Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

MBT 2100

Roller Brake Tester

Original Operating Instructions

BA022401-en

Pos: 1 /-----For mat---- -/MAN UELLER UM BRUCH Sei tenumb ruch @ 0\mod _11 34403 5776 87_0.d ocx @ 127 7 @ @ 1

Page 2

2

BA022401-en

Pos: 2 /-----Forma t-----/Inhaltsverzeichnis - 3 Ebenen @ 5\mod_1168867441046_ 75.docx @ 72920 @ @ 1

Contents

1 Safety ...................................................................................................................... 5

1.1 Introduction ......................................................................................................................................... 5

1.2 Symbols .............................................................................................................................................. 5

1.3 Intended Use ....................................................................................................................................... 5

1.4 Safety Instructions for Installation and Initial Operation ........................................................................ 5

1.5 Safety Instructions for Operation ......................................................................................................... 6

1.6 Danger Zone ....................................................................................................................................... 7

1.7 Safety Instructions for Servicing ........................................................................................................... 7

1.8 Safety Features ................................................................................................................................... 7

1.9 Accessories ......................................................................................................................................... 8

1.10 What to Do in the Event of an Accident ............................................................................................... 8

2 Description ............................................................................................................. 10

2.1 General Information ........................................................................................................................... 10

2.2 Specifications .................................................................................................................................... 15

3 Operation ............................................................................................................... 16

3.1 Display .............................................................................................................................................. 16

3.2 Remote Control ................................................................................................................................. 18

3.3 Test Procedure .................................................................................................................................. 20

3.3.1 Standard Mode without Remote Control ........................................................................................... 21

3.3.2 Standard Mode Automatic 4-Wheel Drive Recognition ...................................................................... 22

3.3.3 Standard Mode Blink Mode ............................................................................................................... 23

3.3.4 Standard Mode Reco 1-Procedure ................................................................................................... 25

3.3.5 Standard Mode Reco 1-4-Wheel Drive .............................................................................................. 27

3.3.6 Standard Mode Motorcycle Procedure .............................................................................................. 29

3.3.7 Standard IFB Mode Motorcycle ......................................................................................................... 31

3.3.8 Standard IFB Mode with 4-Wheel Drive ............................................................................................. 33

3.3.9 Standard IFB Mode Procedure .......................................................................................................... 35

3.3.10 NL Mode with IFB.............................................................................................................................. 37

3.3.11 NL Mode with Reco 1 ....................................................................................................................... 39

3.3.12 NL Mode without Remote Control ..................................................................................................... 41

3.3.13 NL Mode Wheel Circumference ......................................................................................................... 42

3.4 Deceleration Chart ............................................................................................................................. 43

4 Maintenance .......................................................................................................... 44

4.1 Annual Inspection .............................................................................................................................. 44

4.2 Maintenance by the Operator ............................................................................................................ 44

4.2.1 Checking the Chain Tension .............................................................................................................. 44

4.2.2 Greasing the Sensor Roller Hinges .................................................................................................... 46

4.3 Error Codes ....................................................................................................................................... 47

4.4 Care Instructions ............................................................................................................................... 47

4.5 Spare Parts ....................................................................................................................................... 47

Page 3

3

BA022401-en

5 Dismantling ............................................................................................................ 48

6 Contents of the Declaration of Conformity .............................................................. 48

7 Company Information ............................................................................................. 49

Pos: 3 /-----Forma t-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mo d_1134403577687_0.do cx @ 1277 @ @ 1

Page 4

4

BA022401-en

Pos: 4 /-----Forma t-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mo d_1134403577687_0.do cx @ 1277 @ @ 1

Page 5

5

BA022401-en

Pos: 5 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1/S/Überschrift 1: Sicherheit @ 6\mod_1174482399906_75.docx @ 76962 @ 1 @ 1

1

Safety

Pos: 6 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Einführung @ 6\mod_1174482219062_75.docx @ 76793 @ 2 @ 1

1.1

Introduction

Pos: 7 /Technische Dokumentation/Alle Geräte/Inhalte/Sicherheit/Inhalt: Einführung Sicherheit_12pt @ 25\mod_1324455248318_75.docx @ 1138886 @ @ 1

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

safety instructions are not covered by the product liability regulations.

Pos: 8 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Symbole @ 6\mod_1174482270875_75.docx @ 76865 @ 2 @ 1

1.2

Symbols

Pos: 9 /Technische Dokumentation/Alle Geräte/Inhalte/Sicherheit/Inhalt: Symbole Sicherheit_12pt @ 25\mod_1324456650897_75.docx @ 1139046 @ @ 1

Important safety instructions. Failure to comply with instructions could result in

personal injury or property damage.

Important information.

Pos: 10 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/B/Überschrift 1.1: Bestimmungsgemäßer Gebrauch @ 6\mod_1176734022203_75.docx @ 88746 @ 2 @ 1

1.3

Intended Use

Pos: 11 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Bestimmungsgemäßer Gebrauch BPS_12pt @ 26\mod_1326368132160_75.docx @ 1504745 @ @ 1

This equipment is to be used exclusively for the brake testing of motor vehicles.

Observe the rated axle load.

The equipment shall not be modified without the express written consent of the

manufacturer. In case of non-compliance the declaration of conformity becomes

void.

Pos: 12 /Technische Dokumentation/Alle Geräte/Inhalte/Sicherheit/Inhalt: Bestimmungswidriger Gebrauch allg_12pt @ 25\mod_1324455015938_75.docx @ 1138843 @ @ 1

Any use other than described is inappropriate.

Pos: 13 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften für Installation und Erstinbetriebnahme @ 24\mod_1310565059431_75.docx @ 1023543 @ 2 @ 1

1.4

Safety Instructions for Installation and Initial Operation

Pos: 14 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Sicherheitsvorschriften für die Inbetriebnahme BPS_12pt @ 26\mod_1326368324234_75.docx @ 1504789 @ @ 1

• The system shall only be commissioned by MAHA service technicians or

authorized service partners.

• All parts of the electrical equipment must be protected from moisture and

wetness.

• The system shall not be installed and operated in hazardous locations or wash

halls.

• The operator must provide for optional safeguards (e.g. warn lamps, barriers,

etc.) depending on local conditions.

• Wear safety shoes and gloves.

• Safeguard roller set with suitable means (e.g. cordon chains or strap).

• The display must be installed in a secure area and folded into the wall when not

in use (wall hinges optionally available).

Page 6

6

BA022401-en

• When folding the display, grasp it on the edges. Danger of pinching!

• Ensure that a lockable emergency-stop main switch is installed based on

installation instructions before connecting the feed line. Use motor protection

switch and cable cross sections as per specification. Reference in circuit

diagram (standard delivery), nameplate. Fuse max. X.X A (see nameplate).

• The main switch must be provided by the customer and installed on-site. It

must be positioned in direct vicinity to the tester and takes over the emergencystop function.

Pos: 15 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften für den Betrieb @ 6\mod_1174482268953_75.docx @ 76826 @ 2 @ 1

1.5

Safety Instructions for Operation

Pos: 16 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Sicherheitsvorschriften für den Betrieb BPS_12pt @ 26\mod_1326700788796_75.docx @ 1505493 @ @ 1

• The system shall only be operated within its performance limits.

• The system shall only be operated by trained personnel.

• The system and surrounding area must be kept clean.

• Switch off the system when not in use and secure the main switch against

restart with a padlock.

• In emergency situations switch off system with main switch or emergency-stop

switch.

• No persons shall be in the danger zone of the system. Rotating or moving parts

(e.g. test stand rollers) are dangerous.

• Danger of carbon monoxide poisoning with running vehicle engine in closed

rooms. The operator is responsible for providing sufficient air exchange.

• Avoid unnecessary strain on vehicle and tester.

• Drive the vehicle slowly on to the tester.

• Check the danger zone before driving the vehicle onto the tester.

• When the vehicle with the driven axle is on the roller set, exit only with running

roller drive. Exiting with roller drive at standstill can destroy the motors due to

extreme roller acceleration.

• The system shall not be operated without functioning slip monitoring. This can

cause tire damage.

• Never jump start a vehicle with the system. This can lead to equipment

damage.

• No 4 wheel-drive vehicles shall be tested on the standard roller set. Damage to

vehicle and system are possible. When in doubt contact your responsible

service representative.

• The vehicle must be closed during testing. If persons outside of the vehicle are

endangered, use noise protection.

• The operator shall not leave the vehicle during testing.

• No vehicle shall be parked in/on the roller set or on the optional ramps.

Pos: 17 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/G/Überschrift 1.1: Gefahrenzone @ 19\mod_1266938122676_75.docx @ 782826 @ 2 @ 1

Page 7

7

BA022401-en

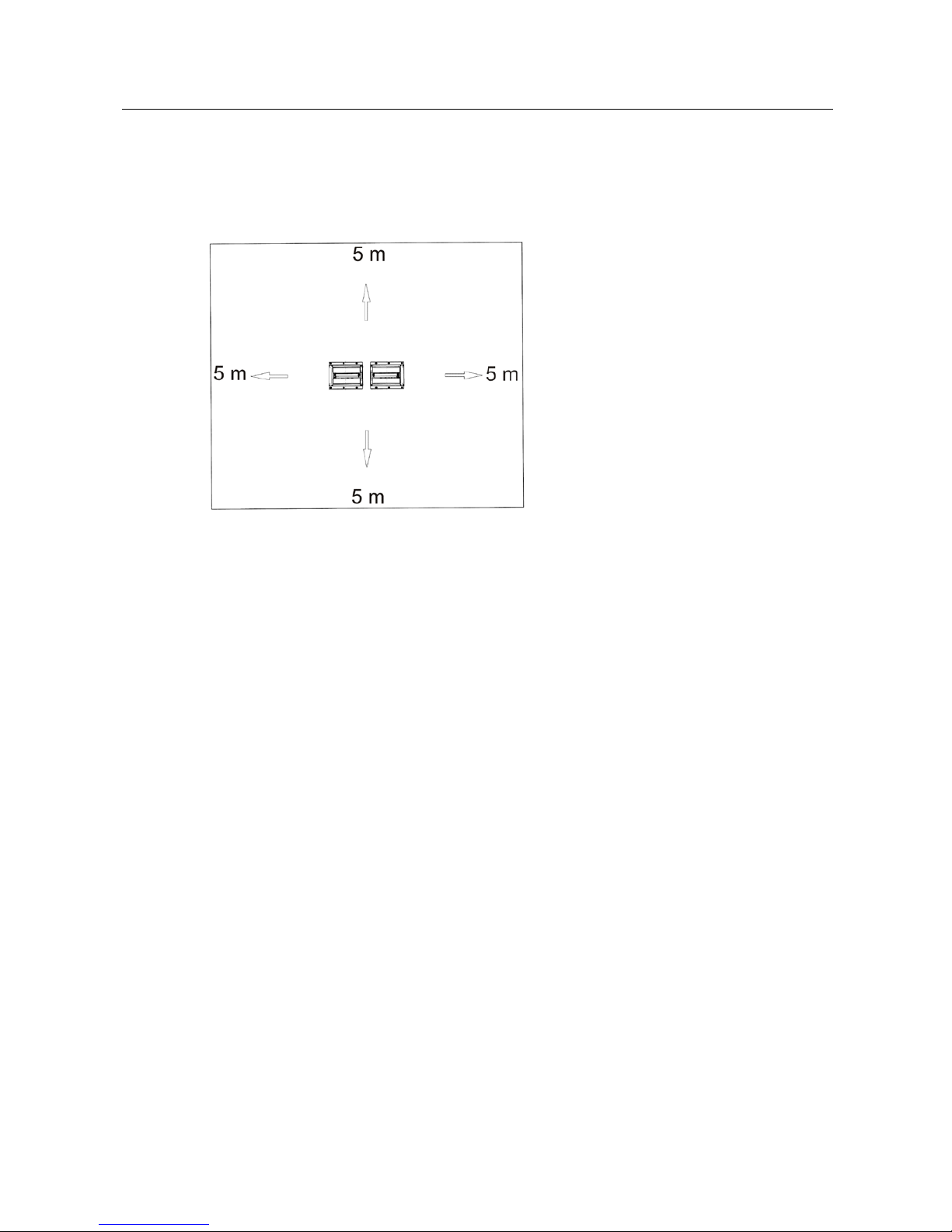

1.6

Danger Zone

Pos: 18 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Gefahrenzone - 5m Abstand (Text) BPS_12pt @ 26\mod_1326700917541_75.docx @ 1505537 @ @ 1

During brake tester operation no persons are allowed in the danger zone:

5 (five) meters

around the roller set in all directions.

Pos: 19 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Gefahrenzone - 5m Abstand (Bild) BPS @ 19\mod_1266938260034_0.docx @ 784017 @ @ 1

Pos: 20 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitsvorschriften für Servicearbeiten @ 6\mod_1174482270640_75.docx @ 76850 @ 2 @ 1

1.7

Safety Instructions for Servicing

Pos: 21 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Sicherheitsvorschriften für Servicearbeiten BPS_12pt @ 26\mod_1326700977270_75.docx @ 1505581 @ @ 1

• Service work shall only be done by MAHA service technicians or authorized

service partners.

• Work on electric parts of the system shall only be done by trained electricians.

• The main switch must be switched off and secured against restart before doing

repair, maintenance and set-up work.

• Fire danger due to rubber abrasion on the roller set. Clean regularly. Remove

abrasion before maintenance work.

• The main switch must be secured and if necessary the motor protection switch

turned off when doing work in the roller set.

• When working on the control cabinet or on the roller sets pay attention to the

heating (optional) or hot parts.

• Immediately turn off the tester when it starts up unintentionally. Contact the

service department.

Pos: 22 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/S/Überschrift 1.1: Sicherheitseinrichtungen @ 6\mod_1174483324765_75.docx @ 77103 @ 2 @ 1

1.8

Safety Features

Pos: 23 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Sicherheitseinrichtungen (Text) BPS_12pt @ 26\mod_1326701513692_75.docx @ 1505625 @ @ 1

The safety features (partly optional) are to be inspected regularly by an authorized

service technician. Official guidelines must be followed at all times.

The equipment

shall not be operated when the safety features are defective!

•

Lockable Main Switch

Serves as normal On and Off switch for the equipment and as emergency switch.

The switch can be padlocked to protect it against unauthorized usage.

•

Emergency Switch

Page 8

8

BA022401-en

Is used for quick switch-off during operation. Interrupts the power supply to the

equipment.

•

Startup Monitoring

Prevents the rollers from starting up in case the wheels are blocked (seized

bearings, jammed brake pads). This feature helps prevent the vehicle tyres from

being damaged.

•

Sensor Rollers

The RPM difference between equipment rollers and sensor rollers determines the

slip. Both sensor rollers must be pushed down in order to start the roller brake

tester.

•

Visual and Audible Warning Devices

These must be positioned at a suitable location and must be easily seen or heard

at all times. In the event that the warning devices are defective, the brake tester

must be shut down until they are fully functional again.

•

Pit Safety

Light barrier or infrared movement sensor. If any person enters the safety area, the

brake tester is switched off.

•

Yellow-Black Marking Tape

The yellow-black marking tape around roller set and pit serves to mark out the

brake tester and nust be replaced if defective. Part # 19 6014 (Ø 38 mm) /

19 6015 (Ø 50 mm).

•

Warning and Information Labels

Warning and information labels are attached to the equipment. These must not be

changed or removed and must be replaced if unreadable (see below for part

numbers).

Pos: 24 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Sicherheit/Inhalt: Sicherheitseinrichtungen/Aufkleber (Bilder) BPS @ 23\mod_1297085082534_0.docx @ 971558 @ @ 1

54 2132 54 2683

Pos: 25 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/Z/Überschrift 1.1: Zubehör @ 7\mod_1197021536541_75.docx @ 136790 @ 2 @ 1

1.9

Accessories

Pos: 26 /Technische Dokumentation/Alle Geräte/Inhalte/Sicherheit/Inhalt: Zubehör_12pt @ 25\mod_1324457135414_75.docx @ 1139114 @ @ 1

The equipment shall be operated only with accessories which have been

approved or permitted by MAHA.

Pos: 27 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/V/Überschrift 1.1: Verhalten bei Unfällen @ 19\mod_1267177245337_75.docx @ 794600 @ 2 @ 1

1.10

What to Do in the Event of an Accident

Pos: 28 /Technische Dokumentation/Alle Geräte/Inhalte/Sicherheit/Inhalt: Verhalten bei Unfällen_12pt @ 34\mod_1381128863435_75.docx @ 1837175 @ @ 1

• The injured person is to be removed from the danger area. Find out where

dressing and bandages are kept. Seek first-aid.

Page 9

9

BA022401-en

• Provide first-aid (stop bleeding, immobilise injured limbs), report the accident

and seal off the accident site.

• Immediately report any accident to your supervisor. Make sure a record is kept

of every occasion first-aid is provided, e.g. in an accident book.

• Remain calm and answer any questions that may arise.

Pos: 29 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 10

10

BA022401-en

Pos: 30 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1/B/Überschrift 1: Beschreibung @ 6\mod_1174482271453_75.docx @ 76889 @ 1 @ 1

2

Description

Pos: 31 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Allgemeines @ 6\mod_1182865005781_75.docx @ 97736 @ 2 @ 1

2.1

General Information

Pos: 32 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Beschreibung Allg @ 28\mod_1333529921514_75.docx @ 1577877 @ @ 1

This brake tester belongs to the group of roller brake testers. This class includes

two different measuring methods to record brake forces:

• the testing of drive torque or

• the testing of drive power

The former is applied in this brake tester. It consists of a proven roller set and an

open-ended electronic system based on a processor board with an integral

operating system.

Pos: 33 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Inhalt: Allgemeines zur Bremsprüfung_12pt @ 27\mod_1327392687866_75.docx @ 1513207 @ @ 1

General Information about Brake Testing

To avoid skidding it is important that the brake forces of the individual wheels of

one axle are the same. Just as important is the minimum brake torque for each

individual wheel, so that when braking no vehicle brake is overburdened.

Consequently, each wheel is tested individually on the brake tester.

For measuring the brake force, a static and a dynamic method are available. Using

the static method the force necessary to rotate a wheel which is positioned on a

plate, with applied brakes is determined. The dynamic method is more practice

orientated - whereby the wheel is brought up to a predetermined RPM by the

motor driven roller set and then the brakes are applied. A sensor roller measures

the wheel revolutions. A comparison of the drive roller RPM to the sensor roller

RPM determines how large the slippage is. For safety reasons, all MAHA brake

testers automatically interrupt the brake test at a slippage of approximately 30%.

The measurement principle is the same for both methods of testing. The drive

motor is supported in a rotary fashion (motor housing not supported); without any

additional support, the drive shaft and the housing would counter rotate when

under load, depending on the force distribution. The additional support consists of

a flexible beam, on which the housing rests. The steel beam bends corresponding

to the torque produced by the motor, which the beam resists. The torque is zero

at the beginning of the static test. With the dynamic test method, the torque is just

high enough to set the drive rollers with the vehicle wheel in motion with the

brakes not applied.

A strain gauge is mounted on the transverse beam which converts the brake force

into a usable electrical value.

For this brake tester the dynamic test method is used. This method ensures the

most accurate measurement. In addition, there is simply no alternative for 4 wheel

drive brake testing.

Vehicles with

One

Driven Axle

Drive the wheel axle to be tested onto the roller set. This will push both sensors

rollers down which measure the RPM of the wheels. Now both drive motors of the

roller set will slowly accelerated to nominal speed turning both vehicle wheels

Page 11

11

BA022401-en

forward. When the drive motors have reached nominal speed a comparison is

made between the nominal drive roller speed and the sensor roller speed in order

to be able, at any time, to switch off the drive motors when a slippage of 30% is

exceeded. (This is to protect the drive motors against overload and the tires

against excessive wear.)

The READY indicator will light up, signaling that the test rig is ready to start the

brake test. During brake tests the vehicle is decelerated to a point, that at least

one sensor roller exceeds 30% slippage and the drive motors are switched off.

4-Wheel Drive Vehicles

On non-permanent 4-wheel drive vehicles the brakes are tested with the 4-wheel

drive switched off, just like vehicles with only one drive axle.

Principle of 4 Wheel Drive

On 4-wheel drive vehicles the torque applied to the drive shaft is evenly distributed

to all four wheels, i.e. a quarter of the total torque will be applied to each wheel.

The same applies for the brake torques that arise when braking. When testing 4

wheel drive vehicles it must therefore be ensured that no brake torque will be

transferred from one vehicle wheel to the other. This is accomplished if no torque

is applied to the drive shaft of the differential during the brake test.

The following example will explain this in detail:

In order to simulate a defective brake, one brake is disabled. Now only one brake

of the axle to be tested is enabled. If the brake test is done on a standard test

stand where the torque is not eliminated from the drive shaft, the same force

applies to the strain gauges of both drive motors, i.e. the same brake torque will

be indicated. This would lead to the false assumption that the brakes are fully

intact. If the test was conducted correctly, no brake torque would be indicated for

the wheel with the disabled brake and the actual brake torque applied to the other

wheel would appear.

If both wheels of the axle to be tested are rotating forward during the brake test,

the vehicle will be lifted out of the test rig, as torque is transferred by the drive

shaft to the wheels of the other vehicle axle. To prevent this, the wheels counter

rotate with the same RPM, one vehicle wheel is driven in forward direction and the

other wheel in reverse direction. This eliminates the torque built-up in the

differential against the drive shaft and transmission of torque to the other vehicle

axle.

Page 12

12

BA022401-en

As the brake characteristics depend on the rotating direction of the wheels (the

brake linings and brake drums are ground in forward direction), only the brake

torque of the wheel rotating in forward direction is measured. For this reason, the

brake test has to be done separately for each wheel.

In order to obtain a reliable comparision between the brake forces of both wheels

of the same axle, the same pedal force will have to be applied at the brake test of

the left and right wheel. To accomplish this, a pedal force meter can be connected

to the vehicle's brake pedal.

It is also possible to measure the current pressure Pm of the hydraulic brake by

means of a pressure sensor.

Testing of various 4-wheel drive types

There are three different types of 4-wheel drives:

a) Disengageable drive shaft leading to the differential

b) Viscous clutch (VC) in the drive shaft leading to the differential

c) Rigid drive shaft between the differentials

a) Disengageable drive shaft leading to the differential

On vehicles equipped with non-permanent 4-wheel drive, the brakes are tested

with the 4-wheel drive switched off, just like vehicles with only one drive axle.

b) Viscous clutch (VC) in the drive shaft leading to the differential

There are two different viscous clutch types. The soft viscous clutch has a

higher torsibility (viscosity) than the hard viscous clutch, therefore no torque is

transferred to the other wheels when the drive shaft rotation is low.

Page 13

13

BA022401-en

As described above, brake tests on 4-wheel drive vehicles are feasible if both

wheels on the same axle counter-rotate at the same speed. As, in practice, the

circumference of the left and right wheel is not exactly the same due to different

tire tread depths and uneven tire pressure, the RPM of the two drive motors is

normally different. Therefore the drive motors must control their speed in order to

obtain the same RPM for both wheels.

Approximately the same speed of the roller set drive motors will be sufficient for a

4-wheel drive vehicle having a soft viscous clutch in the drive shaft as no brake

torque is transferred by the viscous clutch when the drive shaft rotation is low.

Therefore the speed control of the drive motors alone will be sufficient in this

case.

Contrary to the above, when testing the brakes of 4-wheel drive vehicle having a

hard viscous clutch in the drive shaft, both wheels on the same axle must rotate

synchronously during the brake test, as the clutch viscosity is so low that even the

slowest rotation of the drive shaft will transfer brake torque to the other wheels.

c) Rigid drive shaft between the differentials

To perform a brake test on a 4-wheel drive vehicle having a rigid drive shaft, the

wheel rotations must be exactly controlled in such a way that no brake torque

can be transferred by the drive shaft.

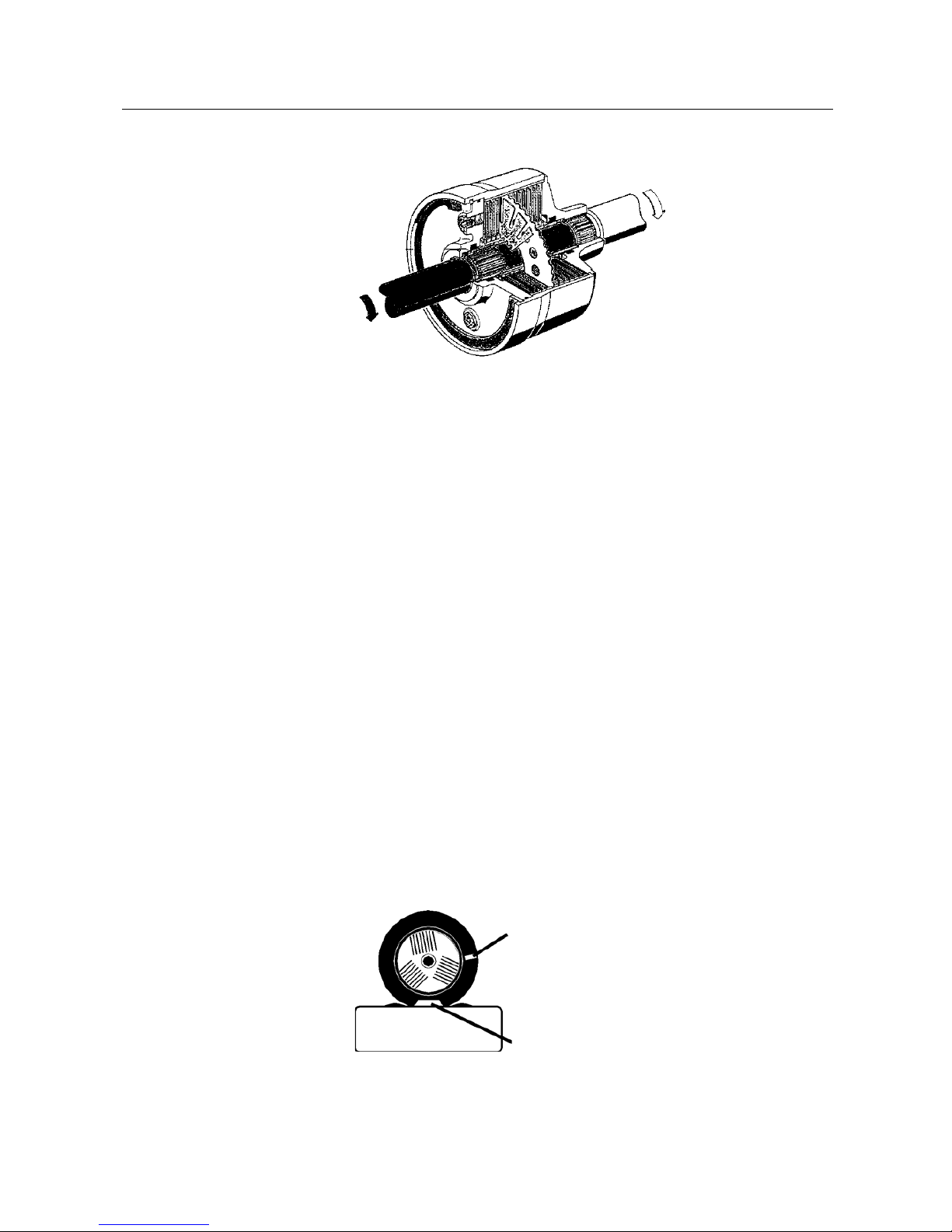

Controlling the synchroneous rotation of the wheels

In order to control synchronous rotation of the wheels, reflector strips are fastened

to the sides of the wheels which trigger a signal via two photo-electric cells,

mounted on the side of the roller set.

Reflector strips

Light barrier

Page 14

14

BA022401-en

On vehicles equipped with a rigid drive shaft or with a hard

viscous clutch the wheels cannot be individually turned. If one

vehicle wheel is turned forward in the roller set, the other wheel

(on the same axle) will be turning backwards in a synchronous

manner. If one wheel is turned slowly in forward or backward

direction, one will note that the other wheel starts turning with a

little delay. This slight delay in following the other wheel to turn is

caused by the gear play (backslash of teeth) inside of the

differential.

Tooth play

To perform a brake test on a 4-wheel drive vehicle having a rigid drive shaft, the

wheel rotation must be controlled in such a way that no brake torque can be

transferred by the drive shaft. This is achieved by staying within the gear play of

the differential during the brake test. The differential will be in a "balance" state.

To be able to effectively use this, the exact backlash of teeth is assessed in a

learning mode:

Initially the left drive motor will be switched on to accelerate the left vehicle wheel

to nominal speed. As the right drive motor is switched off and thus running free,

the left wheel is dragging the right wheel along. The flanks of a tooth in the

differential touch each other on one side. Now the first limit position of gear play is

measured by the reflector strips and the photo electric cells. The procedure is now

reversed, the left drive motor of the roller set is switched off and the right vehicle

wheel is accelerated to nominal speed. This time the left wheel is dragged along

and in the differential the flanks of teeth touch each other on the opposite side.

The second limit position of the gear play will now be measured. Out of the two

measured limit positions the center of gear play is calculated. This "center of gear

play" is used to control the rotation of wheels during the brake test.

During the brake test, both drive motors are accelerated to a speed where the

"center of gear play" is reached. One vehicle wheel will rotate forward, the other in

opposite direction. As soon as the nominal speed is reached by both wheels, and

no brake torque is being transferred to the drive shaft, brake testing may be

started.

As with standard vehicles, the drive motors will be switched off if excessive slip

occurs.

Pos: 34 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 15

15

BA022401-en

Pos: 35 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/T/ Überschrift 1. 1: Technische Daten @ 7\mod_1184075526343_75.docx @ 99711 @ 2 @ 1

2.2

Specifications

Pos: 36 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-S ERIE S/022 401 MBT 2100/BA/ Inhal t: 022 4 Techn ische Da ten @ 54\m od_1530857364702_75.docx @ 3042908 @ @ 1

Standard

Option

Axle load (drive-over) max. [kg] 3000 4000 / 5000

Drive power [kW] 2 x 3 2 x 4

Test speed [km/h] 3 5

Measurement range [kN] 2 x 0…6 2 x 0…8

Display accuracy

2 % of the measurement range

end value

2 % Difference left – right

Track width min….max. [mm] 780…2200 780…2800

Roller diameter [mm] 202

Test stand dimensions [mm]

Height 280

Width 680

Length 2320 2925

Voltage supply [V] 3~ 400 3~ 230

Frequency [Hz] 50/60 50/60

Fuse (slow) [A] 16…25

Roller

friction

Dry Steel / synthetic ca. 0.9 / ca. 0.9

wet Steel / synthetic ca. 0.7 / ca. 0.8

Pos: 37 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 16

16

BA022401-en

Pos: 38 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1/B/Überschrift 1: Bedienung @ 6\mod_1174482271218_75.docx @ 76877 @ 1 @ 1

3

Operation

Pos: 39 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/D/Überschrift 1.1: Display @ 8\mod_1203421747708_75.docx @ 147611 @ 2 @ 1

3.1

Display

Pos: 40 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Display (Bild) @ 24\mod_1304407371911_0.docx @ 1002463 @ @ 1

Pos: 41 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 17

17

BA022401-en

Pos: 42 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Display (Text) @ 28\mod_1333530151434_75.docx @ 15779 65 @ @ 1

A Differential display

Read the difference between the right and left-hand

brake value in % on the differential display. The

differential display is only triggered after a fixed total

brake force is exceeded.

B Power on lamp

The test stand is active when the lamp above this

symbol is lit.

C Brake Front Axle / Parking Brake / Rear Axle

D Print

E Ready lamp

When the lamp above this symbol lights up, the

brake pedal/parking brake can be operated.

F

Automatic 4WD

recognition

G Motorcycle

H Delete

I

Remote control

(optional)

In course of the brake test with remote control the

lamp shows the following signals:

1st-Interval front axle; 2nd-Interval parking

brake; 3rd-Interval rear axle;

permanent light Measurement value available,

print possible; permanent blinking New vehicle.

Pos: 43 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 18

18

BA022401-en

Pos: 44 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/F/Überschrift 1.1: Fernbedienung @ 7\mod_1184152042500_75.docx @ 99994 @ 2 @ 1

3.2

Remote Control

Pos: 45 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften ohne Nummerierung/Überschrift: > RECO 1 @ 21\mod_1277893050057_0.docx @ 862443 @ @ 1

RECO 1

Pos: 46 /Technische Dokumentation/Prüf- und Sicherheitstechnik/Archiv/Z2 Fernbedienungen/2601 RECO 1/TI/Inhalt: E126 Fernbedienung RECO 1 (Bild) @ 21\mod_1277808734534_0.docx @ 861868 @ @ 1

Pos: 47 /Technische Dokumentation/Prüf- und Sicherheitstechnik/Archiv/Z2 Fernbedienungen/2601 RECO 1/TI/Inhalt: E126 Fernbedienung RECO 1 (Text)_12pt @ 27\mod_1327394842267_75.docx @ 1513653 @ @ 1

A

Motors Off

B

Start Motor left

C

Start Motor right / Start Ovality test

D

Menu item upwards

E

Confirm

F

Menu item downwards

Pos: 48 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

A B D C E

F

Page 19

19

BA022401-en

Pos: 49 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften ohne Nummerierung/Überschrift: > IFB / FFB @ 21\mod_1277892982039_0.docx @ 862403 @ @ 1

IFB / FFB

Pos: 50 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2301 MBT LON/BA/Inhalt: 0223 Fernbedienung FFB / IFB (Bild) @ 21\mod_1277121814678_0.docx @ 858773 @ @ 1

Pos: 51 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

S T D G H L Q J I K M N P

O

R

Page 20

20

BA022401-en

Pos: 52 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2301 MBT LON/BA/Inhalt: 0223 Fernbedienung FFB / IFB (Tabelle) @ 27\mod_1327394916024_75.docx @ 1513697 @ @ 1

Key

Function

D

F4 Start Ovality test

H

F8 Pointer stop

I

F9 Store Front axle

J

F10

Store Parking brake

Re-display MSD measurement value

K

F11 Store Rear axle

L

F12 Auto OFF

G

F7 Start Print menu

M

* Confirm

N

#

Select Sensor

Quit Noise detection

O

Program 1 key

P

Shift key

Q

Motor Off left

R

Motor On right

S

Motor On left

Pos: 53 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/P/Überschrift 1.1: Prüfablauf @ 8\mod_1200574029101_75.docx @ 140824 @ 2 @ 1

3.3

Test Procedure

Pos: 54 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Prüfabläufe @ 28\mod_1333530467681_75.docx @ 1578009 @ @ 1

Following test procedures are available:

• Standard mode without remote control

• Standard mode automatic 4 wheel-drive recognition

• Standard mode blink mode

• Standard mode Reco 1-procedure

• Standard mode Reco 1-4 wheel drive procedure

• Standard mode motorcycle procedure

• Standard IFB mode with motorcycle

• Standard IFB mode with 4 wheel drive

• Standard IFB mode procedure

• NL mode with IFB

• NL mode with Reco 1

• NL mode without remote control

Page 21

21

BA022401-en

• NL mode wheel circumference

Pos: 55 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-Mode ohne Fernbedienung @ 24\mod_1305103755925_75.docx @ 1005733 @ 3 @ 1

3.3.1

Standard Mode without Remote Control

Pos: 56 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode ohne Fernbedienung neu @ 24\mod_130441871 8210_75.docx @ 10029 53 @ @ 1

Without remote control

MBT – test flow without remote control

Drive on to RS

Automatic roller set

Ready for braking, Light signal on

Brake up to slip or release before.

Stop rollers!

The pointers go to the max. brake value

The rollers start after 2 seconds again, pointers

do to zero and/or roller resistance.

Axle change and new measurement can start.

Page 22

22

BA022401-en

Pos: 57 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-Mode Automatische Allraderkennung @ 24\mod_1305103860376_75.docx @ 1005763 @ 3 @ 1

3.3.2

Standard Mode Automatic 4-Wheel Drive Recognition

Pos: 58 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode Automatische Allraderkennung neu @ 24\mod_13044216 32389_75.do cx @ 1002983 @ @ 1

Without remote control

Automatic 4 wheel-drive recognition

(Drive Control Pro)

Display is optional

Drive on to RS

Automatic roller start

INFO

After 1X o 2X (DC PRO) start up monitoring the

test stand switches into 4 wheel drive mode.

(4x4 LED lights up)

Left-hand wheel rotates in test

direction, the right-hand wheel

in the opposite direction.

Ready for braking when light signal on.

Brake until slip limit or release before. Pay attention:

If the brake value of 500N is not

exceeded within 10 seconds after roller

start, the wheel measurement is stopped

and the right-hand side automatically

started. If the 500N is not exceeded here

either, the rollers stop and an axle change

must be done.

Rollers stop!

Max. brake force is displayed on the respective

test side.

INFO

After 2 seconds the rollers start again

automatically to test the second side.

Right-

hand wheel rotates in test direction,

the left-hand wheel in the opposite

direction.

After testing the left and right-hand side the

pointers remain on the max. value. The rollers

do not start up again.

Do axle change.

Pos: 59 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-M

ode Blink-Modus @ 24\mod_1305105336580_75.do cx @ 1005793 @ 3 @ 1

Page 23

23

BA022401-en

3.3.3

Standard Mode Blink Mode

Pos: 60 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode Blink Modus neu @ 24\mod_1304490896036_75.docx @ 1003023 @ @ 1

MBT-test procedure with Reco 1 and Drucker

Drive on to roller set

Status lamp optical procedure

FA: 1 blink -»- Pause

Automatic roller start PB: 2 blinks -»- Pause

RA: 3 blinks -»- Pause

Lights up permanently: print possible.

Activate pointer stop

Permanent quick blinking: delete

measurement

Manual Auto OFF:

Measurement completion

if necessary.

Light blinks for axle measurement

Type of axle

change possible

using arrow up or

downt. (FA, PB,

RA)

Ready for braking when LED lit

Brake up to slip or release before

Rollers stop !

Pointers go to max. brake value!

Repeat

measurement

possible with arrow

up once and then

down

Rollers start again. Storage possible.

Store measurement

Axle change, new measurement can start

Page 24

24

BA022401-en

Automatic print out after FA,

PB, RA (only if function

activated)

Manual print out

(only possible outside of the

roller set)

Lights up

p

ermanently

Start print out

After printing the status lamp blinks very quickly. If this is confirmed

with the blue enter key , all measurement values are deleted.

Permanent quick blinking

Pos: 61 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 25

25

BA022401-en

Pos: 62 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-Mode Reco 1-Ablauf @ 24\mod_1305105402879_75.docx @ 1005823 @ 3 @ 1

3.3.4

Standard Mode Reco 1-Procedure

Pos: 63 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode Reco 1-Ablauf neu @ 24\mod_1304496804618_75.docx @ 1003403 @ @ 1

MBT-test procedure with Reco 1 and printer

Drive onto roller set

Automatic roller start

Axle type change

possible with arrow

up or down /FA, PB,

RA)

Ready for brakikng, when LED lights up

Brake until slip limit or release before

Rollers stop!

The pointers go to the max. brake value!

Repeat

measurement

possible with arrow

once up and down

Rollers start again. Storage possible.

Store measurement

Axle change, new measurement can start

Final evaluation after

“Auto Off“

After measurement of the rear

axle (RA) the final evaluation

follows and the printer symbol

is automa-

tically active. After printing of the blue enter key

the print out is done.

Printing is only possible outside of the roller set.!

Display x2 = Brake force total

Display x10 = deceleration in %

if a scale is present.

Page 26

26

BA022401-en

If only one axle should be

printed out, do a “Auto Off“

The final evaluation is done. Printing is now

possible.

Pos: 64 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 27

27

BA022401-en

Pos: 65 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-Mode Reco 1 -Allrad-Ablauf @ 24\mod_1305105490206_75. docx @ 1005853 @ 3 @ 1

3.3.5

Standard Mode Reco 1-4-Wheel Drive

Pos: 66 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode Reco 1-Allrad-Ablauf neu @ 24\mod_1304504794395_75.docx @ 1003623 @ @ 1

MBT 4 WD Test Procedure with

Reco 1 and Printer

Select 4WD: (only possible outside of RS)

Scroll to 4x4 with the Motor On key. .

Confirm the mode with the enter key.

Press again to activate the measurement (FA

blinks)

Note: If the RS is not occupied within 30 sec,

there is a reset to the standard mode!

Autom. 4 WD recognition if 4x4 not pre-selected.

(DC = Drive Control)

(Wait once for start up monitoring DC Single)

(Wait twice for start up monitoring DC PRO)

Drive onto roller set

Automatic roller start

INFO

Left-hand wheel rotates in

testing direction, the righthand in the other direction.

Use arrow up or

down for axle

change. (FA, PB, RA)

Ready for braking when LED lights up.

Brake until slip or release beforehand

Note: If after roller start the brake value of 500 N is

not exceeded within 10 sec, the wheel

measurement is stopped and the right side

automatically started. If the 500 N is also not

exceeded here, the rollers stop and an axle

change must be done.

Rollers stop.

Max. brake force is displayed on the respective

test side.

To repeat measurement use arrow up

once and down again.

After change the rollers

start again. (only DC

PRO!!)

After 2 sec the rollers start again to test the 2nd

side.

Rollers stop, measurement can be saved.

Page 28

28

BA022401-en

Save measurement

Axle change, new measurement can start, or print.

Final evaluation after

"Auto Off"

After measuring the rear axle

(RA) the final evaluation is

done and the printer symbol

is automatically active.

The printout appears after pressing the blue

Enter key .

Printing is only possible outside of the roller set!

Display x 2 = Brake force total.

Display x 10 = Deceleration in %

if weighing machine is available.

If only one axle is to be

printed an "Auto Off" must

be done. Then the final

evaluation is done.

Printing is now possible.

After confirming the waste

basket with Enter

the measurement is

deleted.

Pos: 67 /-----Format-----/MANUELLER UM BRUCH Seitenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

Page 29

29

BA022401-en

Pos: 68 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-Mode Motorrad-Ablauf @ 24\mod_1305105535867_75.docx @ 1005883 @ 3 @ 1

3.3.6

Standard Mode Motorcycle Procedure

Pos: 69 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode Motorrad-Ablauf neu @ 24\mod_1304679213084_75.docx @ 1004263 @ @ 1

MBT-Motorcycle test procedure with Reco 1

(test only possible on left-hand roller set)

Left motorcycle:

Scroll to motorcycle mode with the Motor-On-

key . Confirm the mode using the enter key.

Pay attention: If the RS is not occupied within

30 sec. there is a reset to the standard mode!

FA blinks for axle measurement

Left-side RS occupied

Start Left-side with RC

Timer runs out (left-hand pointer

display)

Automatic roller start after timer run out. (Left

pointer goes to zero in seconds intervals. Now

the motor starts.)

Ready for braking when LED lights up

Brake until slip or release beforehand

Rollers stop

Pointer moves to the max. brake value!

Measurement is automatically stored.

Axle change , new measurement can start or print.

Page 30

30

BA022401-en

Final evaluation

After measuring the rear axle (RA) the final

evaluation is done and the printer symbol is

automatically active. The print out appears

after pressing the blue Enter key .

Printing is only possible outside of the roller

set!

Display x 2 = Brake force total

Display x 10 = decleration in %

If scale is available.

After confirming the waste basket with Enter

the measurement is deleted.

Pos: 70 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 31

31

BA022401-en

Pos: 71 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-IFB-Mode Motorrad @ 24\mod_1305105592167_75.docx @ 1005913 @ 3 @ 1

3.3.7

Standard IFB Mode Motorcycle

Pos: 72 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard IFB Mode Motorrad neu @ 24\mod_1305018917823_75.docx @ 1005053 @ @ 1

MBT-Motorcycle test procedure with IFB

(test only possible in left-hand roller set)

Select motorcycle:

Scroll to motorcycle mode with the motor-on-

key. Use star key to confirm the mode.

Pay attention: if the roller set is not occupied

within 30 sec. There is a reset back to Standard

mode!

FA blinks for axle measurement

Drive on to left roller set side

Start left side with the remote control

Timer runs out (left-han

d pointer

display)

Automatic roller start after timer expires. (Left-

hand pointer moves in seconds to zero. Now

the motor starts)

Ready for braking when LED lights up

Brake up to slip limit or release before

Rollers stop

The pointer goes to the max. brake value!

Measurement is automatically stored after 5 seconds.

Axle change, new measurement can start or print

Manual Auto OFF!

e.g. printing of only one

axle test.

Page 32

32

BA022401-en

Final evaluation

After measurement of the RA the final

evaluation follows. After pressing the key the

print out follows.

Printing is only possible outside of the roller

set!

Display 2 times= Brake force total.

Display x10 = deceleration in %

if a scale is present.

Delete measurement with

+

or drive onto anew.

Pos: 73 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.doc x @ 1277 @ @ 1

Page 33

33

BA022401-en

Pos: 74 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-IFB-Mode mit Allrad @ 24\mod_1305105637282_75.docx @ 1005943 @ 3 @ 1

3.3.8

Standard IFB Mode with 4-Wheel Drive

Pos: 75 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard IFB Mode mit Allrad neu @ 24\mod_1304934632233_75.do cx @ 1004463 @ @ 1

MBT-4 wheel drive test procedure with Reco 1

and printer

Select 4 wheel drive:

Use the motor-on-key scroll to 4x4.

Confirm the mode with the star key.

Pay attention: if the roller set is not occupied

within 30 sec. then it returns to standard mode !

Autom. 4 wheel drive if 4x4 not pre-selected.

(Drive-Control Pro)

(wait 2x start-up monitoring)

Drive on to roller set

Automatic roller start

INFO

Left-hand wheel rotates in

test direction, the righthand one in the opposite

direction.

Ready for braking when LED lights up

Brake until slip limit or release before

Pay attention: If the brake value of 500N is not

exceeded within 10 seconds after roller start, the

wheel measurement is stopped and the right-hand

side automatically started. If the 500N is not

exceeded here either, the rollers stop and an axle

change must be done.

Rollers stop!

The pointer goes to the max. brake value!

Repeat

measurement

possible. Delete

axle measurement.

Repeat

measurement!

After 2 seconds, the rollers start again to test

the second side.

Roller stops, measurement ready for storage

Page 34

34

BA022401-en

Store: Front axle Parking brake Rear axle

Axle change! New measurement can start or

print.

Manual Auto OFF!

e.g. printing of only one axle

measurement.

Start printing.

Final evaluation

Print out is only possible outside of the roller set.

Display x2 = Brake force total

Display x10 = decleration in %

if a scale is present.

Delete measurement with

+

or drive on again.

Pos: 76 /-----Format-----/MANUELLER UM BRUCH Seitenumbruch @ 0\mod_1134403577687_0. docx @ 1277 @ @ 1

Page 35

35

BA022401-en

Pos: 77 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/S/Überschrift 1.1.1: Standard-IFB-Mode @ 24\mod_1305105687623_75.docx @ 10059 73 @ 3 @ 1

3.3.9

Standard IFB Mode Procedure

Pos: 78 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard IFB Mode Ablauf neu @ 24\mod_1304923911060_75.doc x @ 1004293 @ @ 1

MBT-test procedure with remote control IFB (without

LED)

Drive on to roller set

LED display is only needed when

option 4x4, motorcycle or 2nd driving

direction is present.

Automatic roller start

Ready for braking when light signal on

Activate pointer Stopp

slowly brake until slip limit or release before

Stop rollers!

the pointer goes to the max. brake value.

Roller starts again.

Storage possible!

Delete axle measurement

.

Repeat measurement

Store: Front axle Parking brake Rear axle

Axle change! New measurement can start.

Manual Auto OFF!

e.g. print of only one axle

measurement.

Page 36

36

BA022401-en

Start print

Final evaluation

Print out is only possible outside of the roller set

Display x2 = Brake force Ges.

display x10 = deceleration in %

as long as a scale is present.

Pos: 79 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 37

37

BA022401-en

Pos: 80 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/N/Überschrift 1.1.1: NL-Mode mit IFB @ 24\mod_1305105739119_75.docx @ 1006003 @ 3 @ 1

3.3.10

NL Mode with IFB

Pos: 81 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 NL Mode mit IFB neu @ 24\mod_1305098531708_75.docx @ 1005633 @ @ 1

APK-test procedure with IFB remote control (optional pedal force meter)

Drive on to roller set

Automatic roller set

Activate pointer stop

Measurement front and rear axle Measurement parking brake

Slowly brake

Lamp blinks permanently

Ready lamp blinks once

Measurement point P1 is measured.

One wheel rotation (1WR)

Brake until slip and release brake (no

APK-procedure necessary)

Brake until slip limit

Pedal steady

Ready lamp blinks twice

Measurement point P2 is measured.

Valid APK measurement after two

wheel rotations (2WR)

Release brake or brake until slip.

Stop rollers.

The pointer goes to the last valid APK value and not

to the max. value!

The rollers start again, storing possible.

Page 38

38

BA022401-en

Store: Front axle Parking brake Rear axle

Axle change! New measurement can start or

print.

Manual Auto OFF!

e.g. print of only one axle

measurement.

Start print

Print out is only possible outside of the roller set.

Pos: 82 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 39

39

BA022401-en

Pos: 83 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/N/Überschrift 1.1.1: NL-Mode mit Reco 1 @ 24\mod_ 1305105950239_75.doc x @ 1006033 @ 3 @ 1

3.3.11

NL Mode with Reco 1

Pos: 84 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 NL Mode mit Reco 1 neu @ 24\mod_1305094637249_75.docx @ 1005603 @ @ 1

APK-test procedure with Reco 1 and printer

Drive on to roller set

Optical Procedure

FA: blink once -»- Pause

Automatic roller start

PB: blink twice -»- Pause (no APK procedure

necessary)

RA: blink three times -»- Pause

Lights up permanently: print possible.

Activate pointer Stopp

Permanent rapid blinking: delete

measurement

Manual Auto OFF:

e.g. printing of only one

axle measurement

Pointer stop active. Light blinks

Slowly brake

Ready lamp blinks once

Measurement point P1 is measured.

One wheel rotation (1RU)

Brake up to slip

Pedal steady

Ready lamp blinks twice

Measurement point P2 is measured.

Valid APK measurement after two wheel

rotations (2WR)

Release brake or brake up to slip.

Stop rollers!

The pointers go to the last, valid APK value and

not to the max. value!

Rollers start again. Storage possible.

Page 40

40

BA022401-en

St

orage measurement

Axle change, new measurement can start

Automatic print out after

measurement of FA, PB, RA

(only when function activated)

Manual print out

(only possible outside of roller

set)

Lights

permanently

Start print out

Pos: 85 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_11344035 77687_0.docx @ 1277 @ @ 1

Page 41

41

BA022401-en

Pos: 86 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/N/Überschrift 1.1.1: NL-Mode ohne Fernbedienung @ 24\mod_1305106004745_75.docx @ 1006063 @ 3 @ 1

3.3.12

NL Mode without Remote Control

Pos: 87 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 NL Mode ohne Fernbedienung neu @ 24\mod_1305023457296_75.docx @ 1005123 @ @ 1

APK-test procedure without remote control

Drive on to roller set

Automatic roller start

Slowly brake

Measurement point P1 is measured.

One wheel rotation (1WR)

Ready lamp blinks

once

Brake up to slip limit, keep pedal steady.!

Measurement point P2 is measured. Valid APK

measurement after two wheel rotations. (2WR)

Ready lamp blinks

twice

Release brake or brake up to slip.

Rollers stop

The pointers go back to the last, valid APK value

and not to the max. value!

The rollers start again, pointers go back to zero.

Axle change or new measurement can start.

Pos: 88 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/N/Überschrift 1.1.1: NL-Mode Radumfang @ 24 \mod_1305106043745_75.d ocx @ 1006093 @ 3 @ 1

Page 42

42

BA022401-en

3.3.13

NL Mode Wheel Circumference

Pos: 89 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 NL Mode Radumfang neu @ 24\mod_1305019677002_75.do cx @ 1005093 @ @ 1

Version control with strain gauge detuning

Switch on test stand

Pointer initialization (~10 sec)

Display of the version number e.g. 300R100

Display 5

Strain gauge detuning.

visible at pointer.

Press power on key

Test stand is ready for testing

Enter wheel circumference

Press power on key 5 sec. Zero point check

After 5 sec.

• Pointers go to 60 cm.

• Each key press increases it by 1 cm.

• Permanent pressing reduces by 2 cm.

• After 5 sec. without value change automatic

storage As confirmation the left-hand pointer

goes to the same value.

Blinks in this mode

Value is stored until new vehicle is executed!

Pos: 90 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 43

43

BA022401-en

Pos: 91 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/A/Überschrift 1.1: Abbremstabelle @ 8\mod_1203419773557_75.docx @ 147594 @ 2 @ 1

3.4

Deceleration Chart

Pos: 92 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Abbremstabelle @ 28\mod_1337586480163_75.docx @ 159839 1 @ @ 1

Permiss

Axle

Load in

kg

Axle Brake Force in kN

200

50

100

300

33

67

100

400

25

50

75

100

500

20

40

60

80

100

600

17

33

50

67

83

100

700

14

29

43

57

71

86

100

800

13

25

38

50

63

75

88

100

900

11

22

33

44

56

67

78

89

100

1000

10

20

30

40

50

60

70

80

90

100

1100

9

18

27

36

45

55

64

73

82

91

100

1200

8

17

25

33

42

50

58

67

75

83

92

100

1300

8

15

23

31

38

46

54

62

69

77

85

92

100

1400

7

14

21

29

36

43

50

57

64

71

79

86

93

100

1500

7

13

20

27

33

40

47

53

60

67

73

80

87

93

100

1600

6

13

19

25

31

38

44

50

56

63

69

75

81

88

94

100

Deceleration in %

Pos: 93 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 44

44

BA022401-en

Pos: 94 /Technische Dokumentation/Papierkorb/Überschriften/Überschrift 1: Instandhaltung @ 11\mod_1231318736629_75.docx @ 289550 @ 1 @ 1

4

Maintenance

Pos: 95 /Technische Dokumentation/Alle Geräte/Inhalte/Warnung!/Inhalt: Warnung - Hauptschalter aus bei Instandhaltung_12pt @ 26\mod_1324465229892_75.docx @ 1140563 @ @ 1

Danger! Electric shock hazard!

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Pos: 96 /Technische Dokumentation/Papierkorb/Überschriften/Überschrift 1.1: Jährliche Überprüfung @ 6\mod_1174482245718_75.docx @ 76817 @ 2 @ 1

4.1

Annual Inspection

Pos: 97 /Technische Dokumentation/Alle Geräte/Inhalte/Info!/Inhalt: Info - Jährliche Überprüfung_12pt @ 25\mod_1324460481075_75.docx @ 1139412 @ @ 1

• The maintenance interval prescribed by the manufacturer is

12 (twelve) months

.

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

• Maintenance work shall be done only by authorized and trained service

technicians provided by the manufacturer, licensed dealers or service partners.

• In case of non-compliance the manufacturer's warranty becomes void.

Pos: 98 /Technische Dokumentation/Papierkorb/Überschriften/Überschrift 1.1: Instandhaltung durch den Betreiber @ 6\mod_1178543544390_75.docx @ 91370 @ 2 @ 1

4.2

Maintenance by the Operator

Pos: 99 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1.1/K/Überschrift 1.1.1: Kettenspannung prüfen @ 18\mod_1254744431734_75.docx @ 457139 @ 3 @ 1

4.2.1

Checking the Chain Tension

Pos: 100 /Technische Dokumentation/Alle Geräte/Inhalte/Info!/Inhalt: Info - Wartungsintervall: Monatlich_12pt @ 26\mod_1324463913433_75.docx @ 1140268 @ @ 1

Maintenance interval: Monthly

Pos: 101 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Inhalt: Inst Kettenspannung (Text) IW 2/4/7/10_12pt @ 26\mod_1326874773072_75.docx @ 1511503 @ @ 1

Check the chain tension for the first time 14 working days after initial operation,

then monthly:

1 Remove cover plates from roller set.

2 Grease the chain (A) well with multi-purpose grease along its entire length.

While greasing, turn the rollers by hand.

3 Check that the chain has a slack of approx. 5 mm in either direction.

Page 45

45

BA022401-en

If the chain does not have enough tension, proceed as follows:

4 Open the fastening screws (B).

5 Tighten the tensioning screw (C) until the chain has the proper tension.

6 Retighten the fastening screws.

Brake testers with elevated roller sets: Tightening torque

500 Nm

7 Recheck the chain tension.

8 Reinstall the cover plates to the roller set.

Pos: 102 /-----Format-----/MANUELLER UMBRUCH Zeilenschaltung @ 7\mod_ 1195138965731_0.doc x @ 132177 @ @ 1

Pos: 103 /-----Format-----/ MANUELLER UMBRUCH Zeilenschaltung @ 7\mod_119 5138965731_0.docx @ 132177 @ @ 1

Pos: 104 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Inhalt: Inst Kettenspannung (Bilder) MBT 3x00 @ 18\mod_1254727296554_0.docx @ 456256 @ @ 1

Pos: 105 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.doc x @ 1277 @ @ 1

Page 46

46

BA022401-en

Pos: 106 /Technische Dokumentation/Papierkorb/Überschriften/Überschrift 1.1.1: Tastrollenscharniere schmieren @ 18\mod_1254744523806_75.docx @ 457166 @ 3 @ 1

4.2.2

Greasing the Sensor Roller Hinges

Pos: 107 /Technische Dokumentation/Alle Geräte/Inhalte/Info!/Inhalt: Info - Wartungsintervall: 200 h / 12 Monate_12pt @ 26\mod_1324463609793_75.do cx @ 1140170 @ @ 1

Maintenance interval: 200 hours / 12 months

Pos: 108 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Inhalt: Inst Tastrollen (Text) MBT 3x00/4x00/7x00_12pt @ 26\mod_1326874914374_75.docx @ 1511547 @ @ 1

Grease the sensor roller hinges every 200 (two hundred) operating hours or once

annually.

1 Remove the cover plates from the roller set.

2 Treat the greasing points (D) using a spray lubricant. Move the sensor roller up

and down.

3 Reinstall the cover plates to the roller set.

Pos: 109 /Technische Dokumentation/Prüf- und Sicherheitstechnik/00 BPS Alle/Inhalte/Inhalt: Inst Tastrollen (Bilder) MBT 3x00 @ 18\mod_1254732674783_0.docx @ 456550 @ @ 1

Pos: 110 /-----Format-----/MANUELLER UM BRUCH Seitenumbruch @ 0\mod_1134403 577687_0.do cx @ 1277 @ @ 1

Page 47

47

BA022401-en

Pos: 111 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/F/Überschrift 1.1: Fehlercodes @ 14\mod_1240470968985_75.docx @ 366697 @ 2 @ 1

4.3

Error Codes

Pos: 112 /Technische Dokumentation/Prüf- und Sicherheitstechnik/02 Rollen-BPS Pkw/2401 MBT 2100/BA/Inhalt: 0224 Standard Mode Fehlercodes @ 28\ mod_1337586022012_75. docx @ 1598303 @ @ 1

Error

code

Description Remedy

12

Connection to multi-function

display missing

Contact service

32

Left sensor roller impulse sensor

defective

Check motor protection switch.

If o.k. contact service.

33

Both sensor roller impulse

sensors defective

Check motor protection switch.

If o.k. contact service..

34

Right sensor roller impulse

sensor defective

Check motor protection switch.

If o.k. contact service.

40

Zero point of the brake force

strain gauge outside of range

Contact service

41

Only left-hand sensor roller

pressed

Drive onto both sides of test stand.

42

Only right-hand sensor roller

pressed

Drive onto both sides of test stand.

50 Scale zero point outside of range

Roller set may not be occupied when

switching on.

51

Test stand is already occupied

when switching on.

Exit test stand with vehicle and switch

main switch off/on.

Pos: 113 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/P/Überschrift 1.1: Pflegehinweise @ 15\mod_1245912234854_75.docx @ 395780 @ 2 @ 1

4.4

Care Instructions

Pos: 114 /Technische Dokumentation/Alle Geräte/Inhalte/Inhalt: Pflegehinweise - Alle Geräte_12pt @ 26\mod_1324468886116_75.docx @ 1141252 @ @ 1

• Periodically clean the equipment and treat it with a care product.

• Repair damage to the paintwork immediately to prevent corrosion.

• Usage of caustic cleaning agents or high pressure and steam jet cleaners may

lead to equipment damage.

Pos: 115 /Technische Dokumentation/Alle Geräte/Inhalte/Info!/Inhalt: Info - Pflegehinweise_12pt @ 26\mod_1324461215655_75.docx @ 1139602 @ @ 1

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment!

Pos: 116 /Technische Dokumentation/Alle Geräte/Überschriften/Überschriften 1.1/E/Überschrift 1.1: Ersatzteile @ 18\mod_1255596847002_75.docx @ 474414 @ 2 @ 1

4.5

Spare Parts

Pos: 117 /Technische Dokumentation/Alle Geräte/Inhalte/Inhalt: Ersatzteile - Alle Geräte_12pt @ 26\mod_1324468768120_75.docx @ 1141219 @ @ 1

To ensure safe and reliable operation, only use original spare parts supplied by the

equipment manufacturer.

Pos: 118 /-----Format-----/MANUELLER UMBRUCH Seitenumbruch @ 0\mod_1134403 577687_0.doc x @ 1277 @ @ 1

Page 48

48

BA022401-en

Pos: 119 /Technische D okumen tation/ Alle G eräte/ Überschr iften/ Übers chrifte n 1/D/Üb erschr ift 1: Demon tage @ 19\mod _12 66336 8228 63_75.d ocx @ 74 2452 @ 1 @ 1

5

Dismantling

Pos: 120 /Te chn isch e Dok umen tation/A lle G eräte/In halte/I nhalt: Demon tage - Al le Gerä te_ 12p t @ 2 6\mod_1324466078229_75.docx @ 1140857 @ @ 1

Decommissioning and dismantling of the equipment may be done only by

specially authorized and trained personnel provided by the manufacturer, licensed

dealers or service partners.

Pos: 121 /-----F orma t-----/M ANUE LLE R UMB RUC H Z eile nsc hal tu ng @ 7\mod_1195138965731_0.docx @ 132177 @ @ 1

Pos: 122 /Technische D okumen tation/ Alle G eräte/ Überschr iften/ Übers chrifte n 1/I/ Überschrif t 1: I nhalt d er Kon form itäts erklä rung @ 22\m od_1292856748432_75.docx @ 958616 @ 1 @ 1

6

Contents of the Declaration of Conformity

Pos: 123 /Technische D okumen tation/ Alle G eräte/In halt e/Inhalt : Inha lt der K onform itätser klärung allg_ 12pt @ 26\mod_1324468436145_75.docx @ 1141120 @ @ 1

MAHA Maschinenbau Haldenwang GmbH & Co. KG

herewith declares as a manufacturer its sole responsibility to ensure that the

product named hereafter meets the safety and health regulations both in design

and construction required by the EC directives stated below.

This declaration becomes void if any change is made to the product that was not

discussed and approved by named company beforehand.

Pos: 124 /Tech nische Dok umen tati on/Br emsp rüfte chnik/ MBT- SERI ES/ 02 240 1 MB T 2 100/B A/I nha lt: 022 4 In ha lt der Ko nform itätserk lärung @ 54\mod_1530860864774_75.docx @ 3043063 @ @ 1

Model:

MBT 2100 / 2110 / 2120 / 2130

Designation:

Roller Brake Tester

Rated Axle Load 3000 kg (4000 / 5000 kg optional)

Motor Power 2 x 2.25 kW (2 x 4 kW optional)

EC Directives:

2006/42/EC; 2014/30/EU

EN Standards:

EN 12100-1/-2; EN 13850; EN 13857; EN 349; EN

60204-1; EN 61000-6-3, EN 61000-6-2

Pos: 125 /-----F orma t-----/M ANUELLE R UMBR UCH Seitenum bruc h @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 49

49

BA022401-en

Pos: 126 /Te chn isch e Dok umen tation/A lle G eräte/Üb erschr iften/Üb erschr iften 1/ F/Übers chrif t 1: Fir men-Inf ormat ion @ 7\mod_ 1187 3386 25828_ 75.do cx @ 1040 47 @ 1 @ 1

7

Company Information

Pos: 127 /Technische D okumen tation/ Alle G eräte/In halt e/Inhalt : Firmen -Inf ormat ion M AHA @ 53\ mod_ 1529400378770_75.docx @ 3037518 @ @ 1

© MAHA Maschinenbau Haldenwang GmbH & Co. KG

Legal notice based on ISO 16016:

The reproduction, distribution and utilization of this document as well as the communication of its

contents to others without explicit authorization is prohibited. Offenders will be held liable for the

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

The contents of this edition have been checked with great care. However, errors cannot be fully

excluded. Subject to technical change without notice.

Document

Document No.: BA022401-en

Approval Date: 2018-07-06

Manufacturer

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20

87490 Haldenwang

Germany

Phone: +49 8374 585 0

Fax: +49 8374 585 590

Mail: maha@maha.de

Web: http://www.maha.de

Service

MAHA Service Center

AutomoTec GmbH

Maybachstraße 8

87437 Kempten

Germany

Phone: +49 8374 585 100

Fax: +49 8374 585 491

Mail: service@automo-tec.com

Web: http://www.maha.de/service-center.htm

=== Ende der Liste für Textm arke In halt ===

Loading...

Loading...