MAHA POWERDYNO MSR, POWERDYNO MSR 500, POWERDYNO MSR 1000, POWERDYNO MSR 1050, POWERDYNO MSR 800 Original Operating Instructions

...Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

MSR

Single Roller Dynamometer

Original Operating Instructions

BA053101-en

Pos: 1 /Technische D okumen tation/A lle Ger äte/T iteltex te/Titel text: MS R - Alle Typen @ 24\mod_1303997516266_0.docx @ 1000449 @ @ 1

MSR 500

MSR 800

MSR 830

MSR 850

MSR 1000

MSR 1050

Pos: 2 /Tec hnisc he Dok um entat ion /Le istu ngsm es ste chn ik/P OWE RDYN O/ 053 101 M S R/B A/In halt : 05 31 Tite lbild @ 42\ mod_ 1435 0441 04527_ 0.docx @ 22584 84 @ @ 1

Pos: 2 /-----For mat---- -/MAN UELLER UMBRUCH S eitenumb ruch @ 0\m od_11 34403 5776 87_0.d ocx @ 1 278 @ @

Pos: 3 /-----For mat---- -/MAN UELLER UMBRUCH S eitenumb ruch @ 0\m od_11 34403 5776 87_0.d ocx @ 1 277 @ @ 1

Page 2

2

1

Safety .................................................................................................................. 7

2

Description ........................................................................................................ 12

Pos: 4 /-----For mat---- -/Inh altsv er zeic hn is - 3 Eb e nen @ 5\m od_11 68867 4410 46_75. docx @ 72 920 @ @ 1

Contents

1.1 Introduction .............................................................................................................. 7

1.2 Symbols ................................................................................................................... 7

1.3 Intended Use ........................................................................................................... 7

1.4 Safety Instructions for Commissioning ...................................................................... 7

1.5 Safety Instructions for Operation............................................................................... 8

1.6 Safety Instructions for Servicing ................................................................................ 9

1.7 Danger Zone .......................................................................................................... 10

1.8 Safety Information about Tires ................................................................................ 10

1.9 Safety Information about the Eddy Current Brake ................................................... 11

1.10 Safety Features ...................................................................................................... 11

1.11 Accessories ........................................................................................................... 11

1.12 What to Do in the Event of an Accident .................................................................. 11

2.1 General Information ................................................................................................ 12

2.2 Specifications ......................................................................................................... 13

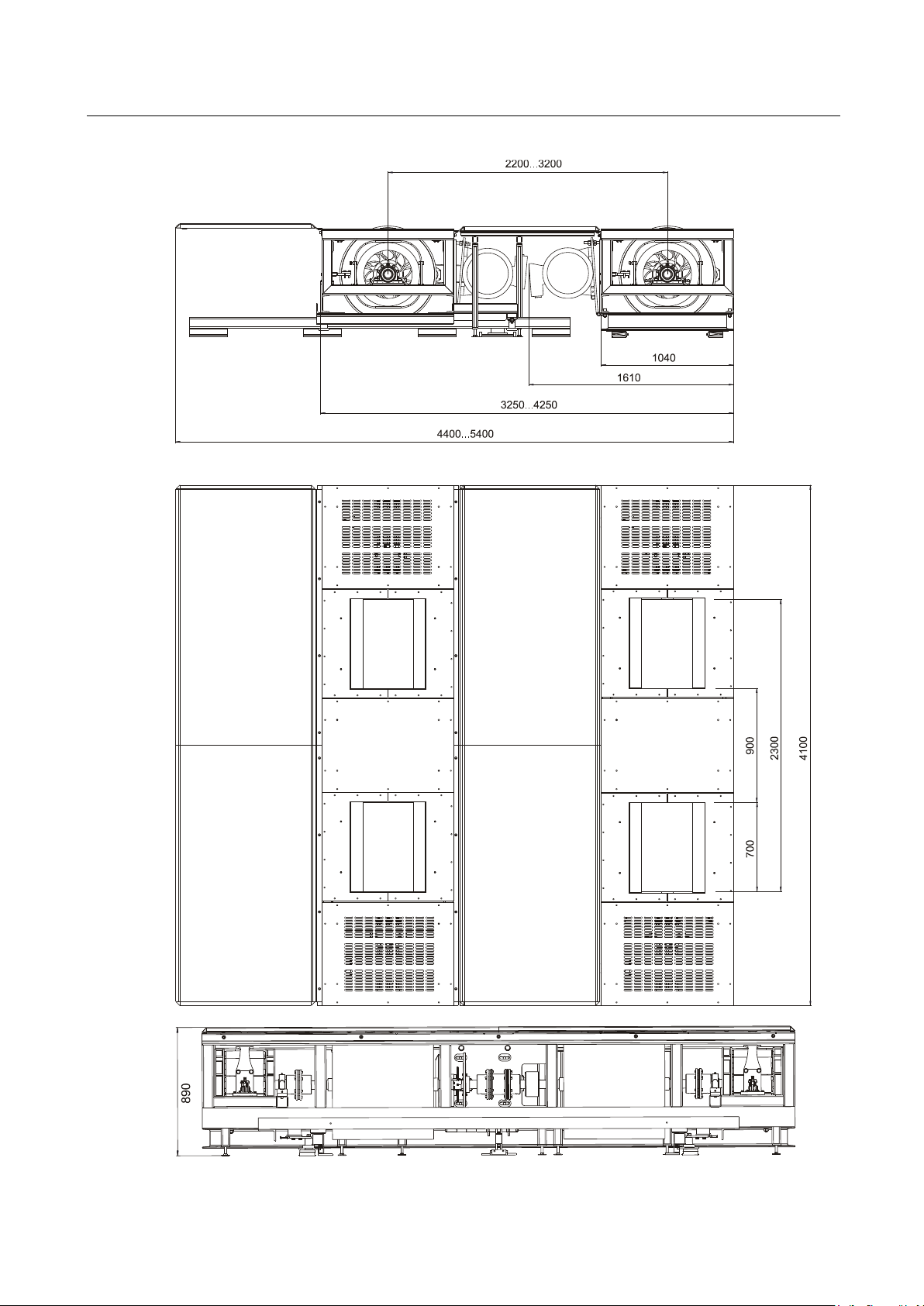

2.2.1 Dimensions ............................................................................................................ 13

2.2.2 Communication Desk ............................................................................................. 15

2.2.3 MSR 500/1 ............................................................................................................ 16

2.2.4 MSR 500/2 ............................................................................................................ 17

2.2.5 MSR 500/2 4WD .................................................................................................... 18

2.2.6 MSR 500/3 4WD .................................................................................................... 19

2.2.7 MSR 800 ............................................................................................................... 20

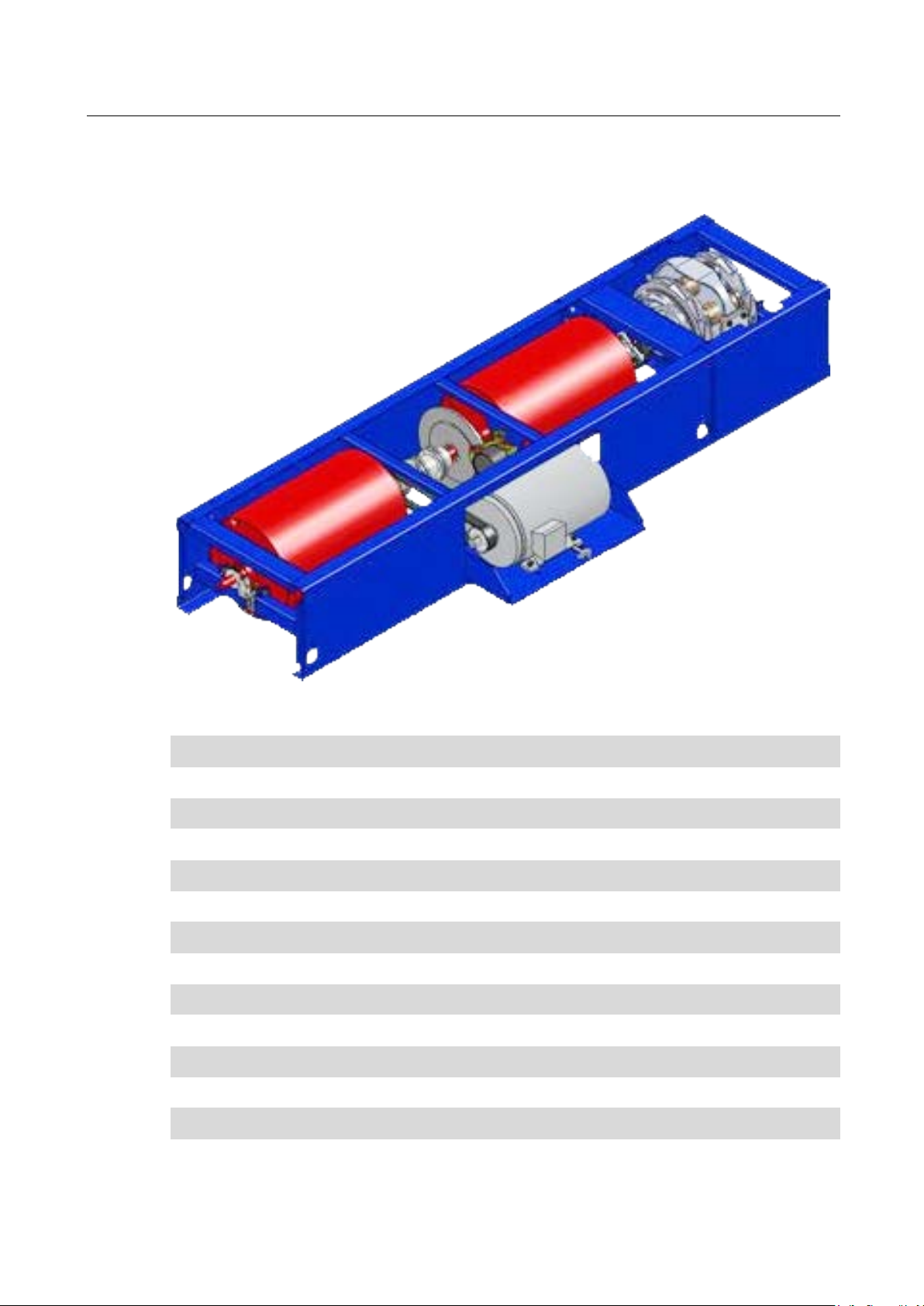

2.2.8 MSR 830 ............................................................................................................... 21

2.2.9 MSR 850 ............................................................................................................... 22

2.2.10 MSR 1000 ............................................................................................................. 23

2.2.11 MSR 1050 ............................................................................................................. 24

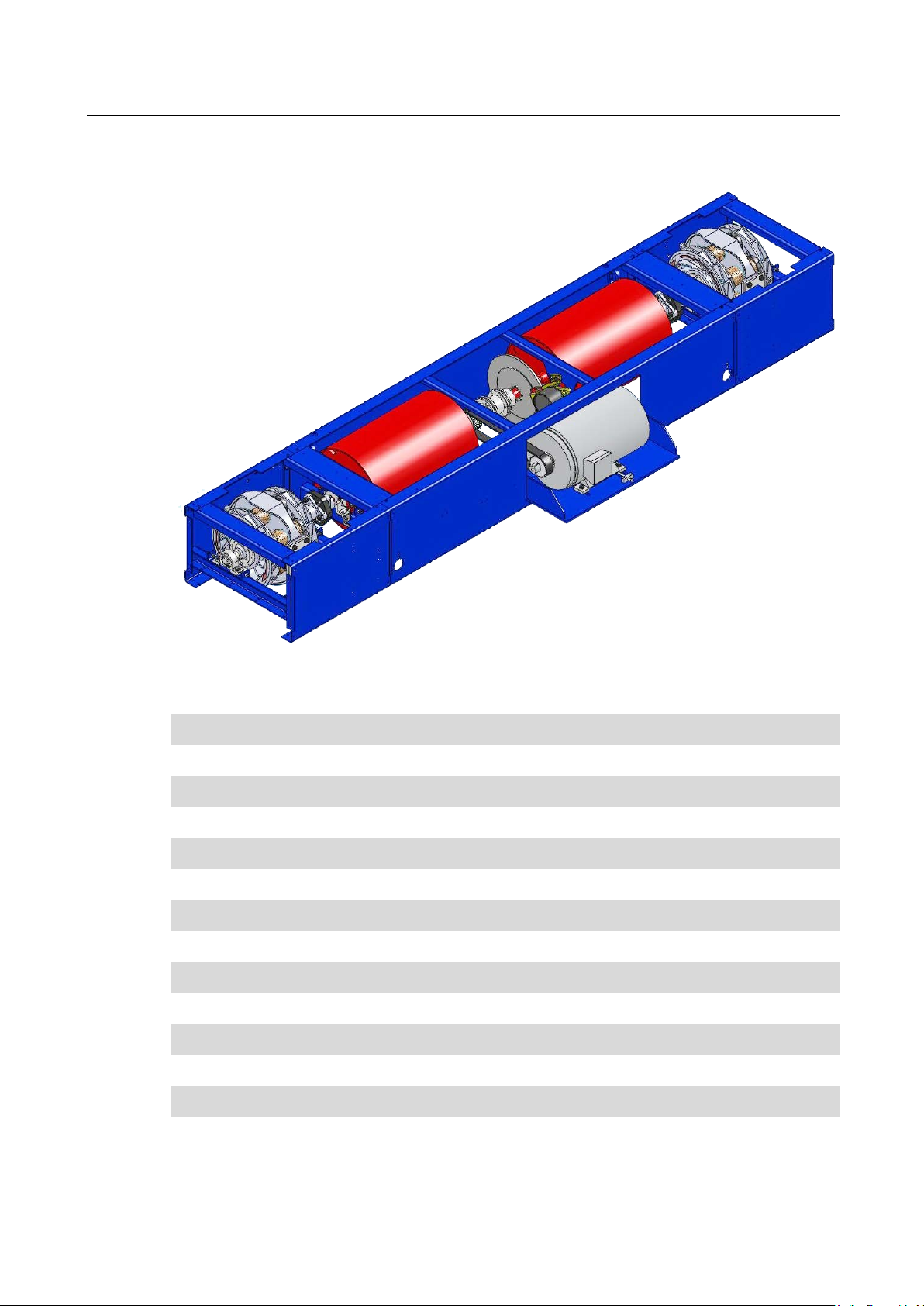

2.3 Main Switch ........................................................................................................... 25

2.4 Controls and Indicators .......................................................................................... 25

2.5 Emergency Stop .................................................................................................... 26

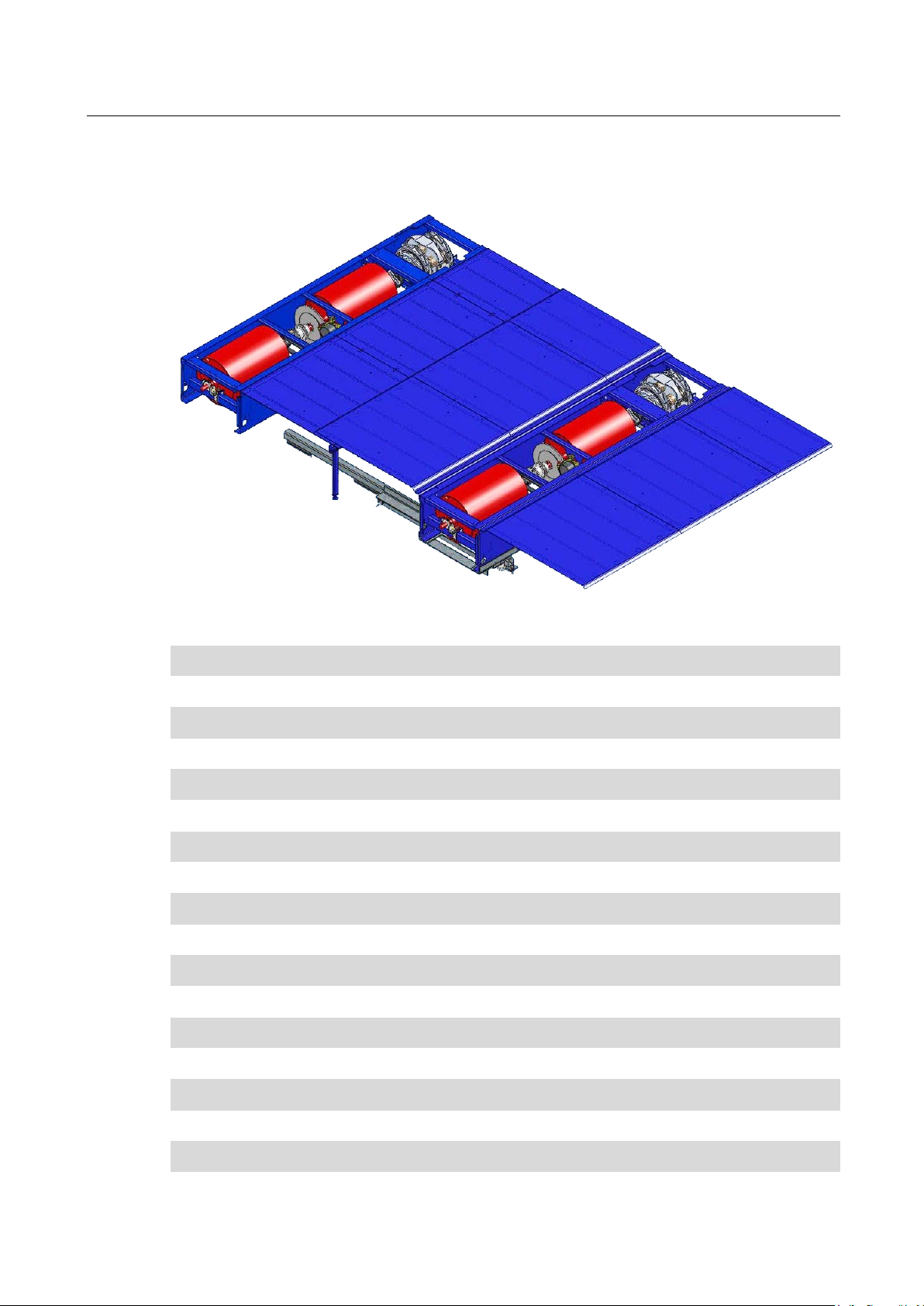

2.6 Remote Control ...................................................................................................... 27

2.7 Description of the Interface Box .............................................................................. 29

2.7.1 RPM Module (Standard) ......................................................................................... 31

2.7.2 Environmental Module (Standard) ........................................................................... 33

2.7.3 OBD Module (Optional)........................................................................................... 34

BA053101-en

Page 3

3

3

Description of the SINAMICS Components .......................................................... 44

4

Transport and Storage ....................................................................................... 47

5

Installation and Initial Operation ........................................................................... 47

6

Installation ......................................................................................................... 47

7

Software ............................................................................................................ 51

8

Preparations for Testing...................................................................................... 59

2.7.4 Pressure/Temperature Module (Optional) ................................................................ 34

2.7.5 Analog Input Module (Optional) ............................................................................... 35

2.8 Analog Output Card (Optional) ................................................................................ 35

2.9 Measurement Programs ......................................................................................... 36

2.10 Calculation Basis .................................................................................................... 37

2.10.1 Road Load ............................................................................................................. 37

2.10.2 Torque ................................................................................................................... 38

2.10.3 Extrapolation of the Engine Power with Gasoline Engines ....................................... 39

2.10.4 Extrapolation of the Engine Power with Diesel Engines (Naturally Aspirated or

Supercharged) .................................................................................................................... 40

2.10.5 Extrapolation of the Engine Power with Turbodiesel Engines ................................... 41

2.10.6 Calculate Engine Factor fm ..................................................................................... 42

2.10.7 4 Wheel Drive Operation ......................................................................................... 43

3.1 Special Safety Instructions for the SINAMICS Components .................................... 44

3.2 Mains Connection for Booksize Drive Assembly ...................................................... 45

3.3 Basic Setup ........................................................................................................... 46

6.1 Requirements for the Place of Installation ............................................................... 47

6.2 Safety Measures .................................................................................................... 47

6.2.1 Heat Balance ......................................................................................................... 47

6.2.2 Exhaust Suction System ......................................................................................... 49

6.2.3 Fresh Air Supply for the Test Room ........................................................................ 50

7.1 System Requirements ............................................................................................ 51

7.2 Starting the Setup .................................................................................................. 51

7.3 Selecting the Setup Language ................................................................................ 52

7.4 Selecting the Destination Folder ............................................................................. 53

7.5 Selecting the SQL Server ....................................................................................... 53

7.6 Selecting the Dyno Type......................................................................................... 54

7.7 Selecting Features .................................................................................................. 54

7.8 Installing Drivers ..................................................................................................... 55

7.9 Finishing the Setup ................................................................................................. 55

7.10 Additional Settings under Windows 7 or higher ....................................................... 56

BA053101-en

Page 4

4

9

Program Structure ............................................................................................. 63

10

Measurements ................................................................................................... 69

8.1 Switch on the Dyno ................................................................................................ 59

8.2 Drive onto Dyno and Secure Vehicle ....................................................................... 59

8.3 Connect the RPM Sensor ....................................................................................... 60

8.4 Connect Oil Temperature Probe ............................................................................. 61

8.5 Attach Exhaust Suction System .............................................................................. 61

8.6 Position Cooling Air Fan ......................................................................................... 61

8.7 Bring the Vehicle up to Operating Temperature ...................................................... 62

8.8 Vehicle Ready for Testing ....................................................................................... 62

8.9 Exit the Dynamometer ............................................................................................ 62

9.1 General Information ................................................................................................ 63

9.2 Tree Model ............................................................................................................. 64

9.3 Screen Design ........................................................................................................ 65

9.3.1 Status Line ............................................................................................................. 65

9.3.2 Main Screen ........................................................................................................... 67

9.3.3 Button Bar ............................................................................................................. 67

9.4 Starting the Program .............................................................................................. 68

9.5 End Program / Switch off Dyno .............................................................................. 68

10.1 Load Simulation ..................................................................................................... 69

10.1.1 Identical Functions ................................................................................................. 69

10.1.2 Constant Traction................................................................................................... 74

10.1.3 Constant Speed ..................................................................................................... 76

10.1.4 Driving Simulation ................................................................................................... 77

10.1.5 Constant Engine RPM ............................................................................................ 79

10.1.6 Standstill ................................................................................................................ 79

10.1.7 Drive Dyno ............................................................................................................. 80

10.2 Measure Engine Power .......................................................................................... 80

10.2.1 Display Last Measurement ..................................................................................... 80

10.2.2 Continuous Measurement ...................................................................................... 81

10.2.3 Discrete Measurement ........................................................................................... 84

10.3 Engine Flexibility Test ............................................................................................. 86

10.4 Speedometer Check .............................................................................................. 87

10.4.1 Vehicle Speed ........................................................................................................ 87

10.4.2 Mileage .................................................................................................................. 89

10.5 Load Adaption (Optional) ........................................................................................ 89

10.5.1 Coefficient Adaption based on ECE ........................................................................ 90

BA053101-en

Page 5

5

11

Settings ............................................................................................................. 93

12

Diagnosis / Service ........................................................................................... 112

13

Maintenance .................................................................................................... 117

10.5.2 Coefficient Adaption based on SAE J2264 ............................................................. 91

10.6 Lug-Down Test (Option) ......................................................................................... 92

11.1 Database ............................................................................................................... 93

11.1.1 Identical Functions ................................................................................................. 93

11.1.2 Performance Curves .............................................................................................. 96

11.1.3 Time Diagram ....................................................................................................... 100

11.1.4 Vehicle Data ......................................................................................................... 101

11.1.5 Load simulation profile.......................................................................................... 102

11.1.6 Driving Cycle Data ................................................................................................ 104

11.2 Vehicle Data ......................................................................................................... 105

11.3 RPM Setting ......................................................................................................... 106

11.3.1 Driving Trial .......................................................................................................... 107

11.4 Special Settings ................................................................................................... 108

11.5 Select Dyno Type ................................................................................................. 109

11.6 Units .................................................................................................................... 109

11.7 Language ............................................................................................................. 110

11.8 Device / Interfaces................................................................................................ 110

11.8.1 OBD Settings (Optional) ....................................................................................... 111

12.1 Dyno Status ......................................................................................................... 112

12.2 Driver’s Aid Setup (Optional) ................................................................................. 112

12.2.1 Test Driving Cycle ................................................................................................ 113

12.2.2 Edit Profile ............................................................................................................ 114

12.2.3 New Profile........................................................................................................... 114

12.2.4 Delete Profile ........................................................................................................ 115

12.3 Backup/Restore Database ................................................................................... 115

12.3.1 Backup Database ................................................................................................ 115

12.3.2 Restore Database ................................................................................................ 115

12.3.3 Delete Table ......................................................................................................... 116

12.3.4 Delete Database ................................................................................................... 116

13.1 Important Information ........................................................................................... 117

13.2 Annual Inspection ................................................................................................. 117

13.3 Maintenance by the Operator ............................................................................... 117

13.3.1 Roller Set ............................................................................................................. 117

13.3.2 Eddy Current Brake .............................................................................................. 117

BA053101-en

Page 6

6

14

Dismantling ...................................................................................................... 119

15

Disposal .......................................................................................................... 119

16

Diagnosis of SINAMICS Components ................................................................ 120

17

Company Information ....................................................................................... 125

13.3.3 Bearing Positions ................................................................................................. 118

13.4 Troubleshooting ................................................................................................... 118

13.5 Care Instructions .................................................................................................. 119

13.6 Spare Parts .......................................................................................................... 119

16.1 LEDs after the Control Unit has booted ................................................................ 120

16.2 Smart Line Module 16kW and 36kW .................................................................... 122

16.3 Single Motor Module / Double Motor Module ....................................................... 123

16.4 Sensor Module Cabinet 30 (SMC30) .................................................................... 124

Pos: 5 /-----For mat---- -/MAN UELLER UMBRUCH S eitenumb ruch @ 0\m od_11 34403 5776 87_0.d ocx @ 1 277 @ @ 1

BA053101-en

Page 7

7

1

Safety

1.1

Introduction

1.2

Symbols

1.3

Intended Use

1.4

Safety Instructions for Commissioning

Pos: 6 /Technische D okumen tation/A lle Ger äte/ Überschr iften/ Übersc hriften 1/S/Üb erschri ft 1: Si cherheit @ 6\mod_1174482399906_75.docx @ 76962 @ 1 @ 1

Pos: 7 /Technisc he Dokum enta tion/ All e Gerä te/ Übers chrif ten/Üb ersc hrift en 1 .1/E/ Übers chr ift 1.1: E inführ ung @ 6\m od_1174482219062_75.docx @ 76793 @ 2 @ 1

Pos: 8 /Tec hnisc he Dok um entat ion/A lle Ge räte/ In halte/S ic herhe it/Inha lt: E inf ühru ng Si cher heit @ 6\mod_1175609639562_75.docx @ 87528 @ @ 1

Thoroughly read this manual before operating the equipment and comply with the instructions.

Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these safety

Pos: 9 /Technische D okumen tation/A lle Ger äte/ Überschr iften/ Übersc hriften 1.1/S/ Überschr ift 1. 1: Sym bole @ 6\ mod_1174482270875_75.docx @ 76865 @ 2 @ 1

Pos: 10 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Sicher heit/In halt: Sy mbo le Sicher heit @ 14\mod_1239866667866_75.docx @ 361518 @ @ 1

instructions are not covered by the product liability regulations.

Important safety instructions. Failure to comply with instructions could result in personal injury or

property damage.

Important information.

Pos: 11 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/B/Übers chrift 1.1: Bestimm ungsgemä ßer Gebrauch @ 6\mod_117 673 402 220 3_ 75.d ocx @ 8 874 6 @ 2 @ 1

Pos: 12 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ - Arc hiv -/00 L PS Alle/ Inhalte/ Inhalt: Bestimm ungs gemä ßer Gebr auch LP S @ 22\mod_1289554938563_75.docx @ 939803 @ @ 1

This dynamometer is to be used exclusively for the performance testing of motor vehicles. It is not

suitable for brake testing or noise detection. Observe the rated axle load.

The equipment may not be modified without the express written consent of the manufacturer. In

Pos: 13 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Sicher heit/In halt: Bes timm ungsw idriger Gebrau ch allg @ 20\mod_1269438225062_75.docx @ 828842 @ @ 1

Pos: 14 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/S/ Übersc hrift 1.1: Sic herheit svorschr iften f ür di e Inbe triebnahm e @ 6\m od_1174482269156_75.docx @ 76838 @ 2 @ 1

Pos: 15 /Tec hn isch e Do kum ent ation/ Leist ungsm ess techn ik/- Arc hiv -/00 L PS Alle/ Inhal te/Inhal t: Sicher heitsv orschr iften für die I nbetri ebnahm e LPS @ 22\mod_1290588545708_75.docx @ 946285 @ @ 1

case of non-compliance the declaration of conformity becomes void.

Any use other than described is inappropriate.

• Only authorized service technicians may install and commission the test stand.

• The test stand may not be installed and operated in fire-endangered operation facilities, outside

or in damp rooms (e.g. wash halls).

• Mount components of the vehicle fixing unit in advance on a suitable lift on the test stand.

• Warning stickers must be attached by the operator:

– Hearing damage due to high noise level. Wear hearing protection.

– Severe eye injuries due to flying particles. Wear protective goggles! Operator is responsible.

• Wear personal protective clothing as required or as regulated by law. The personal protective

Pos: 16 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

clothing must meet the safety-technical regulations for the respective work application.

BA053101-en

Page 8

8

1.5

Safety Instructions for Operation

Pos: 17 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/S/ Übersc hrift 1.1: Sic herheit svorschr iften f ür den Betri eb @ 6\m od_1174482268953_75.docx @ 76826 @ 2 @ 1

Pos: 18 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/- Ar c hiv -/ 00 LPS A lle/Inh alte/In halt: Sicher heitsvorsc hrif ten für de n Be trieb LPS @ 22\mod_1290586764080_75.docx @ 946197 @ @ 1

• The dynamometer may only be used and operated exclusively for its intended purpose and only

within its performance limits.

• The dynamometer may only be operated by trained personnel. Dynamometer and working area

must be kept clean.

• The dynamometer may only be operated by persons who are physically and mentally fit. These

persons should be well rested and not under the influence of alcohol, drugs or medication.

• When not in use the system must be switched off and the main switch protected against re-

start.

• No persons may be in the danger zone of the dynamometer. Rotating or moving parts are dan-

gerous.

• Pay close attention to accident prevention regulations.

• Never climb on roller sets and lifting bar even when locked.

• Avoid unnecessary strain on vehicle and test stand. Drive the vehicle slowly onto the test stand.

• Damage to low lying vehicles is not covered by the warranty.

• Regularly check the tightness of the cover plate attachment screws.

• No persons may be in the pit with dynamometers in conjunction with a working pit while a vehi-

cle with rotating wheels is on the roller set.

• Wear personal protective clothing. If necessary wear protective goggles. Particles ejected from

rotating vehicle wheels can cause severe injuries. Wear tightly fitting working clothes and bind

long hair together. Clothing or hair can get caught and pulled into machinery.

• Danger of hearing damage due to high noise level! Use hearing protection approved up to

120 dB(A). Noise levels over 110 dB(A) can be reached during vehicle testing. The operator is

responsible for determining the noise level in vehicle and test room. When necessary, wear suitable hearing protection. The operator must attach warning stickers.

• Danger of carbon monoxide poisoning by poisonous vehicle exhaust. The test stand may only

be operated if the room in which the test stand is installed has sufficient exhaust suction and

ventilation including the appropriate warning system.

• Avoid steering movement during the vehicle test. These cause certain forces to act on the vehi-

cle fixing in particular on the attachment units on the test vehicle. Vehicle doors and windows

must be closed during the test drive.

• Before exiting the vehicle, put the vehicle into idle and/or put the gear to NEUTRAL. If neces-

sary decelerate the vehicle in a controlled manner avoiding steering movements. Wait until vehicle and rollers have stopped moving before exiting the vehicle. Danger of body parts and clothing being pulled into rotating rollers and vehicle wheels.

• Keep dyno surface clean and dry. Danger of slipping when surface is wet, oily or icy! Do not

place any objects (tools, material etc.) on the dynamometer. Wear protective shoes with antislip soles and steel toe caps to avoid slipping and mechanical injuries. Parts which protrude

more than 20 mm out of the floor are to be marked with black-yellow tape.

• In addition to the danger zone, the operator is responsible for confining the area of the test

room in which no persons are allowed during testing with a safety catch device or a cell wall.

Mark the danger zone (roller width + 1100 mm) on both sides behind the vehicle up to cell

wall/safety catch device.

• Danger of accident due to vehicle fixing fracturing! Do a visual check for damage to the vehicle

fixing before each use. Never start the test operation without suitable and correctly installed vehicle fixing. Lower lifting bar before fixing the vehicle. Fix the test vehicle at the back and front

side to the dynamometer and secure against lateral break out and swinging movements. The

vehicle fixing must be adjusted to the vehicle being tested and may only be used within its stat-

BA053101-en

Page 9

9

1.6

Safety Instructions for Servicing

ed purpose and performance limits. Installation of the vehicle fixing exclusively by skilled, trained

personell. Inspect attachment units on the test vehicle for strength. Pay attention to manufacturer’s information and/or load capacity. Pull on the parking brake and raise the lifting bar before removing the vehicle fixing. The use of unsuitable vehicle fixing, in particular external vehicle

Pos: 19 /Techn ische Dok ument atio n/Al le Geräte/Üb erschrift en/Überschr iften 1.1/S/Üb erschrif t 1.1: Sicherheit svorschrift en für Servicearbe iten @ 6\mod_1174482270640_75.docx @ 76850 @ 2 @ 1

Pos: 20 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ - Arc hiv -/0 0 LPS A lle/Inh alte/In halt: Si cherhei tsvorsc hriften für S ervicear beiten LPS @ 22\mod_1290586480412_75.docx @ 946152 @ @ 1

fixing increases the danger of injuries and can impair safety.

• Service work may only be carried out by authorized service technicians.

• The operating mode selection switch must be put in the correct position with repair, mainte-

nance and set-up work. Remove the key to protect against unauthorized usage.

• The safety devices must be set by authorized service technicians.

• The safety devices may not be replaced or circumvented.

• Wear tight-fitting safety gloves when doing setup work to reduce the danger of pinching. Wear

a protective helmet when doing service work in the test stand pit to avoid impact injuries.

• Life-threatening electrical voltage! Only authorized electricians are allowed to work on the

electrical parts of the equipment based on valid electro-technical rules and guidelines. Before

doing any work on the test stand electrics switch off all voltage and secure against re-starting.

Test for absence of voltage! Cabinet contains components with storage charge. After switching

off all voltages life-threatening voltage can still be present for at least 5 minutes! Check for

discharge before starting work! Lock circuit box and store key securely. Hand out key only if

needed to authorized electricians.

• Errors and deviations from normal operating conditions are to be inspected only by trained skil-

led workers who are authorized to do this kind of work. Circuits which are fed by an uninterruptible power supply are still under voltage even after the test stand has been switched off

from the mains connection. The control has circuits which are tapped before the mains disconnection device of the test stand and are not voltage-free after switch off using the mains disconnection. All equipment which are connected before the mains disconnection device are

wired with the colors YELLOW or ORANGE. Pay attention to calibration instructions.

• Use suitable lifting device with sufficient load capacity to open heavy test stand components.

The heaviest components can weigh up to 300 kg. Removal only by qualified skilled personnel.

Adhere to all valid safety regulations and relevant work protection guidelines. Lift test stand

components only on the designated lifting points.

• Use suitable lifting device with sufficient load capacity for removal and transport of heavy test

stand components. The heaviest components can weigh up to 300 kg. Removal and transport

only by qualified skilled personnel. Adhere to all valid safety regulations and relevant work pro-

Pos: 21 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

tection guidelines. Lift test stand components only on the designated lifting points.

BA053101-en

Page 10

10

1.7

Danger Zone

1.8

Safety Information about Tires

Pos: 22 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/ G/Über sc hrif t 1.1: G efa hrenz one @ 19\ mod_ 126 69381 22676_ 75.do cx @ 782 826 @ 2 @ 1

Pos: 23 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ - Arc hiv -/00 L PS Alle/ Inhalte/ Inhalt: Gefahr enzon e (Text) LPS A lle @ 23\mod_1298391517468_75.docx @ 978993 @ @ 1

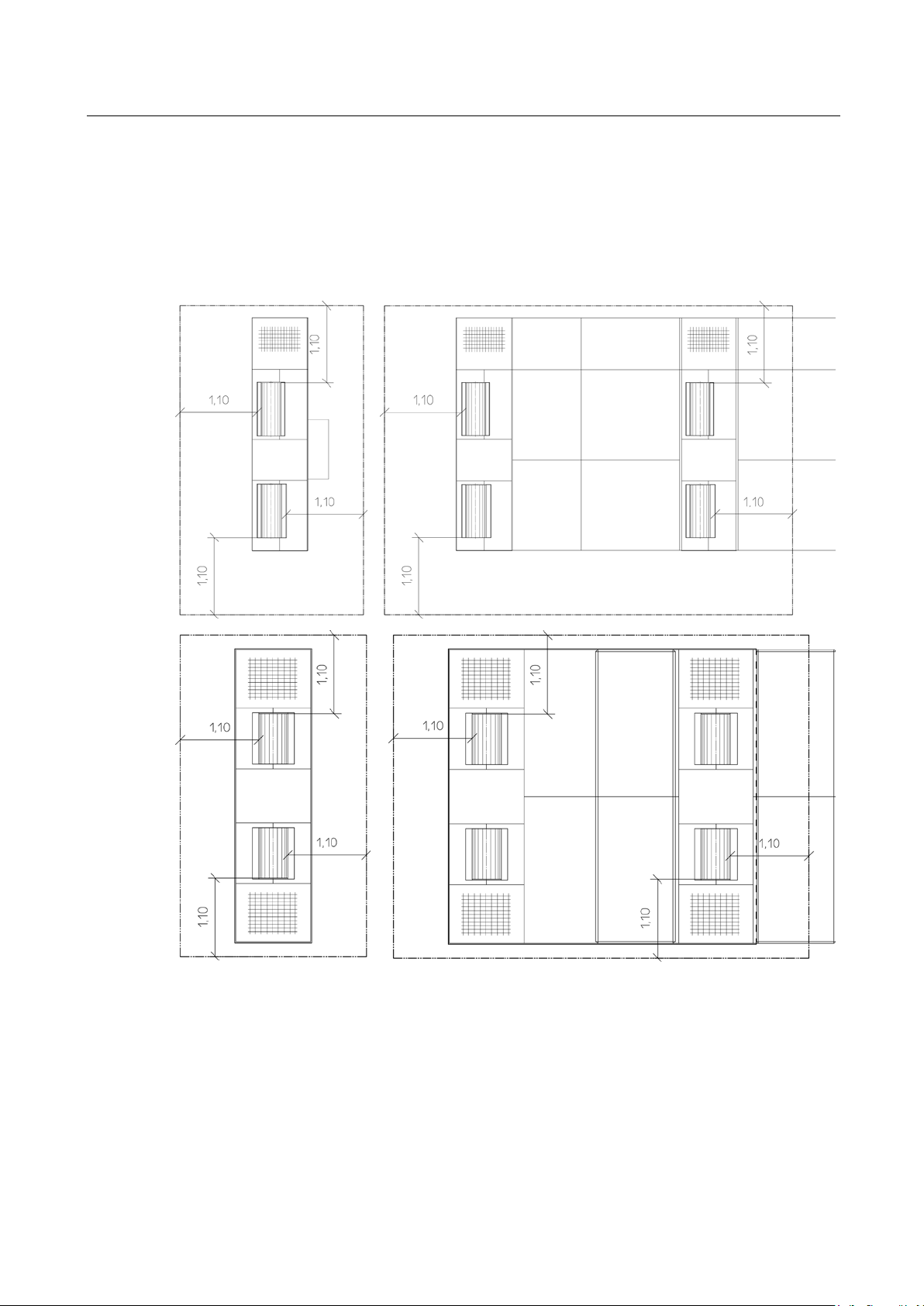

During dynamometer operation no persons are allowed to stay in the danger zone. See illustration

Pos: 24 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 5310 1 MS R/BA/I nha lt: 0 531 G efahr enz one ( Bilder ) @ 24\mod_1305641273004_0.docx @ 1007835 @ @ 1

for minimum distance.

MSR 500 MSR 500 4WD

Pos: 25 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/S/Überschrift 1.1: Sicherheitshinweise zu den Reifen @ 13\mod_1234944733138_75.docx @ 343007 @ 2 @ 1

MSR 800 MSR 1000 4WD

Pos: 26 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ - Arc hiv -/00 L PS Alle/ Inhalte/ Inhalt: Sicher heitsh inweis e zu d en Re ifen LPS @ 13\ mod_1234174659560_75.docx @ 335356 @ @ 1

• Check tire pressure and do a visual check of the tires for any signs of damage.

• To avoid tire damage we recommend that test tires be used during the performance test.

• No vehicles should be tested which have snow tires, racing tires or retreaded tires!

• Pay attention that the fastest permissible speed for the tires is not exceeded!

• Check the alignment weights on the rims to make sure they are tight before testing.

BA053101-en

Page 11

11

1.9

Safety Information about the Eddy Current Brake

1.10

Safety Features

Lockable Main Switch

Pit Safety (optional)

Warning and Information Labels

1.11

Accessories

1.12

What to Do in the Event of an Accident

Pos: 27 /Techn ische Dokume ntat ion/A lle Ger äte/ Übersc hrift en/ Übersc hrifte n 1.1/ S/Übe rsch rift 1. 1: Sich erheit shin weise zur Wir belstromb remse @ 8\mod_ 120 06549 42824 _75.d ocx @ 141 073 @ 2 @ 1

Pos: 28 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ - Arc hiv -/00 L PS Alle/ Inhalte/ Inhalt: Sicher heitsh inweis e zur Wirbelstr ombrem se @ 8\mod_1200655009969_75.docx @ 141090 @ @ 1

• Pay attention to tire size! No test should be done with tires under 12”!

The eddy current brake can heat up significantly during long lasting usage. The brake rotors may

become red hot.

After a long lasting measurement under load, the eddy current brake should continue to be rotated

without load by the vehicle at a speed of approx. 50 – 80 km/h.

The rotating rotors suck cooled air from the side and throw it radially off. The eddy current brake is

Pos: 29 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/S/Übersc hrift 1. 1: Sicherhe itsei nrichtun gen @ 6\mod _1174 4833 24765_ 75.d ocx @ 77 103 @ 2 @ 1

Pos: 30 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ - Arc hiv -/00 L PS Alle/ Inhalte/ Inhalt: Sicher heitse inrich tungen ( Text) LPS @ 22\mod _12 905 908 267 77_75.d ocx @ 94 6329 @ @ 1

thereby effectively cooled preventing heat build-up at the rotors damaging the coil insulation.

The safety features must be checked regularly by an authorized service technician. Pay attention to

statutory requirements. The dyno shall not be operated with defective safety features.

Serves as a normal On and Off switch and as an emergency switch. The switch can be protected

against unauthorized usage by locking with a padlock.

Light barrier or infrared movement sensor. Issues audible and visual signals in the event that persons are in the working pit.

Warning and information labels are attached to the dyno. The labels shall not be changed or

removed. Defective warning and information labels must be replaced.

Pos: 31 /Tec hn isch e Do kumentatio n/Alle Geräte/ Überschrift en/Überschr iften 1.1/Z /Überschr ift 1.1: Zubehör @ 7\mod _11 97021 5365 41_75.d ocx @ 13 6790 @ 2 @ 1

Pos: 32 /Technische Dokument ation/Alle Gerät e/Inhalte/ Sicherhe it/Inhalt: Zubeh ör @ 22\mod _128 818 85362 64_ 75.d ocx @ 927028 @ @ 1

The equipment shall be operated only with accessories which have been approved or permitted by

Pos: 33 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/V /Übersc hrift 1 .1: Ver halten bei U nfällen @ 19\m od_ 126 7177 2453 37_7 5.docx @ 79460 0 @ 2 @ 1

Pos: 34 /Technische Dokument ation/Alle Gerät e/Inhalte/ Sicherhe it/Inhalt: Verha lten bei Unfälle n @ 34\mod_1381128804654_75.docx @ 1837123 @ @ 1

MAHA.

• The injured person is to be removed from the danger area. Find out where dressing and band-

ages are kept. Seek first-aid.

• Provide first-aid (stop bleeding, immobilise injured limbs), report the accident and seal off the

accident site.

• Immediately report any accident to your supervisor. Make sure a record is kept of every occa-

sion first-aid is provided, e.g. in an accident book.

Pos: 35 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

• Remain calm and answer any questions that may arise.

BA053101-en

Page 12

12

2

Description

2.1

General Information

RPM module

Environmental module

Analog module

OBD module

Pressure/Temperature module

Pos: 36 /Tec hn ische Dokum entation/ Alle Geräte/Üb erschriften/ Überschri ften 1/B/Üb erschrift 1: Beschr eibung @ 6\mod_1174482271453_75.docx @ 76889 @ 1 @ 1

Pos: 37 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/A/Übersc hrift 1.1: Allgem eines @ 6\mod_1182865005781_75.docx @ 97736 @ 2 @ 1

Pos: 38 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 5310 1 MS R/BA/I nha lt: 0 531 Bes chr eibun g Al lgem eines @ 14\mod_1241595173293_75.docx @ 371141 @ @ 1

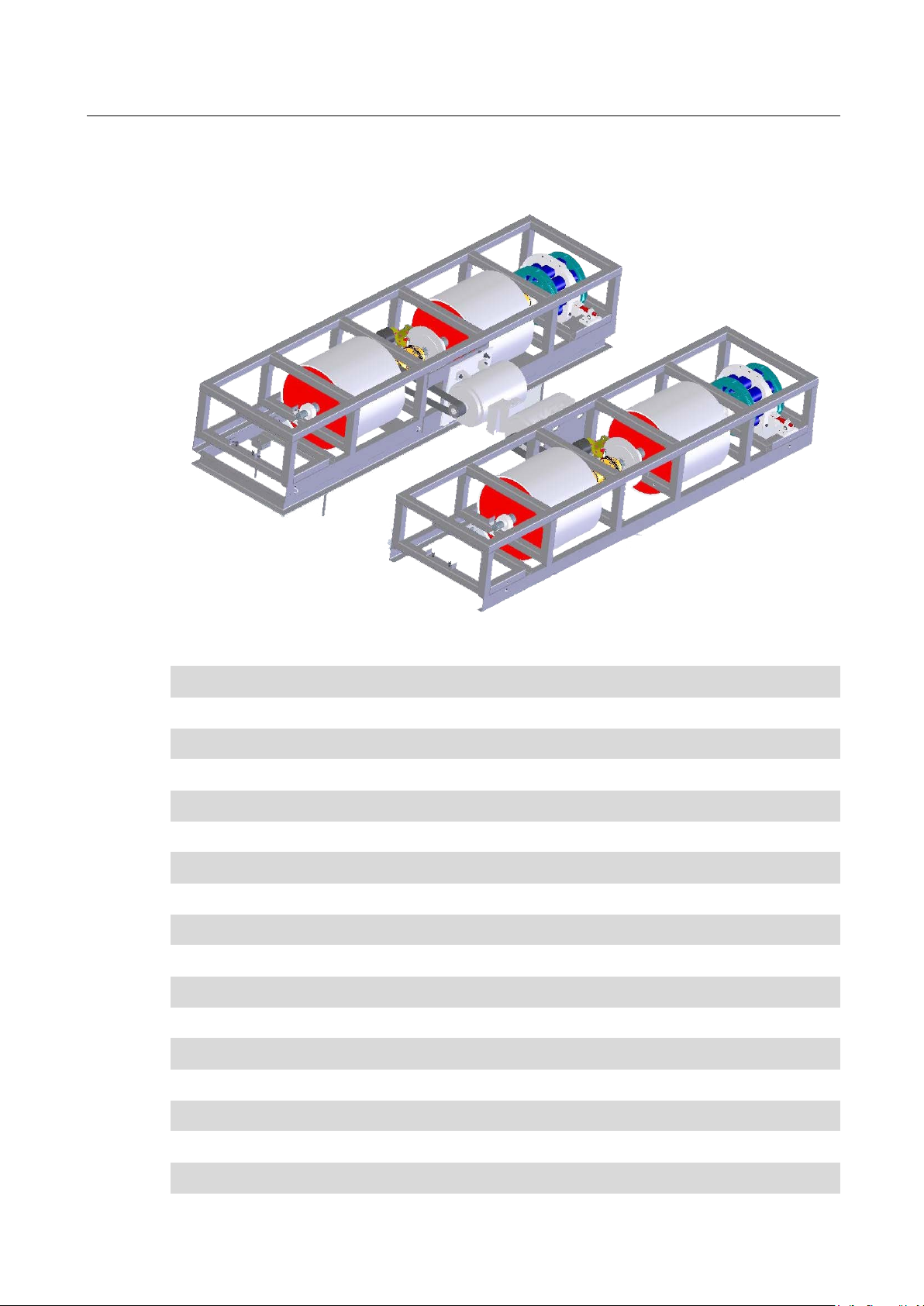

The single roller dynamometer MSR consists of:

• A communication desk with PC, monitor, keyboard and wheel mouse (depending on ver-

sion)

• A remote control

• One or two roller sets

Optionally available are:

• A cooling air fan which is connected to the communication desk and is operated via the radio

remote control.

• An interface box via which the following modules can be connected:

Acquisition of engine RPM via Trigger tongs (Otto engine), Piezo clamp sensor (Diesel engine),

TDC-sensor (manufacturer-specific, upon request), Diagnostic plug (manufacturer-specific, upon

request), Oil temperature probe (up to max. 180°C) and much more.

Acquisition of ambient temperature, intake air temperature, air pressure and humidity, fuel

temperature

Acquisition of analog signals

Aquisition of OBD data

Recording of 2 temperatures and 2 pressures each

• To determine performance data of DIN 70020, EWG 80/1269, ISO 1585, SAE J1349 or JIS

D1001 a barometer and a humidity sensor are installed in the interface box (Graphic package is

(*)

prerequisite)

.

• MAHA emission testers, gasoline (MGT5) and diesel (MDO2 and MDO2 LON) which can be

connected to the dyno

• DIN A4 ink jet printer, color

• Fuel consumption device for gasoline and diesel engines. (Krupp/AIC)

• Analog output card to process measured variables as analog signal

(e.g. display of issued variables on an external analog instrument

(*) These options are not connected to the interface box but separately on the dyno.

Pos: 39 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

(*)

.

(*)

(*)

(*)

).

BA053101-en

Page 13

13

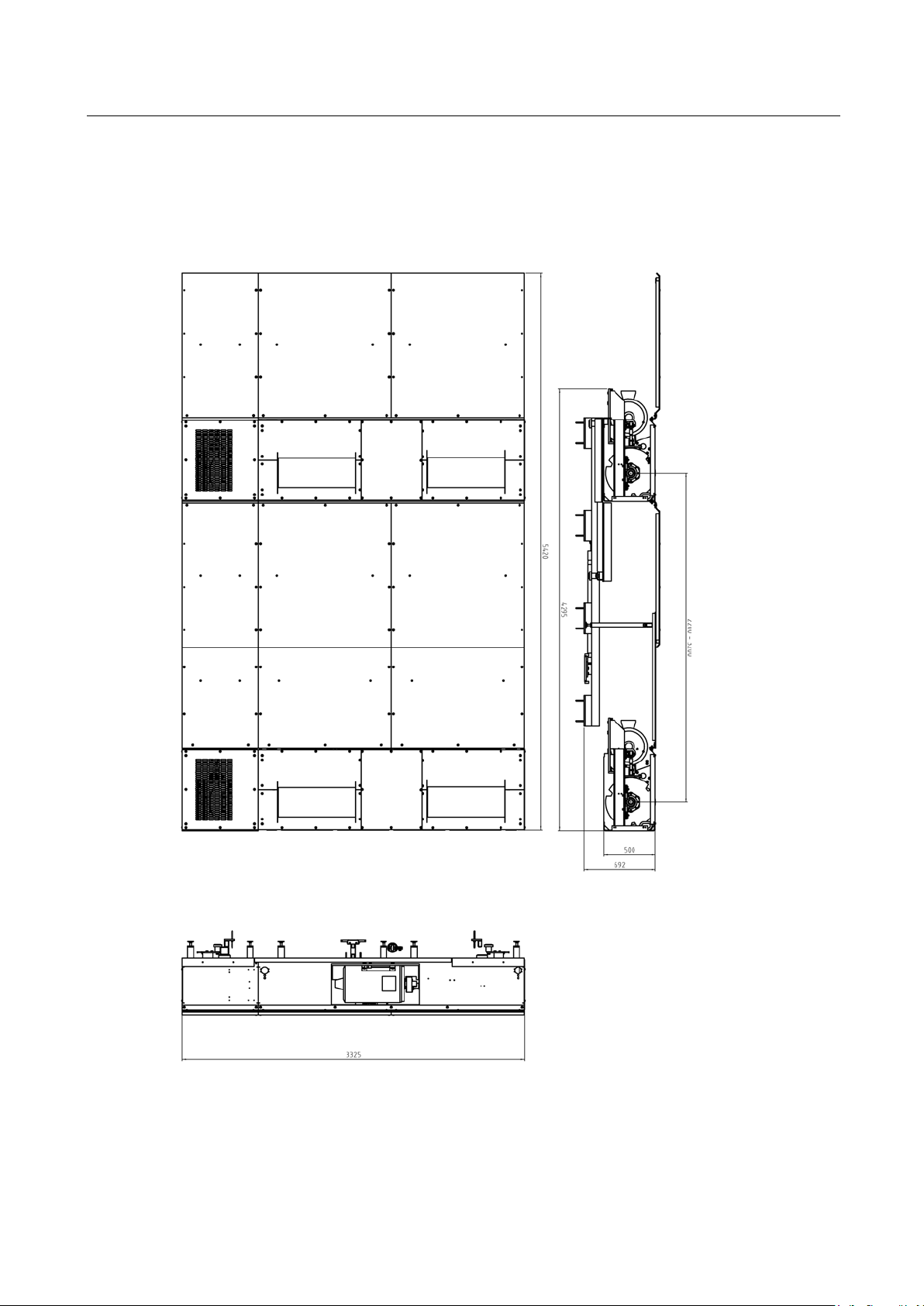

2.2

Specifications

2.2.1

Dimensions

MSR 500

Pos: 40 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/T/Übers chrift 1.1: Technis che Daten @ 7\mod _1 184075526343_75.docx @ 99711 @ 2 @ 1

Pos: 41 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1.1/A/Übers chrift 1.1.1 : Abmessunge n @ 14\mod_1241595523910_75.docx @ 371167 @ 3 @ 1

Pos: 42 /Technische Dokume ntatio n/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 Abmessungen (Bilder) MSR 500 @ 23\mod_12983 909 220 89_0.d ocx @ 978 971 @ @ 1

Pos: 43 /Tec hn isch e Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 Abmessungen (Bilder) MSR 1000 @ 14\mod_1241595624149_0.docx @ 371193 @ @ 1

BA053101-en

Page 14

14

MSR 1000

Pos: 44 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1.1/K/Über schrift 1. 1.1: Komm un ika tions pu lt @ 13\m od_1 23417 52964 30_7 5.docx @ 3354 86 @ 3 @ 1

BA053101-en

Page 15

15

2.2.2

Communication Desk

Pos: 45 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 5310 1 MS R/BA/I nha lt: 0 531 K ommun ika tions pult ( Bild er) @ 23\mod_1296722871974_0.docx @ 969333 @ @ 1

A

B

Pos: 46 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYNO/053101 MSR/BA/Inhalt: 0531 Kommunikationspult (Text) @ 23\mod_1297151385424_75.docx @ 971753 @ @ 1

Communication desk, Version A .................................................................... 670 x 1400 x 800 mm

Pos: 47 /-----For mat -----/MAN UE LLE R UM BR UCH Se iten umb ruc h @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Communication desk, Version B (available from March 2011) ........................ 350 x 1230 x 860 mm

BA053101-en

Page 16

16

2.2.3

MSR 500/1

1-Axle Roller Set with 1 Eddy Current Brake and 1 Electric Motor

Pos: 48 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1. 1/M/Über schrift 1.1.1: MSR 5 00/1 @ 24\m od_13 05615 9950 73_0.d ocx @ 1 00740 1 @ 3 @ 1

Pos: 49 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 310 1 MS R/B A/In ha lt: 0 531 MSR 5 00/1 ( Bi ld) @ 23\ mod_1296463645669_0.docx @ 968263 @ @ 1

Pos: 50 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 5310 1 MS R/BA /In ha lt: 0 531 MSR 500/ 1 ( Tex t) @ 22\m od_1295432174832_75.docx @ 963400 @ @ 1

Roller diameter 504 mm / 20"

Rolling circumference 1583 mm

Roller length 750 mm

Track width (min….max.) 700…2200 mm

Roller wall thickness 12 mm

Total weight of Roller set 1630 kg

Mech. inertia weight approx. 280 kg

Permissible axle load 2500 kg

Maximum speed 300 km/h

Motor power 22 kW

Wheel power stat. / dyn. 260 / 1000 kW

Const. tractive force 7000 N

Fuse with / without drive 63 / 16 A

Supply voltage 3 x 400 + N + PE

Pos: 51 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1. 1/M/Über schrift 1.1.1: MSR 5 00/2 @ 24\m od_13 05616 1336 11_0.d ocx @ 1 00743 1 @ 3 @ 1

BA053101-en

Page 17

17

2.2.4

MSR 500/2

1-Axle Roller Set with 2 Eddy Current Brakes and 1 Electric Motor

Pos: 52 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 310 1 MS R/B A/In ha lt: 0 531 MSR 5 00/2 ( Bi ld) @ 23\ mod_1296464800590_0.docx @ 968323 @ @ 1

Pos: 53 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 5310 1 MS R/BA/ In halt: 0 531 MSR 500/ 2 ( Tex t) @ 22\m od_1295432706059_75.docx @ 963460 @ @ 1

Roller diameter 504 mm / 20"

Rolling circumference 1583 mm

Roller length 750 mm

Track width (min….max.) 700…2200 mm

Roller wall thickness 12 mm

Total weight of Roller set 1940 kg

Mech. inertia weight approx. 305 kg

Permissible axle load 2500 kg

Maximum speed 300 km/h

Motor power 22 kW

Wheel power stat. / dyn. approx. 520 / 2000 kW (Peak)

Tractive force approx. 14000 N

Fuse with / without drive 63 / 40 A

Supply voltage 3 x 400 + N + PE

Pos: 54 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 18

18

2.2.5

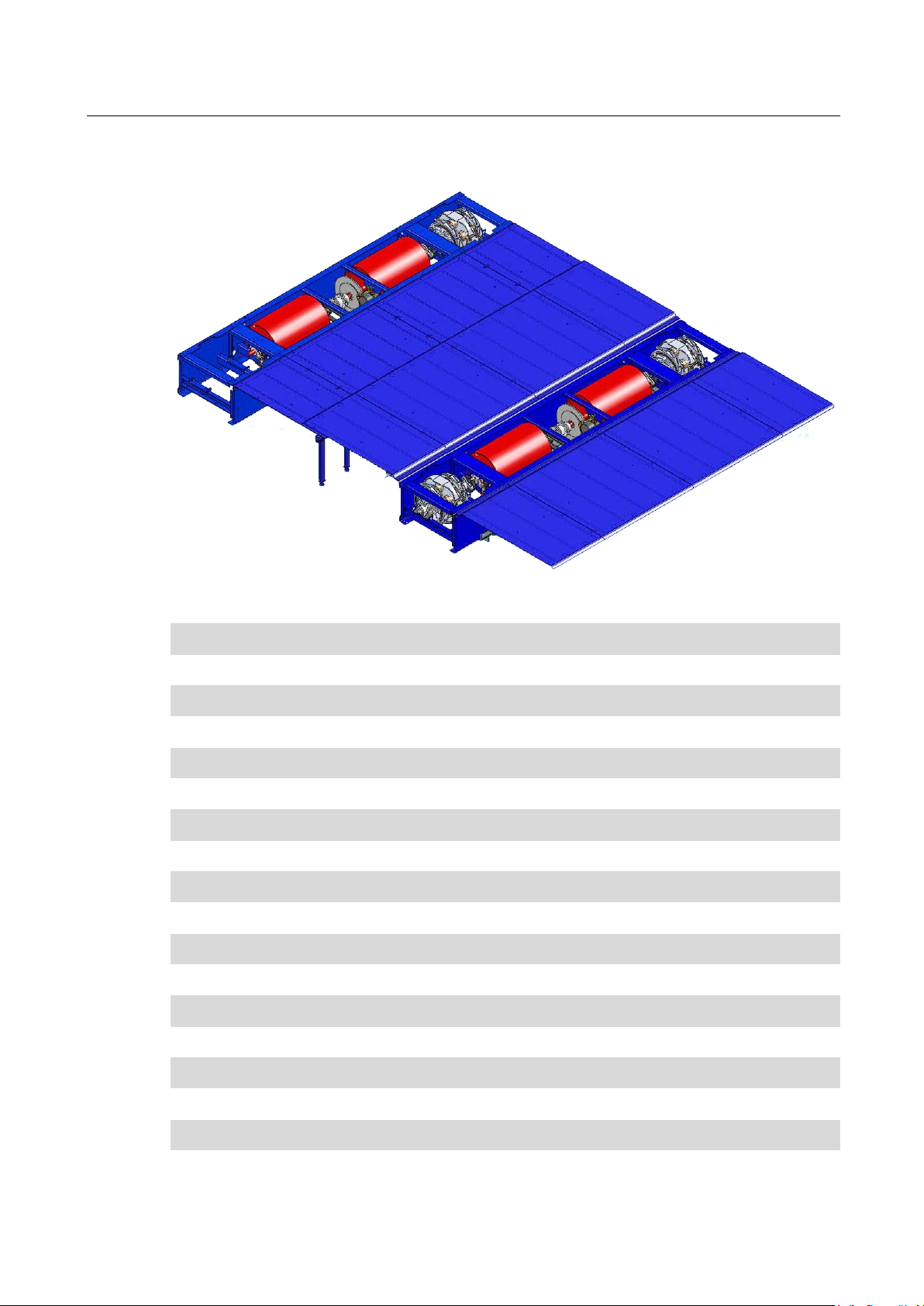

MSR 500/2 4WD

4WD with 1 Eddy Current Brake and 1 Electric Motor per Axle

Pos: 55 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1. 1/M/Über schrift 1.1.1: MSR 5 00/2 4WD @ 24\mod_1305616199956_0.docx @ 1007461 @ 3 @ 1

Pos: 56 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 310 1 MS R/B A/In ha lt: 0 531 MSR 5 00/2 4W D (B ild) @ 23\m od_1296464625288_0.docx @ 968293 @ @ 1

Pos: 57 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 310 1 MS R/B A/In ha lt: 0 531 MSR 5 00/2 4W D (Tex t) @ 22\mod_1295435416655_75.docx @ 963520 @ @ 1

Roller diameter 504 mm / 20"

Rolling circumference 1583 mm

Roller length 750 mm

Track width (min….max.) 700…2200 mm

Roller wall thickness 12 mm

Total weight of Roller set 4130 kg

Mech. inertia weight 2 x 280 kg

Permissible axle load 2500 kg

Maximum speed 300 km/h

Maximum speed of a tracked, non-driven axle approx. 200 km/h

Motor power 2 x 22 kW

Wheel power Front axle stat. / dyn. 260 / 1000 kW (Peak)

Wheel power Rear axle stat. / dyn. 260 / 1000 kW (Peak)

Tractive force Front axle approx. 7000 N

Tractive force Front axle approx. 7000 N

Fuse 63 A

Supply voltage 3 x 400 + N + PE

Pos: 58 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1. 1/M/Über schrift 1.1.1: MSR 500/3 4WD @ 24\mod_1305616255864_0.docx @ 1007491 @ 3 @ 1

BA053101-en

Page 19

19

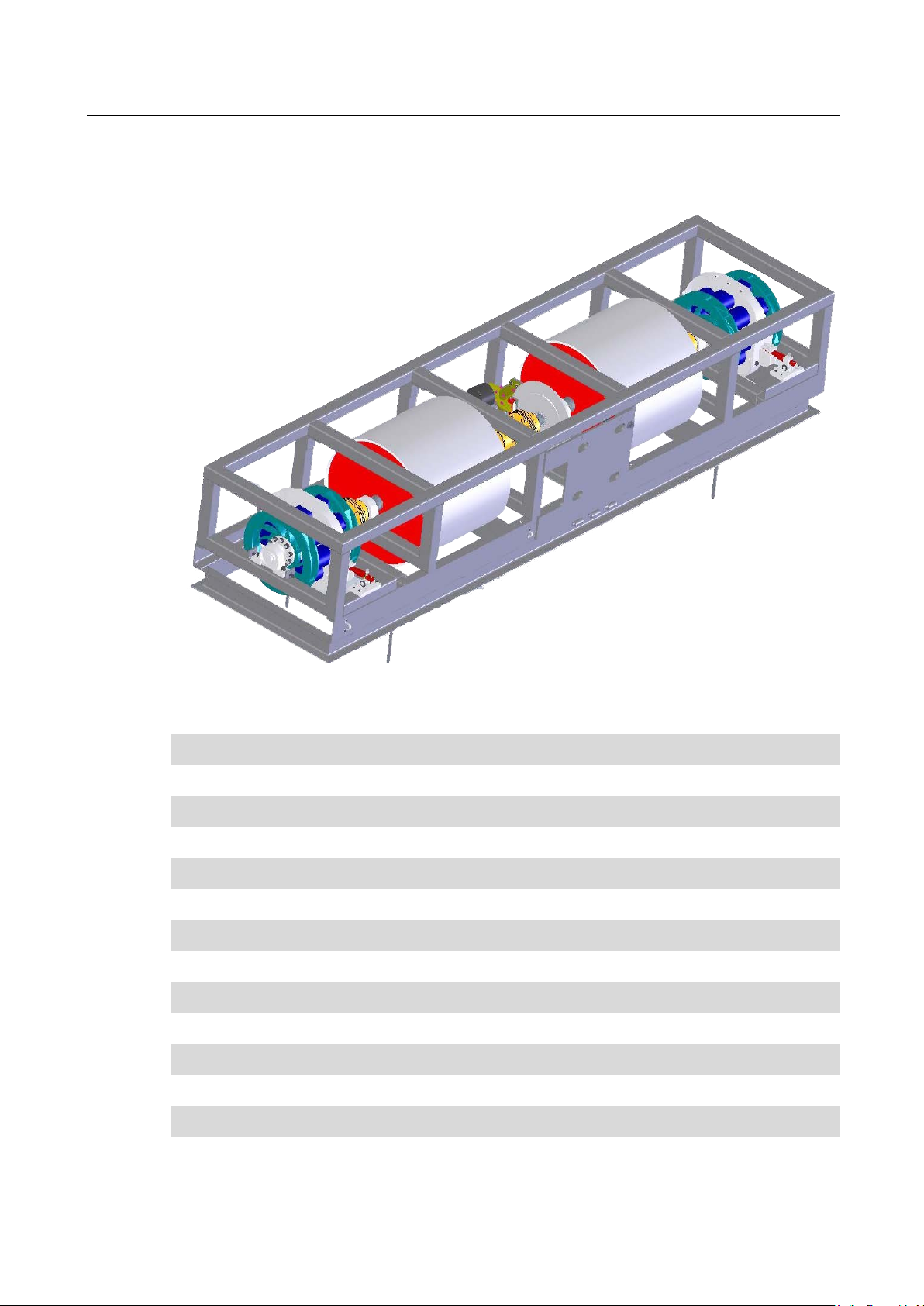

2.2.6

MSR 500/3 4WD

4WD with 1 Eddy Current Brake FA, 2 Eddy Current Brakes RA, 1 Electric Motor per Axle

Pos: 59 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 310 1 MS R/B A/In ha lt: 0 531 MSR 5 00/3 4W D (B ild) @ 23\mod_1296464996919_0.docx @ 968353 @ @ 1

Pos: 60 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 310 1 MS R/B A/In ha lt: 0 531 MSR 5 00/3 4W D (Tex t) @ 22\mod_1295435803655_75.docx @ 963580 @ @ 1

Roller diameter 504 mm / 20"

Rolling circumference 1583 mm

Roller length 750 mm

Track width (min….max.) 700…2200 mm

Roller wall thickness 12 mm

Total weight of Roller set 4395 kg

Mech. inertia weight 1 x 280 kg / 1 x 305 kg

Permissible axle load 2500 kg

Maximum speed 300 km/h

Maximum speed of a tracked, non-driven axle approx. 200 km/h

Motor power 2 x 22 kW

Wheel power Front axle stat. / dyn. 260 / 1000 kW (Peak)

Wheel power Rear axle stat. / dyn. 520 / 1000 kW (Peak)

Tractive force Front axle approx. 7000 N

Tractive force Front axle approx. 14000 N

Fuse 63 A

Supply voltage 3 x 400 + N + PE

Pos: 61 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 20

20

2.2.7

MSR 800

1-Axle Roller Set

Pos: 62 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1. 1/M/Über schrift 1.1.1: MSR 8 00 @ 24\mod_1306494127905_0.docx @ 1013813 @ 3 @ 1

Pos: 63 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 800 (Bild) @ 23\mod_1298447556531_0.docx @ 9 790 71 @ @ 1

Pos: 64 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 800 (Text) @ 14\mod_1241597479700_75.docx @ 371613 @ @ 1

Roller diameter 762 mm / 30"

Rolling circumference 2393 mm

Roller length 700 mm

Track width (min….max.) 900…2300 mm

Roller wall thickness 20 mm

Total weight of Roller set 1910 kg

Mech. inertia weight approx. 700 kg

Permissible axle load 2500 kg

Maximum speed > 300 km/h

Wheel power approx. 660 kW

Const. tractive force not available

Fuse 16 A

Pos: 65 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Supply voltage 230 V + N + PE

Page 21

21

2.2.8

MSR 830

1-Axle Roller Set with 1 Eddy Current Brake

Pos: 66 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1. 1/M/Über schrift 1.1.1: MSR 8 30 @ 24\mod_1305616305111_0.docx @ 1007521 @ 3 @ 1

Pos: 67 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 830 (Bild) @ 23\mod_12984482086 73_0.d ocx @ 979 137 @ @ 1

Pos: 68 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 830 (Text) @ 14\mod_1241597837603_75.docx @ 371639 @ @ 1

Roller diameter 762 mm / 30"

Rolling circumference 2393 mm

Roller length 700 mm

Track width (min….max.) 900…2300 mm

Roller wall thickness 20 mm

Total weight of Roller set 2270 kg

Mech. inertia weight approx. 700 kg

Permissible axle load 2500 kg

Maximum speed > 300 km/h

Wheel power approx. 700 kW (Peak)

Tractive force approx. 8600 N

Fuse 20 A

Supply voltage 3 x 400 V + N + PE

Pos: 69 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 22

22

2.2.9

MSR 850

1-Axle Roller Set with 2 Eddy Current Brakes

Pos: 70 /Tec hn isch e Do kumentatio n/Alle Geräte/ Überschrift en/Überschr iften 1.1. 1/M/Überschr ift 1.1.1: MSR 85 0 @ 24\mod_1306494212398_0.docx @ 1013843 @ 3 @ 1

Pos: 71 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 850 (Bild) @ 23\mod_12984483036 66_ 0.d ocx @ 9 791 62 @ @ 1

Pos: 72 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 850 (Text) @ 14\mod_1241598845809_75.docx @ 371695 @ @ 1

Roller diameter 762 mm / 30"

Rolling circumference 2393 mm

Roller length 700 mm

Track width (min….max.) 900…2300 mm

Roller wall thickness 20 mm

Total weight of Roller set 2630 kg

Mech. inertia weight approx. 750 kg

Permissible axle load 2500 kg

Maximum speed > 300 km/h

Wheel power approx. 1400 kW (Peak)

Tractive force approx. 17200 N

Fuse 40 A

Supply voltage 3 x 400 V + N + PE

Pos: 73 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 23

23

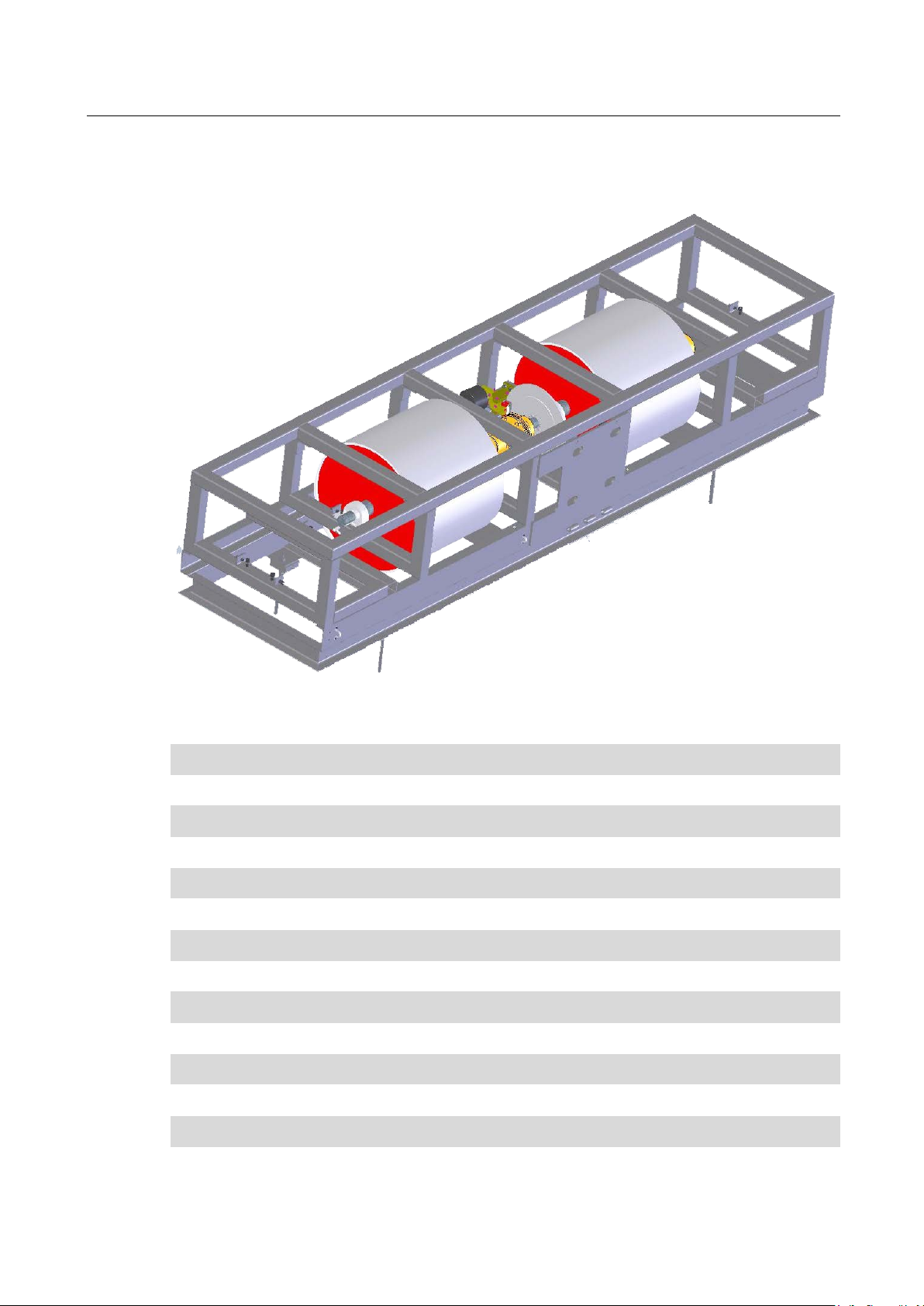

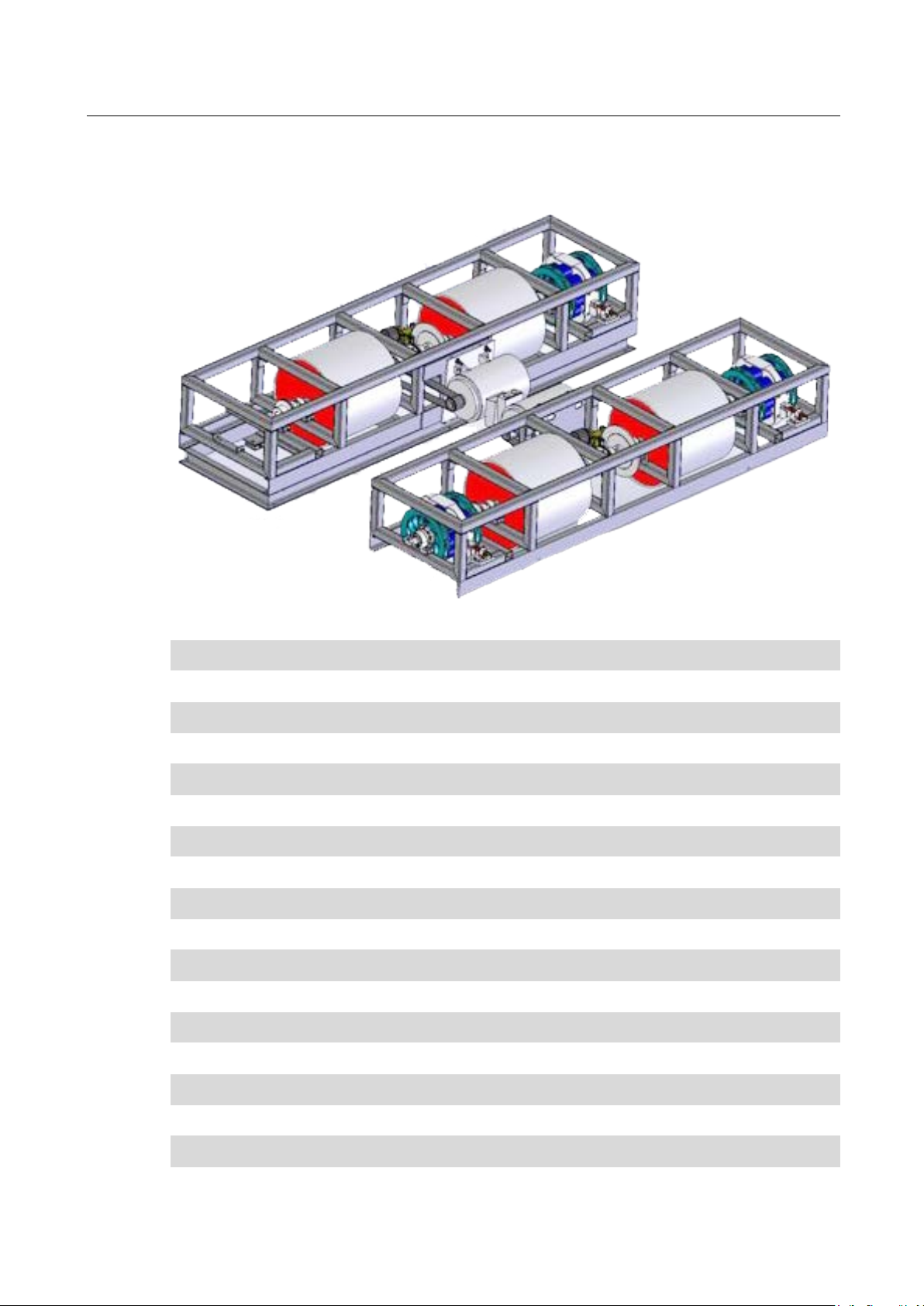

2.2.10

MSR 1000

4WD with 1 Eddy Current Brake and 1 E-Machine per Axle

Pos: 74 /Technisch e Dok ument ation/Al le Gerät e/Über schrift en/Über schri ften 1. 1.1/M/ Überschr ift 1 .1.1: MSR 10 00 @ 24\ mod_1306493890113_0.docx @ 1013753 @ 3 @ 1

Pos: 75 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 5310 1 MS R/BA/I nha lt: 0531 MSR 1000 (Bild) @ 23\mod_1298448477424_0.docx @ 979192 @ @ 1

Pos: 76 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 1000 (Text) @ 14\mod_1241599234153_75.docx @ 371747 @ @ 1

Roller diameter 762 mm / 30"

Rolling circumference 2393 mm

Roller length 700 mm

Track width (min….max.) 900…2300 mm

Roller wall thickness 20 mm

Total weight of Roller set 5610 kg

Mech. inertia weight 2 x 700 kg

Permissible axle load 2500 kg

Maximum speed > 300 km/h

Maximum speed of a tracked, non-driven axle approx. 200 km/h

Motor power 2 x 30 kW

Wheel power Front axle approx. 700 kW (Peak)

Wheel power Rear axle approx. 700 kW (Peak)

Tractive force Front axle approx. 8600 N

Tractive force Rear axle approx. 8600 N

Fuse 63 A

Supply voltage 3 x 400 V

Pos: 77 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 24

24

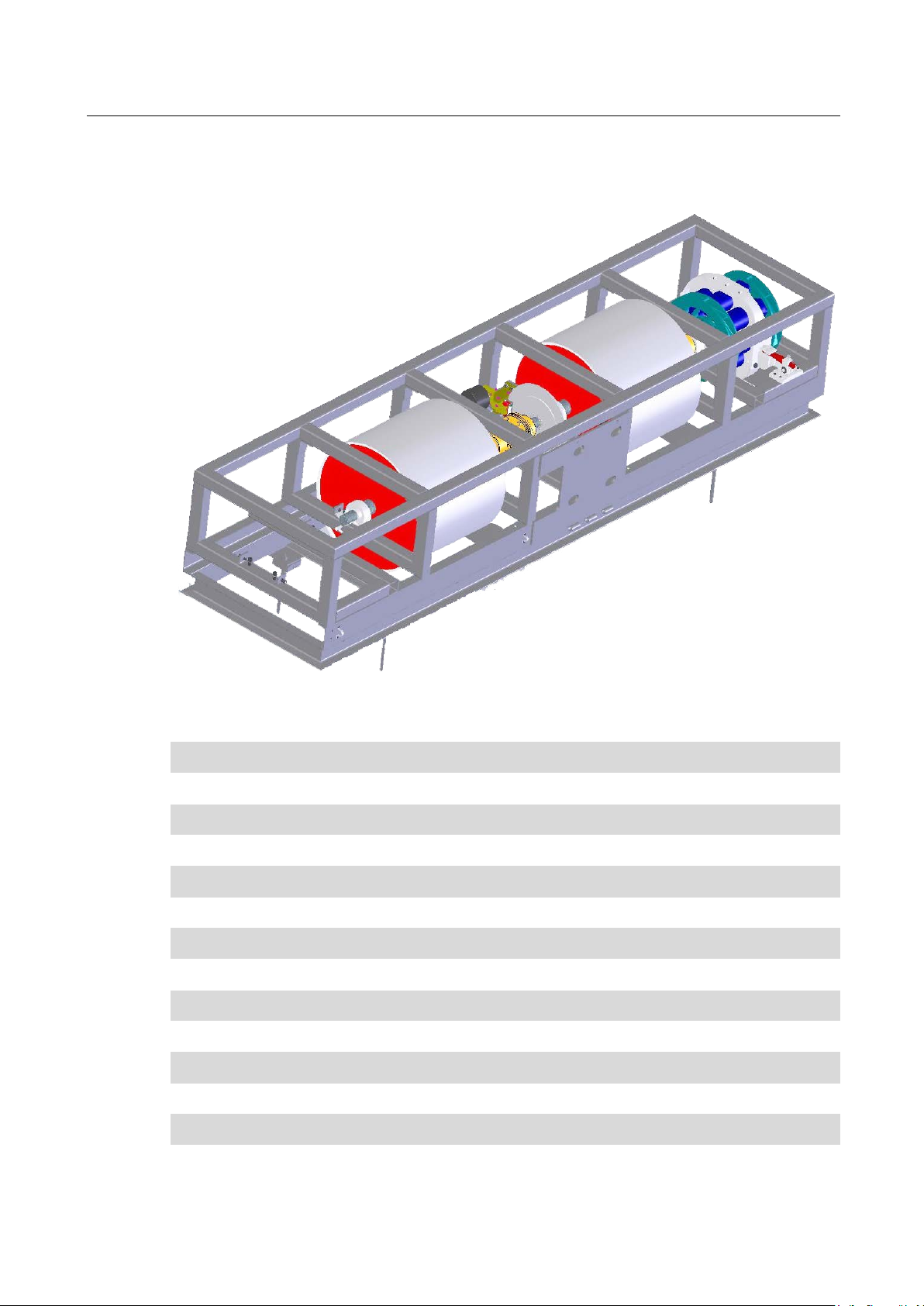

2.2.11

MSR 1050

4WD with 1 Eddy Current Brake FA, 2 Eddy Current Brakes RA, 1 Electric Motor per Axle

Pos: 78 /Technische Dokume ntatio n/Alle Geräte/ Übers ch rift en/ Über schr ift en 1.1. 1/M /Üb ersc hr ift 1 .1. 1: M SR 1 050 @ 2 4\mod_1306494009976_0.docx @ 1013783 @ 3 @ 1

Pos: 79 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 1050 (Bild) @ 23\mod_1298448681304_0.docx @ 979222 @ @ 1

Pos: 80 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 MSR 1050 (Text) @ 14\mod_1241599445142_75.docx @ 371773 @ @ 1

Roller diameter 762 mm / 30"

Rolling circumference 2393 mm

Roller length 700 mm

Track width (min….max.) 900…2300 mm

Roller wall thickness 20 mm

Total weight of Roller set 5970 kg

Mech. inertia weight 1 x approx. 700 kg / 1 x approx. 730 kg

Permissible axle load 2500 kg

Maximum speed > 300 km/h

Maximum speed of a tracked, non-driven axle approx. 200 km/h

Motor power 2 x 30 kW

Wheel power Front axle approx. 700 kW (Peak)

Wheel power Rear axle approx. 1400 kW (Peak)

Tractive force Front axle approx. 8600 N

Tractive force Rear axle approx. 17200 N

Fuse 63 A

Supply voltage 3 x 400 V + N + PE

Pos: 81 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 25

25

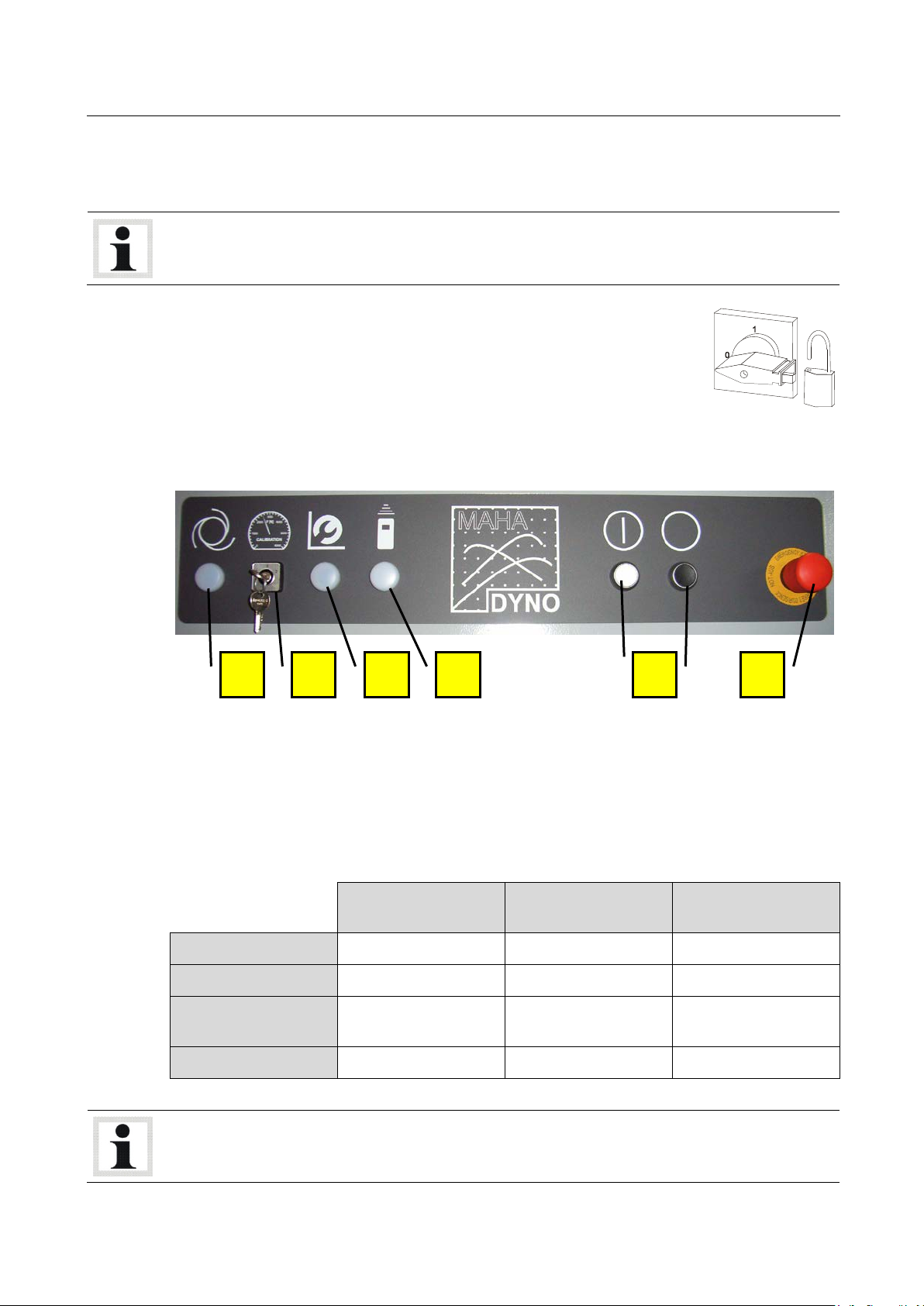

2.3

Main Switch

2.4

Controls and Indicators

A

D

B

E

C

F

Operating Modes

Position 1: OPERATI-

ON

Position 0: CALIBRA-

TION

Position 2:

SETUP

Pos: 82 /Technische Dok umentatio n/Alle Geräte/ Überschrift en/Überschr iften 1.1/H /Überschr ift 1.1: Hauptschal ter @ 6\mod_ 11775 92858 312_ 75.do cx @ 906 35 @ 2 @ 1

Pos: 83 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Info!/I nhalt: I nfo - Hauptschalter @ 23\mod_1298624423518_75.docx @ 979863 @ @ 1

The main switch is located at the side wall of the communication desk.

Pos: 84 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Inhal t: Haupts chalt er v1 - A lle Geräte @ 23\mod_1298376098685_75.docx @ 978845 @ @ 1

• Main switch in position 0: Power supply OFF

• Main switch in position 1: Power supply ON

• When in position 0, the main switch can be protected against tampering

by means of a padlock.

Pos: 85 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/B/Übers chrift 1.1: Bedien - und Anz eigeelemen te @ 23\mod_ 12962 20301 443_ 75.do cx @ 9681 07 @ 2 @ 1

Pos: 86 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 Bedien- und Anzeigeelemente (Bild) @ 24\m od_1305638503474_0.docx @ 1007773 @ @ 1

Pos: 87 /-----For ma t-----/MA NUEL LER UM BRUC H Zeile nscha ltun g @ 7\mod_ 1195 1389 65731_ 0.doc x @ 13217 7 @ @ 1

Pos: 88 /-----For ma t-----/MA NUEL LER UM BRUC H Zeile nscha ltun g @ 7\mod_ 1195 1389 65731_ 0.doc x @ 13217 7 @ @ 1

Pos: 89 /Techn ische Dok ument atio n/Le istun gsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 Bedien- und Anzeigeelemente (Text) @ 23\mod_1296549358503_75.docx @ 968523 @ @ 1

Locking Brake ON ON ON

Hydraulic System OFF OFF ON

Power Section of Eddy

Current Brake

Motors/Converters ON OFF (Safety Stop) OFF (Safety Stop)

Operating Mode Selector Switch

Control ON/OFF

EMERGENCY STOP

ON OFF OFF

B C A D E F

OPERATION Indicator Lamp

SETUP Indicator Lamp

REMOTE CONTROL Indicator Lamp

Each time the operating mode is changed, the control is disabled and must be re-enabled using

the Control ON button.

BA053101-en

Page 26

26

Enabling / Disabling the Dynamometer

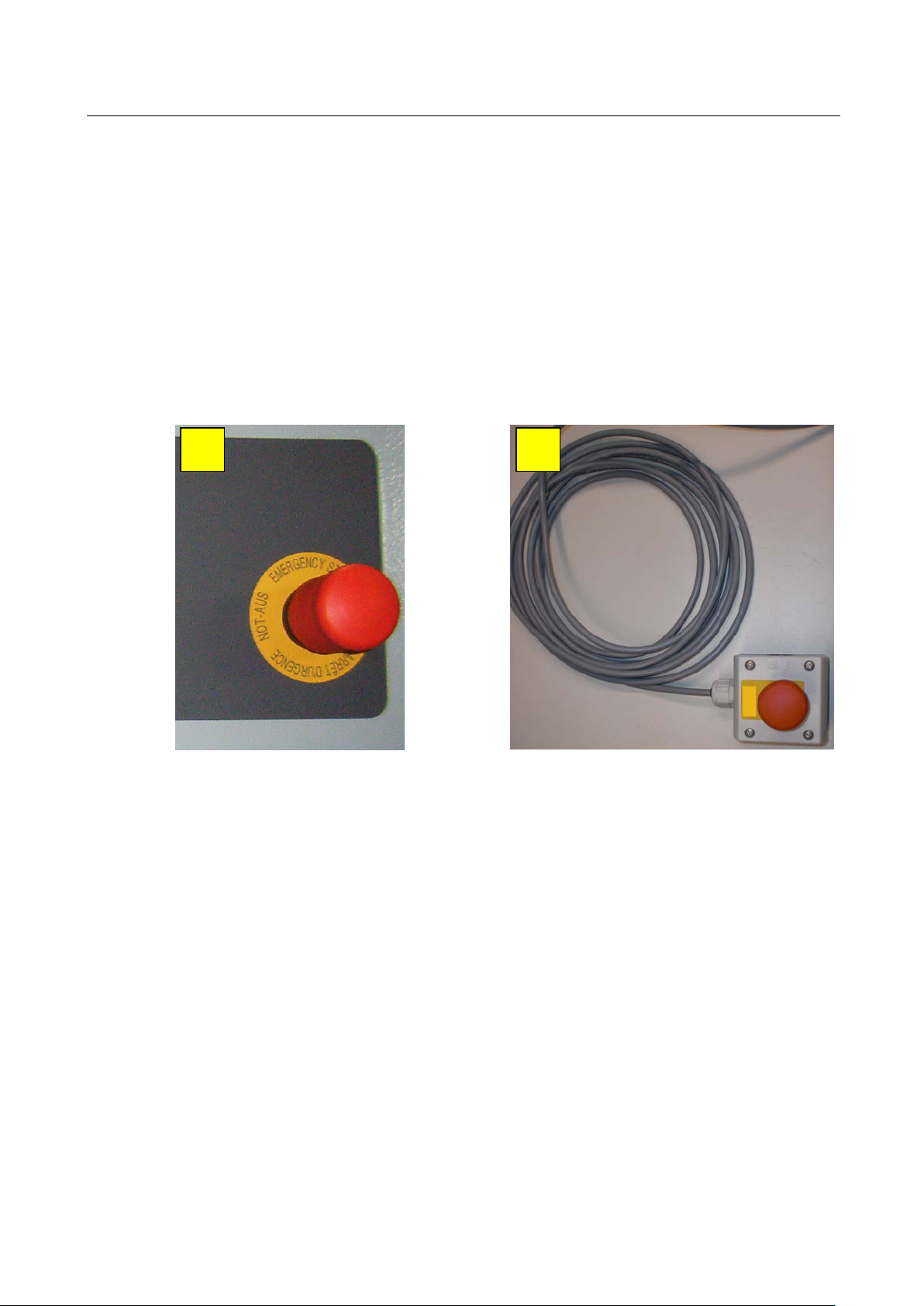

2.5

Emergency Stop

A

B

ON

1 Main switch ON.

2 Set operating mode selector switch to re-

3 Control ON.

Dyno is ready for operation.

Pos: 90 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/N /Überschr ift 1 .1: No t-Ha lt @ 23\mod_1297171316373_75.docx @ 972449 @ 2 @ 1

Pos: 91 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 Not-Halt (Bild) @ 24\mod_1305639886912_0.docx @ 1007804 @ @ 1

OFF

1 Control OFF.

2 Main switch OFF.

quired position.

Dyno is shut down.

A B

Pos: 92 /Technische Dokumentation/Leistungsmesstechnik/POWERDYNO/053101 MSR/BA/Inhalt: 0531 Not-Halt (Text) @ 2 3\mod_1296551173826_75.docx @ 968643 @ @ 1

EMERGENCY STOP

at Communication Desk

Push the mushroom button to enable the EMERGENCY STOP:

Motor converters OFF

Power section of eddy current brake OFF

All outputs for hydraulic and pneumatic systems OFF

Pos: 93 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

Program must be restarted

Portable EMERGENCY STOP

for Motor-Driven Dynamometers

BA053101-en

Page 27

27

2.6

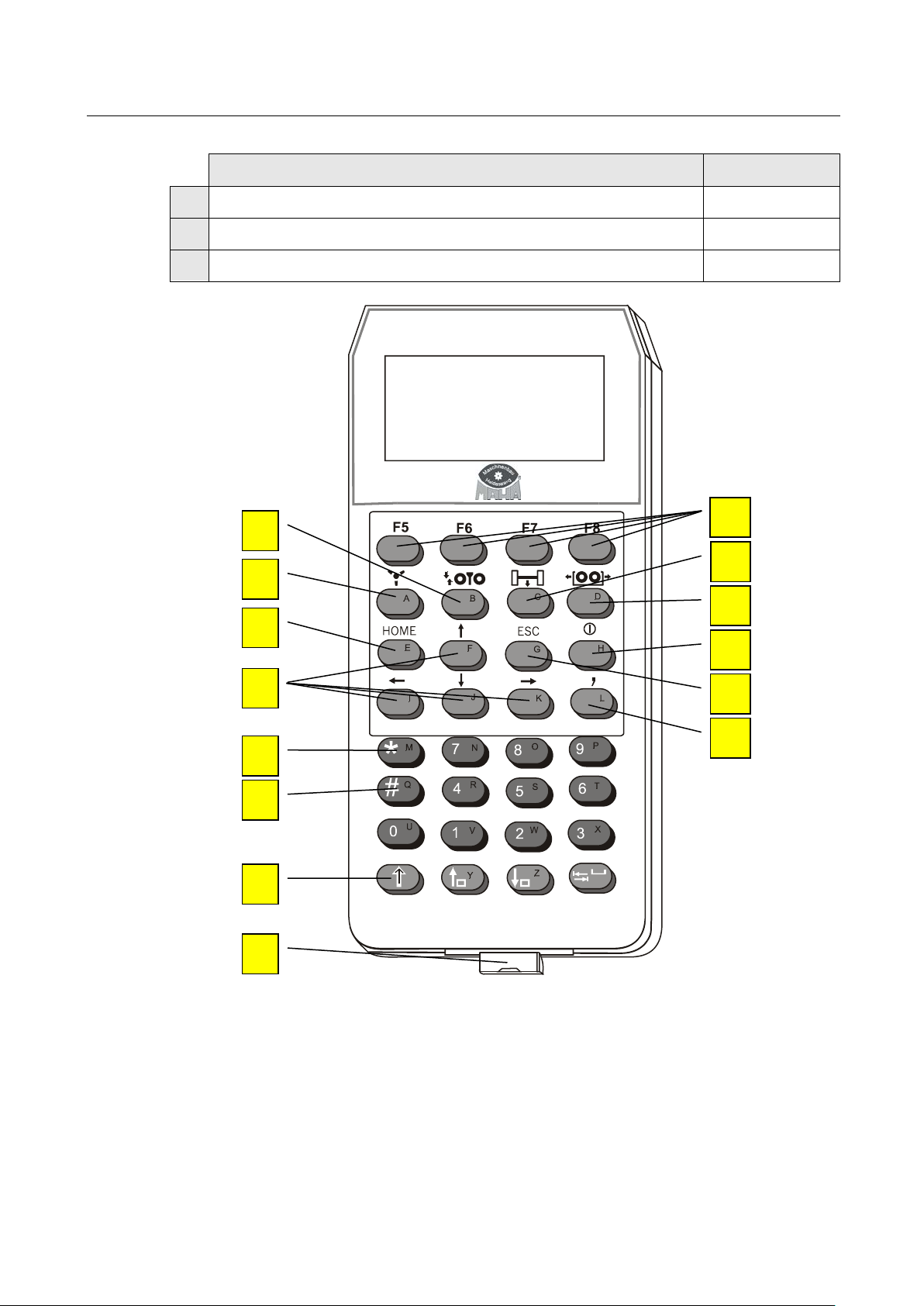

Remote Control

Remote Control

PC Keyboard

1

2

3

4

5

6

7

8

9

10

11

Pos: 94 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/F/Übers chrift 1.1: Fernbed ienung @ 7\mod_1184152042500_75.docx @ 99994 @ 2 @ 1

Pos: 95 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 230 1 L PS 30 00 R100/ BA /In hal t: 0 523 Fern bed ien ung ( Tex t) @ 13\m od_1234179191060_75.docx @ 335824 @ @ 1

The functions of the program can also be selected via the remote control. The remote control can

be operated directly from the vehicle.

The signal is transmitted by radio. The receiving antenna for the signal is located in the desk.

Should several dynos each with its own remote control be operated in one room, the remote

controls must be set to different channels.

As soon as the remote control is switched on and radio connection to the dyno exists, the green

control lamp will light up permanently on the operation desk. The green control lamp will blink

briefly each time a key is pressed.

When not in use the remote control should always be stored in the re-charging box to avoid a total

discharging of the battery. The re-charging box is equipped with a "re-charge overload protection”.

The re-charging time for a fully discharged battery is about 12 to 14 hours. During the re-charging

procedure the red LED on the re-charging box will light up and "Battery recharging" appears on

the display of the remote control.

To switch on the remote control press the ON key. The remote control has an automatic switch off

(Timeout) which can be variably set. The remote control switches off when no key has been

pressed during this time.

The letters on the remote control can be selected by pressing the SHIFT key. Press again to return

to the normal operation mode. The display "SHIFT" appears in the window when the SHIFT key

has been pressed.

Pos: 96 /Techn ische Dok ument atio n/Le istun gsmess tec hnik/ PO WERDYN O/0 523 01 L PS 300 0 R1 00/ BA/I nha lt: 052 3 Fer nbed ie nun g ( Tabe lle) @ 13\mod_1234943754775_75.docx @ 342981 @ @ 1

The remote control keyboard consists of two pads: Function key pad + Number pad.

Use this key to activate the lifting bar. It can then be operated with the

cursor keys.

F3 + Cursor keys

Switch fan on / off F2

Deletes an entire line

Selection of a menu item

(In combination with the function key F5 and the cursor keys target values can be increased or decreased in some menus.)

Confirmation of inputs Return

Deleting the character before the cursor position

Discarding of inputs

Backspace

Switch over to letter mode

Connection for Pedal force sensor

In some menus special functions can be opened. The key assignments

vary in the different menus. Four boxes with diverse functions are located on the lower screen edge in these menus. These options are select-

F5 to F8

ed with the function keys F5 to F8 on the remote control. If the button

bar has further levels, these can be displayed using the cursor keys.

Use this key to activate the load simulator. It can then be operated with

the cursor keys.

F4 + Cursor keys

Use this key to activate the roller set adjustment. It can then be operated

with the cursor keys.

BA053101-en

Page 28

28

Remote Control

PC Keyboard

12

13

14

Pos: 97 /Tec hn isch e Do kum ent atio n/Le ist un gsmes s techn ik/ PO WER DYNO /05 230 1 L PS 30 00 R100/ BA /In hal t: 0 523 Fern bed ien ung ( Bi ld) @ 13 \mod_1234876860125_0.docx @ 342615 @ @ 1

Switch on remote control

Exit a program part

Input of a comma

1

2

3

4

5

6

7

8

Pos: 98 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

9

10

11

12

13

14

BA053101-en

Page 29

29

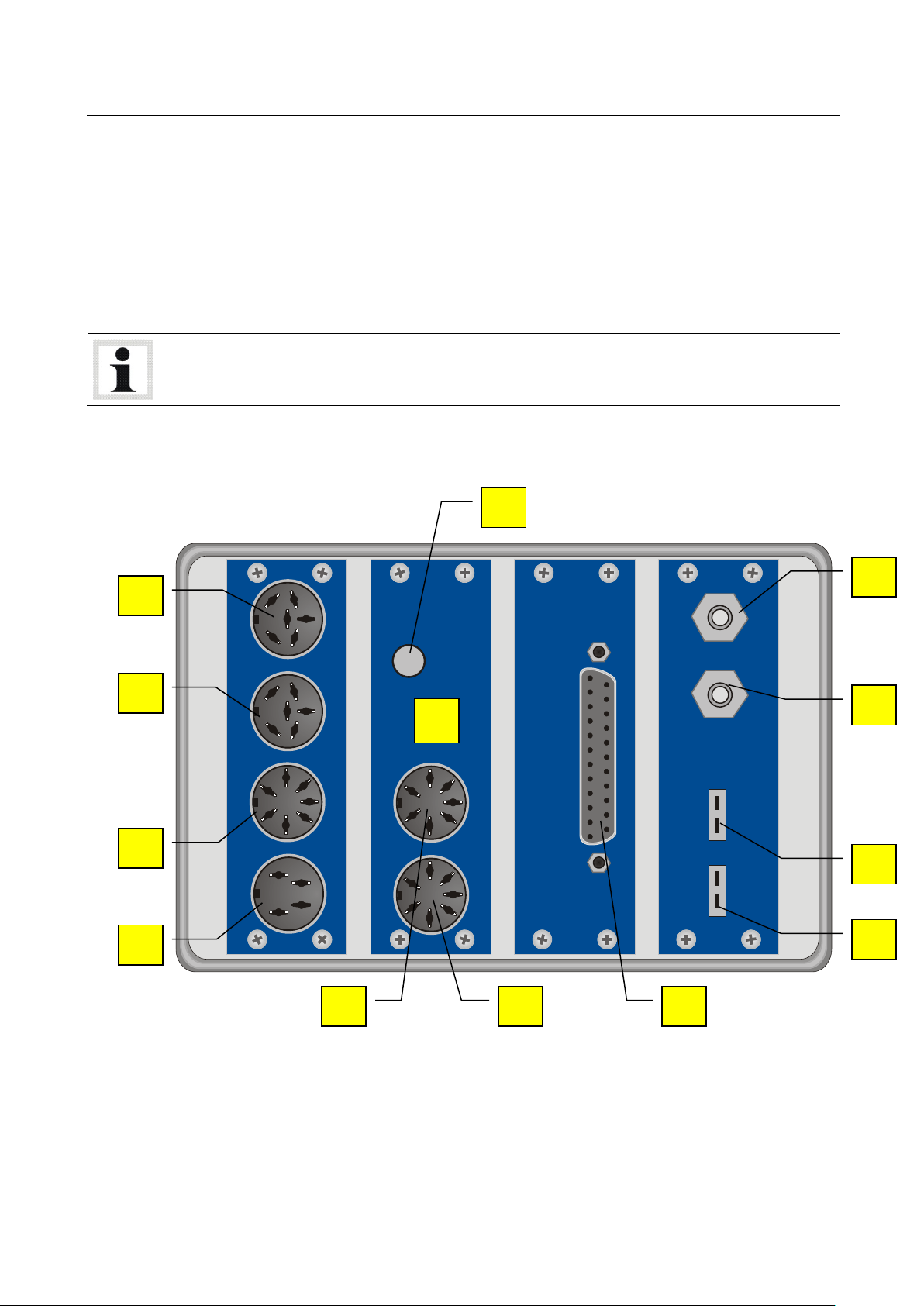

2.7

Description of the Interface Box

DRZ PTH OBD P2T2

A B D C H

E F I M L K J

G

Pos: 99 /Tec hn isch e Dokum entatio n/Alle Geräte/ Überschrift en/Überschr iften 1.1/SC H/Übersc hrift 1.1: Schnittst ellenbox @ 13\mod_1234179450859_75.docx @ 335876 @ 2 @ 1

Pos: 100 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Sc hni ttst elle nbox ( Text 1) @ 13\m od_1234179543447_75.docx @ 335902 @ @ 1

The Interface Box records engine RPM, environmental data, OBD data, temperature, pressure and

analog signals. This is done via modules. A maximum of 4 modules can be installed in the interface

box.

Additional modules can be installed in a second interface box which is connected parallel and, if

desired, adapted to customer requirements.

As standard equipment, the interface box 1 has an RPM and an environmental module.

Dimensions (H x W x L)

Weight

Pos: 101 /-----F orm at-----/ MAN UEL LE R UMB R UCH Z ei lens cha ltu ng @ 7\mod_1195138965731_0.docx @ 132177 @ @ 1

Pos: 102 /-----F orm at-----/ MAN UEL LE R UMB R UCH Z ei lensc hal tung @ 7\mod_1195138965731_0.docx @ 132177 @ @ 1

Pos: 103 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Sc hni ttst elle nbox (Bild ) @ 23\mod_1297161281106_0.docx @ 972044 @ @ 1

approx. 120 x 170 x 160 mm

approx. 1.0 kg

Pos: 104 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 30

30

DRZ

A

B

C

D

PTH

E

F

G

H

OBD (Option)

I

P2T2 (Option)

J

K

L

M

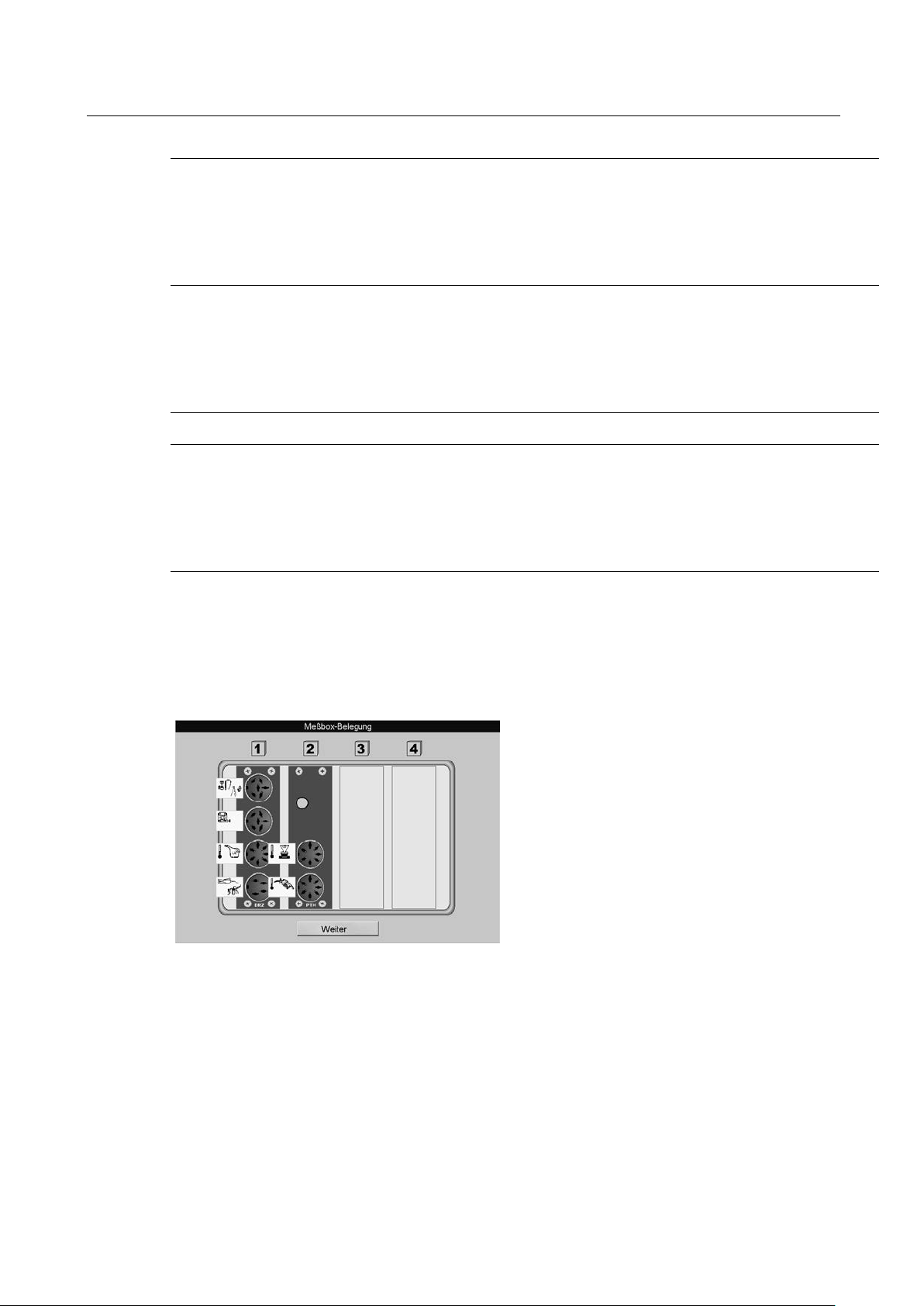

Display the Interface Box Assignment

Pos: 105 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Sc hni ttst elle nbox (Text 2) @ 13\mod_1234252898101_75.docx @ 336301 @ @ 1

Piezo clamp, TDC sensor Light barrier

Piezo clamp, TDC sensor Light barrier

Oil temperature probe

Trigger tongs

Fuel temperature

Intake air temperature

Atmospheric pressure

Humidity sensor

OBD

Pressure 1

Pressure 2

Temperature 1

Pos: 106 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Sc hni ttst elle nbox -Be legung ( Text) @ 13\ mod_1234253839295_75.docx @ 336327 @ @ 1

1 The assignment of the interface box appears using the keys <SHIFT> + <F1> .

2 Use <CONTINUE> or <RETURN> to exit this screen.

Pos: 107 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Sc hni ttst elle nbox -Be legun g (Bild) @ 13\mod_1234254152 771_ 0.docx @ 33635 3 @ @ 1

Pos: 108 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Temperature 2

BA053101-en

Page 31

31

2.7.1

RPM Module (Standard)

Trigger Tongs

(D)

Piezo Clamp

(A)

(B)

Clamp W

Pos: 109 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1.1/ D/Über schrif t 1.1. 1: Drehza hlmod ul (Sta ndard ) @ 1 3\mod _12 34254 5269 44_75.d ocx @ 33 6379 @ 3 @ 1

Pos: 110 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Dr ehza hlm odu l (S ta ndar d) @ 30\ mod_1363358323459_75.docx @ 1724326 @ @ 1

The RPM module is used to record the RPM and oil temperature (Plug-in card CAN DRZ).

The following RPM sensors/sources can be used:

The RPM signal is picked up at the ignition cable (spark plug or distributor ignition coil) with the

trigger tongs. The trigger tongs should be placed as close as possible to the spark plug and as far

as possible from the next ignition cable. The trigger tongs take up the high voltage signal

inductively which is conducted from the distributor to any random cylinder. The pulse is relayed

from the trigger tongs to the test box where it is converted to an RPM signal.

Attachment:

Position

on the interface box.

Piezo clamp is only used with diesel engines. The piezo clamp consists of a piezo element which

recognizes pressure differences at the lead-in and then converts them into electric pulses. It is

important that the piezo clamp which is used is suitable for only one diameter of the fuel line and

should only be placed at a straight section of the line at any cylinder (attach ground clamp on the

same injection line).

Attachment:

Position

or

on the interface box.

The alternator RPM is ascertained through the clamp W. The number of pulses per rotation at the

alternator (proportional to the crank shaft RPM) should be known or must be determined by an

external measuring device. This is necessary because individual vehicle models have different

transmissions between crank shaft and alternator. The RPM determination at the clamp W is only

used with diesel engine vehicles.

BA053101-en

Page 32

32

TDC Sensor

(A)

(B)

Light Barrier

Notes on adjusting the engine rpm via the light barrier

two

(A)

(B)

Driving Trial

The TDC sensor is always manufacturer-specific, i.e. depending on the vehicle manufacturer the

corresponding diagnostic plug is used for the RPM signal pick up.

The TDC sensor offers an extremely accurate

RPM measurement.

Once f

rot/min

is reached, an RPM of 12000

max

-1

is displayed.

The level must be between 30 mV and 30 V

so that an RPM pulse is recognized

Attachment:

• Position

or

on the interface box.

The light barrier is used when no direct way of determining the RPM at the engine is possible. The

transmission ratio to the engine RPM must be 1:1. If the light barrier is attached to the cardan

shaft, the transmission ratio must be between 0.5 and 2. The light barrier must be positioned in

such a way that via a reflector which is attached either to the vibration absorber, drive belt, or

cardan shaft, the RPM can be picked up free of any interference (no vibration influence etc.).

When making adjustments in the lower rpm range (drive shaft rpm < 800), we recommend using

reflectors in order to double the number of impulses generated.

When doing so, please remember the following:

• The reflectors must be systematically placed around the engine, exactly opposite one another.

Prominent points on the engine housing can be used to position the reflectors.

• When entering the gear ratio you must also double the previous value.

Attachment:

Position

or

on the interface box.

If none of the above mentioned alternatives is available for determining an RPM measurement, a

driving trial can be used to do the same. The RPM is converted from the dyno roller speed.

BA053101-en

Page 33

33

OBD Module

Oil Temperature Probe (Optional)

(C)

2.7.2

Environmental Module (Standard)

Fuel Temperature (Optional)

Intake Air Temperature

Ambient Temperature

At the beginning of a test a pre-determined RPM value must be approached ('Test gear' / Gear

transmission close to 1:1) while in a specific gear. This RPM value will be stored.

During the performance test the software will convert the roller’s current RPM into engine RPM.

(Please note: The calculated RPM will only correspond if the vehicle is driven in the 'test gear'.)

Automatic transmission vehicles without converter lockup cannot use the driving trial method, because the engine RPM deviates due to converter slip.

The RPM is read from the OBD data.

Driving trials should only be done when the engine is warmed up to operational temperature. The

oil temperature meter is used to determine the oil temperature and to monitor it during the testing

procedure.

Oil temperature probe for car and truck, with

variable length (100 to 1500 mm), with plug and

6 m supply line.

Attachment:

Position

Pos: 111 /Te ch nis che Dok ume nta tion /A lle G er äte/ Übe rsc hr ifte n/Üb er schr ifte n 1 .1. 1/U/ Über sc hr ift 1.1. 1: Umwe ltm odu l (S tandard) @ 13\m od_12 34256 46353 0_7 5.docx @ 33649 1 @ 3 @ 1

Pos: 112 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Um we ltmod ul ( Sta ndard) @ 13\mod_1234256864083_75.docx @ 336517 @ @ 1

on the interface box.

The environomental module is used to record the environmental data (Plug-in card CAN PTH).

• Fuel temperature (Optional)

• Intake air temperature

• Ambient temperature

• Air pressure

• Humidity

The fuel temperature is recorded using the interface box and the fuel consumption device and and

can be used as additional information for the fuel consumption measurement.

The intake air temperature is recorded using the interface box and is used for projection of the

engine performance based on DIN 70020, EWG 80/1269, ISO 1585, SAE J1349 or JIS D1001.

The ambient temperature is recorded using the interface box.

BA053101-en

Page 34

34

Air Pressure

Humidity

2.7.3

OBD Module (Optional)

(OBD)

2.7.4

Pressure/Temperature Module (Optional)

Pressure 1 + 2

Exhaust Gas Temperature

The air pressure is recorded using the interface box and is used for projection of the engine

performance based on DIN 70020, EWG 80/1269, ISO 1585, SAE J1349 or JIS D1001.

The humidity is recorded using the interface box and is used for projection of the engine

performance based on DIN 70020, EWG 80/1269, ISO 1585, SAE J1349 or JIS D1001.

The current air temperature , ambient pressure and relative humidity is included in the calculation

with the given standards (DIN 70020, EWG 80/1269, ISO 1585, SAE J1349 and JIS D1001)

Pos: 113 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1.1/O /Über schr ift 1.1. 1: OBD-M odul (Option) @ 13\mod_1234257204298_75.docx @ 336543 @ 3 @ 1

Pos: 114 /Te ch nisc he D ok umen tati on/Leistungsmesstechnik/POWERDYNO/052301 LPS 3000 R100/BA/Inhalt: 0523 OBD-Modul (Option) (Text) @ 13\mod_1234257277407_75.docx @ 336659 @ @ 1

The OBD module is used for recording the OBD data (Plug-in card CAN OBD Module). This OBD

data is different depending on the vehicle manufacturer.

Attachment:

Pos: 115 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 OBD -Modul (Op tion) (Bild) @ 1 3\mod_ 1234 2583 59352_ 0.docx @ 33668 5 @ @ 1

Pos: 116 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1.1/ D/Über schrif t 1.1. 1: Druck/ Temper aturm odul ( Option) @ 13\m od_1 23425 84321 20_7 5.docx @ 3367 11 @ 3 @ 1

Pos: 117 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Dr uck/ Tem per atur mod ul ( Op tion) @ 13\mod_1234258485560_75.docx @ 336737 @ @ 1

• Position

on the interface box (see section

The pressure/temperature module is used to record 2 temperatures and 2 pressures (Plug-in card

CAN P2T2).

Pressure 1 +2 is user specific. The test range stretches from– 0.9 to + 4.0 bar and can for example

be used to determine the intake pressure, turbocharger pressure, etc.

The exhaust gas temperature is used as monitor check of the combustion process and to judge its

quality.

The high temperature sensor consists. of a Ni-Cr-Ni thermo element with compensation line.

The measurement range stretches from 0 to 1000 °C.

Pos: 118 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

"Description of the Interface Box"

).

BA053101-en

Page 35

35

2.7.5

Analog Input Module (Optional)

2.8

Analog Output Card (Optional)

Pos: 119 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1.1/A /Über schr ift 1.1. 1: Anal ogein gangsm odul (Option) @ 13\mod_1234258646518_75.docx @ 336763 @ 3 @ 1

Pos: 120 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 An alo gein ga ngsm odul (Opti on) (Text) @ 13\m od_1234258712534_75.docx @ 336789 @ @ 1

The analog input module is used to record 4 analog signals (Plug-in card CAN AIN4).

Pos: 121 /Technische Dokum entati on/Leis tungsm esstech nik/POWE R DYNO/0 523 01 LPS 3 000 R10 0/B A/I nhal t: 05 23 A na loge in gangs m odu l (Opt ion ) ( Bild ) @ 13\mod_1234258797503_0.docx @ 336815 @ @ 1

Measurement data from –10 V to +10 V or from –20 mA to +20 mA can be recorded.

Pos: 122 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/A/ Übers chrift 1.1: A nalog-Au sga ngs karte (Option) @ 13\mod_1234259302517_75.docx @ 336841 @ 2 @ 1

Pos: 123 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 An alo gaus gan gska rte (Option) @ 13\mod_1234259391712_75.docx @ 336867 @ @ 1

The analog output card (Plug-in card LON OUTA) is used for further processing of measured

values as analog signals for an external device (e.g. analog display, digital display).

There are 4 analog outputs available from –10 V to +10 V.

The plug-in card LON OUTA is connected in the communication desk.

Pos: 124 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA053101-en

Page 36

36

2.9

Measurement Programs

Load Simulation

Measure Engine Power

Extrapolation of the Engine Power (Optional)

Flexibility Test

Speedometer Test

Road Load Adaption (Optional)

Lug-Down Test (Optional)

Pos: 125 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/M/ Über schrif t 1.1: M esspr ogramm e @ 13\mod_1234259459658_75.docx @ 336893 @ 2 @ 1

Pos: 126 /Te ch nisc he D ok umen tati on/ Leis tu ngsm ess tech ni k/PO WE RDYN O/0 523 01 L PS 3 000 R10 0/B A/ Inh alt: 052 3 Mes spr ogr amm e @ 1 3\mod_1234259499194_75.docx @ 336939 @ @ 1

This dynamometer provides an exact simulation of defined road load conditions.

Fuel consumption measurement and exhaust analysis, as well as serial monitoring of vehicles can

be carried out.

The following operation modes can be selected for conducting the various measurement tasks:

•

The user can pre-select from various load conditions which make possible the determination of

e.g. a specific engine diagnosis or vehicle climbing power. Depending upon need, various load

conditions can be simulated such as constant traction, a constant speed, a constant RPM or a

driving simulation.

•

Use this menu item to determine the vehicle’s engine power (continuous and discrete

measurement).

•

Extrapolation of the engine power based on DIN 70020, EWG 80/1269, ISO 1585, JIS D 1001,

SAE J 1349.

•

The engine flexibility can be checked using this menu item. Once the flexibility test has been called

up the vehicle weight and road load must be entered as in the road load simulation test.

•