Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

MBT 1000 EUROSYSTEM

Roller Brake Tester for Motorcycles and Lightweight Vehicles

Original Operating Instructions

BAE12901-en

Pos: 1 /-----For mat---- -/MAN UEL LER UM BRUC H Seite numbr uch @ 0\mod_ 113 44035 77687_ 0.doc x @ 1277 @ @ 1

Page 2

2

BAE12901-en

Pos: 2 /-----For mat---- -/Inha ltsv er zeic hnis - 3 Ebe nen @ 5\mod_ 116 88674 41046_ 75.do cx @ 729 20 @ @ 1

Contents

1 Safety ...................................................................................................................... 3

1.1 Introduction ......................................................................................................................................... 3

1.2 Symbols .............................................................................................................................................. 3

1.3 Intended Use ....................................................................................................................................... 3

1.4 Inappropriate Use ................................................................................................................................ 3

1.5 Requirements on Operating and Service Personnel ............................................................................. 3

1.6 Safety Instructions for Installation and Initial Operation ........................................................................ 4

1.7 Safety Instructions for Operation ......................................................................................................... 4

1.8 Danger Zone ....................................................................................................................................... 5

1.9 Safety Instructions for Servicing ........................................................................................................... 5

1.10 Safety Features ................................................................................................................................... 6

1.11 Accessories ......................................................................................................................................... 7

1.12 What to Do in the Event of an Accident ............................................................................................... 7

2 Description ............................................................................................................... 8

2.1 General Information ............................................................................................................................. 8

2.2 Overview ............................................................................................................................................. 9

2.3 Specifications .................................................................................................................................... 10

2.4 Noise Emission .................................................................................................................................. 10

3 Transport and Storage ........................................................................................... 11

4 Installation and Initial Operation .............................................................................. 11

5 Operation ............................................................................................................... 11

5.1 Main Switch....................................................................................................................................... 11

5.2 Control Unit ....................................................................................................................................... 12

5.3 Test Procedure .................................................................................................................................. 13

6 Maintenance .......................................................................................................... 14

6.1 Annual Inspection .............................................................................................................................. 14

6.2 Care Instructions ............................................................................................................................... 14

6.3 Spare Parts ....................................................................................................................................... 14

6.4 Chain Drive Maintenance: Cleaning, Retensioning, Lubricating .......................................................... 15

6.5 Greasing the Sensor Roller Hinges .................................................................................................... 17

7 Dismantling ............................................................................................................ 19

8 Disposal ................................................................................................................. 19

9 Contents of the Declaration of Conformity .............................................................. 20

10 Company Information ............................................................................................. 21

Pos: 3 /-----For mat---- -/MAN UELLER UM BRUCH Sei tenumb ruch @ 0\mod _11 34403 5776 87_0.d ocx @ 127 7 @ @ 1

Page 3

3

BAE12901-en

Pos: 4 /Technische D okumen tation/A lle Gerä te/ Überschrif ten/Über schr iften 1/S /Überschr ift 1: Sicherhei t @ 6\mod_1174482399906_75.docx @ 76962 @ 1 @ 1

1

Safety

Pos: 5 /Technisc he D okum entat ion/A lle G erä te/ Übersc hrifte n/Üb ersc hrift en 1 .1/E/ Übers chrif t 1. 1: E inführ ung @ 6\mod_1174482219062_75.docx @ 76793 @ 2 @ 1

1.1

Introduction

Pos: 6 /Technisc he Dokum en tation/ All e Gerä te/In halte /Sic herhe it/In halt : Ei nführ ung Sicher hei t_12p t @ 2 5\mod_1324455248318_75.docx @ 1138886 @ @ 1

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

safety instructions are not covered by the product liability regulations.

Pos: 7 /Technische D okumen tation/A lle Gerä te/ Überschrif ten/Über schr iften 1.1/S/ Übersc hrift 1. 1: Sym bole @ 6\mod_1174482270875_75.docx @ 76865 @ 2 @ 1

1.2

Symbols

Pos: 8 /Technische D okumen tation/A lle Gerä te/In halte/S icherhe it/Inha lt: Symb ole Si cher heit_12p t @ 25\m od_1324456650897_75.docx @ 1139046 @ @ 1

Important safety instructions. Failure to comply with instructions could result in

personal injury or property damage.

Important information.

Pos: 9 /Technische D okumen tation/A lle Gerä te/ Überschrif ten/Über schr iften 1 .1/B/Üb ersc hrift 1.1 : Best immungs gemäßer Geb rauch @ 6\mod _1176 7340 22203_ 75.d ocx @ 88 746 @ 2 @ 1

1.3

Intended Use

Pos: 10 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-S ERIE S/ E1 2901 MB T 10 00 E URO SYS TEM /BA/ In halt: E1 29 B est imm ungs gem äße r Geb ra uch @ 4 1\mod_1421400610826_75.docx @ 2184918 @ @ 1

This equipment is to be used exclusively for the testing of motorcycles and

lightweight vehicles. Observe the rated axle load.

The equipment shall not be modified without the express written consent of the

manufacturer. In case of non-compliance the declaration of conformity becomes

void.

Pos: 11 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/B/Überschr ift 1.1: Bestimm ungswidr iger Gebrauch @ 18\mod_1255530265027_75.docx @ 471571 @ 2 @ 1

1.4

Inappropriate Use

Pos: 12 /Technische Dokumentat ion/Alle Gerät e/Inhalte/S icherhe it/Inhalt: Bestimm ungswid riger Gebrau ch allg_12pt @ 25\mod_1324455015938_75.docx @ 1138843 @ @ 1

Any use other than described is inappropriate.

Pos: 13 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/A/Üb ersc hrift 1.1: Anf orderun gen a n das Bed ienun gs- und Servic eperson al @ 3 4\mod_1380637497630_75.docx @ 1835413 @ 2 @ 1

1.5

Requirements on Operating and Service Personnel

Pos: 14 /Technische Dokume ntation/ Alle Ger äte/I nhalte/S icher heit/ Inhal t: A nford erun gen a n das Be dienu ngs- und Serv icepers onal_1 2pt (2 016-12-22 08 :48:1 2) @ 34\m od_1 380 637 3483 20_ 75.d ocx @ 183 536 9 @ @ 1

All persons employed in the operation, maintenance, installation, removal and disposal of the device must

• be at least 18 years old,

• be trained and instructed in writing,

• have read and understood this manual

• be on record as having been instructed in safety guidelines.

Pos: 15 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 4

4

BAE12901-en

Pos: 16 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/S/Üb ersc hrift 1.1: Sic herheits vorschr iften f ür Ins talla tio n und E rsti nbe triebn ahme @ 24\m od_131 0565 05943 1_75.d ocx @ 102354 3 @ 2 @ 1

1.6

Safety Instructions for Installation and Initial Operation

Pos: 17 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Sic herh eit/ Inhalt : Sic herhe itsv orschr ifte n für die Inbe trieb nahme BP S_12p t @ 26\mod_1326368324234_75.docx @ 1504789 @ @ 1

• The system shall only be commissioned by MAHA service technicians or au-

thorized service partners.

• All parts of the electrical equipment must be protected from moisture and wet-

ness.

• The system shall not be installed and operated in hazardous locations or wash

halls.

• The operator must provide for optional safeguards (e.g. warn lamps, barriers,

etc.) depending on local conditions.

• Wear safety shoes and gloves.

• Safeguard roller set with suitable means (e.g. cordon chains or strap).

• The display must be installed in a secure area and folded into the wall when not

in use (wall hinges optionally available).

• When folding the display, grasp it on the edges. Danger of pinching!

• Ensure that a lockable emergency-stop main switch is installed based on instal-

lation instructions before connecting the feed line. Use motor protection switch

and cable cross sections as per specification. Reference in circuit diagram

(standard delivery), nameplate. Fuse max. X.X A (see nameplate).

• The main switch must be provided by the customer and installed on-site. It

must be positioned in direct vicinity to the tester and takes over the emergencystop function.

Pos: 18 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/S/Üb ersc hrift 1.1: Sic herheits vorschr iften f ür den Betri eb @ 6\mod_1174482268953_75.docx @ 76826 @ 2 @ 1

1.7

Safety Instructions for Operation

Pos: 19 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Sic herh eit/ Inhalt : Sic herhe itsv orschr ifte n für den Betr ieb BPS_1 2pt @ 26\ mod_ 1326700788796_75.docx @ 1505493 @ @ 1

• The system shall only be operated within its performance limits.

• The system shall only be operated by trained personnel.

• The system and surrounding area must be kept clean.

• Switch off the system when not in use and secure the main switch against re-

start with a padlock.

• In emergency situations switch off system with main switch or emergency-stop

switch.

• No persons shall be in the danger zone of the system. Rotating or moving parts

(e.g. test stand rollers) are dangerous.

• Danger of carbon monoxide poisoning with running vehicle engine in closed

rooms. The operator is responsible for providing sufficient air exchange.

• Avoid unnecessary strain on vehicle and tester.

• Drive the vehicle slowly on to the tester.

• Check the danger zone before driving the vehicle onto the tester.

Page 5

5

BAE12901-en

• When the vehicle with the driven axle is on the roller set, exit only with running

roller drive. Exiting with roller drive at standstill can destroy the motors due to

extreme roller acceleration.

• The system shall not be operated without functioning slip monitoring. This can

cause tire damage.

• Never jump start a vehicle with the system. This can lead to equipment dam-

age.

• No 4 wheel-drive vehicles shall be tested on the standard roller set. Damage to

vehicle and system are possible. When in doubt contact your responsible service representative.

• The vehicle must be closed during testing. If persons outside of the vehicle are

endangered, use noise protection.

• The operator shall not leave the vehicle during testing.

• No vehicle shall be parked in/on the roller set or on the optional ramps.

Pos: 20 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/G/ Übersc hrift 1.1: Gefa hrenzo ne @ 1 9\mod _126 69381 22676_ 75.d ocx @ 78 2826 @ 2 @ 1

1.8

Danger Zone

Pos: 21 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Sic herh eit/ Inhalt : Ge fahr enzone - 5m Abstand (Text) BPS_12p t @ 26\mod_1326700917541_75.docx @ 1505537 @ @ 1

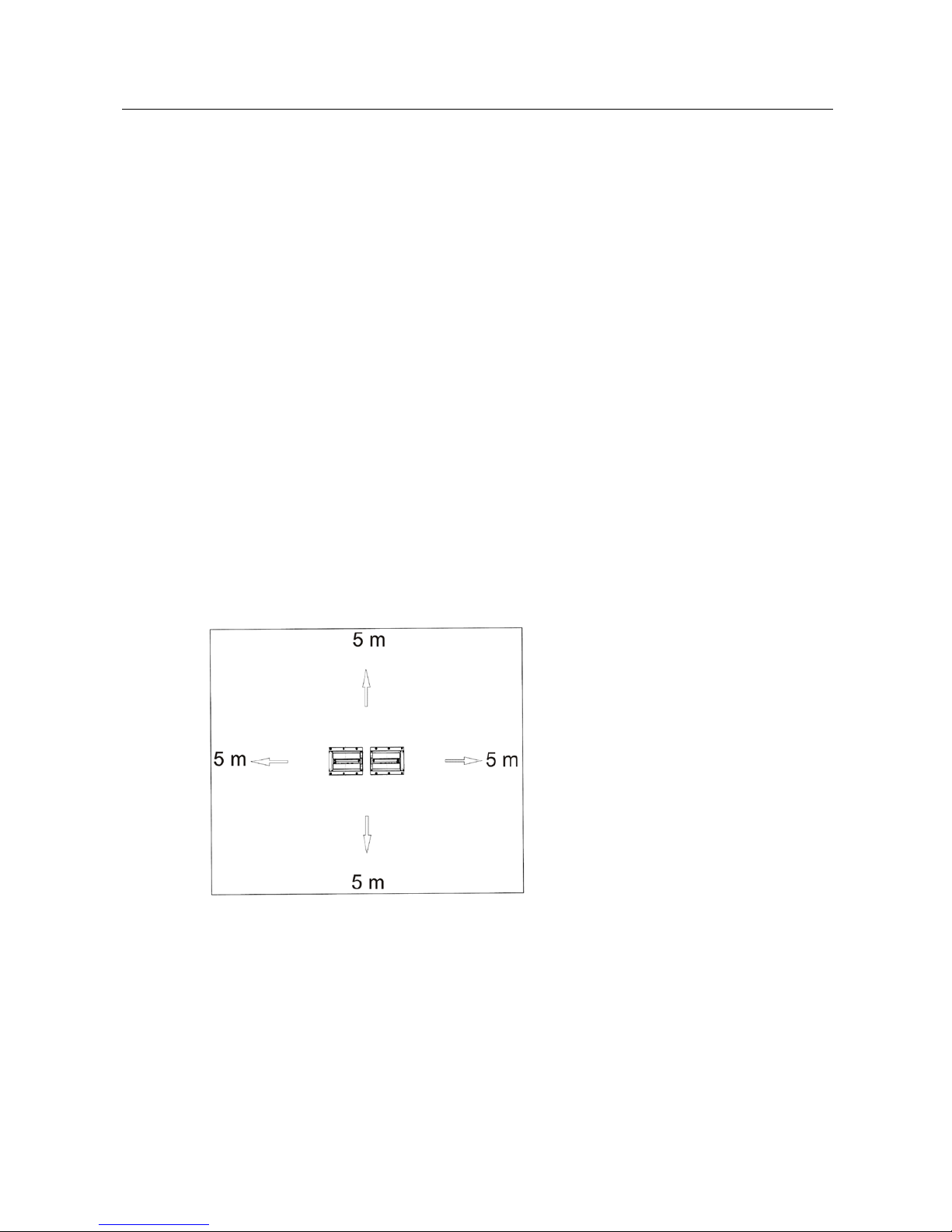

During brake tester operation no persons are allowed in the danger zone:

5 (five) meters

around the roller set in all directions.

Pos: 22 /Techn ische Dokum ent atio n/Brem spr üftec hn ik/- Ar chiv -/- Brem sprüf techn ik Alle -/ Inha lte/S icher hei t/Inha lt: G efa hrenzo ne - 5m Abstand (Bild) BPS @ 19\mod _12 66938 26003 4_0.d ocx @ 784 017 @ @ 1

Pos: 23 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/S/Üb ersc hrift 1.1: Sic herheits vorschr iften f ür Servi cearbeit en @ 6\mod_1174482270640_75.docx @ 76850 @ 2 @ 1

1.9

Safety Instructions for Servicing

Pos: 24 /Techn ische Dokum ent atio n/Brem sprüf tec hnik/- Ar c hiv -/- Br emspr üftechn ik Alle -/ In halte/S iche rhe it/Inha lt: S ic herhe itsvor schri fte n für Servi cearb eite n BPS _1 2pt @ 26\mod_1326700977270_75.docx @ 1505581 @ @ 1

• Service work shall only be done by MAHA service technicians or authorized

service partners.

• Work on electric parts of the system shall only be done by trained electricians.

• The main switch must be switched off and secured against restart before doing

repair, maintenance and set-up work.

• Fire danger due to rubber abrasion on the roller set. Clean regularly. Remove

abrasion before maintenance work.

Page 6

6

BAE12901-en

• The main switch must be secured and if necessary the motor protection switch

turned off when doing work in the roller set.

• When working on the control cabinet or on the roller sets pay attention to the

heating (optional) or hot parts.

• Immediately turn off the tester when it starts up unintentionally. Contact the ser-

vice department.

Pos: 25 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/S/Übersc hrift 1.1: Sicherhe itseinr ichtun gen @ 6\mod_ 1174 4833 24765_ 75.do cx @ 7710 3 @ 2 @ 1

1.10

Safety Features

Pos: 26 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Sic herh eit/ Inhalt : Sic herhe its einric htun gen ( Text) BPS _12pt @ 2 6\mod_1326701513692_75.docx @ 15056 25 @ @ 1

The safety features (partly optional) are to be inspected regularly by an authorized

service technician. Official guidelines must be followed at all times.

The equipment

shall not be operated when the safety features are defective!

•

Lockable Main Switch

Serves as normal On and Off switch for the equipment and as emergency switch.

The switch can be padlocked to protect it against unauthorized usage.

•

Emergency Switch

Is used for quick switch-off during operation. Interrupts the power supply to the

equipment.

•

Startup Monitoring

Prevents the rollers from starting up in case the wheels are blocked (seized

bearings, jammed brake pads). This feature helps prevent the vehicle tyres from

being damaged.

•

Sensor Rollers

The RPM difference between equipment rollers and sensor rollers determines the

slip. Both sensor rollers must be pushed down in order to start the roller brake

tester.

•

Visual and Audible Warning Devices

These must be positioned at a suitable location and must be easily seen or heard

at all times. In the event that the warning devices are defective, the brake tester

must be shut down until they are fully functional again.

•

Pit Safety

Light barrier or infrared movement sensor. If any person enters the safety area, the

brake tester is switched off.

•

Yellow-Black Marking Tape

The yellow-black marking tape around roller set and pit serves to mark out the

brake tester and nust be replaced if defective. Part # 19 6014 (Ø 38 mm) /

19 6015 (Ø 50 mm).

•

Warning and Information Labels

Warning and information labels are attached to the equipment. These must not be

changed or removed and must be replaced if unreadable (see below for part

numbers).

Pos: 27 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Sicher heit/I nhalt: Sic herheits einric htunge n/Aufkleb er (Bild er) BPS @ 23\m od_12 97085 0825 34_0.d ocx @ 9 71558 @ @ 1

Page 7

7

BAE12901-en

54 2132 54 2683

Pos: 28 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Über schri ften 1. 1/Z/Üb erschr ift 1. 1: Zube hör @ 7\mod _11 97021 5365 41_75.d ocx @ 13 6790 @ 2 @ 1

1.11

Accessories

Pos: 29 /Technische Dokume ntation/ Alle Ger äte/I nhalte/S icher heit/In halt: Z ubehör_1 2pt @ 25\mod_1324457135414_75.docx @ 1139114 @ @ 1

The equipment shall be operated only with accessories which have been

approved or permitted by MAHA.

Pos: 30 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/V/ Übersc hrift 1 .1: Verh alten b ei Unfä llen @ 19\m od_12 67177 2453 37_75. docx @ 79 4600 @ 2 @ 1

1.12

What to Do in the Event of an Accident

Pos: 31 /Technische Dokume ntation/ Alle Ger äte/I nhalte/S icher heit/In halt: Ver halten b ei U nfällen_ 12pt @ 34\mod_1381128863435_75.docx @ 1837175 @ @ 1

• The injured person is to be removed from the danger area. Find out where

dressing and bandages are kept. Seek first-aid.

• Provide first-aid (stop bleeding, immobilise injured limbs), report the accident

and seal off the accident site.

• Immediately report any accident to your supervisor. Make sure a record is kept

of every occasion first-aid is provided, e.g. in an accident book.

• Remain calm and answer any questions that may arise.

Pos: 32 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 8

8

BAE12901-en

Pos: 33 /Technische Dokume ntation/ Alle Ger äte/Übers chriften/ Überschrifte n 1/B/Übers chrift 1: Beschre ibung @ 6\mod_1174482271453_75.docx @ 76889 @ 1 @ 1

2

Description

Pos: 34 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/A/Übersc hrift 1.1: Allgemei nes @ 6\mod_1182865005781_75.docx @ 97736 @ 2 @ 1

2.1

General Information

Pos: 35 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-SE RIES/E 10101 EUROSY STEM Standard/ BA/Inhalt: E 101 Beschre ibung Al lgemeines @ 26\mod_1326701721816_75.docx @ 1505669 @ @ 1

The safety test lane EUROSYSTEM uses modular design. It is easily expandable

and has the following function groups as standard equipment: side-slip tester,

shock tester, brake tester. In addition, all kinds of MAHA test equipment can be

connected. Test equipment from other manufacturers can be integrated in some

instances.

PC and screen display as well as EUROSYSTEM software are standard

equipment. This test lane-specific software developed by MAHA is based on the

Windows operating system and is network-compatible. The measurement values

can be processed on your own computer network.

Measurement data can be stored with or without remote control and organized in

databases. An additional analog display (pointer) can be used.

Pos: 36 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 9

9

BAE12901-en

Pos: 37 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/Ü/Überschr ift 1.1: Übers icht @ 7\mod_ 11870 87953 953_7 5.doc x @ 10369 8 @ 2 @ 1

2.2

Overview

Pos: 38 /Technische Dokume ntation/ Bremsp rüftec hnik/MBT-SERIE S/E 129 01 M BT 100 0 E UROS YS TEM/ BA/I nha lt: E1 29 Übe rs ich t (Bi lder ) @ 41\m od_1421409403608_0.docx @ 2185242 @ @ 1

Pos: 39 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-S ERIE S/ E1 2901 MB T 10 00 E URO SYS TEM /BA/ In halt: E1 29 Übers icht ( Legend e) @ 41\mod_1421410491305_75.docx @ 2185288 @ @ 1

Examples:

A

Flush-floor version

B

Surface-mounted version

Illustrations show highest expansion stage with roller sets 1 + 2 and clamping device.

Pos: 40 /-----For ma t-----/MANUELLER UM BRUC H Se ite num br uch @ 0\m od_1134403577687_0.docx @ 1277 @ @ 1

A

B

Page 10

10

BAE12901-en

Pos: 41 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/T/Überschr ift 1.1: Technis che Daten @ 7\mod_1184075526343_75.docx @ 99711 @ 2 @ 1

2.3

Specifications

Pos: 42 /Tec hnische Do kument ation/Br emspr üftechn ik/MBT-SE RIES /E129 01 MBT 1000 E UROSYS TEM/BA/ Inhal t: E129 Technis che Daten ( Tabel le) @ 4 0\mod_1415007623249_75.docx @ 2138985 @ @ 1

RS1 RS2

Fuse 25 A time-delay

Drive power 3 kW

Roller set dimensions

(H x W x L)

280/315* x700 x 1150 mm 280/315* x1400 x 1150 mm

Display range 0 – 3 kN

Testable wheel bases 800 – 1500 mm

Testable wheel diameters 380 – 700 mm

Test speed 5 km/h

Wheel load (drive-over load) 1000 kg

Roller centre distance 380 mm

Roller diameter 202 mm

Roller length 350 mm 1100 mm

Power supply 3 x 400 V/NPE 50 Hz

*315 mm height only in conjunction with dynamometer

Pos: 43 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/L/Überschr ift 1.1: Lärmem ission @ 13\mod_ 12367 67272 078_7 5.doc x @ 35457 9 @ 2 @ 1

2.4

Noise Emission

Pos: 44 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-SERIES/E10101 EUROSYSTEM Standard/BA/Inhalt: E101 Lärmemission @ 26\mod_1326714188804_75.docx @ 1507042 @ @ 1

The noise emission during a vehicle test results mainly from the vehicle’s engine.

The noise emission varies from vehicle to vehicle and cannot be attributed to the

testing equipment.

Roller Brake Tester

The noise emission value created by the brake tester (roller drive) is less than

70 dB(A) in the work area of the operator.

Shock Tester

The noise emission value created by the shock tester (oscillating test plates) is

between 75 and 80 dB(A) in the work area of the operator.

Side-Slip Tester

The noise emission value created by the side-slip tester is less than 70 dB(A) in

the work area of the operator.

Pos: 45 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 11

11

BAE12901-en

Pos: 46 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1/T/ Über schr ift 1: Tra nsp ort und Lage ru ng @ 20\mod_1268732488860_75.docx @ 826153 @ 1 @ 1

3

Transport and Storage

Pos: 47 /Technische Dokumentat ion/Alle Gerät e/Inhalte/I nhalt: Transp ort und Lagerung _12pt @ 26\mod_1324468980166_75.docx @ 1141285 @ @ 1

Check package to ensure it is complete, in accordance with the order

confirmation. Report any transport damage to the carrier immediately.

During loading, unloading and transport always use suitable lifting equipment,

material handling equipment (e.g. cranes, forklifts, etc.) and the right load handling

attachments and slings. Always ensure that the parts to be transported are

suspended or loaded properly so that they cannot fall, taking into account size,

weight and the centre of gravity.

Store the packages in a covered area, protected from direct sunlight, at a low

humidity and with temperatures between 0...+40 °C (32…104 °F). Do not stack

packages.

When unpacking, take care to avoid any possibility of injury or damage. Keep at a

safe distance when opening the package strapping, do not allow any parts to fall

out.

Pos: 48 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1/M/Über schr ift 1: M ontage und Er stinbe triebnahm e @ 18\mod_1255417443299_75.docx @ 463797 @ 1 @ 1

4

Installation and Initial Operation

Pos: 49 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nhalt: M onta ge und Erstinb etrieb nahme_ 12pt @ 26\mod_1324468562877_75.docx @ 1141153 @ @ 1

Installation and initial operation of the equipment may be done only by authorized

and trained service technicians provided by the manufacturer, licensed dealers or

service partners.

Pos: 50 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1/B/ Überschri ft 1: Bedienung @ 6\mod_1174482271218_75.docx @ 76877 @ 1 @ 1

5

Operation

Pos: 51 /Tec hnisch e Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/H/Überschr ift 1.1: Hauptsch alter @ 6\mod _117 75928 58312_ 75.d ocx @ 90 635 @ 2 @ 1

5.1

Main Switch

Pos: 52 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nhalt: H aupts chalter v2 - A lle Gerä te_1 2pt @ 30\m od_1351692594628_75.docx @ 1671389 @ @ 1

• Main switch in position 0: Power supply OFF

• Main switch in position 1: Power supply ON

• When in position 0, the main switch can be protected against

tampering by means of a padlock.

Pos: 53 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 12

12

BAE12901-en

Pos: 54 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1. 1/B/Überschr ift 1.1: Bedienei nheit @ 6\mod_1177424155343_75.docx @ 90114 @ 2 @ 1

5.2

Control Unit

Pos: 55 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-SERIES/E12901 MBT 1000 EUROSYSTEM/BA/Inhalt: E129 Bedieneinheit (Bilder) @ 41\mod_1421406400641_0.docx @ 2185150 @ @ 1

Pos: 56 /Tec hn isch e Dok ument atio n/Brem sprüf tec hnik/M BT-SER IE S/E 129 01 M BT 100 0 EUR OSY STE M/ BA/I nhal t: E129 Be die neinh ei t (L egend e) @ 4 1\mod_1421407129636_75.docx @ 2185196 @ @ 1

A

Emergency stop button

D

Lifting bar Speedometer tester (opt.)

B

Motors On/Off

E

Clamping device, front (option)

C

Lifting bar Brake tester (left: option)

F

Clamping device, rear (option)

The control unit is continuously movable along the handrail and can be swivelled

sideways after pulling it in a forward direction.

Pos: 57 /-----For ma t-----/MA NUE LLE R UM BR UCH Se iten um bru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

A

B C D

E F

Page 13

13

BAE12901-en

Pos: 58 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/P/Üb ersc hrift 1.1: Pr üfablauf @ 8\mod_1200574029101_75.docx @ 140824 @ 2 @ 1

5.3

Test Procedure

Pos: 59 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Inf o!/In halt : Inf o - Brem spr üfun g VO R Sch lupfab scha ltun g be ende n @ 41\mod_1421412099129_75.docx @ 2185494 @ @ 1

IMPORTANT NOTICE

The statutory requirements for the verification of braking efficiency do not demand

that the brake test be completed until slippage cutoff occurs.

Automatic slippage cutoff should be generally regarded as a safety feature,

not

as

the cutoff point for brake testing.*

It is adequate to terminate the test at approx. 90% of the maximum braking force.

This method is strongly recommended to help prevent tyre damage!

* Please note the implementing provisions for braking efficiency determination.

Pos: 60 /Tec hnische Do kument ation/Br emspr üftechn ik/MBT-S ERIE S/ E1 2901 MB T 10 00 E URO SYS TEM /BA/ In halt: E1 29 P rüfab la uf ( Tex t) @ 41\mod_1421659346487_75.docx @ 2185650 @ @ 1

1 Enter the roller set with the front wheel/axle (A).

2 Secure the rear wheel/axle with the clamping device (B).

3 Perform the brake test.

4 Open the clamping device at the rear wheel/axle.

5 Enter the roller set with the rear wheel/axle.

6 Secure the front wheel/axle with the clamping device.

7 Perform the brake test.

8 Open the clamping device at the front wheel/axle.

9 Exit the brake tester.

Pos: 61 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-SERIES/E12901 MBT 1000 EUROSYSTEM/BA/Inhalt: E129 Prüfablauf (Bilder) @ 41\mod_1421660434643_0.docx @ 2185752 @ @ 1

Pos: 62 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ MBT-S ERIE S/ E1 2901 MB T 10 00 E URO SYS TEM /BA/ In halt: Inf o - M BT E UROSY STE M-BA beigef ügt @ 41\m od_1421660105247_75.docx @ 2185696 @ @ 1

For a detailed description of the test lane software please see the operating instructions MBT EUROSYSTEM (document No. BAE10101-en, included).

Pos: 63 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

A B

Page 14

14

BAE12901-en

Pos: 64 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr ifte n 1/I/Über schrift 1: Instand haltun g @ 28\mod_1 33215 98125 36_ 75.docx @ 1565 908 @ 1 @ 1

6

Maintenance

Pos: 65 /Technische Dokume ntation/ Alle Ger äte/I nhalte/W arnu ng!/Inha lt: War nung - H auptsc halter aus bei Instand haltu ng_12pt @ 26\m od_1324465229892_75.docx @ 1140563 @ @ 1

Danger! Electric shock hazard!

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Pos: 66 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/J/Üb ersc hrift 1.1 : Jähr liche Überp rüfu ng @ 28\mod_1332230089694_75.docx @ 1566204 @ 2 @ 1

6.1

Annual Inspection

Pos: 67 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nfo!/I nhalt: I nfo - J ährliche Überpr üfung_1 2pt @ 25\mod_1324460481075_75.docx @ 1139412 @ @ 1

• The maintenance interval prescribed by the manufacturer is

12 (twelve) months

.

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

• Maintenance work shall be done only by authorized and trained service techni-

cians provided by the manufacturer, licensed dealers or service partners.

• In case of non-compliance the manufacturer's warranty becomes void.

Pos: 68 /Tec hn isch e Do kume nt atio n/A lle Ger äte /Üb ersc hr ifte n/ Über schr ift en 1.1/ P/Üb er sc hrif t 1. 1: P fle geh inwe ise @ 15\m od_12 4591 22348 54_7 5.docx @ 39578 0 @ 2 @ 1

6.2

Care Instructions

Pos: 69 /Technische Dokumentat ion/Alle Gerät e/Inhalte/I nhalt: Pflegeh inweise - Al le Geräte _12pt @ 26\mod_1324468886116_75.docx @ 1141252 @ @ 1

• Periodically clean the equipment and treat it with a care product.

• Repair damage to the paintwork immediately to prevent corrosion.

• Usage of caustic cleaning agents or high pressure and steam jet cleaners may

lead to equipment damage.

Pos: 70 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nfo!/I nhalt: I nfo - Pflegehinweise_12pt @ 26\mod_1324461215655_75.docx @ 1139602 @ @ 1

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment!

Pos: 71 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/E/ Übersc hrift 1 .1: Ersatz teile @ 18\m od_12 5559 68470 02_7 5.docx @ 47441 4 @ 2 @ 1

6.3

Spare Parts

Pos: 72 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nhalt: Er satzte ile - Alle Gerät e_12pt @ 2 6\mod_1324468768120_75.docx @ 1141219 @ @ 1

To ensure safe and reliable operation, only use original spare parts supplied by the

equipment manufacturer.

Pos: 73 /-----For ma t-----/MAN UEL LER UM BRUCH Seitenum br uch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 15

15

BAE12901-en

Pos: 74 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/I/ Überschr ift 1.1: Ins tandhaltu ng des Kette ntriebs : Re inigen, N achspan nen, S chmier en @ 3 6\mod_1394630342377_75.docx @ 1918730 @ 2 @ 1

6.4

Chain Drive Maintenance: Cleaning, Retensioning, Lubricating

Pos: 75 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nfo!/I nhalt: I nfo - W art ungs int erv all: M ona tl ich_ 12pt @ 26\mod_1324463913433_75.docx @ 1140268 @ @ 1

Maintenance interval: Monthly

Pos: 76 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Inha lt: 0200 Kett en i nstand halt en E inleit ung_ 12p t @ 33\mod _1 374 065 9366 93_ 75.d ocx @ 1 809 475 @ @ 1

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Remove the roller set covers from above the chains, reinstall before restarting the

brake tester.

Pos: 77 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/I nhalt: 0200 Ketten reinigen_1 2pt @ 33\mod_1374064814451_75.docx @ 1809387 @ @ 1

Cleaning the Chains

The chains can normally be cleaned using a cloth or brush, stubborn dirt can be

removed with petroleum solvent or benzine. Do not use pickles or acids! Reapply

a new anticorrosive film immediately after using degreasing agents (see section

"Greasing the Chains").

Pos: 78 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/I nhalt: 02 00 Ketten nachspa nnen_12p t @ 33\mod_1374065445290_75.docx @ 1809431 @ @ 1

Retensioning the Chains

Check the chain slack: the chain should be movable by hand approx. 5 mm up

and down. If the chain needs retensioning, proceed as follows:

• Open the fastening screws.

• Adjust the chain tension using the tensioning screw.

• Tighten the fastening screws (see table for torque figures).

• Recheck the chain slack.

Pos: 79 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Inha lt: 0200 Kett en na chspa nn en - Anz ugsm om ent e @ 3 4\mod_1378969980518_75.docx @ 1825309 @ @ 1

Brake tester

model

Thread

Strength

Tightening

torque

Position

Required for chain

tensioning?

MBT

1xxx/2xxx/3xxx

M10 8.8 50 Nm Running roller yes

M16 8.8 120 Nm Motor mount yes

MBT 4xxx

M18 8.8 350 Nm Running roller yes

M20 8.8 350 Nm Motor mount only for RS1

MBT 5xxx

M16 8.8 220 Nm Running roller no

M18 8.8 350 Nm Motor mount yes

MBT 6xxx/7xxx

M18 8.8 350 Nm Running roller yes

M20 8.8 350 Nm Motor mount only for RS1 + RS3

MBT 7xxx

M18 8.8 500 Nm

Raised running

roller

yes

M27 8.8 500 Nm Motor mount 3:4 no

Pos: 80 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Inha lt: 0200 Kett en sc hmier en_1 2pt @ 3 3\mod_1374063619890_75.docx @ 1809299 @ @ 1

Page 16

16

BAE12901-en

Lubricating the Chains

The service lifetime of the chains directly depends on correct lubrication. Provided

that the lubricating film is continuously maintained, chain wear can be reduced to

a minimum

Recommended lubricant: LongLub adhesive lubricant (MAHA part # 35 1020)

• Lubricate the chain over its entire length while turning over the rollers by hand.

Important: The lubricant must contact the chain links!

Pos: 81 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/I nhalt : 0200 Ketten schm ieren (B ild) @ 33\mod_1374060263983_0.docx @ 1809079 @ @ 1

Pos: 82 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 17

17

BAE12901-en

Pos: 83 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Inha lt: I nst K ette nsp annu ng (B ilder) IW 10 @ 22\m od_ 128 5658 467 283_ 0.d ocx @ 9 020 83 @ @ 1

Pos: 84 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/ Inha lt: I nst K ette nsp annu ng (Le ge nde) _12p t @ 35\ mod_1393514825943_75.docx @ 1912343 @ @ 1

A

Chain

B

Fastening screws

C

Tensioning screw

Pos: 85 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1.1/T/ Überschr ift 1. 1: Tastr ollensc harnier e schm ieren @ 36\m od_ 139 46304 6953 1_75.d ocx @ 1 91877 4 @ 2 @ 1

6.5

Greasing the Sensor Roller Hinges

Pos: 86 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nfo!/I nhalt: I nfo - W artun gsint ervall : 200 h / 12 Mo nate_ 12pt @ 26\ mod_1324463609793_75.docx @ 1140170 @ @ 1

Maintenance interval: 200 hours / 12 months

Pos: 87 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/I nhalte/ Inha lt: Ins t Tastr ollen (Text) IW 2/4/7/ 10_12p t @ 41\mod_1421655991818_75.docx @ 2185604 @ @ 1

B B

C

A

Page 18

18

BAE12901-en

Grease the sensor roller hinges every 200 (two hundred) operating hours or once

annually.

1 Remove the cover plates from the roller set.

2 Treat the greasing points (D) using a spray lubricant. Move the sensor roller up

and down.

3 Reinstall the cover plates to the roller set.

Pos: 88 /Techn ische Dokum ent atio n/Brem spr üftec hnik/ - Arc hiv -/- Bremsp rüftec hnik A lle -/In halte/I nhalt: Ins t Tastrol len (Bild er) IW 10 @ 22\mod_1285659960275_0.docx @ 902343 @ @ 1

Pos: 89 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.do cx @ 127 7 @ @ 1

D D

Page 19

19

BAE12901-en

Pos: 90 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1/D/ Überschr ift 1: Demontage @ 19\mod_1266336822863_75.docx @ 742452 @ 1 @ 1

7

Dismantling

Pos: 91 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nhalt: Demontage - Alle Geräte_12pt @ 26\mod_1324466078229_75.docx @ 1140857 @ @ 1

Decommissioning and dismantling of the equipment may be done only by

specially authorized and trained personnel provided by the manufacturer, licensed

dealers or service partners.

Pos: 92 /Technische Dokumentat ion/Alle Gerät e/Übersc hriften/Über schriften 1/G/ Überschr ift 1: Geräteentsor gung @ 6\mod_1174482271625_75.docx @ 76901 @ 1 @ 1

8

Disposal

Pos: 93 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nhalt: Gerät eentsor gung dur ch B etreiber allg_1 2pt @ 26\mod_1324467874153_75.docx @ 1140955 @ @ 1

Pay attention to the product and safety data sheets of the lubricant used. Avoid

damage to the environment. Should a disposal of the device be necessary it must

be done in adherence with locally applicable legal regulations regarding

environmental protection. Remove all materials properly sorted out and bring them

to a suitable waste disposal service. Collect operating materials such as grease,

oils, coolant, solvent-based cleaning fluids etc. in suitable containers and dispose

of in an environmentally protective manner.

Pos: 94 /Technische Dokumentat ion/Alle Gerät e/Inhalte/I nhalt: Gerät eentsorgung über Fachbetr ieb (alternativ)_ 12pt @ 26\mod _1 324 468 1208 52_ 75.d ocx @ 1 141 022 @ @ 1

Alternatively, you may take the equipment to a specialised waste management

plant to ensure that all components and operating liquids are properly disposed

of.

Pos: 95 /-----For ma t-----/MAN UE LLE R UM BR UCH Se iten umb ru ch @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 20

20

BAE12901-en

Pos: 96 /Technische Dokume ntation/ Alle Ger äte/Üb ersc hriften/ Überschr iften 1/I/Über schr ift 1: In halt der Konf ormitäts erklär ung @ 2 2\mod_ 12928 56748 432_ 75.do cx @ 958 616 @ 1 @ 1

9

Contents of the Declaration of Conformity

Pos: 97 /Technische Dokume ntation/ Alle Ger äte/I nhalte/I nhalt: I nhal t der K onformi tätserkl ärung a llg_1 2pt @ 26\mod_1324468436145_75.docx @ 1141120 @ @ 1

MAHA Maschinenbau Haldenwang GmbH & Co. KG

herewith declares as a manufacturer its sole responsibility to ensure that the

product named hereafter meets the safety and health regulations both in design

and construction required by the EC directives stated below.

This declaration becomes void if any change is made to the product that was not

discussed and approved by named company beforehand.

Pos: 98 /Techn isch e Dok ument atio n/Bre mspr üftec hn ik/MB T-SERI ES /E1 0101 EU ROSY STE M S tand ar d/BA /In hal t: E 101 In halt d er Kon form itä tser klä run g_12p t @ 44\ mod_1461830999778_75.docx @ 2438054 @ @ 1

Model: MBT 1000 EUROSYSTEM / MBT 2250 EUROSYSTEM

MBT 2450 EUROSYSTEM 4WD / MBT 3250 EUROSYSTEM

MBT 3450 EUROSYSTEM 4WD / MBT 4250 EUROSYSTEM

MBT 4450 EUROSYSTEM 4WD / MBT 5250 EUROSYSTEM

MBT 6250 EUROSYSTEM / MBT 7250 EUROSYSTEM

MBT 7450 EUROSYSTEM 4WD

Designation:

Safety Test Lane, consisting of:

Roller Brake Tester:

MBT 1000 EUROSYSTEM:

(optional) Motorcycle Holding Device

Rated Axle Load 2000 kg

Motor Power 2x3 kW

MBT 2250 EUROSYSTEM / MBT 2450 EUROSYSTEM 4WD

MBT 3250 EUROSYSTEM / MBT 3450 EUROSYSTEM 4WD:

Rated Axle Load 3500 kg (optional 4000, 5000 or 8000 kg)

Motor Power 2x3 kW (4 or 5,5 kW optional)

MBT 4250 EUROSYSTEM / MBT 4450 EUROSYSTEM 4WD

MBT 5250 EUROSYSTEM / MBT 6250 EUROSYSTEM:

Rated Axle Load 13 000 kg (optional 15 000 or 18 000 kg)

Motor Power 2x7,5 kW, 2x9 kW, 2x11 kW, 2x15 kW

MBT 7250 EUROSYSTEM / MBT 7450 EUROSYSTEM 4WD:

Rated Axle Load 18 000 kg (optional 20 000 kg)

Motor Power 2x9 kW, 2x11 kW, 2x16 kW

Side-Slip Tester MINC EURO / MINC II EURO:

Rated Axle Load 3000 / 5000 kg

Shock Tester SA2 EURO oder MSD 3000:

Rated Axle Load 1100 kg (optional 2000 kg) or 2200 kg

Speedometer Tester TPS I / II / III; TPS 25

Directives: 2006/42/EC; 2014/30/EU

Standards: DIN EN ISO 12100:2010; DIN EN ISO 13850,

DIN EN ISO 13857,

DIN EN 349; DIN EN 60204-1; DIN EN 61000-6-3,

DIN EN 61000-6-2

Pos: 99 /-----Form at-----/ MAN UE LLE R UM BR UCH Se iten umb ruc h @ 0\mod_1134403577687_0.docx @ 1277 @ @ 1

Page 21

21

BAE12901-en

Pos: 100 /Technische D okumen tation/ Alle G eräte/ Überschr iften/ Übers chrifte n 1/F/Über schr ift 1: Firmen -Infor mation @ 7\m od_11 87338 6258 28_7 5.docx @ 10404 7 @ 1 @ 1

10

Company Information

Pos: 101 /Technische D okumen tation/ Alle G eräte/In halt e/Inhalt : Firmen -Inf ormat ion M AHA @ 42\ mod_1422267670099_75.docx @ 2188049 @ @ 1

© MAHA Maschinenbau Haldenwang GmbH & Co. KG

Legal notice based on ISO 16016:

The reproduction, distribution and utilization of this document as well as the communication of its

contents to others without explicit authorization is prohibited. Offenders will be held liable for the

payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

The contents of this edition have been checked with great care. However, errors cannot be fully

excluded. Subject to technical change without notice.

Document

Document No.: BAE12901-en

Approval Date: 2016-06-01

Manufacturer

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20

87490 Haldenwang

Germany

Phone: +49 8374 585 0

Fax: +49 8374 585 590

Fax Parts: +49 8374 585 565

Internet: http://www.maha.de

E-Mail: maha@maha.de

Hotline: +49 180 66242 60 for Brake Testers and Test Lanes

+49 180 66242 80 for Automotive Lifts

+49 180 66242 90 for Dynamometers and Emission Testers

Service

AutomoTec GmbH

Maybachstraße 8

87437 Kempten

Germany

Phone: +49 180 66242 50

Fax: +49 180 66242 55

Internet: http://www.automo-tec.com

E-Mail: service@automo-tec.com

=== Ende der Liste für Textm arke In halt ===

Loading...

Loading...