Operation Manual

Container Crusher

MAHLE AFC-9 &

EN

CFC-16

en | 2 |

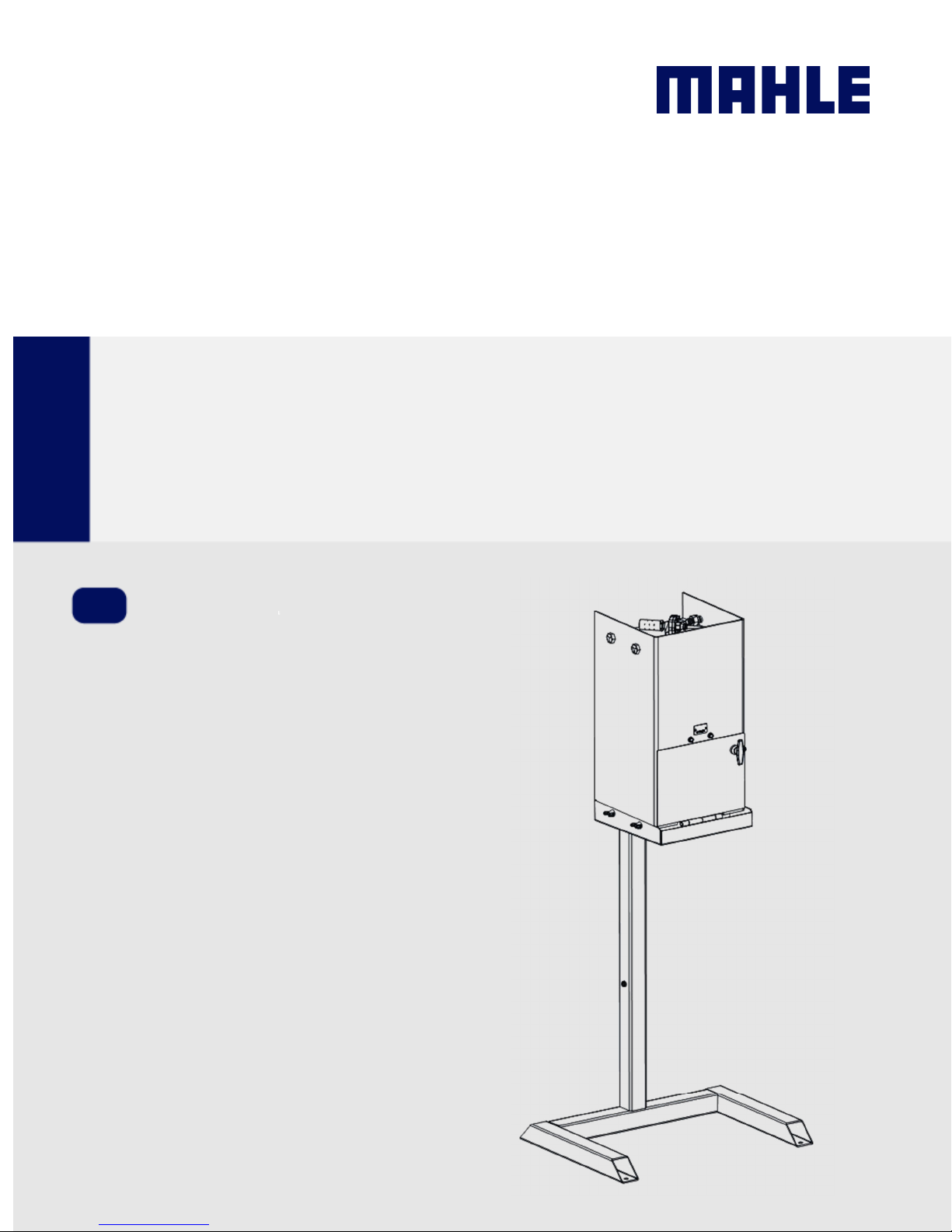

AFC-9/CFC

-16

EVERY PERSON WHO OPERATES THIS

READ THIS MANUAL

EQUIPMENT NEEDS TO KNOW AND

UNDERSTAND ALL OF THE INFORMATION IN

THIS MANUAL – FAILURE TO DO SO COULD

RESULT IN SERIOUS INJURY OR DEATH.

CAREFULLY AND

RETAIN FOR YOUR

RECORDS

AFC-9/CFC

-16 | 3 |

en

Contents

Contents

1. Safety Regulations ................................................ 4

1.1 Warnings ....................................................... 4

1.2 Safety instructions for transporting unit ........ 4

2. Foreword ................................................................ 5

2.1 From the manufacturer ................................. 5

3. Symbols Use .......................................................... 5

3.1 Signal words ................................................. 5

4. Responsibilities ..................................................... 6

4.1 Receiving inspection ..................................... 6

4.2 Owner and/or operator responsibilities ......... 6

5. Specifications ........................................................ 6

5.1 AFC-9 ........................................................... 6

5.2 CFC-16 ......................................................... 6

6. Product Description .............................................. 7

6.1 Component identification .............................. 7

6.2 Features ........................................................ 7

7. Installation ............................................................. 8

8. Operation ............................................................... 9

8.1 Operation of the container crusher................ 9

8.2 Door handle operation .................................. 9

9. Maintenance and Inspection .............................. 10

9.1 Inspection ................................................... 10

9.2 Maintenance instructions ............................ 10

9.3 Control valve actuation adjustment ............. 10

10. Troubleshooting .................................................. 11

11. Maintenance Chart .............................................. 12

12. Notes .................................................................... 14

en | 4 |

AFC-9/CFC

-16

Safety Regulations

1. Safety Regulations

1.1 Warnings

To avoid serious injury or death, read this manual

carefully before operating this unit. Call the manufacturer

using the contact information printed on the back cover

of this manual if you have any questions. Failure to

understand and obey safety instructions may result in

unsafe or improper use of this product.

The owner / manager must keep this manual for

future reference, and make sure the warning labels

on the product are legible and intact at all times.

Replacement labels and manuals are available from

the manufacturer. Call the manufacturer using the

contact information on the back cover of this manual

if you have any questions.

The unit is required to be anchor bolted to a level

concrete floor, for safe operation. It is

recommended to anchor the machine to the floor with

four 3/8 or 1/2 in. diameter anchor bolts.

This unit is recommended for crushing spin-on oil

filters, cartridge oil filters with paper elements,

and empty paint cans up to 1 gallon in size. Do not

crush aerosol cans, cylinders of compressed gas, fuel

filters, or containers of flammable liquids or solvents.

Crushing plastic containers is not recommended.

Do not modify this unit or alter the operation in any

way to circumvent the interlocking door

mechanism. Modifications to the machine will void all

warranties expressed or implied.

Wear safety glasses and gloves when operating

the unit and handling the crushed oil filters and paint

cans.

Never hold the filter by the top when loading and

unloading. Always hold the filter by the sides with the

gasket end down.

Do not use this unit to perform any operations

other than to crush oil filters or empty paint cans.

This unit is for crushing spin-on oil filters, cartridge oil

filters with paper elements, and empty paint cans up

to 1 gallon in size. Paint from full or partially full cans

can solidify and clog the holes in the catch basin.

Clean up any spilled oil immediately so it will not

cause a slipping hazard.

Do not stack oil filters inside the crushing

chamber.

1.2 Safety instructions for transporting unit

Failure to understand and obey safety instructions

may result in unsafe or improper use of this product.

Failure to understand and obey this warning may

result in injury and/or property damage.

The crushing module is very heavy and it is

recommended to use a shop crane capable of

handling the load or lift truck to perform the lifting. Do

not move the unit with the crushing module in the

raised position. Always lower the crushing module to

its shipping position. The unit is top heavy and can tip

over if the crushing module is raised and the unit is

not anchored to the floor.

Do not smoke when operating this unit and do not

operate this unit when someone else in the vicinity is

smoking.

AFC-9/CFC

-

16 | 5 |

en

Foreword

Immediate

or

injury.

impending

or

injury

Possible

injury

Possible

Possible property

2. Foreword

2.1 From the manufacturer

Thank you for your purchase. To complement the

offering of A/C, fluid and nitrogen service equipment,

MAHLE Service Solutions has partnered with Gray

Manufacturing to provide the highest quality hydraulic

and pneumatic equipment available for the professional

service technician. This equipment adheres to high

standards promised in the MAHLE guarantee including

the assurance of innovation and reliability that comes

with the Gray Manufacturing name. Please contact

MAHLE Service Solutions’ customer service at (800)

468-2321 or tech.mss@us.mahle.com with any

comments or questions.

3. Symbols Use

3.1 Signal words

Signal words call attention to a safety message or

messages, or a property damage message or messages,

and designate a degree or level of hazard seriousness.

Signal words used in this manual include:

Keyword

DANGER

WARNING

CAUTION

NOTICE

Probability of

occurrence

impending danger

Possible

danger

dangerous

situation

damage to

property

Severity of danger if

instructions not observed

Death

Death

Minor

damage

severe

severe

en | 6 |

AFC-9/CFC

-16

Responsibilities

4. Responsibilities

4.1 Receiving inspection

Before attempting to operate this equipment, thoroughly

read and understand this manual. Completely remove all

tape and packaging. Inspect the equipment immediately

upon delivery. If shipping damage is evident, inform the

delivering carrier immediately and contact the

manufacturer using the contact information on the back

cover of this manual.

4.2 Owner and/or operator responsibilities

The owner of this equipment must read these

instructions and maintain them for future reference and

for instructing any other users of the equipment. The

owner is responsible for keeping all warning labels and

instruction manuals legible and intact. Replacement

labels and literature are available from the manufacturer.

The owner must never authorize or allow anyone to use

this equipment until the operator has read and

understood the information in this manual and on the

accompanying labeling on the equipment itself.

5. Specifications

5.1 AFC-9

Model AFC-9 US units Metric units

Height 77.125 in 195.9 cm

Width 20.5 in 52.1 cm

Depth 16.75 in 42.6 cm

Weight 242 lb 109.8 kg

Height (Crushing chamber) 9 in 22.9 cm

Width (Crushing chamber) 8 in 20.3 cm

Depth (Crushing chamber) 8 in 20.3 cm

Air Inlet ¼ female NPT ¼ female NPT

Air Pressure 100-200 PSI 6.9-13.8 Bar

Catch Basin Connection ¾ female NPT ¾ female NPT

If this equipment is being used in an occupational setting

(or workplace), the employer should ensure that all

personnel working with and around the equipment know

of the risks associated with its use. Personnel involved in

the use and operation of this equipment shall be careful,

competent, trained, and qualified in the safe operation of

the equipment and its proper use when servicing motor

vehicles and their components. Safety information

provided with this equipment should be emphasized by

the employer and understood by each employee. The

employer must make this manual available to all

personnel using this equipment and all personnel must

read and understand the contents of this manual. If the

operator is not fluent in English, the manufacturer’s

instructions and warnings shall be read to and discussed

with the operator in the operator’s native language by

the employer, making sure that the operator

comprehends its contents and observes the proper

procedures for use of this equipment.

5.2 CFC-16

Model CFC-16 US units Metric units

Height 85.5 in 217.2 cm

Width 20.5 in 52.1 cm

Depth 16.75 in 42.6 cm

Weight 282 lb 127.9 kg

Height (Crushing chamber) 16.25 in 41.3 cm

Width (Crushing chamber) 10 in 25.4 cm

Depth (Crushing chamber) 8 in 20.3 cm

Air Inlet ¼ female NPT ¼ female NPT

Air Pressure 100-200 PSI 6.9-13.8 Bar

Catch Basin Connection ¾ female NPT ¾ female NPT

AFC-9/CFC

-

16 | 7 |

en

Product Description

6. Product Description

6.1 Component identification

Fig. 1: Front view

1 Catch basin

2 Crushing chamber

3 Door

4 Ram & ram cylinder

5 Door handle

6 Control valve & air inlet

7 Catch basin outlet

8 Stand

6.2 Features

Pneumatic Powered Ram: Pneumatic power gives you

the advantages of long life, low maintenance, and quick

crushing action. Also no electrical connections are

required eliminating the electrical hazard and the

problems of dirty and/or faulty connections.

Interlocking Door: The door interlock restrains the door

from opening until the ram is fully raised.

Convenient Operation:::: One hand is required to close

the door and latch it. After the door is latched, the

crushing chamber is completely enclosed to prevent

injuries and to prevent oil splatter.

Versatile Installation: The stand is standard with the

unit, not optional as with many competitors’ equipment.

When crushing oil filters, the catch basin can be

connected to the bottom or either side to a variety of

waste oil containers. The unit can be placed over a

workbench by placing the stand post behind the

workbench.

Large Crushing Chamber: Automotive spin-on filters

and up to 1-gallon paint cans will fit in the crushing

chamber.

en | 8 |

AFC-9/CFC

-16

Insta

llation

7. Installation

1. Locate a suitable place to install the unit. This unit must

be installed indoors on a level surface. The unit is

required to be anchor bolted to a concrete floor, for safe

operation.

2. Position the crusher in the desired location in your shop.

Mark the floor for the anchor bolt location to match the

holes in the base of the stand. Four 3/8 or 1/2 inch

diameter anchor bolts are recommended to install the

unit. Install the anchor bolts according to the

manufacturer’s instructions. Secure the unit to the floor

with the anchor bolts.

3. The unit is shipped with the crushing module fastened

to the stand in a lowered position.

5. If the unit is to be used solely for crushing empty paint

cans, the catch basin does not need to be connected to

any container. However, a drip pan should be placed

beneath it or the pipe drain fittings should be plugged.

The installation of the unit should provide for easy

removal of the catch basin to remove inadvertent spills

and foreign material, which may accumulate in the catch

basin.

6. Connect the air supply to the air inlet. The inlet

connection is 1/4 female NPT. The unit is now ready for

use. Recommended operating air pressure is 100 psi

minimum for most paint cans and car and light truck

filters, 120-PSI minimum for heavy truck filters.

Maximum recommended air pressure is 200 psi.

CAUTION! The crushing module is very heavy and it is

recommended to use a shop crane capable of handling

the load or a lift truck to perform the lifting. Unbolt the

crushing module from the post. Note: the number of

bolts will depend on the model. Do not remove the 5/16

inch screw from the top of the post, if equipped. Raise

the crushing module from the shipping position to the

working position. Align the mounting holes on the

crushing module with the holes in the stand post and

insert the bolts provided. Secure with the nuts on the

bolts.

4. Connect the catch basin to the appropriate waste oil

container as required by national, state, or local

regulations. The catch basin connection is a 3/4 female

NPT fitting located on the bottom or on the side. If the

opposite side connection is desired, simply remove the

catch basin and install with the connection on the

desired side. The unit may be connected using a 3/4

male NPT fitting and pipe to a remote waste oil tank.

Another option is to connect the catch basin to a drum.

Use a 3/4 pipe close nipple, a 1 in. I.D. oil resistant hose

and a hose clamp to connect the hose to the catch

basin. Install the hose in the bung of the drum and cut

the length of the hose so it will fit in the drum 2 to 4 in.

The installation must provide for the easy removal of the

catch basin as sludge and semi-solid residue from oil

filters may accumulate. The catch basin requires

periodic cleaning to remove solid residues. All such

residues must be transferred to an acceptable

container.

7. If for any reason the unit does not operate properly after

reviewing the steps above consult the Troubleshooting

section in this Owner’s Manual or contact the

manufacturer using the contact information printed on

the back cover of this manual for further instructions and

assistance. Please have the model number and serial

number of your crushing equipment available. The serial

number is permanently stamped on a metal tag located

above the door.

AFC-9/CFC

-

16 | 9 |

en

Operation

8. Operation

8.1 Operation of the container crusher

1. Place empty paint can with the lid removed or oil filter

with the open end down in the center of the crushing

chamber.

2. Close door and turn door handle clockwise

approximately 180 degrees. You may walk away to

perform other tasks. Upon returning, the filter or paint

can will be crushed. If you want to crush containers in

succession, listen for air to stop flowing (up to 45

seconds). Some noise and vibration usually

accompany the crushing process.

3. To remove the crushed paint can or filter, turn the

door handle counterclockwise and air will exhaust

from the ram cylinder. The door will not open until the

ram is fully raised (approximately 10 seconds). Open

the door and remove the crushed, empty paint can or

oil filter.

8.2 Door handle operation

Door closed and handle full clockwise, door is latched

and ram extends (Fig. 2).

Fig. 2: Turn handle full clockwise to crush cans

Door closed and handle turned 90 degrees counterclockwise, air exhausts, ram retracts and door remains

closed (Fig. 3).

4. Note: A filter may be crushed for extended periods of

time. The unit can be left under pressure until the next

filter or can is ready for crushing. The catch basin

outlet can become clogged with sludge and semisolid

waste from filters. It is necessary to remove the catch

basin and clean it periodically. Deposit solid residue in

acceptable containers. The oil level in the catch basin

can be viewed through the opening beneath the door

when the door is closed. You may crush several filters

at one time if they are all of similar height and you

have adequate air pressure.

CAUTION: Crushing multiple filters of different

heights or materials can damage the crushing

module. Always have the filters arranged so that they

do not cause the ram to load unevenly.

Fig. 3: Turn handle 90 deg. counterclockwise to retract ram

Handle turned fully counter-clockwise, air exhausts and

ram retracts, door will open when ram is fully retracted

(Fig. 4).

Fig. 4: Turn fully counterclockwise to retract ram and open door

en | 10 |

AFC-9/CFC

-16

Maintenance and Inspection

9. Maintenance and Inspection

WARNING - The equipment must be inspected

according to the requirements of this section. Failure

to properly inspect the equipment could lead to

severe injury or death. The equipment must be

removed from service and inspected immediately if it

is subjected to an abnormal load or a shock load. If

any irregularities or problems are detected during an

inspection, the equipment must be removed from

service immediately and repaired. Contact the

manufacturer at the numbers and address printed on

the back cover of this manual.

9.2 Maintenance instructions

WARNING - All inspection and maintenance procedures

must be performed after the equipment has been removed

from service. Failure to do this may result in personal injury

and/or property damage.

All warning and capacity labels should be readable

and complete. Wash external surfaces of jack, labels,

and decals with a mild soap solution.

Lubricate all rotating and sliding portions of the jack

monthly.

9.1 Inspection

The owner must inspect, or appoint a knowledgeable

person to inspect the unit for signs of corrosion and / or

excessive wear. Visual inspection should be made

before each use of the unit, checking for abnormal

conditions. Regular inspections should be made weekly

for daily use and monthly for intermittent use. Each unit

must be inspected immediately if subjected to an

abnormal load or shock. Any unit which appears to be

damaged in any way, is found to be badly worn, or

operates abnormally shall be removed from service until

necessary repairs are made.

Inspect the door for closure and door handle latching

operation. The door should close easily and the door

handle should loosely latch with a 90-degree rotation

of the door handle. Further 90-degree rotation of the

handle should clamp the door shut and actuate the

control valve. There should be the sound of air

flowing for up to 45 seconds until the ram is fully

lowered and the air pressure in the ram cylinder

equalizes with the air supply.

After the air stops flowing, check the unit for

excessive leaks. An excessive leak is a leak which

can be heard and which degrades the performance

of the unit. Minor leaks do not adversely affect the

operation of the unit.

Unlatch the door and the air should exhaust from the

ram cylinder. The door should not open until the ram

has returned to its fully raised position

(approximately 10 seconds).

Inspect crushing chamber for damage or worn parts.

If any irregularities or problems are detected during

an inspection, the unit must be removed from service

immediately and repaired. Contact the manufacturer

using the contact information on the back cover of

this manual.

9.3 Control valve actuation adjustment

Note: The setscrew on the door that actuates the

control valve and the pawl on the door handle latch

are adjusted at the factory and should never need

adjustment.

1. Make sure the two screws securing the control valve

on the right hand side of the unit are tight. Make sure

the two screws securing the handle latch to the door

are tight and the two jam nuts securing the latch pawl

to the stem are tight.

2. Loosen the jam nut securing the set screw on the

door and back the setscrew out. Close door and turn

door handle fully clockwise to solidly latch the door.

3. Using a hex wrench, slowly tighten the setscrew until

the top platen lowers and there is no air leakage

detected around the spool of the control valve.

Tighten the setscrew 1/2 turn further and secure the

setscrew with the jam nut.

4. Rotate the latch handle 1/4 turn counterclockwise.

The air should exhaust and the ram should retract, but

the pawl should remain loosely engaged with the door

closed.

5. Rotate the latch fully counterclockwise and the door

should open. Repeat steps 2 through 5 if the door

does not operate correctly.

AFC-9/CFC

-

16 | 11 |

en

Troubleshooting

10. Troubleshooting

This section is a list of potential problems and

solutions. If the solution listed fails to correct the

problem, call the manufacturer at the numbers and

address printed on the back cover of this manual.

Please have the model number, and serial number of

your jack available. The serial number is permanently

stamped on a metal tag located

the shroud at the top

Problem Cause/Solution

Ram does not actuate

.

• Not connected to air supply. Connect unit

to adequate air supply (see Installation

instructions section of manual).

• Setscrew on door is not properly actuating

the control valve. Adjust setscrew (see

Control Valve Actuation Adjustment

section).

above the door or on

• Air pressure too low. 100 psi will

adequately crush most car and light truck

filters. Heavy truck filters require a

minimum of 120 psi.

• Some brands or models of oil filters are

Inadequate crushing

action

Oil is running over the

catch basin

stronger than other brands and therefore

will not crush as flat.

• Excess air leakage. Locate source of

leak(s) and repair.

• Crushing too many filters at one time or

there is too big of height difference in the

filters you are crushing at one time. Crush

filters individually.

• Make sure vehicle is in neutral and baking

brake is disengaged. Always chock wheels

on opposite end prior to lifting.

en | 12 |

AFC-9/CFC

-16

Maintenance Chart

11. Maintenance Chart

Action Date Details

Receiving inspection

Person

responsible

AFC-9/CFC

-16 | 13 |

en

Maintenance Chart

Action Date Details

Person

responsible

en | 14 |

AFC-9/CFC

-16

Notes

12. Notes

AFC-9/CFC

-

16 | 15 |

en

Notes

670

-

90747

MAHLE Aftermarket Inc.

10 Innovation Drive

York, PA 17402 U.S.A.

Phone: (800) 468-2321

Fax: (717) 755-8304

E-mail: tech.mss@us.mahle.com

www.servicesolutions.mahle.com

Loading...

Loading...