MAHA MBT 2400 LON 4WD, MBT 3400 LON 4WD, MBT 4200 LON COMPETENCE, MBT 4200 LON CLASSIC, MBT 5200 LON W COMPETENCE Original Operating Instructions

...Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

MBT LON

Roller Brake Tester

Original Operating Instructions

BA022301-en

Pos: 1 /Technische D okumen tation/A lle Ger äte/T iteltex te/Titel text: M BT LON - Alle Ty pe n @ 30\mod_1352879906587_0.docx @ 1676381 @ @ 1

MBT 2200 LON

MBT 2400 LON 4WD

MBT 3200 LON

MBT 3400 LON 4WD

MBT 4200 LON COMPETENCE/CLASSIC

MBT 4400 LON 4WD

MBT 5200 LON W COMPETENCE/CLASSIC

MBT 6200 LON W CLASSIC

MBT 7200 LON W COMPETENCE/CLASSIC

MBT 7400 LON 4WD

Pos: 2 /-----For mat---- -/MAN UELLER UMBRUCH S eitenumb ruch @ 0\m od_11 34403 5776 87_0.d ocx @ 1 277 @ @ 1

Page 2

2

Pos: 3 /-----For mat---- -/Inh altsv er zeic hn is - 3 Ebe nen @ 5\mod _116 88674 41046_ 75.d ocx @ 72 920 @ @ 1

Contents

1 Safety ...................................................................................................................... 5

1.1 Introduction ......................................................................................................................................... 5

1.2 Symbols .............................................................................................................................................. 5

1.3 Intended Use ....................................................................................................................................... 5

1.4 Inappropriate Use ................................................................................................................................ 5

1.5 Requirements on Operating and Service Personnel ............................................................................. 5

1.6 Safety Instructions for Installation and Initial Operation ........................................................................ 6

1.7 Safety Instructions for Operation ......................................................................................................... 6

1.8 Danger Zone ....................................................................................................................................... 7

1.9 Safety Instructions for Servicing ........................................................................................................... 7

1.10 Safety Features ................................................................................................................................... 8

1.11 Accessories ......................................................................................................................................... 9

1.12 What to Do in the Event of an Accident ............................................................................................... 9

2 Description ............................................................................................................. 10

2.1 General Information ........................................................................................................................... 10

2.2 Noise Emission .................................................................................................................................. 10

2.3 Specifications .................................................................................................................................... 11

3 Transport and Storage ........................................................................................... 18

4 Installation and Initial Operation .............................................................................. 18

5 Operation ............................................................................................................... 18

5.1 Main Switch....................................................................................................................................... 18

5.2 Analog Displays ................................................................................................................................. 19

5.3 Remote Control ................................................................................................................................. 24

5.4 Menu Structure ................................................................................................................................. 27

5.5 Car Brake Tester with MAH-DOT and IFB ......................................................................................... 30

5.6 Car Brake Tester with MAH-DOT and RECO 1 .................................................................................. 31

5.7 Truck Brake Tester with MAH-DOT and FFB ..................................................................................... 33

5.8 Truck Brake Tester with MAH-DOT and RECO 1 .............................................................................. 35

5.9 Option Drive Control .......................................................................................................................... 36

5.10 Noise Detection with IFB / FFB / RECO 1 .......................................................................................... 38

5.11 MSD 3000 ......................................................................................................................................... 40

5.12 Clock Changing between Daylight Saving Time/Standard Time ......................................................... 42

5.13 Test Procedure with Software ........................................................................................................... 43

6 Maintenance .......................................................................................................... 46

6.1 Annual Inspection .............................................................................................................................. 46

6.2 Care Instructions ............................................................................................................................... 46

6.3 Spare Parts ....................................................................................................................................... 46

6.4 Chain Drive Maintenance: Cleaning, Retensioning, Lubricating .......................................................... 47

6.5 Greasing the Sensor Roller Hinges .................................................................................................... 51

BA022301-en

Page 3

3

6.6 Troubleshooting ................................................................................................................................ 52

7 Dismantling ............................................................................................................ 55

8 Disposal ................................................................................................................. 55

9 Contents of the Declaration of Conformity .............................................................. 56

10 Company Information ............................................................................................. 57

Pos: 4 /-----For mat---- -/MANUELLER UMBRUC H Seite numbruc h @ 0\mod_ 11344 03577 687_ 0.docx @ 1277 @ @ 1

BA022301-en

Page 4

4

Pos: 5 /-----For mat---- -/MAN UELLER UMBRUCH S eitenumb ruch @ 0\m od_11 34403 5776 87_0.d ocx @ 1 277 @ @ 1

BA022301-en

Page 5

5

1

Safety

1.1

Introduction

1.2

Symbols

1.3

Intended Use

1.4

Inappropriate Use

1.5

Requirements on Operating and Service Personnel

Pos: 6 /Technische D okumen tation/A lle Ger äte/ Überschr iften/ Übersc hriften 1/S/Üb erschrift 1: Sich erheit @ 6\mod_1174482399906_75.docx @ 76962 @ 1 @ 1

Pos: 7 /Technisc he Dokum enta tion/ All e Gerä te/ Übers chrif ten/Üb ersc hrift en 1 .1/E/ Übers chr ift 1.1: E inführ ung @ 6\m od_1174482219062_75.docx @ 76793 @ 2 @ 1

Pos: 8 /Techn ische Dokum en tati on/All e Gerä te/I nhal te/S icher heit/I nha lt: Ei nführ ung Sicher hei t_12p t @ 25\mod_1324455248318_75.docx @ 1138886 @ @ 1

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

Pos: 9 /Technische D okumen tation/A lle Ger äte/ Überschr iften/ Übersc hriften 1.1/S/ Übers chrift 1.1: Sym bole @ 6\mod_1174482270875_75.docx @ 76865 @ 2 @ 1

Pos: 10 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Sicher heit/In halt: Sy mbo le Sicher heit_1 2pt @ 25\mod_1324456650897_75.docx @ 1139046 @ @ 1

safety instructions are not covered by the product liability regulations.

Important safety instructions. Failure to comply with instructions could result in

personal injury or property damage.

Important information.

Pos: 11 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/B/Übers chrift 1.1: Bestimm ungsgemä ßer Geb rauch @ 6\m od_1 17673 40222 03_75. docx @ 88746 @ 2 @ 1

Pos: 12 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/In halte/Sic herheit/Inha lt: Bestimmu ngsgemäßer G ebrauch BPS_ 12pt @ 26\mod_1326368132160_75.docx @ 1504745 @ @ 1

This equipment is to be used exclusively for the brake testing of motor vehicles.

Observe the rated axle load.

The equipment shall not be modified without the express written consent of the

manufacturer. In case of non-compliance the declaration of conformity becomes

Pos: 13 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/B/Übers chrift 1.1: Bestimm ungswid riger Gebrauc h @ 18\mod_1255530265027_75.docx @ 471571 @ 2 @ 1

Pos: 14 /Technische Dokument ation/Alle Gerät e/Inhalte/ Sicherhe it/Inhalt: Bestimm ungsw idriger Gebrau ch allg_12pt @ 25\mod_1324455015938_75.docx @ 1138843 @ @ 1

Pos: 15 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/A/ Übersc hrift 1.1: Anf order ungen a n das Bedien ungs- und Serv iceper sonal @ 34\mod_1380637497630_75.docx @ 1835413 @ 2 @ 1

Pos: 16 /Technische Dokume ntatio n/Alle Geräte/ Inhal te/Si cher heit/I nhal t: Anf ord erun gen a n das Bed ienu ngs- u nd Servi cepers onal_1 2pt (2 016-12-22 08 :48:1 2) @ 34\m od_1 380 637 3483 20_ 75.d ocx @ 183 536 9 @ @ 1

void.

Any use other than described is inappropriate.

All persons employed in the operation, maintenance, installation, removal and disposal of the device must

• be at least 18 years old,

• be trained and instructed in writing,

• have read and understood this manual

Pos: 17 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

• be on record as having been instructed in safety guidelines.

BA022301-en

Page 6

6

1.6

Safety Instructions for Installation and Initial Operation

1.7

Safety Instructions for Operation

Pos: 18 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/S/ Übersc hrift 1.1: Sic herheit svorschr iften f ür Ins ta llatio n und Ers tinbe triebn ahme @ 24\m od_131 0565 05943 1_75.d ocx @ 102354 3 @ 2 @ 1

Pos: 19 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/S icherh eit/ Inha lt: S icher heitsv ors chrifte n f ür die Inbe trieb nahm e B PS_ 12pt @ 26\mod_1326368324234_75.docx @ 1504789 @ @ 1

• The system shall only be commissioned by MAHA service technicians or au-

thorized service partners.

• All parts of the electrical equipment must be protected from moisture and wet-

ness.

• The system shall not be installed and operated in hazardous locations or wash

halls.

• The operator must provide for optional safeguards (e.g. warn lamps, barriers,

etc.) depending on local conditions.

• Wear safety shoes and gloves.

• Safeguard roller set with suitable means (e.g. cordon chains or strap).

• The display must be installed in a secure area and folded into the wall when not

in use (wall hinges optionally available).

• When folding the display, grasp it on the edges. Danger of pinching!

• Ensure that a lockable emergency-stop main switch is installed based on instal-

lation instructions before connecting the feed line. Use motor protection switch

and cable cross sections as per specification. Reference in circuit diagram

(standard delivery), nameplate. Fuse max. X.X A (see nameplate).

• The main switch must be provided by the customer and installed on-site. It

must be positioned in direct vicinity to the tester and takes over the emergency-

Pos: 20 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/S/ Übersc hrift 1.1: Sic herheit svorschr iften f ür den Betri eb @ 6\m od_1174482268953_75.docx @ 76826 @ 2 @ 1

Pos: 21 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/S icherh eit/ Inha lt: S icher heitsv ors chrifte n f ür den Be trieb BPS_12pt @ 26\mod_1326700788796_75.docx @ 1505493 @ @ 1

stop function.

• The system shall only be operated within its performance limits.

• The system shall only be operated by trained personnel.

• The system and surrounding area must be kept clean.

• Switch off the system when not in use and secure the main switch against re-

start with a padlock.

• In emergency situations switch off system with main switch or emergency-stop

switch.

• No persons shall be in the danger zone of the system. Rotating or moving parts

(e.g. test stand rollers) are dangerous.

• Danger of carbon monoxide poisoning with running vehicle engine in closed

rooms. The operator is responsible for providing sufficient air exchange.

• Avoid unnecessary strain on vehicle and tester.

• Drive the vehicle slowly on to the tester.

• Check the danger zone before driving the vehicle onto the tester.

BA022301-en

Page 7

7

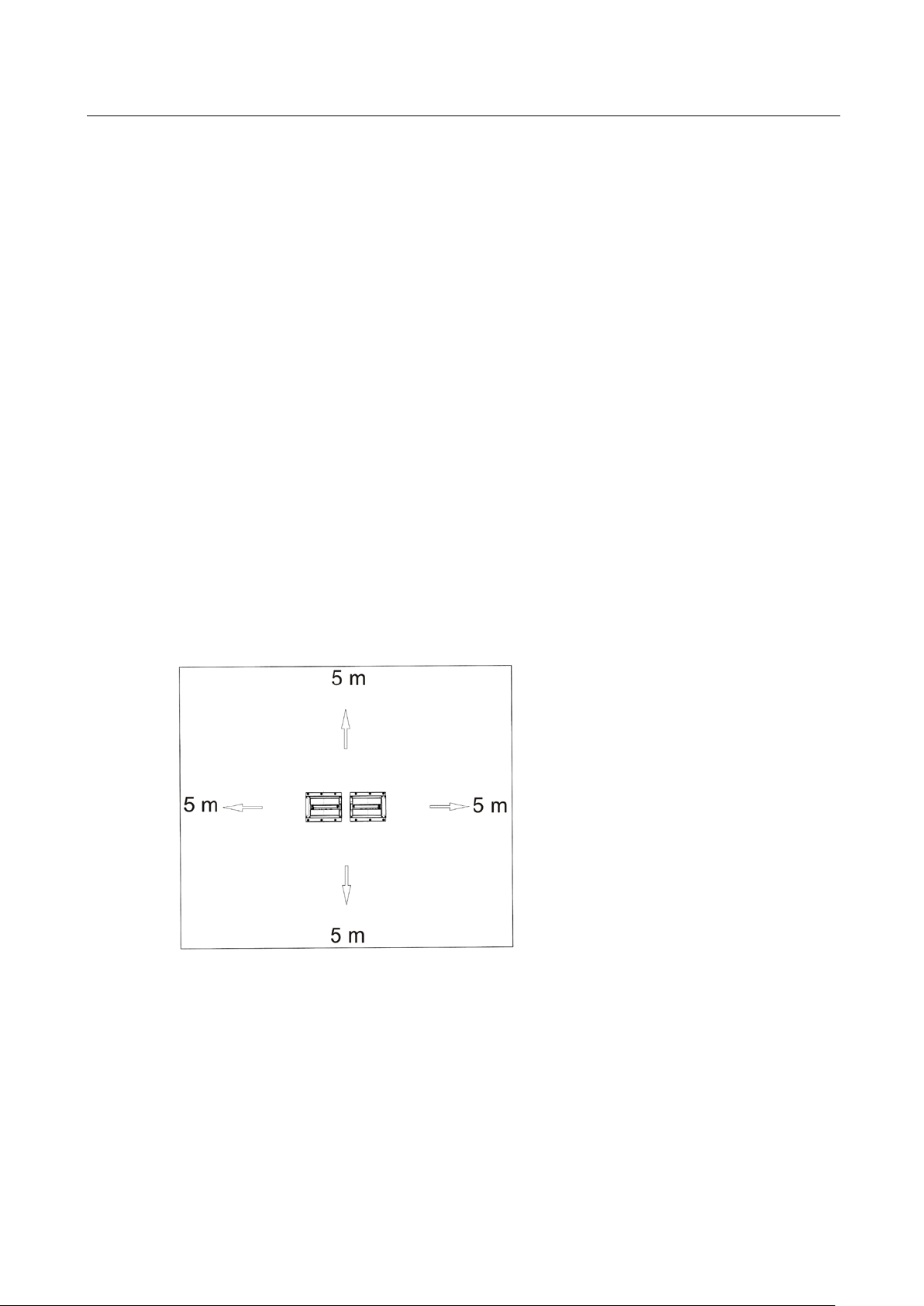

1.8

Danger Zone

5 (five) meters

1.9

Safety Instructions for Servicing

• When the vehicle with the driven axle is on the roller set, exit only with running

roller drive. Exiting with roller drive at standstill can destroy the motors due to

extreme roller acceleration.

• The system shall not be operated without functioning slip monitoring. This can

cause tire damage.

• Never jump start a vehicle with the system. This can lead to equipment dam-

age.

• No 4 wheel-drive vehicles shall be tested on the standard roller set. Damage to

vehicle and system are possible. When in doubt contact your responsible service representative.

• The vehicle must be closed during testing. If persons outside of the vehicle are

endangered, use noise protection.

• The operator shall not leave the vehicle during testing.

• No vehicle shall be parked in/on the roller set or on the optional ramps.

Pos: 22 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr ifte n 1. 1/G/ Übers chr ift 1.1: G efahr enzo ne @ 19\mod _12 6693 81226 76_75.d ocx @ 78 2826 @ 2 @ 1

Pos: 23 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/S icherh eit/ Inha lt: G efahr enzo ne - 5m Abs tan d ( Tex t) B PS_ 12pt @ 26\m od_1326700917541_75.docx @ 1505537 @ @ 1

During brake tester operation no persons are allowed in the danger zone:

Pos: 24 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/S icherh eit/ Inha lt: G efahr enzo ne - 5m Abstand (Bild) BPS @ 19\mod _1266 9382 60034_ 0.d ocx @ 784 017 @ @ 1

Pos: 25 /Technische Dokume ntatio n/Alle Geräte/ Überschrift en/Überschr iften 1.1/S/ Überschrif t 1.1: Sicherheit svorschr iften für Servicearb eiten @ 6\mod_1174482270640_75.docx @ 76850 @ 2 @ 1

around the roller set in all directions.

Pos: 26 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Bremsprüftechnik All e -/I nha lte/Sic herh eit/ Inha lt: S icherhe itsv orsc hrifte n f ür Ser vicea rbe iten BPS_ 12pt @ 2 6\mod_1326700977270_75.docx @ 1505581 @ @ 1

• Service work shall only be done by MAHA service technicians or authorized

service partners.

• Work on electric parts of the system shall only be done by trained electricians.

• The main switch must be switched off and secured against restart before doing

repair, maintenance and set-up work.

• Fire danger due to rubber abrasion on the roller set. Clean regularly. Remove

abrasion before maintenance work.

BA022301-en

Page 8

8

1.10

Safety Features

Lockable Main Switch

Emergency Switch

Startup Monitoring

Sensor Rollers

Visual and Audible Warning Devices

Pit Safety

Yellow-Black Marking Tape

Warning and Information Labels

• The main switch must be secured and if necessary the motor protection switch

turned off when doing work in the roller set.

• When working on the control cabinet or on the roller sets pay attention to the

heating (optional) or hot parts.

• Immediately turn off the tester when it starts up unintentionally. Contact the ser-

Pos: 27 /Technische Dokument ation/ Alle Gerät e/Übers chrift en/Über schrifte n 1.1/S/ Übersc hrift 1.1: Sic herheit seinric htunge n @ 6\mod_1174483324765_75.docx @ 77103 @ 2 @ 1

Pos: 28 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/S icherh eit/ Inha lt: S icher heits einr ichtun gen ( Text) BP S_12p t @ 26\mod_1326701513692_75.docx @ 1505625 @ @ 1

vice department.

The safety features (partly optional) are to be inspected regularly by an authorized

service technician. Official guidelines must be followed at all times.

shall not be operated when the safety features are defective!

•

Serves as normal On and Off switch for the equipment and as emergency switch.

The switch can be padlocked to protect it against unauthorized usage.

•

The equipment

Is used for quick switch-off during operation. Interrupts the power supply to the

equipment.

•

Prevents the rollers from starting up in case the wheels are blocked (seized

bearings, jammed brake pads). This feature helps prevent the vehicle tyres from

being damaged.

•

The RPM difference between equipment rollers and sensor rollers determines the

slip. Both sensor rollers must be pushed down in order to start the roller brake

tester.

•

These must be positioned at a suitable location and must be easily seen or heard

at all times. In the event that the warning devices are defective, the brake tester

must be shut down until they are fully functional again.

•

Light barrier or infrared movement sensor. If any person enters the safety area, the

brake tester is switched off.

•

The yellow-black marking tape around roller set and pit serves to mark out the

brake tester and nust be replaced if defective. Part # 19 6014 (Ø 38 mm) /

19 6015 (Ø 50 mm).

•

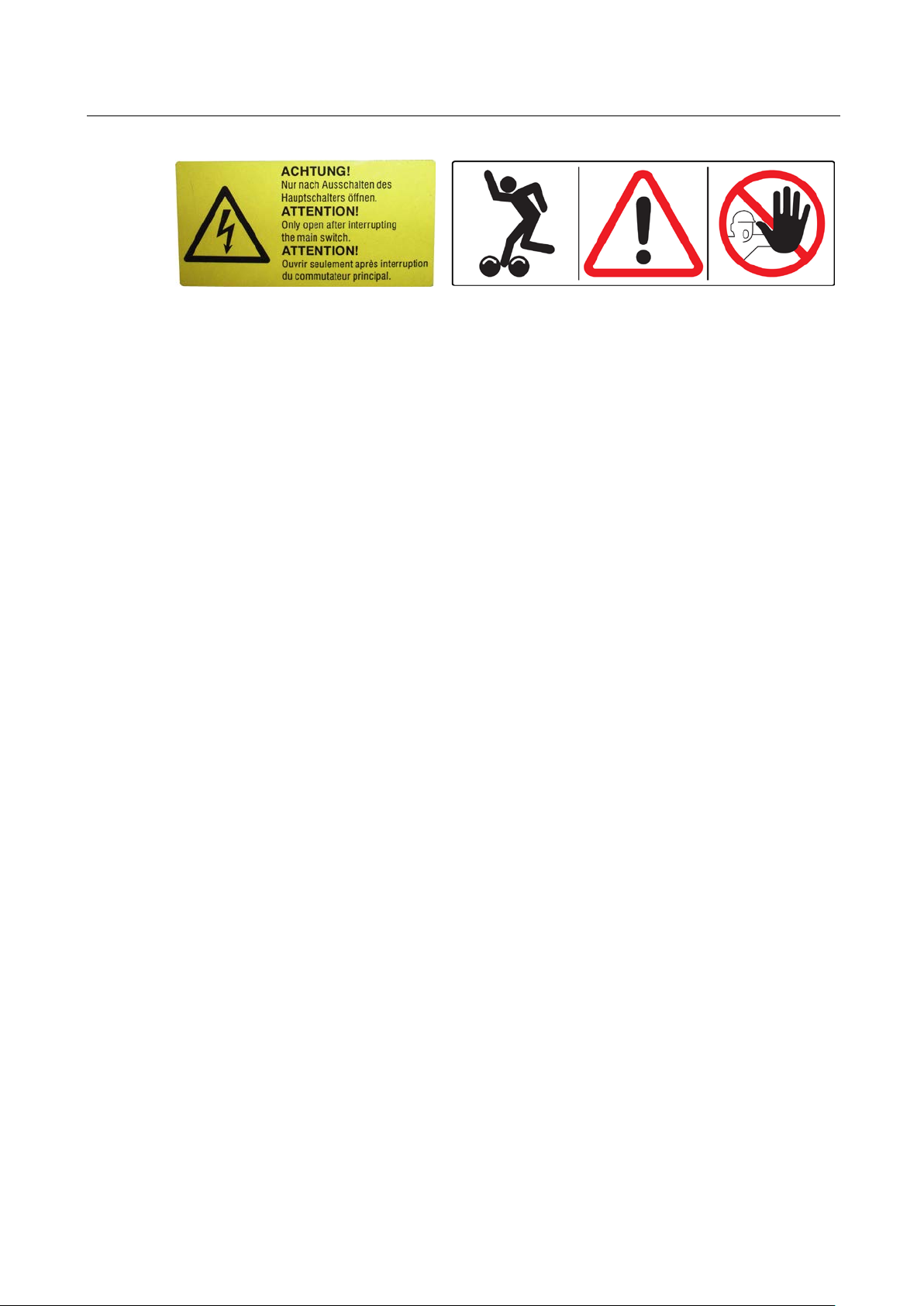

Warning and information labels are attached to the equipment. These must not be

changed or removed and must be replaced if unreadable (see below for part

Pos: 29 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/Sic herhei t/Inhalt : Sicherhe itseinr ichtun gen/Aufk leber (Bi lder) BPS @ 2 3\mod_ 12970 85082 534_ 0.docx @ 97155 8 @ @ 1

BA022301-en

numbers).

Page 9

9

1.11

Accessories

1.12

What to Do in the Event of an Accident

54 2132 54 2683

Pos: 30 /Technische Dokume ntatio n/Alle Geräte/ Überschrift en/Überschr iften 1.1/Z /Überschr ift 1.1: Zubehör @ 7\mod _11 97021 5365 41_75.d ocx @ 13 6790 @ 2 @ 1

Pos: 31 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Sicher heit/In halt: Z ubehör_ 12pt @ 25\mod_1324457135414_75.docx @ 1139114 @ @ 1

The equipment shall be operated only with accessories which have been

Pos: 32 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1.1/V /Übersc hrift 1 .1: Ver halten bei U nfällen @ 19\mod_1267177245337_75.docx @ 794600 @ 2 @ 1

Pos: 33 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Sicher heit/In halt: V erhalt en bei Unfälle n_12p t @ 34\mod_1381128863435_75.docx @ 1837175 @ @ 1

approved or permitted by MAHA.

• The injured person is to be removed from the danger area. Find out where

dressing and bandages are kept. Seek first-aid.

• Provide first-aid (stop bleeding, immobilise injured limbs), report the accident

and seal off the accident site.

• Immediately report any accident to your supervisor. Make sure a record is kept

of every occasion first-aid is provided, e.g. in an accident book.

Pos: 34 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

• Remain calm and answer any questions that may arise.

BA022301-en

Page 10

10

2

Description

2.1

General Information

2.2

Noise Emission

Roller Brake Tester

Shock Tester

Side-Slip Tester

Pos: 35 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1/ B/Überschri ft 1: Beschreibun g @ 6\mod_1174482271453_75.docx @ 76889 @ 1 @ 1

Pos: 36 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/Üb erschriften 1. 1/A/Übersc hrift 1.1: Allgem eines @ 6\mod_1182865005781_75.docx @ 97736 @ 2 @ 1

Pos: 37 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERI ES /0 2230 1 MBT LON / BA/I nhal t: 022 3 Bes chr eib ung A ll gem eines @ 27\mod_1327392298693_75.docx @ 1513163 @ @ 1

This brake tester belongs to the group of roller brake testers. This class includes

two different measuring methods to record brake forces:

• the testing of drive torque or

• the testing of drive power.

The former is applied in this brake tester. It consists of a proven roller set and an

open-ended electronic system based on a processor board with an integral

operating system.

Pos: 38 /Tec hn ische Do kumentat ion/Alle Geräte/ Überschr iften/Übers chriften 1.1/L/ Überschrif t 1.1: Lärmem ission @ 13\mod_ 123 67672 72078_ 75.do cx @ 354 579 @ 2 @ 1

Pos: 39 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERIES/ E10101 EU ROSYSTEM Standard /BA/Inhalt: E101 Lärmemission @ 26\mod_1326714188804_75.docx @ 1507042 @ @ 1

The standard brake tester can be expanded to a complete test lane.

The noise emission during a vehicle test results mainly from the vehicle’s engine.

The noise emission varies from vehicle to vehicle and cannot be attributed to the

testing equipment.

The noise emission value created by the brake tester (roller drive) is less than

70 dB(A) in the work area of the operator.

The noise emission value created by the shock tester (oscillating test plates) is

between 75 and 80 dB(A) in the work area of the operator.

The noise emission value created by the side-slip tester is less than 70 dB(A) in

Pos: 40 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

the work area of the operator.

BA022301-en

Page 11

11

2.3

Specifications

MBT 1000 EUROSYSTEM

Pos: 41 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/T/Übers chrift 1.1: Technis che Daten @ 7\mod_1184075526343_75.docx @ 99711 @ 2 @ 1

Pos: 42 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Archiv -/- Brem sprüf techn ik Alle -/I nhalte/I nhalt: Technisc he Daten MBT 100 0 (Tabelle) @ 41\mod_1418897792157_75.docx @ 2176224 @ @ 1

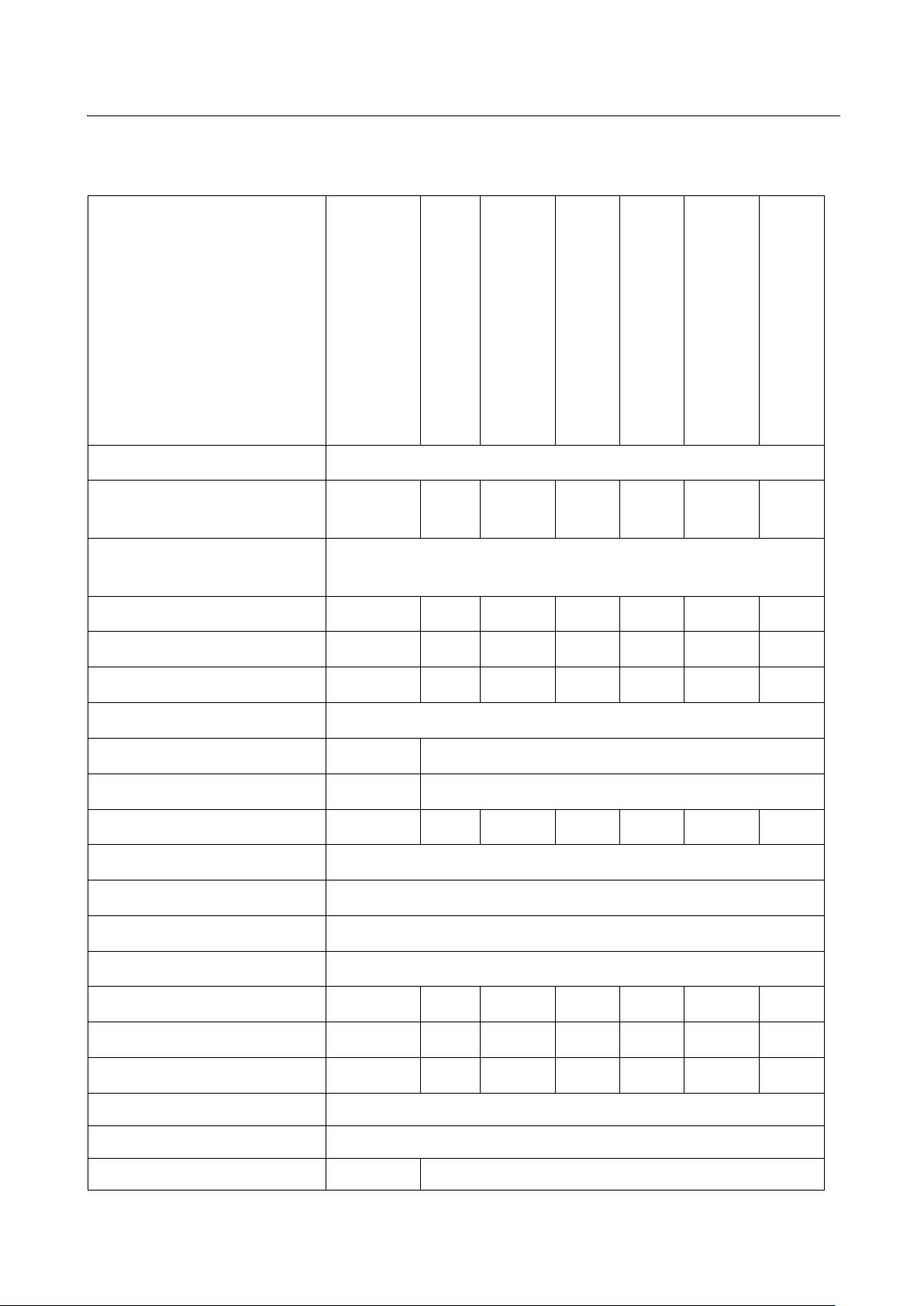

Version MCD 1000 MCD 2000 MCD 2000 PC

Absicherung (träge) 25 A

Antriebsleistung 3 kW

Messwertanzeige max. 2500 N

Messwertanzeige min. 0 N

Netzfrequenz 50 Hz

Netzspannung 400 V

Ovalität in kN

Phasen 3

Prüfgeschwindigkeit 5 km/h

Radlast (überfahrbar) 2000 kg

Rollenachsabstand 400 mm

Rollendurchmesser 202 mm

Rollenlänge 730 mm

Rollensatz Breite 680 mm

Rollensatz Höhe 280 mm

Rollensatz Länge 1420 mm

Pos: 43 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 12

12

MBT 2000

Pos: 44 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/In halte/Inha lt: Technisc he Daten MBT 2000 (Tabe lle) @ 41\mod_1418900165015_75.docx @ 2176316 @ @ 1

Version

MBT 2100

MBT 2200 LON

MCD 1000

MCD 2000

MCD 2000, PC

ALLRAD MCD 2000

MBT 2250 EUROSYSTEM

MBT 2250 EUROSYSTEM

MBT 2250 EUROSYSTEM

MBT 2450 EUROSYSTEM

MBT 2450 EUROSYSTEM

Absicherung (träge) 25 A

Analoganzeige Durchmesser

Antriebsleistung der Motoren

350 mm - - - - - -

3,0 kW

Anzeigekasten Breite 840 mm - - - - - -

Anzeigekasten Höhe 470 mm - - - - - -

Anzeigekasten Tiefe 100 mm - - - - - -

Laufrollendurchmesser 202 mm

Messwertanzeige 0 – 6 kN 0 – 8 kN

Netzfrequenz max. 60 Hz 50 Hz

ALLRAD MCD 2000, PC

Netzfrequenz min. 50 Hz - - - - - -

Netzspannung 400 V

Phasen 3

Prüfgeschwindigkeit 5 km/h

Rollenachsabstand 400 mm

Rollensatz Breite 680 mm - - - - - -

Rollensatz Höhe 280 mm - - - - - -

Rollensatz Länge 2320 mm - - - - - -

Spur max. 2200 mm

Spur min. 780 mm

Zul. Achslast (überfahrbar) 3000 kg 3500 kg

Pos: 45 /-----For ma t-----/MANUELLER UM BRUC H Se i tenum br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 13

13

MBT 3000

Pos: 46 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/In halte/Inha lt: Technisc he Daten MBT 3000 (Tabe lle) @ 41\mod_1419235715127_75.docx @ 2177314 @ @ 1

Version

MBT 3200 LON

MBT 3250 EUROSYSTEM

MCD 1000

MBT 3250 EUROSYSTEM

MCD 2000

MBT 3250 EUROSYSTEM

MCD 2000, PC

Absicherung (träge) 35 A

MBT 3400 LON ALLRAD

MBT 3450 EUROSYSTEM

ALLRAD MCD 1000

MBT 3450 EUROSYSTEM

ALLRAD MCD 2000

MBT 3450 EUROSYSTEM

ALLRAD MCD 2000, PC

Antriebsleistung der Motoren

5,5 kW

Messwertanzeige 0-8 kN / 0-16 kN

Netzfrequenz - 50 Hz - 50 Hz -

Netzfrequenz max. 60 Hz - 60 Hz

Netzfrequenz min. 50 Hz - 50 Hz

Netzspannung 400 V

Phasen 3

Prüfgeschwindigkeit 5 km/h

Rollenachsabstand 400 mm

Rollendurchmesser 202 mm

Rollensatz Breite 680 mm

Rollensatz Höhe 280 mm

Rollensatz Länge 2925 mm

Spur max. 2800 mm - 2800 mm

Spur min. 870 mm - 870 mm

Zulässige Achslast (überfahrbar)

Pos: 47 /-----For mat -----/MAN UE LLE R UM BR UCH Se iten umb ruc h @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

8000 kg

BA022301-en

Page 14

14

MBT 4000

Pos: 48 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/In halte/Inha lt: Technisc he Daten MBT 4000 (Tabe lle) @ 41\mod_1419239558273_75.docx @ 2177360 @ @ 1

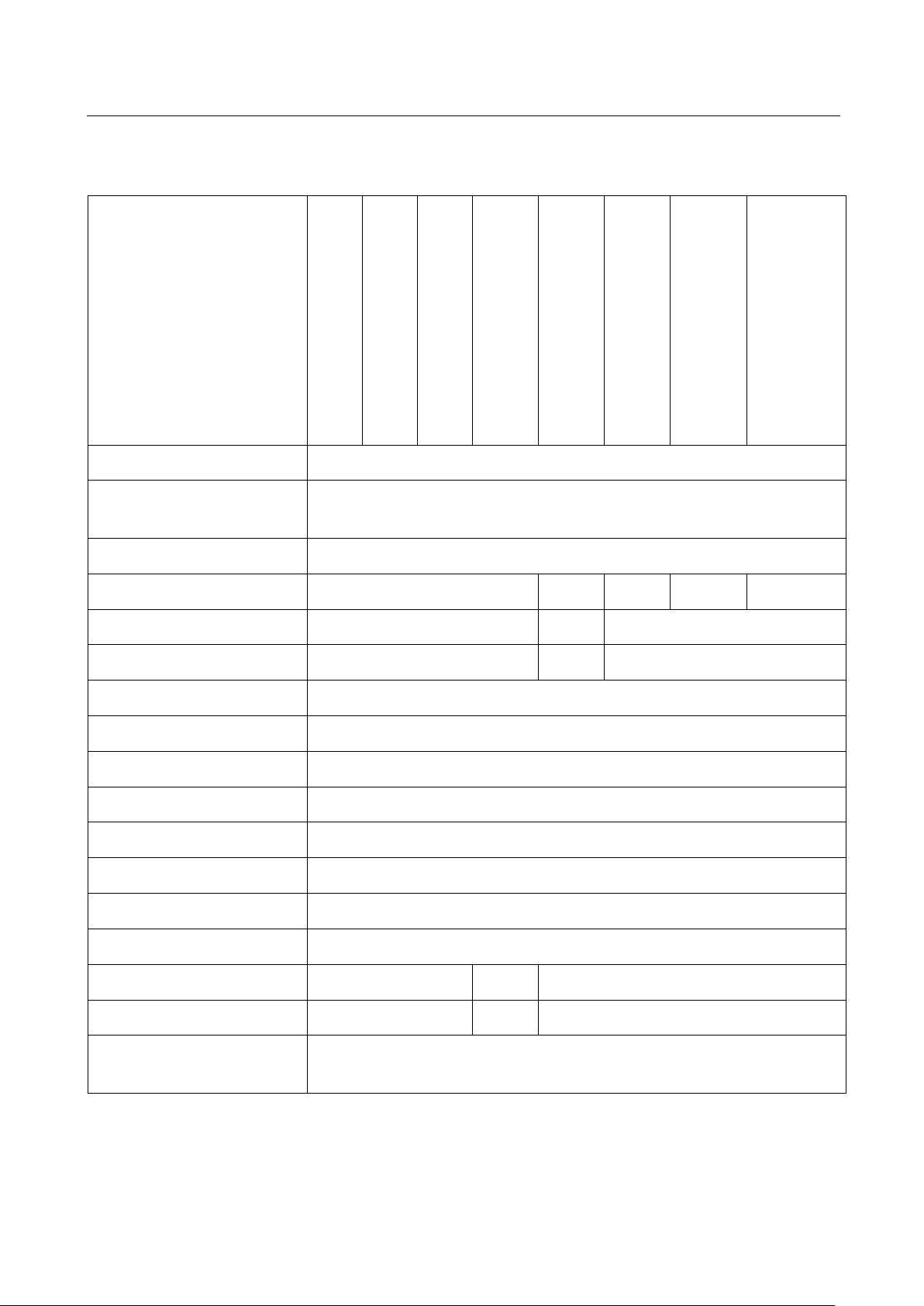

Version

MBT 4200 LON CLASSIC

MBT 4200 LON W CLASSIC

MBT 4200 LON W COMPE-

TENCE

Absicherung (träge) 50 A

Antriebsleistung der Motoren

9 kW

Netzfrequenz 50 Hz

Netzspannung 400 V

Phasen 3

Prüfgeschwindigkeit 2,3 km/h

Rollenachsabstand 430 mm

Rollendurchmesser 202 mm

Rollensatz Länge 1000 mm

Zulässige Achslast (überfahrbar)

Pos: 49 /-----For mat -----/MAN UE LLE R UM BR UCH Se iten umb ruc h @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

13000 kg

MBT 4250 EUROSYSTEM

MCD 2000

MBT 4250 EUROSYSTEM

MCD 2000 PC

MBT 4450 EUROSYSTEM

ALLRAD, MCD 2000

BA022301-en

Page 15

15

MBT 5000

Pos: 50 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/In halte/Inha lt: Technisc he Daten MBT 5000 (Tabe lle) @ 41\mod_1419241459116_75.docx @ 2177496 @ @ 1

Version

MBT 5200 LON CLASSIC

MBT 5200 LON W COMPE-

TENCE

Absicherung (träge) 63 A

Antriebsleistung der Motoren

11 kW

Gewicht pro Rollensatz 800 kg

Netzfrequenz 50 Hz

Netzspannung 400 V

Phasen 3

Prüfgeschwindigkeit 2 km/h

Rollenachsabstand 450 mm

Rollendurchmesser 130 mm

Rollenlänge 1220 mm

Rollensatz Breite 1171 mm

Rollensatz Höhe 460 mm

MBT 5250 EUROSYSTEM

MCD 2000

MBT 5250 EUROSYSTEM

MCD 2000 PC

Rollensatz Länge 2042 mm

Zulässige Achslast (überfahrbar)

Pos: 51 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

18000 kg

BA022301-en

Page 16

16

MBT 6000

Pos: 52 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nhalte/I nhalt : Technisc he Daten MB T 60 00 ( Tab ell e) @ 41\mod_1419244506240_75.docx @ 2177682 @ @ 1

Version

MBT 6200 LON W CLASSIC

MBT 6250 EUROSYSTEM

MCD 2000

Absicherung (träge) 63 A

Antriebsleistung der Motoren

11 kW

Netzfrequenz 50 Hz

Netzspannung 400 V

Phasen 3

Prüfbarer Raddurchmesser max.

Prüfbarer Raddurchmesser min.

2200 mm

800 mm

Prüfgeschwindigkeit 3 km/h

Rollenachsabstand 685 mm

Rollendurchmesser 265 mm

MBT 6250 EUROSYSTEM

MCD 2000 PC

Rollenlänge 1600 mm

Spurbreite max. 3600 mm

Spurbreite min. 400 mm

Zulässige Achslast (überfahrbar)

Pos: 53 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

18000 kg

Page 17

17

MBT 7000

Pos: 54 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/Inha lt: Techn isc he Daten MB T 700 0 (Tab ell e) @ 41\ mod_1419246681173_75.docx @ 2177728 @ @ 1

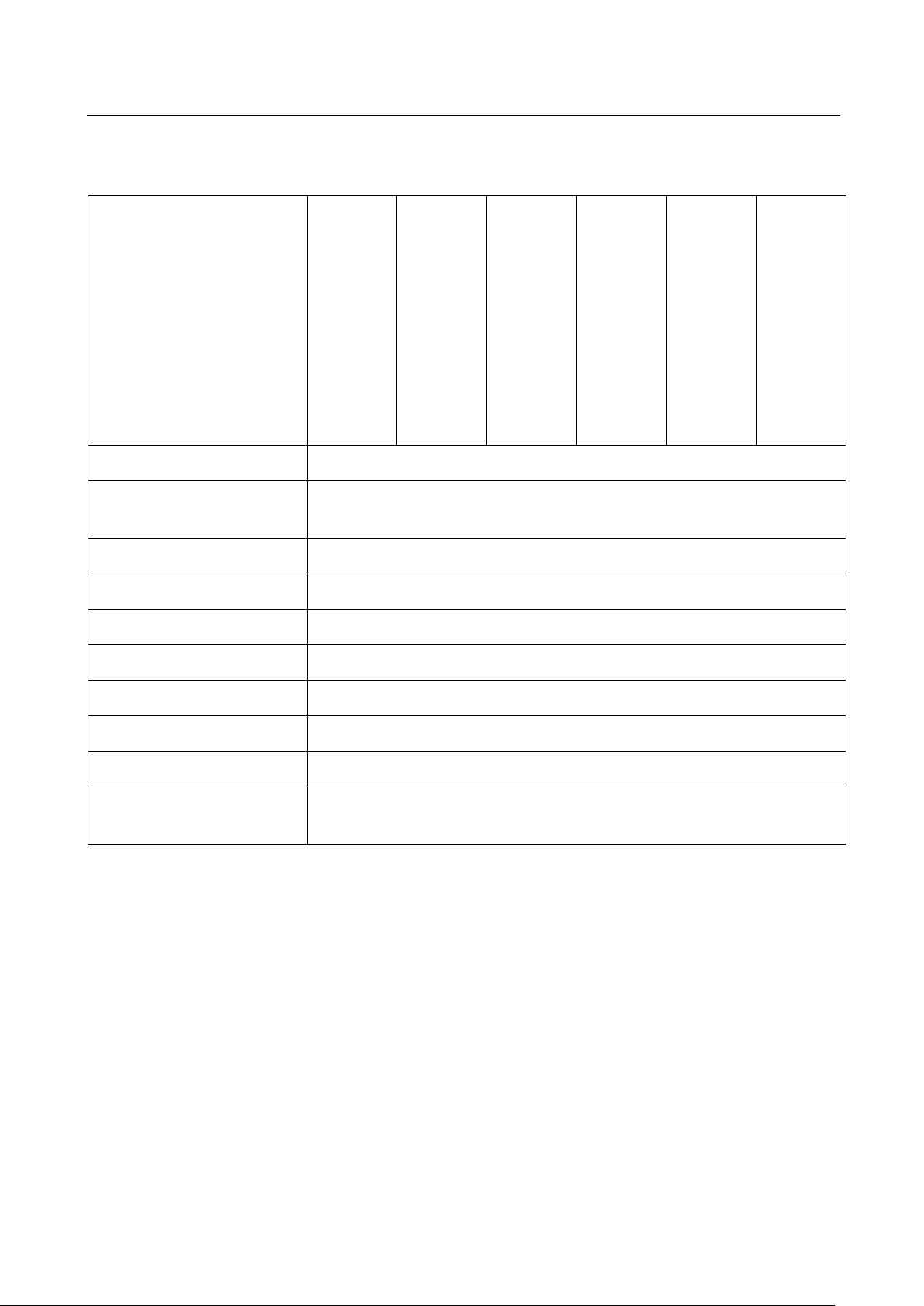

Version

MBT 7200 LON CLASSIC

MBT 7200 LON W CLASSIC

MBT 7200 LON W COMPE-

TENCE

Absicherung (träge) 63 A

Antriebsleistung der

Motoren

11 kW

Netzfrequenz 50 Hz

Netzspannung 400 V

Phasen 3

Prüfgeschwindigkeit 3 km/h

Rollenachsabstand 475 mm

Rollendurchmesser 265 mm

Rollenlänge 1150 mm

Zulässige Achslast

(überfahrbar)

Pos: 55 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

18000 kg

MBT 7250 EUROSYSTEM

MCD 2000

MBT 7250 EUROSYSTEM

MCD 2000, PC

MBT 7450 EUROSYSTEM

ALLRAD, MCD 2000

BA022301-en

Page 18

18

3

Transport and Storage

4

Installation and Initial Operation

5

Operation

5.1

Main Switch

Pos: 56 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1/T/ Überschri ft 1: Transp ort und Lageru ng @ 20\mod _1 268732488860_75.docx @ 826153 @ 1 @ 1

Pos: 57 /Technische Dokument ation/Alle Gerät e/Inhalte/ Inhalt: Tra nsport und Lageru ng_12pt @ 26\mod_1324468980166_75.docx @ 1141285 @ @ 1

Check package to ensure it is complete, in accordance with the order

confirmation. Report any transport damage to the carrier immediately.

During loading, unloading and transport always use suitable lifting equipment,

material handling equipment (e.g. cranes, forklifts, etc.) and the right load handling

attachments and slings. Always ensure that the parts to be transported are

suspended or loaded properly so that they cannot fall, taking into account size,

weight and the centre of gravity.

Store the packages in a covered area, protected from direct sunlight, at a low

humidity and with temperatures between 0...+40 °C (32…104 °F). Do not stack

packages.

When unpacking, take care to avoid any possibility of injury or damage. Keep at a

safe distance when opening the package strapping, do not allow any parts to fall

Pos: 58 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften 1/M/Üb ersc hrift 1: M ontag e und E rstinbe triebn ahme @ 18\mod_1255417443299_75.docx @ 463797 @ 1 @ 1

out.

Pos: 59 /Technische Dokume ntatio n/Alle G eräte/ Inhalte/ Inhalt: M onta ge und Ersti nbetrieb nahme_ 12pt @ 26\mod_1324468562877_75.docx @ 1141153 @ @ 1

Installation and initial operation of the equipment may be done only by authorized

and trained service technicians provided by the manufacturer, licensed dealers or

Pos: 60 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1/ B/Überschri ft 1: Bedienung @ 6\mod_1174482271218_75.docx @ 76877 @ 1 @ 1

Pos: 61 /Tec hn ische Do kumentat ion/Alle Geräte/ Überschr iften/Übers chriften 1.1/H /Überschr ift 1.1: Hauptsch alter @ 6\mod_ 117 75928 58312_ 75.do cx @ 906 35 @ 2 @ 1

Pos: 62 /Technische Dokume ntatio n/Alle Geräte/ Inhalte/ Inhal t: Haupts chalt er v2 - A lle Geräte_1 2pt @ 30\mod_1351692594628_75.docx @ 1671389 @ @ 1

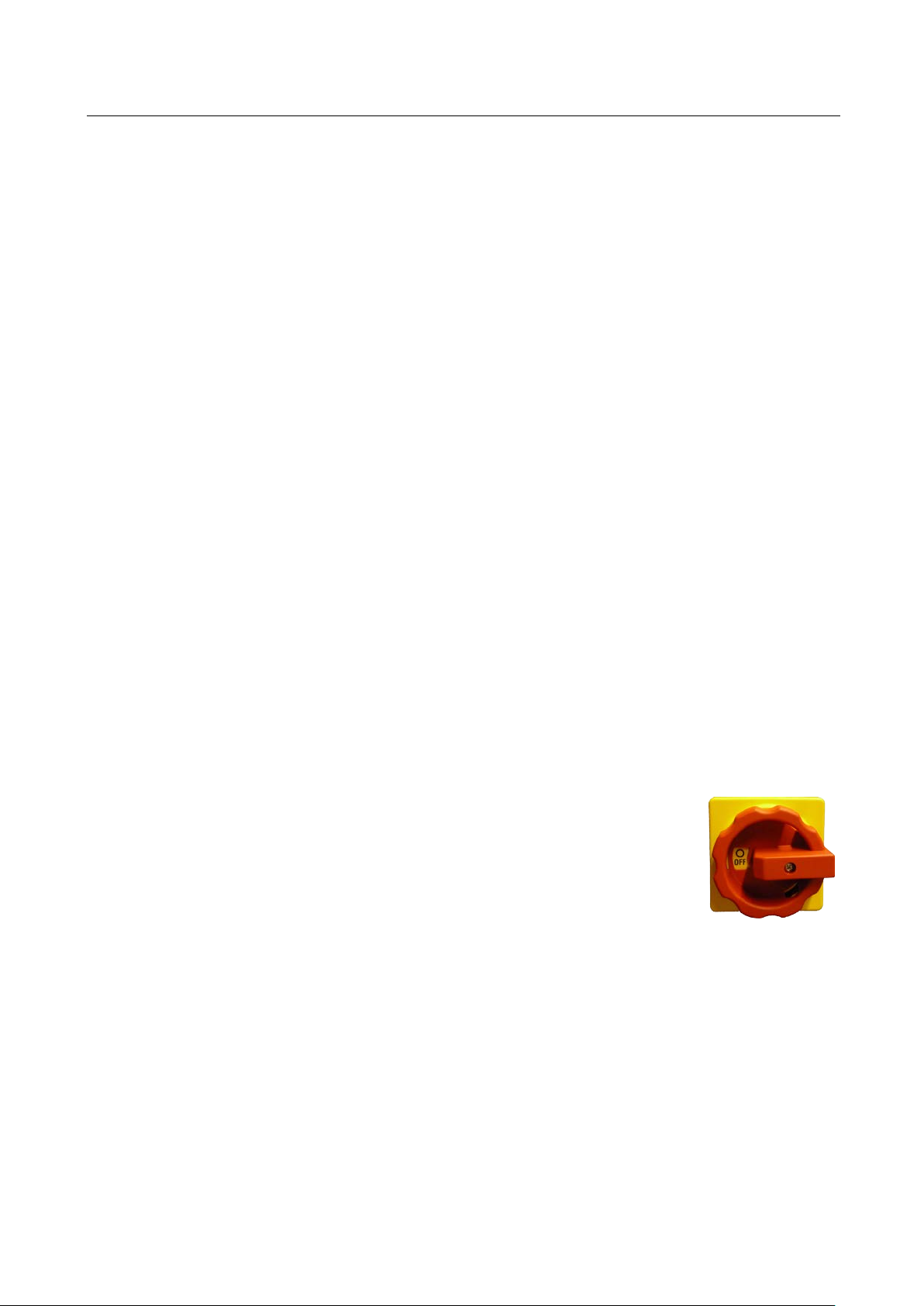

service partners.

• Main switch in position 0: Power supply OFF

• Main switch in position 1: Power supply ON

• When in position 0, the main switch can be protected against

tampering by means of a padlock.

Pos: 63 /-----For mat -----/MAN UE LLE R UM BR UCH Se iten umb ruc h @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 19

19

5.2

Analog Displays

A

F

B

G

C

H

D

I

E

A B C E D F G H I

Pos: 64 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/A/Übersc hrift 1.1: Analo ganzeigen @ 24\mod_1310542639702_75.docx @ 1023453 @ 2 @ 1

Pos: 65 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERIES/022301 MBT LON/BA/Inhalt: 0223 Display MBT 2x00 LON (Bild) @ 23\mod_12967349 729 94_ 0.d ocx @ 9 696 18 @ @ 1

Pos: 66 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERIES/022301 MBT LON/BA/Inhalt: 0223 Display MBT 2x00 LON (Tabelle) @ 27\mod_1327394295645_75.docx @ 1513477 @ @ 1

Indicator: Power On

Indicator: Ready to test

Indicator: Error

Selector switch: Motorcycle/Car/Truck

Selector switch: Single wheel (option)

Pos: 67 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

Dig. display: Brake force diff.

LED display: Difference %

Analog display, left

Analog display, right

BA022301-en

Page 20

20

A

G

B

H

C

I

D

J

E

K

F

J I H K A

B C D

E F G

Pos: 68 /Tec hn isch e Do kume ntatio n/Brem spr üftec hnik/M BT-SERIES/022301 MBT LON/BA/Inhalt: 0223 Display MBT 3x00 (Bild) @ 7\mod_1197021904989_0.docx @ 136841 @ @ 1

Pos: 69 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERI ES /0 2230 1 MBT LON / BA/I nhal t: 022 3 Disp lay M BT 3x 00 ( Tab elle ) @ 27\ mod_1327394449319_75.docx @ 1513521 @ @ 1

Signal lamp: Power On

Signal lamp: Ready for test

Signal lamp + Acknowledge button:

Error

Signal lamp: Factor 2

Selector switch: Single wheel

Selector switch: Motorcycle/Car/Truck

Pos: 70 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Selector switch:

Shock absorber Mm/%

Dig. display: Brake force diff.

LED display: Difference %

Analog display, left

Analog display, right

Page 21

21

A

I

B

J

C

K

D

L

E

M

F

N

G

O

H

P

J P I H K A L N B

O

M C D E F

G

Pos: 71 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERI ES /0 2230 1 MBT LON / BA/I nhal t: 022 3 Disp lay M BT 4x 00/ 7x 00 LON C LAS SIC (B ild) @ 7\mod_1197023080530_0.docx @ 136937 @ @ 1

Pos: 72 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERIES/022301 MBT LON/BA/Inhalt: 0223 Display MBT 4x00/7x00 LON CLASSIC (Tabelle) @ 27\mod_1327394588753_75.docx @ 1513565 @ @ 1

Signal lamp: Power On

Signal lamp: Ready for test

Signal lamp + Acknowl. button: Error

Signal lamp: Factor 10

Selector switch: Single wheel

Selector switch: Mot.cycle/Car/Truck

Selector switch: Shock abs. Mm/%

Digital display: Brake force diff.

Pos: 73 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

LED display: Difference %

Analog display, left

Analog display, right

Digital display: Weight

Dig. display: Brake press. Pm

Dig. display: Brake pressure Px

Digital display: Deceleration

Ticker

BA022301-en

Page 22

22

I O L M I H G

J K J

N A B

C D E

F

Pos: 74 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERI ES /0 2230 1 MBT LON / BA/I nhal t: 022 3 Disp lay M BT 4x 00/ 7x 00 LON C OMP ETEN CE + 4 WD ( Bild ) @ 7\mod_1197023660534_0.docx @ 136973 @ @ 1

Pos: 75 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 23

23

A

I

B

J

C

K

D

L

E

M

F

N

G

O

H

Pos: 76 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERIES/022301 MBT LON/BA/Inhalt: 0223 Display MBT 4x00/7x00 LON COMPETENCE + 4WD (Tabelle) @ 27\mod_1327394716048_75.docx @ 1513609 @ @ 1

Signal lamp: Power On

Analog display, 0…40 kN

Signal lamp: Ready for test

Signal lamp + Acknowl. button: Error

Selector switch: Single wheel

Selector switch: Mot.cycle/Car/Truck

Selector switch: Shock abs. Mm/%

Digital display: Brake force diff.

LED display: Difference %

Pos: 77 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Analog display, 0…8 kN

Digital display: Weight

Dig. display: Brake pressure Pm

Dig. display: Brake pressure Px

Digital display: Deceleration

Ticker

BA022301-en

Page 24

24

5.3

Remote Control

IFB / FFB

S T D

G

H L Q J I

K

M

N P O

R

Pos: 78 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/F/Übers chrift 1.1: Fernbed ienung @ 7\mod_1184152042500_75.docx @ 99994 @ 2 @ 1

Pos: 79 /Tec hn isch e Do kume ntat ion/Al le G erät e/Über schr iften/ Übe rschr ifte n oh ne Num mer ierun g/Übe rsc hrift : > I FB / F FB @ 21\m od_ 127 789 2982 039_ 0.d ocx @ 862 403 @ @ 1

Pos: 80 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERIES/022301 MBT LON/BA/Inhalt: 0223 Fernbedienung FFB / IFB (Bild) @ 21\mod_1277121814678_0.docx @ 858773 @ @ 1

Pos: 81 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 25

25

Key

Function

D

H

I

J

K

L

G

M

N

O

P

Q

R

S

Pos: 82 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERI ES /0 2230 1 MBT LON / BA/I nhal t: 022 3 Fer nbed ien un g FF B / I FB ( Tab el le) @ 27\m od_1327394916024_75.docx @ 1513697 @ @ 1

F4 Start Ovality test

F8 Pointer stop

F9 Store Front axle

F10

F11 Store Rear axle

F12 Auto OFF

F7 Start Print menu

* Confirm

#

Program 1 key

Shift key

Motor Off left

Motor On right

Motor On left

Pos: 83 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

Store Parking brake

Re-display MSD measurement value

Select Sensor

Quit Noise detection

BA022301-en

Page 26

26

RECO 1

A

B

C

D

E

F

A B D C E

F

Pos: 84 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften oh ne Nummerier ung/Übersc hrift: > RECO 1 @ 21\m od_12 77893 05005 7_0.d ocx @ 86 2443 @ @ 1

Pos: 85 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/Z 2 Fer nbed ie nung en/ 260 1 REC O 1/ TI /Inh alt : E 126 Fernb ed ien ung REC O 1 ( Bi ld) @ 21\ mod_1277808734534_0.docx @ 861868 @ @ 1

Pos: 86 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/Z 2 Fer nbed ie nung en/ 260 1 REC O 1/ TI /Inh alt : E 126 Fernb ed ien ung REC O 1 ( Tex t)_ 12p t @ 27\mod_1327394842267_75.docx @ 1513653 @ @ 1

Motors Off

Start Motor left

Start Motor right / Start Ovality test

Menu item upwards

Confirm

Menu item downwards

Pos: 87 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 27

27

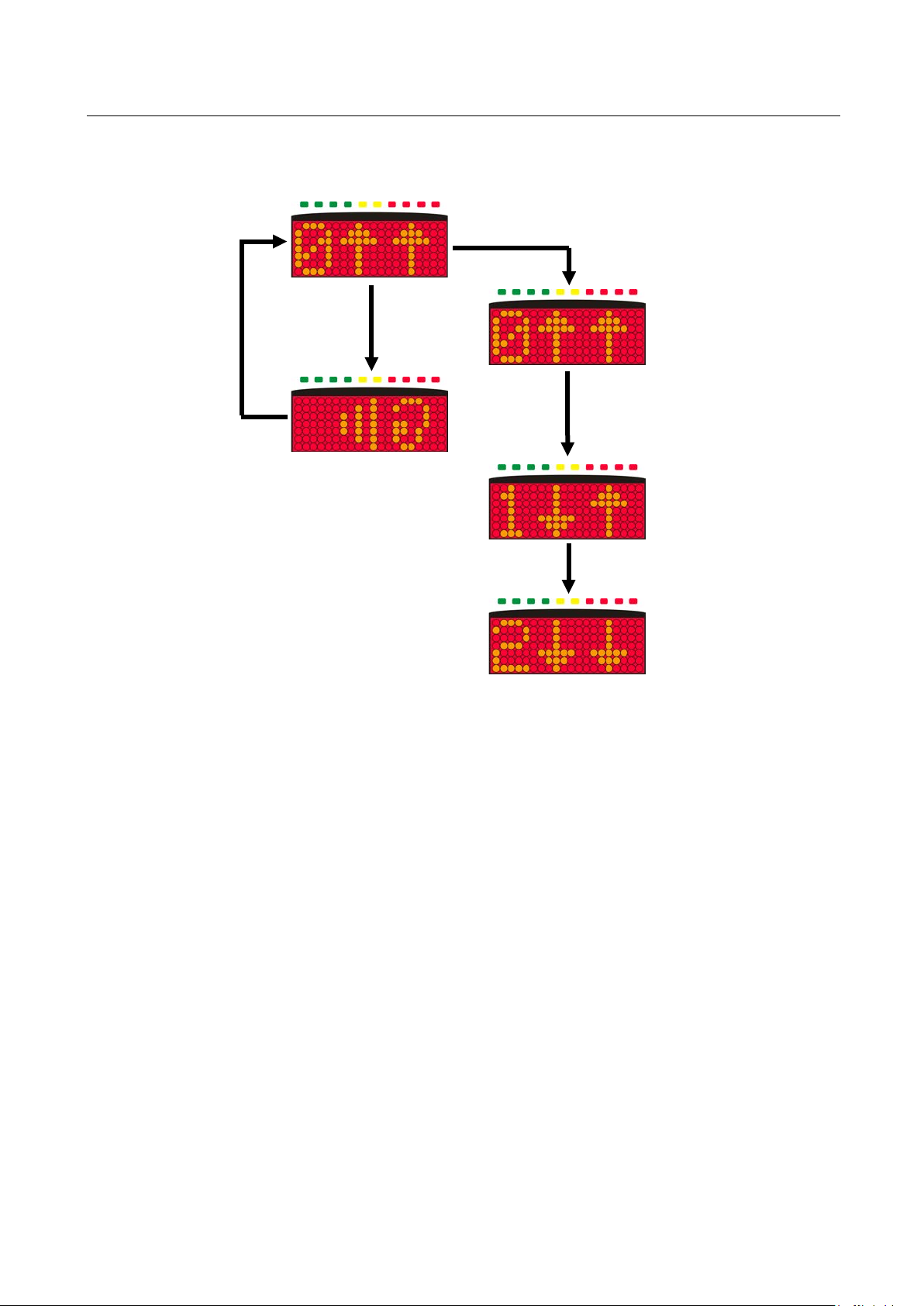

5.4

Menu Structure

Pos: 88 /Technische Dokume ntatio n/Alle Gerät e/Über sc hrift en/Üb erschr ifte n 1. 1/M/ Übers chr ift 1 .1: Me nüs trukt ur @ 2 0\mod _127 35039 41569 _75.d ocx @ 8 45788 @ 2 @ 1

Pos: 89 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/I nfo!/In ha lt: Inf o - Men üaufr uf nur außer halb Roll ensatz m öglich @ 41\mod_1419322434463_75.docx @ 2178104 @ @ 1

Menü-Aufruf nur außerhalb Rollensatz möglich!

Pos: 90 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/I nhalt : Me nüstr uktur (Abl auf) IWST @ 20\mod_1273504649880_75.docx @ 845818 @ @ 1

Pos: 91 /Techn ische Dok ument atio n/Brem spr üftec hnik /- Arc hiv -/- Brems prüf technik A lle -/I nha lte/I nhalt : Me nüstr uktur (Dia gramm ) I WST @ 20\mod_1273498931892_0.docx @ 845698 @ @ 1

1 OPEN

2 SELECT

3 CONFIRM

Pos: 92 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

Geräuschsuche

(nur Pkw!)

Haupt-Fahrtrichtung

Allrad-Gegenlauf

Gegen-Fahrtrichtung

BA022301-en

Page 28

28

► IWST 380 R120 or higher

Pos: 93 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften oh ne Numme rier ung/Üb ersc hrift: > A b IWST 3 80 R120 @ 4 1\mod_1418730654899_75.docx @ 2175154 @ @ 1

Pos: 94 /Techn ische Dok ument atio n/Brem spr üftec hnik /MB T-SERI ES /0 2230 1 MBT LON / BA/I nhal t: 022 3 Me nüs truk tur ( Di agram m) ab I WS T 3 80 R 120 @ 4 1\mod_ 14187 33808 614_ 0.docx @ 2175 246 @ @ 1

Haupt-Fahrtrichtung

Geräuschsuche

(nur Pkw!)

Pos: 95 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

Allrad-Gegenlauf

Gegen-Fahrtrichtung

BA022301-en

Page 29

29

► IWST 380 R120 4WD or higher

Pos: 96 /Technische Dokume ntatio n/Alle Geräte/ Übersc hriften/ Überschr iften ohne N ummer ierun g/Übersc hrift: > Ab IWS T 3 80 R120 Allr ad @ 4 1\mod_1418730803894_75.docx @ 2175200 @ @ 1

Pos: 97 /Tec hn isch e Do kume ntatio n/Brem spr üftec hnik/M BT-SE RIE S/ 022 301 M BT L ON/ BA/ Inh alt: 0 223 Me nüs tr uktur ( Diagr amm ) a b IW ST 380 R12 0 Al lrad @ 4 0\mod_1415087307036_0.docx @ 2139244 @ @ 1

Allrad VISCO

Geräuschsuche

(nur Pkw!)

Pos: 98 /-----For ma t-----/MA N UEL LER UMB RUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

Allrad-Starr

(Nur mit Lichtschranken möglich)

Allrad-Mode

Standard-Mode

BA022301-en

Page 30

30

5.5

Car Brake Tester with MAH-DOT and IFB

Brake Tester without Weighing Machine

1 5 8 0

Pos: 99 /Technische Dokument ation/Alle Gerät e/Übersc hriften/Üb erschriften 1. 1/P/Übersc hrift 1.1: PKW-Pr üfst and m it M AH-DO T u nd IFB @ 2 1\mod_ 127 78806 7466 1_75.d ocx @ 862 013 @ 2 @ 1

Pos: 100 /Te ch nisc he D ok umen tati on/ Bre mspr üftech nik/M BT-S ERIE S/ 0223 01 M BT LON/ BA/I nha lt : 02 23 M AH- DOT P lat ine (B ild) 2 @ 40\m od_ 14150 15205 466_0.d ocx @ 2 13909 1 @ @ 1

Pos: 101 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Be die nung PK W MAH -DO T und I FB (Text) 3 @ 41\mod_1418718037351_75.docx @ 2174958 @ @ 1

1 Drive onto roller set.

2 Press star key (M) for pointer stop.

3 Brake until slip or max. brake force.

4 Storage with keys F9 to F11.

• Front axle: F9 (I)

• Parking brake: F10 (J)

• Rear axle: F11 (K)

5 After testing, an auto OFF must be done. F12 (L) (not required with PC program

LON BASIC).

6 Use F7 (G) to start the print menu.

7 Enter the number of the print program, 1 or 2 and confirm with star (M) (not

required with PC program LON BASIC).

• An ovality measurement can be started with F4 (D).

• Re-display of the measurement values with F9 to F11.

• Re-display of the side-slip tester with Shift + Axle number + key F9 (I).

• Re-display of the shock absorber with Shift + Axle number + key F10 (J).

• Differential display of the brake force is numerical and via the LED bar.

Pos: 102 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Inf o PKW M AH-DOT und IFB @ 41\mod_1418720449557_75.docx @ 2175004 @ @ 1

New vehicle (NEW) with pound key (N) and star (M). (Delete all test values).

If there is a side-slip tester, shock absorber tester or both, it is necessary after the

Auto OFF procedure to set up a new vehicle (NEW). If not, then the measurement

values from the previous vehicle are still active.

Pos: 103 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SERIES/022301 MBT LON/BA/Inhalt: 0223 Prüfstand ohne Waage PKW2 @ 41\mod_1418722375130_75.docx @ 2175057 @ @ 1

With brake testers w/o weighing machine the vehicle weight must be entered after

the Auto OFF. The axle symbol changes constantly with the weight unit.

The weight entry is done directly via the numerical keypad of the remote control

and is confirmed with the star key (*). The left analog display runs synchronously

with the weight entry. Example: Entry of 1580 kilogram total weight.

Pos: 104 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Enter

on the keypad and confirm with the star (*) key.

Page 31

31

5.6

Car Brake Tester with MAH-DOT and RECO 1

Pos: 105 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/P/ Übers chrift 1.1: PK W-Prü fsta nd m it MA H-DO T und RE CO 1 @ 21\mod_1277881348839_75.docx @ 862103 @ 2 @ 1

Pos: 106 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Be die nung PK W MAH -DO T und REC O 1 ( Bi lder ) @ 21\mod_1277189731517_0.docx @ 858873 @ @ 1

A

C D

E

Pos: 107 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Be die nung PK W MAH -DO T und RE CO 1 (Tex t) @ 27\mod_1327397964107_75.docx @ 1514093 @ @ 1

1 Drive onto roller set.

B

F

2 Press blue Return key for pointer stop. Front axle symbol starts flashing (A).

3 Brake to slip or max. brake force.

4 Store with blue Return key.

5 Do axle change.

6 The symbol for Parking brake now flashes (B).

7 The parking brake measurement and rear axle measurement (C) are done using

the same procedure.

8 After storing the rear axle exit the roller set.

9 Now PRT (D) is flashing for printing. After confirming with the blue Return key,

the first LED of the differential display is flashing for print program. Use the

scroll key to select between program 1 or 2. Confirm again with Return and

print is done.

• Point 8 is omitted with PC program LON BASIC.

• An ovality measurement can be done with the right-hand Motor-ON key. The

ready lamp on the test stand is OFF during the measurement time.

BA022301-en

Page 32

32

Brake Tester without Weighing Machine

• Re-display of the measurement value: Use the scroll key to go to the axle and

press Return. Re-display of side-slip and shock absorber is not possible with

the RECO 1.

• If NEW (E) is confirmed with Return, then all existing measurement values are

deleted.

If there is no weighing machine, this can be entered at the end after Auto OFF

using the scroll key and Return. Visible by the last 4 LEDs (F) which are flashing,

and by the analog pointer.

If there is a side-slip tester, shock absorber tester or both, a new vehicle (NEW)

must be set up after Auto OFF. If not, these measurement values from the previous vehicle are still active.

Pos: 108 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 33

33

5.7

Truck Brake Tester with MAH-DOT and FFB

Pos: 109 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/ L/Übersc hrift 1 .1: L KW-Prüf stand m it MAH -DOT und FFB @ 21\m od_ 12778 81554 584_7 5.docx @ 86216 3 @ 2 @ 1

Pos: 110 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Be die nung L KW M AH-D OT und FFB (Text ) @ 27\mod_1327398079546_75.docx @ 1514137 @ @ 1

1 Drive onto roller set.

2 Active pressure sensor starts flashing. If several Px sensors are registered,

another sensor can be selected using the desired sensor number and pound

key (#). After the measurement the sensors cannot be allocated!

3 Press F8 (H) key for pointer stop.

4 Brake until slip or max. brake force.

5 Enter axle number 1 to 9, F9 for Service brake or F10 for Parking brake and

confirm with star key (*).

6 Do axle change and test all axles. Once all axles are tested, do an Auto Off

using Remote control F12 (L).

• Press F12. END flashes at the display. Confirm with the star key.

• END stops flashing. Calculations are started.

• After the calculations are complete, [E] appears. Now printing can be done.

7 The print program is started with F7 (G). Enter program number 1, 2, 3, 4 or 9

and confirm with the star key (*). Printout follows.

• An ovality measurement can be started with F4 (D).

• Re-display of the Service brake with axle number + key F9 (I).

• Re-display of the Parking brake with axle number + key F10 (J).

• Re-display of the Final evaluation with 0 + key F9 or F10.

Pos: 111 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

• Re-display of the Side-slip tester with Shift + axle number +key F9 (I).

BA022301-en

Page 34

34

Brake Tester without Scale

Pos: 112 /Te ch nisc he D okum enta tion/ Bremsp rüfte chnik/M BT- SERIE S/ 0223 01 M BT LON /BA/ In halt : 02 23 P rüfs ta nd o hne Waa ge LKW FF B 3 ( Text) @ 27\mod_1327398201270_75.docx @ 1514181 @ @ 1

With brake testers without scale the vehicle weight must be entered after the Auto

OFF. The axle symbol (A) changes constantly with the weight unit (B). Display 1, if

present, flashes for input.

The weight entry is done directly via the numerical keypad of the remote control

and is confirmed with the star key (*). The input is displayed on Display 1 (C). The

analog display runs synchronously with the weight input.

Example: Entry of 15.80 tons.

Pos: 113 /Te ch nisc he D ok umen tati on/Br emsp rüfte chnik/M BT- SERIE S/ 0223 01 M BT LON /BA/ In halt : 02 23 P rüfs ta nd o hne Waa ge LKW FF B 3 ( Bild er) @ 2 1\mod_1277202240788_0.docx @ 860153 @ @ 1

Enter 1 5 8 0 via the keyboard and confirm with star (*) key.

A

C

Pos: 114 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

B

BA022301-en

Page 35

35

5.8

Truck Brake Tester with MAH-DOT and RECO 1

Brake Tester without Scale

Pos: 115 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/ L/Übersc hrift 1 .1: L KW-Prüf stand m it MAH -DOT und RECO 1 @ 21\mod_127 78814 37722_ 75.d ocx @ 86 2133 @ 2 @ 1

Pos: 116 /Te ch nisc he D ok umen tati on/Br emsp rüftec hnik/M BT-S ERIE S/ 0223 01 M BT LON /BA/ Inh alt : 02 23 B edie nu ng L KW MAH -DOT un d RECO 1 (Text) @ 27\mod_1327398290937_75.docx @ 1514225 @ @ 1

1 Drive onto roller set.

2 Active pressure sensor (A) starts flashing. If several Px sensors are registered,

another sensor can be selected using the scroll key. After the measurement,

allocation of the sensors is not possible!

3 Press the blue Return key for pointer stop.

4 Brake to slip or max. brake force.

5 Press blue Return key for filing mode. Use the scroll key to select Service brake

(B) or Parking brake (C).

6 Use the scroll key to select axle 1 to 9 and confirm with Return. Measurements

are stored (D + E).

7 Do axle change and test all axles using the above procedure. Once all axles are

tested, do an Auto OFF (F) using remote control (O).

8 For printing, select the print mode using the scroll key and confirm with Return.

Now PRT (G) is flashing for print. After confirmation with the blue Return key the

first LED of the differential display flashes for print program 1. Use the scroll key

to select program 1, 2, 3, 4 or 9. Confirm print program with Return, printout is

Pos: 117 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Pr üfs tand ohn e Waage LKW RECO 1 (Text) @ 41\mod_1418723207295_75.docx @ 2175103 @ @ 1

done.

With brake testers without scale the vehicle weight must be entered after the Auto

OFF. The axle symbol (A) changes constantly with the weight unit (B), and the last

4 LEDs are flashing.

The entry is done with the scroll-up key of the Reco1. As soon as the weight input

is confirmed with Return, the corresponding LED changes to permanent light. The

analog display runs synchronously with the weight input.

Example: Entry of 15.80 tons.

The last 4 LEDs are flashing.

1 Press the scroll-up key once and confirm with Return. (The first LED goes to

permanent light.)

2 Press the scroll-up key five times and confirm with Return.

3 Press the scroll-up key eight times and confirm with Return.

4 Confirm the last LED with Return for 0.

Pos: 118 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Pr üfs tand ohn e Waa ge LK W RECO 1 ( Bild er) @ 21\mod_1277196719094_0.docx @ 859383 @ @ 1

5 The MAH-DOT changes to the Print symbol.

BA022301-en

Page 36

36

5.9

Option Drive Control

A

Pos: 119 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/O/ Übers chrift 1.1: Op tion Drive C ontrol @ 21\mod_1277881917245_75.docx @ 862223 @ 2 @ 1

Pos: 120 /Tec hnis che D okum enta tion/ Brem spr üftech nik/M BT-S ERIE S/ 0223 01 M BT LON /BA/ Inh alt : 02 23 B edie nu ng Dr iv e C ontr ol (B ilde r) @ 2 1\mod _12 77290 5195 24_0.d ocx @ 860 353 @ @ 1

A

Pos: 121 /Te ch nisc he D okum enta tion/ Bremsp rüfte chnik/M BT- SERIES/022301 MBT LON/BA/Inhalt: 0223 Bedienung der Option Drive Control (Text) @ 27\mod_1327401257433_75.docx @ 1514373 @ @ 1

1 Drive onto the roller set with a 4WD vehicle.

2 After 2-time start-up monitoring the test stand switches automatically to DCO.

The DCO lamp starts flashing. The left roller starts automatically in driving

direction, the right-hand one in the opposite direction.

3 Brake with connected pedal force meter to max. brake force or slip. Release

brake. The display shows the driving direction of the wheels (Fig. A).

B

B

4 Now the right-hand wheel starts automatically in driving direction, the left-hand

wheel in opposite direction. Brake to the same pedal force of the left-hand

wheel. Once pedal force is reached, release brake. The rollers stop without re-

starting. The display shows the wheels’ driving direction. Pointers go to the

maximum value respectively. Now store at the respective axle using the remote

control. Change to the next axle.

5 Test the other axle as described above.

Store using keys F9 –F11.

• Front axle: F9 (I)

• Parking brake: F10 (J)

• Rear axle: F11 (K)

After the measurements an “Auto OFF“ must be done.

F12 (L)! (not necessary if evaluation is done via PC-LON BASIC Program)

BA022301-en

Page 37

37

Special Features

• When exiting the roller set, the test stand returns automatically to Standard

mode.

• Repeat measurement: After measurement of the left-hand and right-hand

wheels the rollers are at a standstill. Now storage is possible, or the measure-

ment can be repeated with the green key, or the Parking brake can be tested.

• Outside of the roller set the DCO can be activated with “Auto Off“ key (L) and

the arrow-up key (Y). Confirm with the star key (M). DCO lamp starts flashing.

This saves from doing the start-up monitoring twice in the roller set.

• After 3 start-up monitorings the rollers stop and the tester changes from Drive

Control Mode to manual standard mode. Motors can be started individually via

Pos: 122 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

the remote control. The display shows DC as optical help (Fig. B).

BA022301-en

Page 38

38

5.10

Noise Detection with IFB / FFB / RECO 1

Activation via IFB / FFB

unoccupied

Activation via RECO 1

Pos: 123 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/G/ Übers chrift 1.1: Ger äuschs uche m it IF B / FFB / REC O 1 @ 21\mod _127 78820 21473 _75.d ocx @ 86 2253 @ 2 @ 1

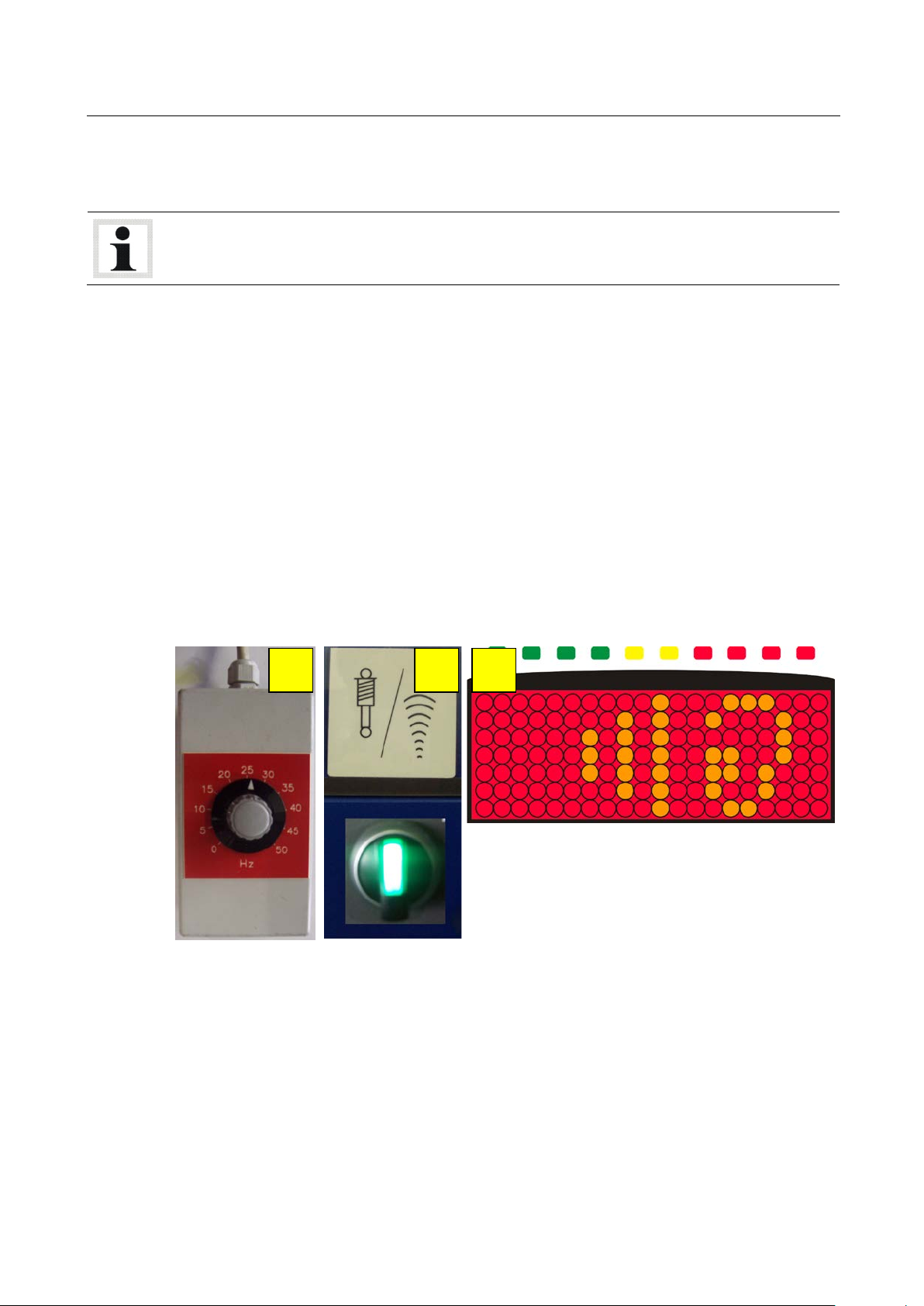

Pos: 124 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SERI ES/ 0223 01 MB T LON /BA/I nha lt: 0223 B edie nung Gerä uschs uche mit IFB / FFB (Tex t) @ 27\m od_ 132 74023 411 18_75.docx @ 1514417 @ @ 1

Activation is only possible with unoccupied tester.

1 Press Auto-Off key (Display shows END).

2 Select Noise Detection symbol (C) with the arrow key and confirm with the star

key.

3 Drive onto the shock absorber tester.

4 Start the respective side with motor On left / right.

5 The motor RPM can be regulated using the potentiometer (A). Only when

rotary switch on the tester is set to Noise Detection.

6 Press one of the red keys for motor stop.

7 Noise detection can be quit using the pound key (#) with

stand.

• The switch on the tester (B) must be set to Noise Detection for RPM regulation

Pos: 125 /Te ch nisc he D ok umen tati on/Br emsp rüfte chnik /M BT-SERI ES/ 0223 01 MB T LON /BA/I nha lt: 0223 B edie nung Gerä uschs uche mit IFB / FFB / REC O 1 (Bild er) @ 2 1\mod _1277 3622 25072_ 0.doc x @ 86048 3 @ @ 1

Pos: 126 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Be die nung Ger äu schs uc he m it RE CO 1 ( Text ) @ 27\mod_1327402435941_75.docx @ 1515061 @ @ 1

of the motors. Otherwise no RPM regulation is possible.

A B C

test

BA022301-en

1 Press the Motor Off key.

2 Select Noise Detection symbol (C) using the arrow key. Confirm with Return.

3 Drive onto shock absorber tester.

4 Start the respective side with Motor ON left / right.

5 The motor RPM can be regulated using the potentiometer (A). Only when

rotary switch on the test stand is set to Noise Detection.

6 Press the motor OFF key for motor stop.

Page 39

39

unoccupied

7 Noise detection can be quit using Motor OFF key with

• The switch (B) on the test stand must be set to Noise Detetcion for the RPM

Pos: 127 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

regulation of the motors. Otherwise no RPM regulation is possible.

test stand.

BA022301-en

Page 40

40

5.11

MSD 3000

Test

Pos: 128 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schriften 1.1/M/Überschrift 1.1: MSD 3000 @ 24\mod_13064 88669 901_0. docx @ 1 01318 3 @ 2 @ 1

Pos: 129 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SERIES/022301 MBT LON/BA/Inhalt: 0223 Bedienung MSD 3000 (Bilder) @ 21\mod_12773671 61654_ 0.doc x @ 860633 @ @ 1

A

B C

D E

Pos: 130 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LON/BA/Inhalt: 0223 Bedienung MSD 3000 (Text) @ 27\mod_1327402629870_75.docx @ 1515105 @ @ 1

1 Drive onto the MSD (A). Weight measurement (B)!

2 Both sides start up simultaneously (C).

3 After measurement completion the pointers move to test value 0 to 0.3 D. If the

test value is above 0.3, the pointers move slightly above 0.3 D.

• The display changes between the unit (D) and the difference (E) in % until the

tester is exited. The differential value is based on the left and right measurement

value.

• If the measurement value of a wheel is under 0.13 D, or if the difference is

> 29%, then an additional single wheel measurement is done of each wheel.

The display flashes during the single wheel measurement (C).

BA022301-en

4 Measurement values are automatically stored without remote control.

With 2 additional AN5-Displays the wheel weight is displayed during the measurement procedure, and the measurement value 0…0.3 is displayed after completed measurement.

Page 41

41

Printing and Re-display of the Measurement Values

not

(Re-display of the measurement values is

control.)

• The print program is started with F7. Enter Program 1 and confirm with star key

(*). Printout follows.

• Re-display of the shock absorber with Shift + Axle number + key F10.

If AN5 displays are present, press the F10 key again to switch to the wheel

weight.

• Re-display of the side-slip tester with Shift + Axle number + key F9 if available.

• New vehicle (NEW) with pound key # and star key * (Delete all measurement

Pos: 131 /-----Format-----/MA NUELLE R UMBR UCH Seitenum bruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

values).

possible with the RECO remote

BA022301-en

Page 42

42

5.12

Clock Changing between Daylight Saving Time/Standard Time

One Hour Forward

one hour forward

One Hour Back

one hour back

Pos: 132 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/ U/Übersc hrift 1.1: Um stellu ng S ommerzei t/Norm alze it @ 21\mod_ 12778 8175 6766_ 75.d ocx @ 862 193 @ 2 @ 1

Pos: 133 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES/ 02230 1 MBT LON/BA/I nhalt: 02 23 Ums tellun g Somme r-/W interz eit @ 2 7\mod_ 1327 402 73058 0_75.docx @ 1515149 @ @ 1

1 Turn on the main switch of the tester by holding the power-on key down and

waiting until the left-hand pointer (small measurement range 0-8 kN) moves to

3.2 (kN) Now release the power-on key.

2 Press the Start key twice so that the pointer moves to 4.2 (kN) (small

measurement range left).

3 Now press the Return key (↵ or *) on the remote control.

4 The clock has now been put

header is printed out with the new time.

5 Switch the main switch off and on again. Now the tester is ready for operation

with the new time.

1 Turn on the main switch of the tester by holding the power-on key down and

waiting until the left-hand pointer (small measurement range 0-8 kN) moves to

3.2 (kN). Now release the power-on key.

2 Press the start key three times so that the pointer moves to 4.4 (kN) (small

measurement range left).

3 Now press the Return key (↵ or *) on the remote control.

4 The clock has now been put

header is printed out with the new time.

5 Switch the main switch off and on again. Now the tester is ready for operation

with the new time.

The changeover only takes place on the control PCB and is not shown on the

simultaneous display.

Pos: 134 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

. As confirmation the customer

. As confirmation the customer

BA022301-en

Page 43

43

5.13

Test Procedure with Software

Button

Key

Assignment

Pos: 135 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/P/ Übers chrift 1.1: Pr üfabla uf mit Softw are @ 9\m od_1207903111456_75.docx @ 184601 @ 2 @ 1

Pos: 136 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ M BT-SE RIES /02 230 1 MB T LO N/ BA/I nha lt: 022 3 Pr üfa bla uf m it LO N BASIC @ 27\mod_1327402841773_75.docx @ 1515193 @ @ 1

F2 Previous page

F3 Next page

F4 Start page (main menu)

Page ↑

One level up

Page ↓ One level down

F1 Start help

F12 Start printout

Esc Exit page

► When the green LED in the main

menu lights up, the system is ready

for testing.

BA022301-en

Page 44

44

1 Conduct a brake test for front axle, parking brake and rear axle.

Selection between digital and analog

display:

• Main menu

• <F7> System

• <2> Settings

• <K> Softdips miscellaneous

• <22> IWST

► After test completion this screen ap-

pears.

BA022301-en

Page 45

45

2a Use <1> to load an existing data rec-

ord.

3a Use <5> to store the measurement

intermediately, e. g. if you want to re-

peat the test later.

2b Use <6> to create a new data record.

3b Use <4> to finish and save the

measurement.

4 Use <F12> to print out the test re-

sults.

5 To exit the program, press <Esc> in

the main menu and confirm with

<F2>.

Pos: 137 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 46

46

6

Maintenance

6.1

Annual Inspection

12 (twelve) months

6.2

Care Instructions

6.3

Spare Parts

Pos: 138 /Te ch nisc he D ok umen tation/A lle G eräte/ Überschr iften/Üb erschr iften 1/I /Über schrif t 1: Ins tandh altung @ 28\mod_1332159812536_75.docx @ 1565908 @ 1 @ 1

Pos: 139 /Technische Dokum entati on/Alle G eräte/I nha lte/Warn ung!/Inh alt: War nun g - Haup tschal ter aus b ei Ins tand halt ung_ 12p t @ 26\mod_1324465229892_75.docx @ 1140563 @ @ 1

Danger! Electric shock hazard!

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Pos: 140 /Te ch nisc he D ok umen tati on/A ll e Ger äte/Überschr iften/Üb erschrifte n 1.1/J/Überschr ift 1.1: Jährli che Überprüfun g @ 28\mod_1332230089694_75.docx @ 1566204 @ 2 @ 1

Pos: 141 /Tech nische Dok umen tati on/A lle G eräte/ Inha lte/ Info!/I nha lt: Inf o - Jähr liche Überpr üfung_ 12p t @ 25\mod _132 446 048 107 5_ 75.d ocx @ 1 139 412 @ @ 1

• The maintenance interval prescribed by the manufacturer is

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

• Maintenance work shall be done only by authorized and trained service techni-

cians provided by the manufacturer, licensed dealers or service partners.

• In case of non-compliance the manufacturer's warranty becomes void.

Pos: 142 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/P/ Übers chrift 1.1: Pf legehi nweise @ 15\mod_1245912234854_75.docx @ 395780 @ 2 @ 1

.

Pos: 143 /Tech nische Dok umen tati on/A lle G eräte/ Inha lte/ Inhalt : Pf lege hinwe ise - Alle Geräte_ 12pt @ 26\mod_1324468886116_75.docx @ 1141252 @ @ 1

• Periodically clean the equipment and treat it with a care product.

• Repair damage to the paintwork immediately to prevent corrosion.

• Usage of caustic cleaning agents or high pressure and steam jet cleaners may

Pos: 144 /Tech nische Dok umen tati on/A lle G eräte/ Inha lte/ Info!/I nha lt: Inf o - Pfle gehi nweise_ 12p t @ 26\mod_1324461215655_75.docx @ 1139602 @ @ 1

lead to equipment damage.

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment!

Pos: 145 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/E/ Über schrift 1.1: Er satz teile @ 18\ mod_1255596847002_75.docx @ 474414 @ 2 @ 1

Pos: 146 /Technische Dokum entati on/Alle G eräte/I nha lte/Inha lt: Ersatz teile - Alle Ger äte_12pt @ 26\mod_1324468768120_75.docx @ 1141219 @ @ 1

To ensure safe and reliable operation, only use original spare parts supplied by the

Pos: 147 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

equipment manufacturer.

BA022301-en

Page 47

47

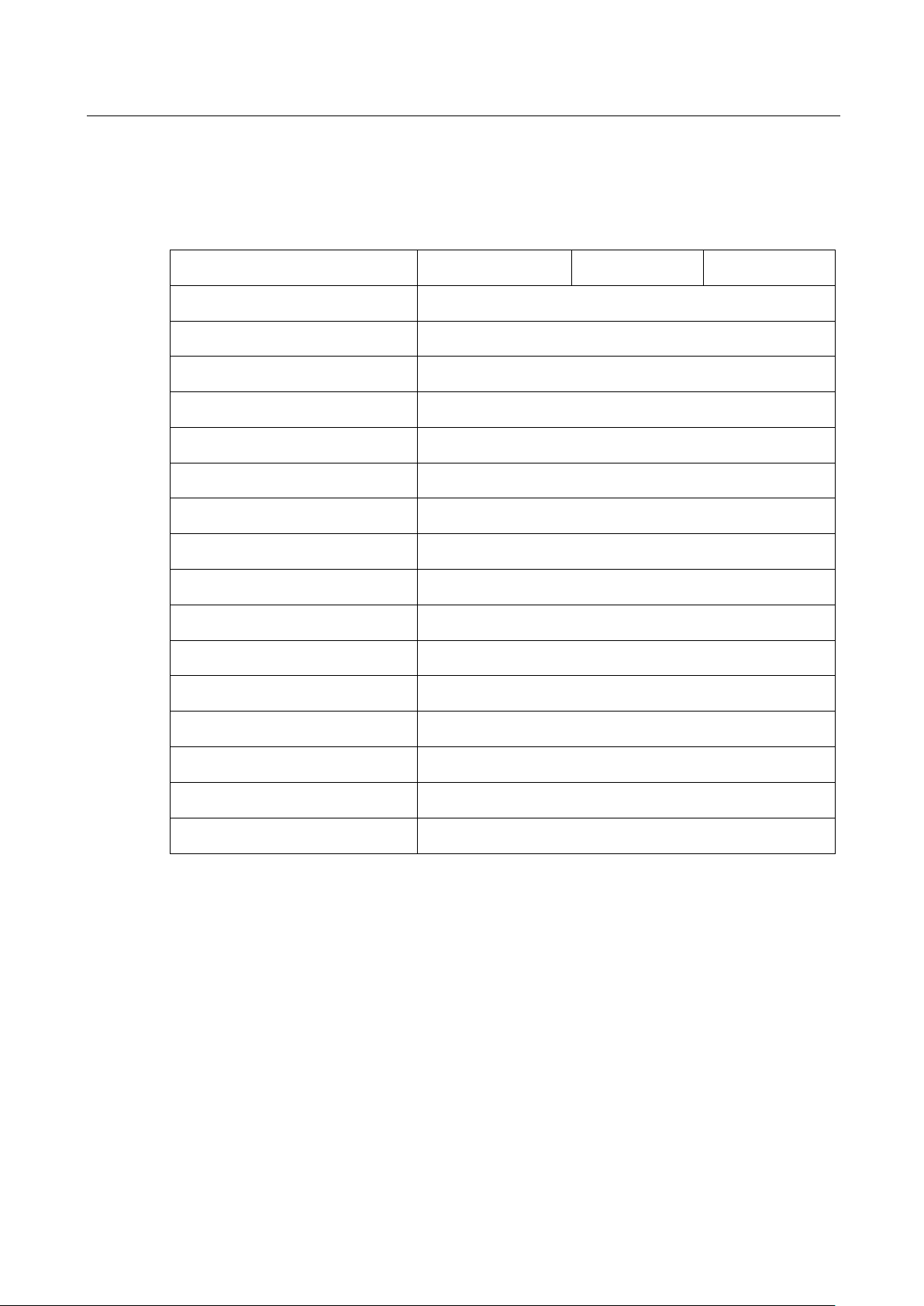

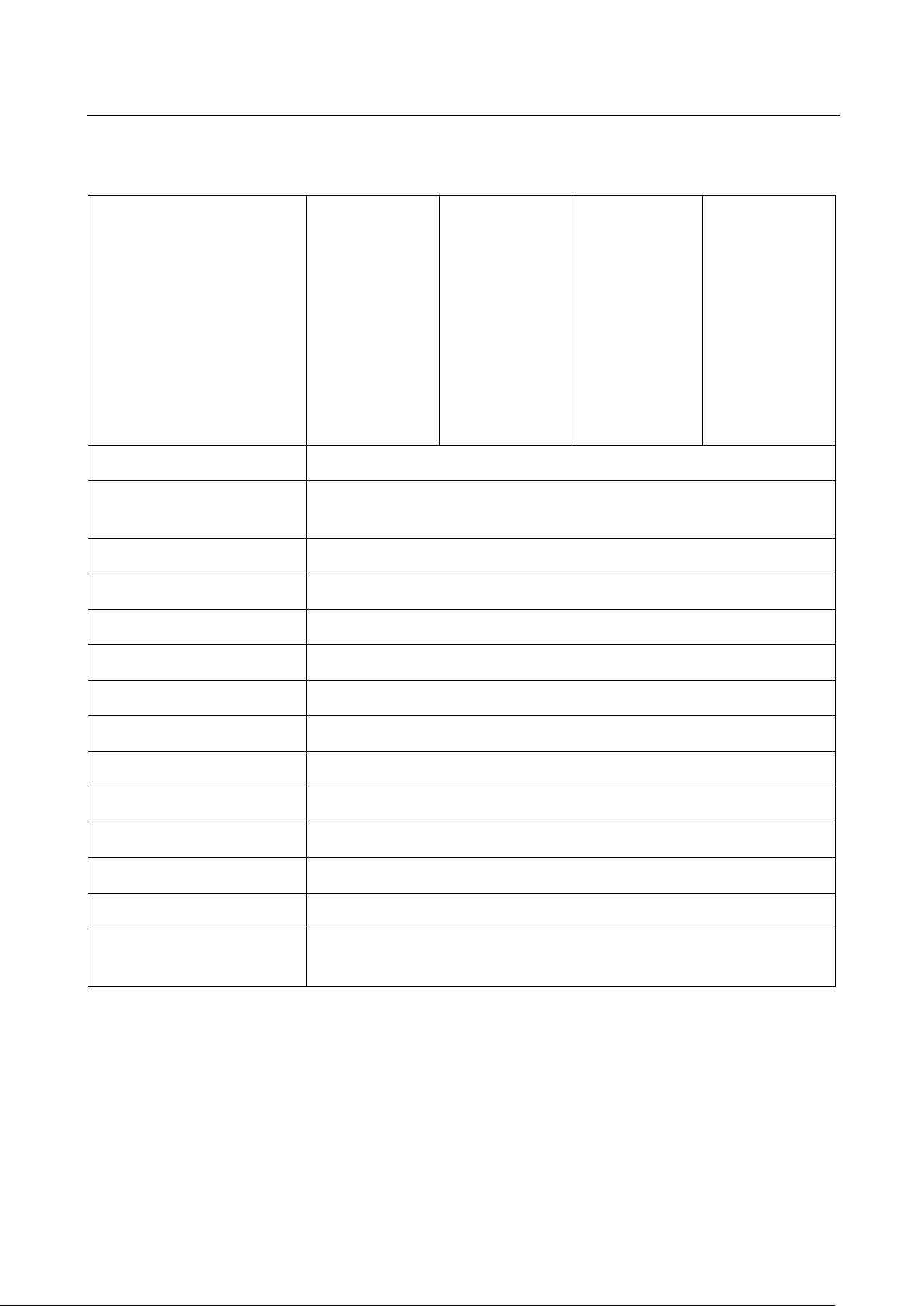

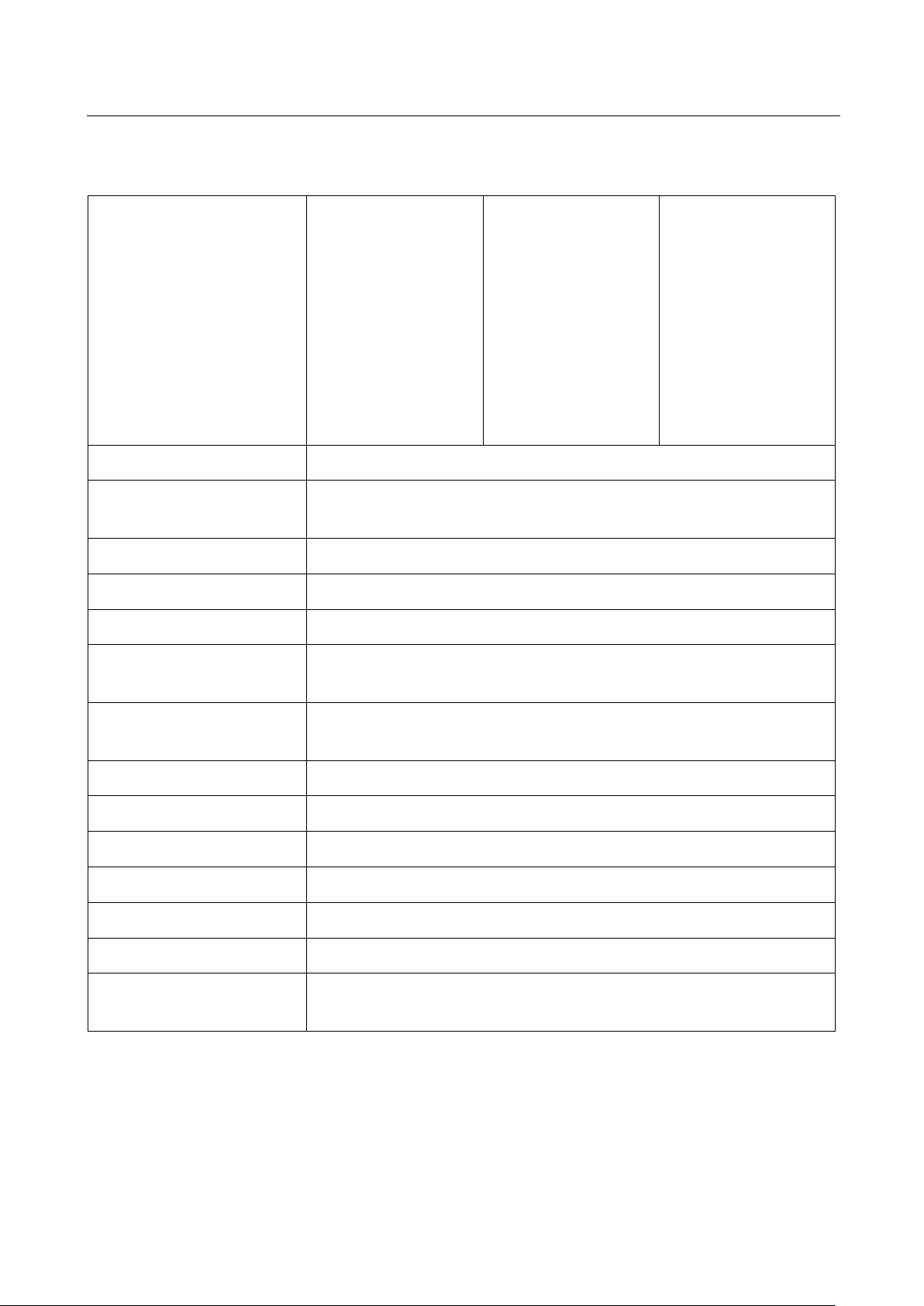

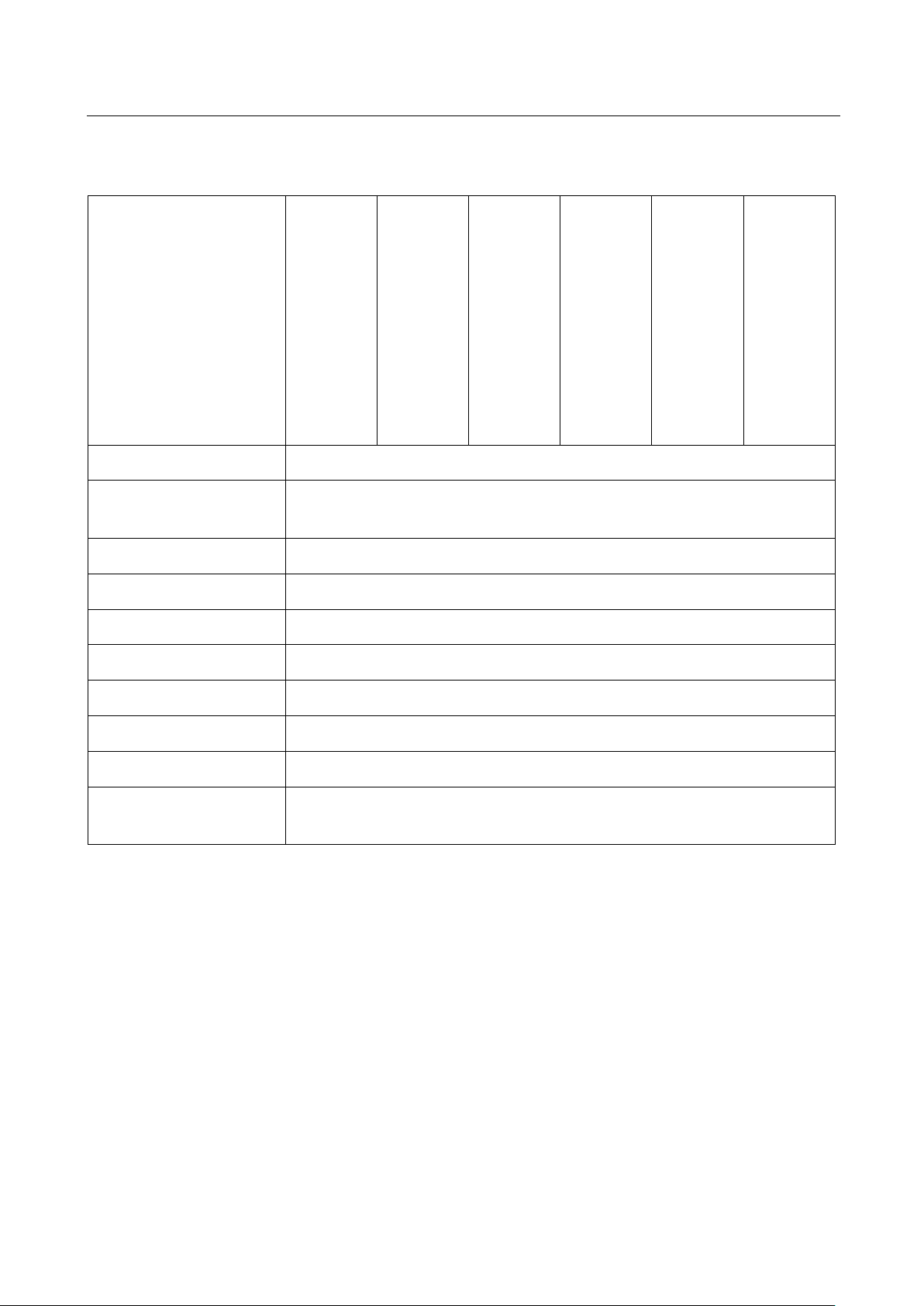

6.4

Chain Drive Maintenance: Cleaning, Retensioning, Lubricating

Cleaning the Chains

Retensioning the Chains

Brake tester

model

Thread

Strength

Tightening

torque

Position

Required for chain

tensioning?

Pos: 148 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/I/ Über schrift 1.1: I nstandh altung d es Ket tentrieb s: R einigen, N achsp annen, Schmi eren @ 36\mod_1394630342377_75.docx @ 1918730 @ 2 @ 1

Pos: 149 /Te ch nisc he D ok umen tati on/A ll e Ger äte/I nha lte/I nfo!/I nha lt: Inf o - W artu ngsin terva ll: Mona tlich _12p t @ 26\mod_1324463913433_75.docx @ 1140268 @ @ 1

Pos: 150 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh alte/I nhal t: 0 200 Kette n ins tand ha lten E in leitu ng_1 2pt @ 3 3\mod_1374065936693_75.docx @ 1809475 @ @ 1

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Remove the roller set covers from above the chains, reinstall before restarting the

Pos: 151 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh alte/I nhalt: 0200 Kette n rein igen_1 2pt @ 33\mod_1374064814451_75.docx @ 1809387 @ @ 1

brake tester.

The chains can normally be cleaned using a cloth or brush, stubborn dirt can be

removed with petroleum solvent or benzine. Do not use pickles or acids! Reapply

a new anticorrosive film immediately after using degreasing agents (see section

Pos: 152 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh alte/ Inhal t: 0 200 Kette n nac hspan ne n_12pt @ 3 3\mod_1374065445290_75.docx @ 1809431 @ @ 1

"Greasing the Chains").

Check the chain slack: the chain should be movable by hand approx. 5 mm up

and down. If the chain needs retensioning, proceed as follows:

• Open the fastening screws.

• Adjust the chain tension using the tensioning screw.

Maintenance interval: Monthly

• Tighten the fastening screws (see table for torque figures).

Pos: 153 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar chiv -/- Br ems pr üfte chnik A lle -/Inh alte/In halt: 0200 Ke tten nac hspanne n - Anzu gsmom ente @ 3 4\mod_1378969980518_75.docx @ 1825309 @ @ 1

• Recheck the chain slack.

MBT

1xxx/2xxx/3xxx

MBT 4xxx

MBT 5xxx

MBT 6xxx/7xxx

MBT 7xxx

M10 8.8 50 Nm Running roller yes

M16 8.8 120 Nm Motor mount yes

M18 8.8 350 Nm Running roller yes

M20 8.8 350 Nm Motor mount only for RS1

M16 8.8 220 Nm Running roller no

M18 8.8 350 Nm Motor mount yes

M18 8.8 350 Nm Running roller yes

M20 8.8 350 Nm Motor mount only for RS1 + RS3

M18 8.8 500 Nm

Raised running

roller

yes

M27 8.8 500 Nm Motor mount 3:4 no

Pos: 154 /-----F orm at-----/ MANUE LLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 48

48

Lubricating the Chains

Important: The lubricant must contact the chain links!

Pos: 155 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inhal te/Inhalt: 0200 Ketten schmier en_12pt @ 33\mod_1374063619890_75.docx @ 1809299 @ @ 1

The service lifetime of the chains directly depends on correct lubrication. Provided

that the lubricating film is continuously maintained, chain wear can be reduced to

a minimum

Recommended lubricant: LongLub adhesive lubricant (MAHA part # 35 1020)

• Lubricate the chain over its entire length while turning over the rollers by hand.

Pos: 156 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inhal te/In halt: 0 200 Ke tten schm ieren (Bild) @ 33\ mod_1374060263983_0.docx @ 1809079 @ @ 1

Pos: 157 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 49

49

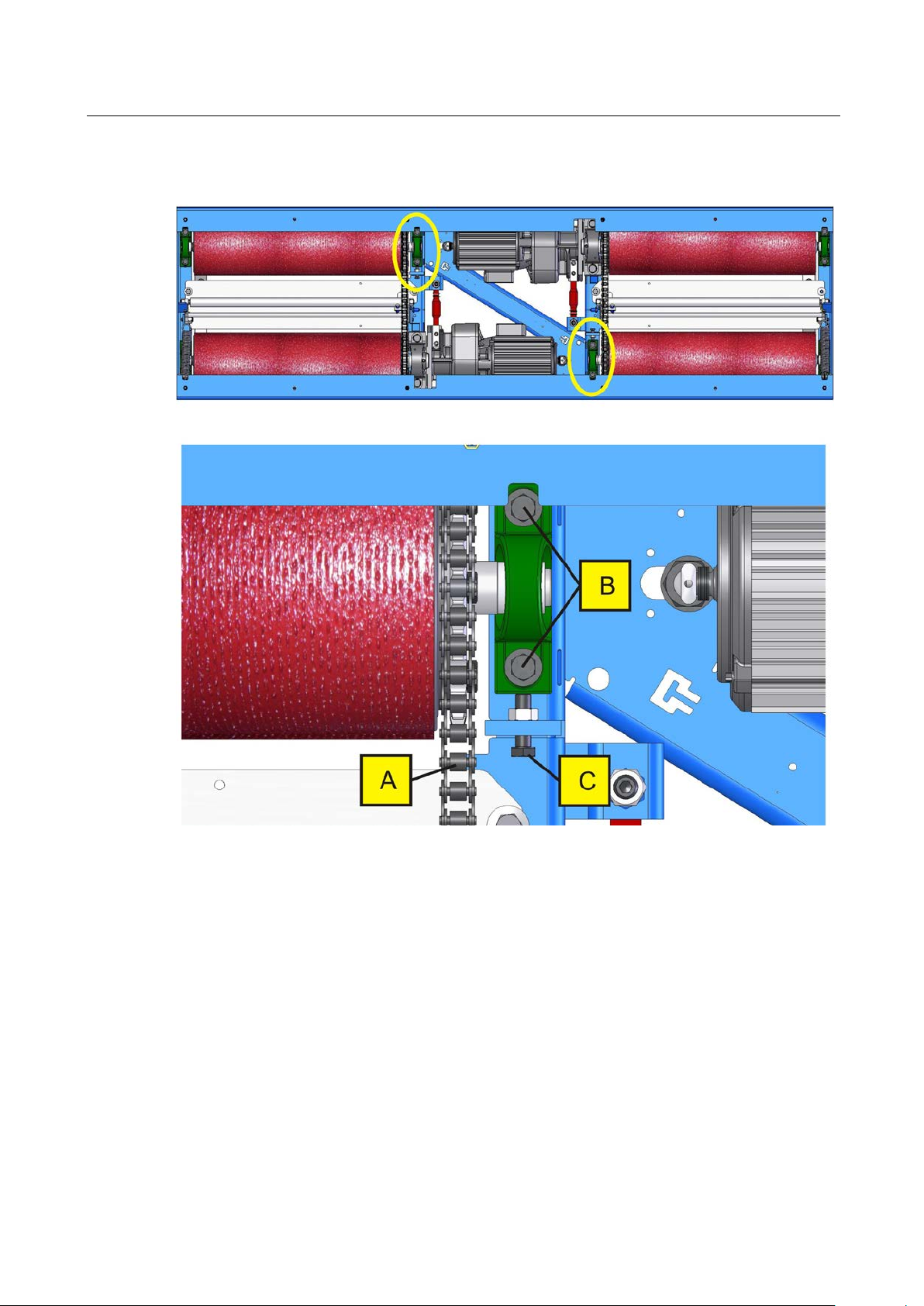

► M BT 3x00

A

B

C

Pos: 158 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n ohne N umm erierung/ Übers chrift: > MBT 3x00 @ 23\mod_1297073990557_0.docx @ 971184 @ @ 1

Pos: 159 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh alte/ Inhal t: I nst Ke ttens pa nnun g (Bi lder) M BT 3x00 @ 1 8\mod_ 12 54727 296 554_ 0.d ocx @ 456 256 @ @ 1

Pos: 160 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh alte/ Inhal t: 0 200 Kette n nac hspan ne n (Leg ende) @ 3 8\mod_1402493705606_75.docx @ 2023775 @ @ 1

Chain

Pos: 161 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Fastening screws

Tensioning screw

BA022301-en

Page 50

50

► M BT 4x00/7x00

A

B

C

B

Pos: 162 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n ohne N umm erieru ng/Übers chrift: > M BT 4x 00/7x0 0 @ 38\mod _14 04283 3952 54_0.d ocx @ 204 9124 @ @ 1

Pos: 163 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh al te/I nhal t: Inst Ke ttens pa nnun g ( Bild er) MB T 4x 00/ 7x0 0 @ 18\mod_1254730465742_0.docx @ 456523 @ @ 1

C

B

Pos: 164 /Tech nis che D okume nta tion/ Brems prüf tech nik/- Arch iv -/- B rem spr üfte ch nik A lle -/Inh alte/ In halt: 0200 Kette n nac hsp anne n (Leg ende) @ 38\mod_1402493705606_75.docx @ 2023775 @ @ 1

Chain

Pos: 165 /-----F ormat -----/M ANUELLE R UMBR UCH Seitenum bruch @ 0\ mod_1134403577687_0.docx @ 1277 @ @ 1

A

Fastening screws

Tensioning screw

BA022301-en

Page 51

51

6.5

Greasing the Sensor Roller Hinges

► M BT 3x00

Pos: 166 /Technische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n 1.1/ T/Übersc hrift 1.1: Tas trolle nschar niere sc hmier en @ 36\mod_1394630469531_75.docx @ 1918774 @ 2 @ 1

Pos: 167 /Tech nische Dok umen tati on/A lle G eräte/ Inha lte/ Info!/I nha lt: Inf o - Wart ungs in terv all: 20 0 h / 12 M on ate _12p t @ 26\mod_1324463609793_75.docx @ 1140170 @ @ 1

Pos: 168 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inh al te/I nhal t: Inst Tas tro llen (T ext) M BT 3x 00/ 4x00/ 7x 00_ 12p t @ 26\mod_1326874914374_75.docx @ 1511547 @ @ 1

Grease the sensor roller hinges every 200 (two hundred) operating hours or once

annually.

1 Remove the cover plates from the roller set.

2 Treat the greasing points (D) using a spray lubricant. Move the sensor roller up

and down.

Pos: 169 /Tech nische Dokum entati on/Alle G eräte/ Übers chrifte n/Über schrifte n ohn e Numm erieru ng/Über schrift: > M BT 3x00 @ 23\mod_1297073990557_0.docx @ 971184 @ @ 1

Pos: 170 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ - Ar ch iv -/- Br ems pr üfte chn ik A lle -/Inhalte/I nhalt: Inst T astroll en (B ilder) M BT 3x0 0 @ 18\m od_1254732674783_0.docx @ 456550 @ @ 1

3 Reinstall the cover plates to the roller set.

Maintenance interval: 200 hours / 12 months

Pos: 171 /-----F orm at-----/M ANUELLE R UMBR UCH Seite numbru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

BA022301-en

Page 52

52

► M BT 4x00/7x00

6.6

Troubleshooting