MAHLE ACX2180H, ArcticPRO ACX2250, ACX2150, ArcticPRO ACX2280 Operation Manual

MAHLE ACX2180H

en 2 | ACX2180H |

| ACX2180H | 3

en

Contents

1

Symbols use

1.1

In the documentation ................................. 4

1.1.1

Warning notices- Structure and

meaning 4

1.1.2 Symbols in this documentation

1.2

On the product ............................................ 4

2

Important notes .............................. 4

2.1

User group

2.2

Agreement

2.3

Obligation of contractor

2.4

Safety regulations

2.4.1 ACX2180H

2.5

Safety devices ............................................ 8

2.6

Proper disposal ........................................... 8

2.7

Recycled material disposal ....................... 8

2.8

Packaging disposal .................................... 8

2.9

Disposal of combo filter ............................. 8

2.10

Technical Data ............................................ 8

2.11

Glossary....................................................... 8

3

Product description ....................... 9

3.1

Application

3.2

Scope of delivery

4

Description of unit ....................... 10

5

Input Selection ............................. 12

5.1

Selection and function key ...................... 12

5.2

Display screen .......................................... 13

5.3

Main Menu Options .................................. 13

5.4

Unit Features ............................................ 13

5.4.1

EcoLOCK ® couplers (optional) ........ 13

5.4.2 Locking caster brakes

5.4.3 Power supply cable and switch

5.5

Functional description

6

Equipment installation ................ 15

6.1

Unpacking ACX2180H

7

Commissioning ............................ 16

7.1

Connections and positioning

7.2

First start-up verification

7.3

Setup

............................................ 4

................................................. 4

................................................. 4

......................... 5

................................... 6

............................................. 6

.................................................. 9

..................................... 9

....................... 13

.......................... 14

......................... 15

..................... 16

......................................................... 17

......... 4

...... 13

.............. 16

7.4

Internal Bottle Fill

8

A/C service preparation .............. 18

8.1

Preliminary preparation

8.2

Non-condensable gas discharge

8.3

Charge Modes

8.3.1 Quick Modes

8.3.2 Zero tolerance mode

9

A/C system service ...................... 19

9.1

Automatic cycle setup ............................. 19

9.2

Manual cycle setup .................................. 19

9.3

Recovery process .................................... 20

9.4

Vacuum process ...................................... 20

9.5

Charge process ........................................ 20

9.6

Flushing after changing type of Oil .. 21

9.7

Vehicle Pressure Check

9.8

Unit of measure

9.9

9.10

10

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

Clock

Setting language .................................... 21

Maintenance ................................. 22

Maintenance interval

Filling internal refrigerant cylinder

Self test

Pressure zero

Counters

Long life pump test

Vacuum pump oil change

Replace filter dryer

Printer maintenance (optional)

Adjustment ................................. 21

.................................................... 23

................................................... 23

10.10 Periodic checks

11

Spare parts ................................... 26

12

Maintenance ................................. 27

12.1

Vacuum pump oil change ....................... 27

12.2

Filter dryer change ................................... 29

12.3

Refrigerant load cell calibration check .. 32

12.4

Other checks/maintenance/repairs ....... 33

12.5

Notes .......................................................... 35

.................................. 17

....................... 18

....... 18

......................................... 18

......................................... 18

......................... 18

.................. 21

................................... 21

............................ 22

.... 22

......................................... 23

............................... 23

.................... 24

................................. 24

.......... 25

...................................... 25

en 4 | ACX2180H |

Warning

symbol

KEYWORD - Nature and source of hazard!

Consequences of hazard in the event of failure

to observe action and information given.

Hazard prevention action information.

Key word

Probability of

occurrence

Severity of danger

if instructions not

observed

impending

Death or severe injury

impending

Death or severe injury

Possible

Minor injury

Symbol

Designation

Explanation

Warns about possible property

damage

Practical hints and other useful

information.

1.

2.

Instruction consisting of several

steps.

Instruction consisting of one step.

An instruction produces a visible

intermediate result.

There is a visible final result on

completion of the instruction.

1

Symbols use

1.1

In the documentation

1.1.1

Warning notices- Structure and meaning

Warning notices warn of dangers to the user or people in

the vicinity. Warning notices also indicate the

consequences of the hazard as well as preventive action.

Warning notices have the following structure

The key word indicates the likelihood of occurrence and the

severity of the hazard in the event of non-observance:

:

1.1.2

Symbols in this documentation

1.2

On the product

Observe all warning notices on products and ensure

they remain legible.

2

Important notes

Before start up, connecting and

operating MAHLE products it is

absolutely essential that the Original

instructions/owner’s manual and, in

particular, the safety instructions are studied carefully.

By doing so you can eliminate any uncertainties in

handling MAHLE products and thus associated safety

risks upfront; something which is in the interests of your

own safety and will ultimately help avoid damage to the

device. When a MAHLE product is handed over to

another person, not only the Original instructions but

also the safety instructions and information on its

designated use must be handed over to the person.

2.1

User group

The product may be used by skilled and instructed

personnel only. Personnel scheduled to be trained,

familiarized, and instructed or to take part in a general

training course may only work with the product under the

supervision of an experienced person. All work conducted

on pressurized equipment may be performed by persons

with sufficient knowledge and experience in the field of

refrigeration, cooling systems and coolants and, also be

aware of the risks involved in the use of pressurized

devices

2.2

Agreement

By using the product you agree to the following regulations:

Copyright

Software and data are the property of MAHLE or its

suppliers and protected against copying by copyright

laws, international

regulations. Copying or sell

part thereof is impermissible and

event of any infringements MAHLE reserves the right to

proceed with criminal prosecution and to claim for

damages.

agreements and other national legal

ing of data and software or any

punishable; in the

Wear protective goggles.

Wear protective gloves.

| ACX2180H | 5

en

Liability

All data in this program is based—where possible—on

manufacturer and importer details. MAHLE does not accept

liability for the correctness and completeness of software and

data; liability for damage caused by faulty software and data is

ruled out. Whatever the event, MAHLE liability is restricted to

the amount for which the customer actually pays for the

product. The disclaimer of liability does not apply to damages

caused by intent or gross negligence on the part of MAHLE.

Warranty

Any use of non-approved hardware and software will result in

a modification to our product and thus to exclusion of any

liability and warranty, even if the hardware or software has in

the meantime been removed or deleted.

No changes may be made to our products. Our products may

only be used in combination with original accessories and

original service parts. Failing to do so, will render null and void

all warranty claims.

This product may only be operated using MAHLE approved

operating systems. If the product is operated using an operating

system other than the approved one, then our warranty

obligation

null and void. Furthermore, we will not be held liable for

damage and consequential damage incurred through the use

of a non-approved

pursuant to our supply conditions will be rendered

operating system.

2.3

Obligation of contractor

The contractor is obliged to ensure that all measures

geared

towards the prevention of accidents, industrial

diseases, labor- related health risks are taken and

measures towards making the workplace fit for people

to work in are carried out.

Basic rules

The contractor is bound to ensure that all electrical

equipment and operating material is set up, modified

and maintained by skilled electricians only or under

the guidance and supervision of a skilled electrician in

accordance with electrical engineering principles.

Furthermore, the contractor must ensure that all

electrical equip

operated in keeping with electrical engineering

principles.

If a piece of electrical equipment or operating

material is found to be defective, i.e. It does not or no

longer complies with electrical engineering principles,

the contractor must ensure that the fault is rectified

immediately and, in the event that imminent danger

exists, also ensure that the electrical equipment or

the electrical operating material is not used.

Tests (taking Germany as an example)

The contractor must ensure that all electrical systems and

equipment are tested by a qualified electrician or under the

guidance of a qualified electrician to ensure they are in proper

working order:

— Before starting for the first time.

— After modifications or repairs before starting

— At given intervals. Set intervals such as to ensure that

ment and operating material is

faults that can be expected to occur are determined in

good time.

The test is to take the electrical engineering principles

relating hereto into account.

Upon request of the free trade association, a test manual is

to be maintained into which specific entries are made.

en 6 | ACX2180H |

Avoid all skin contact with the refrigerant. The low

boiling point of the refrigerant (approx. -30° C) can

lead to frostbite. Should refrigerant come into contact

with the skin, remove any moistened clothing

immediately and rinse the area of skin affected with

generous amounts of water.

Never inhale refrigerant, dye and oil vapors. The

vapors can irritate the eyes, nose and respiratory

system. If liquid refrigerant or UV dye comes into

contact with the eyes, rinse them thoroughly with

water for 15 minutes. Then obtain medical attention

even if no pain is felt

Never use compressed air with R134a. Certain

mixtures of air and R134a are highly flammable.

Such mixtures are a potential hazard and may lead

to fire or explosions and thus cause damage or

injury.

If high-voltage components or high-voltage wires are

handled incorrectly, there is a risk of fatal injury from

high voltage and the possible transmission of current

through the body.

2.4

Safety regulations

2.4.1

MAHLE product.

ACX2180H

Always carefully study and follow all the safety regulations before using the

Avoid all skin contact with the UV dye. Should UV dye

come into contact with the skin, remove any moistened

clothing immediately and rinse the area affected with

generous amounts of water.

R134a is not to be mixed with other refrigerants. The

mixing of refrigerants could damage the vehicle air

conditioning system.

De-energizing is only to be performed by a qualified

electrician, a qualified electrician for specific tasks (hybrid) or

a power systems engineer.

R134a is colorless, with weak characteristic smell and

heavier than air. It may flow into repair pits. Should

refrigerant escape, Provide for sufficient ventilation

(particularly in repair pits) and leave the workshop.

Never swallow UV dye. Should it be swallowed inadvertently,

never attempt to induce vomiting. Drink generous amounts of

water and obtain medical attention.

Before connecting the ACX2180H to a vehicle air conditioning

system or an external refrigerant bottle, make sure the quickrelease couplings are not leaking. Only ever use external

refrigerant bottles provided with safety valves and certified

in line with applicable standards.

Before switching off the ACX2180H, make sure all charging

and drainage operations have been completed. This

prevents damage to the unit and reduces the risk of

refrigerant escaping into the environment.

Work on vehicles with high-voltage components is only ever

to be performed in a safe de-energized condition by persons

with the minimum qualification “Trained to perform electrical

work”.

Even after deactivating a high-voltage vehicle electrical

sys

tem, the high-voltage battery may still be live.

Operating condition cannot be established from any running

noise, as the electric machine is silent when stationary.

In gear positions "P" and "N" the engine or electric motor

may start spontaneously depending on the charge of the

high-voltage battery.

Never open or damage high-voltage batteries.

On vehicles that have been in an accident , never touch high-

voltage components or exposed high-voltage wires before

deactivating the high-voltage vehicle electrical system.

The ACX2180H must be constantly monitored when in

opera

tion. Never leave the ACX2180H unattended when in

operation. Vehicle A/C service using the ACX2180H must be

prepared and implemented such that the vehicle air

conditioning syst em

example by removing the radiator or engine).

circuit does not have to be opened (for

Refrigerant extracted from a vehicle air conditioning system

may be contaminated with moisture, lubricant, dirt and traces of

other gases.

If the refrigerant has been contaminated by being

mixed with other gases, remove the contaminated

refrigerant and add fresh R134a before using the

ACX2180H for A/C service.

R134a is not to be used in areas in which there is a

danger of explosion. Fire, open flames and smoking

are prohibited.

The ACX2180H unit should not be exposed to

excess moisture or be operated in wet areas

Position the ACX2180H on all four wheels on a flat,

vibration- proof surface so that proper operation of the

scales is guaranteed

Vehicle A/C service using the ACX2180H must be prepared

and implemented such that the vehicle air conditioning

system circuit does not have to be opened (for example by

removing the radiator or engine).

The ACX2180H can be secured in position by locking

the caster brake.

| ACX2180H | 7

en

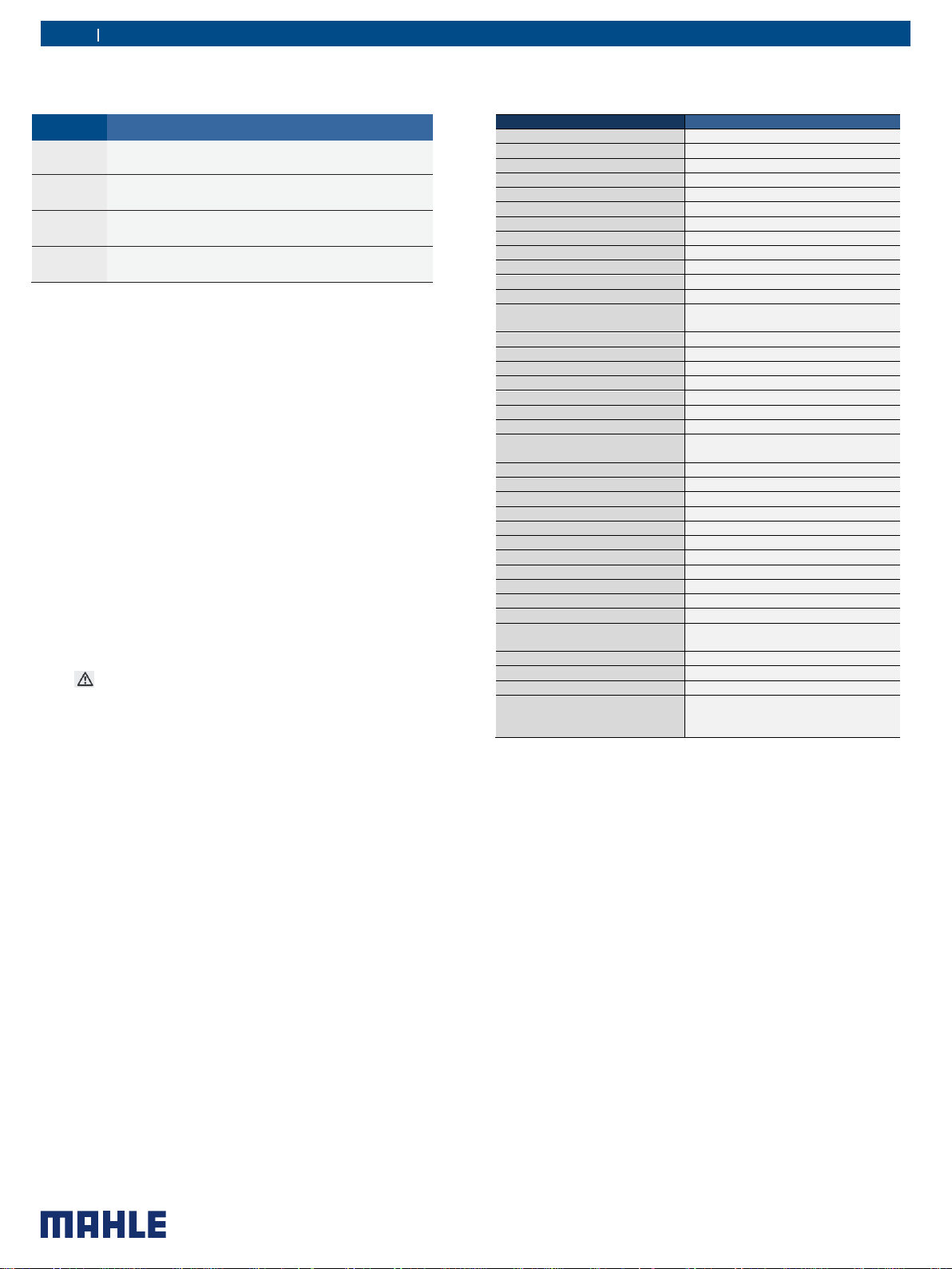

Parameters

Rated voltage

110 VAC ± 10%

Rated frequency

50/60Hz

Rated current

10A

Rated tripping current

30mA

Tripping switch

C

The ACX2180H must always be transported in its operating

position. Never lay the ACX2180H on its side, as oil could

then escape from the vacuum pump or the built in compres

could be damaged.

for protecting the ACX2180H against damage resulting from

natural catastrophes.

There are no additional safety systems

sor

We recommend calibrating the scales at least once per year.

Contact customer service for calibration of the scales.

The ACX2180H must be subjected to regular maintenance by

service personnel or authorized agents to ensure the safety of

the unit.

Disconnect power before performing any maintenance or

service to unit.

Never perform any maintenance work which is not expressly

recommended in this manual. Contact customer service if

components have to be replaced other than in the course of

maintenance work.

The ACX2180H must be connected to a properly grounded

electrical connection.

If there is damage to the ACX2180H, terminate usage

imme

diately and contact customer service.

The service hoses and service quick-release couplings must be

regularly checked for wear and replaced if damaged.

The ACX2180H must be operated in an environment

corresponding to the directive BGR 157 with respect to the

exchange of air.

Observe local laws or directives as to ensure the safety of the

pressurized device.

Follow the pertinent legal regulations or directives to ensure

safe handling of pressurized devices.

For safety reasons it is advisable to use a residual current

operated circuit breaker (rccb) with the following

specifications:

Never remove any components from inside the ACX2180H

except for maintenance or repair purposes.

Avoid using an extension cord with the unit. If necessary,

use a good condition (three wire grounded, #14AWG or

larger) extension cord of the shortest possible length. In

addition, the current drawn by all devices connected to the

wall socket must not exceed 15A total.

en 8 | ACX2180H |

Description

Function

Pressure

switch

Switches the compressor off in the normal operating

pressure is exceeded

Safety valve

The safety valve opens if the design pressure is exceeded

Circuit

Breaker

Interrupts the power supply if overcurrent is applied to the

ACX2180H

Vents

The ACX2180H is provided with vents in the housing to

ensure the exchange of air even when switched off.

Description

Specification

R134a tank capacity

12L

Service pressure

400PSI

Maximum content

22lbs.

Method to weigh gas content

Load cell

Recovered oil container

250ml

Vacuum pump

2CFM dual stage

Vacuum pump oil quantity

250ml

Compressor capacity

0.87cu in/14cc

Dryer filter

90kg recovered R134a

Non-condensable gas purge

Automatic via solenoid valve

HP and LP taps

Automatic

Display

7 inch capacitive touch screen

Software updating

USB type A or USB type B direct

connect to PC

Printer (optional)

Thermal, 24 columns

All functions

Automatic and manual

Recycling mode

Single pass

Memory for customized cycles

100 records

Flushing

With integrated solenoid valves

System pressure diagnostics

Manual and automatic

Dryer filter replacement alarm

Active

Vacuum pump oil replacement

alarm

Active

Full/empty tank check alarm

Active

Full oil container check alarm

Visual

Empty oil container alarm

Visual

Dimension H x W x D

119 x 74 x 74 cm

Dry weight

98kg

Power supply frequency

60Hz

Voltage

120VAC, 1 phase

Total max load

7.5A

Overcurrent protection

12A (circuit breaker)

Operating temperature

50 - 122°F

Humidity

10 90%RH (non-condensing)

Storage temperature and

humidity

-13 to 50°F

10 - 90%RH (non-condensing)

Max operating altitude

6562 ft.

Pollution degree

2

Water degree

0

Certifications

SAE J2788

UL 1963

CAN/CSA STD C22.2NO. 120 – M91

2.5

Safety devices

2.6

Proper disposal

At the end of its service life, this equipment must be

disposed of as follows:

— Contact the service center to have the refrigerant in

the unit recovered and recycled.

— Consign the unit to an authorized collection

center according to local legislation.

2.7

Recycled material disposal

— Return the refrigerant recovered from the

unit to the refrigerant supplier for proper

disposal or recycling.

— Lubricants extracted from the vehicle's

A/C system must be returned to an official

oil collection center

2.8

Packaging disposal

Electronic and electrical A/C service

equipment must never be disposed of with

domestic waste, but recycled appropriately.

— The packaging must be disposed of in

conformity with local legislation.

— This contributes to protecting the

environment

2.9

Disposal of combo filter

— Dispose of the filter via official collection

points or in accordance with the local

regulations. This contributes to protecting

the environment

2.10

Technical Data

2.11

Glossary

Recovery phase: The refrigerant is extracted from the vehicle

air conditioning system, cleaned and routed into the internal

bottle of the ACX2180H. The refrigerant oil collected in the

process is drained into the used oil bottle at the ACX2180H.

Vacuum phase: A vacuum is generated in the vehicle air con-

ditioning system. Measurement of the drop in pressure begins as

soon as the vacuum has been generated.

Charging phase: A certain quantity of refrigerant is added to the

vehicle air conditioning system.

Description of unit |

ACX2180H | 9 en

m

Description

Service hose (high pressure)

Service hose (low pressure)

Quick-release coupling (high pressure)

Quick-release coupling (low pressure)

Used oil bottle

Original instructions

Adapter (external bottle) - US Acme 1/2

Calibration check weight

3

Product description

3.1

Application

ACX2180H is suitable for vehicles with a conventional engine

as well as for hybrid and electric vehicles. ACX2180H features

all the functions required for vehicle A/C service.

The following functions can be implemented:

Refrigerant recovery and recha rging.

Vacuum generation.

Flushing.

The ACX2180H can only be operated with R134a. The

ACX2180H is not to be used for service work on vehicles

with air conditioning systems employing refrigerants other

than R134a, as this will cause damage. Prior to A/C service

check the type of refrigerant used in the vehicle air

condition

3.2

Scope of delivery

ing system.

en

10

| ACX2180H | Description of unit

Fig. 3 Front left view

1.

Vacuum pump oil level sight glass

Fig. 1: Front Left View

1.

Rear Handle

2.

Tool Tray

3.

Status indicator light

4.

LCD display

5.

Low Pressure Gauge

6.

High Pressure Gauge

7.

Front Cover

8.

Locking Caster

9.

Rear Wheel

10.

Printer (optional)

11.

Used oil bottle

Fig. 2: Rear View

1.

Service Hoses

2.

Fan

3.

Vent

4.

Hose Storage

Figure A: Rear Connection View

1.

High Side Parking Coupler

2.

Low Side Parking Coupler

3.

Refrigerant Identifier (Optional)

4.

Power Switch with circuit breaker

5.

Power Cord socket

4

4

Description of unit

Description of unit |

ACX2180H | 11 en

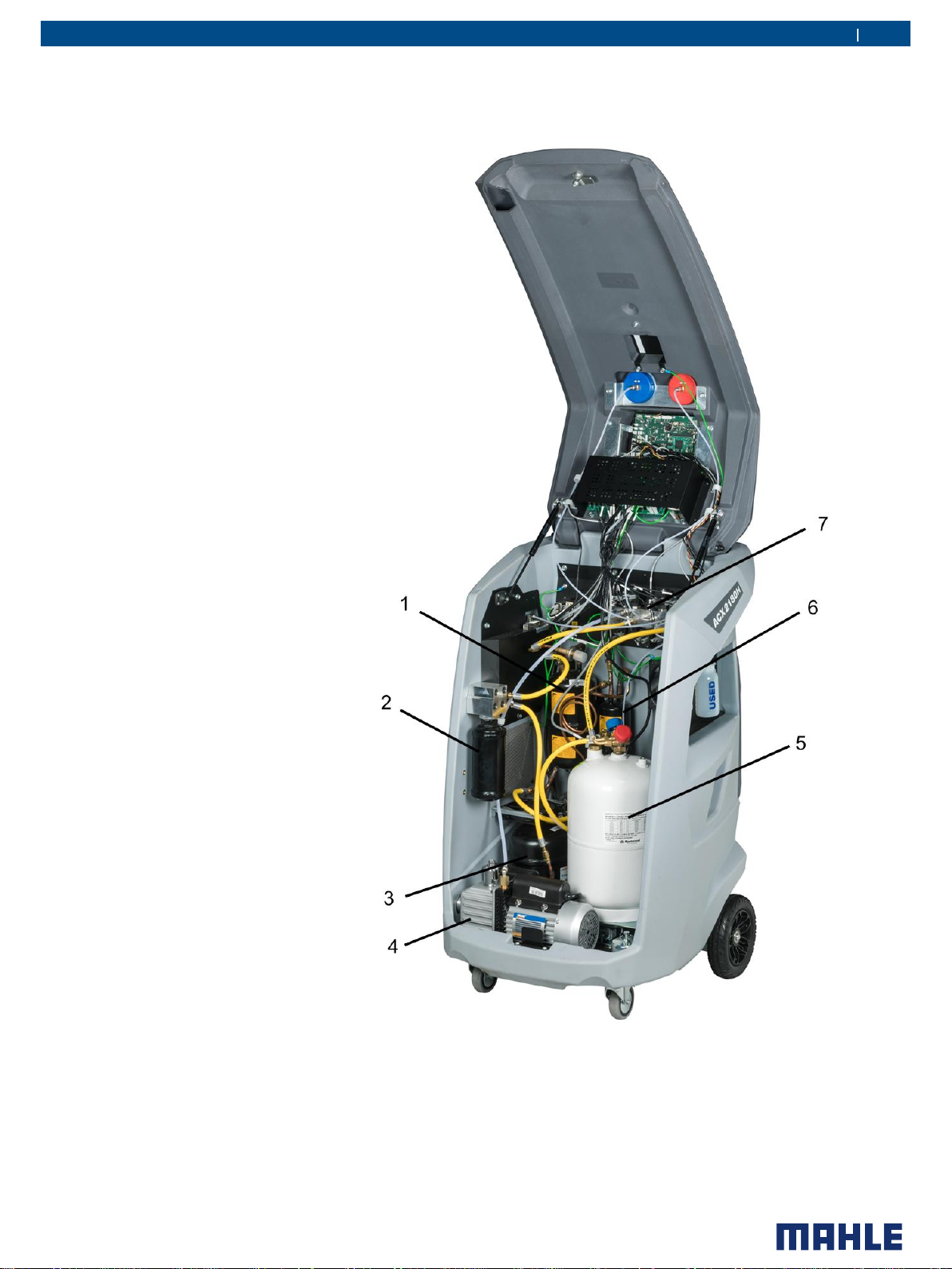

Fig. 4: Internal components

1.

Accumulator/Oil separator

2.

Combo filter

3.

Compressor

4.

Vacuum pump

5.

Refrigerant tank

6.

HS compressor oil separator

7.

Manifold

Loading...

Loading...