuate the air control valve lever and check that the

lift post raises and lowers as expected.

To Operate a Pair of Jacks

Because these jacks are often used in pairs, operating

the air control valves on both jacks simultaneously from

one airline offers advantages. To utilize a single airline,

assemble the air control valve from each jack according

to the Figure below or contact the manufacturer to

purchase a “Valve Tee Connection” kit (#8855-01009):

Fig. 4: Valve tee connection

Jolting caused by the wheels catching on uneven

surfaces can cause physical strain and personal injury.

4. Examine the work area. Use the jack only on hard, level

surfaces capable of safely supporting the load. The jack

must ALWAYS remain in direct contact with the floor.

NEVER attempt to lift from a polished or greasy floor.

Clear the surrounding area of personnel, tools,

equipment, or any other objects that would interfere with

the use of the jack. If these conditions cannot be met,

move the vehicle and jack to an area where the lift can

be performed safely.

5. Chock the vehicle’s wheels. When raising a vehicle from

one end, always chock the wheels that will remain on

the ground. Make sure at least two wheels of the vehicle

remain in contact with the floor at all times — NEVER

use the jack to raise all four wheels of the vehicle from

the floor.

6. Verify that the vehicle’s engine is not running before

raising it.

CLS-10/CLS

-

15 | 9 |

en

Operation

7.3 Identify a lift point on the vehicle and

position the jack

1. Identify a lift point on the vehicle that is capable of

supporting the load. Lift only on areas of the vehicle

specified by the vehicle manufacturer. The lift point must

be strong enough to sustain the lifting force without

damage to the vehicle.

2. If using only one jack to raise one end of the vehicle,

make sure that the jack is balanced side-to- side.

With one jack, it is extremely important to ensure the

load is level and stable during and after lifting. Loads

that are not balanced can result in tipping of the jack

which can result in loss of the load, leading to

personal injury, death, and/or property damage.

3. Position the unit(s) under the vehicle by using the

handle and place according to the vehicle

manufacturer’s recommended lifting points

7.4 Raise the vehicle

1. Raise the lift post manually on each jack to engage

the manufacturer’s recommended lift point. If using

two jacks as a pair, keep both lift posts at equal

heights. For each jack being used, insert the stand pin

in the nearest hole in the lift post so that the stand pin

fully engages both sides of the piston rod. This

position may not fully engage the lift point on the

vehicle until the unit is pressurized to lift the load.

7.5 Support the vehicle.

1. Make sure the vehicle is stable. If using two units,

make sure the vehicle is level. For each jack being

used, check that the stand pin is fully engaged with

the notches on both sides of the head plate. Slowly

release the air pressure to lower the vehicle so that it

is supported by the stand pins (and not the air

pressure from the jack). Fully discharge the air

pressure from the jack.

2. Before beginning work or placing any part of your

body under the vehicle, check one last time to ensure

the vehicle is stable and level (between a pair of jacks

or on a single jack).

3. When work is completed, reverse the process

described in this section to lower the vehicle.

2. If the lift post is not fully engaged with the lift point,

slowly apply air pressure until the lift post saddle

engages the lift points on the vehicle. Before raising

the vehicle, ensure that the lift post saddle is

positioned such that the lift point is cradled and

captured on both sides by the saddle ears on each

side of the lift post. Never lift a load with it resting on

top of an ear of the lift post saddle.

3. Apply air pressure to continue raising the vehicle. If

using a pair of jacks, use the air control valves to keep

the vehicle level while lifting. Once the proper height

has been achieved, insert the other stand pin through

the hole in the piston rod (for each jack being used),

such that the pins fully engage both sides of the head

plate when lowered.

en | 10 |

CLS-10/CLS

-15

Maintenance and Inspection

8. Maintenance and Inspection

WARNING - The jack must be inspected according to

the requirements of this section. Failure to properly

inspect the jack could lead to severe injury or death.

The owner must inspect or appoint a knowledgeable

person to inspect the jack for signs of corrosion,

damage and/or excessive wear. Contact the

manufacturer at the numbers and address printed on

the back cover of this manual.

All inspection and maintenance procedures must be

performed after the jack has been removed from

service. Failure to do this may result in personal injury

and/or property damage.

8.1 Inspection – before each use

Visual inspection should be made before each use of the

jack, checking for abnormal conditions. Regular

inspections should be made weekly for daily use or

monthly for intermittent use. Any jack that appears to be

damaged in any way, is found to be badly worn, or

operates abnormally shall be removed from service until

necessary repairs are made:

8.2 Maintenance instructions

WARNING - All inspection and maintenance procedures

must be performed after the jack has been removed from

service. Failure to do this may result in personal injury

and/or property damage.

The following procedures should be performed

periodically to properly maintain the jack:

Check that all controls operate freely. Wheels should

rotate freely.

All warning and capacity labels should be readable

and complete. Wash external surfaces of jack, labels,

and decals with a mild soap solution. Do not allow

water to run down the ram or the post and into the

cylinder area. If water or any other liquid enters the

cylinder, tilt the jack so the liquid can drain out the

drain hole (shown in the Component Identification

section).

Lubricate all rotating and sliding portions of the jack

monthly.

Inspect piston rod, lift post, and lift extension adapter

regularly and replace if they are cracked, chipped, or

show signs or excessive wear. Holes for the stand

pins must not be elongated or deformed.

Inspect stand pins for deformities or excessive wear.

Stand pins must be able to inset fully into the posts

and piston rod in all positions.

The piston rod should extend and retract smoothly

through its full range.

Inspect hoses for leaks or kinks. Inspect couplings for

damage or air leakage. Replace damaged or defective

hoses or couplings.

The jack must be removed from service and

inspected immediately if it is subjected to an

abnormal load or a shock load. If any irregularities or

problems are detected during an inspection, the jack

must be removed from service immediately and

repaired. Contact the manufacturer using the contact

information printed on the back cover of this manual.

Remember, if you have any doubt about the safe

condition of this jack, DON’T USE IT!

CLS-10/CLS

-15 | 11 |

en

Troubleshooting

9. Troubleshooting

This section is a list of potential problems and solutions.

If the solution listed fails to correct the problem, call the

manufacturer at the numbers and address printed on the

back cover of this manual. Please have the model

number, and serial number of your jack available. The

serial number is located on the capacity tag on the top of

the head plate.

Problem Cause/Solution

• Inadequate air pressure; Increase air

Fails to lift load

pressure but do not exceed 200 psi.

• Airline leaks; locate and correct leaks.

•

Overloaded; use larger-capacity jack.

Fails to hold load

• Stand pin not engaged.

en | 12 |

CLS-10/CLS

-15

Maintenance Chart

10. Maintenance Chart

Action Date Details

Receiving inspection

Person

responsible

CLS-10/CLS

-15 | 13 |

en

Maintenance Chart

Action Date Details

Person

responsible

en | 14 |

CLS-10/CLS

-15

Notes

11. Notes

CLS-10/CLS

-

15 | 15 |

en

Notes

670

-

90725

MAHLE Aftermarket Inc.

10 Innovation Drive

York, PA 17402 U.S.A.

Phone: (800) 468-2321

Fax: (717) 755-8304

E-mail: tech.mss@us.mahle.com

www.servicesolutions.mahle.com

Loading...

Loading...