Page 1

JINMA SERIES TRACTOR

OPERATION MANUAL

JINMA-200

JINMA-204

JINMA-250

JINMA-254

JINMA-300A

JINMA-304A

MAHINDRA YU EDA

(YANCHENG) TRACTOR CO.,LTD

.

Page 2

1

Preface

Jinma series wheeled tractors

(、、、、

JM-200 JM-204 JM-250 JM-254 M-

、)

300A JM-304A

are small four wheel tractors of new type , which are developed

according to the increasingly rising demands of dometic and overseas agricultural

machinery for small new wheeled tractors . The tractors have the characteristics of

saving energy , high efficiency , varied purpose ,beautiful appearance . If you buy

them , you wil l get satisfactory economic pro fit from them .

Jinma series wheeled tractors respectively adopt vertical and energy saving

,,

diesel engine of 20 25 30Hp as their power ;th ey employ direct gears transmission

betwee n engine and transmi ssion syst em . Jinma tractor s have m any types for you t o

choose . They not only have single stage clu tch and dual stage clutch types , but also

have two wheel and four wheel driv e types .They also have creeper devic e for you to

choose if you want your tractors to conduct ditching operation . They have perfect

hydraulic suspension system in performance , wide thread driving tyres of good

adhesive force and low pr essure and reli able (crankp in type and circula ting ball type )

but also have hydraulic steering gear , the users can choose either of them . The

products are featured by their favourable power ,relatively hight traction force ,

compact contruction , high transmission efficiency ,easy operation , convenient repair

and maintenance ,economical oil consupmtion ,easy attachment of implements and

good compreshensi ve usage .

In order to help the customers master the Jinma series tractors' operation ,

adjustment and maintenance , and prolong their service life , make the best possible

use of th em and o btain idea l economi c profit ,we compile the operation m anual ,With

regard to the operation and repair and maintenace , Please consult the operation

manuals of th e diesel engines .

With the development of science and technology and varying in requirement of

customers , the tractors are subject to improvements and perfection in their in their

construction s which will be written about in next editions of the manual . Therefore ,

users of tractors are required to pay attention to where the manual differs from the

actual tractors .

Page 3

2

Precautions

1. Drivers should read the operation manual carefully and be familiar with the

performance, operation and maintenance of the tractor. Otherwise we will not be

responsible for any qua li t y problems ca used by improper ope r ation.

2. Never fill the fuel tank with unfiltered or un-precipit a ted fuel.

3. New tractors must undergo running according to the regulat ions befo re they are

put into use.

4. It is prohibited to turn sharply with one-side braking while tractor runs at high

speed in or de r to avoid overturning or parts damage.

5. Bolts or nuts of wheel disc and of other important parts should be checked

regularly and be tighten ed if they are loos e.

6. During transferring the tractor with a mounted implement, it is not allowed to

drive the tractor at high speed in order to avoid damaging hyd raulic lift system and

suspension system.

℃

7. After opera tion at the area of below 0 in winter, the water sh ould be dra ined

out at idle speed in order not to freeze and damage the tractor parts (not including antiicing fluid).

Page 4

1

CONTENTS

……………………………………………………………………………………………

Prefac e (1)

………………………………………………………………………………………

Precautions (2)

Ⅰ ………………………………………………………………

Chapt er Main Specifications (1)

Ⅱ ……………………………………………………………

Chapter Oper ating the T ra cto r (5)

…………………………………………………………………

1.Fuel and lubric ating oi l (5)

……………………………………………………………………………………

2.Water (6)

……………………………………………………………

3.Ru nning-in of unused tractor (6)

………………………………………………………………

4.Co ntro ls an d ins trum en ts (8)

…………………………………………………

5.Control and operation of the tractor (10)

………………………………………

6.Con tro l and op erat ion of the w orkin g dev ice s (14)

……………………………………………………

7.Use of t he e lectri cal e quip ment (16)

Ⅲ …………………………………………

Chapter Technical Main te na nc e of the T ra ctor (19)

………………………………………………………………………

1.Shift ma intenance (19)

………………………………………………………………

2.First class maintenance (19)

………………………………………………………………

3.Second class maintenance (20)

………………………………………………………………

4.Thir d class m ain te nance (20)

………………………………………………………………

5.Fourth class maintenance (20)

…………………………………………………………………

6.Maintenance in winter (21)

………………………………………………

7.Maintenance for storage of a long time (21)

Ⅳ ……………………………………………………………

Chap ter Adjustment of Tractor (22)

……………………………………………………………………

1.Ad justment of clutch (22)

………………………………………………………………

2.Ad justment of m ain drive (24)

………………………………………………………

3.Adjust me nt of d ifferential lock (27)

……………………………………………………………………

4.Adjustment of brake (28)

………………………………………………………………

5.Adjustment of front axle (30)

…………………………………………………………

6.Ad justment of front drive axle (31)

……………………………………………………………

7.Adjust me nt of w h eel tre ad (33)

………………………………………………………

8.Adjust ment of steering gear (34)

……………………………

9.Construction and adjustment of hydraulic hitch system (39)

…………………………………

10.Use and ad ju stme nt of ai r br ake d evi ce of tra il er (46)

Ⅴ ……………………………

Chapter Main Troubles of Tractors and Trouble Shooting (49)

…………………………………………………………………………………

1.Engine (49)

…………………………………………………………………

2.Tran sm is sion sy ste m (51)

Page 5

2

…………………………………………………………………………………

3.Brake (52)

……………………………………………………

4.Steering gear and walking system (53)

……………………………………………………………

5.Hydraulic hitch system (54)

……………………………………………………………………

6.Electrical system (55)

……………………………………………………………………

7.Electrical system (56)

Ⅵ …………………………………………………………………………

Chapter Appendix (59)

………………………………………………

1.Wiring diagram of the electrical system (59)

……………………………………………………

2.Accessaries for customers to order (59)

3.Dis tribution diagram of rolling bearing

………………………………………

and transmission system of JM series tractors (61)

…………

4.Specifications and distributions of oil seals in JM series tractor's chassis (63)

……………………………………………………………………

5.Sizes of hitch system (65)

…………………………………………

6.OECD approval No. of JM series tractors (67)

Page 6

Ⅰ

Chapter Main Specifications

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Type ×42wheeled ×44wheeled ×42wheeled ×44wheeled ×42wheeled ×44wheeled

Overall

dimen-sions

(mm)

Length

Width(without ballast)

Heitht(to steering wheel)

3080

1250/1410

1910

3080

1250/1410

1910

3080

1280/1440

1930

3080

1280/1440

1930

3200

1280/1440

1930

3200

1280/1440

1930

Wheel base (mm) 1465 1510/1560 1587.5 1588

Wheel tread

(mm)

Front wheel

Rear wheel

1070 -1270

1040-1200

950 / 1050

1040-1200

1070 -1270

1040-1200

950 / 1050

1040-1200

1070 -1270

1040-1200

1050

1040-1200

Ground clearance (mm) 330 275 340 340

Turning radius

(m)

With one-side braking

without braking

±2.4 0.2

±2.8 0.2

±2.8 0.2

±3.0 0.2

±2.75 0.2

±3.0 0.2

±2.8 0.2

±3.0 0.2

±2.75 0.2

±3.0 0.2

±2.8 0.2

±3.0 0.2

Weight

(kg)

Construcional weight

Min.working weight

1040

1160

1140

1270

1040

1060

1140

1270

1170

1290

1270

1400

()

Rated traction force N 4000 4800 5200 5980 5200 5980

()Normal speed km/h six six six six eight eight

:Forward 1 st

2nd

3rd

4th

5th

6th

7th

8th

:Reverse 1st

2nd

1.99 0.37

3.94 0.73

6.57 1.22

9.21 1.72

18.2 3.39

30.36 5.66

1.58 0.29

7.3 1.36

1.68 0.31

3.31 0.62

5.52 1.03

7.75 1.45

15.3 2.85

25.5 4.76

1.33 0.29

6.15 1.15

2.06 0.38

4.07 0.76

6.79 1.27

9.52 1.78

18.8 3.51

31.4 5.85

1.63 0.30

7.55 1.41

1.73 0.32

3.42 0.64

5.71 1.06

8.01 1.49

15.8 2.59

26.4 4.92

1.37 0.26

6.35 1.18

2.12

3.24

5.08

7.00

9.82

14.97

23.49

32.38

2.79

13.52

1.77

2.69

4.23

5.83

8.18

12.46

19.56

26.96

2.32

11.25

Engine

Model LL380 LL380 KM385 KM385 ZN390T ZN390T

Type 3 cylinder ,vertical ,water - cooled , 4-stroke

1

Page 7

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Engine

12-hour power(kW)/rated speed r.p.m 14.7 14.7 18.4 18.4 22.1 22.1

×Bore Stroke(mm) ×80 90 ×80 90 ×85 90 ×85 90 ×90 95 ×90 95

Fuel consumption (g/kw·h) ≤ 245 ≤ 245 ≤ 245 ≤ 245 ≤ 255 ≤ 255

Oil consumption (g /kw·h) ≤ 2.0 ≤ 2.0 ≤ 2.0 ≤ 2.0 ≤ 2.72 ≤ 2.72

Net weight (kg) 250 250 250 250 230 230

Transmission

Clutch Single disc,dry-friction constant mesh OR Dual stage ,gear operation

Gear box (+)× ( )×Supr gear 3 1 2 compound , or supr gear 4+1 2compound Creeper can b chosen

Intermediate drive ×1 2 spiral bevel gear

Differential Closed with 2 planetary bevel gears

Diffierential lock Claw type

Final drive Internally meshed single spur cylindrical gear

Walk

and

operatin

g system

Frame type Frameless rigid connection

Front axle type

inverted U pipe

balancing arm

side bevel gear

drive

inverted U pipe

balancing arm

side bevel gear

drive

inverted U pipe

balancing arm

side bevel

gear drive

Pendulum angle of front axle °12 °8 °12 °8 °12 °8

Tyres

Front wheel

Rear wheel

4.00-16

8.3-24

6.00-12

8.3-24

5.00-15

9.5-24

6.00-16

9.5-24

5.00-15

9.5-24

6.00-16

9.5-24

Tire infation

(pressure kPa)

:Front wheel

:Rear wheel

()in field

()transport atio n

200-250

100-120

120-140

180-200

100-120

120-140

200-250

100-120

120-140

180-200

100-120

120-140

200-250

100-120

120-140

180-200

100-120

120-140

Steering gear

sphere worm steering

Hydraulic steering gear may be chosen for all models

Brake Foot - controlled shoes type Disc type

2

Page 8

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Hydraulic

systems

Type Half remote

Hydraulic pu mp

CBN-E306

gear pump

CBN-E306 / 314

gear pump

CBN-E306

gear pump

CBN-E306 / 314

gear pump

CBN-E310

gear pump

CBN-E310

gear pump

Hydraulic cylinder

×Horizontal single− acting type63 100(mm)

Distributor Slide valve regulating type

Safety valve Direct-acting type

×Rated lifting capacity (N mm) ×3600 610 ×3900 610 ×4200 610 ×4200 610 ×5000 610 ×5000 610

Safety valve release pressure(MPa) ~+16 ( 0 1.6 )

Suspension

mechanism

Connection type of implements rear mounted - point hitch category 0 Ⅰrear mounted - point hitch category

Upper link-hole diameter(mm)

×φ19.5 44

Lower link-hole diameter(mm)

×φ22.5 35

Traction

device

Traction ground clearance(mm) 470 495

Traction pin diameter(mm) Φ20

Power-take-

off

Rear P.T.O shaft ,Nonindepender 540r/min or semi-independent 540r/min dual speed(540r/min ,1000r/min)can be chosen

Electrical

equipments

and gauges

System 12V ,negative pole connected with iron , single phase circuit

Starter 、12V 2.5kW or 3.0kW

Generator 14V 350W

Battery 6-Q(A)-80,80A·h

3

Page 9

Model JM-200 JM-204 JM-250 JM-254 JM300A JM304A

Electrical

equipments

and gauges

Ammeter +() -30~0~ 30 A

Oil pressure gauge ()12V 0~0.5 MPa

Water temperature gauge ℃ 12V (40~100)

pressure gauge 0~1.0 MPa

Head lamp ND118-80T , 20/8W 12V

Rear light WD115-2 , 20/8W.12V

Direction light FT12 , 8W.12V

Electric horn DL87-12

Main filling

capacity (L)

Fuel tank 19 19 19 19 24 24

Engin e oil sump 5

Front drive axle ─ 4.5 / 6 ── 6 ── 6

Transmission box 11 14 11 14 11 14

Lifter 9 14

Steering gear 0.4

Cooling water 10 or 12

4

Page 10

5

Ⅱ

Chapter Operating the Tractor

1.Fuel and lub r icating oil

1) For fuel and lubricating oil for the tractor see Table 2-1.

Table 2-1 Fuel and lubricating oil for the tractor

2) Cautions for filling fuel

Using clear diesel fuel is an important factor to prevent troubles in engine and

prolong the engine's service life. The followings should be observed during filling fuel:

A. Fuel mus t be deposited for over 48 h ours before fuel tank is fill ed with it. Fu el at

the bottom should not be poured into the fuel tank.

B. Filter fuel when filling fuel tank with it.

C. Fuel filling devices must be kept clean.

D. Fuel tank and f uel filte r should be cleaned regularly, and deposited fuel should be

dra ined out.

Component Season and ambient temperature Oil specificatio n

Fuel tank

Summer (ambient temp. above10

℃ )

No.0, -10 light diesel fuel

GB252-87

℃Winter (ambient temp. below10 )

No. -20 light diesel fuel

GB252-87

Engine sump

Lifter

Oil pa n of air cleaner

Injection pump

Hydraulic steering gear

℃Ambient temp. below 0

No. 20 diesel engine oil

GB5323-85

℃Ambient temp. at 0-25

No. 30 diesel engine oil

GB5323-85

℃Ambient temp. above 25

No. 40 diesel engine oil

GB5323-85

Transmission box

Transfe r c ase Front drive

axle Mechanical steering

gear

Summer (ambient temp. above10

℃ )

No. 40 diesel engine oil

GB5323-85

℃Winter (ambient temp. below10 )

No. 30 diesel engine oil

GB5323-85

Grease nipple Without consideration of season

No. ZFG2 calcium base

compound grease

ZBE 36003-88

Bearin g 60203Gen erator

and starter

Without consideration of season

No. ZFG2 com p ou nd

calcium base grease ZBE

36003-88

Page 11

6

2.Water

1)Radiator should be filled with clean soft water so as to eliminate scale in the engine

cooling

syst em whic h wil l re duc e coo lin g effi cie ncy. On ly aft er b eing soft ene d can hard water su ch a s

well water, spring water, etc. be used. Method for softening hard water is as the follows:

A. Boil hard water, then deposit for some time and filter.

B. Put 1.5g of caustic soda into one lit of hard water. When operating the tractor in cold

weather, add cooling water with f re ez e - p ro of li q ui d.

3. Runn ing-in of unuse d tractor

The unused or overhauled tractor can not be put into operation unless it has undergone

running-in. Otherwise its performance will be affected and service life wi ll be shortened.

1)Prep arations before running-i n

A.Clean the outside of the engine.

B.Inspect outside bolts and nuts, and tighten them if necessary.

C.Check the lubricating oil level, and refill to stipulated level if insufficient.

D.Inject grease into lubricating points.

E.Fill with fuel and cooling water

F.Check toe-in (4-10mm) and tire inflation pressure, readjust or reinflate if necessary.

G.Inspect the connections of battery and wires of electrical system.

2)Idle running-in of the engine

After t he engine is started i n accorda nce with specified steps, list en carefu lly and make

sure whether there is abnormal sound, check for leakage of water, air, oil and the readings of

the gauges. When it is made sure that the engine is in normal working condition, the next step

of runn ing-in can be proceeded.

The unlo aded ru nnin g- in l asts 1 5 min ut es, the first 7 minu te s with m inim um th ro ttl e, then

medium throttle for other 5 minutes and then lasts 3 minutes with full throttle.

3)Unloaded and loaded running-in of the tractor

The running-in of the tractor should be done at rated engine speed. The order and time of

running-in should be done according to the standard in Table 2-2.

Page 12

7

Table 2-2 Ru nning-in standa rd of the tractor

Matters needing att ention during running-in process:

A.Chec k on whether the engine runs normally.

B.Check on whether the adjustment of the clutch is normal and the disengagement is

complete.

C. Check on whether the gear shift of the gearbox (including front drive handle,

creeper) is light a nd flexible , and th ere is any a ut om atic gea r d isengag em ent and gear- shiftin g

lock.

D.Check on the function or reliability of the brake.

E.Check on whether the steering gear is flex ible.

F.Chec k on whether the gauges and elect rical equipments are normal and reliable.

During the running-in process, if any abnormal phenomena or failures appear, the

cause should be found out and corrected, then the running-in can be carried on.

After the running-in is completed, the tractor must be undergone the following

maintenance before being put into operation:

A. After the tractor has been stopped, drain out the lubricating oil in the engine sump

while i t is still war m. Wash the sump and oi l filter with diesel fuel . After the di esel fuel has

bee n out, refi ll the sump with new lubricating oil to sp ecified leve l.

B. Drain out the lubricating oil in the transmission box, hydraulic system and front

drive ax le while it is still warm. Th en fill th em with di esel fu el of pro per quan tity an d run the

tractor in 2nd forward and 1st reverse gears for 2-5 minutes for cleaning. As soon as the

tract or is stop ped, dr ain out th e diesel f uel imm ediately and then refil l new lubr icating oil to

specified level.

C.Clean fuel filt er (including filter cartridge in fuel t ank) and air cleane r.

D.Drain out cooling water, clean the cooling system of engine with clean water.

E.Check on and adjust the f ree travel of clutch pedal, the travel of brake pedal and the

Running-

in type

Load

Running-in hours per gear Total Sum

1st 2nd 3rd 4th 5th 6th R1st R2nd

Unlo aded Tract or only 1 1 1 1 0.5 0.5 0.5 0.5 6

Loaded

With trailer

loadedwith 1.2T

goods onhighway

transporta- tion

124422 15

31

Fitted with plough at

plough depth about

13.3 cm in lig ht so il

1243 10

Page 13

8

working condition of the brake.

F.Check on and tighte n the nuts and bolts on all connection positions.

G.Check on injector and valve clearance, adjust them if necessary.

H.Check on working c onditions of el ectrical syst em.

I.Check on and adjust the toe-in of front wheel.

J.Inject grease into each lubricating point.

4. Controls and instr uments

In ord er to opera te the trac tor correct ly, it is nec essary t o familiar ize the func tion of

all controls and instruments as well as their positions on the tractor (Fig.2-1).

1) Auxiliary gear shifting lever: To control the auxiliary speed gear. (Fig.2-2).

2) Main gear shifting leve r: To cont rol the main spee d ge ar. (Fig.2- 2).

3) Ge ar shiftin g pattern p late: It i s located o n the top of gearbo x cover to show the

positions of gear shifting lever.

4) Con trol le ver o f fr ont d rive a xle: Enga ge o r cut off the p ower of fro nt dr ive axle to

achieve 4-wheel drive or 2-wheel drive.

5) Steerin g wheel: It con t r ol s the di rec tio n of tractor runn in g.

6) Clutch pedal: Depress the peda l, then the clutc h is di sengaged.

7) De com pres si ng le ve r: Redu ce t he pres su re i n t he c ylin d ers t o ma ke the en gine st art

easier.

8) Extinguishing lever (Fuel cut-off rod): To make the engine stop.

9) Single-position switch: Pull the switch out, the rear work light is turned on and

push the switch in, it is turned off.

10) Turning signal switch: Turning the switch to the left or right, the left or right

turning signal light will flash to show in the left or right turning.

11) Horn butto n: Press the butt on to sound the hor n, and it will send out alarm signal s.

12) Ammeter: It indicates the current intensity of battery while being charged or

discharged. If t he p ointer de fle cts to " + " side, it m e an s that the b at ter y is being charg ed ; if to

"-" side, it is being discharged.

13) Water temperature gauge: Indicates the water temperature of the engine cooling

system.

14) Tachometer :It irdicates the speed and accumulated working time of the engine.

Air pressure meter : It indicates the air pressure of the brake system(fror 2WD).

15) Oil p ressure gau ge: It indi cates the oil pressu re in main oil lines of th e engine , the

normal oil pressure is 2- 4 kgf/cm

2

(0.2-0.4MPa).

16) Fuel gauge: It indicates the fuel level of the fuel tank.

Page 14

9

Fig.2-1 Controls and Instruments

Page 15

10

17) Two-position switch: Pull the switch to the first position, the headlights (lower

beam) will be lighted, to the second position, the full-beam of the headlights will be lightened.

18) Starting switch: It has two functions: one is for switching on or off the circuit

current and the other is as electrical starting switch.

19) Hand th rottle: Pull the h and throt tle backward, the fuel flow will increase whil e

push it forward, fuel flow will decrease.

20) Creeper shift ing lever: To exchange the normal sp eed and creeper speed.

21) Left and right brake pedals: Turn the braking lock plate right to make left and

right pedals connect with each other and brake at the same time; while separating the

braking lock plate can achieve left or right one-side brake, then one-side brake and turn can

be made.

22) Foot throttle peda l: Depress th e pedal down, the fuel flow w ill increase ; loosen it,

the fuel flow will decrease.

23) Pa rking brake lock pawl: Put the b rake lock pawl on the le ft brake pedal into the

teeth of the brake teeth pla te at the right side of transmission box to keep the brake for a long

period.

24) P.T.O contr ol lever: En gage or dise ngage P.T.O power.

25) Differential lock lever: Used to move right claw to make differential lock

disen gaged or engaged so that the two driving wheels have different speeds or not.

26) Hydr aul ic cont rol lever: When th e lev er is pu shed or pu lled backwa rd, fo rwar d or

into vertical position respectively, the hitch is lifted, lowered or in neutral position.

5. Control and ope ration of the tractor

1) Starting engine

Before starting the en gine, ch eck fuel, lu bricating oil and coo ling water. Check and make

sure ev ery co mpone nt an d electri cal syste m work corre ctly, d rain out th e air in the fu el lines ,

put gear shifting lever in neutral position. If the hydrauli c system is installed on the tractor,

caution: check whether enough hydr aulic oil is filled in the lifter housing.

After the prestarting preparation, start the engine.

A.Set to decompress and rotate the engine crankshaft several turns with the hand

starting handle, check and make sure all moving parts work correctly, and pump oil to

surfac es of mo vi ng par ts.

B. When starting the engine with the hand starting handle, set the hand throttle to full

open position, put the decompression lever to the decompression position, accelerate the

crank ing, the e ngine w ill be st arted along wi th the d ecompres sion lev er ret urn aut omatica lly

to original position.

Page 16

11

C. When switch starting, set the decompression lever to decompression position too.

Turn the

startin g switch clo ckwise to "start" p osition, thus the e ngine is d riven by starter, th e starter

must n ot b e operat ed more than 5-10 sec. for ea c h start. On l y af t er a n interv al o f no t l e ss than

2 minutes can the engine be started again.

D. When switch starting is s uccessf ul, turn the sta rting switch countercl ockwise to th e

charging position of battery.

E. It is not necessary to decompress the engine while switch start ing in summer. Filling

the ra diato r w ith hot w a ter or th e oi l sump with h ea ted e ng in e o i l ca n b e us ed a s s tar tin g aids

in winter.

2) Starting the tractor

After the en g i ne i s star te d , run it at mo de rate s p eed for 5 - 10 min utes for war m -up itself, a f te r

℃

thewater temperature reaches above 70 , tractor can be started according to following

steps:

Page 17

12

A.Lift the implement.

B.Dep ress t he clut ch peda l, pu t t he ge ar sh ift ing l ever i nt o the desi red low er ge ar, rele as e

the parking brake lock pawl of the brake pedal.

C.Observe the environment to confirm that there are no obstructions on the road and

sound the horn to call atte ntion to the people.

D. Incr ease the engine sp eed gradu ally and si multaneo usly rele ase clut ch pedal s o as to

make the tractor start off smoothly

.

3) Operating the tractor

A.During operation make sure that readings on gauges are normal.

B.It is prohibited for oper ator to place his foot on clutch pedal so as to protect clutc h from

beingdamaged because of semi-engaged condition of clutch.

C. In transportation or running on highway, lock the left and the right brake pedals

together with brake lock plate.

D. In field operation, one-side braking can be used to reduce turning radius, but it is

prohibited to use one-side braking for sharp turning when the tractor is running at high

speed or is used for transportation on highway, so as to prevent overturning and protect

comp onents from being damaged.

E. Proper speed should be selected to get best productivity. Table 2-3 shows the speeds

for various operations.

Table 2-3 Speeds for different operations

Operation Gear

Creeper Ditching

L1st Rotary cultivation

L2nd Rotary cultivation, transportation

L3rd Ploughing, harrowing, drilling

H1st Ploughing, harrowing, drilling

H2nd Transportation

H3rd Transportation

R1st To attach implemen ts

R2nd To attach implements

Page 18

13

4) Stopping the tractor

A. Throttle the engine down to lower the speed of the tractor.

B. Depress the clutch pedal quickly and shift the gear-shif ting lever to neutral position.

C. Release the clutch pedal and let engine run idle.

D. Depress the brake pedals to stop the tractor, th en lock the pe dals with the lock pawl.

Note:

In case the tractor has to be stopped suddenly, clutch pedals and brake p edals

should bedepressed s imultaneously. It is pro hibited to depress th e brake pedals only, whi ch

will damage the parts.

E. If the tractor is to be parked for quite a while, the engine should be stopped. After the

engine has been u nloaded, it should run at l ow speed for som e time un til the cooling wate r

temperature drops to

℃

70 or lower, then pull out fuel cut-off rod to bring the engine to a st op.

Note:

It is prohibited to stop the engine at once when its temperature is very high, or to

stop the en gin e wi th decompress ion mecha nism.

F.Turn the preheating/starting switch to "O" and pull out the key. If the tractor is going

to be stored, turn off the fuel tank cock.

℃

G.If the tractor is stopped when the ambient temperature is below 0 , screw of the

radiator cap and turn on the water-drain cock on the bottom of the radiator and on the

cyli nder bl ock t o drain out wa ter a t idle en gine speed s o as to prote ct the b ody an d radi ator

from being froze n (n ot inc luding ad ding anti -icing fluid).

5) Safety regulat ions for operati on

Safety regulations are very important for protecting drivers and tractors from hazard.

They should be obser ved strictly in operation .

A. Inspect carefu lly th e work in g cond iti o n of the engine and ma in compon ents, an d listen

to whether there is abnormal sound or noise. Especially observe the technical state of clutch

and brake. Check and tighten the bolts and nuts on main components of the tractor.

B. Make sure that there is no people or obstacle around the tractor and press horn

button beforestarting off the tractor.

C. Don 't go up a nd do wn t he tra ctor duri ng ru nnin g. Never m ake check or re pair un der

the tractor wh ile the en gin e is still running.

D. Before the tractor goes up or down a slope, proper speed should be selected and don't

coast, turn sharply or shift gears while driving down a slope.

E. In transportation, left and right brake pedals must be locked together. One-side

brakin g can not be used for sharp turning when the tractor is running at high speed or with

full load.

Page 19

14

F. If front en d o f th e tr actor rises up in operat ion , th ro ttl e d ow n the e ng in e, d ise ngag e th e

clutch and reduce the load to protect the tractor from longitudinal overturning.

G. If the engine runs away, immediately pull out the fuel cut-off rod, move

decompression lever to "decompressing" position or plug up fresh air into the engine instead

of disengage clutch .

H.Ligh t ening equipment must work well during operat ion at night.

I.Co ntrol le ver sho uld b e placed in the ne utra l posit ion whe n the fo ur-whe el driv e trac tor

is running idle or being used for transportation.

6. Control and operation of the working devices

1)Control and operation of PTO

PTO can be engaged and disengaged by means of operating the PTO control lever on the

right side of the transmissi on box.

The speed of PTO is 540 rpm or 540 rpm and 1000rpm. When push down (from front and

upper side) the control lever, PTO is engaged; while pull upper the control lever, PTO is

disengaged. The operation steps are as follows:

A. Remov e the PTO sa fet y shield an d draw bar, coup le th e desir ed driven ma chin e to th e

PTO shaft.

B. Put the gear shifting lever at the neutral position.

C.Depress the clutch pedal fully, then shift the PTO control lever to the "engaged"

position.

D.Release the clutch pedal slowly and the driven machine will run. First let the driven

machine run at slightly open throttle for a while to ensure that nothing is wrong with the

driven machine. Then make the throttle wide open and put the driven machine into operat ion.

Note: Wh en the tracto r with implemen t travels fo r a long distanc e, should shif t the contro l

lever to neutral position to cut off the power so as to avoid damaging the implement and

causin g body acci de nt.

2)Control and operation of hy draulic hitch sy stem

Hydraul ic hitch sy stem serves to attach, lift and lower implement, as wel l as adjust and

maintain the working pos ition of implement, so a s to meet different re quirements of va rious

implements and operations.

Move the control lever of the distributor to raise and lower the implement.

According to the type of work to be done, type of implement used and field condition,

hydraulic hitch system provides various functions, so that the satisfactory work quality is

obtained.

A.Posi tion control

In po sition co ntrol, by means of mo ving cont rol lever of the d istribu tor, the p osition of

Page 20

15

implement could be adjusted, if desired position of the implement has been got, set the

position of the stop per on th e return rod to limit t he contr ol lever. T ight en the sto pper on the

rod with screw, so that th e lever can be push ed to the s ame position every ti m e.

Adjustment may be done during plowing period. The supporting wheel for the implement is

not necessary in position cont rol.

B.Floating contro l

Floating control is suitable for field plowing. In floating control, supporting wheel is

needed for implement, During plowing , hold the control lever of distributor at "lowering

position. (i.e. push the control lever of distributor forward with the return stopper. Do not

return the control lever to the neutral position). The hydraulic circuit is in "floating" control.

Using floating control, the plowing depth is controlled by the change of the height of the

supporting wheel. The uniform plowing depth would be obtained in the field with wild

changes of soil resistance.

C.Control of the lowering speed of the implement

Turn the lowering speed adjusting valve to control the lowering speed of the implement.

The lower ing sp eed sh ould be sele cted prope rly ac cordi ng to th e weig ht of the i mplem ent and

hardn ess of soil surfa ce in orde r to p reven t the im plem ent from b eing se ri ously impa cted a nd

damaged.

Turn the lo wering spe ed adju sting val ve clockwis e, the low ering speed will reduce ; turn

the valve coun te rclockwis e, the lowering spee d wi ll inc rease.

D.Operat io n of hi t ch syst em

Adjust the implement according to the implement operation manual before the

implements being attached to the hitch system of the tract ors.

In ploughing, adjust longitudinal and lateral level of plough in order to get the same

ploughing depth of front and rear share.

a) Adjus tin g of lon gitudina l leve l

Adjust the length of the upper link of the hitch, keep the plow frame horizontal in

longitudinal level, so as to keep each share in the same plowing depth. As the front share

plows deeper th an the rear one, or he el of plow go es out fro m bottom of furrow, extend t he

upper link; as the front share plows shallower than the rear one, or rear heel si nks into the

bottom of furrow, shorten the upper link.

b) Adjust ing of lat e r al level

Adjus t len g th of righ t lifting r od , ke ep plow fra me ho rizontal in latera l le vel, as ext en d th e

right li fting rod, the plowin g depth of th e first sh are is inc reased. As shorten t he right l ifting

rod, t he plo ughing dept h of t he fi rst sh are is decrea sed. U sually, the left l ifting rod does not

Page 21

16

requir e a ny ad ju st me nt . O nl y i f th e r i g ht lifting r od is ad ju sted to i ts limits, the lef t li fting rod

would be adjusted to obtain the uniform plowin g depth.

In order to obtain better plowing quality in actual operation, still need to adjust the

plowing width according to the plow operation manual, so that the twifallow and omitted

plowing won't happen. The various adjustments described above are connected. According to

each operation condition, combine the adjustments properly, then can obtain the best results.

The check chains can make the integral unit have good manoeuve rability in the field, and

prevent implement from hitting rear wheels because of the too much crosswise swinging of

the imple ment during turnin g of tractor and lifting the i mp lement in the field ends. As the

implement is in plowing position, the check chains are loosen, a certain swinging scope

betwee n trac tor and imp lement is allow ed. Adju sting th e devi ation tra ction of the im plemen t

throu gh tensioning the check chains is prohi bited during ploughing.

c) While using implements of driving typ e, should pay attention to the length of universal

joint sh aft ; aft er atta chm ent, th ere s houl d be ab out 10 mm axia l cle aran ce betw een P TO shaf t

and universal shaft.

3) Using the diff erential loc k:

In trac tor transpo rtation and o peration, if one drive wh eel slips gr eatly and the tractor

can not move forward, operate the differential lock according to the following steps:

A. Depr ess the clutch pedal, move the gea r shifting lever to the low range gear position.

B. Turn the hand throttle to full open position.

C. Depress down the differential lock lever under the right side of the seat, gradually

release the clutch pedal to engage the clutch, so that two drive wheels rot ate in same speed,

then there is a possibility to drive the tractor through the slippery area.

D. After t he tract or passes t hrough th e slipp ery area, ca n not tu rn the tra ctor, othe rwise

the parts may be damaged.

Note:

Release di fferenti al lock lever and let it return to the original po sition after the

differential lock is engaged.

7. Use of the electr ical equipment

The electrical equipment of the tractor is used to start engine, meet the needs of giving

signals and lighting for operation at night and etc. The electrical system of the tractor is

negative pole connected with iron, 12V single phase circuit.

1) Battery

Batter y rate d voltag e is 12V and its r ated capacit y is 60 or 66 AH; The batt ery is u sed t o

Page 22

17

store the spare electricity produced by the generator. While the engine doesn't work or run at

low speed, the stored electrical en ergy can supp ly electricity for all of the electrical devices

and to start the tractor. While the engine overloads in a short time, the battery can help to

supply electricity. In routine use, the battery should be often checked and maintained in

accordance with the technical maintenance regulations of the tractor.

A. Before us ing the new battery, fi ll the electro lyte stip ulated in table 2-4 to th e requi red

height, t he n keep the b at ter y for 1 5 m i nu tes , a fte r tha t, th e b at ter y can be us ed; after sta rt in g

the engin e, firstly it is b etter to charge the battery for 1-2 hours, w hich is good to extend the

service li fe of the batt ery.

B. Dust and dirt on the outside of the battery should be often cleared away in case

elec tricity l eaks. Che ck to see wh ether th e battery has crack le and ele ctrolyt e leak; kee p the

termin als and all contacts in good connecting condition; keep the air hole on the plasti c cover

unblocked, so as to protect the battery fro m explosion because of too m u ch gas in the ba ttery.

C. Check the height of electrolyte level and specific gravity. In normal use, if the height

of elect rolyte level is below 10-15m m, distilled wat er should be pou red into it in ti me. Well

water or river water can't be used. So as to prevent impurity from entering electrolyte. If

electrolyte overflows much under unusual conditions, it can be added. The density of

elec trolyte in electrol ytic cel l should be not lower than 1.2g /cm3; if th e densit y is too low , the

battery should be charged in time.

D.The time of continuous starting should not be more than 10 seconds in case

overdischarge. The battery should be charged at regular interval. The single voltage of the

charged battery should be 2-2. 1 V.

Table2-4 Density of electrolyte

2) Use of generator and regulator

A. Generator should be used with regulator.

B. The genera tor is co nnec ted with gr oun d by negat ive pol e. The ge nera tor is connec ted

with the regulator and the battery by negative pole. The positive and negative poles of

genera to r, relay a nd b att ery can no t b e co nn ec ted in wro ng wa y. Otherw is e th e generator and

regul ator ma y be damaged.

C. Che cki ng th e gen er ator by s hort circ ui t is p rohi bi ted . Meg aoh mmet er o r A. C. po we r

Temperature

of ele ctrolyte(0

℃

)

0-5 5-10 10-15 15-20 20-25 25-30 30-35 35-40 40-45

Densit y(g/cm3) 1.305 1.300 1.295 1.290 1.285 1.280 1.275 1.270 1.265

Page 23

18

of more than 100V is not allowed to check generator insulation; only multimeter of high

resista nce ca n be use d to check th e natu re of gener ator in sulat ion; ot herw ise the diode will b e

punctured.

3) The starte r

A. Keep the starter clean and the contacts between wires in good condition.

B. The time for each starting should not be over 10 seconds. The shortest interval

between two startings must be more than 2 minutes. If the engine can not be started after

several startings, the trouble should be found out and removed, then the engine can be

restarted.

C. If the eng ine is st arted in winter , it shou ld be p rehea ted and th en can be star ted w ith

the starter.

Page 24

19

Chapter Ⅲ Technical Maintenance of the Tractor

In order to keep the tractor in excellent condition, prolong its service life and reduc e

troubl es, the use rs must often chec k the tech nical co nditions o f the tra ctor an d strictl y carry

out technical maintenance of all classes.

Table 3-1 Technical Maintenance Perio dic Table

In actual use, users can add and perfect the contents and methods of maintenance

according to concrete conditions.

1. Shift maintenanc e

1) Clean dirt and sludge on the tractor and implements. Under the extremely dusty

circumstances, the air filter should be cleaned.

2) Check all main fastening bolts and nuts on the tractor outside, especially whether

front and rear wheel nuts are loose, tighten if necessary.

3) Exami ne th e liqu id le vel in oil s ump, ra diat or, fu el tan k an d lift er; re fill if ne cessary .

Only after the engine has stopped for more than 15 minutes can the oil lever in oil sump be

examined.

4) Check whet her there is leakage of oil, water and air; remove if nec essary.

5) Check the tire pressure, and in flate if necessary.

6) Grea se the poi nts accor ding to the table 2-1. Befo re greasing, the sludge a nd water

should be squeezed from the l ubricating points.

7) Check the specif ied tools supplied.

2. First clas s maintenance

Carry out the foll owing maintenance afte r every 50 hours of operati on:

1) Carry out the maintenance items in shift maintenance.

2) Clean air filter, and replace oil in the filter house.

3) Chec k the fan belt tension (When pressing the middle part of the longer side of the

belt, the belt drops about 15-25 mm under the force of about 10N, then the tension is

suitable), adjust if necessary.

4) Check and adjust the free travels of clutch pedal and brake pedals.

Maintenance class Working hours of the tractor (h)

Shift m aintenance After ev ery shif t or every 10-12 hours of operat ion

First class maintenance Every 50 hours of operation

Second class maintenance Every 2 50 hours of operation

Third class maintenanc e Every 500 hours of operation

Fourth class maintenance Every 1000 hours of operation

Page 25

20

5) Check the oil level in transmission box and front drive axle, refill if necessary.

6) Wipe the battery with a piece of cloth, check the electrolyte level which should be 1015 mm above the polar plates, refill with distilled if necessary . Smear the terminals with

grease to avoid corrosion.

3. Second class maintenance

Carry out the following maintenance after every 250 hours of operation;

1) Complete first class maintenance items.

2) Repl ace the engin e oil in engin e sump, flus h engine sump , oil pump st rainer and oi l

filter.

4. Thi rd class maint enance

Carry out the following maintenance after every 500 hours of operation.

1) Complete second class maintenance items.

2) Check and adjust inlet and exhaust valve clearance, injection pressure and spray

atom ization of the injector accordin g to the requirem ents in the engine operation manual.

3) Clean fuel tank and fuel cartridge.

4) Flus h t ransmission box, replace lub ricating oil.

5) Flus h t he filter of hydrauli c lifter, chec k the oil cleanliness degree , fl ush the inside of

lifter house and replace with fresh oil i f necess ary.

6) Check and adjust front wheel toe- in (The toe - in should be 4-10 mm). Check the

clearance of the front wheel bearing, and adjust if necessary. Replace the grease in the front

wheel hubs.

°

7) Check the free travel of the steering wheel (The free angle should be less than 15 ),

adjust if necessary.

8) Check the oil level in steering gear, and refill if necessary.

5. Fourth class ma intenance

Carry out the foll owing main tenance afte r every 1000 hours of operation;

1) Complete third class maintenance.

2) Carry out maintenance items accordi ng to regulati ons in diesel engine operation

manual.

3) Clean the fuel tank with 25% hydrochloric acid solutio n , then flush it with clean

water.

4) Disassemble the starter and generator, clean off the grease in the bearings and

replace it with fresh grease. Meanwh ile examin e the transmission me chanism of th e starter.

5) Clean the gathered carbon in the silencer and exhaust mani fold.

6) Immerse the front bearing and release bearing of the clutch into dissolved high

temp erature- resistant grease, and refill with fresh grease.

Page 26

21

7) Chec k and adjust the meshing backlash and pri n t of the main drive b evel gears, the

bearin g clearan ce an d pr eload of the be vel gears.

8) Clean the oil filter in the hydraulic lifting system, replace the oil in the system with

fresh oil.

9) Clean steering gear, replace the lubricating oil in it.

10) After the maintenance has been done, run the maintained tractor for a short time

for trial to see whether every part is in normal condition.

6. Maintenance in winter

℃

While the tractor is used below 5 , the users should carry out special maintenance on

the tractor. Besides completing the every shift maintenance, the following regulations should

also be obeyed.

1) The engine is not allo w ed to be started if there is no water in the cool ing system. Hot

℃

water of 60-80 can be poured into the radiator for easy starting the engine.

2) After cold starting, the engine should be preheated for a period of time; operation

℃

can not be conduct ed until the wat er temperature is above 60 .

3) If the tractor will stop for a long time after operation, the water (without anti- icing

fluid in it ) in the cooling system should be drained out. Water temperature of draining out is

℃

50-55 .

4) Choose fuel and lubricatin g oil according to air temperature or seaso n.

5) In cold season, in order to start the engine easily, the tractor can be stored in a warm

storehouse.

7. Maintenan ce for storage of a long period

The tractor for storage of a long period should be fully examined on its technical

condition; the tractor whose technical condition is perfectly normal can be put into the

storehouse.

1) Store the tractor in dry storehouse; support the front and rear wheels off the ground

with wood pieces. If storing in the open air for limited condition, cover the tractor with tarp

and dig drains around the tractor. The place for storing should be far away from fire (kitchen

house, oil depot and etc.)

2). Clean the outside of the tractor and lubricate each lubr ication point with grease

according to table 2-1.

3). Drain out the cooling water, dismount the battery for storage and cover the exhaust

manifol d mouth well.

4). Star t the engine to run fo r 20 minutes eve ry three month s to see whethe r the tractor is in

normal condition.

Page 27

22

Ⅳ

ter AChapdjustm ent of Tractor

1. Adjus tment of clutch

Due to cont inuous wear o f parts during opera tion of the clutc h, clutch slip an d clutch

incomplete disengagement will happen, which can't make the tractor work normally;

therefore adjustment of clutch should be timely made.

1) Adjustment of du al stage clu tc h

Fig. 4-1 is connection-controlled dual stage clutch. It mainly consists of three parts:

driving part, driven part and controlling part. Driving part rotates with the engine flywheel;

only when the clutch engages can the driven part rotate with the engine.

Dual stage clutch should be adjusted on a fixture. The adjusting steps are as follows:

Adjust the length of adjusting bolt (11) to make the distance between 3 release levers (19) and

the end face s of PTO clutch pressur e plate (4) is 96.8mm, and the dist ance diffe renc e betw een

3 release levers and PTO clutch pressure plate is no more than 0.1mm; after adjustment

×

tighten it with nut M10 1.

Page 28

23

When adju sting the free trave l of the cl utch pedal (F ig. 4- 1), firstl y adj ust the l ength of

clutch push rod (15) to ensure that the clearance between end faces of three release levers and

±

release bearing is 2.5 0.5mm and the idle travel of release rock arm is 3.5-5mm; after

adjustment tighten it with nut M10.

Position limit adjustme nt of working trav el of clutch pedal : loosen nut (10) , then turn

adjusting bolt (11) to make the working travel under release rock arm (12) is 25mm, then

tighten nut (10).

2) Adjustment of single stage clutch

Fig.4-2 is sin gle - disk and dr y single sta ge clutch . It is made up of c lutch spri ng(1),

clutch driven plate(2) ,clutch pressure plate(3) ,release lever(6) ,adjusting nut (7) ,release

bearing (9) and its operation mechanism.

The adjuting methods of single stage clutch are as follows:

A. Position adjustment of release levers

In re asse mb lin g the clu tc h,t ur n adj us tin g nut (7 ) to make th e di stan ce b et ween wo rk in g

Page 29

24

faces o f release levers and the workin g face of pressure plate b e B=45mm. Wh en the c lutch

engag es, t he gap A=2- 3mm betw een rele ase bea ring (9 ) an d re lease l evers (6) sh ould be kept ;

and 3 working faces of the release levers (6) should be in the same plane , the allowed

deviation is 0.25 mm.

B.Free trav el ad ju stm ent of clu tc h ped al

Turn pus h ro d a dj us t in g fo rk ( 16 ) to cha nge th e ef fec tiv e length of push rod (14) unt il it

reache s the free travel of the clutch p edal L=8-1 2 mm (whi le the corres ponding f ree travel

under the release rock arm (17) is L1=3.5-5.5 mm ).

C. Position limit adjustment of working travel of clutch pedal

Turn li mit ing ad just ing bo lt (1 8) until th e work in g trav el u nder releas e roc k arm( 17) i s

L2=13- 17mm . In opera tion the free travel of the c lutch peda l should be of ten checked and

ensured.

2. Adjustment of main drive

1)Preloa d ad justment of the coni ca l bearing

Durin g a ssembling there shou ld be some preloa d on two conical b earings (3) 2007111

(on t wo end s of diffe rent ial) an d two coni cal b ear ing 2 7305 (10) ( on se con d sh aft) (Fig .4-3) for

Page 30

25

reduci ng axial displacement and increasing supporting rigidity of the spiral bevel gears under

operation. After operation for a period, as the conical bearings wears, the former preload will

disappear gradually, and moving clearance will occur between the two conical bearings when

the two moving clearance is more than 0.1 mm, the conical bearings should be preloaded

again.

A. Prel oa d ad ju st m en t of second shaft conical bearin g

Adjus t the screw in g tightn es s of the loc king nu t (1 1) near th e bearin g u nt i l th e tors io nal

friction torque of the second shaft (9) is 0.7-1.1 N.m. After adjustment, insert locking slice

(12), then tightly screw the second locking nut (11).

B. Preload adjustm en t of differen tial conic al bearing

Insert the adj usting shi ms ( 5) in same q uantit ies bet ween the two sides of tra nsmiss ion

box (2 ) and the be aring seat s (4) of con ical bear ings, then tightl y screw the bolts (6) of the

bearing sea ts; and turn second s ha ft ( 9) , if th e torsiona l t orq u e i s 0 .4- 0.7 6 N.m mo re th an that

of the co ndition tha t the d iff er en tial is not mounted , then th e pr elo ad i s s ui table. In su ch case,

any axial displac ement of the crown gear sh ould not exist with the axially applied thrust.

2) Adjustment of meshing prints and backlas h of the spiral bevel gears

A. Standard of meshing backlash and me shing pri n t

The required mesh backlash is 0.1-0.25 mm. The ideal mesh prints distribute in the

middl e of the work ing teeth surface an d are sli ghtly nea r the small end of the tee th; me shing

prints are like spot s; meshing print height is not less than 50% of tooth height, the length of

meshing print is not less than 60% of tooth length.

B. Ins pection o f m esh backlash and me sh print

a. Inspec tion of mesh bac kla sh

There are two methods of inspection: One is dial gauge inspection. During measuring,

put contact terminal on the teeth surfaces of big ends of bevel gear, and fix bevel pinion,

swing bevel gear in rotatin g dire ction; if th e reading of the dial gauge is 0.1 4-0.3m m(circu lar

cleara nce), the b acklash i s correc t. The othe r method is as follo ws: Using a lead w ire of 15 -

∽

20mm lon g and 0. 5mm thick or a fuse bent int o " " sh ape, put it between the un meshed

teeth s ur faces of t he b evel g ear and p ini on(i. e. b etwe en th e c onve x sur fac e of t he be ve l pin ion

and th e concav e surfac e of the be vel ge ar) and rotate th e gear pa ir, th en the th ickness of the

extruded part where the lead slice is near the big ends of the gears is the vertical gear

backlash. The gear backlash should be among the range of 0.1-0.25mm(vertical backlash). It

is bette r to measur e th re e o r m or e po in ts well dist rib u ted along th e c irc um fe rence of th e be ve l

gear and take the average value of measuring the gear backlash in the three or more points.

b. Inspection of mesh print

Page 31

26

Colori ng meth od is adop ted in th e inspect ion of th e mesh prin t. Smea r red-le ad pain t

evenly on the fa ces of the bevel gear tee th. Turn th e b e ve l gears s everal times until the di stinct

contac t traces a re im pr inted on the t eet h faces of th e bevel p in ion . T h e p rint imprinted on th e

teeth faces of the bevel pinion is mesh print. As the spiral direction of the bevel pinion is righthanded, when the tractor forwards, the force is applied on the concave face of the bevel

pinion , the readlea d pain t shoul d be smeare d on th e conve x face o f the bevel ge ar; wh ile t he

tractor reverse, the force is applied on the convex face of the bevel pinion, the red-lead paint

should be smeared on the concave face of the bevel gear

.

Table 4-1 Adjustment of mes h print of bevel gear

Note: solid line arrow shows the adjustment of mesh print and dotted line shows the

adjustment of mesh backlash .

Page 32

27

c. Adjustment of mesh backlash and mesh print

Durin g adjustmen t, the bevel gear and pinion axially m oving will change both mesh

backlash and me sh print. If the me sh print requ irement is contr adictory to m esh backlash,

correc t m es h p rint shou ld mainly be en su red, an d t he ad justment ra ng e of mesh b ac klash can

be enl arge d (Es pe cial ly wh en t he gea r and bea ring wears an d the re ad justm ent is ne eded , the

backlash can be enlarged). But the mesh backlash should be not less than 0.1mm.

During normal op eration of the tractor, the normal mesh backlash and mesh point will

both change, under this condition, so long as teeth faces contact is normal, only the mesh

backla sh incr eases , and thi s increas e of back lash du e to gear wear nee d not be adjuste d. But

after the overha ul of the tractor or when replaci ng a new pair of main driv e g ears or bevel

bearing, the mesh print and backlash should be ensured at the same time by careful

adjust ment.

Note: A s th e b evel pin i on an d the bev el gear ar e a pair of ma t c he d gears, b e sure no t to

make pairs in disorder. The spiral bevel gears should be replaced together with the bearings,

if possible. Otherwise, it will affect their service life.

3. Adjustment of differential lo ck

The differential lock can be adjusted through bolt (3) and nut (4). During adjusting,

the gap be tw ee n le ft c law (9) and rig ht cla w (7) should be abo ut 2mm . Screw in or out th e b ol t

(3) to increase or r educe the gap. After the adjust ment has been done, use nut (4) to ti ghten

bolt (3). (Fig.4-4)

Page 33

28

4. Adjustment of brake

After the tractor has worked for a period, t he wear of the friction disc of the brake

makes the gap between friction disc and brake drum or friction disc and brake case and

brake cover incr ease and aff ect the brak e perform anc e. Exc essiv e free tr avel w ill cau se br ake

ineffectiveness. So the brake should be regularly adjusted to ensure the safety walk of the

tractor. When one of the following faults of the brake appears, adjustment should be done in

time. (No matter the tractor is new or old).

a. Free travel of brake pedal is excessive and cause brake ineffectiveness.

b. F re e travel of brak e pedal is too s mall and keep th e brak e in se mi-bra king s t at e ; t h e

brake case al s o generates heat.

c. Left and right braking force is unidentical and tractor yaw motion appears.

1)Adjustment of block brake(shoe brake)

A. Free travel adjustment of brake pedal is the displacement measured from the

highest position of the pedal ,when resistance is felt by pressing the pedal .The travel should

be in the r ange of 55-65 mm ( Fig.4-5 ) .D u ring ad ju s t me nt ,fi rs tl y lo osen th e locki ng nut (9 ) on

brake pull rod (8) and change the length of the brake pull rod ,then pres s the brake ped al (5)

from its high est po siti on un til l the dis place men t it 55 -65m m and the gap betwee n brak e dr um

(13) an d brake s hoe(12) is elim inated . Make the left and r ight bra ke pull ro d adjus tment be

identical ,the tighten them with locking nut (9) (Fig.4-5).

B.Tractor yaw motion adjustment

Page 34

29

While left and ri ght brake adjustment is unidentic al and the tractor running in h igh

speed is braked in emergency , unidentical tyre print length (l eft and right ) and yaw motion

appear .In such case ,the brake pull rod should be shortened in the side with short print

length of tire ,or vice versa, to make both sides of the driving wheels to be braked

simultaneously and reliably ,then retighten the locking nut (9) . Subsequently ,check in the

3rd gear firstly ,a fter above adjustment has been done ,the check in the 4th gear again.

2) Adjustment of disc brake

A. Fre e state adj ustment of d isc brake pe dal is the displaceme nt measured from the

highest

Loosen the outer locking nut M10 (5) on adjusting rod (1) and turn the inner nut M10

(4) to change the mounting a ngle of t he rock a rm (2) th rough the longitudi nal motio n of th e

self-position cushion (3) and ensure that the central connecting line of the upper and lower

holes inclines to rear from the plu mb lin e. After ad ju stment, lock it with lo ck in g nut (5) . (F ig. 4

-6)

Page 35

30

B. Travel adjust ment of brake ped al

Loosen the locking nut (7) on pull rod adjusting fork (6) and turn brake pull rod

adjustin g fo rk to ch ange th e length of the pull rod (8) u nt il the disp lac emen t (from the h ighest

position of the brake pedal to friction disc assembly being completely braked) of the brake

pedal is 85-9 5mm. When the lef t and r ight pe dal are locked to geth er, step ping on t he ped als

can simultaneously brake the left and right wheels; after adjustment, lock it with nut (7).

(Fig.4-6)

If the a bov e a djus tin g ran ge ca n no t per fec tly m ake th e free st ate an d br ak e sta te o u t,

they can be adjusted through increasing or reducing the brake cover gaskets (11) between

brake cover (12) and brake case (10). If the brake travel is too small, increase the gaskets; if

the brake travel is too big, reduce or remove the gaskets. (Fig.4-6)

C. Brak e yaw motion adjus tm ent

Refer to the adjustment of shoe brake

5. Adjustment of front axle

1) Axial clearance adjustment of front wheel beari ngs

The normal axial clearance between front w heel bearings (8) and (9) is 0.1-0.2mm(Fig .4

-7). During operation, when the clearance is more than 0.4mm, the front wheel will swing to

left or right during walking; and the bearings are eas il y broken by shock lo ad, so adjustment

Page 36

31

should be made timely. During adjustment, firstly support the front wheels off the ground,

and dismantle the bearing cover and pull out the split cotter on nut (6), then screw nut (6)

until the bearing clearance is eliminated , and return the nut (6) in 1/15-1/7 turn, then lock the

nut with split cotte r, and assemb le the bearin g cover .

2) Adjustmen t of f r on t wheel toe-in

During the operation of the tractor, the front wheel toe-in will change due to

deforma tion and wear out of th e parts of steerin g mechanism an d front axle. If the to e-in is

not adju sted in time , the w ear of t he fr ont wh eel will acce lerate. T he adj ustmen t ste ps of toein are as follows:

a. Stop the tractor on level ground, place the front wheels on rectilinear walking

position.

b. Me asure t he dis tance A a nd B be tween the tw o wheels (Distan ce A i s the distanc e

between the forefront o f the two wheels. B is the distanc e between the rearmost en ds of the

two wheels.) at the s ame horizonta l plane through the ce nters of the two wheels circumference.

c. Loosen the locking nuts (1) and (3) on both sides of t he knuckle rod (2 ); turn the

knuckl e rod to make B-A=4-10m m, then retighten knuckle rod (2) with nuts (1) and (3).

6. Adjustment of fro nt drive axle

1) Adjustment of main drive (Fig.4-9)

During assembling, choose the suitable

bearing seat gasket (9) of driving bevel gear

and adjust the adjusting nuts (3) on the both

sides to make the mesh backlash of the gear

pairs of the main drive be 0.15-0.30mm, and

ensure the contacting area, i.e. the meshing

contact traces of the gear pairs should be

adjusted to the middle of gear tooth faces and slightly nearer to the small end; and should

also ensure that no axial movement of the bearings on either end will appear, and that the

differential assembly could turn freely. Adjust the position of the concave slot of the nut to

make the locating plate of the cover be inserted smoothly, then lock the nut.

Page 37

32

2) Adjust ment of side reduction gear pairs (Fig.4-10)

During assembling, choose gasket (13) of driving shaft cover to keep the mesh

backlash of side reduction gear pairs among 0.2-0.4mm, and ensure meshing contact trac es.

Page 38

33

3) Adjustment of interme di ate driven gear pairs (Fig.4 -9)

Durin g assembling, c hoose adjusting shim (2 ) of the s tanding shaft to keep the mesh

back lash among 0.2-0.4mm and ensure meshing contact traces.

7. Adjustment of wheel tread

1) Adjustmen t of f r on t wheel tread

The front wheel treads of Agracat Series Tractors have the following two types:

adjustable wheel tread and non-adjustable wheel tread. The adjustable wheel tread is

adjusted in step through extension sleeve housing. The adjusting range is 970-1270mm. Every

step clearance is 100mm

.

Page 39

34

2) Adjustment of rear wheel tread

The wheel tread of the back wheels can be steplessly adjusted through changing or

turning over the f ixed posit ion of the d riving wheel hubs in th e driving s haft. It can be als o

adjusted in steps throu gh turn ing over the w he e l r i m s or exch anging the right an d l eft dr i v i n g

wheels .

The a djustm ent rang e of the first -st ep wh eel t read is L 1-L 2; th e n ormal whee l tre ad is

L2. The a djustment range o f the second- step wheel tre ad is L3-L4 ( see Fig.4-11) . Numerical

Ⅰ

value of L1-L4 can be referred to in chapter .

8. Adjustment of steering gear

There ar e th re e k inds of ste er ing gear o f A gr aca t S eries Tra ctors: cr an kp in ty pe (Fig.4 -

12), circulating ball type (Fig.4-13) and hydraulic steering gear (Fig.4-14).

1) Adjustme nt of crankpi n typ e steering gear (Fig.4-12)

Page 40

35

A. Adjustment of bear ing clearance

In order to ensure the normal work of the steering gear, the clearance of the bevel

bearings 7204 on either end of steering worm should be adjusted. When the bearings wear out

to make the a xial clearance inc rease, the clearan ce should be adjus ted timely; i.e. make th e

upper and lower moving play of the steering worm be not more than 0.1mm through

increasing or reducing the quantity of adjusting shim (11).

B. Adjustment of mesh clearance of steering worm and crankpin

During operation, the mesh clearance will increase due to the wear out of the steering

worm and crankpin, and the idle angle of the steering wheel also increases. When the idle

°

angle of the steering wheel is more than 25 (or the arc length along the outside of the

steering wheel is more than 90mm), the clearance should be adjusted.

Page 41

36

Page 42

37

Adjustin g method: loos en nut (7), turn adjust ing screw (8) to make rock arm sha ft (2)

move axially and therefore th e mesh clearance is changed.

When th e r oc k a rm shaft is in midd le po si tion, the free trav el of steering wheel outside is

°

50-55mm , i.e. the id le an gle o f the steer ing w hee l is n o more than 15 , then the a djus tment

is suitable. After adjustment, lock nut (7).

2) Adjustme nt of circulating ball type steeri ng ge ar

A. Adjustment of bear ing clearance

In order to ensure the normal work of the steering gear, the clearance of the bevel

bearings 7304 on both ends of the rock arm shaft should be adjusted. When the bearings wear

out and the axial clearance of the bearings increases, the clearance should be adjusted in

time; i.e. make the upper and lower moving play of the steering worm be not more than

0.1mm through increasing or reducing the quantity of adjusting shim (7).

B. Adjustment of mesh clearance of rock arm shaft (with steering worm and nut

assembly) and fa n teeth of rock arm shaft.

During operation, the mesh clearance will increase due to the wear out of fan teeth of the

rock ar m s ha ft (w it h steerin g w or m an d n ut a ssembly) a nd th e id l e a ngl e of th e steering whee l

will also increase; so adjustment should be made in time. Loosen nut (2), turn adjusting screw

(1) to make rock arm shaft move axially and therefore the above mesh clearance is changed

.

3) Construction and adjustment of balance string type hydraulic steering gear

A. Wo rking p ri n ciple of balance string type hydrau lic st ee r in g gears BZZ serie s ba lance

string type hydraulic steering ge ars are adopted in the hy draulic s teering gear s of Agracat

series tractors; their structure diagram is as Fig.4-14. It is mainly made up of steering control

valve and steering measuring device.

Page 43

38

Valve sleeve of the steering control valve (6) is connected with valve core (7) through

plug (5), and spring leaf is fixed in the middle of the valve. The hole in the valve core (for

mounting the plug) is a little bigger than the hole in valve sleeve (6), so they can rotate

relatively, the outside of the valve core connects with connecting piece (1).

The stator (13) and rear cover (10) of steering measuring device are fixed together with

valve body (3) of steering control valve by bolt. Rotor (9) connects with valve sleeve (6)

through connection shaft (8) and plug (5). Rotor (9) and stator (13) are balance string type

needle wheel mesh pair. The rotor has 6 short outer pendulum string curve teeth of equal

distan ce, while the stato r has 7 arc n eedle teet h. During w orking, the stator is st ill and the

rotor r ot ates roun d the center of th e stato r a t t he radius of a ce rt ain eccentric distan ce. Wh en

the rot or rotat es rou nd cent er of th e stator (revol ution) , it al so rotat es roun d its axi al line in

opposi te directio n (rotatio n). As the rot or makes a ci rcuit and it ca n rotates ro und the sta tor

center for -6/(7-6)=-6 circuits, rotor makes one circuits, the oil liquid will be squeezed out

×

from the teeth slot (6 7=4 2), and the displacement at unit volume is large.

B. Adju st m ent of balance s tring type hydra u lic steering gear.

As the ro tatin g times or circu its of th e steeri ng whe el conc ern the ra ted dis placem ent o f

Page 44

39

the stee ring gear, whic h has be en de cided dur ing de sign ing; if the r adia l or ax ial cl eara nce o f

the sta tor and rot or pair is too big to cause no m anpower s teering, th en the roto r and stator

pair should be replaced. In other conditions, adjustmen t is not needed.

9. Construction and adjus tment of hydraulic hitch system

Hydra ulic hi tch sys tem cons ists o f hydr aulic s ystem a nd hit ch devi ce. Hydr aulic system

is an open circulating circuit system controlled by pressure circuit. The hitch device is rearattached 3 point hitch. Hydraulic system mainly consists of semi-separation attachment type

hydraulic lifter, gear pump, oil f ilter and their oil pip es (which connect them together).

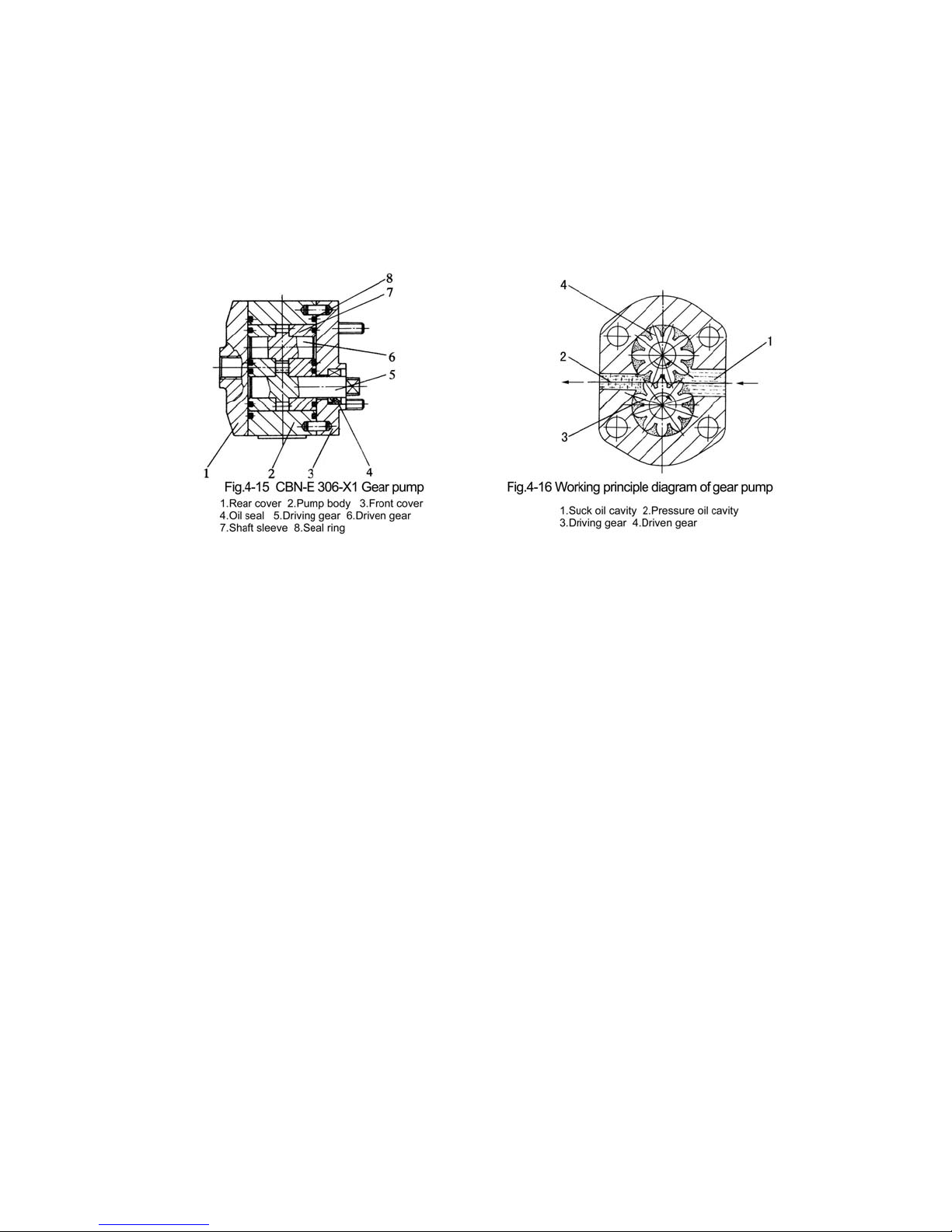

1) Working principle of gear pump

The gear pu mps atta ched to Agracat serie s tractor s are CB N model vo lume type outs ide

mesh gear pumps (Fig.4-15). They are all left handed pumps except the right hand ed pumps

on Ag racat-1 60, 164 tr ac tors. The gear pump s ar e mo unte d on the back e nd f ace of t he righ t

side of the gear ca se of the d iesel en gi ne front, w hich are driv en by engi ne s. The ge ar pump is

made up o f a p air of outsid e mesh sh aft gear (5) and ( 6), gear body (2 ), sleeve (7) an d rear

cover (1) and front cover (3).

The wo rking prin ciple of the gear pump is as Fig.4-16 . Take left -handed gear pum p as

example: After starting the engine, the driving gear of gear pump rotates counterclockwise,

and the oil enters the teeth from the pressure oil cavity and fill the teeth with oil. The oil

entered the pump is surrounded and contained by sleeve, meshed teeth and pump body and

two oil cavities which are not connected with each other are formed: suck oil cavity and

pressure oil cavity. The gear rotates right cavity (suck oil cavity) and the inner gear teeth

return mesh to make the volume be tween gear te eth increase and form part va ccum, and the

oil in the tank is sucked in . Meanwhil e the inner gear teeth of le ft cavity (pre ssure oil cavity)

begin to mesh (teeth int o each other) to sq ueeze the oil amon g the teeth out of the oil pum p.

Page 45

40

With the rotation of the engine, the oil in the cavity will continuously flow into the lifter

through gear pump.

During working, there is pressure difference between the suck oil cavity and pressure oil

cavity of the gea r pump, the hi gh pres sure oi l of pres sure oil cav i ty w ill leak an d return to th e

suck o il ca vi ty al ong th e clea ranc e of th e en d fac es of th e ge ar a nd s lee ve, g ear t ip and p ump

body a nd th e clearance formed by ba d ge ar mesh; which will cause p um p vo lume loss and the

heat of the hydraulic system. Too much volume loss will not make the gear pump form

normal working pressure; if seriously, the gear pump can't lift the implements.

In ord er t o red uce t he vo lume los s of the ge ar pump, co mple te flo ati ng sl eeve i s ad opted

in the pump, which has hydraulic automatic compensation and axial balance construction.

During working, the s leeve can fl oat in the pump body; the po sition of the sleeve is decided by

the force appli ed on the sleeve. The w idth of the pump body is 0.09 -0.18mm bigger than the

width sum of ge ar and sle eve. A fter mo unti ng , the front and rea r cove r are press ed ti ghtl y on

the pump body, the seal ring between the covers are compressed and the sleeve is pressed

tightly on the two end faces of the gear, thus not big clearance forms between sleeve and

covers. When the oi l pressu re in the ge ar r ises, the oil p ressure ap ply on th e b ack of the sle eve

throug h the cleara nce (Fig. 4-17), which ensures the good coo peration of the sle eve and gea r

stick end faces. This action is called hydraulic automatic compensation.

2) Lifter

A. Working principle of valve (simple direction exchange valve)

The str ucture a nd workin g principl e of the sim ple dire ction ex change val ve is as Fig.4-

19.

Main control valve (1) can be respectively put on lifting, neutral and lowering positions

throug h pu l li ng operati on handle (5). When main control valve (1) is on ne utral po si t io n (Fig- 4

-19b), the oil from the oil pump into the direction exchange valve flows back into oil tank

Page 46

41

through retu rning o il cavit y A a ccordi ng to the flo w di rection desi gnated by the arro w of the

Fig4-19(b). The n the e ntering oil cavity B and r et u rn ing oil ca vity C of the c ylinde r a re sea l ed

by main control valve (1); the oil cylinder is on seal and lock condition, and the implements

are mainta ine d in the fixe d po sition.

When the main control valve (1) is pushed to the lowering position (Fig.4-19d) from

neutra l pos ition , the re turning oil ca vity C is opene d, the oi l in th e cylin der is sq ueez ed back

into oil tank via returning oil cavity C under the action of the weight of the implement

acco rdin g to t he f lo w d ire ction de sig na ted by the arr ow in the Fi g.4- 19 d, t he n th e im plem ent

is l owering . In s uch ca se the oil f rom oi l pump i nto di rectio n exch ange v alve st ill fl ows b ack

into oil tank through return ing oil cavity A .

When the main control valve is pushed to lifting position from neutral position (Fig.419c), t he re turning oil cavit y A c loses , wh ile en terin g oi l cav ity B op ens. The n the oil from oi l

from oil p ump into di rec tion exch ange v alve ente rs t he oil c yli nder via oil ca vity B ac cord ing

to the flow direction designated by the arrow in Fig.4-19c, and push the piston forward, then

the implement begins to rise.

Syst em safet y valv e is adde d and establi shed i n the d irecti on exc hange v alve i n order to

prevent the hydraulic components from being damaged due to overload during the rising of

the implem en t.

Page 47

42

Page 48

43

B. Working principle of lifter

Fig.4- 20 is a wor king pr inciple di agram of pos ition adju sting of the l ifter (with simple

direction exchange valve and high adjustable performance). While pulling the operation

handle (1 0) to l owerin g positi on, po sitio n locati ng ste el ba ll (8) f alls in to lo wering the position

locatin g slot B o n p osition l ocating block (7), m ea nw h ile m a in con tro l valve (5) m o ves rig ht to

the lower p ositi on . The oil i n th e cylind er flow s bac k into oil tan k thr ough main co ntrol valv e

(5), and the implemen t begins to fal l down. Wit h the implem ent fall ing grad ually, sto p pin (2 )

fixed on the stop plate of the lift shaft and the lift shaft together rotate around the lift shaft