Page 1

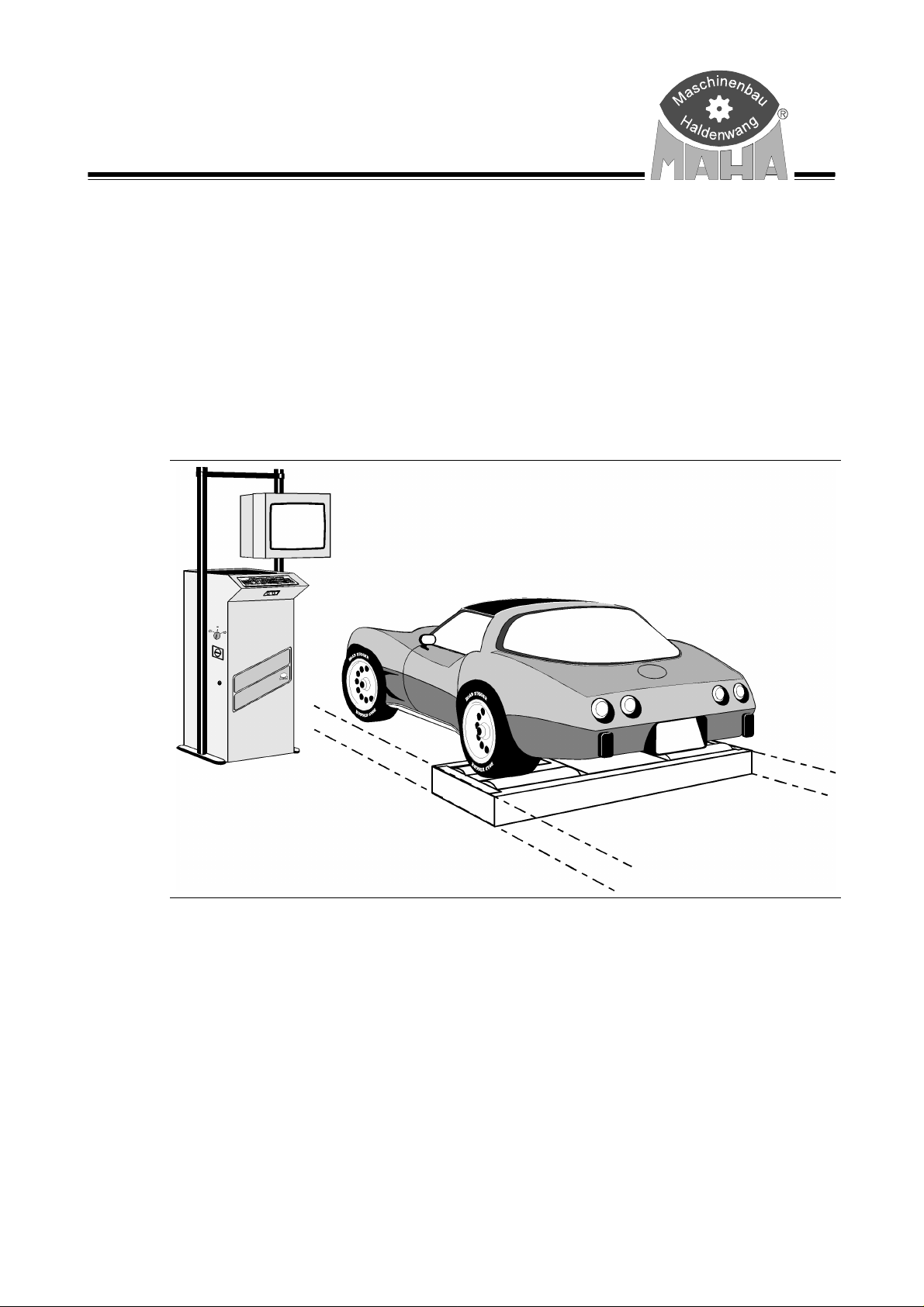

TPS II for Eurosystem

Speedometer Tester

for trucks, passenger cars and transporters

Addition to the operating manual for Eurosystem TRUCK

Original Operating Instructions

D1 1005BA1-GB01

Page 2

TPS II Eurosystem TRUCK

DITION

E

1.edition of this Operating Manual dated 23 October 2000

Addition to the Operating Manual for Eurosystem TRUCK

Eurosystem software version V 2.10

© MAHA GMBH & CO. KG

All rights reserved. Any reproductions of this document, partial or complete, are only allowed

with prior consent of MAHA Gm

ights reserved in cases of patent granting or registration of design.

All r

The contents of this version have been checked with great care. However, errors cannot be fully

excluded. Please contact MAHA should you find errors of any kind.

Subject to technical change without notice.

These instructions are intended for users with previous technical knowledge in the field of

vehicle testing technology and MS Windows operating system applications.

Windows and Windows for Workgroups are registered trademarks of the Microsoft Corporation.

bH & Co. KG

ANUFACTURER

M

ERVICE

S

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoy

en 20

D-87490 Haldenwang/Allgäu

Telephone: 08374 / 585-0

Telefax: 08374/ 585-499

Internet: http://www.maha.de

e-mail: maha@maha.de

MAHA Maschinenbau Haldenwang GmbH & Co. KG

- S

ervice Dept. Hoyen 20

D-87490 Haldenwang/Allgäu

Hotline: 08374 / 585 + extension

260 for brake testers, test lanes

280 for lifting technology

290 for performance testers, exhaust and air conditioning service equipment

Service: 08374 / 585-110 to - 113, - 115

Telefax: 08374 / 585-491

II D1 1005BA1-GB01

Page 3

TPS II Eurosystem TRUCK

ABLE OF CONTENTS

T

1 Safety .........................................................................................................................1

1.1 Introduction ....................................................................................................................................1

1.2 Safety Instructions .........................................................................................................................1

2 Description ................................................................................................................3

2.1 Introduction ....................................................................................................................................3

2.2 Usage, Range of Application .........................................................................................................3

2.3 Installation......................................................................................................................................3

2.4 Noise Emission ................................................................................................................. .............4

2.5 Equipment Overview......................................................................................................................4

2.6 Technical Specifications TPS II .....................................................................................................4

3 Operations .................................................................................................................5

3.1 Introduction ....................................................................................................................................5

3.2 Testing Procedure..........................................................................................................................5

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

Securing the Test Vehicle ..............................................................................................6

Speedometer Test..........................................................................................................6

Travel Distance Test.......................................................................................................8

Storage of Test Values.................................................................................................10

Reviewing of Measurements........................................................................................10

Prepare New Test.........................................................................................................10

4 Maintenance & Troubleshooting............................................................................11

4.1 Maintenance ................................................................................................................................11

4.2 Troubleshooting ...........................................................................................................................12

D1 1005BA1-GB01 III

Page 4

TPS II Eurosystem TRUCK

IV D1 1005BA1-GB01

Page 5

TPS II Eurosystem TRUCK

1 Safety

1.1 Introduction

Please read the standard operating procedures and user’s manual thoroughly and carefully

before commissioning the machinery and comply with the instructions. The operating manual

should always be conveniently stored to be readily available at all times.

This operating manual is an addition to the operating manual for the testing lane Eurosystem

TRUCK. All safety instructions provided in chapter 1 of these operating instructions must be

complied with.

Apart from the safety instructions mentioned above, no additional safety instructions apply for

the operation of the speedometer tester. The speedometer tester is not equipped with any

additional safety features.

1.2 Safety Instructions

The speedometer tester may only be operated by trained, authorized personnel.

The speedometer tester may only be used and operated for its intended purpose: Testing

the tachometer function up to 160 km/h up to 13 t axle load.

Sudden or strong braking actions and jerky accelerations are forbidden.

The vehicle must be secured with tightening belts onto the roller set.

Always drive straight onto the test stand’s rollers. Front-wheel drive vehicles must maintain a

straight driving direction.

Running vehicle engines represent potential carbon monoxide poisoning. The

operator/owner is responsible for providing sufficient air ventilation.

Due to the high noise level (>90 dB), appropriate ear protection should be worn.

No persons are allowed in the vicinity of the rollers while the test stand is in operation!

D1 1005BA1-GB01

1

Page 6

TPS II Eurosystem TRUCK Safety

2

D1 1005BA1-GB01

Page 7

TPS II Eurosystem TRUCK

2 Description

2.1 Introduction

The speedometer tester is designed for vehicles with their speedometer connection at the

driven axle

2.2 Usage, Range of Application

The speedometer tester is a roller tester for the inspection of the speedometer function of

passenger cars and transporters. The speedometer tester permits the measurement of speed

deviation as well as the deviation of the mileage meter.

Trucks, passenger cars and transporters up to a total axle load of 13 t can be tested. The

speedometer tester and the surrounding work area must be kept clean.

The tester is automatically on when the test vehicle is driving at more than 5 km/h on the rollers.

If the speed falls below 5 km/h, the tester switches off automatically.

The recorded measuring values are transmitted to the Eurosystem communication desk and

then displayed on the screen. The storing and the reviewing of measurements is described in

the operating manual for the testing lane Eurosystem TRUCK.

2.3 Installation

The test stand may only be installed and commissioned by the manufacturer's trained

authorized personnel or other qualified technicians of MAHA dealers or representatives. MAHA

instructions must be followed when installing or expanding the testing device.

The manufacturers CE conformity declaration becomes invalid when the installation is not don e

by qualified service technicians. MAHA is not liable for damage caused by unqualified, unautho-

rized installation. Further, the manufacturers warranty also becomes invalid.

D1 1005BA1-GB01 3

Page 8

TPS II Eurosystem TRUCK Description

2.4 Noise Emission

The noise emission test was conducted during the speedometer test, at the highest test speed

of 160 km/h.

Test results

A-evaluated sound pressure level: 105,0 dB(A) (averaged with all measuring points, see

measuring protocol)

A-evaluated acoustic power level: 103,4 dB(A) (calculation based on DIN 45635 Part 1)

Due to the high noise in the test room, ear protection should be worn.

2.5 Equipment Overview

2.6 Technical Specifications TPS II

Max. axle load 13 t

Testing speed 0 to 150 km/h

Weight 950 kg

Tracking width 820 to 2620 mm

Roller diameter 318 mm

Roller length 900 mm

Roller axle separation 457 mm

Dimensions roller set (HxWxL) 400 x 842 x 3000 mm

Air pressur lifting device min. 5 bar

Exit support Pneumatic lifting device with brake

4

D1 1005BA1-GB01

Page 9

TPS II Eurosystem TRUCK

3 Operations

3.1 Introduction

Please also read chapter 3, Eurosystem PC-Program, in the operating manual for the testing

lane Eurosystem TRUCK.

The storing and the reviewing of measurements is described in the operating manual for the

testing lane Eurosystem TRUCK.

3.2 Testing Procedure

In order to start the test procedure, the monitor

must show the main menu. The instruction line

must show the following message:

No vehicle loaded. Select with <1>.

If this message does not appear press

<F8 NEW VEHICLE>.

Now the test lane is ready for a vehicle to be

driven on.

When the vehicle drives onto the individual

equipment the corresponding test screen is

blended in.

Always pay attention to the

(in the description this is indicated by

The recorded measurement values are automatically taken over in the temporary memory and

remain there until they are stored in connection with customer/vehicle or until they are

overwritten when a new test is conducted.

The following guides the user through the testing procedure step by step. You should be familiar

with the usage of the individual screen elements and the keyboard. If this is not the case, please

read the following sections of the operating manual for the testing lane Eurosystem TRUCK:

3.4 Screen Design

3.5 Using the Main Mask

3.6 Using the Button Strip

messages and instructions on the instruction line

Instruction text ).

during testing

D1 1005BA1-GB01

5

Page 10

TPS II Eurosystem TRUCK Operations

3.2.1 Securing the Test Vehicle

It is highly recommended to tie down the test vehicle with a restraining strap system. The tie

plates for fastening the restraining straps are available at the manufacturer. The restraining

strap system avoids skidding of the test vehicle within the roller set.

In order to secure the vehicle, the two restraining straps must be laid around the vehicle’s

towing lug and fixed on the tie plates. Front-wheel drive vehicles have to be secured at the front,

rear-engine drive vehicles at the rear. Cover the restraining straps in the area around the towing

lug with a wear-resistant hose to avoid excessive abrasion.

3.2.2 Speedometer Test

Rotating test stand rollers are potentially dangerous! Risk of injury!

The speedometer tester permits the measurement of the difference between the actual vehicle

speed and the speed displayed on the tachometer of the vehicle.

The speedometer test can be conducted by using the keyboard or the remote control. If a

remote control is not available, a second person will be needed to perform the test.

1 Drive onto the test stand

Drive the driven axle of the vehicle

a.

slowly onto the roller set.

⇒

The vehicle must be positioned

straight

Apply the parking brake.

b.

and

centered

on the roller set.

2 Preparations

Secure the vehicle with tightening belts.

3 Lower lifting device

Press key <T>.

a.

The following screen appears:

Use the <F9> key to select the lifting

b.

device (raise/lower).

Use the <ESC> key to leave this screen.

ATTENTION : Starting from software

version V2.12 the <F4> key must be used

instead of the <T> key to lower the lifting

device. The function of the <F9> key for

switching over the lifting device

(raise/lower) is still the same.

4 Start the testing program

Accelerate the vehicle up to 5 km/h to start

the testing program.

⇒

The screen opposite appears.

6

Accelerate the vehicle to the target value

D1 1005BA1-GB01

Page 11

Operations TPS II Eurosystem TRUCK

The peak of the green arrow indicates the

target speed, the bottom indicates the

tolerance range (±5 km/h). The black arrow

shows the actual speed of the vehicle.

5 Conduct the test

Accelerate the vehicle up to the indicated

target value as per vehicle speedometer.

⇒

The recorded test values will be

displayed.

If the actual speed is within the tolerance

range for 3 sec., the test values will

automatically be stored.

⇒

The next target speed will be indicated.

The measuring value can also be stored by pressing the

target speed. If a remote control is not available, a second person is needed to store the value

by using the keyboard.

Use the

Use the

It is possible to intervene in the automatic test procedure by pressing <F5>. The measuring

values will be stored and the test procedure continues. If the test is repeated, the measuring

values in the temporary memory will be overwritten.

-key to go to the previous target speed.

<F6>

-key to go to the next target speed.

<F7>

6 Repeat the test

The test must be repeated for every target

speed as described in step 4.

The test can be aborted by pressing the

<ESC>-key.

7 Exit the test stand with lift beam

Press <T> on the keyboard or on the

remote control. After the vehicle is lifted,

slowly exit the roller set in forward direction.

key, in order to display the next

<F5>

D1 1005BA1-GB01

7

Page 12

TPS II Eurosystem TRUCK Operations

3.2.3 Travel Distance Test

The speedometer test can be conducted by using the keyboard or the remote control. If a

remote control is not available, a second person will be needed to perform the test.

1 Drive onto the test stand

Drive the driven axle of the vehicle

a.

onto the roller set.

⇒

The vehicle must be positioned

straight

set.

Apply the parking brake.

b.

2 Preparations

Secure the vehicle with tightening belts.

3. Lower lifting device

Press key <T>. The following screen

a.

appears:

Use the <ESC> key to leave this screen.

Use the <F9> key to select the lifting

b.

device (raise/lower).

ATTENTION : Starting from software

version V2.12 the <F4> key must be used

instead of the <T> key to lower the lifting

device. The function of the <F9> key for

switching over the lifting device

(raise/lower) is still the same.

and

centered

on the roller

4 Start the testing program

Accelerate the vehicle up to 5 km/h to start

the testing program.

Ì

The screen opposite appears.

Accelerate the vehicle to the target

value

5. Activate the travel distance test

Press <F8> travel distance to switch to the

corresponding test mode. The screen

opposite appears.

Enter correction factor

The standard setting for the correction

factor is 100%. The correction factor

defines the relation of the tire

circumference on the road to the tire

circumference on the test stand rollers.

8

D1 1005BA1-GB01

Page 13

Operations TPS II Eurosystem TRUCK

6 Conduct the test

a. Enter the mileage of the vehicle via the

number keys of the keyboard or remote

control.

b. Confirm with <RETURN>.

c. Accelerate the vehicle to approx. 20

km/h.

Pay attention to the vehicle’s tachometer.

After a distance of 100 m is traveled press

<F5>. Repeat this process ten times.

⇒

The recorded test values and the

average travel distance will be displayed.

By pressing <F6> the recorded measuring

values will be deleted.

7 Terminate the test

If desired, the test can be aborted with the

<F8> key. The main screen of the

speedometer test appears:

Press <ESC> again to return to the main

menu. In the main menu select <3> „Select

measurement“. Select <6> „External

devices“, then <C> to review the

measuring values. The screen opposite

appears.

8 Exit the test stand with lift beam

Press

remote control. After the vehicle is lifted,

slowly exit the roller set in forward

direction.

The recorded measurement values are automatically taken over in the temporary memory. If the

test is repeated, the measuring values in the temporary memory will be overwritten.

on the keyboard or on the

<T>

D1 1005BA1-GB01

9

Page 14

TPS II Eurosystem TRUCK Operations

3.2.4 Storage of Test Values

The storage of test values is described in the operating manual for the testing lane Eurosystem

TRUCK: ⇒Section 3.17 „Storage of Test Values“.

3.2.5 Reviewing of Measurements

The reviewing of test values is described in the operating manual for the testing lane

Eurosystem TRUCK: ⇒ Section 3.19 „Reviewing of Measurements“.

3.2.6 Prepare New Test

Make sure that the temporary storage is empty for beginning a new test procedure and the main

menu appears with the message:

After properly storing the test values the main menu appears automatically in test readiness. It

is also possible that the instruction line shows a different ready message or that a test has been

aborted and is to be started again from the very beginning.

No vehicle loaded. Select with <1>.

Activate the following box in the main menu:

A message about test readiness appears in the

instruction line

No vehicle loaded. Select with <1>.

:

10

D1 1005BA1-GB01

Page 15

TPS II Eurosystem TRUCK

4 Maintenance & Troubleshooting

4.1 Maintenance

To ensure proper functioning and longevity of the speedometer tester regular servicing

schedules should be followed.

Maintenance schedule:

Lubricate drive shaft once every 200 operating

200 h200 h

hours with universal-type lubricant.

The anchoring of the roller set as well as all

fasteners and screws should be thoroughly

inspected every 200 operating hours.

200 h

200 h200 h

The bearing sleeves of the rollers have

permanent lubrication. Under normal operating

conditions maintenance is not necessary.

D1 1005BA1-GB01

11

Page 16

TPS II Eurosystem TRUCK Maintenance

4.2 Troubleshooting

All work done on electrical parts of the equipment is to be carried out by trained, qualified

electricians or service technicians of the manufacturer or its dealers only. For any kind of

service or repair work the main switch must be switched off and locked.

MALFUNCTION POSSIBLE CAUSE REMEDY

No voltage

Vehicle cannot leave roller set

in backward direction.

Speed indication wrong or no

speed indication

Car lift device (TPS 2) lowers

by itself

Rollers are rotating although

the car lift device is lifted

➀

Voltage has been

interrupted

➁

Control power fuse F1

defective.

➂

Defective transformer fuse.

Free-wheel roller clutch is

defective.

Distance between RPM

impulse sensor and gear is too

large

Loss of pressure in pipe, air

bellow or valve.

Brakes are defective. Replace brakes.

- Restore voltage to

communication desk.

Exchange free-wheel roller

clutch.

Readjust distance (max. 0,8

mm)

Seal up leak or replace faulty

component

12

RPM impulse sensor

A

Drive shaft flange

B

Drive shaft flange

C

Roller

D

Support bracket

E

Bearing

F

Freewheel

G

D1 1005BA1-GB01

Page 17

Loading...

Loading...