Page 1

© 2016 Mahindra REVA Electric Vehicles Ltd (MREVA), Bangalore. All rights reserved. This Manual

cannot be reproduced or copied, in whole or par t without the written permission of MREVA, Bangalore.

Released by:

Technical Hub Mahindra Reva

Electric Vehicle Pvt. Ltd.

Rev 1 - 2016

SAFETY, ROADSIDE ASSISTANCE &

MAN No: 00340

FIRST RESPONDERS MANUAL

Models applicable: e o City & Tech X

2

Page 2

Page 3

FOREWORD

This user manual explains on safety, road assistance and first responders operations with related

information including warnings, cautions that needs to be followed while providing support and

assistance to occupants.

This is an electric vehicle powered by battery pack. Improper and wrong operations / techniques /

procedures while providing support may cause serious personal injury or result in death.

Please read this manual carefully in advance for understanding the features of the vehicle and to provide

assistance in incidents involving this vehicle. Following recommended given procedures are the best

practices for helping in providing support with required informations.

1

Page 4

2

2.0 IMPORTANT INFORMATION

Safety symbols

Please carefully read, understand & follow the safety symbols / instructions in this manual.

Legend of the symbols

You will see various safety symbols in this manual & are used in the below following ways. Obey all safety

messages with words DANGER, WARNING, CAUTION & NOTE having special meanings.

This indicates a hazardous situation which, if not avoided, will result in death or serious personal injury.

DANGER

Indicates the presence of a hazard situation that could cause death or serious personal injury.

All information, illustrations and specifications in this ‘Manual’ were in effect at the time of printing.

Mahindra Reva Electric Vehicles Ltd. in the course of product development reserves the right to discontinue

or change / modify information /specifications or design at any time without notice, without any liability &

obligation whatsoever.

WARNING

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION

Note indicates important information on vehicle’s use & maintenance to which particular attention should be

paid.

The symbol below indicates NO , Do Not do this or Never

Note

CAUTION

Caution without safety alert indicates a potentially hazardous situation which, if not avoided, may result in

property damage.

Copyright reserved 03 2016 REV -R0

! In case if you use any medical electric devices like implantable cardiac pace maker or cardio vascular

defibrillator, do check the electric medical device supplier / manufacturer on concerns of effects that

EV charging or discharging system on implanted such devices prior to their operation.

! It is also advised not to stay in the vehicle or access vehicle during charging as it may effect function

of electric medical devices and could result in personal injury or death.

! Also make sure that there is no foreign particles or water traces in charge plug or port as any of

these can result in electric short circuit or shock causing serious injury or death. Hence do not

touch metal contacts on the cable or plug.

! Ensure that power socket is switched off before accessing charge cable.

! Do not handle the charge cable or port with wet hands as it may cause electric shock resulting to

injury or death.

WARNING

Page 5

1.0 Foreword.................................................................................

2.0 Important information............................................................

3.0 About Mahindra Reva Electric Vehicle....................................

4.0 Vehicle identification number.................................................

5.0 Vehicle specification...............................................................

6.0 High voltage components identification and location............

7.0 Emergency response steps.....................................................

8.0 Identifying of high voltage system status................................

9.0 Vehicle battery disconnect......................................................

10.0 Operational procedures..........................................................

11.0 Fuse box details......................................................................

12.0 Lubricant chart.......................................................................

13.0 Personal protective equipments and insulated tools.............

14.0 Accessing occupants and rescue............................................

15.0 Process for shutting down high voltage system......................

16.0 Handling damaged car at accident location............................

17.0 Airbag access, deployment and dismantling..........................

18.0 Road side assistance...............................................................

19.0 Changing flat tyre...................................................................

20.0 Caution note...........................................................................

01

02

05

06

06

07

09

10

12

13

14

14

15

16

18

19

20

22

24

26

3

CONTENTS

Page 6

4

Page 7

3.0 ABOUT MAHINDRA REVA ELECTRIC VEHICLE

5

This is an electric vehicle that is powered by high voltage battery pack. It has two type of battery used for

its operation. Car has 72V electric system with battery that powers drive system and other is a 12 volts

auxiliary battery that powers 12Volt accessories and other control units. The 72V battery pack is housed

in the battery compartment located beneath front seats of the vehicle.

Vehicle requires to be plugged in for charging battery pack once stored energy is discharged in drive. The

vehicle has a regenerative braking system that tops up battery pack when ever accelerator is released and /

or brake is applied while vehicle is in motion.

Vehicle Identification:

Interior:

Gear lever

Infotainment screen

Instrument panel cluster

Start / Stop button

Steering wheel with Logo

Hood release lever

electric

Logo

Logo

Model

Vehicle

Type

Exterior:

Page 8

6

4.0 VEHICLE IDENTIFICATION NUMBER

LOCATION OF VEHICLE IDENTIFICATION NUMBER PLATE:

The VIN plate is located under the front hood. Open hood, and the cover to see vehicle identification plate is

riveted on chassis strut cross member and it is a 17 digit alpha numeric number.

eg. VIN number- 17 digits MB7D8RXBACJH00001

5.0 VEHICLE SPECIFICATION

General

2 door hatch-back

right hand drive

4 adults [driver(D)+3]

3278 mm

1575 mm

1570 mm

1958 mm

172 mm

942 Kgs.

1262 Kgs.

320Kgs

3850 mm

Rack & pinion

Welded tubular steel space

frame

Type

Seating capacity

Overall length

Overall width

Overall height

Wheelbase

Ground clearance

Kerb weight

Gross vehicle weight

Pay load

Turning radius

Steering gear box

Frame type

Tyre (front & rear)

Tyre pressure- (Laden):

driver(D), D+1 or D+2:

Tyres

165 / 60 R 14 / 79T, tubeless

Front: 32psi & rear: 38psi

Front & rear : 32psi

The RNFB mode selection lever provides reverse /

neutral / forward / boost modes of operation.

2 pedal operation (brake and accelerator)

4 operating modes (R,N,F,B)

Controls

VIN plate

VIN punch

Page 9

7

6.0 HIGH VOLTAGE COMPONENTS IDENTIFICATION AND LOCATION

REAR TUB OVERVIEW:

Over view:

1. Fast charge port

2. Fast charge port contactor

3. Charger input - 220V AC

4. Charge port

5. Charge port harness

6. Charger

7. Charger - 72V output

8. Shunt

9. Traction control unit

10. Main contactor

11. Battery pack power cables

12. Battery power pack

13. Air conditioner motor

14. Air conditioner controller

15. Data port

16. Wake up relay

17. Auxiliary 12V battery

18. IEMS

19. Telematic unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Main

contactor

Motor

Controller

Charger

Fast charge

contactor

Data port

IEMS

Page 10

8

Near rear hatch lock

On the rear bumper & next

to rear number plate

Rear tub

Electronics

Under the rear tub &

on the trailing arm

Below front

seats

Under Hood

Rear tub

Electronics

Rear tub

Electronics

Plug socket for charging vehicle battery

with 220V15A AC input.

Rear tub

Electronics

Rear tub

Electronics

Rear tub electronics

& near LH side trim seat

LOCATION

FUNCTIONAL DESCRIPTION

COMPONENT

Plug socket for Fast charging vehicle battery

with 200A DC input.

Contactor for Fast charging vehicle battery

with 200A DC input.

Charges vehicle battery with 72V O/P at 23A &

provides low voltage(12V)supply to accessories.

Converts 72V DC to 3-phase AC for propelling

vehicle.

Comes on at key authentification & powers

Motor controller.

Gets power from Controller and propels

vehicle through transmission and wheels.

Accepts & stores energy, provides energy for

vehicle drive & accessory system.

It is an integrated system which in turn coupled

with compressor for vehicle HVAC operation.

It provides power supply to many control

systems for monitoring & recording.

It monitors & manages the complete working

of the system and records data.

Idle mode Drive mode Regenerative mode

COMPONENTS LOCATION AND LAYOUT

1 2

3 4

5

6

7

8

Vehicle status on infotainment screen

1. Bus Bar

2. BMS & CB Board

3. Pack sense Harness

4

. Contactor HV Positive

5. Contactor HV Negative

6

. Pre charge Board

7 . Main Fuse

8 . Battery number 23

Battery compartment layout and

components location

Page 11

For road accident incidents:

! Do a visual check for any leak from bottom side of the vehicle due to impact, refer battery handling

document.

! In the event of fire, follow procedures as this is an EV and should use AB type extinguisher for dozing

fire.

! In the event of rear collision, check extent of damage to on board regular / fast charging ports, check

vehicle system layout.

CAUTION

ACCIDENTS:

The vehicle 72V battery is of Li-ion type and has solvents as electrolyte. In the event of fire or any high

impact accident damaging battery / battery compartment, first responder is advised to check vehicle for

extent of damage, damages to 72V DC system. Then check the damage to battery and its compartment.

Battery electrolyte is colour less and has sweet odor, in the event of coming in contact may irritate skin and

eyes. Use excess water to rinse area of contact and see a doctor immediately. This is highly flammable and in

the event of any fire, ABC type fire extinguisher (Recommended for electrical hazards) to be used for

dozing it. Since battery modules are sealed and small in size, electrolyte will not leak in large quantity.

9

7.0 EMERGENCY RESPONSE STEPS

CAUTION

JUMP STARTING

Vehicle system has an 72volts battery pack

& auxiliary battery that powers the control

systems. Do not ‘jump start’ any battery in

the system & do not use vehicle battery to

jump start any other vehicles.

! The vehicle has sealed Li-ion battery pack. Improper handling of battery could lead to risk of severe burns and

electrical shock that may result in serious injury or death and also may cause damage to environment.

! As vehicle uses a 72 volts battery system, some of the systems could be hot before & after their usage. Hence

pay attention and follow warning labels located at places in vehicle.

! Never try to access, remove parts / cables / connectors which can cause shock or severe burns or result in

serious injury or death. 72 volts cables are colour coded in Orange and systems are not user serviceable.

For accident cases:

1. If vehicle is in drivable condition, move vehicle off the road, park and switch off drive system.

2. Check for any exposed 72 volts cables / parts. To do so check the picture indicating voltage layout of system.

Never touch any exposed 72 volts wiring and avoid any possible electric shock.

3. For any reason to tow the vehicle, do it with recovery vehicle support. In the event of not doing so, drive motor

may generate electricity, can cause damage to EV components and may result in fire.

4. If vehicle cannot be assessed for extent of damage, do not touch vehicle and contact nearest authorised service

center or customer care executive.

5. For any requirements of body repair due to accidents, vehicle should be delivered to authorised service center to

evaluate damage and take necessary precautions. Damaged Li-ion battery modules could pose safety risks to

untrained technicians & repair person.

WARNING

BATTERY PACK VOLTAGE

BATTERY CAPACITY

NUMBER OF MODULES

BATTERY DIMENSION

BATTERY PACK WEIGHT

210 Ah

72 Volts

215 X 135 X 220

23 (69 cells)

165 Kilograms

Page 12

72V SAFETY MEASURES

The below safety measures are set with 72V system.

1. The 72V positive(+) and negative(-) are insulated from the vehicle chassis.

2. The 72V components are labelled and harnesses are orange colour coded for easy identification to isolate

/ help, protect occupants & emergency responders from any electric shock.

IDENTIFYING 72V SYSTEM IS ON:

1. If the key switch LED is illuminated green then 72V system is active.

2. If the charge indicator on cluster is blinking then 72V system and also 230V AC supply is active.

3. If the HVAC is operating then the 72V system is active.

8.0 IDENTIFYING HIGH VOLTAGE SYSTEM STATUS

OFF

START

STOP

(72V drive system active)

i) Drive or Idle:

3. WATER SUBMERSION:

In the event of ‘Water submersion’, to isolate the vehicle:

a) Power switch should be turned off, if possible & then remove the vehicle out of water.

b) Using appropriate PPE, drain water from vehicle.

c) Do not access any vehicle parts when vehicle is submerged in water.

10

2. FIRE HAZARD:

In the event of ‘Fire hazards’ to extinguish the fire use large amount of water possibly from hydrants.

Using less water may cause generation of toxic gasses from the chemical reaction of battery pack. In case

of vehicle fire, do contact ‘fire department’ for immediate support for extinguishing the fire. Shut down the

‘High voltage system’ by following the safety procedure. In the event of major damages to EV components,

use appropriate PPE’s for accessing the ‘High voltage components’.

The battery compartment, rear tub houses major electronic and electrical components. For any emergency

access, do check reference page to identify parts and observe high voltage symbol to take appropriate

precaution while working on the system.

If it is necessary to touch any of these high voltage systems, do wear appropriate personal protective

equipments to isolate and shut off the high voltage system. To avoid any shock / electrocution risk, never

touch with bare hands as the battery pack may maintain charge even when the high voltage system is

isolated. Insulate the high voltage damaged parts to prevent accidental access.

SSB BUTTON

Page 13

ii) Charging:

72V charge system active

230V AC power supply system active

Fast charge port

If yes, turn off the switch, pull out the plug from the socket to cut off the 230 volts power supply. And then

pull out the charge cable from the vehicle.

iii) Drive or Charge or Idle:

Check if ‘Cooling’ or ‘Heating’ light on climate controls is ON / blinking . If so turn off by rotating the knob to

off position.

11

EVSE

CHARGE LIGHT

(Green)

EVSE

Close charge port lid

Climate controls (Heating & cooling)

AC COOLING / HEATER KNOB

OFF

1

2

3

4

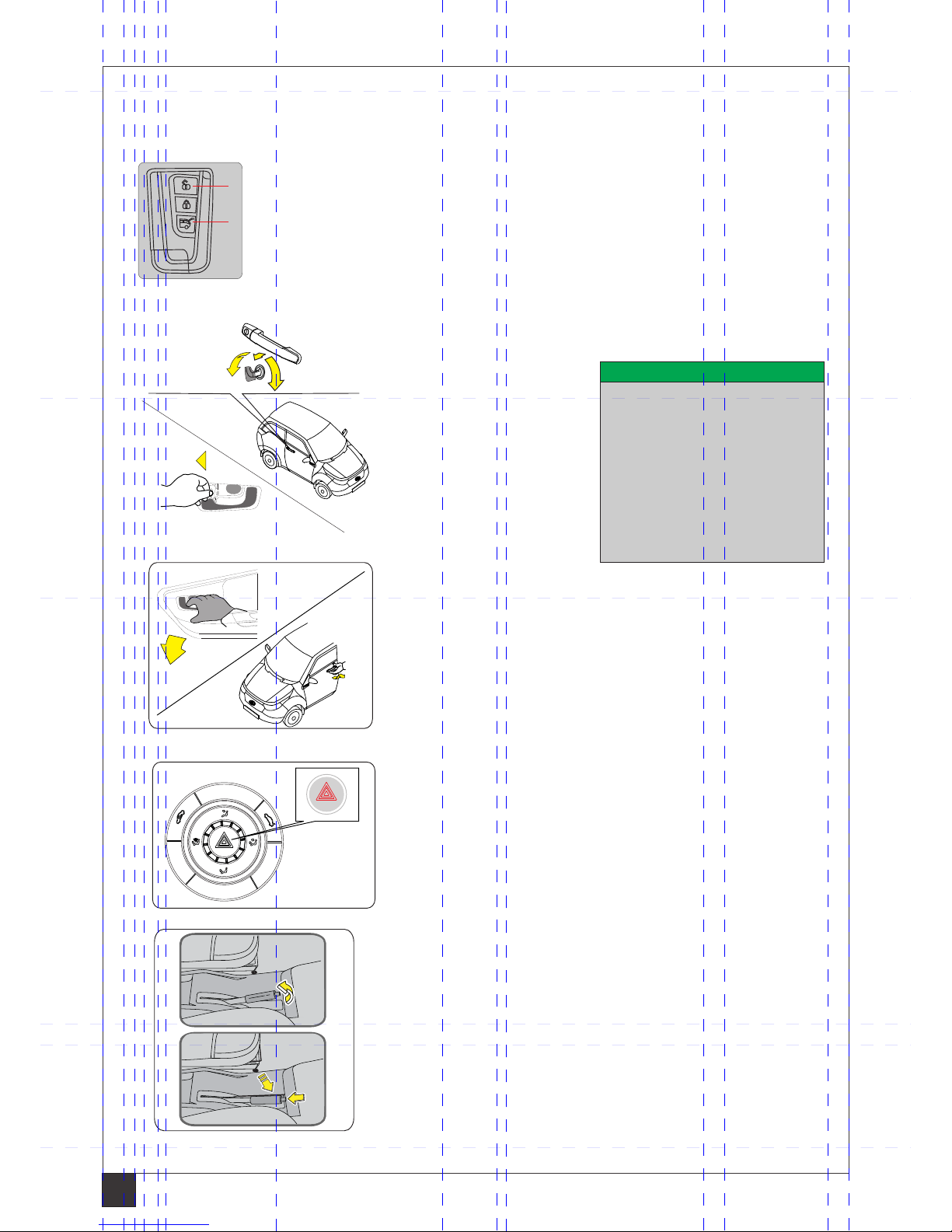

If central door lock is working, to open doors, do operate

key fob buttons as below.

1. Press to lock

2. Press to unlock

3. Rear hatch release

4. Slide the button to release manual key for key fob

KEY FOB OPERATION

Page 14

12

Unlock

(anti-clockwise)

VEHICLE DISCONNECT BUTTON

Battery disconnect:

In the event of any requirement, if first responder or user wants to deactivate the vehicle, same can be done by

pressing the ‘Battery Disconnect Button’ once after opening the data port cover by a screw driver. The vehicle

72V electric system gets disconnected immediately from battery system and low voltage lines get disconnected

within 2 minutes. To activate , press the button once again and to activate the car by press, hold wake up button

for 10 seconds.

Data port

In the event of requirement to disconnect the 72 volts battery system, below procedure has to be followed.

9.0 VEHICLE BATTERY DISCONNECT

Screw to open cover

Page 15

A) Check if the vehicle door operations are working fine, lower the door window glasses using power

window switch & using key fob or button on climate control open the rear hatch.

B) Turn off the start stop button (SSB)- Check the status LED on the switch and if in ‘Green’ then press the

switch once to turn it off. Verify by checking the status LED on the switch if it has turned off.

C) Open the hood, remove close out cover and isolate the power to other switched 72V systems by removal

of ignition relay 1 & 2

Power

window switch

Hatch

release

Rear Hatch Release Button

Key fob

13

10.0 OPERATIONAL PROCEDURES

Identifying 72V system is on:

1. If key switch LED is illuminated green then 72V system is

active.

2. If charge indicator on cluster is blinking then 72V system and

also 230V AC supply is active.

3. If HVAC is operating then 72V system is active.

START

STOP

OFF

START

STOP

ON

Emergency exit:

To come out of car in emergency due to central door lock

failure / accident, use rear hatch glass release on tail light trim

panel by removing grommet and pulling release cable. Rear

hatch will open.

HOOD RELEASE LEVER

+

+

Fuse box

Page 16

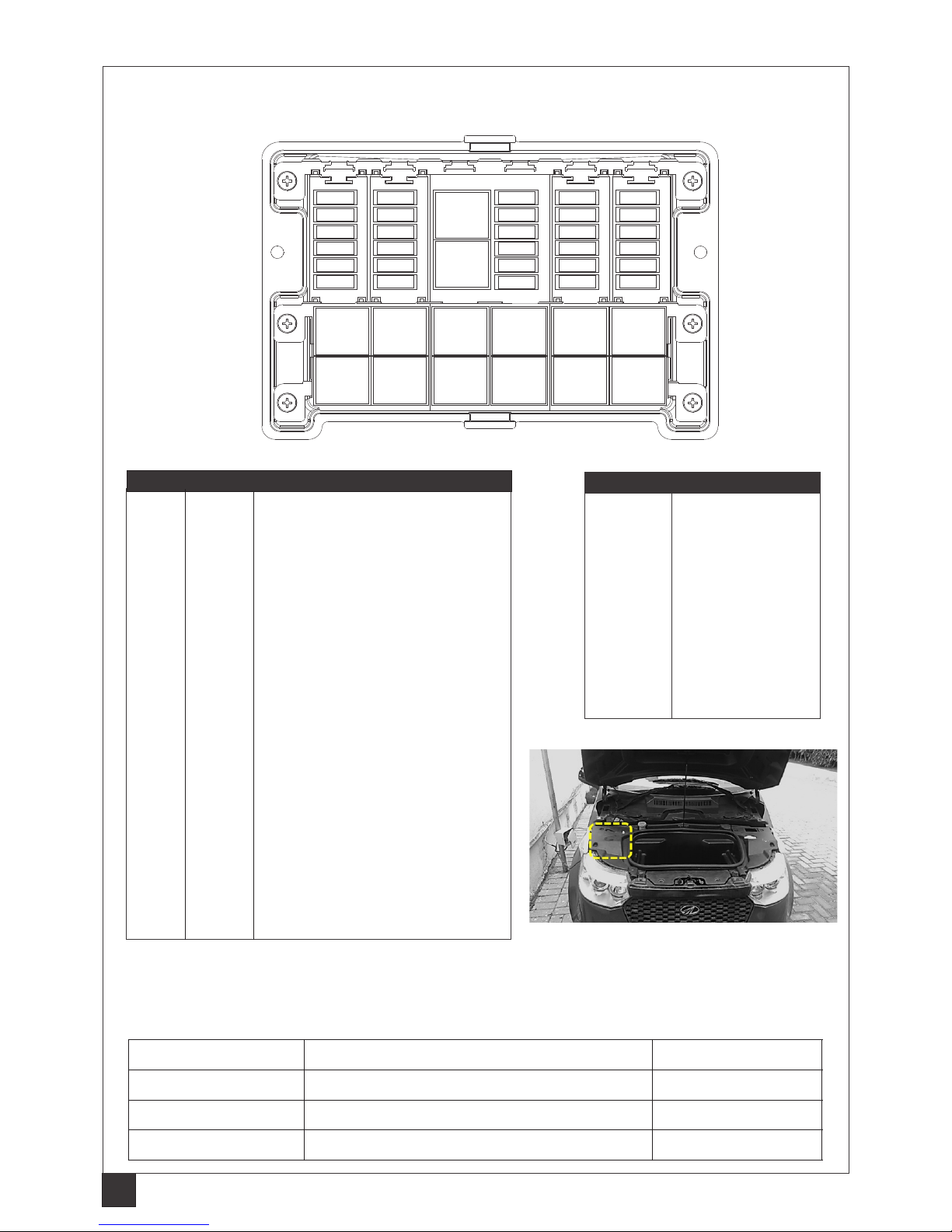

11.0 FUSE BOX DETAILS

Fluid leaks:

Check for leaks from battery and take appropriate measures to prevent personal injuries. Other fluids like wind

shield washer fluid, brake fluid & AC gas are same as in conventional cars that are to be dealt in same way.

14

RELAY CN 188

FR.FOG LAMP

RELAY CN 185

PARK LAMP

RELAY CN 186

REMOTE

BLOWER

RELAY CN 184

A/C HEATER

RELAY CN 182

HI BEAM

RELAY CN 187

CONDENSOR

RELAY CN 166

KEY RELAY

DRIVER

DUMMY

RELAY CN 183

LOW BEAM

RELAY CN 192

LATCH

RELAY CN 199

WIPER

(Hood open-

Wiper off)

RELAY CN 155

WASHER

MOTOR REAR

RELAY CN 169

IGNITION-2

RELAY CN 168

IGNITION-1

F1 F7

F8

F9

F10

F11

F12F6

F5

F4

F3

F2

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

Fuse box

F1 15A Head lamp low beam LH & RH

F2 3A Relay H/L low & high beam, position lamp

F3 20A Brake lamp, hazard, side indicator & HMSL

F4 5A Horn

F5 15A Front & rear wiper

F6 15A LH & RH door lock & rear hatch release

F7 15A Head lamp high beam LH & RH

F8 5A Position, roof, license lamps & back illumination

F9 5A Remote blower, A/C heater relay, cooling fan coil

F10 5A Rear washer motor

F11 10A Relay coil, BLDC condenser fan

F12 15A Blower fan & speed regulator module (SRM)

F13 30A Power window motor LH & RH

F14 20A Electric vacuum pump (EVP)

F15 15A Rear hatch defroster

F16 7.5A Front fog lamp-DRL

F17 3A Relay -key ON/OFF (ignition)

F18 3A OVRM, H/L adjuster LH & RH, switch

F19 3A Instrument cluster

F20 10A Infotainment system

F21 3A HVAC module(hatch & hazard) & IP cluster

F22 5A Anti-lock brake system (ABS)

F23 3A Air-bag

F24 3A Seat belt reminder (SBR)

F25 3A Ignition I/P to BCM & IEMS

F26 7.5A Aux 12V socket

F27 3A Ignition I/P to KSI SSR

F28 10A Tree switch- wiper & washer supply

F29 3A IGN I/P to HVAC, infotainment & OBD

F30 10A PRNDL, reverse lamp, camera & motor fan

Fuse no Rating (A) Circuit protected

Relay no Relay name

CN166 Key relay driver

CN168 Key relay 1

CN169 Key relay 2

CN182 Head light low beam

CN183 Head light high beam

CN184 Air condition-heater

CN185 Park lamp

CN186 Remote blower

CN187 Condenser fan

CN188 Front fog lamp

CN192 Latch

CN199 Wiper

Fuse box location

TYPE MATERIAL QUANTITY

A/C HFO- 1234YF (tetrafluropropane) 475±5grams

Brake fluid DOT-3 (Glycol Ether) 400 ML

Transmission oil Klubersynth GE475W90APIGL5 600 ML

12.0 LUBRICANTS CHART

Page 17

15

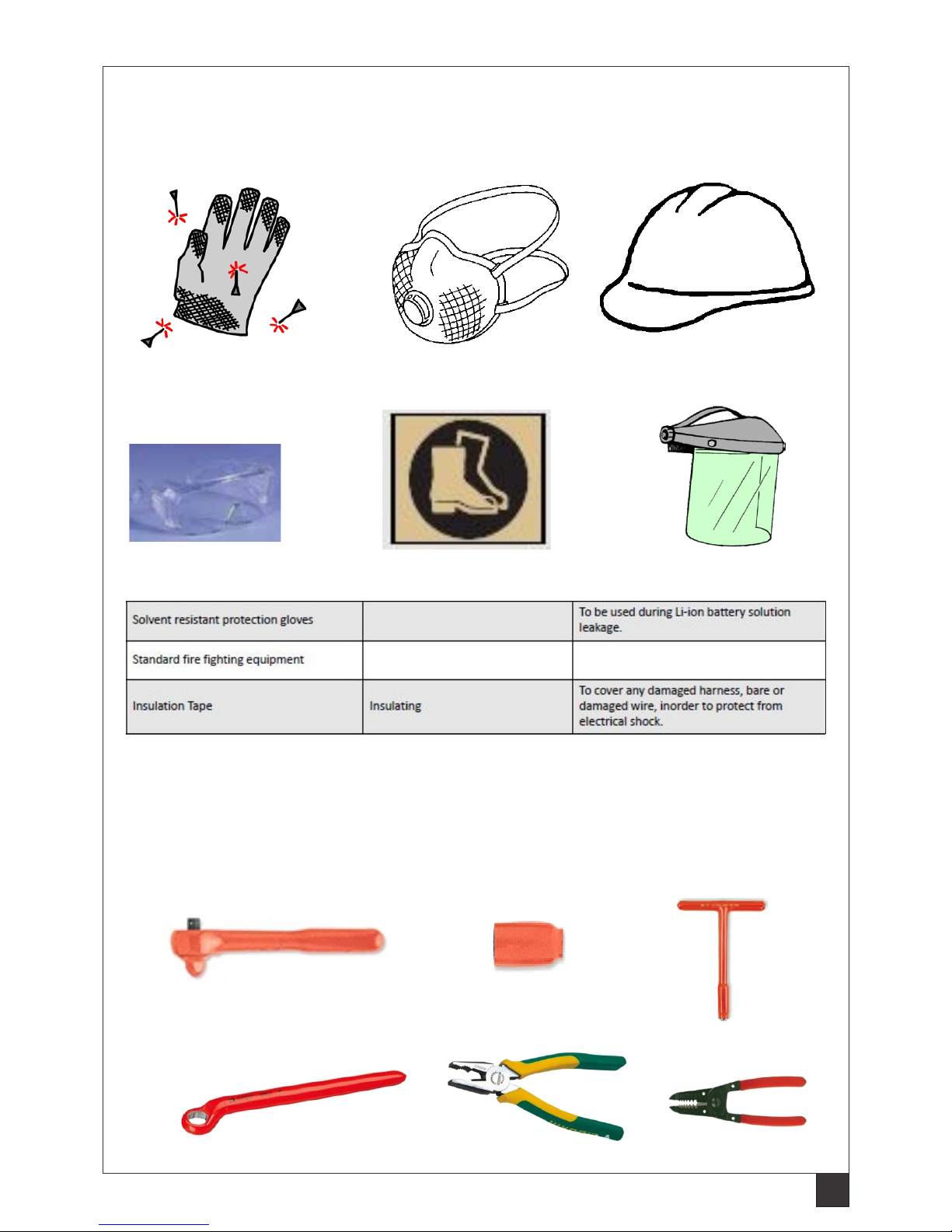

13.0 PERSONAL PROTECTIVE EQUIPMENTS AND INSULATED TOOLS

Always while performing any inspection, wear appropriate personal protective equipments before accessing

and working on car. Do not use damaged equipments at all instances to prevent personal injury. Always inspect

personal protective equipments periodically for deterioration and damages before use.

INSULATED TOOLS:

Always while performing any inspection, check or accessing electrical components in car, do use appropriate

insulated tools and equipments. Usage of these will prevent shock, personal injury ensuring safety during working

on car.

Insulated gloves (1000V)

Mask

Head gear

Goggles

Safety shield

Safety shoes

Page 18

UNLOCK

(anti-clockwise)

UNLOCK

14.0 ACCESSING OCCUPANTS AND RESCUE (Emergency response)

Hatch

release

Door unlock

DOOR LOCK:

TO UNLOCK MANUALLY:

To unlock the vehicle manually

in the event of central locking

inoperative, turn the key in anticlockwise direction respectively

as shown in the figure.

To unlock from inside, push door

lock lever backward as indicated

in the figure.

CENTRAL DOOR LOCK

TO UNLOCK :

To unlock using key fob, press the ‘Door unlock’ button once and both

the doors gets unlocked. In the event of not unlocking and central door

locking is inoperative, use general tools to open the doors and in

emergency cut open the doors at the hinges or at the door latch catcher.

II. Use the key fob to open the rear hatch by pressing the hatch release

button on the key fob once. The hatch gets released, if the key fob is not

working use the hatch release button on the climate control to release

the hatch.

DOOR LOCK

TO OPEN:

To open the doors, pull the door handle towards you to

unlock the door latch. And from inside use the door inner

handle to open by pulling it gently towards you as

indicated in the figure.

HAZARD WARNING:

Press the switch to activate the hazard warning lights.

All six external turn signal indicators will flash

simultaneously. To turn off the lights, press the switch

once again. This should be used to warn the traffic in the

event of any emergency.

1

2

3

PARKING BRAKE OPERATION

To Engage brake:

(1) Pull parking brake lever upwards.

To Disengage:

Press the button (2) on the lever and release the handle (3)

with a slight downward push while holding the release button

pressed. Make sure the handle has gone down fully for

complete release of parking brake prior to driving the vehicle.

The car has been equipped with

factory fitted central door

locking (CDL) system. Hence the

keys must be used to lock/

unlock the doors only when the

CDL system is not functional. It

is advisable to operate the

remote while the car is within

range.

Note

16

Page 19

17

REAR SEAT LOCK LATCH

IN EMERGENCY:

1. Remove the window glass if not lowered.

2. Open the doors.

3. Adjust the front seats for easy access by sliding and reclining as shown below.

PRESS

I. TO ACCESS THE FRONT SEAT FROM REAR

For accessing & adjusting the front seating position in the event

of evacuation either the recliner lever or tab can be used. To

adjust pull them and seat will slide and recline forward, release

the lever for locking.

II. RECLINING THE REAR SEAT REST

To adjust and fold the rear back rest to access from rear hatch,

release the rear seat rest latch by pulling both side tabs upwards

simultaneously and pushing the rest forward.

III. SEAT BELT

The seat belts are supplement restraint systems and to

release / remove the seta belts press the catcher downwards

as shown in the figure. The seat belt gets disengaged to access

and if seat belt cannot be unfastened, cut the belt in the event

of any emergency.

Recliner lever

Page 20

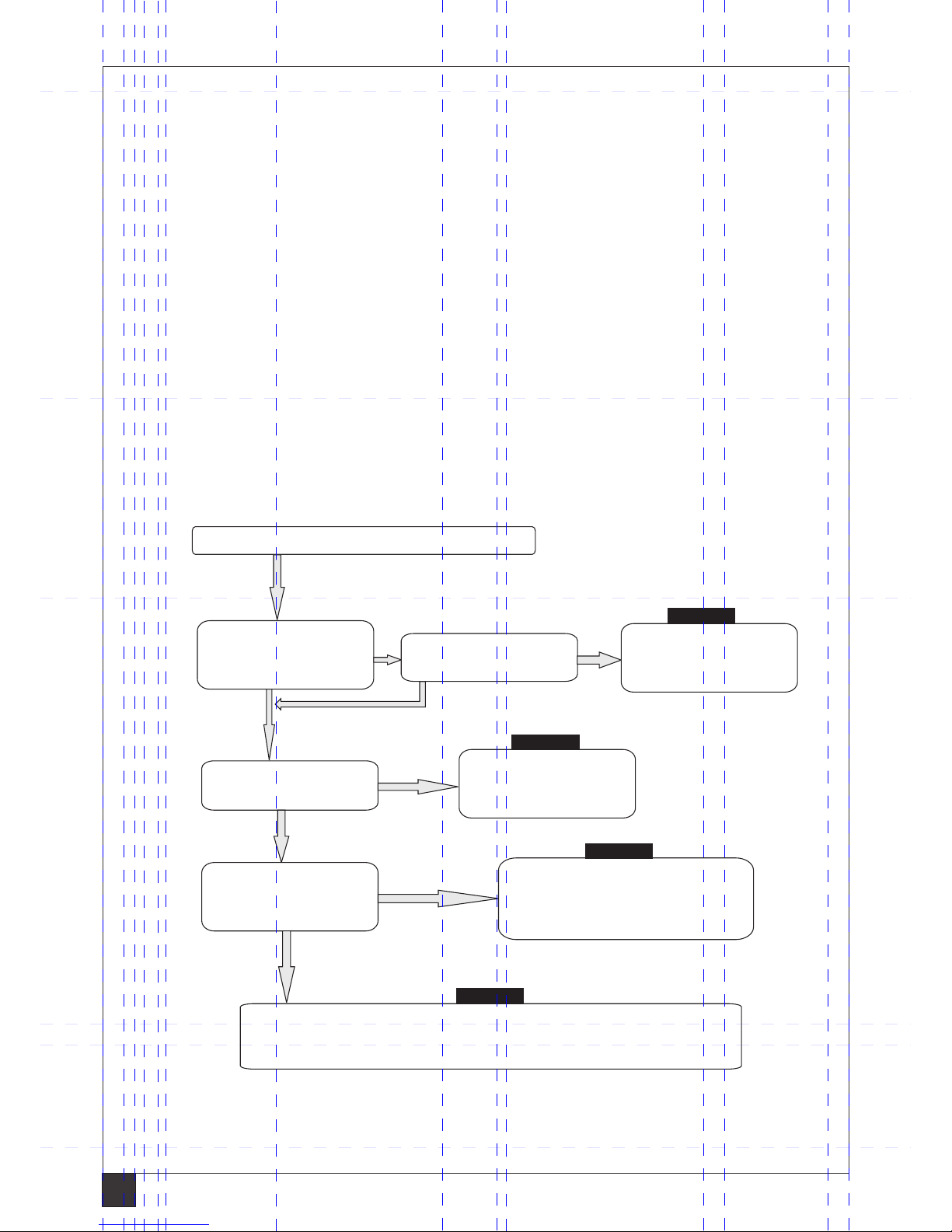

15.0 PROCESS FOR SHUTTING DOWN HIGH VOLTAGE SYSTEM

For shutting down the high voltage systems in the vehicle, first evaluate the extent of damage. Turning off

the key switch, isolate battery positive, insulating it will cuts off power supply to other components and

systems.

If the vehicle is damaged heavily, like battery pack damage / deformed, broken, use appropriate PPE’s

for battery handling.

Guidelines:

a) Always ensure to wear appropriate PPE’s during accessing the vehicle.

b) If the charge cable is connected to the vehicle, remove the same by refering the charge cable

disconnecting procedure (ii) in page .

c) Check for ‘key switch’ being ‘off ’

d) Check for ‘HVAC’ if the remote air conditioning is operational and disable it.

Note: The remote air conditioning system is a feature that can be enabled by the user via telematics by

a ‘personal computer’ or ‘Mobile App’.

Flow chart for easy understanding & shutting down the vehicle high voltage supply.

Evaluate level of damage in the vehicle

Is vehicle have any

damage? (72V system

damaged / cuts / cracks)

Is the hood is operational

& Open the hood

Is vehicle rear tub can be

accessed & are insulated

tools / PPE’s available?

Is vehicle 72V system

is active?

Remove the key relays

from the fuse box.

Check fuse box layout

Open & access the rear tub

electronics and isolate 72 volts

system by disconnecting battery

positive and insulating it

Turn off the key switch.

Follow the procedure as

in the next page

In the event of not able to isolate the high voltage system, use appropriate

‘personal protective equipment’ and perform the rescue actions.

Yes

No

No

No

No

Yes

Yes

Yes

In the event of not able to do 1,2 & 3 then do the step 4

STEP 1

STEP 2

STEP 3

STEP 4

18

Page 21

19

16.0 HANDLING DAMAGED CAR AT ACCIDENT LOCATION

Always the car should be approached with caution while inspecting for level of damage. Evaluate for ectent of

damage (location and severity of damage, airbag deplyment etc.). The high voltage should be accessed with

appropriate presonal protective equipments with proper identification of components as per illustration in

given in page. Different situations are explained under for accessing occupants in case of any hazard.

i. High impact with high voltage system intact and occupants can be accessed without extrication tools:

Open the doors with manual key from key fob or open emergency rear hatch release to get the occupants

out of the car with emergency 72V system shutdown. The occupants assistance to begin immediately

without any waiting period.

ii. High impact with high voltage system intact and occupants cannot be accessed without extrication tools:

Wear appropriate personal protective equipments, use necessary tools to cut through the door mounting

hinge locations (in the event of rear hatch not opening and central door lock failure / jammed) to remove

door from car and extricate the occupants. Use emergency disconnect switch to isolate 72V system.

Hinge location

iii. High impact with high voltage system damaged:

Evaluate the extent of damage and if there is any evidence of damage to high voltage battery pack or

system ( arcing / sparking or orange colour high voltage cables damage, battery electrolyte smell). Do take

extreme care as there may be still risk of high voltage exposure. The car has to be accessed with extreme

caution to initiate high voltage system isolation and rendering assistance in occupants extrication. In the

event of limited access to deactivate the high voltage system, do wear appropriate personal protective

equipments, use necessary tools, follow appropriate risk management to prevent shock or electrocution

and extricate the occupants.

Page 22

20

Follow the airbag supplementary restraint system (SRS) deployment procedure before accessing

and dismantling process. This procedure is applicable for driver airbag (DAB), passenger airbag

(PAB) and seat belt pre-tensioners (front left and right).

1. Safety Precautions for removal or deployment of airbags eliminates the potential for hazardous

reactions during processing.

2. Follow the below precautions while disassembling the airbag SRS components or the wiring

point of those components.

• Be cautious while handling the ECU that activates the airbags and pretensioners.

• Do not carry the airbag module and seatbelt pretensioners by wires attached to inflators or other gas

generating devices.

• While handling the airbag, make sure the trims/covers (through which the airbag deploys) point away

from self or other persons and seatbelts shall not be handled on the webbing.

• If testing or deployment is required, make sure there is sufficient space around the airbag module so as

to allow the bag to inflate freely.

• Never place your head or body close to the front of an un-deployed airbag while dismantling.

• Do not drop the ECU while it is connected to airbag modules.

• Do not reuse the airbag, its ECU or any of its components that have been removed from a vehicle.

• An airbag that has been removed from a vehicle should never be installed in any other vehicle.

• Make sure the airbag is deployed fully, as the live airbag initiator can potentially discharge even after it is

separated from the airbag assembly, thereby causing serious injury or damage of equipment.

• Only trained personnel must remove the airbag inflator or pre-tensioner gas generator from the airbag

assembly.

• Wear appropriate protection, including eye and ear protection, during air bag deployment.

• Do not dispose of an undeployed airbag/pre-tensioners through normal disposal channels until it has

been fully deployed.

WARNING

AIRBAG AND COMPONENTS

17.0 AIRBAG ACCESS, DEPLOYMENT AND DISMANTLING (emergency response)

Page 23

21

Deployment of Airbags/Pre-tensioners

The airbag and pretensioner deployment shall be conducted only by trained personnel.

Recommended Procedure for Deployment of Airbags/Pre-tensioners within the Vehicle:

Note:

• The airbags must be deployed completely prior to emergency access (if required) and disposal.

• When deploying the airbag module or seat belt pre-tensioner, ensure that the vehicle is empty.

• Make sure that a battery is available to use as the power source to deploy the airbag.

1. After performing the “Preparation for Dismantling” procedure, disconnect the body wiring harness from

airbag modules, such as airbag ECU (under dead pedal on firewall), passenger airbag (PAB) (part of

instrument panel), driver airbag (DAB)(steering wheel horn pad) and seat belt pre-tensioners (below

rear quarter trim).

2. Wait for at least 60 seconds until the energy-reserve capacitor (part of ECU) gets discharged.

3. Make a jumper-wiring harness using two wires of 2 meters or longer. Connect the two leads together at

one end of the harness to avoid accidental deployment.

4. Cut the wires leading to the airbags and pre-tensioners. Allow at least 4 inches of wires to splice into the

jumper.

5. Connect the ends of the jumper-wiring harness to the ends of the wires leading to the airbag module

and seatbelt pre-tensioners. Cover the two wire leads using tape or other insulating material to prevent

the leads from contacting each other.

6. Make sure that all airbag modules and seatbelt pre-tensioners are properly mounted and secured in the

vehicle. Reinstall the DAB (part of steering wheel hornpad) and PAB on the vehicle with a tightening

torque of 10 Nm. Install the seat belt pre-tensioner with a tightening torque of 50 Nm.

7. Clear all loose items to ensure safe deployment procedure (for e.g., clear the front seat for DAB

deployment).

8. Notify all the people in the area about the airbag deployment and make sure that they are at least 30

feet away from the vehicle.

9. Separate the leads of the wiring harness and touch the leads on the terminals of a 12 V automotive

battery. Once the contact is made, airbag/pre-tensioner deployment will occur.

10. Leave the fully deployed airbag(s) in the vehicle, or remove for separate recycling.

11. The airbag modules are hot after deployment. Allow the airbags to cool for approximately 30 minutes

and the dust to settle before approaching the vehicle.

Always work from the side of DAB module or from the side or under of the front PAB module.

• Activate only one airbag module or seat belt pre-tensioner at a time.

• Keep water and other liquids away from the airbags.

• Never apply water to a deployed airbag module or seat belt pre-tensioner.

• Be sure to wear gloves when handling the deployed airbag module or seat belt pre-tensioner.

• Eventhough there is no poisonous gas produced upon the airbag deployment, be careful not to inhale

gas since it irritates the throat and can cause choking.

• Do not disassemble components of airbag module and seat belt pre-tensioner.

• Do not resuse the airbag module, seat belt pre-tensioner and ECU under any circumstances.

• If powder from the airbag contacts the skin, wash immediately with water.

WARNING

Page 24

22

BREAKDOWN VEHICLE RECOVERY (TOWING)

RECOMMENDED VEHICLE RECOVERY PROCEDURE IN THE EVENT OF BREAKDOWN

In emergency for breakdown of the vehicle, it is advised to follow the below types and adopt suitable one

to recover vehicle to the nearest service center. Normally break down vehicle can be recovered by below

3 types that are illustrated and explained that are safe. The second and third methods should be adopted if

a flat bed type is not available.

1. Flat bed: The break down vehicle is loaded on to back of the recovery truck. This is the safest and best

way of vehicle recovery.

2. Wheel lift: The tow truck pivot arms go below the tires of front and lift them off the ground. While the

other two wheels are on the ground. Ensure that key switch is off and hand brake released

prior to towing the vehicle with this option.

Note

! The third option should be used in the event of non availability of the above two options for recovering the

breakdown vehicle.

! Should follow and adhere to the given procedures while towing the breakdown vehicle.

3. Towing: This type of recovering the breakdown vehicle is by ‘Towing’ the broken vehicle. This requires a

set of simple steps to be performed prior to towing the breakdown vehicle as below.

1. Use towing cable and connect the breakdown vehicle to the recovery vehicle

2. Turn off the Key switch (SSB)

3. Switch on the Hazard warning

4. Release the hand brake

5. Caution & advise the maneuvering person of the breakdown vehicle

18.0 ROADSIDE ASSISTANCE

Remove toe-hook and mount it by rotating clockwise for towing as shown above

2. Wheel lift type - from front

Tow hook mounting point

Towing hook

1. Flat bed towing

Page 25

23

3. Towing by cable: The break down vehicle is fixed with a tow hook and using a towing cable, it is towed by

another vehicle.

START

Step 2

2

3

Step 3

For unexpected breakdown of the vehicle, push the car towards one side of the road. Organize for the

recovery vehicle and if not available, arrange for towing vehicle. Take the tow hook available in the tool kit. Tow

hook mounting threaded holes are provided at front LH side ends of the chassis frame near the bottom grill

below number plate. Fix the hook by turning it in the holes in anticlockwise. Tie one end of the towing rope to

the tow hook eye and the other to the vehicle towing the break down vehicle. While towing, key should be in

off position, hand brake in released condition and towing speed limited to less than 12 mph . This requires

another person for handling the break down vehicle.

! Always switch on hazard of both vehicles to caution other users of road

while towing breakdown vehicle.

! Do not tow the break down vehicle at more than 12 mph speed.

! Always maintain a gap of 4 meters between breakdown & towing vehicle.

! Always tow the vehicle without jerks to avoid snapping of the towing eyelet.

CAUTION

For road accident incidents:

Check if the vehicle is drivable, if so drive

off to road side, apply hand brake and turn

off start stop button.

CAUTION

Turn off ‘Start / Stop Button’ (SSB)

Release ‘Parking Brake’

Towing by cable (Maximum speed 12miles/hr)

Press parking brake release button 2 and

then push the parking brake lever 1 to

completely down position.

Mahindra e o cover- Road side assistance for breakdown and accidents:

2

If your vehicle breaks down or is involved in a crash, our service provider will recover your vehicle and all its

passengers within the legal carrying capacity of the vehicle to the Mahindra authorised service centre

workshop at Hayes Middlesex, or to a local workshop nominated by Mahindra or its authorised service

partner. If the breakdown occurs outside of Mahindra authorised service centre opening hours or if our

service provider cannot deliver the vehicle within Mahindra authorised service centre opening hours, our

service provider will provide recovery to your home address. You can call to arrange for vehicle recovery

during the Mahindra authorised service centre or service partner opening hours in the next working day.

Mahindra authorised service centre opening hours are Monday to Saturday 08.00 to 18.00 (GMT)

Once the vehicle has been taken to a Mahindra authorised workshop, it is then owners responsibility to

instruct the repairer to make any repairs required. The coverage applies for breakdowns occurring in Great

Britain only.

Recovery information:

a) Breakdown recovery from ETA national recovery

b) Coverage is with car sale for first year

c) Breakdown recovery covered in Great Britain only

d) Unlimited coverage plan

Mahindra e o cover toll free no: 08000 737 283

2

Page 26

24

Step 1: Use wheel spanner from tool kit purchased to remove the wheel.

A

B

Step 3: Place the jack, align the jack to jack mounting location beneath the car.

Step 4: If required remove the hubcap by holding the cap

on the top and tapping it gently. Loosen the fourwheel nuts, ½ turn with wheel spanner. Locate

the jack point nearest to the flat tyre you need to

change.

19.0 CHANGING A FLAT TYRE

The car can roll of the jack and seriously

injuring anyone underneath. Follow the

directions for changing a tyre exactly and

never get under the vehicle when only the

jack supports it.

CAUTION

Jack points

Step 2: Provide stopper to the wheel parallel to flat

tyre before Jacking up the vehicle for changing the

wheel.

The spare wheel, jack, jack handle, towing

hook and tool kit are car accessories that

does not come along with initial car

purchase. They are to be purchased by car

user for their use based on requirement.

Note

Page 27

25

Step 5: Once aligned to the jack point, turn the end bracket

clockwise until the top of the jack contacts the jack

point. Make sure the jack point tab is resting in the

jack notch. Use the jack rod to raise the vehicle

until the flat tyre is just off the ground.

Step 6: Remove the wheel nuts and flat tyre. Temporarily

place the flat tyre on the ground with the outside

surface of the wheel facing up. You could scratch the

wheel if you put it face down.

Step 7: Before mounting the spare tyre, wipe any dirt off the

mounting surface of the wheel and hub with a clean

cloth. Wipe the hub carefully, it may be hot from

driving. Put on the spare tyre. Put the wheel nuts

back on finger-tight, then tighten them in a

crisscross pattern with the wheel wrench until the

wheel is firm against the hub.

Step 8: Lower the car to the ground and remove the jack.

Tighten the wheel nuts securely in the same criscross pattern.

Tighten the wheel nuts to recommended torque (70Nm) and

re-fix the hubcap by placing it in its original position and

tapping it gently at center. Now the vehicle is ready to drive.

Page 28

26

Note:

DANGER:

HIGH VOLTAGE REPAIR IS

UNDER PROGRESS

DO NOT TOUCH

Sign: .........................................

DANGER:

HIGH VOLTAGE REPAIR IS

UNDER PROGRESS

DO NOT TOUCH

Sign: .........................................

FOLD HERE

Print this page and put it on the vehicle roof while carrying out the service

If the vehicle needs to be kept / stored unattended, ensure to put the below caution note on the breakdown

vehicle.

20.0 CAUTION NOTE

Page 29

Page 30

For Feed back and assistance contact:

Mahindra Reva Electric Vehicles Ltd.

Add: # 2, Road No 3, Bommasandra phase IV,

Industrial Area, Jigani Link Road, B’lore - 560099

e-mail: customercare@mahindrareva.com

Loading...

Loading...