MAHLE ACX150, ACX250 User Manual

EN | 1 | ACX150/250 | CONTENTS

1 CONTENTS

1 CONTENTS 1

2 General instructions 3

2.1 General notes 3

2.2 General instructions 3

2.3 Manufacturer identification 3

3 Safety conditions 3

3.1 Personal safety information 3

3.1.1 Definitions 3

3.1.2 Personal safety

information 4

3.2 Important information on

service equipment safety 7

3.3 Safety devices 7

4 Layout of the manual 7

4.1 Use of the manual 7

4.2 Symbols 8

4.2.1 Safety 8

4.3 Glossary 8

4.4 Guidelines for the handling of

refrigerant 9

4.4.1 Precautions for

refrigerant storage 9

4.4.2 Conditions of refrigerant

and system 10

4.4.3 Recycling capacity 10

5 Product description 10

5.1 Application 10

5.2 Scope of delivery 10

5.3 Description of the unit 10

5.4 User interface 11

5.4.1 Main menu 12

5.5 E³ connect quick couplers 13

6 Technical features 14

7 Installation 15

7.1 Equipment installation 15

7.1.1 Unpacking ACX150/250

15

REFRIGERANT SCALE SCREW

RELEASE 16

8 Commissioning 16

8.1 Connections 16

8.1.1 Positioning and

connection 17

8.2 Initial verification 17

8.3 New oil bottle filling 18

8.4 UV dye bottle filling 19

9 Setup 19

10 A/C system charge 20

10.1 Preliminary operations 20

10.2 Non-condensable gas

discharge 21

10.3 Quick mode and zero

tolerance charge mode 22

11 Automatic cycle 22

11.1 Automatic cycle data loading

22

11.2 Automatic cycle data setting 23

12 Manual cycle 24

12.1 Recovery 24

12.2 Vacuum 24

12.3 Charge 24

12.4 Flushing (with optional

accessories) 25

12.5 Hoses drain 25

13 Special test 25

13.1 AC performance test 25

13.2 Refrigerant clean 26

14 Maintenance 26

14.1 Report exporting 26

14.2 Internal cylinder fill 26

14.3 Self leak test 27

14.4 Cylinder refrigerant view 27

14.5 Air purge 27

14.6 Pressures zero 27

14.7 Counters 28

14.8 E³ pump - pump oil change 28

14.9 Dryer filter replacement 29

14.10 System info 30

14.11 System update 30

11.1.1 Database 22

11.1.2 Last cycle 22

11.1.3 My database 23

11.1.4 Direct input 23

11.2.1 Electric Compressor

Function 23

14.8.1 Oil pump visual check 29

© MAHLE

14.12

Maintenance of printer

31

14.13 Periodic checks 31

14.14 Refrigerant type

replacement 32

15 Disposal 32

15.1 A/c service unit disposal 32

15.2 Recycled materials disposal 32

15.3 Packaging disposal 32

16 Spare parts 32

EN | 2 | ACX150/250 | CONTENTS

© MAHLE

EN | 3 | ACX150/250 | General instructions

2 General

instructions

2.1 General notes

All rights reserved.

This manual may not be reproduced, in

part or entirely, either in printed or digital

form.

It may be printed out solely for use by the

user and operators of the equipment to

which it refers.

MAHLE and resources used for the

drawing up of this manual will not be held

responsible for the incorrect use of the

manual while they guarantee that

information in the manual have been duly

checked.

The product can be subject to changes

and improvements. MAHLE reserves the

right to change without notice the

information contained in the manual.

Authorised MAHLE Centre, in

accordance with the practice described

in Chapter 12 of this manual.

This equipment is intended solely for use

by professionally trained operators

familiar with the basics of refrigeration,

refrigeration systems, refrigerants and the

hazards associated with pressurised

equipment.

Careful reading of the present manual by

the owners, the users and the operators

is required for a correct and safe use of

the tool.

The user shall not be entitled to open the

product since maintenance operations

are reserved to the authorised service

centre.

2.3 Manufacturer

2.2 General instructions

Pressure equipment undergoes checks

before commissioning and periodical

checks during operation, in compliance

with rules and law provisions in force in

the country where the tool is used.

The operator is responsible for operating

the equipment in conformity with local

legislation.

The equipment is designed for

recovering and recycling

R1234yf/R134a refrigerant fluid from

automotive A/C plant.

The equipment is intended to be used

by automotive and similar repair and

service workshops.

The switch between the two refrigerant

types, from R134a to R1234yf, can only

be performed by a technician of an

3 Safety conditions

3.1 Personal safety

3.1.1 Definitions

DANGEROUS AREAS:

Any area within or close to the equipment

implying risk for the safety and health of

exposed persons.

EXPOSED PERSON:

Any person completely or partially

standing in a dangerous area.

identification

The ACX equipment is manufactured by:

MAHLE Aftermarket GmbH

Service Solutions Europe

Pragstr. 26 - 46, 70376 Stuttgart,

Germany

Phone: +49 711 501-14003

information

© MAHLE

EN | 4 | ACX150/250 | Safety conditions

OPERATOR:

The person/s charged with operating the

machine for its intended purpose.

CLASSIFICATION OF OPERATORS

The operator can be classified according

to two main categories, which, in some

cases, refer to one single person:

The operator charged with the

equipment operation has the duty to:

o Start up and monitor the

machine's automatic cycle;

o Carry out simple setting

operations;

o Remove the causes of

equipment stop not implying

breakings of members but

simple operating anomalies.

Maintenance technician a technician

trained by an authorised MAHLE

centre, capable of working on the

machine’s mechanical and electrical

components with its guards open to

make adjustments and to service and

repair it.

USER

Body or person legally responsible for the

equipment.

3.1.2 Personal safety information

The MAHLE ACX 150/250 A/C service

station is particularly simple and reliable

due to its adjustments and functions.

When used correctly it presents no

hazard for the operator, provided he

observes the following general safety

instructions and that the service station is

regularly serviced (incorrect

maintenance/use compromise the

equipment's safety). Before operating the

service station for the first time, read

these instructions carefully. If any part of

the instructions is unclear, contact your

reseller or MAHLE.

This service station may be used by only

one equipment operator, familiar with A/C

and refrigeration systems and the hazards

associated with refrigerants and high

pressure equipment.

WORKPLACE: The station can work with

both R134a and R1234yf (the two

refrigerants cannot be stored within the

station at the same time).

Refrigerant R1234yf is defined as

flammable refrigerant.

Nonetheless, although refrigerant R134a

is not defined as flammable, mixtures of

air or oxygen with R134a may become

flammable under very particular

conditions.

The equipment must be operated

outdoor or in a well-ventilated location

(at least 1 air change per hour). The

workshop has to be equipped with

ventilation systems able to ensure air

change in every environment area or

carry out periodical ventilation by

opening the areas.

Use the equipment away from heat

sources or hot surfaces. The equipment

must not be used in explosion risk

environments (potentially explosive

atmospheres). Before using it, put the

equipment on a levelled plane and secure

position, blocking it with suitable wheel

stops.

Do not expose the tool to direct sunrays,

heat sources, rain and jets of water. Do

not smoke near the equipment and during

operations (keep at a distance of at least

1 m).

© MAHLE

EN | 5 | ACX150/250 | Safety conditions

The work area must be monitored by the

operator while the equipment is operating.

ATTENTION: R134a and/or R1234yf

refrigerant fumes/gases are heavier than

air and can gather on the floor or inside

cavities/holes and cause choke by

reducing the oxygen available for

breathing.

At high temperatures, the refrigerant

breaks down releasing toxic and

aggressive substances, harmful for the

operator and the environment.) Avoid

inhaling the system coolants and oils.

Exposure can irritate eyes and the

respiratory tract.

ELECTRICAL CONNECTION: Connect

the power cord solely to a mains supply

which conforms to the ratings on the

machine's nameplate (mounted on its

side). Make sure the mains socket is

grounded.

Maximum impedance allowed in the point

of connection to the mains shall comply

with standard EN 61000-3-11. Starting

currents can cause short voltage drops,

which may affect other equipments under

unfavourable conditions. If impedance in

the point of connection to the mains is

not compliant, this may lead to

interference so please consult the

electrical power network operator before

connecting the equipment.

Never use the service station with a

defective power cord or a different one

from that supplied with the machine. If

damaged, immediately have it replaced

with an original spare part or equivalent

by a MAHLE centre. Before opening the

service station, extract completely the

supply cable from the plug, or you can

get an electric shock.

Do not tamper with or bypass the safety

equipment and settings.

Do not leave the machine powered up

when not in use; shut off the power

supply before leaving the equipment

unused for a long time. Do not forget that

the tool (pressure tool) must always be

protected.

REFRIGERANTS AND LUBRICANTS PERSONAL SAFETY EQUIPMENT AND

PRECAUTIONS: The refrigerants and the

pressure cylinders have to be handled

with care, otherwise there will be possible

health risks.

The operator must wear safety glasses,

gloves and protective clothing suitable to

the work. Contact with the refrigerant can

cause blindness (eyes) and other physical

damages (freezing) to the operator. Avoid

contact with the skin; the refrigerant's low

boiling point (approx. –26 °C for R134a

and approx. -30 °C for R1234yf) can

cause freezing burns.

Further information about safety can be

obtained from the safety sheets of

lubricant and refrigerant producers.

Do not inhale refrigerant or oil vapour.

Keep away from the vent valves and

ventilation coupling, especially when noncondensable gas is being vented.

Never direct the quick couplings (taps)

towards your face or other persons or

animals.

© MAHLE

EN | 6 | ACX150/250 | Safety conditions

OTHER PROHIBITIONS AND USE

LIMITATIONS: Only use pure R134a or

R1234yf refrigerants, refrain from using

on vehicles containing other types of

refrigerants or mixtures of the two

refrigerants or other refrigerants.

Mixture with other types of refrigerant

produces serious damage to the

conditioning and cooling systems. Mixed

refrigerants have to be disposed of

according to the current regulations.

Never use ACX equipment with systems

containing compressed air; mixtures of

R134a or R1234yf with air or oxygen may

be potentially flammable.

Do not modify calibration of safety

devices. Do not remove seals of safety

valves and of control systems. Do not use

external tanks or other storage containers

that are not type-approved or without

safety valves.

Make sure the equipment's aeration and

ventilation ports are not obstructed or

covered while the equipment is operating.

HOSE CONNECTIONS: Hoses may

contain pressurised refrigerant. Before

changing the service couplers, check the

respective pressures in the hoses

(pressure gauge).

Before connection to a car A/C system, to

an external tank/cylinder, check that the

quick couplers are closed (unscrewed HP

and LP valves).

Scrupulously follow the instructions on

the equipment's display.

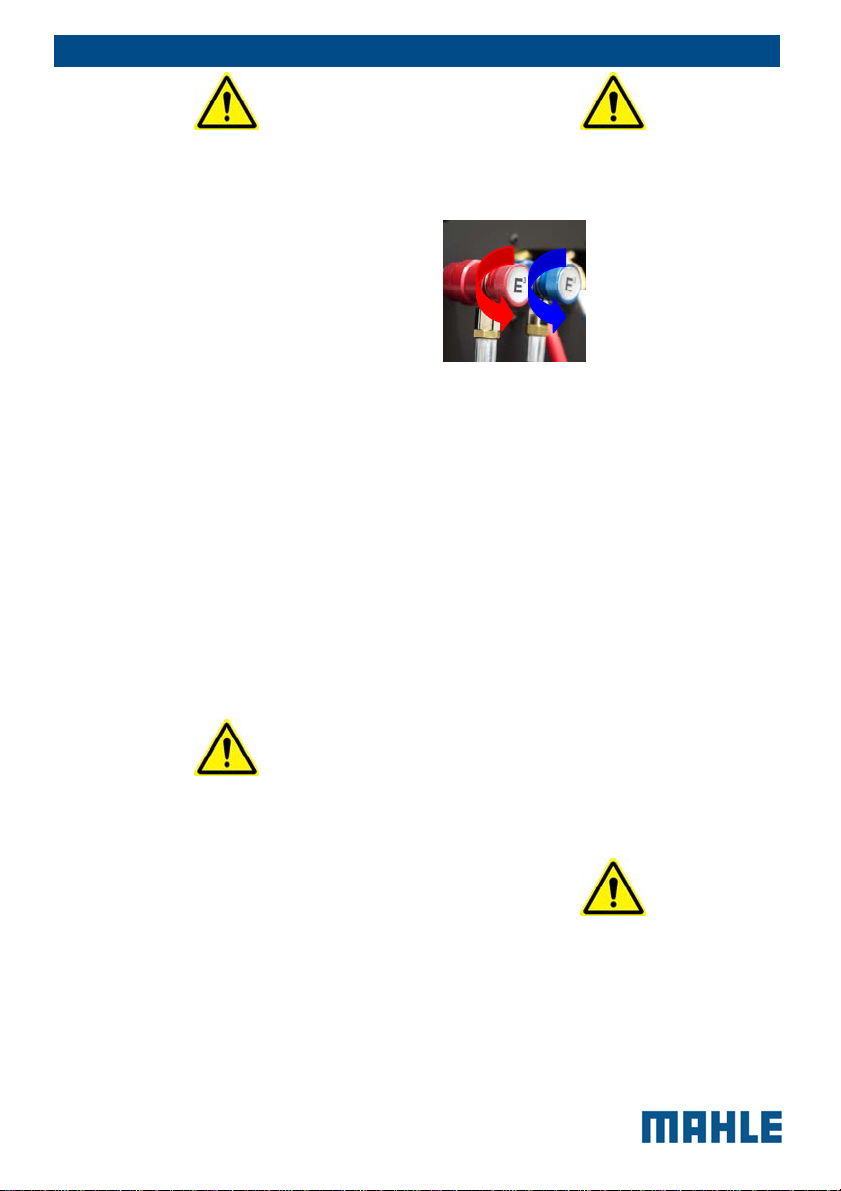

QUICK COUPLERS

CLOSING/OPENING:

Opening (connect to

the vehicle):

clockwise

Closing (detach from

the vehicle):

counter clockwise

MAINTENANCE/GENERAL CLEANING:

The equipment has to be serviced at the

intervals indicated by the equipment itself.

The service station maintenance has to

be performed according to the

procedures described in this manual and

to the current safety regulations.

Use only MAHLE original parts.

When the equipment requires the drier

filter and the vacuum pump oil to be

changed, you have to be careful in the

replacement.

A/C service station maintenance can be

carried out exclusively by a trained

operator or by a service man of a MAHLE

certified seller.

Do not use chemical agents for the

service station cleaning as they could

attack the material or the surface.

STOP FOR LONG PERIOD: Store the

equipment in a safe place, disconnected

from the mains, away from excessive

temperatures, humidity and the risk of

damaging impact.

Contact the Technical Service to run a

safety shutdown of the equipment, and if

© MAHLE

EN | 7 | ACX150/250 | Layout of the manual

scrapping the unit, to drain and recycle

the R134a or R1234yf refrigerant as

required by local legislation.

To resume operation, repeat the

installation (there is no need to register

the unit anew on the website) and run the

commissioning trials and regular

operational checks as required by local

legislation.

3.2 Important information

on service equipment

safety

When using the equipment, the following

operations are not allowed as they might

cause, under certain circumstances,

danger for persons and cause permanent

damage to the equipment itself.

- Do not remove or make

unreadable labels, signs

and/or dangers signs placed

on the equipment and in the

area nearby.

- Do not disable the unit's

safety equipment.

- The electrical system to

which the service equipment

is connected must be

configured as provided by

local legislation.

- Only operators or qualified

staff instructed or certified for

the equipment maintenance

can open the equipment. The

equipment contains parts

which can cause

electrocution: shut off power

to the equipment before

servicing/repairing it.

3.3 Safety devices

ACX 150/250 is equipped with the

following safety devices:

SAFETY PRESSURE SWITCH:

It stops the compressor in case

of excessive pressure.

SAFETY VALVE: The safety

valve opens when the pressure

inside the system reaches a

level higher than the fixed limits.

MAIN SWITCH: Switches the

equipment off by interrupting

the power supply. It is advisable

to pull the power cord plug out

of the mains socket in any case

before starting maintenance

work.

ANY TAMPERING WITH THE

ABOVE-MENTIONED SAFETY

DEVICES IS PROHIBITED.

Failure to observe any of the above

safety instructions voids the

equipment's warranty.

4 Layout of the

manual

4.1 Use of the manual

This manual is an integral part

of the equipment and must be

kept in the equipment's

immediate vicinity by the

purchaser

This manual shall accompany

the equipment in case this is

passed on to a new user.

© MAHLE

The content of this manual has

been drawn up in compliance

with the guide lines of the UNI

standard 10893:2000.

Diffusion, modification or use of

this manual for own aims is

forbidden.

The manual uses symbols which

call the reader's attention to

specific points to facilitate its

use.

It includes all technical,

operating, shutdown,

maintenance, spare parts and

safety information.

In case of doubts on the correct

interpretation of the instructions,

please contact our technical

service to obtain the required

clarifications.

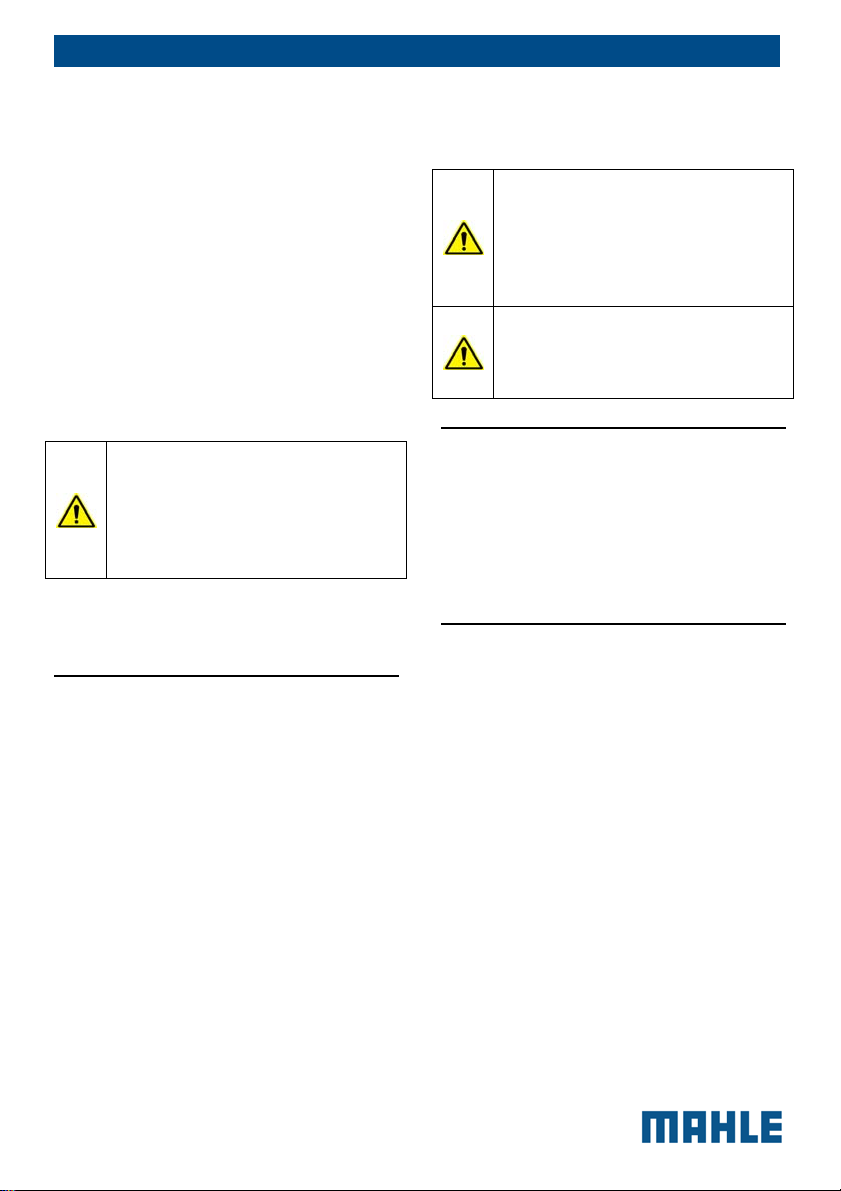

Operations which are

potentially hazardous for the

operator are highlighted with

this symbol.

Such operations can cause

serious injury.

Operations requiring special

attention are highlighted with

this symbol.

Such operations shall be

carried out correctly to avoid

causing damage to objects or

to the surrounding

environment. This symbol also

highlights information to which

special attention must be paid.

Operations which require

careful reading of the manual's

instructions are highlighted

with this symbol.

EN | 8 | ACX150/250 | Layout of the manual

4.2 Symbols

This paragraph describes the safety

symbols which may be posted on the

service equipment.

4.2.1 Safety

ALTERNATING

CURRENT

SAFETY GROUNDING

CONSULT THE

INSTRUCTIONS

MANUAL

ATTENTION!

ELECTROCUTION

HAZARD

CAUTION !: DO NOT

REMOVE THE COVER

(maintenance

technicians only)

USE PROTECTIVE

GLOVES

WEAR PROTECTIVE

GOGGLES

USE ANTI-SMASH

SAFETY SHOES

4.3 Glossary

To make the reading of this manual

easier, we have prepared the list of the

most important technical terms used in

the manual.

Refrigerant: Refrigerant fluid used in

advanced motor vehicle A/C systems.

The following refrigerant fluids

may be used:

R-1234yf CH2CFCF3 2,3,3,3-

Tetrafluoropropene.

R-134a C2H2F4 - 1,1,1,2-

© MAHLE

EN | 9 | ACX150/250 | Layout of the manual

Tetrafluoroethane

A/C system: air conditioning system.

Equipment:

ACX 150/250

service

station for recovering, recycling, draining

and charging the A/C system.

External tank: Refrigerant bottle used to

fill the internal tank.

Internal cylinder: cylinder for refrigerant

storage.

System flushing: Cleaning phase for the

removal of possible polluting substances

from the A/C system or parts of it.

Non condensable gas: Refrigerant

stored in gaseous phase, including air

and nitrogen.

4.4 Guidelines for the

4.4.1 Precautions for refrigerant

Phase: Performance of a single function.

Cycle: Sequence of steps.

Recovery: Extraction of refrigerant from

the vehicle.

Recycling: Cleaning of refrigerant,

includes: separating out oils, removal of

non-condensable gas and

single/multiple pass through filters to

reduce humidity, acidity and particulate

content of the fluid.

Disposal: disposal of refrigerant for

storage followed by

The refrigerant removed from the A/C

system must be handled with care to

prevent or minimise the risk of mixing

with other refrigerants.

This machine is suitable for treating

R134a or R1234yf refrigerants,

individually (not simultaneously).

The external cylinders used to store the

refrigerants must be clearly marked to

prevent mixing different refrigerants.

Cylinders shall be free from oil or other

contaminants and clearly marked so as to

identify the refrigerant contained.

destruction/scrapping by an authorised

waste management centre.

Vacuum cycle: Draining out of a motor

vehicle A/C system and separation out of

condensed matter and humidity, using

only the vacuum pump.

Oil charge: Charge of oil into an A/C

system to ensure the correct charge as

specified by the vehicle's manufacturer.

Charge: filling of refrigerant into the A/C

system in the amount specified by the

manufacturer.

handling of refrigerant

storage

ATTENTION: when handling,

using and storing R-134a or R1234yf refrigerant and dealing

with emergency situations,

MAKE SURE to refer to the

product’s safety sheet.

GET THE SAFETY SHEET

FROM YOUR REFRIGERANT

SUPPLIER AND FOLLOW ITS

INSTRUCTIONS.

REFRIGERANT R1234YF IS

DEFINED AS FLAMMABLE

REFRIGERANT.

© MAHLE

4.4.2 Conditions of refrigerant

and system

The condition of the refrigerant is critical

to the operation of the vehicle's A/C

system. Running repairs properly

following failure or damage safeguards

the quality of the refrigerant itself

(particulates, acids and water).

4.4.3 Recycling capacity

The service equipment's filtering systems

must be replaced regularly (see

maintenance messages) to ensure

effective recycling.

EN | 10 | ACX150/250 | Product description

5 Product

description

5.1 Application

ACX150/250 is suitable for vehicles with a

conventional engine. ACX150/250

features all the functions required for

vehicle A/C service.

The following functions can be

implemented:

Refrigerant recovery and

recharging.

Vacuum generation.

Flushing.

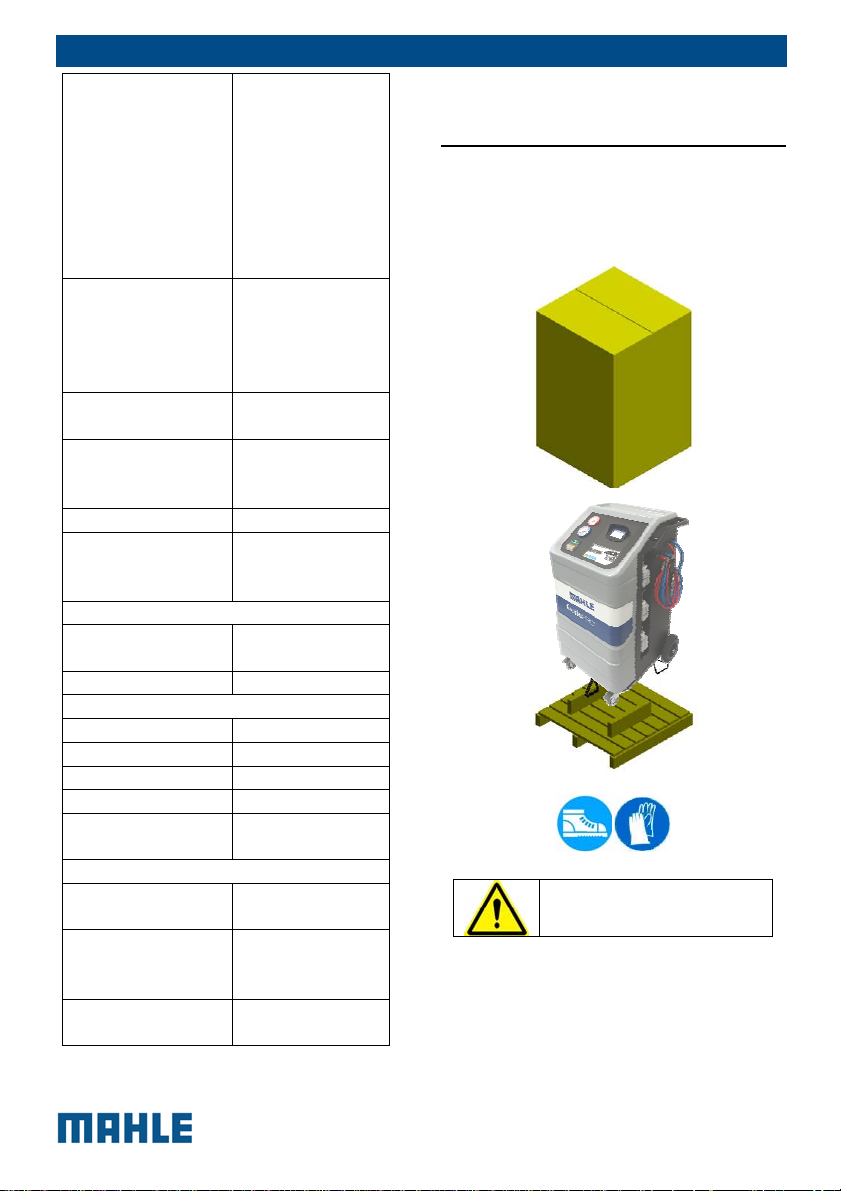

5.2 Scope of delivery

Description

Service hose (high pressure)

Service hose (low pressure)

Quick-release coupling (high pressure)

Quick-release coupling (low pressure)

New oil bottle (2pcs)

UV dye bottle

Used oil bottle

Original instructions

Adapter for external bottle

connection

Hose Flushing Adapter

(built-in)

Safety goggles

Safety gloves

Dust cover

5.3 Description of the unit

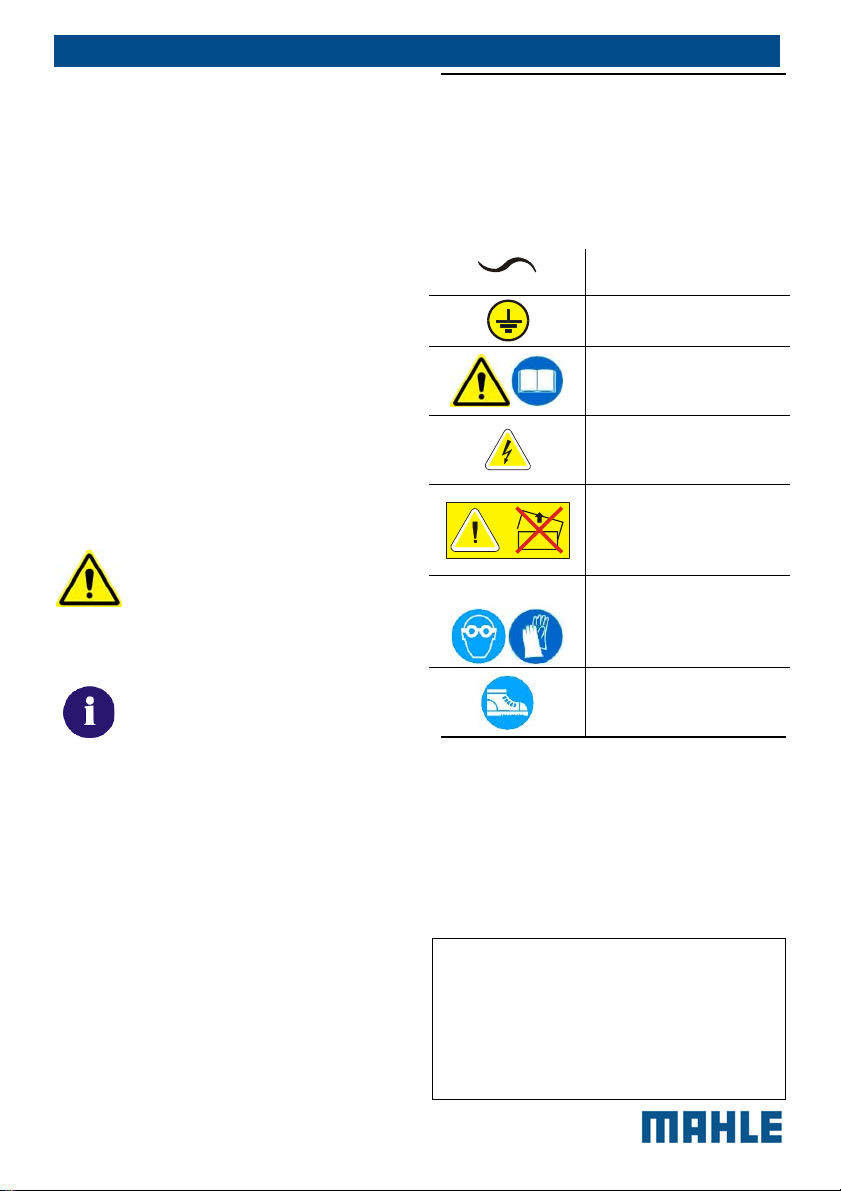

Fig.1: Left-Front view

1

Rear handle and grip

2

Tool tray and storage

3

Display and operating unit

4

ACX150/250 front housing

5

Locking caster

6

Rear wheel

7

New oil bottle

8

UV dye bottle

9

Used oil bottle

10

Low-side parking

11

High-side parking

12

Service hose

© MAHLE

EN | 11 | ACX150/250 | Product description

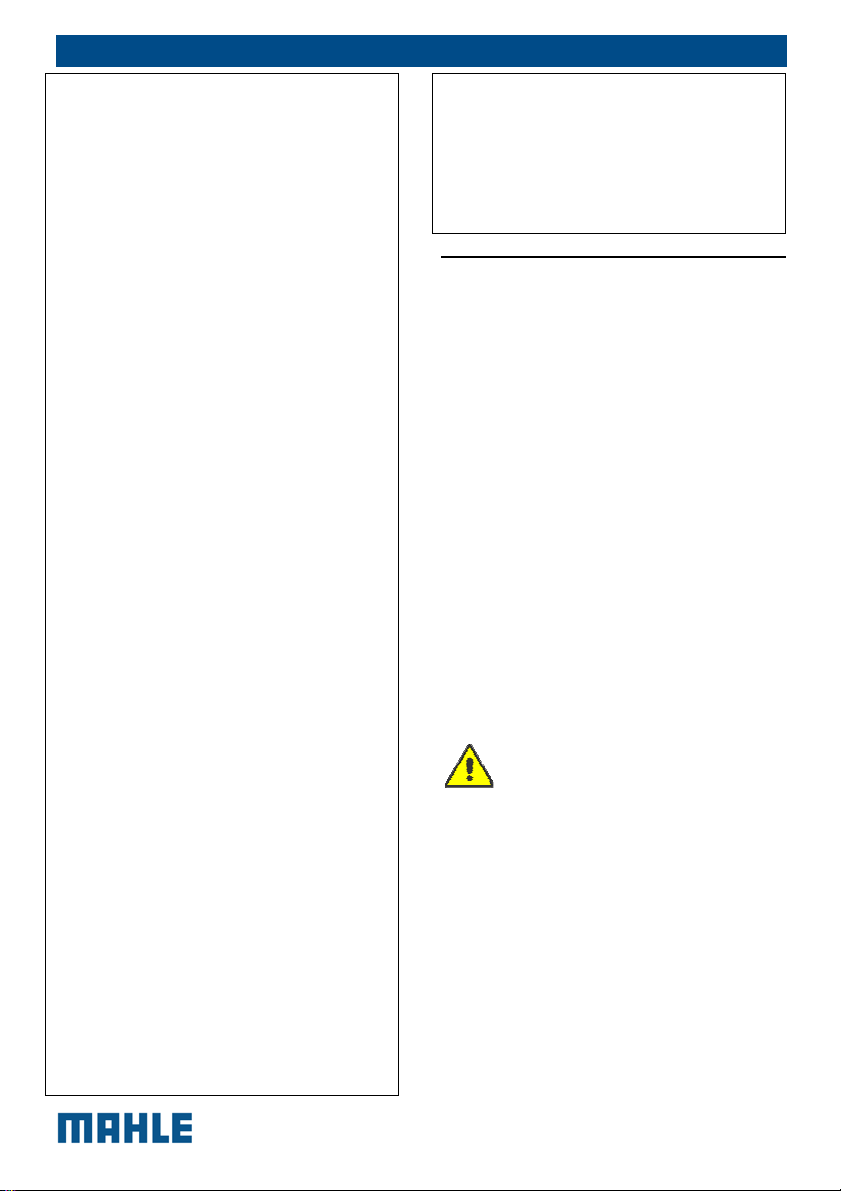

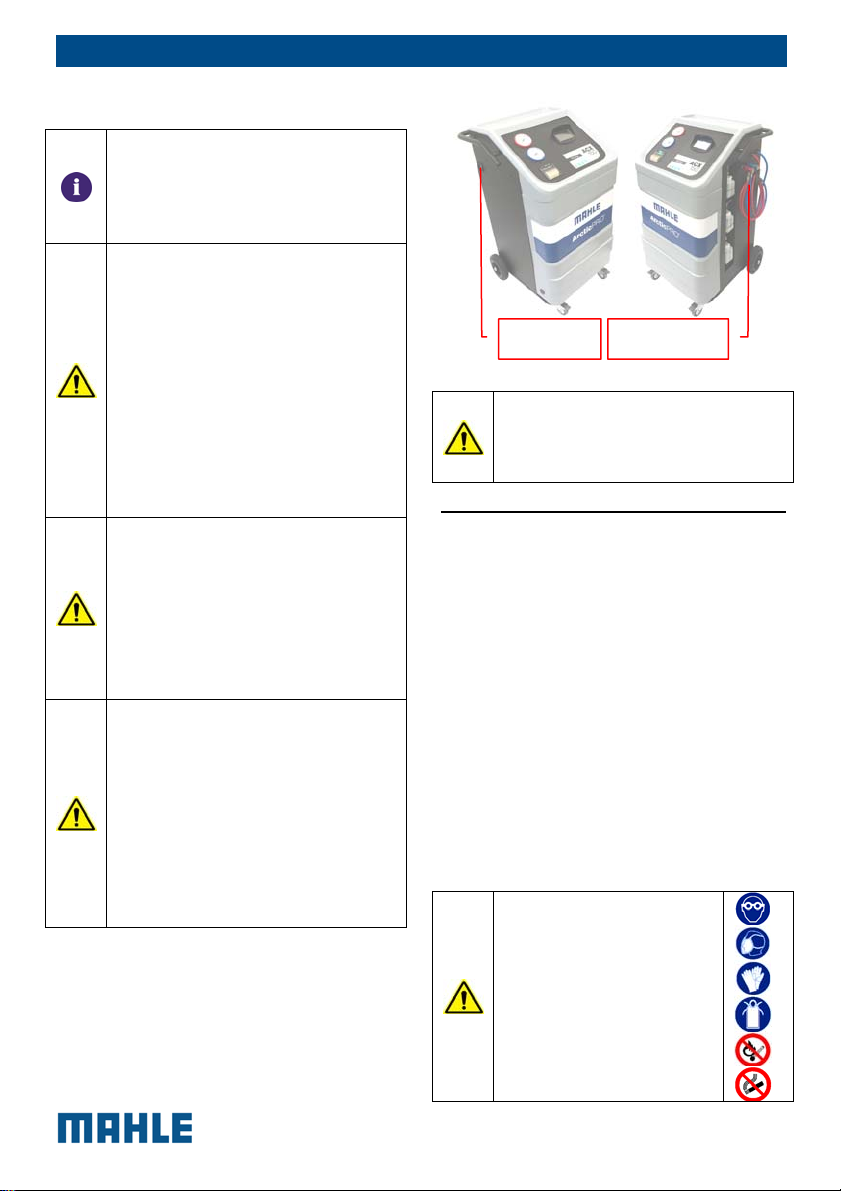

DO NOT USE THE UNIT

UNLESS THE CHARGING

HOSES (HP – LP) ARE

CORRECTLY CONNECTED

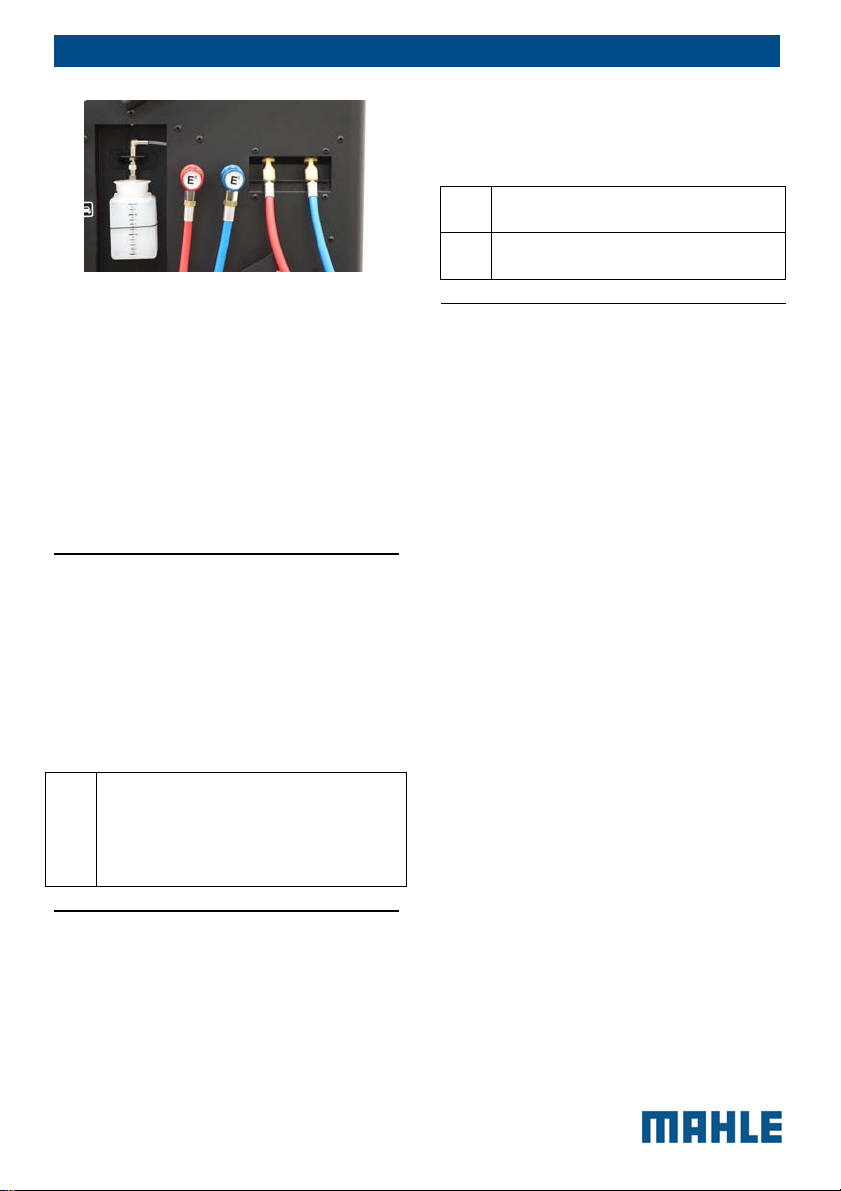

1

2

Fig. 2: Rear view (detail)

1

Fan

2

Vents

1

2

3

Fig. 3: Right-front view (detail)

1

Power cord connector and

Power switch

2

USB type B (Device port to PC)

3

USB type A (Host port to USB

Memory Stick)

The USB type-A connector

can only be used with USB

2.0 portable memory devices

with Mass storage service for

reports export and station

update, or for connection to

MAHLE refrigerant identifier.

Do not connect other types

of devices, such as USB

keyboards or other units.

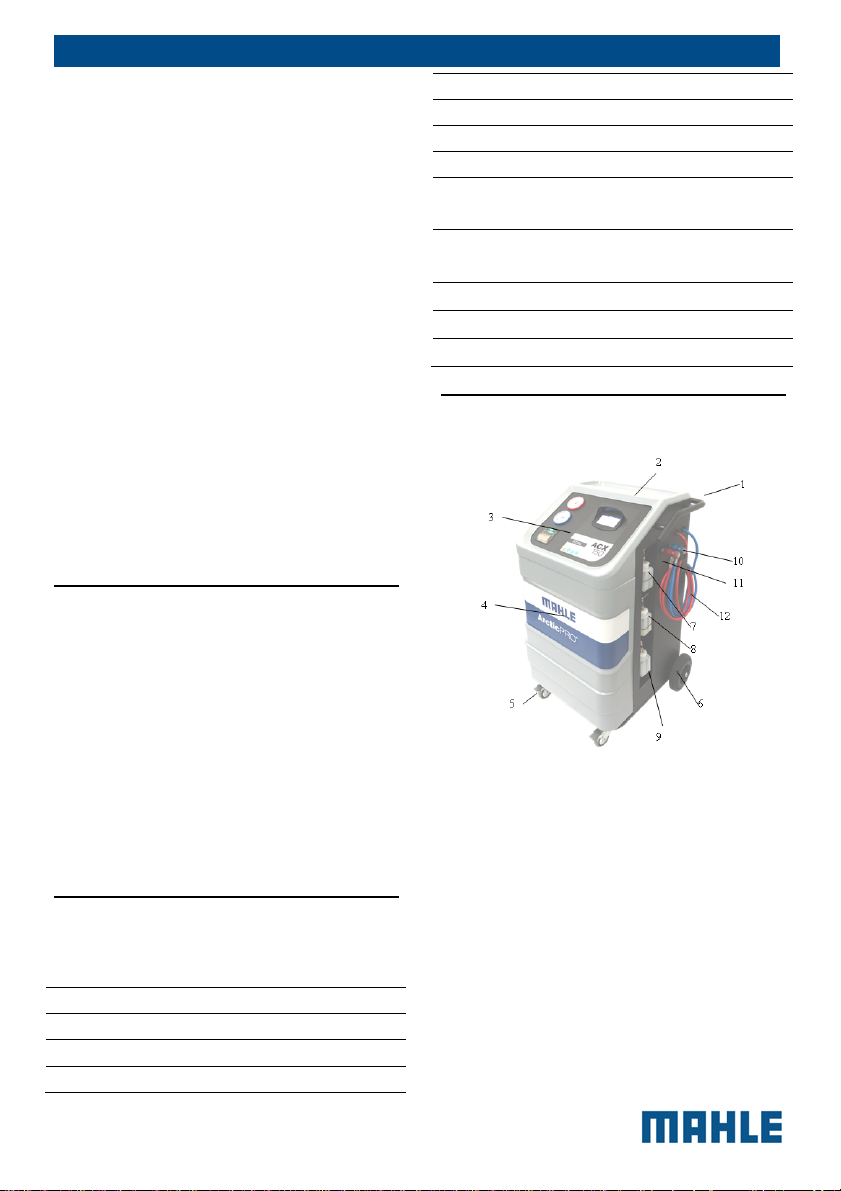

Fig. 4: Display and operating unit

1

High-pressure gauge

2

Low-pressure gauge

3

LCD Display with Touch screen

4

Printer

The pressure gauges (Fig. 4, Pos. 1, 2)

of the display and operating unit are

used to monitor the pressure during the

individual vehicle A/C service phases.

The status of the various service phases

during maintenance is displayed on the

multicolor LCD screen (Fig. 4, Pos. 3).

The menu selection and the necessary

entries are made by way of the touch

screen (Fig. 4, Pos. 3) integrated in the

LCD display. MAHLE supplies a USB

stick for updating the ACX150/250

software. If required, the USB stick can

be inserted in the USB type A socket

(Fig. 3, Pos. 4) to perform updating of

the firmware/software.

5.4 User interface

All settings, controls and service

functions are available on the touch

screen display. It also displays the service

equipment’s status, the progress of A/C

system service and any alarms and error

messages.

© MAHLE

The touch screen is the basic operator

interface and can be operated with the

fingers.

When a button is pressed, a beep sounds.

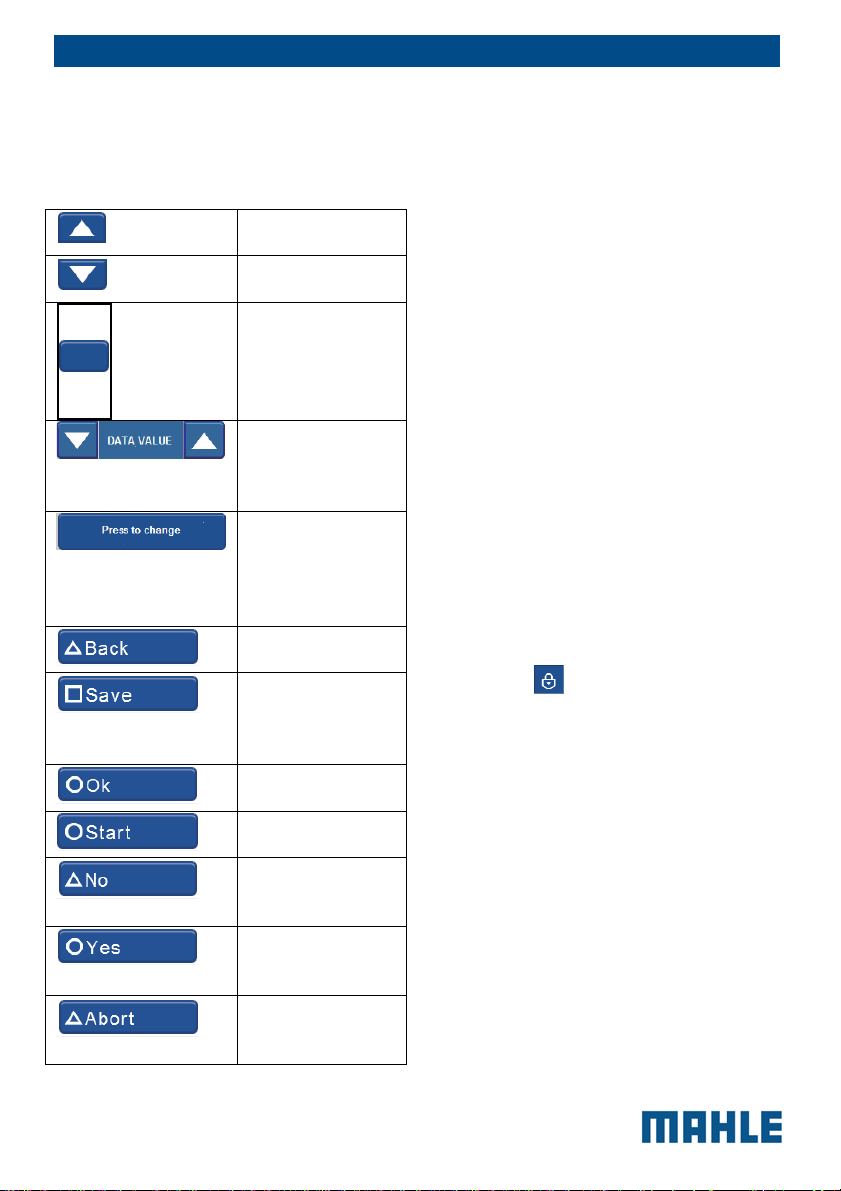

The following functions keys are available:

To move up in the

menu options

To move down in

the menu options

Scroll bar to

move in the menu

options

Arrows to

decrease or

increase the data

value

To enter in the

data changing or

switching the

data to next

option

To return to the

previous page

To save the

programmed

cycle in a

personal memory

To confirm and to

go head

To begin the

cycle

To answer NO to

the displayed

question

To answer YES to

the displayed

question

To interrupt the

operation in

progress

EN | 12 | ACX150/250 | Product description

To select a function in the menu press the

text name of the function, the selection

occurs when the finger is released, the

selected entry is pointed out with a

different colour (from grey to blue) and

the menu screen page changes.

If there are descriptions that need more

space on the screen page, for example

the manual cycle list (see the screen page

below), or in case of setup, it is possible

to display the different entries by moving

the scroll bar to the right side. For this

reason, it is necessary to touch the blue

point on the scroll bar and slide up or

down with the finger.

Lift the finger when you are on the

desired position.

By touching the arrows, the menu moves

one line up or down depending on

whether it is touched on the arrow up or

on arrow down.

If you need to enter free text or identify a

set of data, a keypad automatically

appears (for example, for entering

workshop data (if the printer is present) or

at the end of the service cycle).

If this key

switch to the symbols keyboard.

is active, it is possible to

5.4.1 Main menu

The Main menu of the graphical user

interface allow to select the following

functions:

Automatic cycle

Manual cycle

Special tests

Setup

Maintenance

Service

Each function will be described in the

next chapters.

© MAHLE

EN | 13 | ACX150/250 | Product description

5.5 E³ connect quick

couplers

E³ CONNECT is the INTELLIGENT

COUPLER, that with the suitable

automated procedure in the software

enables to:

reduce the non condensable gas

formation inside the cylinder ;

avoid the refrigerant dispersion

in the air during the

disconnection (puff effect);

check possible SCHRADER

valve leaks before disconnection.

To connect the coupling, position the

coupling on the parking coupler, pull

back the knurled section of the

coupling element and press carefully

onto the connection.

© MAHLE

6 Technical features

Cylinders for R134a or R1234yf

fluids

R134a or R1234yf

cylinder capacity

Maximum

operating

pressure (PS)

PED category

(Dir.97/23/EC)

Weight of

refrigerant content

Safety valve

Type AIRTEK -

Calibration

pressure

PED category

(Dir.97/23/EC)

Containers for oil and detection dye

Recovered PAG

oil container

New PAG oil

container

UV detection dye

container capacity

Pneumatic circuit

Vacuum pump

flow rate

Vacuum level 0.02 mbar

Vacuum pump oil

life

Refrigerant

recovery

compressor cubic

capacity

20 l

20 bar

III

Scale

VS14NPT20HN

BRPED4 20bar

R 1/4 NPT

20 bar

IV

250 ml

250 ml, with OIL

CARE valve

250 ml, with OIL

CARE valve

170 l/min double

stage

60h – extensible

to max 1000 h

with Pump

Monitoring

System

procedure

14 cc

EN | 14 | ACX150/250 | Technical features

Drier filter Every 150Kg of

refrigerant

recovered

Non condensable

gas discharge

Automatic, with

solenoid valve

HP and LP taps Automatic

Safety pressure switch

Type 13/18bar

1/4SAE

Trip pressure 18 bar

PED category

IV

(Dir.97/23/EC)

Pneumatic fittings

Net length of

4,5 m

external HP and

LP hoses

HP and LP

pressure gauges

Analog 80 mm,

pulse-free, 1.0

class

Display Graphic 4,3”

TFT WideScreen

480x272, 65536

colours

Keypad Touch screen

Software updating USB type-A with

USB 2.0 key

USB type-B with

direct

connection to

PC.

Printer (optional) Thermal, 24

columns

Functions and features

Recovered oil

measurement

Automatic

weighing, 1 g

res., 5 g acc.

New oil automatic

charge

With automatic

scale, 1 g res.,

5g acc.

UV dye automatic

Timed

charge

Electric

compressor

With integrated

flushing system

function

© MAHLE

EN | 15 | ACX150/250 | Installation

Flushing “Regular”

function

(standard)

High intensity

flushing

available with

external

accessory

(option)

Database Autodata,

complete

electronic (cars

and industrial

vehicles only)

AC Performance

Test

Recovered oil

measurement

Sound level < 70 dB (A)

Battery type for

internal Real time

clock

Overall dimensions

WxDxH 1050 x 655 x

Loadless weight about 87 kg

Power supply

Frequency 50 Hz

Voltage 230 V ~

Power 800 W

Protection Thermal

Installation

category

Environmental conditions

Operating

temperature

Humidity 10-90% R.H.

Ambient pressure 75 kPa until 106

Manual and

automatic

Automatic

weighing, 1 g

res., 5 g acc.

Lithium CR-

2032 3V

180mAh 3g.

850 mm

10-50°C

(non

condensing)

II

kPa

7 Installation

7.1 Equipment installation

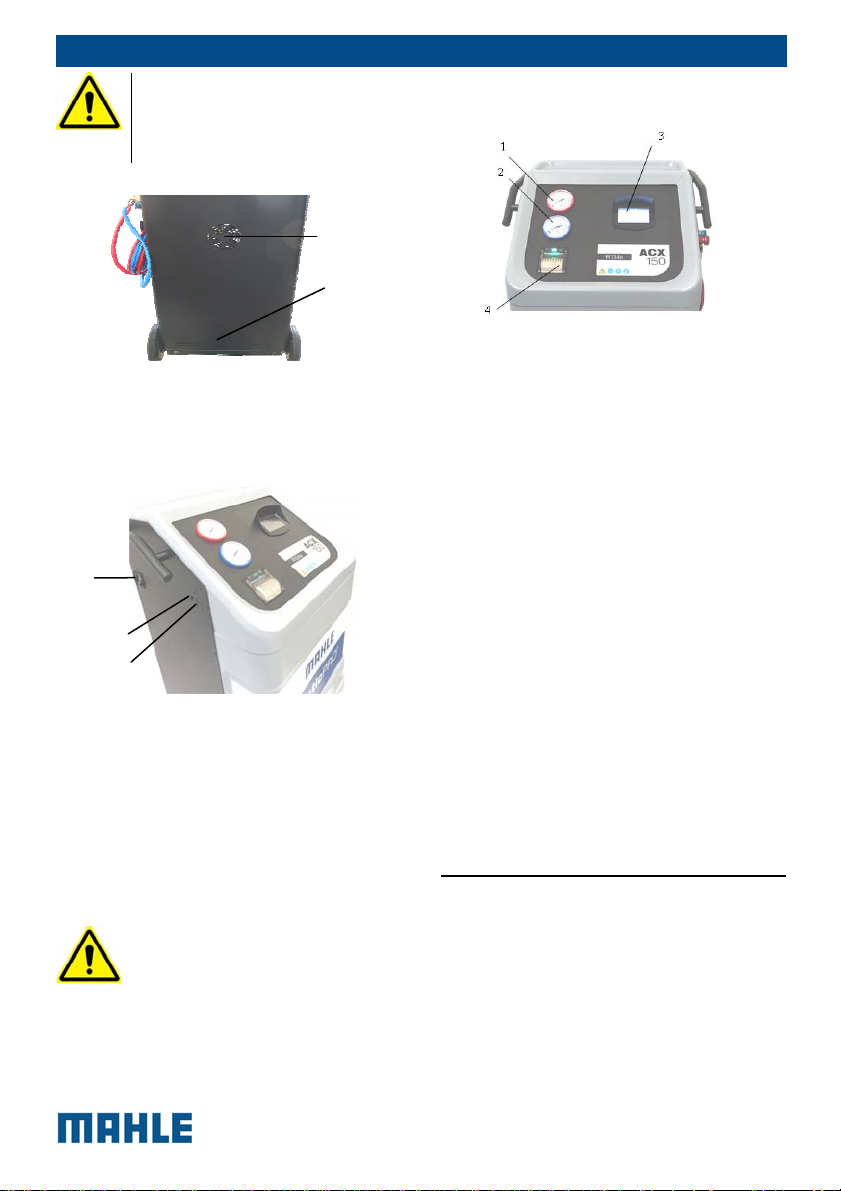

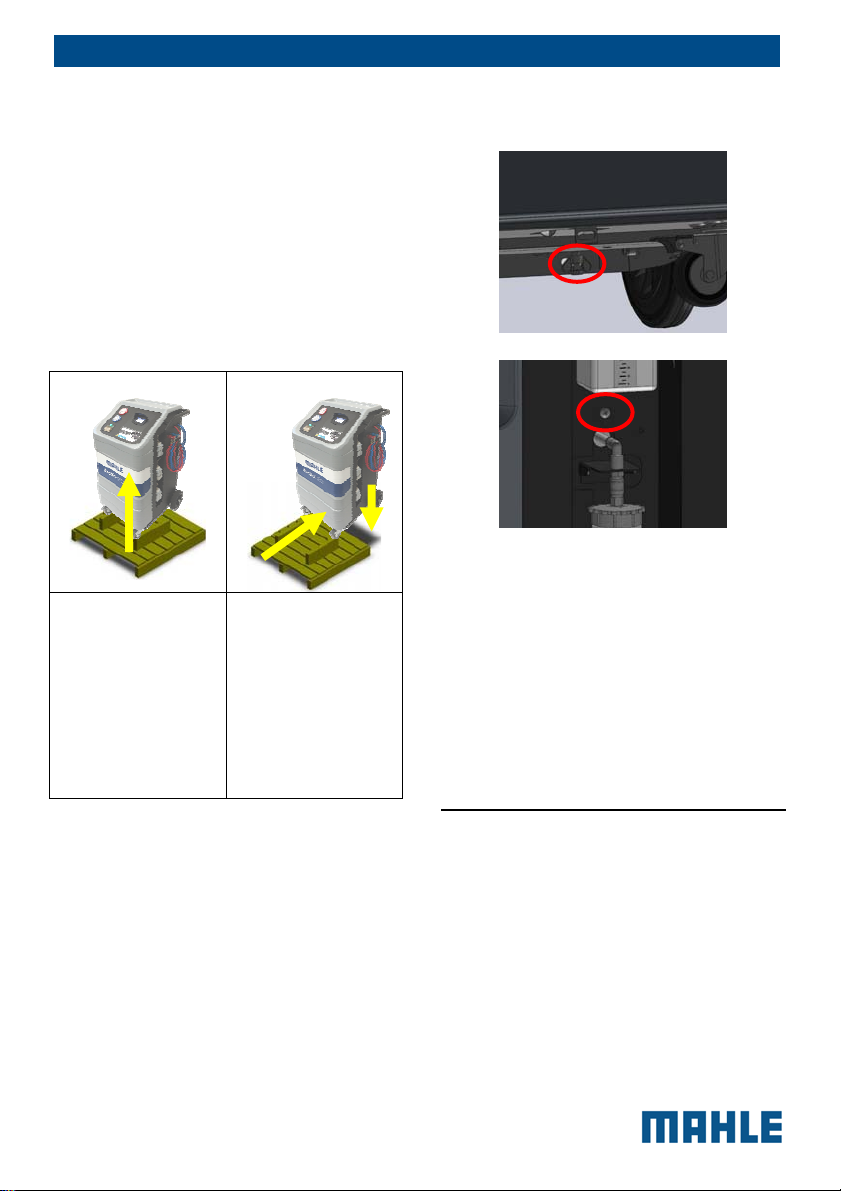

7.1.1 Unpacking ACX150/250

The manufacturer disclaims all

responsibility for damage to objects

and/or persons resulting from the

equipment being wrongly removed from

the pallet, or from the operation being

made by unsuitable personnel, with

RISK OF OVERTURNING

© MAHLE

improper means/protections and

without complying with the existing

laws on manual handling of loads and

with the operations described in this

manual.

Cut the strap and remove the carton.

Cut the straps securing the unit to the

pallet.

Remove the equipment from the

pallet (2 operators required)

EN | 16 | ACX150/250 | Commissioning

REFRIGERANT SCALE SCREW

RELEASE

Lift both front

wheels by

levering with the

handle and on

rear wheels (this

way the operators

must not lift the

full weight of the

unit)

Keep the pallet, carton and scratch

protection film for use when returning the

unit. The unit rolls on wheels; the two

smaller wheels can be locked.

ACX150/250 is supplied with the

accumulation tank empty. This prevents

problems in shipping the unit.

Slowly lower

the unit from the

pallet by means

of the rear wheels

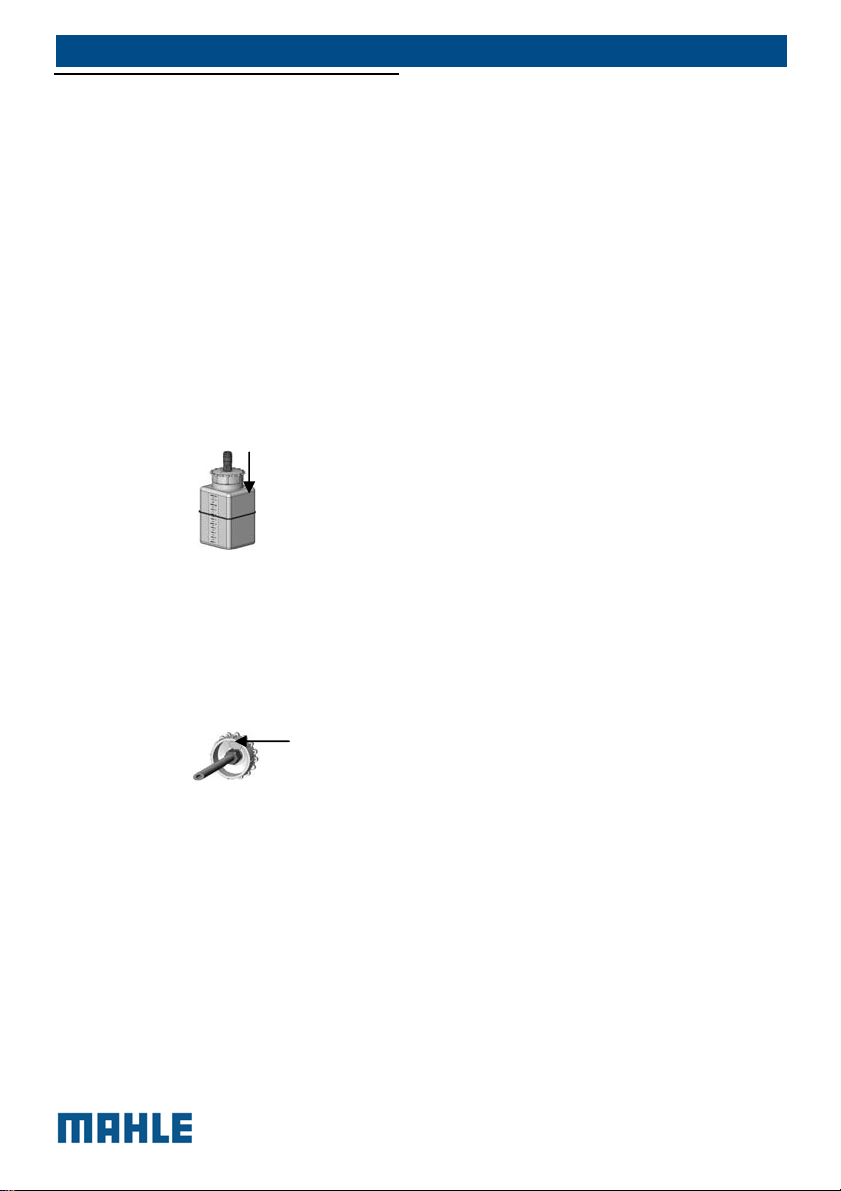

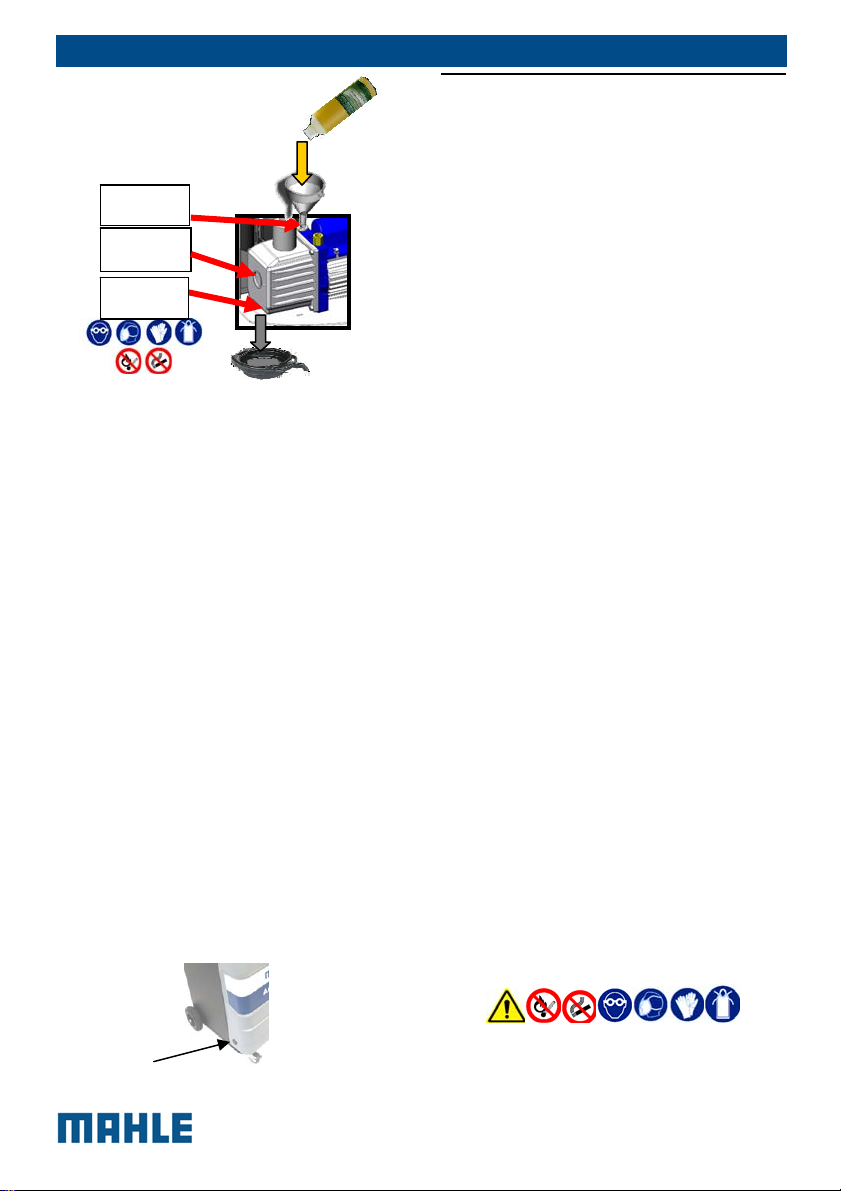

The tool is transported, with the scale

blocked by a locking screw to avoid the

load cell damage. The scales locking

screw is placed on the equipment

bottom/right side (see the box shown

above) and is formed by a bolt. For

commissioning, unscrew the screws.

8 Commissioning

8.1 Connections

The unit has to be positioned on a

horizontal surface to ensure the correct

operation.

The unit has to be connected to the

electric mains following instructions on

the identification plate of the unit applied

next to the main switch, mainly as to

applicable voltage and power.

© MAHLE

EN | 17 | ACX150/250 | Commissioning

8.1.1 Positioning and connection

HANDLING: During handling, the

minimum devices required for

correct handling shall be ensured,

as provided for by accident

prevention provisions.

POSITIONING: Place the unit in a

stable place. The location must be

well ventilated, with a good rate of

change of air. The unit must be

located at least 10 cm from any

potential obstacles to its internal

ventilation. Keep the unit away

from rain and excessive humidity

as they can irreparably damage it.

In addition, the equipment must

never be directly exposed to the

sunrays or to excessive dust.

INSTALLATION: the unit must be

installed by a specialised

technician in scrupulous

observance of in accordance with

electrical engineering principles.

The use of the equipment in

explosive atmosphere is

forbidden.

CONNECTIONS: since the unit is

connected to the main power

supply, it must be properly

grounded with its power plug

GND pin. Failure to ground the

unit can damage it and

constitutes a risk of fatal injury to

the operator. Position the unit so

that the power plug is easy for the

operator to access.

Power mains

connection

Vehicle A/C system

connections

ATTENTION: Leave the quick

coupling taps closed when the

unit is not in use and at the end of

vehicle service operations.

8.2 Initial verification

Execute the following actions in sequence

by following the display guided procedure

and the illustrations on the screen of the

equipment:

Refrigerant weight check

Oil weight check

First tank filling

It is possible to interrupt the initial check

and print a report with the equipment

printer in which the checking status is

reported. The equipment cannot operate

in automatic mode until all the steps of

the initial check have been completed.

CAREFULLY ABIDE BY

THE FOLLOWING

INSTRUCTIONS TO

AVOID DANGER TO

PERSONS, THE

DISCHARGE OF

REFRIGERANT IN THE

ATMOSPHERE

© MAHLE

Let us consider as first filling the one

carried out during the initial check with

internal tank of the equipment free of

refrigerant and containing air.

Set the quantity of refrigerant to fill (at

least 3 kg) and follow the guided

procedure shown on the display.

Check that the equipment hoses are not

connected and positioned in the hose

winder. Start the procedure that initially

implies the creation of vacuum in the

internal tank. This phase will take 15

minutes and will act on the whole

equipment.

Only when the message appears asking

to connect the charge tank, connect the

HP quick coupler (colour red) of the unit

to an external refrigerant tank using the

supplied adaptor.

When the message occurs open the

coupler by turning the knob clockwise.

Open the valve on the external tank.

Just right before reaching the planned

quantity of refrigerant, the unit will stop

and ask the user to close the external

refrigerant tank. Then, the device will

continue the recovery from the hoses and

ends when these are empty. Hence, it is

necessary to open the HP quick-coupler

and disconnect it from the external tank.

Thanks to the E³ CONNECT function, the

refrigerant - usually kept between the

cylinder fitting and the hose quick-coupler

until the end of the process - will not be

released in the environment.

There may be two types of source tanks:

with plunger and without plunger.

Tanks with plunger shall remain upright

to be able to transfer liquid refrigerant; for

this type of tanks connect to the L (liquid)

coupler.

Tanks without plunger have only one

valve, so they must be turned upside

down to transfer the liquid refrigerant.

EN | 18 | ACX150/250 | Commissioning

The LP gauge indicates the pressure

inside the external tank.

After some minutes the unit will

automatically end the function.

At the end the weight of the charged

refrigerant will be displayed.

8.3 New oil bottle filling

To fill the new oil bottle (Fig.1 Pos. 7) it

has to be extracted from its housing by

means of the quick coupler on the top of

the bottle; slightly press downward the

coupler ring nut to extract it.

Fill the bottle by paying special attention

to the “oil care” valve.

This valve is made of a silicon polymer

membrane; it compensates pressure

variations within the bottle and stops

humid air infeed inside thus preserving

the new oil inside.

After filling, close the bottle and place it

back in its seat.

© MAHLE

EN | 19 | ACX150/250 | Setup

8.4 UV dye bottle filling

The UV Dye is a substance made up of a

yellow-green coloured fluorescent

pigment, which means that, when lit by

an ultraviolet lamp, it becomes

fluorescent and thus visible.

The UV dye can therefore be used to

detect leaks of a small entity inside the

auto vehicle A/C system.

To fill the UV dye bottle (Fig.1 Pos. 6) it

has to be extracted from its housing by

means of the quick coupler on the top of

the bottle; slightly press downward the

coupler ring nut to extract it.

Fill the bottle by paying special attention

to the “oil care” valve.

This valve is made of a silicon polymer

membrane; it compensates pressure

variations within the bottle and stops

humid air infeed inside thus preserving

the new oil inside.

After filling, close the bottle and place it

back in its seat.

9 Setup

From the SETUP menu it is possible to

select parameters and activations before

starting cycle:

ELECTRIC COMPRESSOR FUNCTION

by selecting this entry, one may

change the type of Oil to inject into

the A/C system.

E³ CONNECT

by selecting this entry, you can

enable the E³ CONNECT function

(the E³ CONNECT quick coupler

must be present on the car).

CHARGE MODE

by selecting this entry, one may

decide whether to enable use of the

Quick Mode or Zero Tolerance

charge method

AC PERFORMANCE TEST

by selecting this entry, one can

enable or disable the AC

PERFORMANCE TEST.

REFRIGERANT CLEAN

by selecting this entry, one may

decide whether or not to enable the

refrigerant clean function, which

enables an additional recycling,

within the station itself, started in

automatic when it is switched on but

not in use. This function ensures a

higher level of purity of the recycled

refrigerant to the advantage of the

service quality.

RECOVERED GAS AND OIL PRINTING

selecting this entry, you can choose

whether you want to enable

displaying and printing of the

recovered gas quantity. Setting

available only with printer installed.

REPORTS SAVING MODE

by selecting this entry, you can save

the reports of the performed charges

(automatic cycle or Reg. 842/2006).

© MAHLE

REPORT DATA

select what data you would like to

include in the saved and printed

report: -license plate, -km, -client’s

name, -technician’s name

HOSES LENGTH

by selecting this entry, it will be

possible to change the length of the

charge hoses.

UNIT OF MEASURE

selecting this entry, you can modify

the pressure unit of measurement

(switching from Bar to PSI)

CLOCK ADJUSTMENT

by selecting this entry, date and time

of the station may be changed.

GARAGE DATA

by selecting this entry, one can enter

the garage data to be printed on the

end of cycle report.

LANGUAGE

by selecting this entry, any language

present in the database may be set.

In case you choose a language with

unintelligible characters. Switch off

the equipment , keep pressed the

touch screen and switch on the

equipment in the meanwhile, you will

be directed to the language setting

menu.

RIGHT / LEFT-HAND DRIVE

It allows setting the database for

operations on A/C systems of

vehicles with right-hand or left-hand

drive and return the exact value of

gas and oil to be injected.

EN | 20 | ACX150/250 | A/C system charge

STARTUP SCREEN

By selecting this entry, you can

decide whether the startup screen of

the unit will be the databank page or

the main menu page.

DATABASE ACTIVATION

by selecting this entry, you will

receive the “database activation

request code” to be provided to your

distributor in order to be able to buy

the database activation/update and

subsequently receive the “ACX

activation key”.

GAS TYPE:

by selecting this entry, you can learn

the type of gas the unit is set for, to

change the type of gas contact an

Authorised MAHLE Service Centre.

DEFAULT SETUP

By selecting this entry, you can

restore the unit default settings.

MAHLE reserves the right to add

new parameters to make the

equipment increasingly versatile

and adaptable to market’s needs.

10 A/C system charge

10.1 Preliminary operations

The recovery and charge operations have

be carried out after the car /AC system

has run for some time; however, an

excessively hot A/C system has to be

avoided since the next charge phase

could be adversely affected by high

pressures.

The vehicle must not be prepared in a

special way; connecting hoses have to be

© MAHLE

EN | 21 | ACX150/250 | A/C system charge

attached by identifying their position.

Vehicle details necessary for the

performance of the charge/recovery/

vacuum cycle are the amount of

refrigerant and the type and quantity of oil.

These data are often found on the engine

compartment plate or on the technical

manuals.

As to oil quantity technical manuals of

cars, systems as well as available details

in general indicate the total quantity of oil

in the system.

Indeed the amount of oil to be charged is

that extracted during the refrigerant

recovery phase which is very small. In the

car A/C system you have to add only the

oil amount necessary to restore the

amount set by the car manufacturer

FEATURES

Your new A/C service station is equipped

with new E³ CONNECT quick couplers.

These new couplers offer the following

functions:

1. Avoid dispersion of the refrigerant,

allowing the recovery by the tool

(thus protecting the environment and

saving refrigerant).

2. Automatic leak test of the car A/C

system valve at the end of the

service.

After connecting the quick couplers to the

(high pressure) HP and (high pressure) LP

connectors of the vehicle, screw the

valves only when required by the

messages on the tool display.

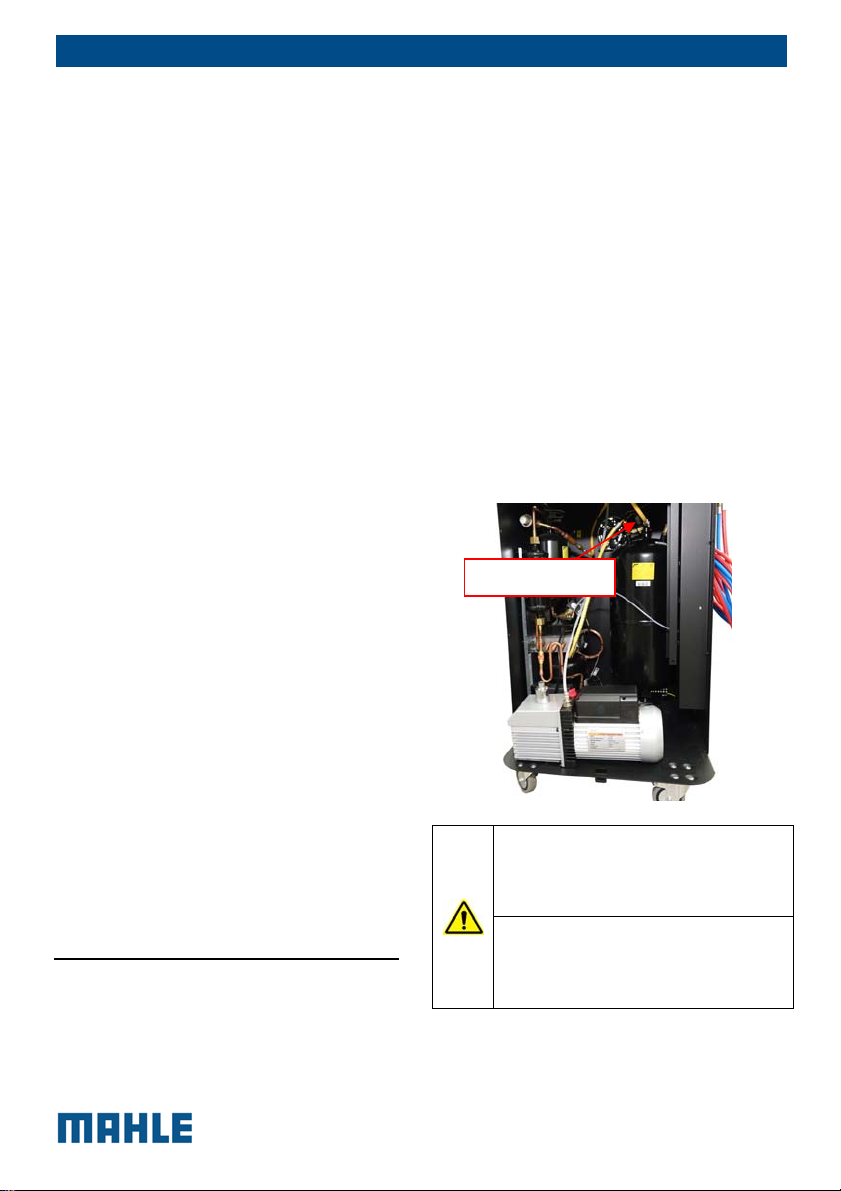

10.2 Non-condensable gas

discharge

The station is equipped with the AIR

PURGE SYSTEM function, which allows

automatically detecting and purging noncondensable gas (mainly air) accumulated

within the tank.

If the station detects non-condensable

gas in the tank, it will automatically run

the non-condensable gas discharge

procedure.

Running this procedure is very important

to ensure the ideal working parameters

for the station operation. The presence of

non-condensable gas in the tank will

increase the pressure inside the tank and,

therefore, will slow down and reduce the

efficiency of charge cycle on the vehicle.

The procedure will take a few minutes,

and its duration may vary according to

the amount of non-condensable gas

within the tank.

NON-CONDENSABLE

GAS VENT VALVE

WARNING: Leave the quick

coupling taps closed when the

unit is not in use and at the end of

vehicle service operations.

WARNING: For the Air Purge

System procedure to be executed

manually, the station must have

been off for at least one hour.

© MAHLE

10.3 Quick mode and zero

tolerance charge mode

ACX150/250 can apply two different

refrigerant charge modes; the first one is

called Quick mode and features the

opening of the charge valve by charging

refrigerant through the HP port. By the

Quick Mode part of the refrigerant

remains into the hoses and is

compensated by software calculation.

Whenever the charge is not completed

the UNIT shifts automatically to the Zero

Tolerance mode.

The Zero Tolerance function is the

second charge procedure, an alternative

to the Quick Mode.

It features a more accurate charge and

guarantees a successful charge (it

however requires a longer time and the

operator's intervention).

If the car A/C system is equipped with

both couplers or with LP coupler only,

there are two slightly different working

modes; in any case if only the HP coupler

is available the Zero Tolerance mode is

not applicable.

With both HP and LP couplers available

the Zero Tolerance features the charge of

the selected refrigerant amount into the

system through the HP hose; then

refrigerant remained into the HP hose is

sucked by the car system – engine and

compressor running – through LP (after

disconnecting and closing the HP

coupler).

In case the LP coupler only is available

the station charges the system with 50%

of the selected amount with car

compressor off and waits for 10 minutes

before recalling the operator. This wait

time – quite rare since most of cars are

equipped with HP coupler too – allows

the refrigerant charged near the

EN | 22 | ACX150/250 | Automatic cycle

compressor – that is LP side – to

evaporate to prevent any damage to the

compressor during the admission of liquid

phase refrigerant. Then, after car and A/C

system switch ON charge continues

through timed charge of refrigerant

through hose LP, such charges start

exclusively if the LP pressure is lower

than 3 bar (this threshold is adjustable).

11 Automatic cycle

The access to Automatic cycle can be

achieved selecting Database, Last Cycle

or My database (a 100 personal

automatic cycle) .

11.1 Automatic cycle data

loading

11.1.1 Database

MAHLE offers customers purchasing

ACX150/250 the possibility of enhancing

potentials of the UNIT through the

database.

This database contains all data related to

the A/C system of most vehicles. Hence,

it will be possible to speed up the charge

operations of the system with the aid of

the data provided by the database.

Make

Model

Version / engine capacity

Year

System

11.1.2 Last cycle

It loads the parameters of the last

automatic cycle.

© MAHLE

EN | 23 | ACX150/250 | Automatic cycle

11.1.3 My database

It allows loading the parameters of the

automatic cycle previously saved by the

user.

11.1.4 Direct input

It loads the default parameters of

automatic cycle.

11.2 Automatic cycle data

setting

After selecting the type of A/C system the

main page is shown with the following

preset values

Vacuum phase (recommended

values but changeable – they do

not depend by the car selected)

Vacuum duration

Leak test duration

Oil Charge mode and quantity of

oil that will be charged into the

system

o OIL: <value> g. It

charges the quantity of

oil that has been set.

o REC. + <value> g. It

charges the quantity of

recovered oil plus the

quantity of oil that has

been set

o NO OIL. No oil is

charged during the

charge cycle

Oil type: It sets the oil type being

used. PAG (ISO46/100/150) or

POE, it does depends by the

selected vehicle.

It is possible to select the charge

of the UV dye (a single shot of about

8 g.)

amount of refrigerant that will be

charged into the system and the

amount of refrigerant available in

the inner tank of the UNIT.

Charge type: It allows selecting

from which hose the service is

carried out, according to the

type of system.

o Charge from HP hose

(red)

o Charge from LP hose

(blue)

o Charge from HP hose

(red) and LP hose (blue)

o Charge from HP hose

(red) on the system low

pressure side. Specific

for some Renault

models.

At the end of the setup, press the

“START” button to start the automatic

cycle.

Or press Save if you want to save this

cycle with a name in a My Database

record.

11.2.1 Electric Compressor

Function

Before connecting the ACX150/250 hoses

to the A/C system of the vehicle, select

the Vehicle Compressor Type.

If the selected type is Electric (high

voltage), a special function named

“Electric Compressor Function” will be

executed to clean the hoses from any

previous oil residue.

When the following message appears:

Connect LP and HP quick coupler to their

support connectors on ACX150/250.

© MAHLE

After the connection, press “YES” to

proceed and follow the instructions

showed on the screen.

12 Manual cycle

The access to manual cycle can be

achieved selecting the functions in the

Manual Cycle menu.

12.1 Recovery

In the MANUAL CYCLE menu select

RECOVERY function.

Press and start the recovery function and

follow the tool instructions. If there is no

pressure inside the system, this function

cannot be started.

POSSIBLE ERROR INDICATION

Too high pressure in the A/C

service unit.

Valves or couplers closed or

system empty.

12.2 Vacuum

From the main menu select MANUAL

CYCLE and press VACUUM.

Connect the HP – LP couplers or the

single coupler to the vehicle system and

screw the couplers. Now set the time for

the vacuum and control phase, if different

EN | 24 | ACX150/250 | Manual cycle

from the default settings. The vacuum

phase is automatically followed by the

“vacuum test” phase.

Press START to start the vacuum phase.

POSSIBLE ERROR INDICATION

System pressurised

POSSIBLE ERROR INDICATION

System not tight

12.3 Charge

In the main menu select MANUAL CYCLE

and then CHARGE.

Set the following items :

Charge mode and quantity of oil

that will be charged into the

system

o OIL <value> g. It

charges the quantity of

oil that has been set.

o REC. + <value> g. It

charges the quantity of

recovered oil plus the

quantity of oil that has

been set

o NO OIL. No oil is

charged during the

charge cycle

Oil type: It sets the oil type being

used. PAG (ISO46/100/150) or

POE

UV: Option for the charge of UV

dye

Amount of refrigerant that will be

charged into the system and the

amount of refrigerant contained

in the inner tank of the UNIT.

Charge type: It allows selecting

from which hose the service is

carried out, according to the

type of system.

© MAHLE

EN | 25 | ACX150/250 | Special test

Connect the couplers to the vehicle

fittings and follow the instructions on the

screen page.

Press START to begin the refrigerant

filling phase.

o Charge from HP hose

(red)

o Charge from LP hose

(blue)

o Charge from HP hose

(red) and LP hose (blue)

o Charge from HP hose

(red) on the system low

pressure side. Specific

for some Renault

models.

POSSIBLE ERROR INDICATION:

The amount of refrigerant in the

A/C service units tank is less than

that required. Closed hoses, charge

impossible.

THIS PHASE HAS TO BE

CARRIED OUT EXCLUSIVELY

ON A/C SYSTEM UNDER

VACUUM (AFTER A VACUUM

PHASE HAS BEEN PULLED).

12.4 Flushing (with optional

accessories)

After performing a lot of charge cycle or

after replacing components or parts of

the /AC circuit on a vehicle it is advisable

to carry out a system flushing.

The system washing (Flushing) consists in

purifying the vehicle cooling system

through several R1234yf/R134a

refrigerant flushes, by recovering it each

time, so that the impurities can be filtered

little by little through the additional filter.

Thanks to its specific design,

ACX150/250 automatically manage the

flushing process so that the process

becomes fully automatic.

Once the (optional) flushing kit has been

installed, as described in the instructions

included in the kit, and after selecting the

specific function for the kit being used,

start the phase.

In case of problems or errors during this

phase, a message will be displayed,

identifying the type of error.

It is possible to interrupt the phase in

progress at any time.

12.5 Hoses drain

To empty the charge hoses completely

perform the HOSES DRAIN phase.

Select in the menu the HOSES DRAIN

function. Wait the end of the procedure.

13 Special test

13.1 AC performance test

To check the vehicle A/C system status –

for instance in case there is no flow of

cold air from flaps – pressure values can

be checked.

Connect the HP - LP couplers or the

single coupler to the vehicle system.

Under the sequence guided by the

software perform the following preliminary

operations on the vehicle:

1. Turn on the A/C system

2. Set temperature at

minimum level.

3. Set fan speed at maximum

level; close all the flaps

except the central one and

© MAHLE

In the MANUAL CYCLES menu, select

the AC PERFORMANCE TEST function.

Execute the AC PERFORMANCE TEST

following the instruction.

And at the end make sure that both

values on LP and HP gauges fall within

the values shown on the display.

It is possible to interrupt the phase in

progress at any time.

set air distribution to

central position.

4. Keep engine at accelerated

idle at constant speed for

at least 2 minutes.

5. Check the pressure values

within about 3 - 5 minutes.

PRESSURE VALUES CHANGE

CONSIDERABLY WHEN

AMBIENT TEMPERATURE

CHANGES. KEEP THIS IN MIND

WHEN CHECKING PRESSURE

VALUES

13.2 Refrigerant clean

By selecting this function, you can start

the refrigerant clean function, allowing for

a further recycle, which is internal to the

station itself. This mode guarantees a

higher level of the service quality.

14 Maintenance

ACX150/250 is a remarkably reliable unit,

manufactured using the highest quality

components, making use of the most

advanced production techniques.

Please contact an authorized technical

service centre for purchasing original

spare parts.

EN | 26 | ACX150/250 | Maintenance

The access to manual cycle can be

achieved selecting the functions in the

Maintenance menu.

INTERVENTIONS ON SERVICE

STATION COMPONENTS

WHICH ARE NOT MENTIONED

MAKE SURE THE TOOL IS

UNPLUGGED FROM THE

POWER MAINS BEFORE

IN THE FOLLOWING

PARAGRAPHS ARE

PROHIBITED.

OPENING.

14.1 Report exporting

In the main menu select MAINTENANCE

and press “REPORT EXPORTING”.

By selecting this function, is possible to

export the report on USB Key and

manage it on PC with ACX Manager.

14.2 Internal cylinder fill

In the main menu select MAINTENANCE

and press “INTERNAL CYLINDER FILL”.

Set the quantity of refrigerant to fill and

follow the guided procedure shown on

the display.

The set value is limited to avoid to fill too

much the internal cylinder.

Only when the message appears asking

to connect the charge tank, connect the

HP quick coupler (colour red) of the unit

to an external refrigerant tank using the

supplied adaptor.

When the message occurs open the

coupler by turning the knob clockwise.

Open the valve on the external tank.

Just right before reaching the planned

quantity of refrigerant, the unit will stop

and ask the user to close the external

© MAHLE

EN | 27 | ACX150/250 | Maintenance

refrigerant tank. Then, the device will

continue the recovery from the hoses and

ends when these are empty. Hence, it is

necessary to open the HP quick-coupler

and disconnect it from the external tank.

Thanks to the E³ CONNECT function, the

refrigerant - usually kept between the

cylinder fitting and the hose quick-coupler

until the end of the process - will not be

released in the environment.

There may be two types of source tanks:

with plunger and without plunger.

Tanks with plunger shall remain upright

to be able to transfer liquid refrigerant; for

this type of tanks connect to the L (liquid)

coupler.

Tanks without plunger have only one

valve, so they must be turned upside

down to transfer the liquid refrigerant.

The LP gauge indicates the pressure

inside the external tank.

After some minutes the unit will

automatically end the function.

At the end the weight of the charged

refrigerant will be displayed.

14.3 Self leak test

In the main menu select MAINTENANCE

and press “SELF LEAK TEST”.

A leak test is carried out on the internal

components of ACX150/250.

This phase includes:

Hoses emptying

Vacuum test

This test allows to check the tightness of

the internal circuits of the equipment from

the solenoid valve, allowing the fluid

outflow from the internal cylinder, to the

manifold, (metallic component housing

the check solenoid valves) to the

compressor infeed, including the dryer

filter leak test.

In case of failed leak test, it is necessary

to check the charge hoses conditions

and the quick couplers leak, and make

the possible repair and then repeat the

test.

14.4 Cylinder refrigerant

view

In the main menu select MAINTENANCE

and press “CYLINDER REFRIGERANT

VIEW”.

The available refrigerant for next

recharging is 2 kg less than the total

contents of the cylinder.

Two kg is the minimum quantity that

should be always left in an operating

ACX150/250.

14.5 Air purge

In the main menu select MAINTENANCE

and press “AIR PURGE”.

By selecting this function, is possible to

check the non condensable gases

condition (high level red area, low level

green area ) and if necessary start

manually the discharge.

14.6 Pressures zero

In the main menu select MAINTENANCE

and press “PRESSURES ZERO”.

This function allows to determine and

store the atmospheric pressure value.

© MAHLE

We recommend running this procedure

every time the ACX150/250 will be moved

from a location to another with a different

altitude.

14.7 Counters

In the main menu select MAINTENANCE

and press “COUNTERS”.

In the COUNTERS page, at any time, the

vacuum pump and compressor hours of

life can be displayed; besides, remaining

time before replacement of vacuum pump

oil and dryer filter can also be displayed.

This is useful to understand if some

maintenance activity should be performed.

14.8 E³ pump - pump oil

change

The ACX150/250 is equipped with a

special function named E³ PUMP that

enables to optimize the vacuum pump oil

use by avoiding the replacement every 60

hours of operation.

E³ PUMP is a special function allowing to

extend even to 1000 hours the life of the

pump oil used in the station. E³ PUMP

function performance is suggested at the

end of 60-hour operation intervals of the

vacuum pump and can be manually

activated in the MAINTENANCE menu

pressing E³ PUMP.

E³ PUMP procedure has to be started

only after checking and, if necessary,

topping up the pump oil level and lasts 1

hour: during this time the tool cannot be

used.

During the procedure the oil is

automatically purified from the gaseous

polluting residues absorbed during the

emptying operations of vehicles air

conditioning systems.

EN | 28 | ACX150/250 | Maintenance

At the end of the procedure, the vacuum

pump performance check is carried out

and a result to the operator is signalled.

In case of negative result you have to

replace the vacuum pump oil.

After 1000 hours of vacuum pump

operation since the last oil change, the E³

PUMP procedure cannot be activated

anymore and you have to replace the oil

according to the following instructions.

Required tools:

1 Hex screwdriver (2.5 mm)

1 Medium-sized flathead

screwdriver

1 Hex key (10 mm)

For replacement, comply with the

instructions outlined below:

1. Disconnect the unit from the

mains.

2. Remove the six screws that fix

the front door of the unit and

remove it.

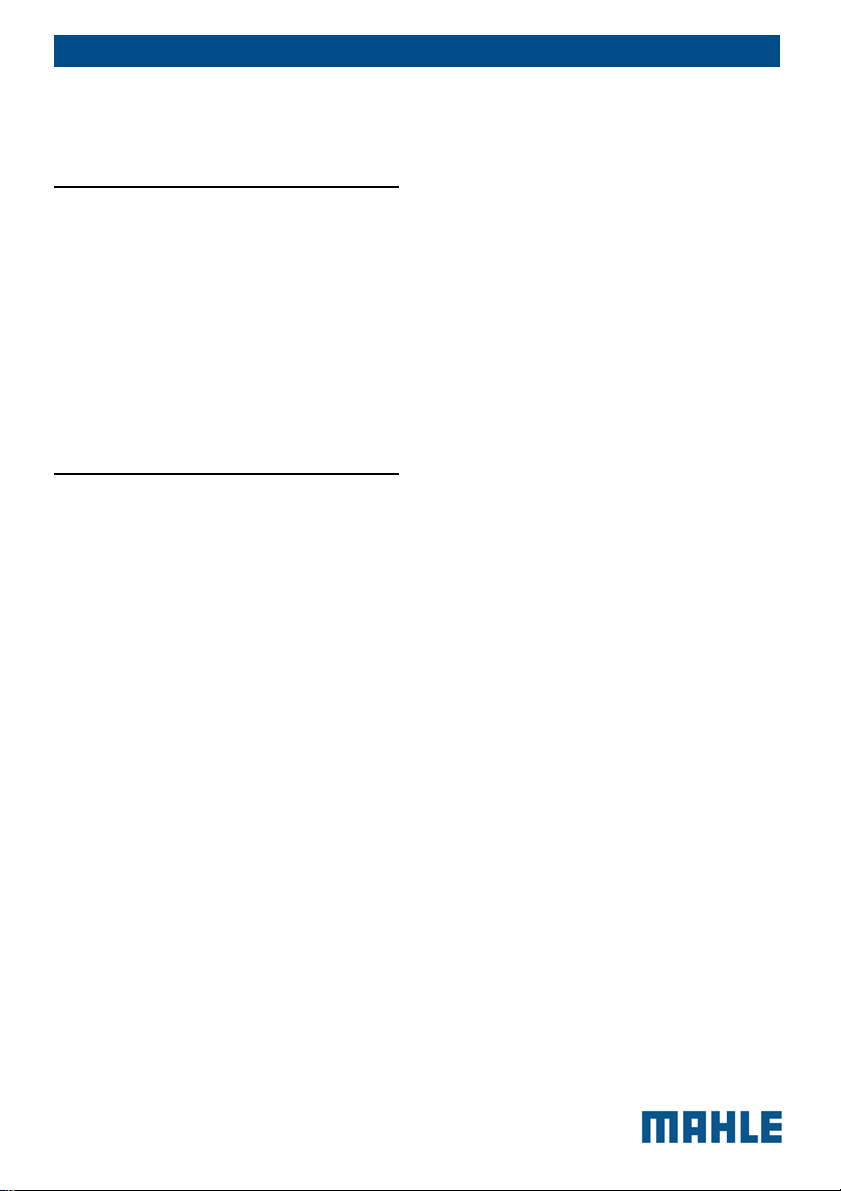

3. Place a bowl underneath the

machine, right under the pump

oil drain hole. Open the upper

plug and then the lower plug to

drain the used oil contained

within the vacuum pump.

© MAHLE

EN | 29 | ACX150/250 | Maintenance

Upper filling plug

Oil inspection

window

Lower

drain plug

4. Once the pump has been

emptied, screw the lower plug

again.

5. Fill the pump with new oil

through the upper opening,

using a funnel if needed. Bring

new oil level halfway through

the oil inspection window.

6. Once the pump has been filled,

close the upper plug.

7. Once oil has been replaced,

switch on the unit and from the

MAINTENANCE menu select

PUMP OIL REPLACEMENT:

press the “RESET” key to set

the counter.

14.8.1 Oil pump visual check

Without opening the equipment is always

possible to remove the rubber tap in the

following position to check level and the

clearness of the oil inside the pump.

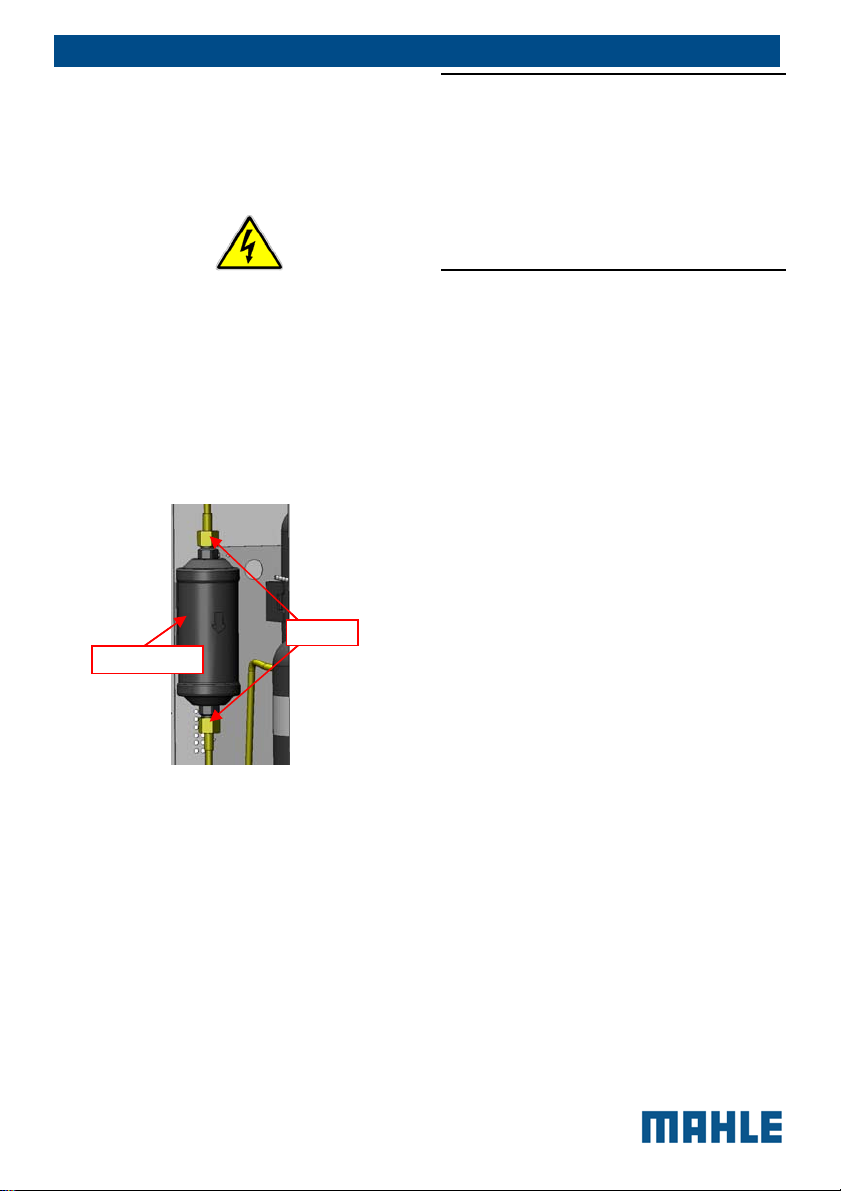

14.9 Dryer filter

replacement

The dehydrator filter must be replaced

after having dehydrated 150 kg of

refrigerant fluid, since the filter capacity to

keep the humidity present in the

refrigerant will run out.

To replace the dryer filter, from the

MAINTENANCE menu select DRYER

FILTER REPLACEMENT: press “START”

to set the counter to zero and to start the

filter replacement procedure. Insert the

code of the new filter. Now you can

replace the filter.

Required tools:

1 Hex screwdriver (2.5 mm)

1 regular or torque Hex key (24

mm)

1 Hex key (17 mm)

For replacement, comply with the

instructions outlined below:

1. disconnect the HP and LP

hoses from other

systems/circuits or vehicles

and close the quick

couplers

2. wait the ends the hoses

emptying.

3. confirm to have already

worn the personal protective

equipment (PPE) and follow

the safety regulations in

force.

© MAHLE

DANGER OF CONTACT WITH R134a

REFRIGERANT and motor vehicle A/C

system oil

4. Before opening the doors of

the equipment, switch off

the equipment and

disconnect the power

supply cord.

DANGEROUS VOLTAGE HAZARD

5. Remove the six screws that

fix the front door of the unit.

6. Unscrew the 2 connection

nuts of the filter by means of

the hex keys.

7. Remove the straps that

wind up the filter

DRYER FILTER

8. Install the new filter paying

attention to the position of

gaskets and to the direction

of the arrow indicating the

fluid flowing direction.

9. Screw the two connection

nuts of the filter.

10. Replace the front panel

11. Carry out the automatic leak

test requested by the

software when switched on

again after the filter

replacement.

NUTS

EN | 30 | ACX150/250 | Maintenance

14.10 System info

In the main menu select MAINTENANCE

and press “INFO”.

In the INFO page, at any time, the

software version and the serial number

can be displayed.

14.11 System update

The firmware (software) can be

updated by way of a USB stick.(where

the new version is stored).

1. Insert the USB stick in

USB port (fig.3 pos.4)

Power on ACX150/250.

2.

In the main menu select

3.

MAINTENANCE and

press “SYSTEM

UPDATE”.

A message will appear

4.

that the unit is loading

an update.

5.

The unit may load an

updated language file,

database file and

configuration file while

updating.

Once unit is updated,

6.

the software version

string on the

introduction screen

during power up will

change.

© MAHLE

Loading...

Loading...