Page 1

OPERATOR'S MANUAL &

INSTALLATION INSTRUCTION

'ML170' Series

Click here to go on

INDEX

Main Menu

contactus@almats.com

Page 2

Includes: Operator’s Manual and Installation

Instructions

Mahindra USA

Model ML170

Front End Loader

1503-1066

Page 3

WARRANTY CONDITIONS

Warranty Coverage:

Mahindra USA, Inc., herein referred to as Mahindra, undertakes to replace or repair any part of a Mahindra loader

where damage has been proven to be caused by defects in material or workmanship.

This Warranty is valid for a period of 1 year for all hydraulic components and attachments and for a period of 2

years for all other loader components from the date of the original retail sale. Parts replaced or repaired under the

terms of this Warranty are guaranteed only until the original warranty expires.

It is further understood and agreed that the defect should be immediately reported to the Selling Dealer. The

Selling Dealer will generally perform Warranty repairs or replacements and the Purchaser shall deliver the

Mahindra Loader to the Dealer’s place of business for repair. In the event Purchaser is located more than 75

miles from the Selling Dealer, any Mahindra Dealer authorized to sell and service Mahindra Products may

perform the repair at its dealership.

The obligation of Mahindra to the Purchaser under this Warranty is limited to the repair or replacement of

defective parts by an authorized Mahindra dealer. Repair or replacement in accordance with this Warranty shall

constitute fulfillment of all liabilities of Mahindra and the Selling Dealer in respect to Mahindra Loaders.

There are no warranties beyond those which expressly appear herein. Any implied warranty of

merchantability or fitness for a particular purpose is specifically excluded here from.

Warranty Provisions:

Mahindra’s liability under this Warranty is subject to the observance by the Purchaser of the following provisions:

- The purchaser shall at all times in the operation of any Mahindra Product, use those brands and grades of

lubricating oils, lubricants or fuel and spare parts officially approved by Mahindra.

- The Mahindra Loaders shall have been used in accordance with the procedures specified in the Operator’s

Manual. This Warranty does not extend to damage resulting from misapplication, abuse, misuse, failure to

perform maintenance, negligence, fire, accidents or changes or faulty mounting carried out by the Purchaser.

When making a Warranty exchange of parts, the Purchaser shall compensate Mahindra for the time that the

parts have been used if they have been exposed to extreme wear.

- Compensation is not paid for physical harm, deadlock, resulting damages, or other losses.

- To obtain warranty service, the Purchaser must (1) report the product defect to an authorized Mahindra

dealer and request repair within the applicable warranty term and (2) present evidence of purchase or date of

original use.

- The Warranty shall be void if the Mahindra Loader has been altered or repaired outside of a Mahindra

dealership in a manner, which, in the sole judgment of Mahindra, affects its performance, stability, or

reliability.

- The customer shall be responsible for transportation expenses for the Mahindra Loader to the dealership or

travel of dealer personnel to customer location for Warranty repair. The customer shall also pay any premium

for overtime labor requested by the customer.

- Temporary repairs or additional costs due to the work being performed after normal working hours will not be

compensated.

- The above warranty is in lieu of all other warranties on Mahindra’s behalf and neither party assumes any

other liability in connection with Mahindra’s Products.

- Any dispute arising between Mahindra and the Purchaser concerning the liability of Mahindra under this

warranty shall be subject to the laws of the State of Texas.

Right To Make Design and Product Changes:

Mahindra reserves the right to make changes in the design and other changes in its Mahindra Products at any

time without incurring any obligation with respect to any product previously ordered, sold or shipped.

2

Page 4

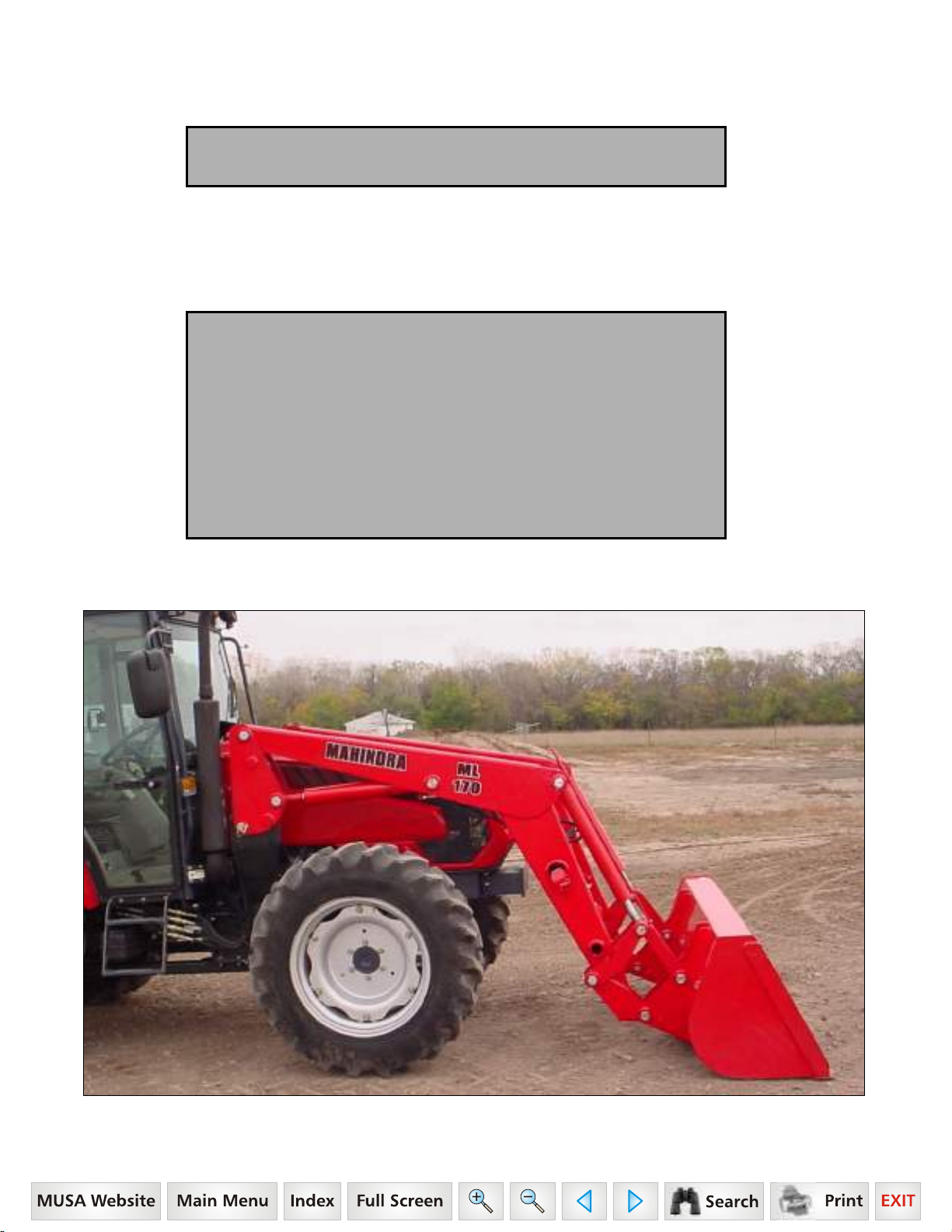

CONGRATULATIONS

You are now the proud owner of a MAHINDRA ML170 Loader. This loader is a product of quality

engineering and manufacturing. It is made of fine materials and under a rigid quality control

system. It will give you long, satisfactory service. To obtain the best use of your loader, please

read this manual carefully. It will help you become familiar with the operation of the loader and

contains many helpful hints about loader maintenance. The immediate use of new techniques in

the manufacture of products may cause some small parts of this manual to be outdated.

Mahindra dealers will have the most up-to-date information. Please do not hesitate to consult with

them.

SAFETY ALERTS

This symbol, the industry’s "Safety Alert Symbol," is used throughout this manual and on labels to warn of the

possibility of personal injury. When you see this symbol, carefully read the messages and be alert to the

possibility of injury or death. It is essential you read these instructions and safety regulations before you attempt

to assemble or use this unit.

DANGER:

WARNING:

CAUTION:

IMPORTANT:

NOTE:

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates that equipment or property damage could result if instructions are not

followed.

Gives helpful information.

3

Page 5

SAFETY

Most tractor and/or loader equipment accidents can be avoided by following simple safety precautions.

The safety information given in this manual does not replace safety codes, insurance requirements, federal, state,

and local laws. Make sure your machine has the correct equipment required by your local laws and regulations.

Understand that your safety and the safety of other persons are measured by how you service and operate this

loader.

Know the position and operations of all controls before you try to operate. Make sure you check all controls in a

safe area before starting.

Read this manual completely and thoroughly and make sure you understand all controls. All equipment has a

limit. Make sure you are aware of the stability and load characteristics of this loader before you begin operation.

This safety alert symbol indicates important safety messages in this manual. When you see this

symbol, carefully read the message that follows and be alert to the possibility of personal injury or

death.

SAFETY PRECAUTIONS

READ MANUALS AND DECALS

1. Read and understand both the tractor and the loader Operator Manuals and all decals before using the

loader.

2. Lack of knowledge can lead to accidents.

3. It is the loader owner’s responsibility to make sure anyone operating the loader reads and understands this

manual first before operating the machine.

4. Follow all safety, operating, and service instructions.

5. Replace damaged or illegible safety labels. See following pages for required labels.

ROPS AND SEAT BELT

6. Equip your tractor with an approved rollover-protective structure (ROPS) or ROPS Cab and seat belt for your

protection.

7. ROPS (Roll-Over Protective Structures) and seat belt equipped tractors are recommended for operator use in

all loader operations.

8. Operator should wear safety hard hat, safety glasses, safety shoes, and other PPE. Avoid wearing loose

clothing or jewelry that may catch in moving parts.

9. Use seat belt as specified by tractor/ROPS manufacturer.

YOURSELF

10. Do not stand, walk, or work under a raised loader bucket or attachment unless it is securely blocked and held

in position.

11. Operate controls only when properly seated in the operator’s seat.

12. Only one person, the operator, should be on the machine when it is in operation.

13. Accidental movement of valve handle/handles or leak in the hydraulic system could cause the loader to drop,

or attachment to dump, causing severe injury.

OTHERS

14. Do not allow anyone in loader work area, under raised loader, or to reach through the loader boom when the

bucket or attachment is raised.

15. A frequent cause of personal injury or death is persons falling off and being run over. Inadvertent movement

of the loader or attachment could result in serious injury or death.

16. Do not permit others to ride on your tractor, loader, bucket, or any attachment.

17. Do not lift or carry anyone on buckets, forks, probes, or any other portion of the loader or loader attachments.

18. Do not allow children or unqualified persons to operate equipment.

4

Page 6

SAFETY PRECAUTIONS

PREPERATION

19. Move the wheels to the tractor manufacturer’s widest recommended settings to increase stability.

20. For better stability, always use a tractor equipped with a wide front axle, never use a tractor equipped with a

tricycle type front axle.

21. Add rear ballast or rear weight to the tractor to compensate for the load and increase stability.

22. Add recommended rear tire liquid weight or rear wheel weights for increased stability.

23. Do not modify, alter, or permit anyone else to modify or alter the loader, any of its components, or any loader

function without first consulting a Mahindra dealer.

24. Assemble, remove, and reinstall the loader only as directed in this manual. Failure to do this could result in

serious personal injury or death.

25. The loader may shift during shipping and handling, making it unstable on the pallet. Support loader with an

overhead hoist or other suitable means prior to removing bands or attaching straps securing loader to pallet.

Failure to do so could result in accidental tip-over of the loader that could cause serious injury to you and/or

bystanders.

BEFORE OPERATION

26. Before starting the engine of your tractor, make sure all operating controls are in park lock or neutral position.

27. Be certain lights and safety markings, as provided by the tractor manufacturer, are clean and operating when

transporting the tractor/loader on public roads. Be certain that the Slow Moving Vehicle (SMV) emblem is

visible. Check with local law enforcement for specific requirements.

OPERATION

28. Add wheel ballast and/or rear weight to counterbalance tractor/loader for stability at maximum loader capacity.

29. Additional counterweight requirements will vary with loader attachments and equipment application.

30. Move and turn the tractor at low speeds.

31. Carry loader boom at a low position during normal operation.

32. Never travel at high speeds with bucket loaded.

33. Use caution when operating the loader with a raised bucket or attachment.

34. Avoid driving over loose fill, rocks, holes, or anything that may be dangerous for loader operation or

movement.

35. Allow for the loader length when making turns.

36. Use caution when handling loose or unstable loads.

37. Gradually stop the loader boom when lowering or lifting loads.

38. When using remote hydraulic tractor valves on some tractors, the loader lift and dump cylinders will continue

moving unless the valve handle/handles are manually returned to neutral, or until relief pressure is reached at

the ends of piston strokes. Observe the bucket movement and maintain control with valve handle/handles.

39. Travel speed should be such that complete control and machine stability is maintained at all times. Where

possible, avoid operating near ditches, embankments, and holes. Reduce speed when turning, crossing

slopes, and on rough, slick or muddy surfaces.

40. A loader attachment should be transported in a low position at slow ground speeds. Make turns slowly and

use the tractor brakes cautiously. A loaded attachment in the raised position alters the center of gravity

location of the machine and increases the possibility of mishaps.

41. Be careful during loading, transporting, and stacking to minimize rolling bales and tractor tip over.

42. Do not use buckets, forks, or other attachments without bale retaining devices.

43. Operate the tractor and loader such that complete control and machine stability is maintained at all times.

44. When using a loader, be alert of bucket or attachment position at all times. Loader in raised position with

bucket or attachment rolled back can dump material onto tractor causing damage or injury to tractor and/or

operator.

LARGE HEAVY OBJECTS

45. Never use loader for handling large heavy objects, such as large round or rectangular bales, logs, and oil

drums unless loader is equipped with attachment that is designed to handle such objects.

46. Handling large heavy objects can be extremely dangerous due to danger of rolling the tractor over.

47. Handling large heavy objects can be extremely dangerous due to danger of upending the tractor.

48. Handling large heavy objects can be extremely dangerous due to danger of the object rolling or sliding down

the loader boom onto the operator.

5

Page 7

49. If you must handle large heavy objects, protect yourself by using caution, moving slowly, and avoiding bumps

and rough ground.

50. If you must handle large heavy objects, protect yourself by never lifting load higher than necessary to clear

the ground.

51. If you must handle large heavy objects, protect yourself by adding rear ballast to the tractor to compensate for

weight of load.

52. If you must handle large heavy objects, protect yourself by never lifting large heavy objects that may roll or fall

on the operator.

53. Never lift any load from any point of the loader with a chain, rope, or cable unless loader is equipped with a

Factory approved attachment that was designed and built for this type of lifting. Always follow lifting

instructions included with these attachments.

54. Use only Factory bale probe or bale retaining devise handler attachment when handling round bales.

55. Do not handle large square bales without a retaining device handler attachment.

56. Do not use buckets, forks, or other attachments without bale retaining devices.

57. Do not use loader for handling large, heavy objects such as logs, tanks, etc.

SAFETY PRECAUTIONS

SLOPES

58. Stay off of slopes too steep for safe operation.

59. Shift down before you start up or down a hill with a heavy load. Avoid "free wheeling."

60. Use extreme caution when operating on a slope.

61. Always operate up and down the slope, never across the slope.

ELECTRICAL

62. Avoid contact with overhead wires, power lines, and obstacles when loader bucket or attachment is raised.

63. Electrocution from power lines can occur with or without contact.

64. Check for underground utilities before digging below grade level.

65. Contact with overhead power lines can cause severe electrical burns or death from electrocution. Make sure

there is enough clearance between raised equipment and overhead power lines.

HYDRAULIC

66. Do not tamper with the relief valve setting. This will void warranty and could cause damage to loader and/or

tractor.

67. Escaping hydraulic fluid under pressure can have sufficient force to penetrate the skin, causing serious

personal injury. Do not use HANDS to search for suspected leaks. If injured by escaping fluid, obtain medical

treatment immediately.

68. Visually check for hydraulic leaks and broken, missing, or malfunctioning parts. Never use your hand to check

for suspected leaks under pressure. Use a piece of cardboard or wood for this purpose. Escaping hydraulic

fluid or diesel fuel leaking under pressure can have sufficient force to penetrate the skin and cause serious

infection or other personal injury. If injured by leaking fluid, seek medical attention immediately.

69. To prevent personal injury, relieve all pressure before disconnecting fluid lines.

70. Before applying hydraulic pressure, make sure all hydraulic connections are tight and components are in

good condition.

71. Be sure to purge all the air from the hydraulic system before attempting to raise or lower this machine.

72. When using remote hydraulic tractor valves on some tractors, the loader lift and dump cylinders will continue

moving unless the valve handle/handles are manually returned to neutral, or until relief pressure is reached at

the ends of piston strokes. Observe the bucket or attachment movement and maintain control with valve

handle/handles.

73. Raised loader or boom can fall due to hydraulic system failure.

74. To avoid serious injury or death: Block up or securely support loader and boom before working underneath.

75. To avoid serious injury or death: Purge all air from hydraulic system before attempting to raise or lower loader

or boom.

76. To avoid serious injury or death: Stand clear if lowering or raising loader or boom.

77. Do not use hand or skin to check for hydraulic leaks. Use cardboard or wood. Wear eye protection.

78. High pressure oil leaks can penetrate skin causing serious injury and gangrene. Consult a physician

immediately.

79. Lower the loader or boom and release hydraulic pressure before loosening fittings.

6

Page 8

SAFETY PRECAUTIONS

AFTER OPERATION

80. Before leaving the tractor seat, lower attachment or loader boom to ground, stop engine, lock parking brakes,

put all controls in neutral, relieve hydraulic pressure, and remove key before leaving operator's seat.

81. Before disconnecting hydraulic lines, relieve all hydraulic pressure.

82. Make sure all parked loaders on stands are on a hard level surface with all safety devices engaged to prevent

loader from falling and being damaged or injuring someone.

83. Always park loader with bucket attached to loader.

84. When a front loader is mounted on the tractor, enter and exit the operator’s seat only from left side of the

tractor.

85. Always park loader with a Factory attachment attached to the loader.

86. Special care should be taken to park or store attachments with points or sharp edges in a safe manner.

87. Make sure all parked loaders are on a hard level surface. Engage all safety devices to prevent loader from

falling and being damaged or injuring someone. Do not repair loader if it is not mounted on the tractor. Loss of

hydraulic fluid or removal of parts could cause loader to collapse resulting in injury.

REPAIR

88. Visually check for hydraulic leaks and broken, missing, or malfunctioning parts.

Make necessary repairs before operation.

89. To keep mounting kit hardware from loosening during loader operation, hardware must be torqued to

specifications noted in operator manual.

90. Always wear safety goggles when servicing or repairing the machine.

91. When servicing or replacing pins in cylinder ends, bucket, etc., always use a brass drift and hammer. Failure

to do so could result in injury from flying metal fragments.

92. Never tow from any point of the loader with a chain, rope, or cable. Doing so could cause a roll over or

serious damage to the loader.

7

Page 9

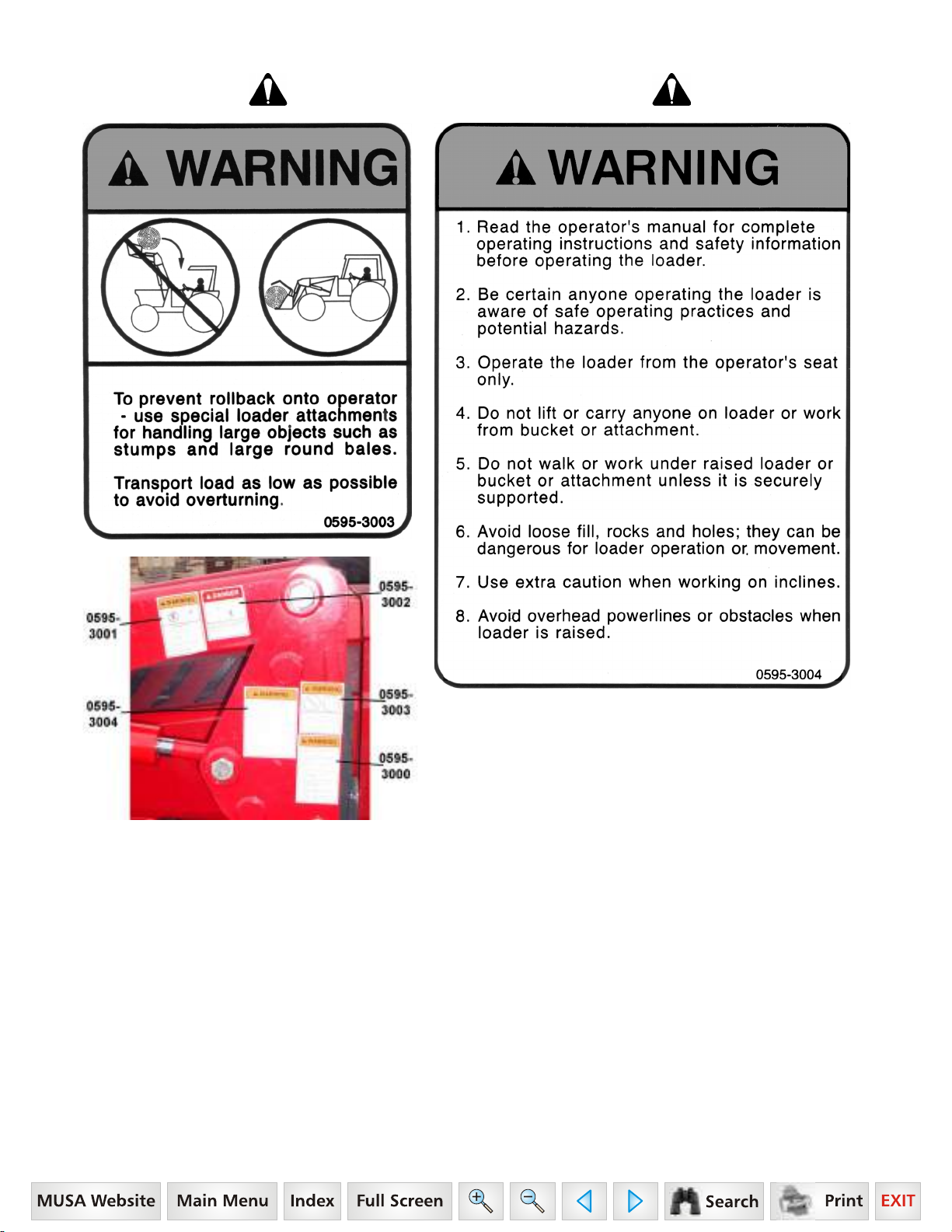

DANGER, WARNING, AND CAUTION

DECAL SAFETY MESSAGES

0595-3000 WARNING DECAL

1. Add recommended rear wheel ballast and/or rear counter-weight for stability.

2. Move wheels to widest recommended setting to increase stability.

3. Move and turn tractor at low speeds.

4. In transport carry the load low.

5. Lower loader to the ground when parked.

6. Before servicing or adjusting equipment:

* lower loader to the ground.

* shut off engine.

7. Relieve hydraulic pressure before disconnecting oil lines.

8. Observe safety recommendations in Loader Operations Manual.

0595-3001 WARNING DECAL

Crushing Hazard

9. Stay away from under lift arms and bucket!

10. Do not stand or work under a raised loader.

11. Support bucket and lift arms before working under loader.

12. Lower loader to the ground before leaving seat.

0595-3002 DANGER DECAL

13. Keep machine clear of overhead power lines to avoid death or serious injury.

0595-3003 WARNING DECAL

14. To prevent rollback onto operator use special loader attachments for handling large objects such as stumps

and large round bales.

15. Transport load as low as possible to avoid overturning.

0595-3004 WARNING DECAL

16. Read the operator’s manual for complete operating instructions and safety information before operating the

loader.

17. Be certain anyone operating the loader is aware of safe operating practices and potential hazards.

18. Operate the loader from the operator’s seat only.

19. Do not lift or carry anyone on loader or work from bucket or attachment.

20. Do not walk or work under raised loader or bucket or attachment unless it is securely supported.

21. Avoid loose fill, rocks, and holes; they can be dangerous for loader operation or, movement.

22. Use extra caution when working on inclines.

23. Avoid overhead powerlines or obstacles when loader is raised.

8

Page 10

DANGER, WARNING, AND CAUTION

DECAL SAFETY MESSAGES

0595-2190 CAUTION DECAL

24. To prevent bodily injury and loader instability when detaching loader, equip loader with a material bucket.

0595-3050 DANGER DECAL

To avoid serious injury or death:

25. Unload only on a level surface.

26. Keep bystanders clear of work area when loading and unloading bales.

0595-3051 WARNING DECAL

27. Do not operate without confirmation that coupler pins are fully engaged.

28. Loader attachment can fall off if not properly attached.

To avoid serious injury or death:

29. Only use loader manufacturer approved attachments.

30. Read all operators manuals and decals before operating. Follow all safety operating and service instructions.

Contact dealer for replacement parts.

0595-3052 WARNING DECAL

To avoid serious injury or death:

31. Do not use pallet fork attachment to lift large objects, round bales, or items that may roll or slide down loader

arms onto the operator.

32. Never operate pallet fork without attaching plate guard.

33. Keep loads below pallet forks attaching plate guard heights.

34. Always transport loads with pallet forks low and level to ground.

35. Always keep pallet forks level when raising loads.

36. Avoid raising loads to full heights with pallet forks rolled back.

37. ROPS (Roll-Over Protective Structures) and seat belt equipped tractors are recommended for operator use in

all pallet fork operations.

38. Do not lift or carry anyone on buckets, forks, probes, or any other portion of the loader or loader attachments.

39. Do not allow riders on tractor, loader, or forks.

40. Avoid contact with electrical power lines by loader or attachments.

0595-3053 CAUTION DECAL

41. Maximum load limit on combined pair of forks is 5700 pounds.

0595-3054 CAUTION DECAL

To avoid serious injury or death:

42. Read operators manual and decals before operating.

43. Follow all safety operating, and service instructions. Contact dealer for replacement.

44. Be careful during loading transporting, and stacking to minimize rolling bales and tractor tip over. ROPS (RollOver Protective Structures) and seat belt equipped tractors are recommended for operator use in all bale

probe operations.

45. Do not allow riders on tractor loader or bale probe.

46. Avoid loading/unloading bales on sloping or uneven surfaces.

47. Avoid transporting with bales raised high. Keep bales tilted back and low to the surface while moving.

48. Approach, penetrate, and transport bales at low speeds. Reduce speeds on curves, hills rough ground, or

when turning.

49. Do not lift anything with bale probe except round bales.

50. Never raise round bale to full height with bale probe rolled back.

51. Park and store bale probe points pointed against bale, building, or other stable object.

9

Page 11

SAFETY DECALS

10

Page 12

SAFETY DECALS

Safety Decal Locations

Important: Safety decals 0595-3000, 0595-3001, 0595-3002,

0595-3003, and 0595-3004 are located on the loader LH

bearing box and are visible as you mount the tractor.

Care of Safety Decals

1. Keep safety decals clean and free of obstructing material.

2. Clean safety decals with soap and water and dry with a

soft cloth.

3. Replace damaged or missing safety decals with new

decals from your Mahindra Dealer.

4. If a component with a safety decal(s) affixed is replaced

with a new part, make sure new safety decal(s) are

attached in the same location(s) as the replaced

components.

5. Mount new safety decals by applying on a clean dry

surface and pressing air bubbles to outside edges.

11

Page 13

TABLE OF CONTENTS

1. Specifications...................................................14

1.1. Attachment Specifications.........................14

2. Introduction ......................................................15

3. Installation Instructions...................................16

3.1. Tractor Preparation...................................16

3.2. Mounting Kit Installation............................17

3.3. Hydraulic Installation.................................21

3.4. Loader Installation.....................................28

3.5. Connect Hydraulics...................................29

3.6. Bucket Level Indicator...............................30

Steering Stop...................................................30

4. Pre-Operation Instructions..............................31

4.1. Hydraulic Fluid..........................................31

4.2. Initial Loader Operation.............................31

4.3. External Loader Valve...............................31

4.4. Loader Mounted Valve Equipped With

Single Handle Controller On A Loader Not

Equipped With Hydraulic Self Level Option32

4.5. Neutral Position.........................................32

4.6. Neutral Lock Position................................32

4.7. Float Position............................................32

4.8. Regenerative Dumping Position ...............33

4.9. Initial Loader Operation.............................33

4.10. Removing Air From Hydraulic System....33

4.11. Relief Noise.............................................33

5. Daily Maintenance & Lubrication....................34

5.1. Daily Checks.............................................34

5.2. Loader Lubrication....................................34

Service Areas...................................................36

10. Pin On Bucket.................................................49

10.1. Installation Instructions To Pin On Quick

Attach .....................................................49

10.2. Installation Instructions Direct To Loader49

11. Pin On Bale Spear..........................................50

11.1. Pin On Bale Probe..................................51

11.2. Assembly Instructions.............................51

11.3. Installation Instructions To Pin On Quick

Attach .....................................................51

11.4. Installation Instructions Direct To Loader 51

11.5. Operating Instructions.............................51

12. Pin On Pallet Fork.......................................... 52

12.1. Pin On Pallet Fork...................................53

12.2. Assembly Instructions.............................53

12.3. Installation Instructions Pin On Quick

Attach .....................................................53

12.4. Installation Instructions Direct To Loader53

12.5. Operating Instructions.............................53

12.6. Parking Instructions................................53

12.7. Parking Stability......................................53

13. Optional Pin On Quick Attach System.........54

13.1. Recommended Loader Factory Approved

Attachments............................................54

13.2. Pin On Quick Attach ...............................54

14. Installing Bucket Or Attachment To Pin On

Quick Attach...................................................55

14.1. Recommended Loader Factory Approved

Attachments............................................55

14.2. Operating Instructions.............................55

6. Operating Instructions.....................................37

6.1. Filling The Bucket .....................................37

6.2. Lifting The Load........................................37

6.3. Carrying The Load....................................37

6.4. Dumping The Bucket ................................38

6.5. Lowering The Bucket................................38

6.6. Operating With Float Control ....................38

6.7. Loading From A Bank...............................38

6.8. Peeling And Scraping ...............................39

6.9. Loading Low Trucks Or Spreaders From A

Pile..........................................................39

6.10. Backfilling................................................39

6.11. Handling Large Heavy Objects ...............40

6.12. Back Grading..........................................40

7. Dismounting The Loader.................................41

8. Mounting The Loader.......................................45

9. Optional Grill Guard.........................................48

9.1. Installation Instructions .............................48

15. Removing Bucket Or Attachment From Pin

On Quick Attach.............................................58

15.1. Operating Instructions.............................58

16. Service And Lubrication For Pin On Quick

Attach..............................................................59

16.1. Keep These Areas Clean........................59

16.2. Lubricate Annually..................................59

17. Optional Skid Steer Tool Carrier System.....60

17.1. Recommended Loader Factory Approved

Attachments............................................60

17.2. Non-Loader Factory Attachments...........60

17.3. Skid Steer Tool Carrier System Service &

Lubrication..............................................61

18. Installation & Operation Of Skid Steer Tool

Carrier System...............................................62

18.1. Installation Instructions...........................62

18.2. Skid Steer Tool Carrier Handles In

Disengaged Position...............................62

18.3. Skid Steer Tool Carrier Handles In

Engaged Position ...................................63

12

Page 14

19. Installing Bucket Or Attachment To Skid

Steer Tool Carrier...........................................64

19.1. Operating Instructions.............................64

20. Removing Bucket Or Attachment From Skid

Steer Tool Carrier...........................................67

20.1. Operating Instructions.............................67

21. Skid Steer Bucket...........................................68

21.1. Skid Steer Bucket ...................................68

21.2. Installation Instructions To Skid Steer Tool

Carrier.....................................................68

22. Skid Steer Bale Spear....................................69

22.1. Skid Steer Bale Probe.............................70

22.2. Assembly Instructions.............................70

22.3. Installation Instructions To Skid Steer Tool

Carrier.....................................................70

NOTES:

22.4. Operating Instructions.............................70

23. Skid Steer Pallet Fork.................................... 71

23.1. Skid Steer Pallet Fork.............................72

23.2. Assembly Instructions.............................72

23.3. Installation Instructions To Skid Steer Tool

Carrier.....................................................72

23.4. Operating Instructions.............................72

23.5. Parking Instructions................................72

24. Trouble Shooting Procedures.......................73

24.1. Trouble Shooting For All Loaders...........73

24.2. Trouble Shooting For Loaders With

Optional Self Leveling.............................77

25. Torque Chart...................................................78

13

Page 15

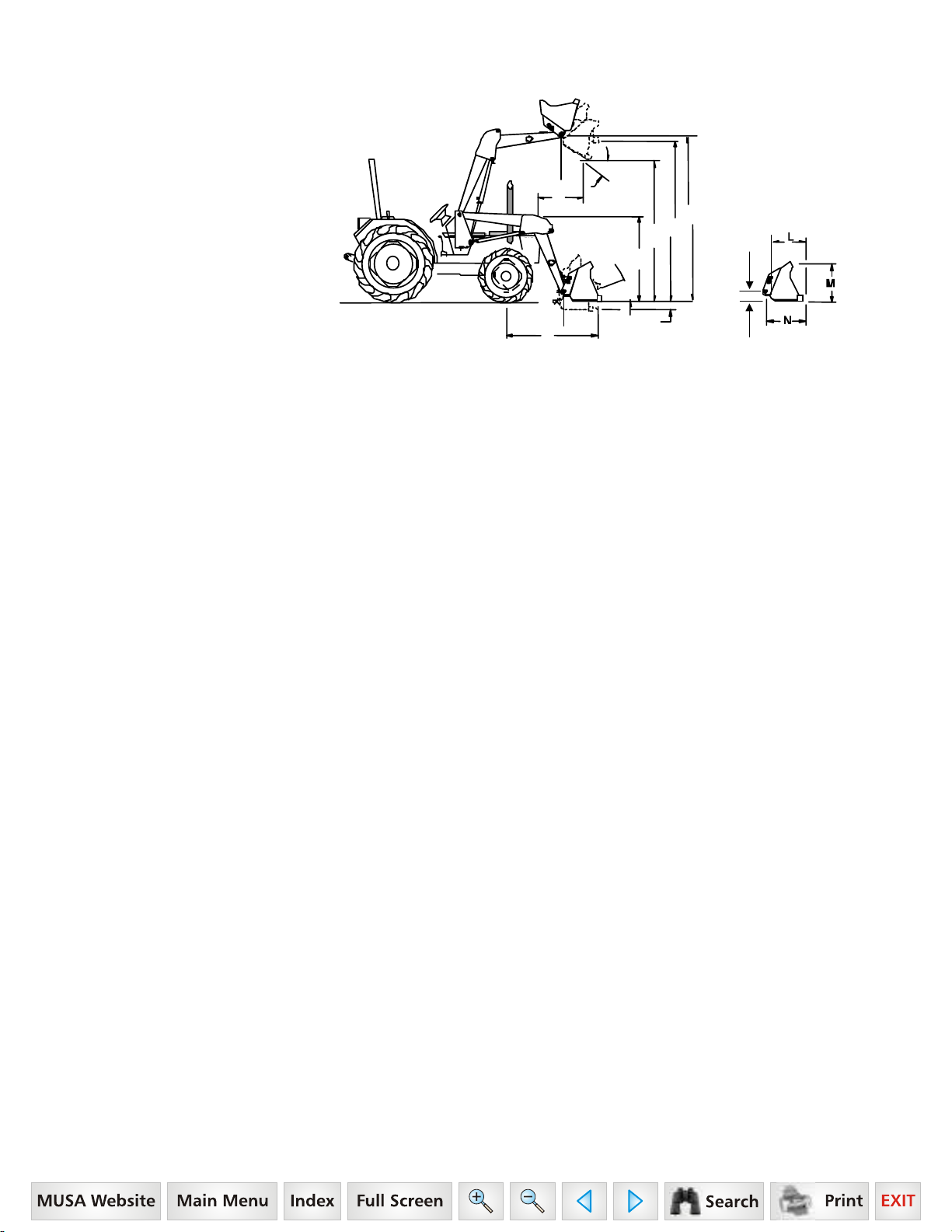

1. SPECIFICATIONS

Model ML170

Front End Loader

For Use With

Model 7010 Tractor

E

U

D

B

C

J

A

P

G

Y

F

H

SPECIFICATIONS OF LOADER:.....................................................................................................................ML170

A. Maximum Lift Height to Pivot Pin ................................................................................................11’ 0" (132")

B. Maximum Lift Height under Level Bucket...................................................................................10’ 3" (123")

C. Clearance with Bucket Fully Dumped...............................................................................8’ 6-1/2" (102.50")

D. Reach at Maximum Lift Height (to Grill Guard)...................................................................2’ 8-3/4" (32.75")

E. Maximum Dump Angle.................................................................................................................42 degrees

F. Reach With Bucket on Ground.......................................................................................................7' 2" (86")

G. Maximum Rollback Angle.............................................................................................................26 degrees

H. Digging Depth........................................................................................................................................6-1/4"

J. Overall Height in Carry Position .......................................................................................5’ 5-1/2"* (65.50"*)

L. Bucket Depth........................................................................................................................................25.86"

M. Bucket Height.......................................................................................................................................26.20"

N. Loader Bucket Pin to Front of Front Cutting Edge ...............................................................................33.46"

P. Loader Bucket Pin to Bottom of Front Cutting Edge ..............................................................................9.00"

U. Lift Capacity to Maximum Height at Pivot Pin ................................................................................... 3300 lb.

Y. Breakout Force at Ground Line at Pivot Pin...................................................................................... 5200 lb.

*Top of Arm at Bucket Pivot Pin with Bucket 12" off ground.

CYCLE TIMES 1000 RPM 1500 RPM 2000 RPM 2500 RPM

Raising Time Ground Line to Maximum Lift Height 16.5 sec........11.5 sec..........7.9 sec..........7.2 sec.

Lowering Time Maximum Lift Height to Ground Line 9.6 sec..........9.0 sec...........7.7 sec..........5.2 sec.

Dumping Time Full Rollback to Full Dump without Regen 10.0 sec.........7.8 sec...........5.4 sec.......... 4.5 sec.

Dumping Time Full Rollback to Full Dump with Regen 6.3 sec..........5.7 sec...........5.0 sec..........4.7 sec.

Rollback Time Full Dump to Full Rollback 7.0 sec..........5.6 sec...........3.5 sec..........3.1 sec.

Lift Cylinder Dia........................................................................................................................................................3"

Tilt Cylinder Dia..................................................................................................................................................2-1/2"

Tire Sizes (specifications taken with).................................................Front: 9.5Lx15.......................... Rear: 16.9x28

Relief Valve Setting (Loader Valve) w/o Hyd. Self Level............................................................................... 2600 psi

Relief Valve Setting (Loader Valve) with Hyd. Self Level .............................................................................. 2600 psi

Specifications taken with Mounting Kit, Hose Kit, and 78" Pin On Standard Bucket.

Specifications based on ASAE standards S301.3 and furnished for general information only as they can vary with different tractor

models. Specifications are subject to change without notice and without liability therefore.

1.1. ATTACHMENT SPECIFICATIONS

BUCKET STRUCK CAPACITY RATED SIZE CAPACITY

78" Pin On Material 18.59 cu. ft. 22.82 cu. ft.

14

Page 16

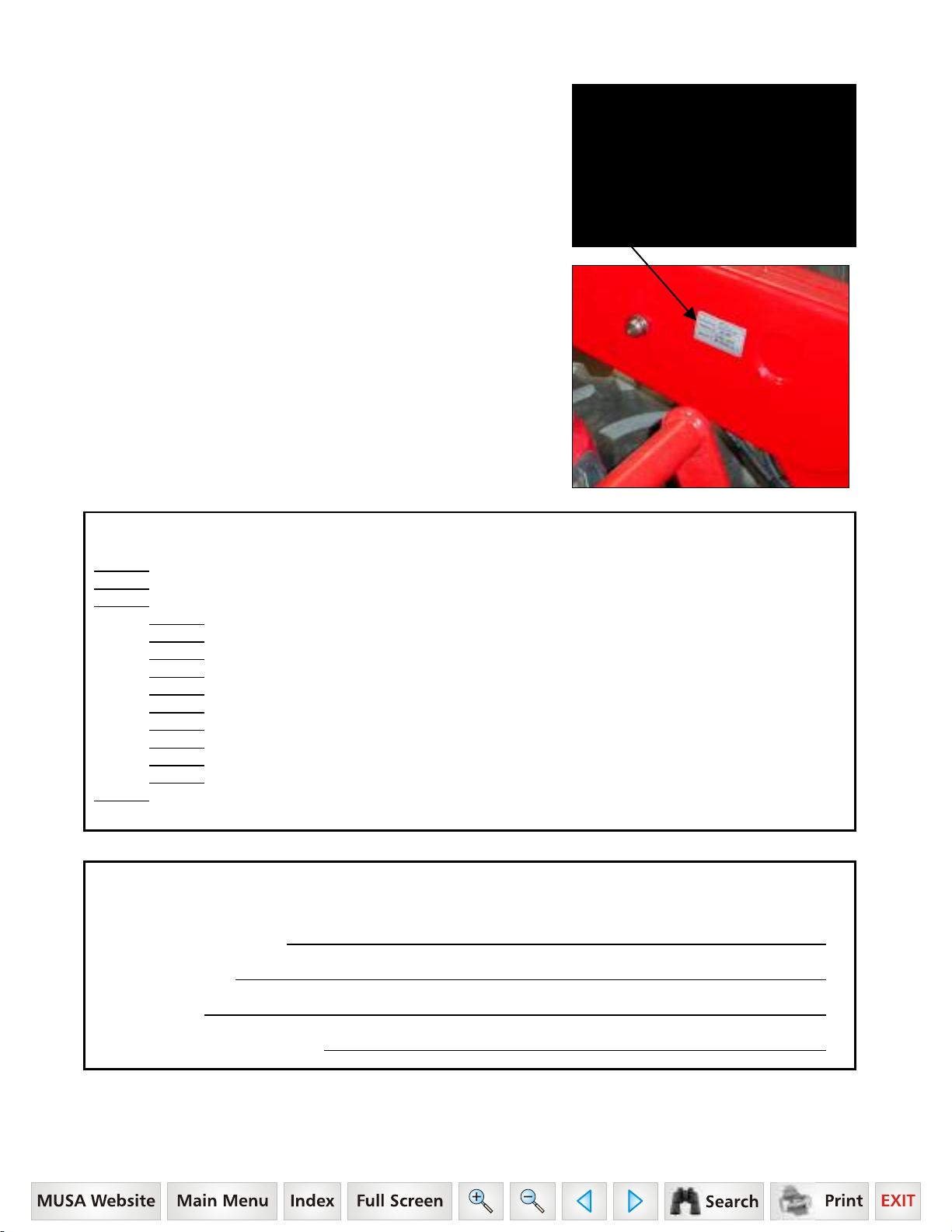

2. INTRODUCTION

This manual provides safety, installation, operation, maintenance,

removing, storing, and reinstalling instructions for your new midmount loader.

Your loader has been designed to give many years of satisfactory

service. Successful operation and long life of the loader depends, of

course, on proper operation and care. Please read this manual

carefully and follow the instructions. Correct operation and

maintenance will save much time and expense.

OBSERVE and follow all CAUTION, WARNING, and DANGER

instructions to help prevent personal injury and damage to the loader.

The reference to right hand (RH) and left hand (LH) used in this

manual refers to the position when standing at the rear of the unit

and facing forward.

If, at any time, you have a service problem with your loader or need

new parts, contact your local Mahindra dealer. Your dealer will need

the loader model number and serial number to give you prompt,

efficient service. The serial number plate is located on the LH inside

front area of boom.

Before operating loader, check that your Dealer has covered the following information with you:

Equipment has been completely assembled as directed.

Equipment has been functionally tested for proper operation.

Purchaser has been instructed in proper & safe operating methods:

Operators Safety Precautions

Tractor Wheel Tread-Tire & Inflation Recommendations

Tractor Hydraulic System & Loader Controls

Rear Ballast Recommendations

Hydraulic System Oil Level

Proper Loader Operation

Loader Removal

Loader Installation

Lubrication - Service Care

Storage

Warranty Coverage & Operators Manual explained to purchaser.

Mahindra ML170 Loader Serial Number Information

LOADER SERIAL NUMBER

DATE PURCHASED

DEALER NAME

AND TELEPHONE NUMBER

15

Page 17

3. INSTALLATION INSTRUCTIONS

CAUTION: Equip your tractor with a ROPS cab or frame for your protection. See your

tractor/ROPS Operator Manual for correct seat belt usage.

Read entire instructions before beginning to install the loader. Personal injury and machine damage may be

prevented if you read and understand these instructions and special safety messages.

When you are in the tractor seat looking forward, the RH and LH sides of the tractor and loader are the same as

your right hand and left hand.

3.1. TRACTOR PREPARATION

3.1.1. Tractor Front Tires

Use front tires of equal size and maintain equal pressure in each tire. The pressure of the front tractor tires must

be increased to the maximum approved pressure recommended by the tire manufacturer to compensate for

additional load placed on the tires with the Front End Loader. See your tractor Operator Manual. Adjust the front

tires to the widest recommended setting on adjustable models for maximum stability. Front end weights must NOT

be used while loader is on the tractor.

3.1.2. Tractor Rear Tires

Maintain equal pressure in each of the rear tires. Use the widest recommended rear wheel setting for maximum

stability.

3.1.3. Tractor Ballast

CAUTION: To help prevent rollover, use recommended rear tractor ballast and widest wheel

settings to maximize stability. See your tractor Operator Manual for recommendations

Front tractor weights must only be used when the loader is parked. Weights must be removed before remounting

loader or serious damage will occur to loader or tractor front axle due to excessive weight.

The use of adequate rear counterweight to counterbalance for maximum loader capacity is required for safe

loader operation. Weight added to the rear of the tractor provides better traction and easier, more efficient loader

operation.

IMPORTANT: Do not exceed the maximum load capacity of the tires on your tractor. See Tire and Wheel

Specifications in tractor Operator Manual for more information.

3.1.4. Remove all loader components from shipping packaging.

WARNING: To avoid serious injury or death: Read before cutting bands or removing attaching

straps. The loader may shift during shipping and handling, making it unstable on the pallet.

Support loader with an overhead hoist or other suitable means prior to removing bands or

attaching straps securing loader to pallet. Failure to do so could result in accidental tip-over of

the loader that could cause serious injury to you and/or bystanders.

CAUTION: Lift and support all loader components safely.

16

Page 18

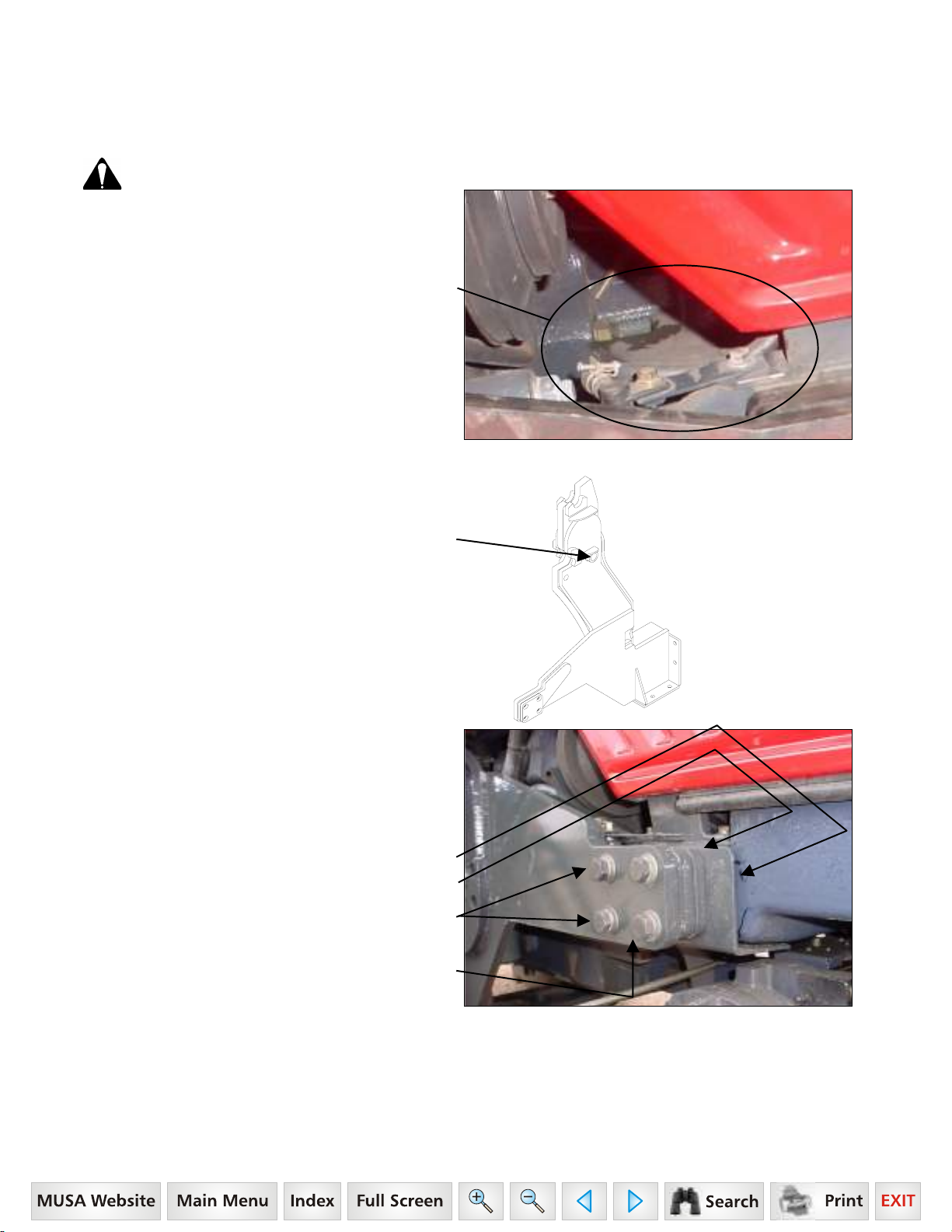

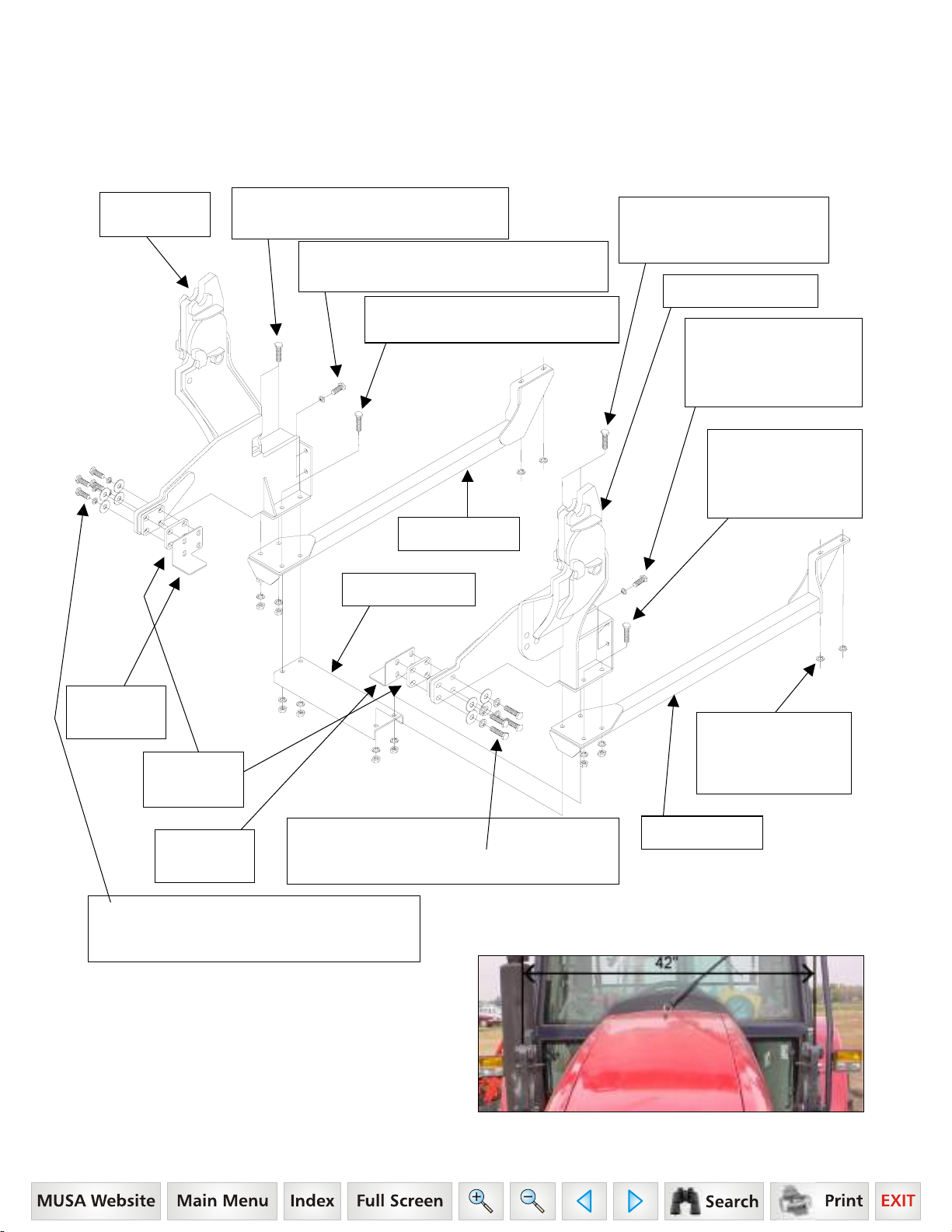

3.2. MOUNTING KIT INSTALLATION

3.2.1. Position the tractor and loader on a hard level surface under a hoist.

3.2.2. Remove front weights from tractor.

IMPORTANT: Do not tighten any hardware until all components are attached onto the tractor.

CAUTION: Lift and support all loader components safely.

3.2.3. Check right hand side of tractor in front axle

area. Reposition components as shown so they will

clear loader bracket.

Reposition components

3.2.4. Position hoist with chain through center bracket

hole to support bracket during installation.

Position hoist with chain

through this hole when

mounting center bracket.

3.2.5. With hoist supporting center bracket, locate

oscillation stop with tab under and toward front of

tractor and 1/2" thick 4-hole spacer between center

bracket and tractor. Install 16mm x 2.0P x 90mm hex

bolts Grade 10.9, 5/8" lockwashers, and 5/8"

flatwashers, 4 places. Do not remove hoist.

Oscillation Stop

Spacer, 4-Hole

16mm x 2.0P x 90mm Grade 10.9 Hex Bolt,

5/8" Lockwasher, and 5/8" Flatwasher,

4 places.

Center Bracket

17

Page 19

3.2.6. With hoist supporting Center Bracket

center bracket, install

16mm x 2.0P x 30mm

Grade 8.8 hex bolts

and 5/8" lockwashers,

2 places inside and

2 places outside

of bracket in front

area of cab.

Do not remove hoist.

3.2.7. From rear axle, remove inside set of bolts and

lockwashers securing 3-point components to rear axle.

Save hardware.

Position of bolts to be removed

one on each side of axle.

16mm x 2.0P x 30mm Grade 8.8

Hex Bolt and 5/8" Lockwasher,

2 places inside (shown in illustration) and

2 places outside (shown in photo).

3.2.8. Install rear rail to center bracket using 5/8" x

1-3/4" hex bolts Grade 5, lockwashers, and hex nuts,

2 places outside only.

Center Bracket

5/8" x 1-3/4" Hex Bolt Grade 5,

5/8" Lockwasher, and 5/8" Hex Nut.

2 places outside only.

Rear Rail

18

Page 20

3.2.9. Install rear rail to rear axle as shown re-using

bolts and lockwashers just removed along with 1/2"

flatwashers included with mounting kit.

Position of bolts previously removed.

Tractor Bolt and Lockwasher along with

Mounting Kit 1/2" Flatwasher, 2 places each side

Rear Rail, 1 place each side

3.2.10. Remove hoist from center bracket.

3.2.11. Install opposite brackets using previous

instructions.

3.2.12. Install crossbrace to RH and LH center brackets

using 5/8" x 2" hex bolts Grade 5, lockwashers,

flatwashers, and hex nuts, 2 places Inside only.

RH Center Bracket

5/8" x 2" Hex Bolt Grade 5,

5/8" Lockwasher, and 5/8" Hex Nut,

2 places each side inside only

RH Rear Rail

Crossbrace

3.2.13.

5/8" x 1-3/4" hardware, securing rear rail to center

bracket is located in outside 2 holes.

5/8" x 2" hardware, securing crossbrace and rear rail to

center bracket is located in inside 2 holes.

NOTE: Do not tighten any of the crossbrace

hardware until all other mounting bracket hardware

is torqued to specifications.

CRITICAL: Torque all mounting kit hardware.

Reference Photo:

RH Rear Rail

Crossbrace

5/8" x 2" hardware,

inside 2 holes each side

LH Rear Rail

5/8" x 1-3/4" hardware,

outside 2 holes each side

19

Page 21

p

,

A. Identify hardware size and grade.

B. Refer to Torque Chart, page 78 and find correct torque for your hardware size and grade.

C. Torque hardware to this specification unless otherwise specified.

IMPORTANT NOTE: To keep mounting kit hardware from loosening during loader operation, hardware

must be torqued to specifications.

Center

Bracket RH

5/8" x 1-3/4" Hex Bolt, Lockwasher,

and Hex Nut, 2 places each side.

16mm x 2.0P x 30mm Hex Bolt Grade 8.8

and 5/8" Lockwasher, 4 places each side.

5/8" x 2" Hex Bolt, Lockwasher,

and Hex Nut

2 places each side.

5/8" x 2" Hex Bolt,

Lockwasher, and Hex Nut,

2 places each side.

Center Bracket LH

16mm x 2.0P x 30mm

Hex Bolt Grade 8.8

and 5/8" Lockwasher,

4 places each side.

5/8" x 1-3/4" Hex

Bolt, Lockwasher,

and Hex Nut

2 places each side.

Oscillation

Stop LH

1/2" 4-Hole

Spacer

16mm x 2.0P x 90mm Hex Bolt Grade 10.9,

5/8" Lockwasher, and 5/8" Hardened

Flatwasher, 4 places each side.

Oscillation

Stop RH

16mm x 2.0P x 90mm Hex Bolt Grade 10.9,

5/8" Lockwasher, and 5/8" Hardened

Flatwasher, 4 places each side.

Rear Rail RH

Crossmember

1/2" Hardened

Flatwasher plus

Tractor Hardware,

2

laces each side.

Rear Rail LH

3.2.14. Verify outside surface of brackets are level and

the centerline measurement from RH to LH towers

reads 42" plus or minus 3/8".

20

Page 22

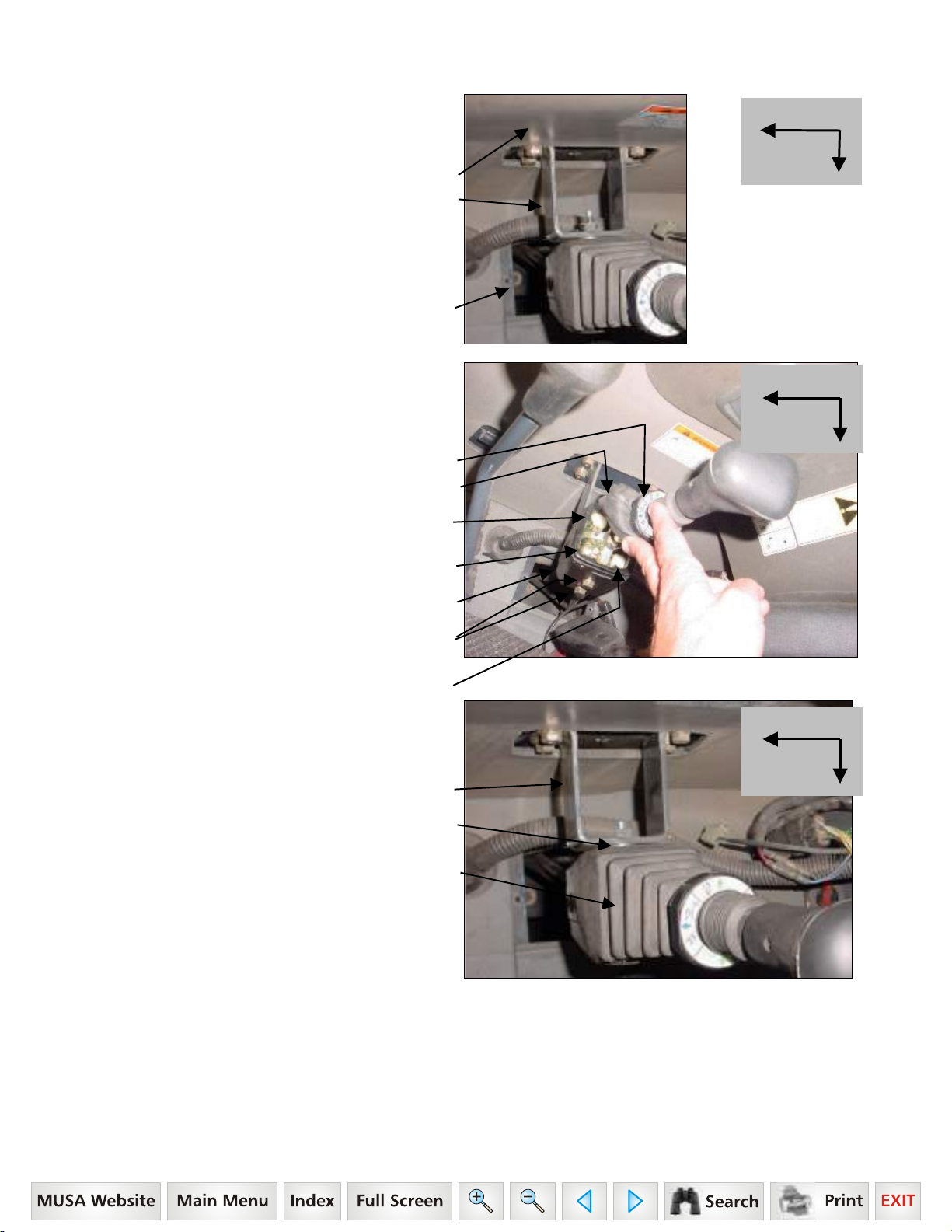

3.3. HYDRAULIC INSTALLATION

r

r

r

3.3.1. Remove RH cab console components to reveal

existing console bracket. Save console components

and console hardware.

RH Cab Wall

Existing Console Bracket

(installed on tractor).

3.3.2. Remove RH cab floor plate cover to reveal

opening to outside of cab. Save floor hardware.

Front of Tracto

Center

of Cab

Cab Floor Opening.

3.3.3. Peel rubber boot back from controller to

expose controller linkage. Position single lever

controller with cables so solid post is positioned

toward front and center of tractor.

Float part of decal faces toward front of tractor.

Rubber Boot, in raised position.

Lift Cable controls Raise & Lift

functions of Loader.

Solid post positioned toward

front and center of tractor.

Single Lever Controller.

8mm x 80mm Hex Bolt Grade 10.9 and

5/16" Lockwasher, 2 places.

Tilt Cable controls Dump & Rollback

functions of Attachment.

3.3.4. Install single lever controller to existing console

bracket using 8mm x 80mm hex bolts Grade 10.9

and 5/16" Lockwashers.

Existing Console Bracket

Front of Tracto

Center

of Cab

Front of Tracto

Center

of Cab

Two 5/16" spacer flatwashers

on top bolt only.

Single Level Controller

with pre-assembled Cables.

21

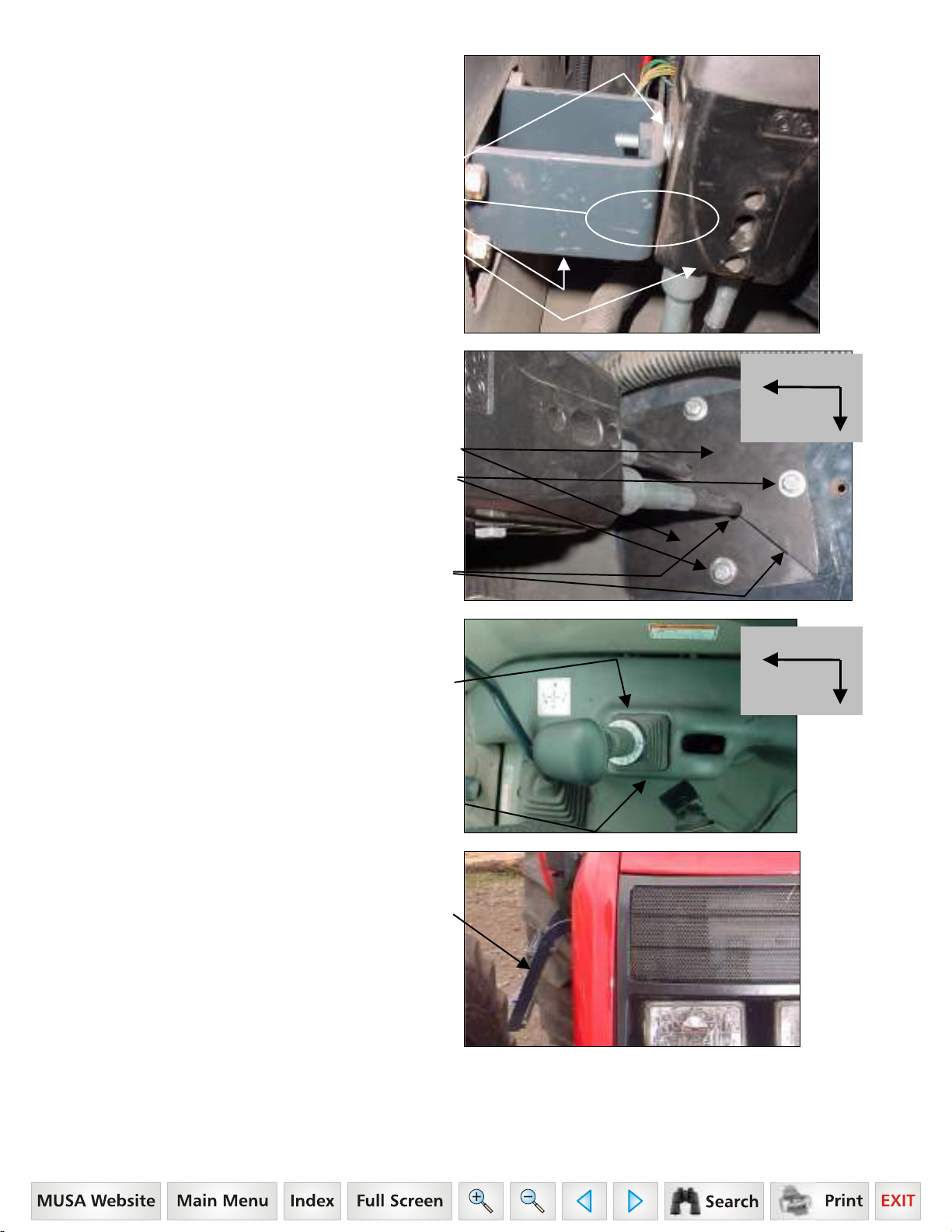

Page 23

IMPORTANT NOTE: Two flatwashers must be

r

r

used on top bolt between controller and console

bracket to tilt handle toward operator. Do not use

flatwashers on bottom bolt.

Two 5/16" spacer flatwashers

on top bolt only.

No Flatwashers on bottom bolt.

Existing Console Bracket

Single Level Controller

3.3.5. Route cables down through cab floor opening.

Install new triangle floorboard plates around cables

re-using floor hardware just removed.

Triangle Floorboard Plates.

Re-use floor hardware.

3.3.6. Apply silicone sealant around cables and

between triangle plates to reduce air and dust leaks.

Silicone sealant

must be supplied by installer.

3.3.7. Reposition rubber boot over single level

controller.

Rubber Boot repositioned.

3.3.8. Reinstall cab console components and secure

using console hardware.

Front of Tracto

Center

of Cab

Front of Tracto

Center

of Cab

Cab Console Components Reinstalled

3.3.9. Remove RH cab step. Save step and step

hardware.

RH Cab Step

22

Page 24

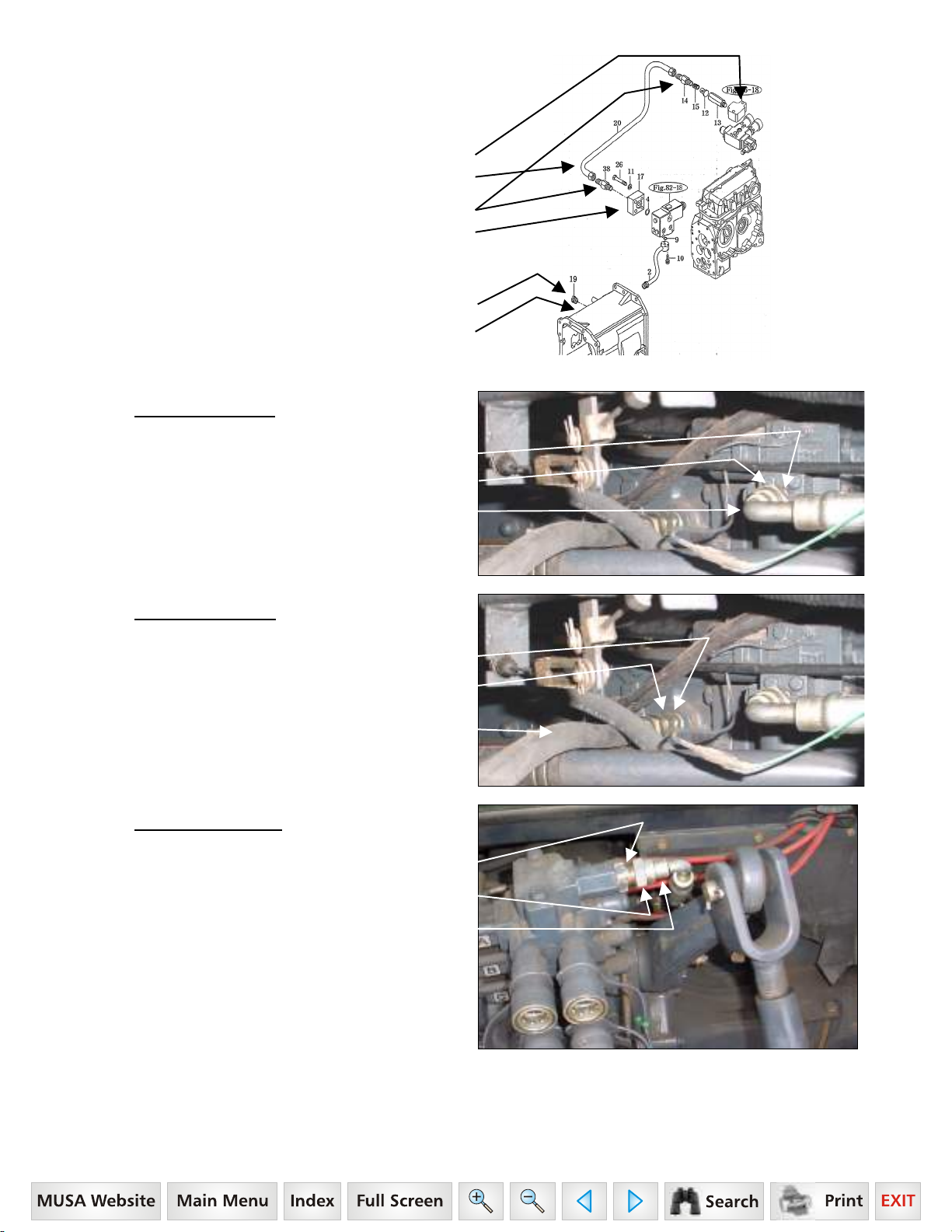

3.3.10. From RH side of tractor underneath cab,

remove hydraulic hose connecting tractor pressure port

to tractor power beyond port. Keep tractor fittings in

place.

Tractor Power Beyond Port Location.

Tractor Hose – Remove.

Tractor Fittings – Do Not Remove.

Tractor Pressure Port Location.

3.3.11. Remove plug from tractor transmission port.

Tractor Plug – Remove.

Tractor Transmission Port

3.3.12. Pressure "IN" Line:

Install 17" hose to tractor

straight fitting in tractor pressure port.

Tractor Pressure Port

Tractor Straight Fitting

Hose 1/2" x 17"

BSPP F 1/2" 90

3.3.13. Return "OUT" Line:

Install fitting and 25" hose

to tractor return port.

Tractor Return Port

Fitting Straight

BSPT F 1/2" x JIC M 7/8"

Hose 1/2" x 25"

JICF 7/8" X JICF 3/4" 90

3.3.14. Power Beyond Line:

Install 60" hose to tractor

straight fitting in tractor power beyond port.

o

x JICF 3/4"

o

Tractor Power Beyond Port

Tractor Straight Fitting

Hose 1/2" x 60"

BSPT M 1/2" 90

o

x JICF 3/4"

NOTE: Do not start tractor engine until these hoses are installed and secured to the loader valve.

23

Page 25

3.3.15. Loaders That Are Not Equipped With Hydraulic Self Leveling: Rotate loader valve so that Port "D" is

upward. Install orifice fitting by dropping it into Port "D" with slot of orifice facing upward. Screw fitting into Port "D"

to secure orifice into port. (Do not install orifice on Loaders equipped with Hydraulic Self Leveling.)

Port "D" in Loader Valve. Orifice (slot upward). Fitting Straight ORBM 3/4" x ORBM 3/4".

Port "D" in Loader Valve.

3.3.16. Install fittings to valve as follows:

(2) (1)

Power Beyond side of valve.

Port "C" Tilt Cylinder Base End

Yellow Tie

Port "D" Tilt Cylinder Rod End

Red Tie

Port "B" Lift Cylinder Rod End

Blue Tie

Port "A" Lift Cylinder Base End

Green Tie

NOTE: Do not tighten power beyond or pressure

hose until they are connected to tractor.

(3)

(1) Port "A", "B", "C", & "D":

Fitting Straight ORBM 3/4"

x ORBM 3/4".

(2) Port "D":

Install Male Quick Coupler,

Install

Power Beyond Port Return "OUT" Port

only into Port "D".

(3) Port "A", "B", & "C":

Install

Female Quick Coupler,

into remaining three ports.

(4) Power Beyond Port:

o

90

JICM 3/4" x ORBM 3/4".

Install Fitting

(6) Return "OUT" Port:

Install Fitting

Straight JICM 3/4" x ORBM 7/8".

(7) Pressure "OUT" Port:

o

90

JICM 3/4" x JICF 3/4".

Install Fitting

(8) Pressure "IN" Port:

Install Fitting

Straight JICM 3/4" x ORBM 7/8".

(9) Pressure "IN" Port:

o

90

JICM 3/4" x JICF 3/4".

Install Fitting

No Relief Plug installed at Factory

Pressure "IN" Port

Tilt

Spool

Lift

Spool

No Relief

Plug

installed

at Factory

(4)

(7)

(6)

(8)

(9)

24

Page 26

3.3.17. Install valve mount to tractor mount located

r

under RH side of cab behind cab step that was just

removed. Secure using 8mm x 20mm hex bolt and

5/16" lockwasher, 3 places.

Valve Mount

8mm x 1.25P x 20mm Hex Bolt

and 5/16" Lockwasher,

3 places.

Tractor Mount

Front of Tracto

3.3.18. Install valve to valve mount under RH side of

cab using 5/16" x 1" hex bolt and 5/16" lockwasher,

3 places.

Valve

5/16" x 1" Hex Bolt

and 5/16" Lockwasher,

3 places.

Valve Mount

3.3.19. Identify and trace cables from Single Lever

Controller.

Raise and Lower (Lift) Cable is Frontward Cable

Dump and Rollback (Tilt) Cable is Rearward Cable

3.3.20. Install raise and lower (lift) cable to upper spool

of valve and dump and rollback (tilt) cable to lower

spool of valve as follows. Refer to photo and illustration

following.

Front of

Tractor

Center of Cab

25

Page 27

A. Thread large jam nuts entire length of threaded hubs

and onto cables.

B. Place dual flange over both cables.

C. Thread sleeves entire length of threaded hubs and

onto cables.

D. Thread small jam nuts onto cable threaded rods until

they bottom out on threads.

E. Place connectors onto threaded rods and against jam

nuts. Align connectors so they will mate with spool

terminal eyes and secure jam nuts against connectors.

F. Slide connectors onto spools and align the holes.

Insert pins through connectors and spool holes.

G. With cables attached to valve and single handle

controller, turn the sleeves onto threaded hubs until

they are flush with the valve face.

NOTE: When turning the sleeves, make sure the single

handle controller remains in the neutral position.

H. Tighten large nuts against sleeves to lock in position.

I. Slide dual flange into position and secure using socket

head cap screws and flatwashers.

NOTE: Over-tightening will distort flange.

Install Install

Dump and Rollback Raise and Lower

(Tilt) Cable to (Lift) Cable to

Lower Spool of Valve Upper Spool of Valve

NOTE: Controller handle can be repositioned slightly

by tightening or loosing sleeves.

Socket Head

Cap Screw and

Flatwasher

Cable

Threaded Hub

Dual Flange

Dual Flange Pin Connector Small Nut Sleeve Large Nut

Socket Head Cap Screw/Flatwasher Spool Terminal Eye Threaded Hub Cable

26

Page 28

Cable Adapter Group

Valve

Pressure

"IN" Port

Return

"OUT" Port

Single Lever

Controller

Solid Post – located

front and center of

Tractor

Triangle Floorboard

Plates

Raise and Lower

(Lift) Cable Frontward

Dump and Rollback

(Tilt) Cable Backward

Pressure "IN" Line

17" hose (opposite of

power beyond port)

Return "OUT" Line

25" hose

Return "OUT" Line

Fitting

Power Beyond Line

60" hose

3.3.21. Route 17" pressure hose to fittings in pressure

port of valve.

17" Pressure Hose

3.3.22. Route 25" return hose to fittings in return port of

valve.

25" Return Hose

3.3.23. Route 60" power beyond hose to fitting in power

beyond port of valve.

60" Power Beyond Hose

3.3.24. Remove all twists from hoses then tighten

hydraulic connections.

3.3.25. Check that all hydraulic connections have been

tightened.

3.3.26. Reinstall RH cab step reusing cab step

hardware.

Cab Step Hardware

Raise and Lower (Lift) Cable

Dump and Rollback (Tilt) Cable

RH Cab Step

27

Page 29

3.4. LOADER INSTALLATION

3.4.1. Remove all loader components from shipping package.

CAUTION: Lift and support all loader components safely.

IMPORTANT: Do not extend tilt cylinders without attachment pinned to loader. Failure to follow these

instructions could cause loader damage and void warranty.

3.4.2. Loader valve hoses and quick couplers have been pre-assembled on loader. Unwrap these hoses by

cutting nylon ties securing them to side of loader.

3.4.3. Before installing loader to tractor, use a hoist to install pin on

bucket or pin on attachment and bucket or skid steer attachment

and bucket on loader. Secure using pins and e-clips, 4 places.

Top Pin 1-1/8" x 7.01",

Grease Fitting 1/4"-28 and E-Clip,

1 place each side.

Bottom Pin 1-1/8" x 7.01",

Grease Fitting 1/4"-28 and E-Clip,

1 place each side.

Refer to Section 10 for Pin On Bucket, page 49.

Refer to Section 11 for Pin On Bale Spear, pages 50 to 51.

Refer to Section 12 for Pin On Pallet Fork, pages 52 to 53.

Refer to Sections 13 to 16 for Optional Pin On Quick Attach System, pages 54 to 59.

Refer to Sections 17 to 20 for Optional Skid Steer Tool Carrier System, pages 60 to 67.

3.4.4. Following these instructions will add stability to loader package and will allow easier handling of loader with

hoist.

3.4.5. Support the loader by using a hoist. Install loader to mounting brackets previously installed on tractor.

Refer to Section 8 — Mounting the Loader, pages 45 to 47.

CAUTION: Lift and support all loader components safely.

28

Page 30

3.5. CONNECT HYDRAULICS

3.5.1. Verify all working port hose connections.

(C) Connect Port "C" to Tilt Cylinder Base End

(D) Connect Port "D" to Tilt Cylinder Rod End

(B) Connect Port "B" to Lift Cylinder Rod End

(A) Connect Port "A" to Lift Cylinder Base End

(1) "PBY" Power Beyond Port.

(2) "OUT" Return Port.

(3) "IN" Pressure Port.

(4) Loader Valve.

3.5.2. Using color nylon ties, install one on each quick coupler fitting. These color ties will allow easy identification

of loader circuits when mounting and dismounting loader.

Port "A" – Green Tie

Lift Cylinder Base End

Port "B" – Blue Tie

Lift Cylinder Rod End

Port "D" – Red Tie

Tilt Cylinder Rod End

Port "C" – Yellow Tie

Tilt Cylinder Base End

Port "A" – Green Tie

Lift Cylinder Base End

Port "B" – Blue Tie

Lift Cylinder Rod End

Port "D" – Red Tie

Tilt Cylinder Rod End

Port "C" – Yellow Tie

Tilt Cylinder Base End

IMPORTANT: Valve Port "C" must be connected to Tilt Cylinder Base End port and Valve Port "D" must

be connected to Tilt Cylinder Rod End port or else Regen Function of Valve will not work correctly.

CAUTION: When properly installed, the external valve handle will control loader hydraulic circuits

as described in Item 4.4, page 32.

29

Page 31

3.6. BUCKET LEVEL INDICATOR

3.6.1. Install bucket level

indicator rod assembly into

bucket level indicator tube

assembly.

3.6.2. Attach bucket level

indicator tube assembly to

base end of RH tilt cylinder

using 5/16 x 1-1/2" hardware.

3.6.3. Attach bucket level

indicator rod assembly to rod

end RH tilt cylinder using

5/16" x 1/2" hardware.

3.6.4. Adjust bucket level tube

for proper alignment with

bucket level rod by sliding

slotted bracket to desired

position and tightening bolt.

3.6.5. After installing loader on tractor, position loader on

ground with bucket flat, then paint or mark end of bucket

level indicator rod so operator can identify when bucket

is level on ground.

Hex Bolt 5/16"

x 1-1/2" Grade 5,

5/16" Lockwasher,

and 5/16" Flatwasher

Bucket Level

Indicator Tube

Assembly

Bucket Level

Indicator Rod

Assembly

Hex Bolt 5/16"

x 1/2" Grade 5 and

5/16" Lockwasher

Paint or

mark

end of

BLI rod.

3.7. STEERING STOP

3.7.1. Set steering stop out to a maximum of 29/32"

between top of nut and top of bolt head.

29/32"

30

Page 32

4. PRE-OPERATION INSTRUCTIONS

4.1. HYDRAULIC FLUID

Check the tractor hydraulic fluid level and fill, if required.

4.2. INITIAL LOADER OPERATION

NOTE: If any loader cavitation is noticed during loader operation, check tractor hydraulic fluid level and

correct.

NOTE: Keep engine speed at low idle during the initial loader operation.

CAUTION: Escaping hydraulic fluid under

pressure can have sufficient force to

penetrate skin, causing serious personal

injury. Before disconnecting lines, be sure

to relieve all pressure.

Before applying pressure to system, be

sure all connections are tight and that lines,

tubes, and hoses are not damaged.

Fluid escaping from a very small hole can

be almost invisible. Use a piece of

cardboard or wood, rather than hands, to

search for suspected leaks.

If injured by escaping fluid, see a doctor at

once. Serious infection or reaction can

develop if proper medical treatment is not

administered immediately.

Cardboard

Hydraulic

Line

Magnifying

Glass

4.3. EXTERNAL LOADER VALVE

CAUTION: When properly installed, the loader valve handle will control loader hydraulic circuits

as described below.

IMPORTANT: Contaminants in hydraulic fluid can cause valve spools to stick. BE ALERT when operating

loader and follow your tractor Operator Manual hydraulic fluid maintenance schedule.

31

Page 33

4.4. LOADER MOUNTED VALVE EQUIPPED WITH SINGLE HANDLE CONTROLLER

ON A LOADER NOT EQUIPPED WITH HYDRAULIC SELF LEVEL OPTION

LOADER WITHOUT SELF LEVEL VALVE:

4.4.1.

single handle control and it will function as described.

Number 3 Position:

Push the handle full forward

to activate float position.

Number 2 Position:

Push the handle forward

to lower loader.

Number 1 Position:

Pull the handle back

to raise loader.

Your loader utilizes a loader mounted valve equipped with

Number 5 Position:

Push the handle outward

to dump attachment.

Number 6 Position:

Push the handle full outward

to activate regen position

which will dump attachment

at a faster rate.

Number 4 Position:

Pull the handle inward

to roll back attachment.

Decal Operation Illustration

View of Decal from

front side of handle

Neutral Lock Position Buttons

View of Decal from

back side of handle

Controller Collar

4.5. NEUTRAL POSITION

The loader external valve has a "neutral position" which prevents movement of the loader or attachment. When

the valve handle is manually released from the work position, the valve spool will return to the neutral position.

4.6. NEUTRAL LOCK POSITION

Push collar down to lock controller into neutral position — Red button is out when neutral position is locked.

Lift collar up to unlock controller from neutral position — Green button is out when neutral position is unlocked.

4.7. FLOAT POSITION

The loader valve has a "float position" incorporated into the lift cylinder circuit which allows the loader to float. This

float feature is important for satisfactory operation when scraping, sweeping, leveling, or any job where it is

necessary to follow the contour of the surface. To activate float position, lower the bucket or attachment and push

the valve handle all the way forward into detent. The valve will stay in float detent position until the operator

manually pulls the valve handle out of detent position to deactivate float.

32

Page 34

4.8. REGENERATIVE DUMPING POSITION

The loader valve has a "Feel Position Regenerative Spool" incorporated in the attachment spool. The tilt cylinders

must be connected to this spool allowing the operator to choose normal dump or fast dump during loader

operation.

NOTE: Use normal dump position when digging with loader. This will allow operator to put full tractor

weight on cutting edge during this operation. The regenerative function can then be used when dumping

load from bucket.

NOTE: Valve circuits must be hooked up correctly to allow regen to operate correctly.

IMPORTANT: If the bucket or attachment does not operate as indicated on the directional decal, lower the

bucket to the ground, stop the engine, and relieve all hydraulic pressure. Recheck hydraulic circuits

hookup to loader valve and correct.

NOTE: Use of regen function during dumping will eliminate attachment cylinder cavitation, which will

reduce or eliminate any free movement of bucket or attachment during loader operation.

CAUTION: Do not tamper with relief valve setting. The relief valve is pre-set at the factory.

Changing the setting can cause overloading of the loader and tractor, which may result in serious

injury.

4.9. INITIAL LOADER OPERATION

NOTE: Keep engine speed at low idle during the initial loader operation.

Before operating the loader, fully raise and lower the boom two or three times. Then raise the loader bucket

approximately four (4) feet above the ground and cycle the tilt cylinders two or three times. Lower the bucket or

attachment to the ground. Check the tractor hydraulic fluid level and fill as required. Refer to the tractor Operator

Manual for the proper hydraulic fluid and the correct hydraulic fluid level.

CAUTION: Before leaving the tractor seat, lower attachment or loader boom to ground, stop

engine, lock brakes, relieve hydraulic pressure, and remove key.

IMPORTANT: Always keep the cylinders in a retracted position when the loader is not in use to guard

against rust and contamination which may cause damage to the cylinder rods and hydraulic system.

4.10. REMOVING AIR FROM HYDRAULIC SYSTEM

Repeat raising and lowering the loader boom and bucket until all the air is removed from the system and the

system responds properly.

Check the tractor hydraulic fluid level and fill, if required.

4.11. RELIEF NOISE

When operating loaders at high RPMs with orifice installed in attachment circuit, some hydraulic oil will go over

pressure relief. This could cause some relief noise from relief cartridge, which is normal.

33

Page 35

5. DAILY MAINTENANCE & LUBRICATION

5.1. DAILY CHECKS

5.1.1. Check all hardware daily before operation. Tighten hardware to torque values as specified in the Torque

Chart, page 78 unless otherwise specified.

IMPORTANT NOTE: To prevent mounting kit hardware from loosening during operation always torque

mounting kit hardware to specified torque noted in Loader Operator Manual. Check bolt torque every 50

hours of loader operation.

5.1.2. With the engine off and the bucket on the ground, inspect all hoses for cuts or wear. Check for signs of

leaks and make sure all fittings are tight.

CAUTION: Escaping hydraulic fluid under

pressure can have sufficient force to

penetrate skin, causing serious personal

injury. Before disconnecting lines, be sure

to relieve all pressure.ı Before applying

pressure to system, be sure all connections

are tight and that lines, tubes, and hoses

are not damaged.ı Fluid escaping from a

very small hole can be almost invisible. Use

a piece of cardboard or wood, rather than

hands, to search for suspected leaks.ı If

injured by escaping fluid, see a doctor at

once. Serious infection or reaction can

develop if proper medical treatment is not

administered immediately.

5.1.3. Service your loader at the intervals and locations as specified. When you service your loader, use only high

quality lubricants. The engine hour meter on the tractor shows the amount of hours the engine has worked. Use

the hour meter to service your loader at the correct time periods.

Cardboard

Hydraulic

Line

Magnifying

Glass

IMPORTANT: Lower the loader boom to the ground and relieve pressure in loader hydraulic lines prior to

doing any service or maintenance operations on the tractor or loader.

Check the tractor hydraulic fluid level as specified in the tractor Operator Manual.

NOTE: When checking hydraulic system fluid level, the loader boom must be on the ground with the

bucket or attachment resting flat on a level surface.

5.2. LOADER LUBRICATION

5.2.1. There are 16 grease fittings on this loader, one at each pivot. Lubricate pivots as specified.

CAUTION: Do not stand, walk, or work under a raised loader or attachment unless it is securely

blocked or held in position. Accidental movement of the valve handle/handles or leaks in the

hydraulic system could cause the loader to drop, or attachment to dump, causing severe injury.

5.2.2. Lower loader boom until bucket or attachment

rests on ground, and relieve all hydraulic pressure

before lubricating.

(1) Lubricate these 16 pivot points

every 10 hours of operation.

NOTE: Lift Cylinder Rod End Grease Zerk

must face downward.

34

Page 36

5.2.3. During initial setup, and as required; apply a

small amount of grease to each tower in areas of tower

bottom receiver (A), tower top receiver (B), and handle

pin bushing (C). This will aid in parking loader.

Tower

5.2.4. Before servicing your tractor, always do one of the following.

. Park the loader off of the tractor. B. Position loader with bucket and/or attachment

level with ground, then relieve all hydraulic

pressure.

CAUTION: Do not stand, walk, or work under a raised loader or attachment unless it is securely

blocked or held in position. Accidental movement of valve handle/handles or leaks in the

hydraulic system could cause the loader to drop, or attachment to dump, causing severe injury.

5.2.5. Clean area identified with arrow of all

material if build up occurs during operation. This

will prevent damage to loader components.

NOTE:

Clean this

area of all

material if

build up

occurs

during

operation.

35

Page 37

5.3. SERVICE AREAS

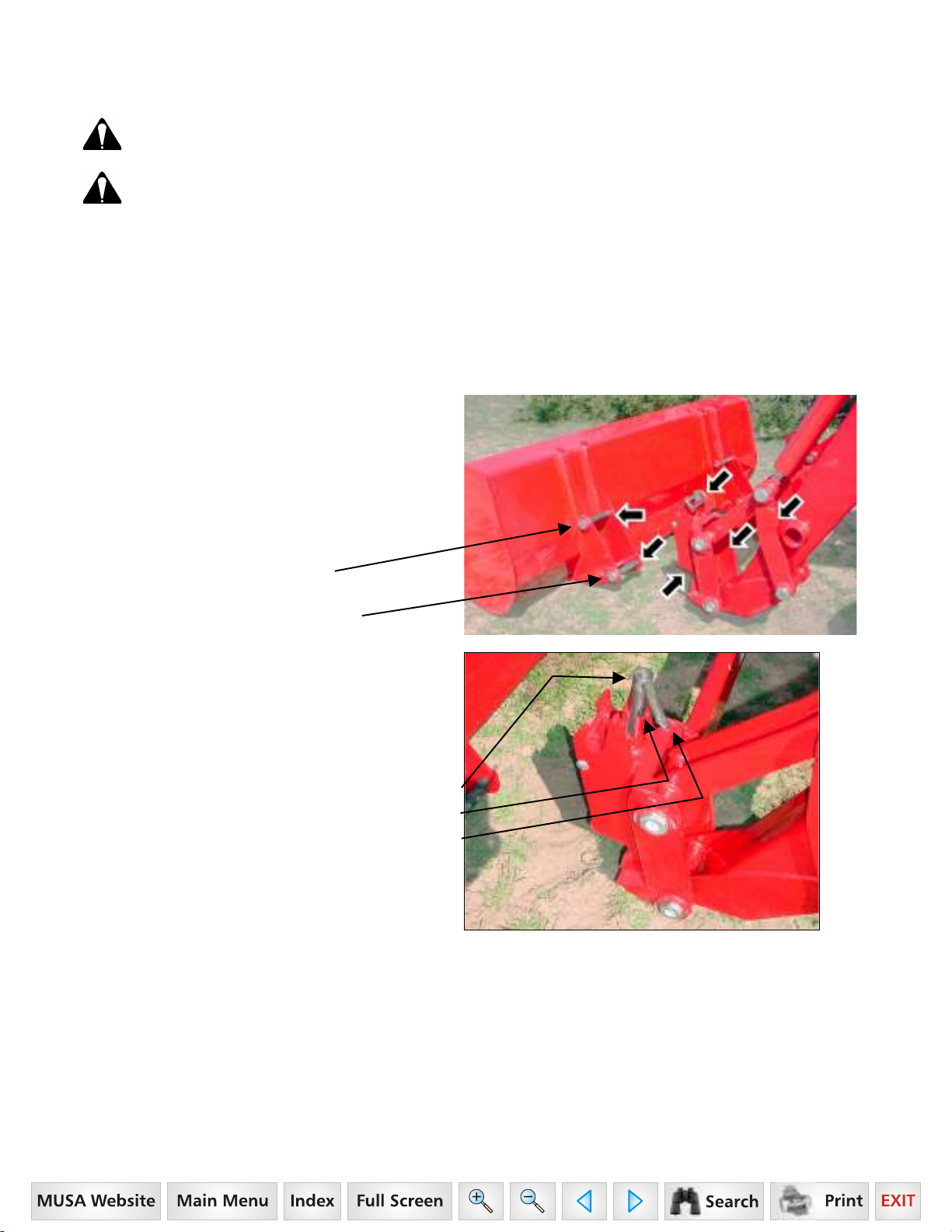

RH SIDE SERVICE NOTE:

5.3.1.

is replaced, always locate and secure hose as shown

in photo to prevent hose from being pinched between

loader and cylinder causing damage to hose.

NOTE: Route hoses so they either do not contact

notch area or they only rest against notch area.

Do not twist hoses so they are pulled against

notch area.

If a lift cylinder hose

RH Lift Cylinder Base End Hose

RH Lift Cylinder Rod End Hose

Nylon Ties

LH SIDE SERVICE NOTE:

5.3.2.

is replaced, always locate and secure hose as shown

in photo to prevent hose from being pinched between

loader and cylinder causing damage to hose.

LH Lift Cylinder Rod End Hose

LH Lift Cylinder Base End Hose

If a lift cylinder hose

Nylon Ties

36

Page 38

6. OPERATING INSTRUCTIONS

The loader should be operated with the tractor engine running from 1700 to 2200 rpm. Excessive speeds are

dangerous, and may cause bucket spillage and unnecessary strain on the tractor and loader.

When operating in temperatures below 30

temperature exceeds 30

The following text and illustrations offer suggested loader and tractor operating techniques.

o

F.

6.1. FILLING THE BUCKET

Approach and enter the pile with a level bucket. Then

rollback and lift the bucket.

The rollback and lifting of the bucket will increase

efficiency because a level bucket throughout the lifting

cycle resists bucket lift and increases breakaway effort.

NOTE: Do not be concerned if the bucket is not

completely filled during each pass. Maximum

productivity is determined by the amount of

material loaded in a given period of time. Time is

lost if two or more attempts are made to fill the

bucket on each pass.

6.2. LIFTING THE LOAD

When lifting the load, keep the bucket positioned to

avoid spillage.

CAUTION: Do not attempt to lift bucket or

attachment loads in excess of the loader

capacity.

o

F, run the tractor engine below 1200 rpm until the hydraulic fluid

6.3. CARRYING THE LOAD

Position the loader in a low position when transporting

a loaded or empty bucket or attachment.

Use extreme care when operating the loader on a

slope. Keep the bucket as low as possible. This keeps

the bucket and tractor center of gravity low and will

provide maximum tractor stability.

CAUTION: Operating the loader on a

hillside is dangerous and is not

recommended.

When transporting a load, keep the bucket as low as

possible to avoid tipping, in case a wheel drops in a rut.

37

Page 39

6.4. DUMPING THE BUCKET

Lift the bucket just high enough to clear the side of the

vehicle. Move the tractor in as close to the side of the

vehicle as possible, then dump the bucket.

6.5. LOWERING THE BUCKET

After the bucket is dumped, back away from the vehicle

while lowering and rolling back the bucket.

6.6. OPERATING WITH FLOAT CONTROL

During operation on hard surface, keep the bucket level

and position the lift control in the float position to permit

the bucket to float on the work surface.ı If hydraulic

down pressure is exerted on the bucket, the cutting

edge will wear faster than normal.

The float position will also avoid mixing of surface

material with stockpile material. The float position will

reduce the chance of surface gouging while removing

snow or other material, or when working with a blade.

6.7. LOADING FROM A BANK

Choose a forward gear that provides a safe ground

speed and power for loading.

CAUTION: Exercise caution when

undercutting high banks. Dirt slides can be

dangerous. Load from as low as possible

for maximum efficiency. Loader lift and

breakaway capacity diminish as loading

height is increased.

Side cutting is a good technique for cutting down a big

pile.

If the pile sides are too high and liable to cause cave-in,

use the loader to break down the sides until a slot can

be cut over the top.

Another method for large dirt piles is to build a ramp

approach to the pile.

38

Page 40

It is important to keep the bucket level when

approaching a bank or pile. This will help avoid gouging

the work area.

6.8. PEELING AND SCRAPING

Use a slight bucket down angle, travel forward, and

hold the lift control forward to start the cut. Make a

short cut and breakout cleanly.

With the bucket level, start a cut at the notch

approximately 2 in. deep. Hold the depth by feathering

the tilt control to adjust the cutting edge up or down.

When the front tires enter the notch, adjust the lift

cylinder to maintain proper depth.

Make additional passes until the desired depth is

reached. During each pass, use only the tilt control

while at working depth. This will allow you to

concentrate on controlling the bucket angle to maintain

a precise cut.

6.9. LOADING LOW TRUCKS OR

SPREADERS FROM A PILE

For faster loading, minimize the angle of turn and

length of run between pile and spreader.