Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

RGA UC

Mobile Column Lift

Original Operating Instructions

BA492401-en

Pos: 1 /Produktfamilien/Hebetechnik/COLUMNLIFT/492401 RGA UC/Inhalt: 4924 Titelbild @ 56\mod_1557234116488_0.docx @ 3139768 @ @ 1

Pos: 2 /-----For mat-----/MANUELLER UMBRUCH Se itenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

Page 2

2

Manufacturer

Service

Pos: 3 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Firmen-Information MAHA 2019 @ 56\mod_1557818397795_75.docx @ 3141940 @ @ 1

BA492401-en

2019-06-12

© MAHA Maschinenbau Haldenwang GmbH & Co. KG

The reproduction, distribution and utilization of this document as well as the communication of its

contents to others without explicit authorization is prohibited. Offenders will be held liable for the

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design. The contents of this edition have been checked with great care. However, errors cannot be

fully excluded. Subject to technical change without notice.

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20

87490 Haldenwang

Germany

Phone: +49 8374 585 0

Fax: +49 8374 585 590

Mail: maha@maha.de

Web: www.maha.de

Pos: 4 /-----For mat-----/MANUELLER UMBRUCH Se itenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

MAHA SERVICE CENTER

Maybachstraße 8

87437 Kempten

Germany

Phone: +49 8374 585 100

Fax: +49 8374 585 491

Mail: service@maha.

de

Web: www.mahaservicecenter.de

BA492401-en

Page 3

3

Contents

1

Safety .................................................................................................................... 5

2

Description .......................................................................................................... 10

3

Operation ............................................................................................................. 13

Pos: 5 /Papierkorb/Format/Inhaltsverzeichnis - 3 Ebenen @ 5\mod_1168867441046_75.docx @ 72920 @ @ 1

1.1 Introduction .............................................................................................................. 5

1.2 Symbols and Signal Words ...................................................................................... 5

1.2.1 Personal Injury .......................................................................................................... 5

1.2.2 Property Damage ..................................................................................................... 5

1.2.3 Information ............................................................................................................... 5

1.3 Intended Use ........................................................................................................... 6

1.4 Inappropriate Use ..................................................................................................... 6

1.5 Requirements on Operating and Service Personnel .................................................. 6

1.6 Safety Instructions for Commissioning ...................................................................... 6

1.7 Safety Instructions for Operation............................................................................... 7

1.8 Safety Instructions for Servicing ................................................................................ 7

1.9 What to Do in the Event of Defects or Malfunctions .................................................. 8

1.10 What to Do in the Event of an Accident .................................................................... 8

1.11 Safety Features ........................................................................................................ 9

1.11.1 Locking Device ......................................................................................................... 9

1.11.2 Braking Motor .......................................................................................................... 9

1.11.3 Phase Sequence Relay ............................................................................................ 9

1.11.4 Thermal Overload Protection .................................................................................... 9

1.11.5 Safety Shutdown after Motor Overload ..................................................................... 9

1.11.6 Warning and Information Labels ............................................................................... 9

2.1 Design and Operating Principle .............................................................................. 10

2.2 Specifications ......................................................................................................... 11

2.3 Sample Nameplate ................................................................................................. 12

3.1 Handling / Moving the Columns .............................................................................. 13

3.2 Controls and Indicators .......................................................................................... 14

3.3 Main Switch ........................................................................................................... 16

3.4 Initial Operation ...................................................................................................... 16

3.5 Positioning, Logging in and Interconnecting the Columns ....................................... 17

3.6 Switching over to Group Mode ............................................................................... 18

3.7 Switching over to Single Mode ............................................................................... 18

3.8 Raising and Lowering ............................................................................................. 19

3.9 Shutdown .............................................................................................................. 19

BA492401-en

Page 4

4

4

Maintenance ........................................................................................................ 22

5

Service Lifetime .................................................................................................... 34

6

Dismantling .......................................................................................................... 34

7

Disposal ............................................................................................................... 34

8

Contents of the Declaration of Conformity ............................................................. 34

3.10 Emergency-down Function, Mechanical ................................................................. 20

3.11 Adjustment of Support Forks .................................................................................. 21

4.1 Annual Inspection ................................................................................................... 22

4.2 Care Instructions .................................................................................................... 22

4.3 Maintenance by the Operator ................................................................................. 23

4.3.1 Lubricants .............................................................................................................. 23

4.3.2 Recirculating Ball Nut ............................................................................................. 23

4.3.3 Moving Gear .......................................................................................................... 24

4.3.4 Options .................................................................................................................. 25

4.3.5 Thrust Washers ...................................................................................................... 26

4.4 Setting the Hydraulic Jack ...................................................................................... 29

4.5 Battery Charge Condition ....................................................................................... 30

4.6 Troubleshooting ..................................................................................................... 31

4.7 Spare Parts ............................................................................................................ 33

Pos: 6 /-----For mat-----/MANUELLER UMBRUCH Se itenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

BA492401-en

Page 5

5

1

Safety

1.1

Introduction

1.2

Symbols and Signal Words

1.2.1

Personal Injury

DANGER

WARNING

CAUTION

1.2.2

Property Damage

NOTICE

1.2.3

Information

Pos: 7 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/S/Überschrift 1: Sicherheit @ 6\mod_1174482399906_75.docx @ 76962 @ 1 @ 1

Pos: 8 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Einführung @ 6\mod_1174482219062_75.docx @ 76793 @ 2 @ 1

Pos: 9 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Einführung Sicherheit_12pt @ 25\mod_1324455248318_75.docx @ 1138886 @ @ 1

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

Pos: 10.1 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Symbole und Signalwörter @ 50\mod_1503314612825_75.docx @ 2923200 @ 2 @ 1

Pos: 10.2 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/P/Überschrift 1.1.1: Personenschäden @ 50\mod_1503389040316_75.docx @ 2923708 @ 3 @ 1

Pos: 10.3 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole und Signalwörter - Personenschäden @ 50\mod_1503389427470_75.docx @ 2923852 @ @ 1

safety instructions are not covered by the product liability regulations.

indicates an immediate hazard which, if not avoided, will result in death or severe

personal injury.

indicates a potential hazard which, if not avoided, could result in death or severe

personal injury.

indicates a potential hazard which, if not avoided, could result in moderate or minor personal injury.

Pos: 10.4 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/P/Überschrift 1.1.1: Produkt-, Maschinen-, Anlagenschäden @ 50\mod_1503389109661_75.docx @ 2923756 @ 3 @ 1

Pos: 10.5 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole und Signalwörter - Produktschäden @ 50\mod_1503389546628_75.docx @ 2923899 @ @ 1

indicates a potentially harmful situation which, if not avoided, could result in damage to the equipment or surrounding objects.

Pos: 10.6 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/I/Überschrift 1.1.1: Informationen @ 50\mod_1503389229939_75.docx @ 2923804 @ 3 @ 1

Pos: 10.7 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole und Signalwörter - Informationen (2019-06-12 10:06:54) @ 50\mod_1503389660901_75.doc x @ 2923946 @ @ 1

indicates important information notes.

Pos: 11 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 6

6

1.3

Intended Use

1.4

Inappropriate Use

WARNING

1.5

Requirements on Operating and Service Personnel

WARNING

1.6

Safety Instructions for Commissioning

WARNING

Pos: 12 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/B/Überschrift 1.1: Bestimmungsgemäßer Gebrauch @ 6\mod_1176734022203_75.docx @ 88746 @ 2 @ 1

Pos: 13 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Bestimmungsgemäßer Gebrauch RG-HBZ_12pt @ 26\mod_1325512374516_75.docx @ 1143563 @ @ 1

• This lift is to be used exclusively for the safe lifting of commercial and agricultur-

al vehicles such as trucks, buses, tractors etc. Observe the rated load capacity.

• The lift may not be modified without the express written consent of the manu-

facturer. In case of non-compliance the declaration of conformity becomes

Pos: 14 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/B/Überschrift 1.1: Bestimmungswidriger Gebrauch @ 18\mod_1255530265027_75.docx @ 471571 @ 2 @ 1

Pos: 15 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Inhalt: WARNUNG - Bestimmungswidriger Gebrauch HBZ_12pt @ 53\mod_1527685460271_75.docx @ 3036085 @ @ 1

void.

Any use other than described is inappropriate, for example:

• Climbing on the lift supports

• Transporting persons on the lift supports

• Usage as mobile work platform or for other lifting operations

Pos: 16 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Anforderungen an das Bedienungs- und Servicepersonal @ 34\mod_1380637497630_75.docx @ 1835413 @ 2 @ 1

Pos: 17 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Anforderungen an das Bedienungs- und Servicepersonal_12pt @ 52\mod_1516807277486_75.docx @ 3001475 @ @ 1

All persons employed in the operation, maintenance, installation, removal and disposal of the device must

• be at least 18 years old,

• be mentally and physically suited for these activities,

• be demonstrably trained and instructed in writing,

• have read and understood the operating instructions, especially the instructions

what to do in the event of defects or malfunctions,

• be on record as having been instructed in safety guidelines,

• have practical experience in working with vehicle lifts and the hazards inherent

in such equipment.

Pos: 18 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften für die Inbetriebnahme @ 6\mod_1174482269156_75.docx @ 76838 @ 2 @ 1

Pos: 19 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Sicherheitsvorschriften für Installation und Erstinbetriebnahme RG-HBZ_12pt @ 26\mod_1325513120340_75.docx @ 1143627 @ @ 1

• Use the lift on a hard, level surface only.

• The standard lift version must not be installed and commissioned in the vicinity

of explosives or flammable liquids.

Pos: 20 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 7

7

1.7

Safety Instructions for Operation

WARNING

1.8

Safety Instructions for Servicing

WARNING

• Ensure that ecologically harmful substances are disposed of only in accordance

Pos: 21 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften für den Betrieb @ 6\mod_1174482268953_75.docx @ 76826 @ 2 @ 1

Pos: 22 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Sicherheitsvorschriften für den Betrieb RG-HBZ_12pt @ 56\mod_1556875808885_75.docx @ 3138630 @ @ 1

• Read the detailed operating manual.

• Use personal protective equipment.

• The lift owner/operator must provide a tidy and clean workplace.

• Carry out a visual and functional check of the equipment every day before start-

ing work.

• Do not exceed the rated load capacity per column as indicated on the lift

nameplate.

• Ensure an unobstructed movement of lift and vehicle.

• The vehicle doors must be closed during lift operation.

• After raising the vehicle briefly, stop and check the lift supports for secure con-

tact with the vehicle.

• Closely watch lift and vehicle during raising and lowering cycles.

• The working area which cannot be overviewed by the operator should be moni-

tored by a second person.

• When operating the lift in single or group mode, make sure the vehicle is not

tilted.

• Do not allow anyone to stay in lift area during raising and lowering cycles.

• Do not allow anyone to climb on lift or inside raised vehicle.

• Keep lift and vehicle free of tools and parts.

• When using the lift outdoors, lower the vehicle and stop operation when the

wind velocity exceeds 6 m/s.

• Push the support forks completely under the wheels or lift points of the vehicle

to be raised.

• Do not drive over or pinch electrical cables.

Pos: 23 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften für Servicearbeiten @ 6\mod_1174482270640_75.docx @ 76850 @ 2 @ 1

Pos: 24 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Sicherheitsvorschriften für Servicearbeiten RG-HBZ_12pt @ 26\mod_1325513609250_75.docx @ 114369 1 @ @ 1

• Service work may be done by authorized service technicians only.

• Turn off and padlock the main switch before doing any repair, maintenance or

setup work.

• Disconnect the mains plug before opening the control box.

• Work on the electrical equipment may be done by service technicians or certi-

fied electricians only.

BA492401-en

Page 8

8

with the appropriate regulations.

1.9

What to Do in the Event of Defects or Malfunctions

WARNING

1.10

What to Do in the Event of an Accident

• Do not use high pressure or steam jet cleaners or caustic cleaning agents for

cleaning the lift,

• Do not replace or override the lift safety devices.

Pos: 25 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/V/Überschrift 1.1: Verhalten im Störfall @ 6\mod_1178097008375_75.docx @ 90829 @ 2 @ 1

Pos: 26 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Inhalt: WARNUNG - Verhalten im Störfall HBZ_12pt @ 54\mod_1534921928842_75.docx @ 3081581 @ @ 1

• In case of defects or malfunctions such as uncontrolled lift movement or defor-

mation of the superstructure, support or lower the lift immediately.

• Turn off the main switch and secure it against unauthorized usage. Contact

service.

Pos: 27 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/V/Überschrift 1.1: Verhalten bei Unfällen @ 19\mod_1267177245337_75.docx @ 794600 @ 2 @ 1

Pos: 28 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Verhalten bei Unfällen_12pt @ 34\mod_1381128863435_75.docx @ 1837175 @ @ 1

• The injured person is to be removed from the danger area. Find out where

dressing and bandages are kept. Seek first-aid.

• Provide first-aid (stop bleeding, immobilise injured limbs), report the accident

and seal off the accident site.

• Immediately report any accident to your supervisor. Make sure a record is kept

of every occasion first-aid is provided, e.g. in an accident book.

Pos: 29 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

• Remain calm and answer any questions that may arise.

BA492401-en

Page 9

9

1.11

Safety Features

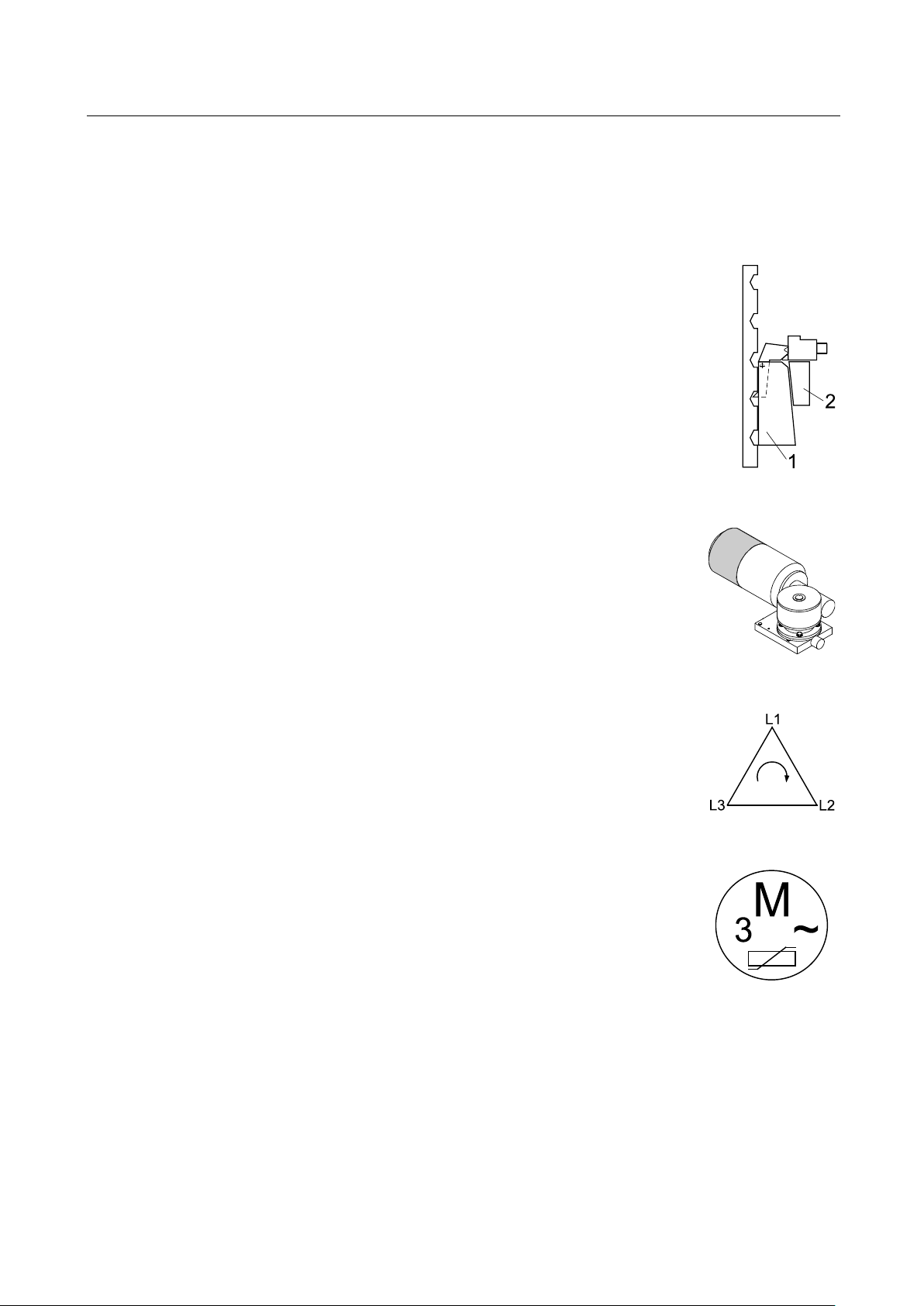

1.11.1

Locking Device

1.11.2

Braking Motor

1.11.3

Phase Sequence Relay

1.11.4

Thermal Overload Protection

1.11.5

Safety Shutdown after Motor Overload

≥ 15 %

1.11.6

Warning and Information Labels

Pos: 30 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitseinrichtungen @ 6\mod_1174483324765_75.docx @ 77103 @ 2 @ 1

Pos: 31 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Sicherheitseinrichtungen RG-HBZ_12pt @ 26\mod_1325513760548_75.doc x @ 1143755 @ 333333 @ 1

The locking device serves to prevent inadvertent lowering motions

caused by gear, load nut or lifting screw failure. The carriage is

blocked by safety wedge (1) and counterwedge (2).

The motors are equipped with AC spring pressure brakes. Once

the motors are switched off, the brakes prevent any further

movements.

The phase sequence relay in the power supply unit ensures safe

and independent operation.

Overload protection via electronically monitored thermoswitches.

The motor load is permanently monitored by the control PCB. If an overload of

occurs, the system will switch off automatically. In this case the lift cannot

be raised any more, but it can be normally lowered to bottom position.

Do not change or remove the warning and information labels. Order replacement

Pos: 32 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

for defective labels.

BA492401-en

Page 10

10

2

Description

2.1

Design and Operating Principle

Complete System

Column

Control

Pos: 33 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/B/Überschrift 1: Beschreibung @ 6\mod_1174482271453_75.docx @ 76889 @ 1 @ 1

Pos: 34 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Aufbau und Arbeitsprinzip @ 15\mod_1245311386403_75.docx @ 390861 @ 1 @ 1

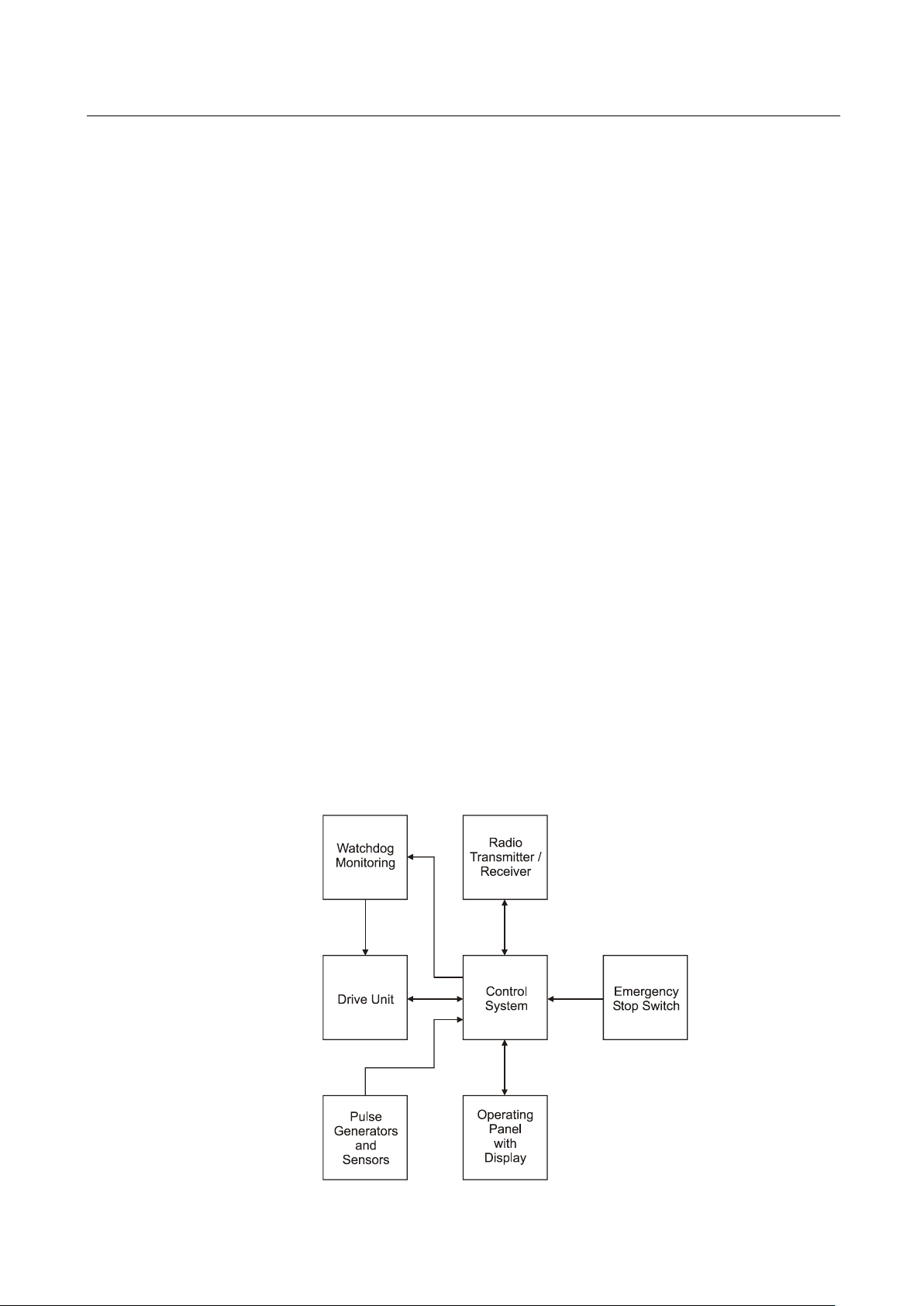

Pos: 35 /Produktfamilien/Hebetechnik/COLUMNLIFT/491901 RGA/BA/Inhalt: 4919 Aufbau+Arbeitsprinzip_12pt @ 56\mod_1560322463867_75.docx @ 3147307 @ @ 1

The complete system of the Mobile Column Lift consists of individual columns,

which can be interconnected (e.g. 4, 6, 8 columns) and used to raise commercial

vehicles. A maximum number of 8 columns per lift system can be logically interconnected. A maximum number of 8 lift systems can be operated parallel, with information exchange on different radio channels.

The complete system can be operated from each individual column. The columns

interact via radio communication, with each lift system using its own channel.

The columns are mechanically designed for engaging the wheels of commercial

vehicles.

They are all identical and interchangeable from system to system. Power supply is

effected via rechargeable batteries.

Each column is equipped with a control unit made up of the following components:

• Operating panel with display

• Microprocessor

• Pulse generators and sensors

• Watchdog monitoring

Pos: 36 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 | 4919 Steuerungsschema MCL/RGB/RGA @ 11\mod_1227620776698_75.docx @ 275412 @ @ 1

• Radio transmitter / receiver

• Drive unit

• Emergency stop switch

Pos: 37 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA492401-en

Page 11

11

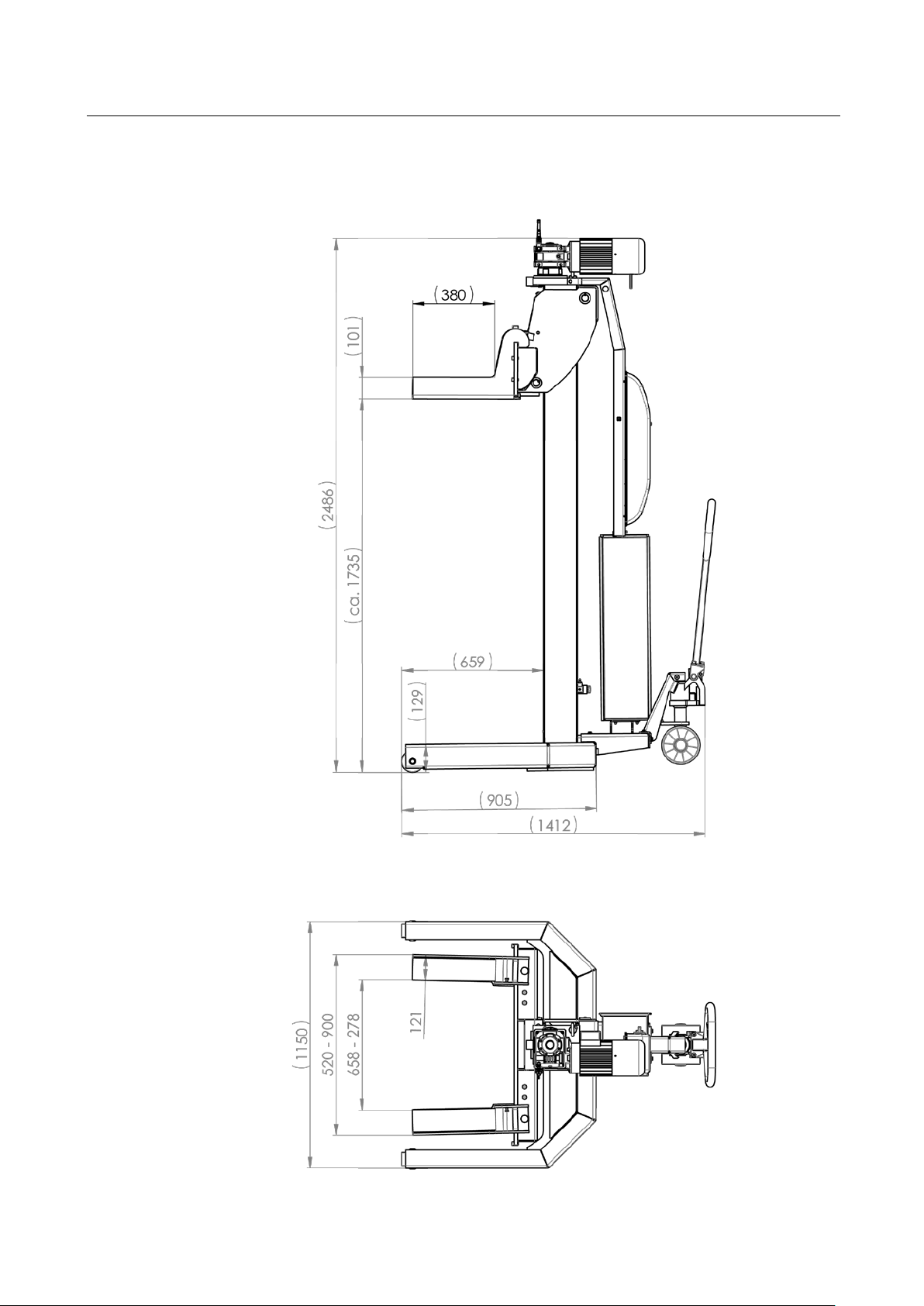

2.2

Specifications

Pos: 38 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/T/Überschrift 1.1: Technische Daten @ 7\mod_1184075526343_75.docx @ 99711 @ 2 @ 1

Pos: 39 /Produktfamilien/Hebetechnik/COLUMNLIFT/492401 RGA UC/Inhalt: 4924 Technische Daten (Bild) @ 56\mod_1557238824509_0.docx @ 3139827 @ @ 1

Pos: 40 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 12

12

2.3

Sample Nameplate

Pos: 41 /Produktfamilien/Hebetechnik/COLUMNLIFT/492401 RGA UC/Inhalt: 4924 Technische Daten (Tabelle) @ 56\mod_1557144635524_75.docx @ 3138900 @ @ 1

Load capacity per column 7500 kg

Full travel 1750 mm

Raising / Lowering time 113 s

Raising speed 920 mm/min

Tyre diameters 550…1500 mm

Motor power 1.5 kW

Protection class IP 54

Control voltage 48 V

Charging voltage 230 V

Net weight per column 545 kg

Surface load 0.5 N/mm

Noise emission < 70 dB(A)

Pos: 42 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/T/Überschrift 1.1: Typenschild-Muster @ 11\mod_1227622206096_75.docx @ 275574 @ 2 @ 1

Pos: 43 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: 4900 Typenschild-Position RG-HBZ_12pt @ 26\mod_1325515642544_75.docx @ 1144043 @ @ 1

Lifts of this model series have one nameplate at the lifting carriage of each column

and also on the supply unit (if present).

In the event of customer complaints, hotline requests or spare parts orders, serial

number and YoM of the lift should always be indicated.

Pos: 44 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: 4900 Typenschild-Muster RG-HBZ MAHA @ 55\mod_1539847355918_75.do cx @ 3093114 @ @ 1

Pos: 45 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

MOBILE COLUMN LIFT

Ser. No./ Date of Production: ***

Project: ***

Type: ***

Charging Voltage ***

Operating Voltage ***

Net weight per column ***

Load capacity per column ***

System of Protection ***

WEEE Reg. No. ***

2

BA492401-en

Page 13

13

3

Operation

3.1

Handling / Moving the Columns

Pos: 46 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/B/Überschrift 1: Bedienung @ 6\mod_1174482271218_75.docx @ 76877 @ 1 @ 1

Pos: 47 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/T/Überschrift 1.1: Transport / Verschieben von Hubsäulen @ 12\mod_1231486358029_75.docx @ 300405 @ 2 @ 1

Pos: 48 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 Transport/Verschieben (Bilder) @ 12\mod_1231486938020_0.docx @ 300505 @ @ 1

Pos: 49 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 Transport/Verschieben (Text) @ 26\mod_1325515805357_75.docx @ 1144075 @ @ 1

Screw a lifting-eye bolt M16 into the tap hole on the motor plate of the column.

Insert a chain or strap through the ring and lift the column using a hoist or forklift.

Close hydraulic valve by putting valve lever in position 3.

Pump with handle to raise the moving gear. Move column to desired position.

To lower the moving gear, open the hydraulic valve by putting the valve lever in

position 1. The column is ready for operation.

Pos: 50 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Position 2 is the neutral position.

BA492401-en

Page 14

14

3.2

Controls and Indicators

A LED Display: Operating Status

B Button: Raise

C Button: Lower

D LED Display: Number of Columns

E Button: Open/Close Column Unit

F LED Display: Column Unit

G LED Display: Channel Number

H Button: Select Channel Number

I LED Display: Operating Mode

J Button: Select Operating Mode

Pos: 51 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/B/Überschrift 1.1: Bedien- und Anzeigeelemente @ 23\mod_1296220301443_75.docx @ 968107 @ 2 @ 1

Pos: 52 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Bedieneinheit (Text) MCL/RGB/RGA_12pt @ 26\mod_1325579838255_75.docx @ 1145043 @ @ 1

Red, yellow and green LEDs indicate the operating status. See also section

"Troubleshooting".

When button is pushed, lift raises until button is released or upper end position

is reached.

When button is pushed, lift lowers until button is released or lower end position

is reached.

Number of LEDs represents number of columns in a column unit. Flashing LED

indicates next free column number in an open column unit.

Use this button to open a closed column unit or to close an open unit.

LED lighting up indicates that the column unit is closed. LED also lights up

when operating mode is changed (see below).

LED lighting up indicates current channel number.

Use this button to switch on to the next available channel. Occupied channels

are skipped, channel 10 is followed by channel 1 and so on.

Current operating mode is indicated by LED.

Use this button to switch on to the next mode. "Single" (one column), "Auto" (all

columns of a column unit) and "Group" (several columns) can be selected.

Pos: 53 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 15

15

Pos: 54 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Bedieneinheit (Bild) MCL/RGB/RGA @ 12\mod_1231487890433_0.docx @ 300630 @ @ 1

Pos: 55 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.doc x @ 1277 @ @ 1

BA492401-en

Page 16

16

3.3

Main Switch

DANGER

Main switch in position 0

Main switch in position 1

3.4

Initial Operation

Pos: 56 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/H/Überschrift 1.1: Hauptschalter @ 6\mod_1177592858312_75.docx @ 90635 @ 2 @ 1

Pos: 57 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Inhalt: GEFAHR - Hauptschalter mit Not-Aus-Funktion HBZ_12pt @ 54\mod_1534922618384_75.docx @ 3081665 @ @ 1

The main switch is used as emergency switch. In case of emergency immediately

turn it to position 0!

Lift is disconnected from power supply

Lift is ready for operation

Pos: 58 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Erstinbetriebnahme @ 10\mod_1219933389748_75.docx @ 240474 @ 2 @ 1

Pos: 59 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 | 4919 INFO - Antenne MCL/RGB/RGA_12pt @ 26\mod_1325583086820_75.docx @ 1145143 @ @ 1

Place the receiving antennae in an upright position before operating the columns.

Pos: 60 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Antenne MCL/RGB/RGA (Bild) @ 35\mod_1393426944951_0.docx @ 1911555 @ @ 1

Pos: 61 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 17

17

3.5

Positioning, Logging in and Interconnecting the Columns

in columns. After closing verify

Pos: 62 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/H/Überschrift 1.1: Hubsäulen aufstellen, anmelden und verbinden @ 6\mod_1178277124484_75.docx @ 91204 @ 2 @ 1

Pos: 63 /Produktfamilien/Hebetechnik/COLUMNLIFT/491901 RGA/BA/Inhalt: 4919 Hubsäulen aufstellen, anmelden und verbinden_12pt @ 56\mod_1560324806433_75.docx @ 3147418 @ @ 1

1 Push the support forks completely under the wheels or lift points of the vehicle

to be raised. Use the lift on a hard, level surface only.

2 Turn the main switch to position 1.

The "Auto" LED flashes.

3 Select the transmission channel. All

columns belonging to the same unit

must be set to the same channel.

4 Confirm using the operating mode

button.

The "Auto" LED lights permanently.

5 Repeat the procedure for all columns.

Number of columns within the unit is displayed.

Before closing the unit check the number of loggedthat it corresponds with the number of columns appearing on the display.

6 Once all columns are logged in, close the unit

using button "0/1".

The "Column unit" LED lights up, lift is ready for

operation.

Pos: 64 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 18

18

3.6

Switching over to Group Mode

3.7

Switching over to Single Mode

Pos: 65 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/U/Überschrift 1.1: Umschalten auf Group-Modus @ 6\mod_1178523038671_75.docx @ 9 1263 @ 2 @ 1

Pos: 66 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Umschalten auf Group-Modus MCL/RGB/RGA_12pt @ 26\mod_1325583767363_75.docx @ 1145207 @ @ 1

1 Switch to Group mode using the op-

erating mode button on the desired

columns.

The "Group" LED lights permanently.

Pos: 67 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/U/Überschrift 1.1: Umschalten auf Single-Modus @ 6\mod_1178526273265_75.docx @ 91290 @ 2 @ 1

Pos: 68 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Umschalten auf Single-Modus MCL/RGB/RGA_12pt @ 26\mod_1325583826298_75.docx @ 1145269 @ @ 1

1 Switch to Single mode using the op-

erating mode button on the desired

column.

The "Single" LED lights permanently.

Pos: 69 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 19

19

3.8

Raising and Lowering

WARNING

transmission

3.9

Shutdown

Pos: 70 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/H/Überschrift 1.1: Heben und Senken @ 6\mod_1178521944593_75.docx @ 91237 @ 2 @ 1

Pos: 71 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Heben und Senken MCL/RGB/RGA_12pt @ 26\mod_1325583908336_75.docx @ 1145341 @ @ 1

When operating the lift in Group or Single mode, make

sure the vehicle is not tilted. Otherwise the vehicle may

fall off the lift!

• Before operating the lift, check that the number of columns appearing on the

• All columns belonging to the same unit must be set to the same channel.

• If the unit is opened there may be interference problems with other

1 Press "Raise" or "Lower" button.

Lift stops once button is released or end position is

Pos: 72 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Ausschalten @ 15\mod_1245314486547_75.docx @ 390887 @ 2 @ 1

Pos: 73 /Produktfamilien/Hebetechnik/COLUMNLIFT/491201 MCL/BA/Inhalt: 4912 Ausschalten MCL/RGB/RGA_12pt @ 26\mod_1325584062028_75.docx @ 1145373 @ @ 1

1 Before shutting down the lift, open

"Column unit" LED goes off.

display corresponds to the number of columns actually logged in.

channels.

reached.

the column unit using button "0/1".

2 Turn main switch to position 0.

Pos: 74 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 20

20

3.10

Emergency-down Function, Mechanical

WARNING

1

2

Pos: 75 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/N/Überschrift 1.1: Notab-Funktion, mechanisch @ 15\mod_1245250921286_75.docx @ 390749 @ 2 @ 1

Pos: 76 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Inhalt: WARNUNG - Manuelles Absenken nur für autorisiertes Personal @ 54\mod_1534924350059_75.docx @ 3081860 @ @ 1

Authorised personnel only! Do not restart the lift before the error has been remedied.

Pos: 77 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 Manuelles Absenken RGE/RGA @ 26\mod_1325584169425_75.docx @ 1145437 @ @ 1

In case of power failure or defects the lift can be lowered manually.

Once the locking device is in engagement, manual lowering is no longer possible.

The following components are required for manual lowering:

A Lever at brake motor B Locking device

1 Pull or shake the safety wedge downward on each column.

2 First push onto the latch using a long screw driver, then additionally push the

manual release lever (in arrow direction).

Intermittently lower the columns in increments of approx. 50 mm, until the lift is

Pos: 78 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 Manuelles Absenken RGE/RGA (Bilder) @ 42\mod_1433145052043_0.docx @ 2249463 @ @ 1

Pos: 79 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

in bottom position.

BA492401-en

Page 21

21

3.11

Adjustment of Support Forks

WARNING

3

Pos: 80 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/F/Überschrift 1.1: Fahrzeugaufnahme anpassen @ 54\mod_1529566025602_75.docx @ 3038022 @ 2 @ 1

Pos: 81 /Produktfamilien/Hebetechnik/COLUMNLIFT/492301 RGE UC/BA/Inhalt: 4923 | 4924 Fahrzeugaufnahme anpassen (Text) @ 54\mod_1529566382774_75.docx @ 3038100 @ @ 1

The fork width can be adjusted to the required tyre diameters or lifting points by

moving the wheel sliders.

• Pull out the locking pin (1) with one hand and hold at the handle.

• Lift the wheel slider (2) by the fork end with the other hand and position it as re-

quired. Position the wheel sliders symmetrically to the lifting column to ensure

an equal load distribution (3).

• Insert the locking pin to secure the wheel sliders.

• Verify that the locking pin is correctly engaged after releasing the fork.

Avoid unequal load distribution. Risk of tilting!

Pos: 82 /Produktfamilien/Hebetechnik/COLUMNLIFT/492301 RGE UC/BA/Inhalt: 4923 | 4924 Fahrzeugaufnahme anpassen (Bild) @ 54\mod_1529567259463_0.docx @ 3038147 @ @ 1

Pos: 83 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA492401-en

Page 22

22

4

Maintenance

DANGER

Risk of death or severe personal injury by electric shock

4.1

Annual Inspection

12 (twelve) months

4.2

Care Instructions

Pos: 84 /Papierkorb/Überschriften/Überschrift 1: Instandhaltung @ 11\mod_1231318736629_75.docx @ 289550 @ 1 @ 1

Pos: 85 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: GEFAHR - Hauptschalter aus bei Instandhaltung_12pt @ 54\mod_1534925207098_75.docx @ 30819 71 @ @ 1

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Pos: 86 /Papierkorb/Überschriften/Überschrift 1.1: Jährliche Überprüfung @ 6\mod_1174482245718_75.docx @ 76817 @ 2 @ 1

Pos: 87 /Produktfamilien/Alle Geräte/Inhalte/Info!/Inhalt: Info - Jährliche Überprüfung_12pt @ 25\mod_1324460481075_75.docx @ 1139412 @ @ 1

• The maintenance interval prescribed by the manufacturer is

• Maintenance work shall be done only by authorized and trained service techni-

.

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

cians provided by the manufacturer, licensed dealers or service partners.

• In case of non-compliance the manufacturer's warranty becomes void.

Pos: 88 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Info!/Inhalt: Info - DGUV Regel 100-500 / DGUV Grundsatz 308-003_12pt @ 47\mod_148361118527 0_75.docx @ 2804763 @ @ 1

Pos: 89 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/P/Überschrift 1.1: Pflegehinweise @ 15\mod_1245912234854_75.docx @ 395780 @ 2 @ 1

Pos: 90 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Pflegehinweise - Alle Geräte_12pt @ 26\mod_1324468886116_75. docx @ 1141252 @ @ 1

• Periodically clean the equipment and treat it with a care product.

• Repair damage to the paintwork immediately to prevent corrosion.

• Do not use caustic cleaning agents or high pressure and steam jet cleaners to

Pos: 91 /Produktfamilien/Alle Geräte/Inhalte/Info!/Inhalt: Info - Pflegehinweise_12pt @ 26\mod_1324461215655_75.docx @ 1139602 @ @ 1

avoid equipment damage.

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment!

Pos: 92 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA492401-en

Page 23

23

4.3

Maintenance by the Operator

4.3.1

Lubricants

NOTICE

4.3.2

Recirculating Ball Nut

Pos: 93 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/I/Überschrift 1.1: Instandhaltung durch den Betreiber @ 28\mod_1332231100716_75.docx @ 1566248 @ 2 @ 1

Pos: 94 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/SCH/Überschrift 1.1.1: Schmiermittel @ 34\mod_1379919730255_75.docx @ 1831057 @ 3 @ 1

Pos: 95 /Produktfamilien/Hebetechnik/COLU MNLIFT/490801 RGE/BA/Inhalt : 4908 | 4919 HINWEIS - Kein Fett mit Festschmierstoffanteil @ 56\mod_1557147474951_75.d ocx @ 31389 37 @ @ 1

For lubrication use a mineral-oil based grease which is suitable for rolling bearings.

Do not use greases containing solid lubricants (such as graphite or MoS2.).

Pos: 96 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/K/Überschrift 1.1.1: Kugelumlaufmutter @ 14\mod_1241506892227_75.docx @ 370083 @ 2 @ 1

Pos: 97 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Inst. durch den Betreiber - Kugelumlaufmutter RGE_12pt @ 26\mod_1325586415833_75.docx @ 1145693 @ @ 1

Twice a year grease the recirculating ball nut with 4…7 strokes from a grease gun.

The lubricator is located at the recirculating ball nut inside the carriage.

BA492401-en

Page 24

24

4.3.3

Moving Gear

To make the lubricator accessible, remove the screws (1 and 3). Then remove cover plate (4) and fastening strip

of rubber cover (2).

Fold down the rubber cover.

Pos: 98 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/F/Überschrift 1.1.1: Fahrgestellrollen @ 14\mod_1241509024011_75.docx @ 370175 @ 3 @ 1

Pos: 99 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Inst. durch den Betreiber - Fahrgestellrollen RGE_12pt @ 26\mod_1325586494707_75.docx @ 1145725 @ @ 1

Periodically oil the rollers of the moving

gear.

If they are equipped with lubricators,

lubricate using a grease gun.

Pos: 100 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.do cx @ 1277 @ @ 1

BA492401-en

Page 25

25

4.3.4

Options

Pos: 101 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/O/Überschrift 1.1.1: Optionen @ 14\mod_1241509783181_75.docx @ 370221 @ 3 @ 1

Pos: 102 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Inst. durch den Betreiber - Optionen RGE_12pt @ 26\mod_1325587111196_75.d ocx @ 1145757 @ @ 1

Recirculating ball nuts with outside lubricator (option) should be greased every six months with four to seven strokes

from a grease gun.

Pos: 103 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.do cx @ 1277 @ @ 1

Carriage axles equipped with a lubricator (option) should be periodically

greased using a grease gun.

BA492401-en

Page 26

26

4.3.5

Thrust Washers

Visual Check with Feeler Gauge

2 mm

2 mm

Pos: 104 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/A/Überschrift 1.1.1: Anlaufscheiben @ 49\mod_1493215373635_75.docx @ 2874053 @ 3 @ 1

Pos: 105 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 | 4919 Anlaufscheiben - Prüfung Blattlehre (Text)_12pt @ 55\mod_1539852778031_75.docx @ 3093151 @ @ 1

Once a month, check the bronze thrust washers for wear using a feeler gauge

(see Fig.). New washers have a thickness of 2 mm. Washers showing an abrasion

Pos: 106 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 | 4919 Anlaufscheiben - Position auf Welle (Bild) @ 49\mod_1493209379772_0.docx @ 2873818 @ @ 1

of more than 1 mm must be replaced.

Pos: 107 /Produktfamilien/Hebetechnik/CO LUMNLIFT/490801 RGE/BA/Inhalt: 4908 | 4919 Anlaufscheiben - Prüfung Blattlehre (Bild) @ 49\mod_1493210270178_0.docx @ 2873865 @ @ 1

Pos: 108 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.do cx @ 1277 @ @ 1

BA492401-en

Page 27

27

Shaking Test with Lifting Carriage

WARNING

Pos: 109 /Produktfamilien/Hebetechnik/COLUMNLIFT/490801 RGE/BA/Inhalt: 4908 | 4919 Anlaufscheiben - Rütteltest (Text)_12pt @ 55\mod_1539852945581_75.docx @ 3093188 @ @ 1

In addition to the visual check, carry out a shaking test with the lifting carriage every three months. To do this, hold the carriage by the support fork, then pull forward with a firm twist.

In the event that the guide rollers run off the guideways during the shaking test,

the lifting column must be removed from operation until the thrust washers have

been replaced.

Pos: 110 /Produktfamilien/Hebetechnik/CO LUMNLIFT/492301 RGE UC/BA/Inhal t: 4923 | 4924 Anlaufsche iben - Rütteltest (Bilder) @ 54\mod_1529572126982_0.d ocx @ 3038289 @ @ 1

BA492401-en

Page 28

28

Pos: 111 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.do cx @ 1277 @ @ 1

BA492401-en

Page 29

29

4.4

Setting the Hydraulic Jack

A: Setting the Lowering Speed

Threaded Pin

Lowering Speed

B: Setting the Responsiveness of the Automatic Lowering Function

Adjusting Screw

Responsiveness

A B

Pos: 112 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Einstellungen am hydraulischen Fahrwagen @ 24\mod_1302611581158_75.docx @ 994317 @ 2 @ 1

Pos: 113 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Einst. am hydr. Fahrwagen (Bilder) RG-HBZ @ 24\mod_1302257252608_0.docx @ 993783 @ @ 1

Pos: 114 /Produktfamilien/Hebetechnik/- Archiv -/49 Radgreifer-Hebebühnen/0001 Radgreifer-Hebebühnen Alle/Inhalte/Inhalt: Einst. am hydr. Fahrwagen (Text) RG-HBZ_12pt @ 26\mod_1325588986528_75.docx @ 1146041 @ @ 1

Note that the jack must be mounted to the column when making any settings.

The lowering valve is located on the right-hand side of the cylinder. To set the

lowering speed, adjust the threaded pin using an Allen key while holding the lock

nut firmly with an open-end wrench. Check for correct setting by carefully lowering

the jack.

Pos: 115 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/L/Überschrift 1.1: Ladezustand der Batterien @ 9\mod_1216809380782_75.docx @ 231034 @ 2 @ 1

OPEN INCREASE

CLOSE REDUCE

The automatic lowering valve is located on the left-hand side of the cylinder.

Remove the screw plug using an Allen key, then insert a flat-tip screwdriver to set

the adjusting screw. Soak up leaking fluid with a rag. Reinstall the screw plug.

OPEN REDUCE

CLOSE INCREASE

BA492401-en

Page 30

30

4.5

Battery Charge Condition

Indication

Charge Condition

Action

Pos: 116 /Produktfamilien/Hebetechnik/COLUMNLIFT/491901 RGA/BA/Inhalt: 4919 Ladezustand der Batterien (Bild) @ 16\mod_1246887757945_0.docx @ 402425 @ @ 1

Pos: 117 /Produktfamilien/Hebetechnik/COLUMNLIFT/491901 RGA/BA/Inhalt: 4919 Ladezustand der Batterien (Text)_12pt @ 35\mod_1393427797965_75.docx @ 1911637 @ @ 1

RED, ORANGE, GREEN

Switching to GREEN

during charging process

• The batteries may be charged at any time regardless of the control unit being

on or off. Do not operate unit while charging.

RED

ORANGE/YELLOW

GREEN

Flashing

Battery flat, only lowering

possible.

Battery weak, operation may

be continued.

Battery fully charged or partly

discharged.

Charge at once.

Charge as soon as

possible.

---

Battery being charged. ---

Battery fully charged.

Disconnect mains

plug.

Pos: 118 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.do cx @ 1277 @ @ 1

BA492401-en

• To charge the batteries connect the mains plug.

• The charging process takes approx. 12 h with a flat battery. Overcharging is

not possible.

• To prevent the batteries from discharging unnecessarily, each control unit

should be disabled completely when the lift is not in use.

• The batteries should be occasionally charged even when not in use. This is to

ensure that their full capacity is available during lift operation and to compensate for any self-discharge losses.

• To avoid exhaustive discharge, any column with undervoltage will switch off au-

tomatically.

• For a long life expectancy the batteries should not be fully discharged.

Page 31

31

4.6

Troubleshooting

Status Indication

Diagnosis

Remedy

ON

Pos: 119 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/F/Überschrift 1.1: Fehlerbehebung @ 8\mod_1206714646748_75.docx @ 179620 @ 2 @ 1

Pos: 120 /Produktfamilien/Hebetechnik/COLUMNLIFT/491901 RGA/BA/Inhalt: 4919 Display-Codes_12pt @ 26\mod_1325590455167_75.docx @ 1146137 @ @ 1

Red Yellow Green

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

and control can be ena-

bled only briefly or not at

all.

OFF OFF OFF

and control cannot be

enabled at all.

If no other LEDs are ON:

Radio system switched off

after 30 sec.

If other LEDs are ON: Radio interference (e.g.

Channel, Mode…). Possible cause:

Devices in the vicinity

transmitting on the

433 MHz band (such as

garage door opener, radio

set…).

Battery undervoltage

Fuse blown, hardware

error.

Briefly press any button to

enable the radio system.

Wait until radio interference has stopped.

Charge batteries using

power cord.

Contact service.

OFF OFF

OFF

OFF

OFF

and lift stops while lower-

ing.

If no other LEDs are ON:

Emergency-stop actuated.

Lift is not yet referenced,

when a new column with

new control is being connected after final assembly.

Level difference between

columns too great.

Lift has contacted obstruction or floor or is

blocked by safety wedge.

Enable emergency-stop

button.

Lower lift with emergencydown function.

Raise lift until yellow LED

goes off.

BA492401-en

Page 32

32

Status Indication

Diagnosis

Remedy

Status Indication

Diagnosis

Remedy

Red Yellow Green

OFF

OFF

and lift stops while raising.

OFF OFF

Lift overloaded.

Sluggish operation. Possible causes: Long standing under load, insufficient

lubrication…

Upper sensor maladjusted.

Hardware error occurred.

EEPROM / Flash error

occurred.

Release button, try again.

Reduce load if necessary.

Release button, try again.

Contact service if required.

Contact service.

Press and hold for 4

seconds control goes

off. Switch on again. If

error persists, contact

service.

Contact service.

Red Yellow Green

FLASH-

ING

OFF OFF Check RPM sensor Contact service.

1 x

2 x OFF OFF --- ---

3 x OFF OFF Check Limit switch Contact service.

4 x OFF OFF Check Safety switch Contact service.

5 x OFF OFF --- ---

6 x OFF OFF

Thermal switch Motor

open

Let motor cool down.

7 x OFF OFF I2T monitoring Let motor cool down.

8 x OFF OFF --- ---

9 x OFF OFF Hardware overcurrent Contact service.

BA492401-en

Page 33

33

Status Indication

Diagnosis

Remedy

turn on again after approx.

4.7

Spare Parts

Red Yellow Green

10 x OFF OFF Battery overcurrent Contact service.

11 x OFF OFF Motor overcurrent Only lowering possible.

12 x OFF OFF Short circuit to earth Contact service.

13 x OFF OFF

14 x OFF OFF

Interruption/Short circuit

Safety wedge

Interruption/Short circuit

Brake

Contact service.

Contact service.

Error Voltage enable 15 V

15 x OFF OFF

Converter, Power board

Contact service.

defective

16 x OFF OFF Memory error, e.g. height Contact service.

Error Voltage enable 15 V

17 x OFF OFF

Control, check PCB if re-

Contact service.

quired

18 x OFF OFF

CPU error, Control PCB

defective

Contact service.

19 x OFF OFF Check Limit switch Contact service.

20 x OFF OFF Check Safety switch Contact service.

Connection error between

21 x OFF OFF

converter and control;

Contact service.

check 4-pole cable (X8)

ON ON ON

Pos: 121 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Ersatzteile @ 18\mod_1255596847002_75.docx @ 474414 @ 2 @ 1

Pos: 122 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Ersatzteile - Alle Geräte_12pt @ 26\mod_1324468768120_75.do cx @ 1141219 @ @ 1

To ensure safe and reliable operation, only use original spare parts supplied by the

Pos: 123 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.doc x @ 1277 @ @ 1

equipment manufacturer.

Error occurred (Watchdog).

Turn off main switch and

5 sec. If error repeats,

contact service.

BA492401-en

Page 34

34

5

Service Lifetime

6

Dismantling

7

Disposal

8

Contents of the Declaration of Conformity

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Model:

Designation:

Directives:

Standards:

Pos: 124 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/L/Überschrift 1: Lebensdauer @ 19\mod_1266336761550_75.docx @ 742423 @ 1 @ 1

Pos: 125 /Produktfamilien/Hebetechnik/- Archiv -/00 Hebetechnik Alle/Inhalte/Inhalt: Lebensdauer HBZ_12pt @ 26\mod_1325656335645_75.docx @ 1146173 @ @ 1

In its standard version, this product is designed for 22,000 load cycles based on

EN 1493. The maximum period of normal use in relation to the possible product

life expectancy shall be evaluated and scheduled by a qualified person during the

Pos: 126 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/D/Überschrift 1: Demontage @ 19\mod_1266336822863_75.docx @ 742452 @ 1 @ 1

Pos: 127 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Demontage - Alle Geräte_12pt @ 26\mod_1324466078229_75.docx @ 1140857 @ @ 1

annual safety inspection.

Decommissioning and dismantling of the equipment may be done only by

specially authorized and trained personnel provided by the manufacturer, licensed

Pos: 128 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/G/Überschrift 1: Geräteentsorgung @ 6\mod_1174482271625_75.docx @ 76901 @ 1 @ 1

Pos: 129 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Geräteentsorgung (ohne RiLi)_12pt @ 56\mod_1557295759940_75.docx @ 3140070 @ @ 1

dealers or service partners.

If you want to dispose of the equipment, please contact your MAHA dealer or the

following address, indicating equipment type, date of purchase and serial number:

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20 | 87490 Haldenwang | Germany

Phone: +49 (0) 8374 585 0

Fax: +49 (0) 8374 585 500

Pos: 130 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Geräteentsorgung über Fachbetrieb (alternativ)_12pt @ 26\mod_1324468120852_75.docx @ 1141022 @ @ 1

Email: info@maha.de

Alternatively, you may take the equipment to a specialised waste management

plant to ensure that all components and operating liquids are properly disposed

Pos: 131 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/I/Überschrift 1: Inhalt der Konformitätserklärung @ 22\mod_12928567484 32_75.docx @ 958616 @ 1 @ 1

Pos: 132 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Inhalt der Konformitätserklärung allg_12pt @ 26\mod_1324468436145_75.docx @ 1141120 @ @ 1

of.

herewith declares as a manufacturer its sole responsibility to ensure that the

product named hereafter meets the safety and health regulations both in design

and construction required by the EC directives stated below.

This declaration becomes void if any change is made to the product that was not

Pos: 133 /Produktfamilien/Hebetechnik/COLUMNLIFT/492401 RGA UC/Inhalt: 4924 Inhalt der Konformitätserklärung @ 56\mod_1557140851705_75.docx @ 3138855 @ @ 1

discussed and approved by named company beforehand.

RGA UC

=== Ende der Liste für Textmarke Inhalt ===

BA492401-en

Mobile Column Lift;

Rated Load Capacity per Column 7500 kg

2006/42/EC; 2014/30/EU

EN 1493; EN 60204-1

Loading...

Loading...