Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

MLT 3000

Headlight Tester

Original Operating Instructions

BA380701-en

Pos: 1 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Titelbild @ 55\mod_1552900817069 _0.docx @ 3126274 @ @ 1

Pos: 2 /-----For mat-----/Seitenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

Page 2

2

Manufacturer

Service

Pos: 3 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Firmen-Information MAHA 2019 @ 56\mod_1557818397795_75.docx @ 3141940 @ @ 1

BA380701-en

2018-11-20

© MAHA Maschinenbau Haldenwang GmbH & Co. KG

The reproduction, distribution and utilization of this document as well as the communication of its

contents to others without explicit authorization is prohibited. Offenders will be held liable for the

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design. The contents of this edition have been checked with great care. However, errors cannot be

fully excluded. Subject to technical change without notice.

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20

87490 Haldenwang

Germany

Phone: +49 8374 585 0

Fax: +49 8374 585 590

Mail: maha@maha.de

Web: www.maha.de

Pos: 4 /-----For mat-----/Seitenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

MAHA SERVICE CENTER

Maybachstraße 8

87437 Kempten

Germany

Phone: +49 8374 585 100

Fax: +49 8374 585 491

Mail: service@maha.

de

Web: www.mahaservicecenter.de

BA380701-en

Page 3

3

Contents

1

Safety .................................................................................................................... 5

2

Description ............................................................................................................ 7

3

Operation ............................................................................................................. 13

Pos: 5 /-----For mat-----/Inhaltsverze ichnis - 3 Ebenen @ 5\mod_1168867441046_75.docx @ 72920 @ @ 1

1.1 Introduction .............................................................................................................. 5

1.2 Symbols and Signal Words ...................................................................................... 5

1.2.1 Personal Injury .......................................................................................................... 5

1.2.2 Property Damage ..................................................................................................... 5

1.2.3 Information ............................................................................................................... 5

1.3 Intended Use ........................................................................................................... 6

1.4 Requirements on Operating and Service Personnel .................................................. 6

1.5 Safety Instructions .................................................................................................... 6

2.1 Requirements for the Place of Installation ................................................................. 7

2.2 Specifications ........................................................................................................... 7

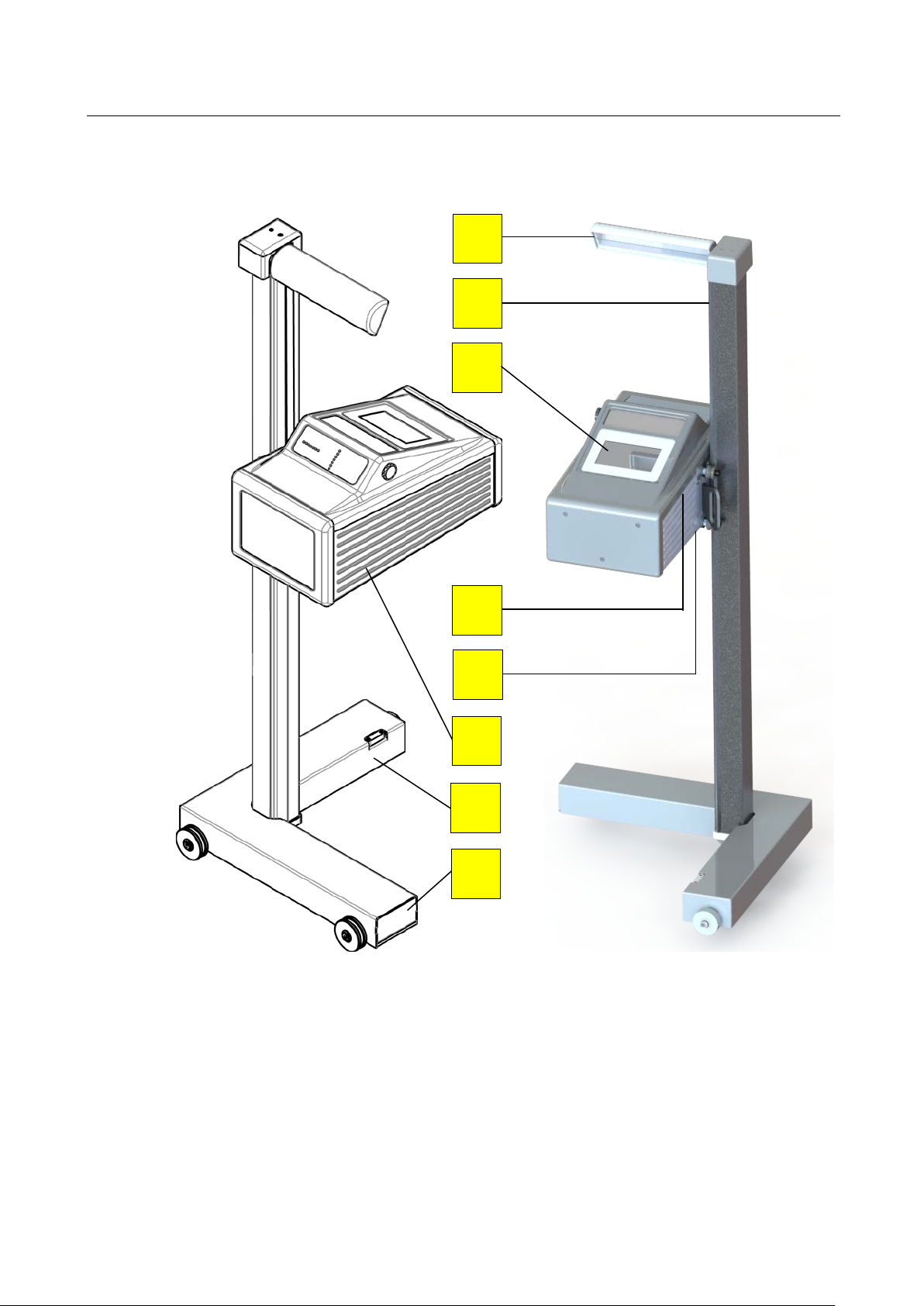

2.3 Design ..................................................................................................................... 8

2.4 Electronic Levelling ................................................................................................... 9

2.4.1 Compensation Coordinate Axes of MLT 3000 .......................................................... 9

2.4.2 Angle Symbols ....................................................................................................... 10

2.5 Definition of Technical Terms .................................................................................. 11

2.5.1 Pitch Angle ............................................................................................................. 11

2.5.2 Low Beam ............................................................................................................. 11

2.5.3 High Beam ............................................................................................................. 12

3.1 Switching On / Off .................................................................................................. 13

3.2 Aligning .................................................................................................................. 14

3.2.1 Laser Alignment Unit (Option) ................................................................................. 14

3.2.2 LED Adjustment Aid (Option) .................................................................................. 15

3.3 Light Selection Buttons .......................................................................................... 16

3.3.1 Headlight Test according to § 29 StVZO (Germany) ................................................ 16

3.3.2 Showing the Button Labels .................................................................................... 17

3.3.3 Adjusting the Pitch Angle ........................................................................................ 17

3.3.4 Choosing the Vehicle Class .................................................................................... 18

3.3.5 Browsing back through the Test Screens ............................................................... 18

3.3.6 Choosing between Left-Hand or Right Hand Traffic ................................................ 19

3.3.7 Manufacturer-Specific Test Instructions (OEM) ....................................................... 19

3.3.8 Navigating through the Test Levels ......................................................................... 21

3.4 Testing the Headlights ............................................................................................ 22

BA380701-en

Page 4

4

4

Energy Management and Troubleshooting ............................................................ 41

5

Maintenance ........................................................................................................ 44

6

Disposal ............................................................................................................... 45

7

Contents of the Declaration of Conformity ............................................................. 45

3.4.1 Test Phase Indication via Light Buttons .................................................................. 22

3.4.2 Measuring .............................................................................................................. 22

3.4.3 Light Selection Buttons Disabled ............................................................................ 23

3.4.4 Adjusting: Setting the Headlights in Real Time ........................................................ 24

3.4.5 Saving the Measurement Values to PDF ................................................................. 25

3.5 Settings ................................................................................................................. 27

3.5.1 Variables ................................................................................................................ 27

3.5.2 User Settings ......................................................................................................... 29

3.5.3 Language ............................................................................................................... 30

3.5.4 Calibrating the Camera according to Directive ........................................................ 31

3.5.5 Country Specifications............................................................................................ 33

3.5.6 Settings with Password .......................................................................................... 34

3.5.7 List of Variables (Extract) ........................................................................................ 35

3.6 Interfaces and Software Updates ........................................................................... 36

3.7 EUROSYSTEM v7.50 ............................................................................................. 38

4.1 Charging the Battery .............................................................................................. 41

4.2 Battery Status ........................................................................................................ 42

4.2.1 Battery Life ............................................................................................................. 42

4.2.2 Energy Saving Function .......................................................................................... 42

4.2.3 Protection against Deep Discharge ......................................................................... 42

4.2.4 Protection against Mechanical Damage .................................................................. 42

4.2.5 Data Recording for Error Analysis ........................................................................... 43

4.3 Troubleshooting ..................................................................................................... 44

5.1 Care Instructions .................................................................................................... 44

5.2 Spare Parts ............................................................................................................ 44

Pos: 6 /-----For mat-----/Seitenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

BA380701-en

Page 5

5

1

Safety

1.1

Introduction

1.2

Symbols and Signal Words

1.2.1

Personal Injury

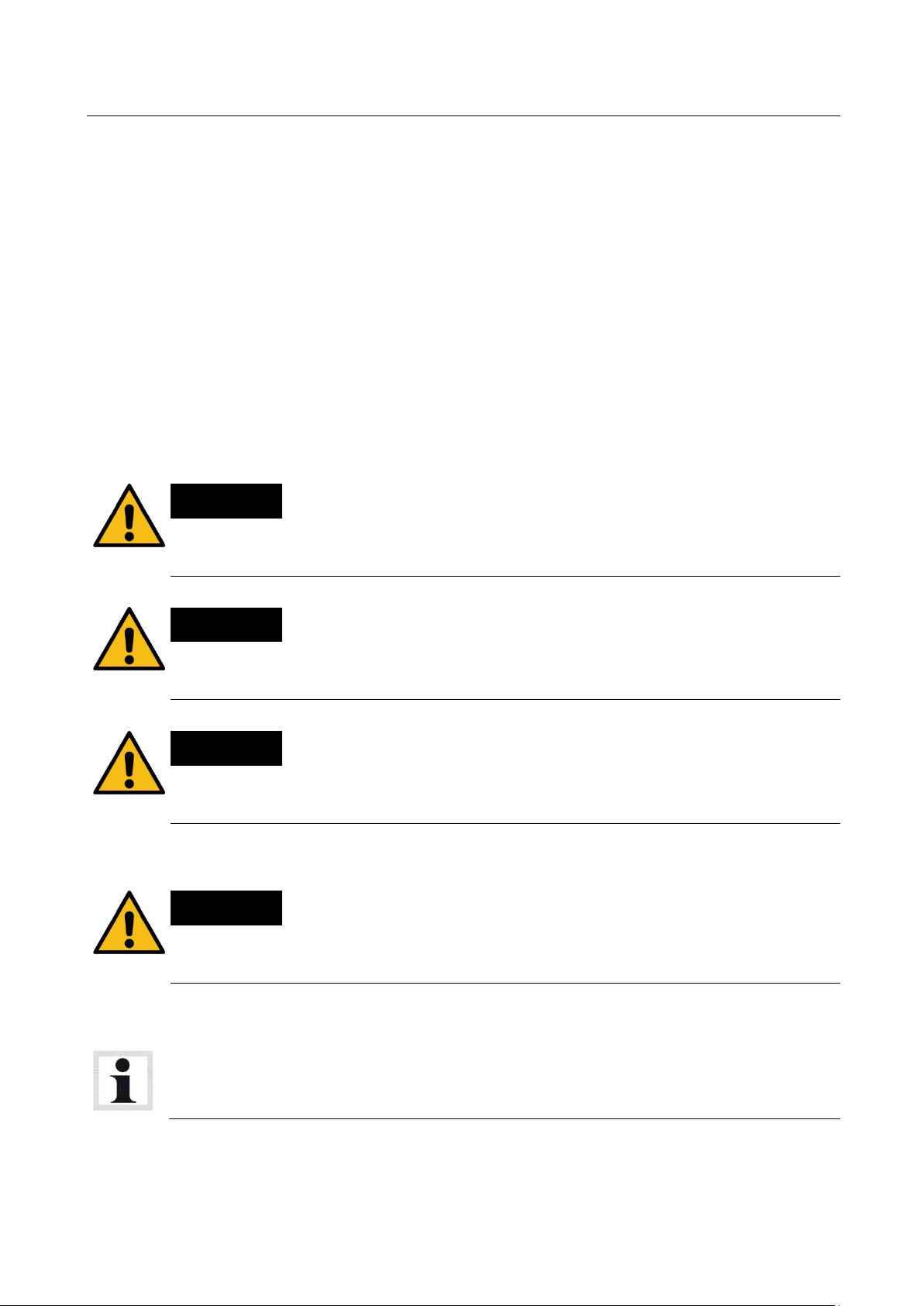

DANGER

WARNING

CAUTION

1.2.2

Property Damage

NOTICE

1.2.3

Information

Pos: 7 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/S/Überschrift 1: Sicherheit @ 6\mod_1174482399906_75.docx @ 76962 @ 1 @ 1

Pos: 8 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Einführung @ 6\mod_1174482219062_75.docx @ 76793 @ 1 @ 1

Pos: 9 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Einführung Sicherheit_12pt @ 25\mod_1324455248318_75.docx @ 1138886 @ @ 1

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

Pos: 10.1 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Symbole und Signalwörter @ 50\mod_1503314612825_75.docx @ 2923200 @ 2 @ 1

Pos: 10.2 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/P/Überschrift 1.1.1: Personenschäden @ 50\mod_1503389040316_75.docx @ 2923708 @ 3 @ 1

Pos: 10.3 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole und Signalwörter - Personenschäden @ 50\mod_1503389427470_75.docx @ 2923852 @ @ 1

safety instructions are not covered by the product liability regulations.

indicates an immediate hazard which, if not avoided, will result in death or severe

personal injury.

indicates a potential hazard which, if not avoided, could result in death or severe

personal injury.

indicates a potential hazard which, if not avoided, could result in moderate or minor personal injury.

Pos: 10.4 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/P/Überschrift 1.1.1: Produkt-, Maschinen-, Anlagenschäden @ 50\mod_1503389109661_75.docx @ 2923756 @ 3 @ 1

Pos: 10.5 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole und Signalwörter - Produktschäden @ 50\mod_1503389546628_75.docx @ 29 23899 @ @ 1

indicates a potentially harmful situation which, if not avoided, could result in damage to the equipment or surrounding objects.

Pos: 10.6 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/I/Überschrift 1.1.1: Informationen @ 50\mod_1503389229939_75.docx @ 2923804 @ 3 @ 1

Pos: 10.7 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole und Signalwörter - Informationen @ 56\mod_1560326812841_75.docx @ 3147455 @ @ 1

indicates important information notes.

Pos: 11 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Page 6

6

1.3

Intended Use

1.4

Requirements on Operating and Service Personnel

WARNING

1.5

Safety Instructions

NOTICE

CAUTION

Pos: 12 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/B/Überschrift 1.1: Bestimmungsgemäßer Gebrauch @ 6\mod_1176734022203_75.docx @ 88746 @ 2 @ 1

Pos: 13 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Bestimmungsgemäßer Gebrau ch_12pt @ 26\mod_1325493887453_ 75.docx @ 1142050 @ @ 1

This device only serves to check and adjust the alignment of vehicle headlights.

This device cannot be modified without the express, written consent of the

Pos: 14 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Anforderungen an das Bedienungs- und Servicepersonal @ 34\mod_1380637497630_75.docx @ 1835413 @ 2 @ 1

Pos: 15 /Produktfamilien/Alle Geräte/Inhalte/Sicherheit/Inhalt: WARNUNG - Anforderungen an das Bedienungs- und Servicepersonal_12pt @ 52\mod_1516807277486_75.docx @ 3001475 @ @ 1

manufacturer. Any infringement renders the conformity declaration invalid.

All persons employed in the operation, maintenance, installation, removal and disposal of the device must

• be at least 18 years old,

• be mentally and physically suited for these activities,

• be demonstrably trained and instructed in writing,

• have read and understood the operating instructions, especially the instructions

what to do in the event of defects or malfunctions,

• be on record as having been instructed in safety guidelines,

• have practical experience in working with vehicle lifts and the hazards inherent

in such equipment.

Pos: 16 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften @ 8\mod_1204545563175_75.docx @ 155576 @ 2 @ 1

Pos: 17 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Sicherheitsvorschri ften @ 54\mod_1532346009263_75. docx @ 3052006 @ @ 1

• This device must only ever be operated within its performance limits.

• All parts of the electrical system must be protected against damp and humidity.

• All service work must be performed by service technicians employed by the

manufacturer or by authorized service partners.

• Never expose the lens to direct sunlight. The bundling of light may cause fire

damage inside the housing.

• Only ever clean the lens with a soft cloth and a glass cleaning agent.

Optional laser alignment unit: Never look into the laser beam (laser class 2M).

Comply with work safety and accident prevention directives (H&SW regulations) in

respect of laser radiation.

Pos: 18 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_ 0.docx @ 1277 @ @ 1

BA380701-en

Page 7

7

2

Description

2.1

Requirements for the Place of Installation

2.2

Specifications

Pos: 19 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/B/Überschrift 1: Beschreibung @ 6\mod_1174482271453_75.docx @ 76889 @ 1 @ 1

Pos: 20 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Anforderungen an den Aufstellort @ 7\mod_1184077643671_75.docx @ 99737 @ 1 @ 1

Pos: 21 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Anforderungen an den Aufste llort @ 54\mod_1536212493413_75. docx @ 3086120 @ @ 1

Pos: 22 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/T/Überschrift 1.1: Technische Daten @ 7\mod_1184075526343_75.docx @ 99711 @ 1 @ 1

Pos: 23 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Technische Daten @ 54\mod_15361459 09641_75.docx @ 3085972 @ @ 1

Please observe your national guidelines and specifications.

Measuring range above hotspot 0…800 mm / 10 m (0…8 %)

Light intensity 0…125 000 cd

above pitch angle 0…300 mm / 10 m (0…3 %)

below 0…700 mm / 10 m (0…7 %)

left 0…1000 mm / 10 m (0…10 %)

right 0…1000 mm / 10 m (0…10 %)

Illuminance 0…200 lx

Measuring distance 100…500 mm

Adjustment path of lens centre above floor 240…1500 mm

Deviation of intensity ±5 %

Deviation from one axle ±5'

Compensation of ground unevenness ±3 %

Temperature +5…+40 °C

Relative humidity 20…80 %

Supply voltage 100…240 V AC, 50/60 Hz

Charging voltage / Battery voltage 24 V DC / 12 V DC

Dimensions (W x H x D) 655 x 1770 x 720 mm

Net weight / Shipping weight 65 kg / 80 kg

Prototype release number TPN100110935

Pos: 24 /-----Format -----/Seitenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

BA380701-en

Page 8

8

2.3

Design

A

E

B

F

C

G

D

H

A B D

G H C E F

Pos: 25 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Aufbau @ 12\mod_1232632872281_75.docx @ 319982 @ 2 @ 1

Pos: 26 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Aufbau (Bilder) @ 54\ mod_1536150020420_0.d ocx @ 3086046 @ @ 1

Pos: 27 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Aufbau (Legende) @ 54\mod_1536149 532463_75.doc x @ 3086009 @ @ 1

Mirror, with optional

laser alignment unit

Column

Display

USB port

Pos: 28 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Charging socket

Casing, with adjusting handle

Carriage, with spirit level

Battery compartment

Page 9

9

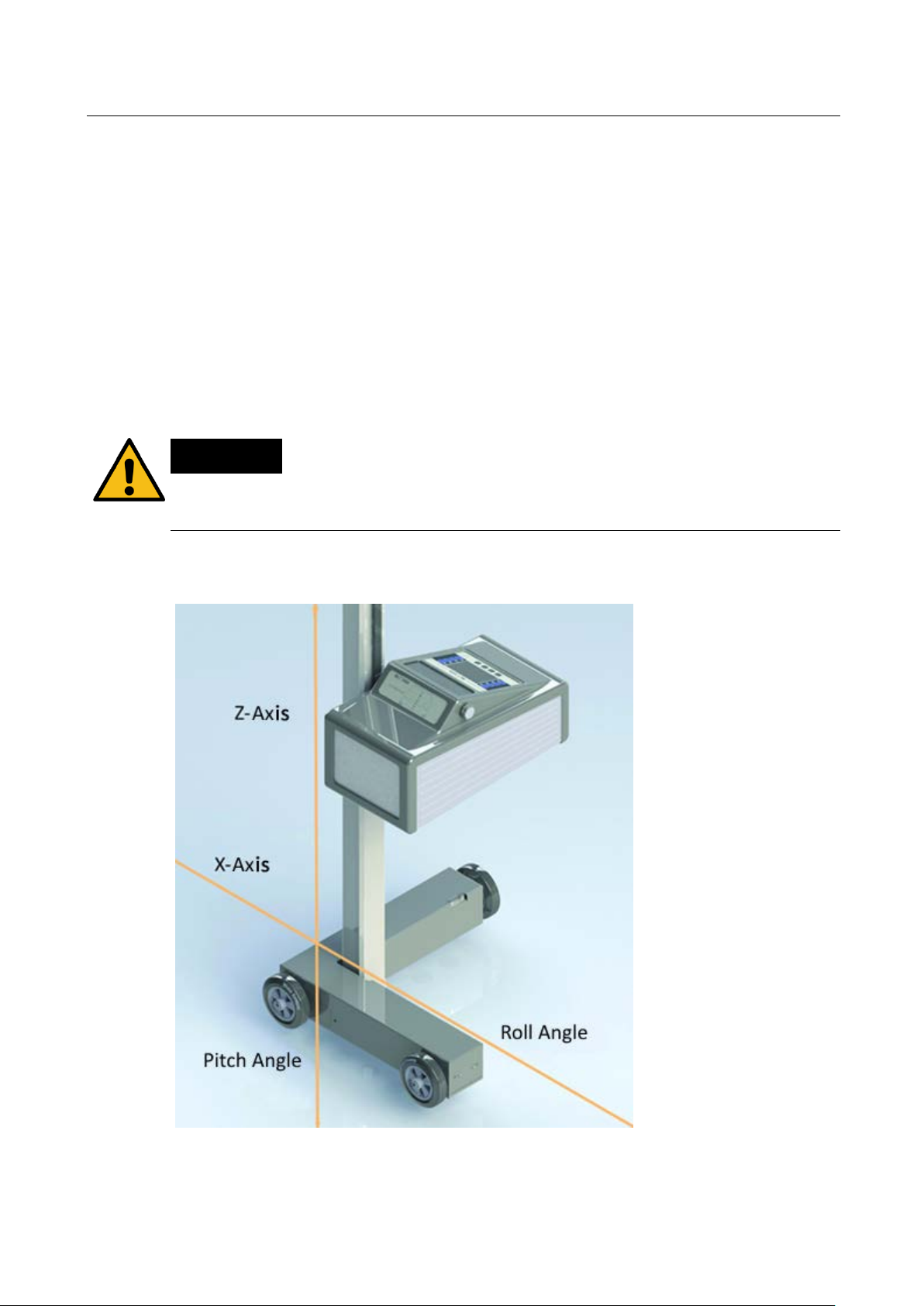

2.4

Electronic Levelling

NOTICE

2.4.1

Compensation Coordinate Axes of MLT 3000

Pos: 29 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Elektronischer Niveauausgleich @ 41\mod_1417423524511_75.docx @ 2159642 @ 2 @ 1

Pos: 30 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Elektronischer Niveaua usgleich (Text) @ 54\mod_ 1531120422247_75. docx @ 3043575 @ @ 1

This headlight tester comes standard with an electronic position sensor which

determines the inclination angle of the device. The software compensates possible

deviations in the X- and Z-axes while calculating the position of the headlights.

The headlight tester may be set up on uneven surfaces even if the ground

unevenness is outside the permissible tolerances, provided that the maximum

unevenness does not exceed the headlight tester’s self-levelling capacity of 3%.

After enabling the respective function, the compensation values can be checked

using a dot or cross hair laser. See section “Operation > Settings > Calibrating the

Camera according to Directive”.

This function must be enabled exclusively by authorised service technicians and is

applicable for the respective test surface only.

Pos: 31 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/K/Überschrift 1.1.1: Kompensations-Koordinatenachsen MLT 3000 @ 55\mod_1542017762248_75.docx @ 3096930 @ 3 @ 1

Pos: 32 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Koordinatenachsen @ 55\mod_ 1542018248398_75.doc x @ 3096968 @ @ 1

Pos: 33 /-----Format-----/Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

BA380701-en

Page 10

10

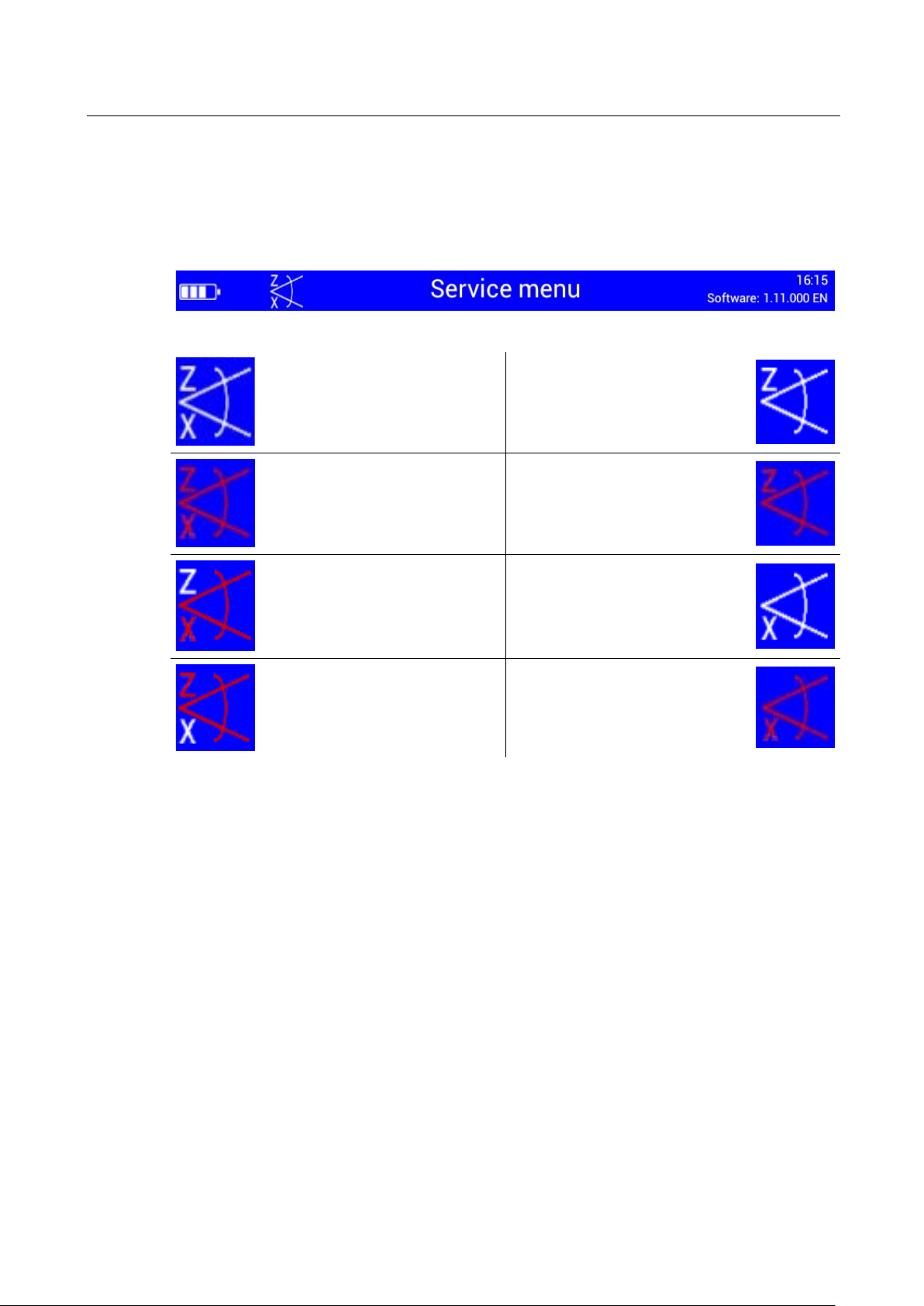

2.4.2

Angle Symbols

axis active, inclination too

axis active, inclination too

Pos: 34 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/W/Überschrift 1.1.1: Winkelsymbole @ 54\mod_1536136536153_75.docx @ 3085897 @ 3 @ 1

Pos: 35 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Winkelsymbole @ 54\mo d_1536138559566_ 75.docx @ 3085935 @ @ 1

Once the adjustment of the inclination sensor has been completed, an angle symbol appears in the info bar to indicate the adjusted/active inclination axes.

Overview of symbols:

Both axes adjusted/active,

headlight tester ready for

operation

Both axes active, inclination

of Z- and X-axis too large,

no measurement possible

Both axes active, inclination

of X-axis too large, no

measurement possible

Both axes active, inclination

of Z-axis too large, no

measurement possible

Pos: 36 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

Z-axis active, headlight test-

er ready for operation

Z-

large, no measurement pos-

sible

X-axis active, headlight test-

er ready for operation

X-

large, no measurement pos-

sible

BA380701-en

Page 11

11

2.5

Definition of Technical Terms

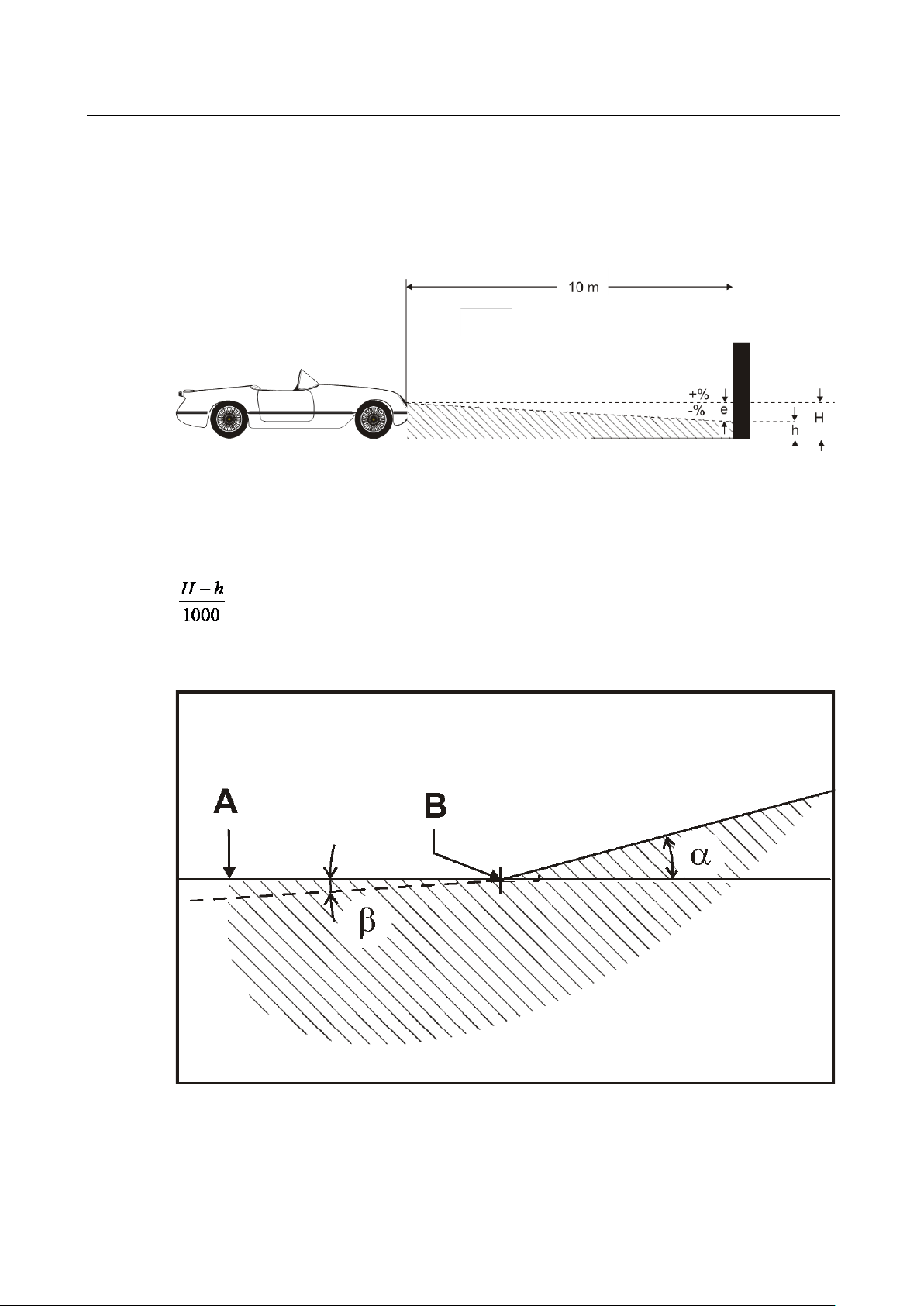

2.5.1

Pitch Angle

2.5.2

Low Beam

Pos: 37 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/B/Überschrift 1.1: Begriffsbestimmung @ 21\mod_1283338711724_75.docx @ 884333 @ 2 @ 1

Pos: 38 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/N/Überschrift 1.1.1: Nickwinkel @ 25\mod_1319632959141_75.docx @ 1067583 @ 2 @ 1

Pos: 39 /Produktfamilien/Scheinwerferprüftechnik/- Archiv -/38 Scheinwerfer-Einstell-Prüfgeräte/0501 LITE 3/BA/Inhalt: 3805 Begriffsbestimmung Nickwinkel (Bild) @ 21\mod_1283343123850_0.docx @ 884364 @ @ 1

Pos: 40 /Produktfamilien/Scheinwerferprüftechnik/- Archiv -/38 Scheinwerfer-Einstell-Prüfgeräte/0501 LITE 3/BA/Inhalt: 3805 Begriffsbestimmung Nickwinkel (Text) @ 26\mod_1325495352529_ 75.docx @ 1142312 @ @ 1

Angle of inclination of light-dark limit against the test surface.

The inclination of headlight lighting bundle against the test surface is expressed as

a percentage, using 10 m as a reference parameter:

X 100

Pos: 41 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/A/Überschrift 1.1.1: Abblendlicht @ 25\mod_1319633029481_75.docx @ 1067613 @ 2 @ 1

Pos: 42 /Produktfamilien/Scheinwerferprüftechnik/- Archiv -/38 Scheinwerfer-Einstell-Prüfgeräte/0501 LITE 3/BA/Inhalt: 3805 Begriffsbestimmung Abblendlicht (Bild) @ 25\mod_1319631975821_0.docx @ 1067463 @ @ 1

Pos: 43 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Page 12

12

A

Light-dark limit

B

Inflection point

α

Yaw angle

α

Rolling angle

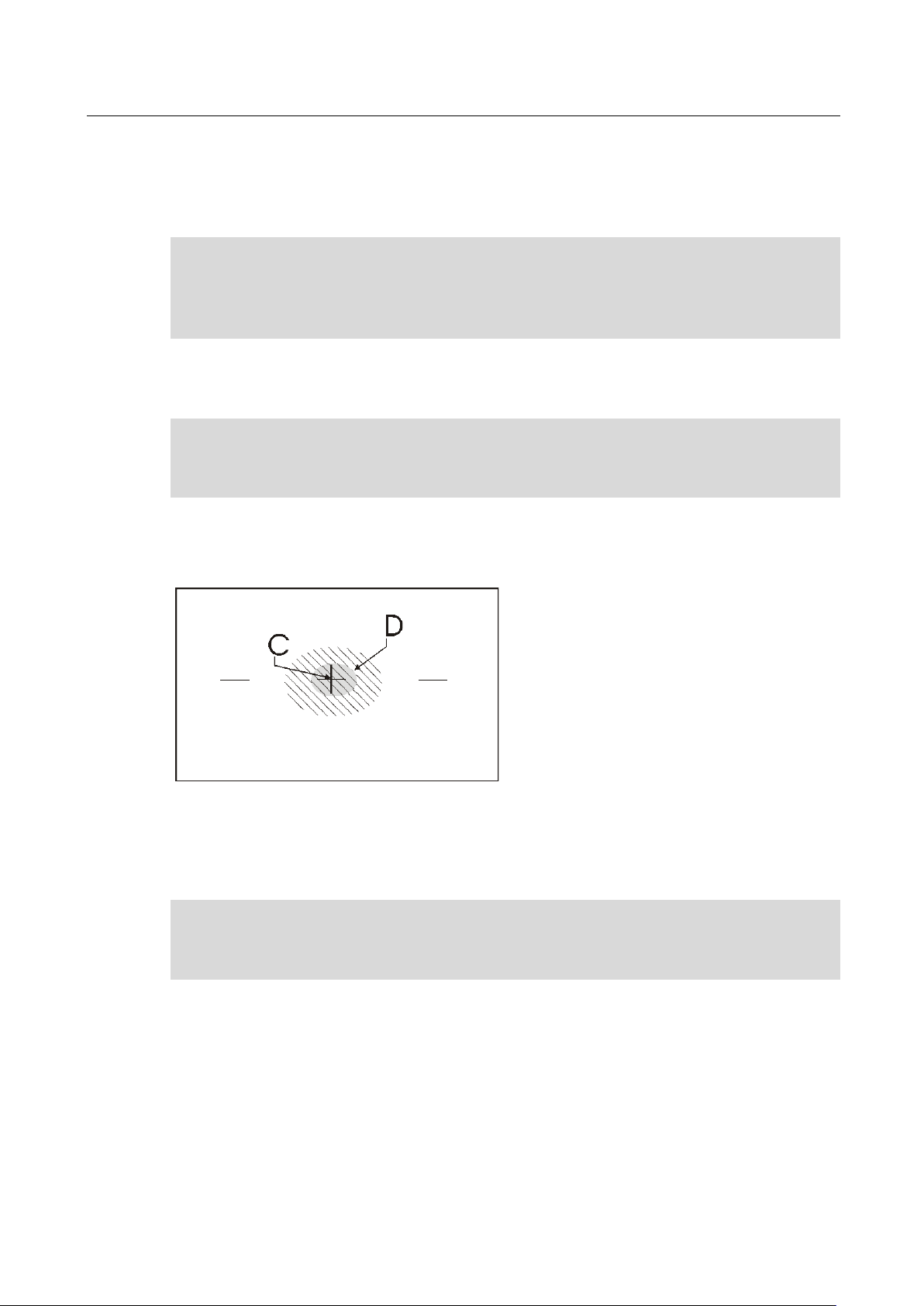

2.5.3

High Beam

C

Central mark

D

Hot spot

Pos: 44 /Produktfamilien/Scheinwerferprüftechnik/- Archiv -/38 Scheinwerfer-Einstell-Prüfgeräte/0501 LITE 3/BA/Inhalt: 3805 Begriffsbestimmung Abblendlicht (Text) @ 26\mod_ 1325495443262_75.doc x @ 1142344 @ @ 1

Boundary for light distribution between ‘top dark’ and ‘bottom light’ for lowbeam lights.

Synonymous with the light-dark limit for asymmetric low-beam lighting. The

deviation of the inflection point is expressed in %. 10 meters is used as the

reference dimension.

Angle between the inflection point on the rising component of the light-dark

limit and the horizontal line for asymmetric low-beam light.

Angle between the left component of the light-dark limit and the horizontal,

usually 0°.

From the central mark, the deviation of hot-spot is specified in X and Y di-

Pos: 45 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/F/Überschrift 1.1.1: Fernlicht @ 25\mod_1319633186648_75.docx @ 1067673 @ 3 @ 1

Pos: 46 /Produktfamilien/Scheinwerferprüftechnik/- Archiv -/38 Scheinwerfer-Einstell-Prüfgeräte/0501 LITE 3/BA/Inhalt: 3805 Begriffsbestimmung Fernlicht (Bild) @ 25\mod_1319632161039_0.docx @ 1067493 @ @ 1

Pos: 47 /Produktfamilien/Scheinwerferprüftechnik/- Archiv -/38 Scheinwerfer-Einstell-Prüfgeräte/0501 LITE 3/BA/Inhalt: 3805 Begriffsbestimmung Fernlicht (Text) @ 26\mod_1325495528426_75.docx @ 1142376 @ @ 1

rections.

Center of light beam for high-beam. The deviation of hot spot from central

mark is expressed in %.10 meters is used as the reference dimension.

Pos: 48 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Page 13

13

3

Operation

3.1

Switching On / Off

Pos: 49 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/B/Überschrift 1: Bedienung @ 6\mod_1174482271218_75.docx @ 76877 @ 3 @ 1

Pos: 50 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Einschalten / Ausschalten @ 20\mod_1271841463134_75.docx @ 838371 @ 3 @ 1

Pos: 51 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Ein-/Ausschalten @ 54\mod_153112136144 7_75.docx @ 3043622 @ @ 1

The headlight tester is operated via touchscreen buttons. The resistive touchscreen reacts to pressure and can also be operated while wearing work gloves.

The On/Off button is on the right-hand side underneath the touchscreen.

Press to confirm Switch Off.

Pos: 52 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Page 14

14

3.2

Aligning

3.2.1

Laser Alignment Unit (Option)

CAUTION

Pos: 53 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Ausrichten @ 21\mod_1283344889785_75.docx @ 884424 @ 1 @ 1

Pos: 54 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Ausrichten Standard (Text ) @ 55\mod_1542026006515_75.d ocx @ 3097275 @ @ 1

When using guide rails, position the device centrally in front of the vehicle.

Without guide rails, the device must be adjusted in front of each headlight. Please

observe your national guidelines and specifications.

The device is correctly aligned when two symmetrical reference points on the front

Pos: 55 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Ausrichten Standard (Bild ) @ 55\mod_1542025471657_0.d ocx @ 3097162 @ @ 1

of the vehicle are located on the black line of the alignment mirror.

Pos: 56 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/L/Überschrift 1.1.1: Laser-Ausrichteinheit (Option) @ 55\mod_1542025718969_75.docx @ 3097199 @ 3 @ 1

Pos: 57 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Laser-Ausrichteinheit (Text) @ 55\mod_1542024633290_75.doc x @ 3097125 @ @ 1

The optional unit is integrated into the mirror holder. The device is correctly aligned

when the laser pointer is parallel to two symmetrical reference points on the front

of the vehicle.

Observe manufacturer’s instructions according to workshop manual.

Never look into the laser beam (laser class 2M). Comply with work safety and accident prevention directives (H&SW regulations) in respect of laser radiation.

The AA Mignon batteries powering the laser are located in the alignment unit and

can be easily replaced.

Pos: 58 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Laser-Ausrichteinheit (Bild) @ 55\mod_1542026341536_0.do cx @ 3097312 @ @ 1

BA380701-en

Page 15

15

3.2.2

LED Adjustment Aid (Option)

A

B

Pos: 59 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/L/Überschrift 1.1.1: LED-Justagehilfe (Option) @ 55\mod_1542025822583_75.docx @ 3097237 @ 3 @ 1

Pos: 60 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 LED-Justagehilfe (Text) @ 55\mod_1542026638860_75.docx @ 3097349 @ @ 1

This optional unit is integrated into the window housing (A) above the Fresnel lens.

The colour LEDs (B) pointing toward the vehicle indicate the direction of adjustment.

Green LED = Optimum setting

Yellow LED = Minor deviation within tolerance range

Red LED = Outside tolerance

Pos: 61 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 LED-Justagehilfe (Bilder) @ 55\mod_1542027192899_0.doc x @ 3097386 @ @ 1

(corresponds to green rating in the display centre)

(corresponds to yellow direction arrows on the display)

(corresponds to red direction arrows on the display)

Pos: 62 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_ 0.docx @ 1277 @ @ 1

BA380701-en

Page 16

16

3.3

Light Selection Buttons

3.3.1

Headlight Test according to § 29 StVZO (Germany)

Pos: 63 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/L/Überschrift 1.1: Lichtauswahltasten @ 34\mod_1380638042998_75.docx @ 1835457 @ 2 @ 1

Pos: 64 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Lichtauswahltasten @ 54\mod_ 1531122680567_75.do cx @ 3043669 @ 33333333 @ 1

Headlight test according to § 29 StVZO (Germany).

BA380701-en

Use the OEM button for manufacturer-specific test instructions.

Page 17

17

3.3.2

Showing the Button Labels

3.3.3

Adjusting the Pitch Angle

When the Info button is activated, the button labels are shown instead of the

symbols.

The pitch angle can be increased or reduced using the Arrow buttons.

BA380701-en

Page 18

18

3.3.4

Choosing the Vehicle Class

3.3.5

Browsing back through the Test Screens

The Truck/Car button activates the appropriate settings for the respective vehicle

class.

BA380701-en

Use the Back Arrow button to browse back through the test screens one by one.

Page 19

19

3.3.6

Choosing between Left-Hand or Right Hand Traffic

3.3.7

Manufacturer-Specific Test Instructions (OEM)

Left-hand/Right-hand traffic can be changed under “User Settings”. Right-hand

traffic is preset by default.

OEM area! Perform the test according to manufacturer’s instructions.

BA380701-en

Page 20

20

Button “ALL“ makes several test levels available.

BA380701-en

Example: testing Volkswagen matrix headlights

OEM area! Perform the test according to manufacturer’s instructions.

Page 21

21

3.3.8

Navigating through the Test Levels

Use the Play button to open the activated test levels one by one.

Pos: 65 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Page 22

22

3.4

Testing the Headlights

3.4.1

Test Phase Indication via Light Buttons

3.4.2

Measuring

Pos: 66 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/SCH/Überschrift 1.1: Scheinwerfer überprüfen @ 34\mod_1380638163696_75.docx @ 1835501 @ 3 @ 1

Pos: 67 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/L/Überschrift 1.1.1: Lichttasten-Überprüfungsphasen @ 55\mod_1542032079057_75.docx @ 3097423 @ 3 @ 1

Pos: 68 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Lichttasten-Überprüfungsphasen @ 55\mod_1542033227276_ 75.docx @ 3097498 @ @ 1

Pos: 69 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/M/Überschrift 1.1.1: Messen @ 34\mod_1380638481628_75.docx @ 1835545 @ 3 @ 1

Green dot = Headlight tested, measurement OK

Red dot = Headlight tested, not OK

Grey dot = Headlight without evaluation

Adjusting direction:

Yellow arrow = Minor deviation within tolerance range

Red arrow = Outside tolerance

Pos: 70 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Messen @ 54\mod_1531128199981_75. docx @ 3043716 @ @ 1

Rating in centre = Headlight within tolerance range

BA380701-en

Page 23

23

3.4.3

Light Selection Buttons Disabled

PA = Pitch Angle; IP = Inflection Point; I = Intensity

Yaw and Rolling angles can be additionally activated under “User Settings”.

Use the Camera button (bottom centre) to change from the Measuring menu to

the Adjusting menu.

Pos: 71 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/L/Überschrift 1.1.1: Lichtauswahltasten gesperrt @ 54\mod_1536219467985_75.docx @ 3086160 @ 3 @ 1

Pos: 72 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Lichtauswahltasten ges perrt @ 54\mod_1536219610626_75. docx @ 3086198 @ @ 1

During measurement the light selection buttons are disabled.

BA380701-en

Page 24

24

3.4.4

Adjusting: Setting the Headlights in Real Time

Pos: 73 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/J/Überschrift 1.1.1: Justieren: Scheinwerfer in Echtzeit einstellen @ 54\mod_1536221003574_75.docx @ 3086240 @ 3 @ 1

Pos: 74 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Justieren @ 54\mod_1531130618584 _75.docx @ 3043763 @ @ 1

Green light button = Current measurement

Use the “New vehicle” button to change back to the Main menu.

Pos: 75 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

BA380701-en

Page 25

25

3.4.5

Saving the Measurement Values to PDF

Pos: 76 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/M/Überschrift 1.1.1: Messwerte in PDF speichern @ 54\mod_1536222755412_75.docx @ 3086278 @ 3 @ 1

Pos: 77 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Messwerte in PDF speichern @ 54\ mod_153622303 6835_75.docx @ 3086316 @ @ 1

Using the USB stick button, all available test values can be saved as PDF to a

USB stick. The button appears only in the Measuring and Adjusting menus and if

a USB stick has been detected by the headlight tester.

The values are saved to folder “MLT3000 Results” with date and time stamp, for

example: “Testvalues14082018_153922.pdf“.

BA380701-en

Page 26

26

Pos: 78 /-----Format-----/Seitenumbruch @ 0\mod_113440357768 7_0.docx @ 1277 @ @ 1

Overview of test results as PDF file (example)

BA380701-en

Page 27

27

3.5

Settings

3.5.1

Variables

Pos: 79 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Einstellungen @ 8\mod_1202226631960_75.docx @ 143852 @ 2 @ 1

Pos: 80 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/V/Überschrift 1.1.1: Variablen @ 13\mod_1235557236306_75.docx @ 347425 @ 3 @ 1

Pos: 81 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellungen - Variablen @ 54\mod_153113111499 9_75.docx @ 3043810 @ @ 1

Limit values as well as user and customer variables can be set directly at the

headlight tester.

BA380701-en

Page 28

28

Grenzwerte, User- und Kundenvariablen können direkt am Gerät angepasst

werden.

Pos: 82 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_ 0.docx @ 1277 @ @ 1

BA380701-en

Page 29

29

3.5.2

User Settings

Pos: 83 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/B/Überschrift 1.1.1: Benutzer-Einstellungen @ 43\mod_1441634078826_75.docx @ 2305151 @ 3 @ 1

Pos: 84 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellungen - Benutzer-Einstellungen @ 54\mod_153113201025 4_75.docx @ 3043857 @ @ 1

Quick access to all important settings.

Pos: 85 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_ 0.docx @ 1277 @ @ 1

BA380701-en

Page 30

30

3.5.3

Language

Pos: 86 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Sprache @ 14\mod_1240307984464_75.docx @ 364273 @ 3 @ 1

Pos: 87 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellungen - Sprache @ 54\mod_1531133400446_75.do cx @ 3043904 @ @ 1

Use the flag button to open the language selection.

Choose the desired language.

Pos: 88 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_ 0.docx @ 1277 @ @ 1

BA380701-en

Page 31

31

3.5.4

Calibrating the Camera according to Directive

Pos: 89 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/K/Überschrift 1.1.1: Kamera nach Richtlinie kalibrieren @ 54\mod_1531204580692_75.docx @ 3044248 @ 3 @ 1

Pos: 90 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellunge n - Kamera nach Richtlinie kalibrieren @ 54\mod_1531204871576_75.docx @ 3044296 @ @ 1

Compensation values can be checked using button “Calibrate camera according

to directive”. No password required.

Choose between Cross hair / Spot laser.

BA380701-en

Page 32

32

Pos: 91 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA380701-en

Page 33

33

3.5.5

Country Specifications

Pos: 92 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/L/Überschrift 1.1.1: Ländervorgaben @ 54\mod_1532351947504_75.docx @ 3052058 @ 3 @ 1

Pos: 93 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellunge n - Ländervorgaben @ 54\mod_1531206538570_75.docx @ 3044391 @ @ 1

Statutory requirements, limit values and country-specific settings.

Switching back from some of the country-specific test procedures requires a

password.

Pos: 94 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA380701-en

Page 34

34

3.5.6

Settings with Password

Pos: 95 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/E/Überschrift 1.1.1: Einstellungen mit Passwort @ 54\mod_1536229509710_75.docx @ 3086353 @ 3 @ 1

Pos: 96 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellunge n - Passwort @ 54\mod_1531206761173_75.d ocx @ 3044486 @ @ 1

The disabled (greyed out) menu items can be accessed only by entering a service

technician password.

Adjustment of the headlight tester is permitted exclusively with the following

calibration equipment approved by MAHA and must be performed by an

authorised service technician.

VP 990175 Laser calibration device with spot laser, model LK1

(no longer available)

VP 990471 Laser calibration device with cross hair laser, model LK2

Pos: 97 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA380701-en

Page 35

35

3.5.7

List of Variables (Extract)

No.

User variables

Default

Min

Max

Customer variables

Pos: 98 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1.1/V/Überschrift 1.1.1: Variablenliste (Auszug) @ 54\mod_1536229650986_75.docx @ 3086391 @ 3 @ 1

Pos: 99 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Einstellunge n - Variablenliste (Auszug) @ 54\mod_1536229768231_75.docx @ 3086429 @ @ 1

3.0 Percentage 0 / Degrees 1 0 0 1

4.0 Lux 0 / Candela 1 0 0 1

6.0 Target value Pitch angle Car 11 0 50

6.1 Target value Pitch angle HGV 30 0 50

8.0 Switch-off time of display in minutes 10 2 1200

10.1 RHT/LHT button enabled 1 / disabled 0 0 0 1

11.0 OEM in main menu enabled 1 0 1

12.0.1 Output yaw/rolling angle on display 0 0 1

1.0 Customer header line 1 0 20

1.0 Customer header line 2 0 20

Pos: 100 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.d ocx @ 1277 @ @ 1

BA380701-en

Page 36

36

3.6

Interfaces and Software Updates

USB

Pos: 101 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Schnittstellen und Software-Updates @ 38\mod_1402651726245_75.docx @ 2039045 @ 2 @ 1

Pos: 102 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Schnittstellen und S W-Updates (Text 1) @ 54\mod_153623114 6098_75.docx @ 3086466 @ @ 1

Software updates are normally performed using a USB stick (FAT32). Procedure:

1 Download the current software version from the MAHA homepage.

www.maha.de/downloads.htm

2 Open the ZIP file by double-clicking.

3 Select the MAHA folder with preset folder structure

and copy it to a USB stick.

4 Connect the USB stick containing the software update to the USB port outside

at the casing. Start installation in the Service menu (see Fig. below).

Pos: 103 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Schnittstellen und SW-Updates - USB-Buchse außen (Bild) @ 54\mod_1531209527821_0.do cx @ 3044580 @ @ 1

Pos: 104 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.d ocx @ 1277 @ @ 1

BA380701-en

Page 37

37

Pos: 105 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Schnittstellen und SW-Updates (Text 2) @ 54\mod_1531209603777_75.docx @ 3044627 @ @ 1

BA380701-en

Page 38

38

3.7

EUROSYSTEM v7.50

Please wait until the software has been installed and restarted.

Interfaces for connecting a computer:

• RS232 as cable connection (round connector, see section “Energy Manage-

ment and Troubleshooting > Charging the Battery”)

• Wireless connection via Bluetooth, order number: VZ 990312

• These interfaces can be used for establishing a connection to MAHA’s EU-

ROSYSTEM software, which is included with the cable or Bluetooth module. Al-

ternatively, the headlight tester can also be integrated into a EUROSYSTEM

Pos: 103 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: EUROSYSTEM v7.50 @ 37\mod_1401264284670_0.docx @ 2001453 @ 2 @ 1

Pos: 106 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: EUROSYSTEM v7.50 @ 37\mod_1401264284670_0.docx @ 2001455 @ 2 @ 1

Pos: 107 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 EUROSYSTEM v7.50 @ 42\mod_1434524259 550_75.docx @ 2255724 @ @ 1

test lane.

After the connection has been established, the yellow indicator lamp is ON.

A Bluetooth symbol appears in the info

bar of the headlight tester.

BA380701-en

Page 39

39

Set variables using System / Settings /

Section, Lanes, External Devices.

• Variable 1: 100

(standalone device only)

• Variable 25: 1

• Variable 26: COM port

Reboot EUROSYSTEM.

Test devices are connected automatically.

After the measurement has been started, all measured values are transferred

to EUROSYSTEM.

The connection to the MLT 3000 is retained until EUROSYSTEM is quit.

Select menu item <Display measurement values>.

Select menu item <Light tester>.

BA380701-en

Page 40

40

An overview of the measured values

appears.

Select the desired measurement.

In this example: second level with dynamic high-beam and motorway light.

The selected measurement data is displayed in detail.

Graphic representation of headlight adjustment in EUROSYSTEM:

Use the camera button on the

MLT 3000 display to switch over to

headlight adjustment. EUROSYSTEM

shows the coordinates, the measured

values and the headlight image in real

time.

The headlight pattern graphics can be

updated manually using the <F6> button.

The image transmission can be completely disabled via soft DIP.

Pos: 108 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.d ocx @ 1277 @ @ 1

BA380701-en

Page 41

41

4

Energy Management and Troubleshooting

4.1

Charging the Battery

Pos: 109 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/E/Überschrift 1: Energiemanagement und Fehlerbehebung @ 34\mod_1380638935605_75.docx @ 1835765 @ 2 @ 1

Pos: 110 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Akku laden @ 25\mod_1316701341413_75.docx @ 1053221 @ 1 @ 1

Pos: 111 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Akku laden (Text 1) @ 54\mod_1531213019885_ 75.docx @ 3044674 @ @ 1

The plug of the charger is inserted into the round (Neutrik) connector on the un-

Pos: 112 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Akku laden (Bild) @ 55\mod_1542099 263455_0.docx @ 309 7540 @ @ 1

derside of the housing (see Fig.).

Pos: 113 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Akku laden (Text 2) @ 54\mod_1536237683204_ 75.docx @ 3086513 @ @ 1

The charging process normally takes 11 hours. Full battery capacity is achieved

when the battery voltage has exceeded 14.00 V during charging.

The battery indicator in the top left-hand corner of the touchscreen corresponds

approximately to the actual charging level.

Pos: 114 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.d ocx @ 1277 @ @ 1

BA380701-en

Page 42

42

4.2

Battery Status

4.2.1

Battery Life

4.2.2

Energy Saving Function

4.2.3

Protection against Deep Discharge

4.2.4

Protection against Mechanical Damage

Pos: 115 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Akkustatus @ 54\mod_1532429144235_75.docx @ 3052688 @ 2 @ 1

Pos: 116 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Akkustatus @ 54\mod_15312147539 26_75.docx @ 3044768 @ 33333 @ 1

The battery has a rated capacity of 9500mAh and can provide up to 20 hours of

continuous workshop operation at an optimum environmental temperature of

20°C.

After 10 minutes of no activity, the display switches off. By tapping the touchscreen, the device is immediately ready for operation.

After 120 minutes of no activity, the unit switches off completely and then needs

to be switched back on manually.

These standard settings can be customised in the user variables.

To protect the battery from deep discharge, the unit switches off beyond 10.8V

battery voltage.

In the event that the device is set into motion while the charger is connected, the

following image is displayed and accompanied by an audible alert:

(Alert must be enabled, see section “Operation > Settings > User Settings”.)

BA380701-en

Page 43

43

4.2.5

Data Recording for Error Analysis

USB

The data records of the battery status allow for an optimum analysis in problem

cases.

A USB stick is needed for data recording. Records with a duration of more than

2 h can be saved by setting variable 9.0 accordingly.

Pos: 117 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Schnittstellen und SW-Updates - USB-Buchse außen (Bild) @ 54\mod_1531209527821_0.do cx @ 3044580 @ @ 1

Pos: 118 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_ 0.docx @ 1277 @ @ 1

BA380701-en

Page 44

44

4.3

Troubleshooting

5

Maintenance

5.1

Care Instructions

NOTICE

5.2

Spare Parts

Pos: 119 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/F/Überschrift 1.1: Fehlerbehebung @ 8\mod_1206714646748_75.docx @ 179620 @ 3 @ 1

Pos: 120 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Fehlerbehebung @ 54\ mod_1531217036362_75. docx @ 3044815 @ @ 1

This message may appear after updating older software versions. Acknowledge

with “Wait”.

Pos: 121 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/I/Überschrift 1: Instandhaltung @ 28\mod_1332159812536_75.docx @ 1565908 @ 1 @ 1

Pos: 122 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/P/Überschrift 1.1: Pflegehinweise @ 15\mod_1245912234854_75.docx @ 395780 @ 2 @ 1

Pos: 123 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Pflegehinweise @ 54\mod_15324353 64832_75.docx @ 3052741 @ @ 1

• The equipment must be periodically cleaned.

• Do not use high pressure and steam jet cleaners nor caustic cleaning agents.

Pos: 124 /Produktfamilien/Alle Geräte/Inhalte/Info!/Inhalt: Info - Pflegehinweise_12pt @ 26\mod_1324461215655_75.docx @ 1139602 @ @ 1

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment!

Pos: 125 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Ersatzteile @ 18\mod_1255596847002_75.docx @ 474414 @ 3 @ 1

Pos: 126 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Ersatzteile - Alle Geräte_12pt @ 26\mod_1324468768120_75.do cx @ 1141219 @ @ 1

To ensure safe and reliable operation, only use original spare parts supplied by the

Pos: 127 /-----Format-----/Seitenumbruch @ 0\mod_1134403577687_0.d ocx @ 1277 @ @ 1

equipment manufacturer.

BA380701-en

Page 45

45

6

Disposal

7

Contents of the Declaration of Conformity

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Model:

Designation:

Directives:

Standards:

Pos: 128 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/G/Überschrift 1: Geräteentsorgung @ 6\mod_1174482271625_75.docx @ 76901 @ 3 @ 1

Pos: 129 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Geräteentsorgung (ohne RiLi)_12pt @ 56\mod_1557295759940_75.docx @ 3140070 @ @ 1

If you want to dispose of the equipment, please contact your MAHA dealer or the

following address, indicating equipment type, date of purchase and serial number:

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20 | 87490 Haldenwang | Germany

Phone: +49 (0) 8374 585 0

Fax: +49 (0) 8374 585 500

Pos: 130 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Geräteentsorgung über Fachbetrieb (alternativ)_12pt @ 26\mod_1324468120852_75.docx @ 1141022 @ @ 1

Email: info@maha.de

Alternatively, you may take the equipment to a specialised waste management

plant to ensure that all components and operating liquids are properly disposed

Pos: 131 /Produktfamilien/Alle Geräte/Überschriften/Überschriften 1/I/Überschrift 1: Inhalt der Konformitätserklärung @ 22\mod_1292856748432_75.doc x @ 958616 @ 3 @ 1

Pos: 132 /Produktfamilien/Alle Geräte/Inhalte/Inhalt: Inhalt der Konformitätserklärung allg_12pt @ 26\mod_1324468436145_75.docx @ 1141120 @ @ 1

of.

herewith declares as a manufacturer its sole responsibility to ensure that the

product named hereafter meets the safety and health regulations both in design

and construction required by the EC directives stated below.

This declaration becomes void if any change is made to the product that was not

Pos: 133 /Produktfamilien/Scheinwerferprüftechnik/MLT-SERIES/380701 MLT 3000/BA/Inhalt: 3807 Inhalt der Konformitätserk lärung @ 44\mod_1464596320588_ 75.docx @ 2494487 @ @ 1

discussed and approved by named company beforehand.

=== Ende der Liste für Textmarke Inhalt ===

MLT 3000 / SEP Comfort

Headlight Tester

2014/30/EU; 2014/35/EU

DIN EN ISO 12100:2010; DIN EN 60204-1;

DIN EN 61000-6-3, DIN EN 61000-6-4

BA380701-en

Loading...

Loading...