MAHA AXPLAY PMS 3/R, AXPLAY PMS 3.5, AXPLAY PMS 3/D, AXPLAY PMS 3/X, AXPLAY PMS 3/XL Original Operating Instructions

...Page 1

Fehler! Verwenden Sie die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie

die Registerkarte 'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.Fehler! Verwenden Sie die Registerkarte

'Start', um Name dem Text zuzuweisen, der hier angezeigt werden soll.

PMS | LMS

Axle Play Detector

Original Operating Instructions

BA010101-en

PMS 3.5

LMS 20.0

PMS 3/D

PMS 3/R

PMS 3/X

PMS 3/XL

PMS 3/D PIT

PMS 3/P PIT

LMS 18/1 MTL

LMS 18/2 MTL

Page 2

2

Manufacturer

Service

BA010101-en

2019-09-10

© MAHA Maschinenbau Haldenwang GmbH & Co. KG

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without explicit authorization is prohibited. Offenders will be held liable for the payment of damages. All

rights reserved in the event of the grant of a patent, utility model or design.

The contents of this edition have been checked with great care. However, errors cannot be fully excluded. Subject to technical change without notice.

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20

87490 Haldenwang

Germany

Phone: +49 8374 585 0

Fax: +49 8374 585 590

Mail: maha@maha.de

Web: www.maha.de

MAHA SERVICE CENTER

Maybachstraße 8

87437 Kempten

Germany

Phone: +49 8374 585 100

Fax: +49 8374 585 491

Mail: service@maha.

de

Web: www.mahaservicecenter.de

BA010101-en

Page 3

3

Contents

1

Safety .................................................................................................................... 5

2

Specifications......................................................................................................... 9

3

Transport and Storage ......................................................................................... 11

4

Installation and Initial Operation............................................................................. 11

5

Operation ............................................................................................................. 12

6

Maintenance ........................................................................................................ 16

7

Dismantling .......................................................................................................... 23

8

Disposal ............................................................................................................... 23

9

Contents of the Declaration of Conformity ............................................................. 23

1.1 Introduction .............................................................................................................. 5

1.2 Symbols and Signal Words ...................................................................................... 5

1.2.1 Personal Injury .......................................................................................................... 5

1.2.2 Property Damage ..................................................................................................... 5

1.2.3 Information ............................................................................................................... 5

1.3 Intended Use ........................................................................................................... 6

1.4 Requirements on Operating and Service Personnel .................................................. 6

1.5 Safety Instructions for Commissioning ...................................................................... 6

1.6 Safety Instructions for Operation............................................................................... 6

1.7 Safety Instructions for Servicing ................................................................................ 7

1.8 Safety Instructions for Handling Hydraulic Fluid ......................................................... 8

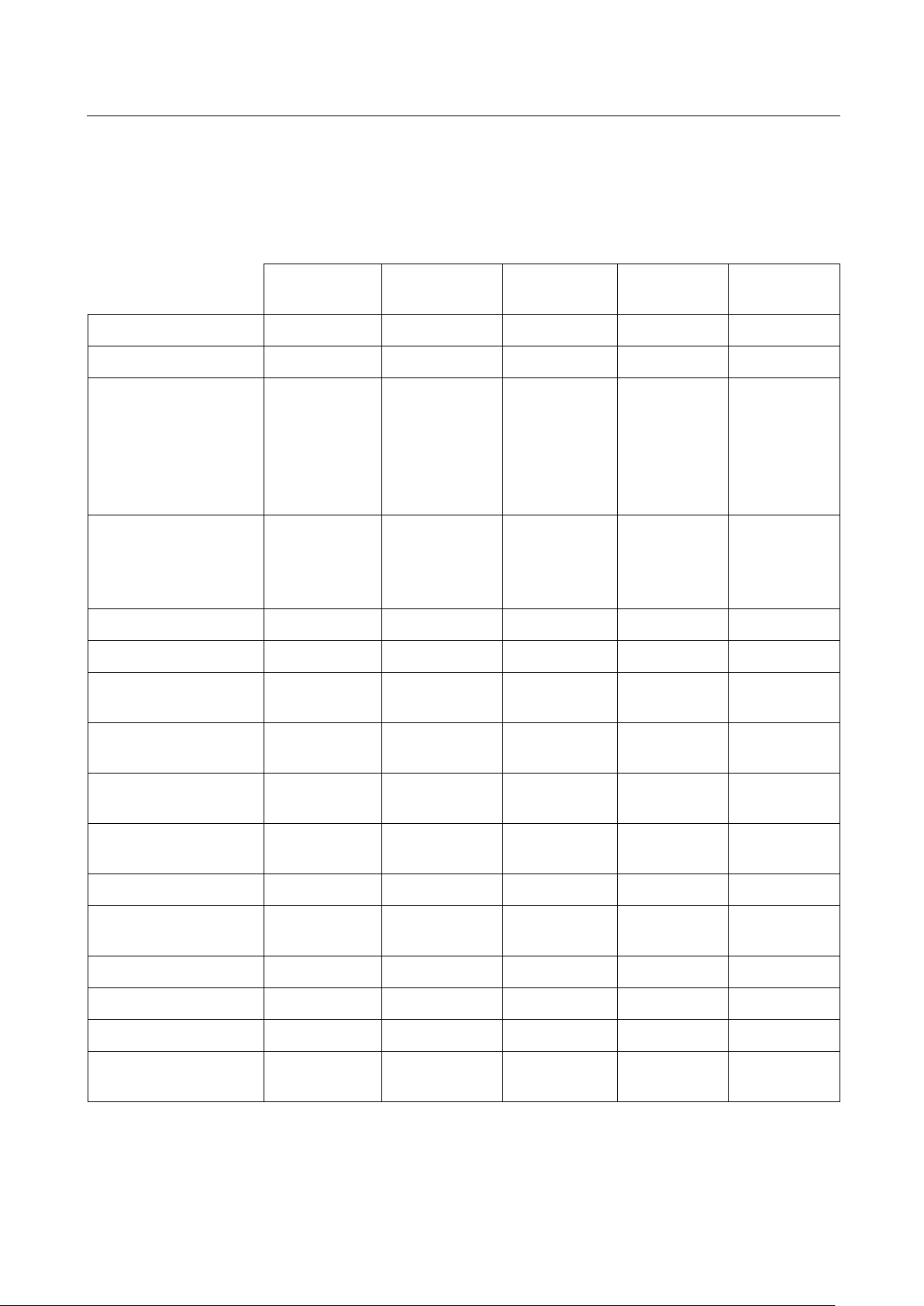

2.1 PMS Specifications .................................................................................................. 9

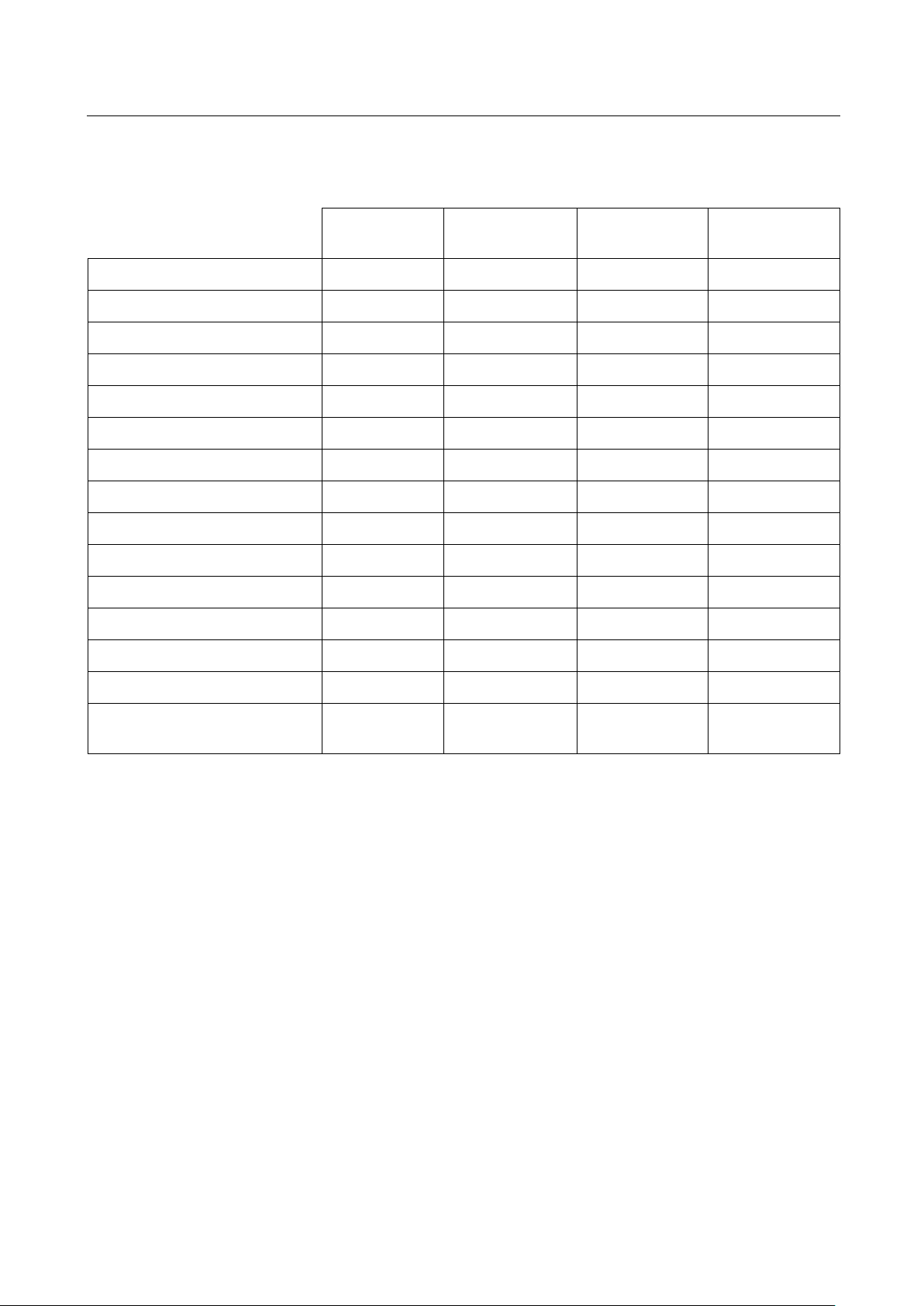

2.2 LMS Specifications ................................................................................................. 10

5.1 Main Switch ........................................................................................................... 12

5.2 Preparing for Operation .......................................................................................... 12

5.3 Operating the Axle Play Detector ............................................................................ 13

5.4 Operating the Cable Hand Lamp ............................................................................ 14

5.5 Operating the Radio Hand Lamp RHL (Option) ....................................................... 14

5.6 Service Mode ......................................................................................................... 15

5.7 Operating Diagrams ............................................................................................... 15

6.1 Maintenance Schedule ........................................................................................... 16

6.2 Annual Inspection ................................................................................................... 16

6.3 Maintenance by the Operator ................................................................................. 17

6.4 Greasing Points ...................................................................................................... 17

6.5 Care Instructions .................................................................................................... 19

6.6 Spare Parts ............................................................................................................ 19

6.7 PMS Variants for Installation on Lift Runways ......................................................... 19

BA010101-en

Page 4

4

10

Annex: Operating Diagrams .................................................................................. 23

BA010101-en

Page 5

5

1

Safety

1.1

Introduction

1.2

Symbols and Signal Words

1.2.1

Personal Injury

DANGER

WARNING

CAUTION

1.2.2

Property Damage

NOTICE

1.2.3

Information

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

safety instructions are not covered by the product liability regulations.

indicates an immediate hazard which, if not avoided, will result in death or severe

personal injury.

indicates a potential hazard which, if not avoided, could result in death or severe

personal injury.

indicates a potential hazard which, if not avoided, could result in moderate or minor personal injury.

indicates a potentially harmful situation which, if not avoided, could result in damage to the equipment or surrounding objects.

indicates important information notes.

BA010101-en

Page 6

6

1.3

Intended Use

WARNING

1.4

Requirements on Operating and Service Personnel

WARNING

1.5

Safety Instructions for Commissioning

WARNING

1.6

Safety Instructions for Operation

WARNING

• Before pressing the transmit button, check whether the channel of the radio

This device is used exclusively to inspect the axle and joint play of vehicles.

Axle play detectors in mobile test lanes are only intended for operation when the

lifting device is lowered.

The unit must not be modified without express written permission from the

manufacturer. Non-compliance invalidates the declaration of conformity.

Any use other than described is inappropriate.

All persons employed in the operation, maintenance, installation, removal and disposal of the device must

• be at least 18 years old,

• be mentally and physically suited for these activities,

• be demonstrably trained and instructed in writing,

• have read and understood the operating instructions, especially the instructions

what to do in the event of defects or malfunctions,

• be on record as having been instructed in safety guidelines,

• have practical experience in working with vehicle lifts and the hazards inherent

in such equipment.

• The equipment shall be installed and commissioned by authorised service per-

sonnel only.

• Observe the detailed operating instructions.

• Comply with legal accident prevention regulations.

• The permissible load capacity according to the rating plate must not be ex-

ceeded.

BA010101-en

Page 7

7

hand lamp matches the receiver’s channel. No equipment that might also re-

1.7

Safety Instructions for Servicing

WARNING

Ensure that ecologically harmful substances are disposed of only in accordance

spond to this channel may be located anywhere on the premises. The unintended operation of other equipment may put people at risk.

Furthermore, no transmission equipment that could respond to the axle play

detector may be located anywhere on the premises.

• To prevent injuries caused by impact or being run over, a sufficient safe dis-

tance from the vehicle to be tested must be maintained when it is being driven

onto and off the test equipment.

• Before testing, the vehicle to be tested must be secured against rolling away.

When used on sloped surfaces (e.g. access ramps in mobile test lanes), it is

advisable to have someone man the driver’s cab during testing so they can respond to unintended movements.

• Wear personal protective equipment.

• A sufficient safety distance from the surface of the test plates’ movement area

must be maintained. Risk of crushing and shearing!

• Test plates must not be walked on, even when not in use. There is a risk of fall-

ing due to unexpected test plate movements. There is a risk of slipping due to

water or ice on the test plates.

• During operation avoid lateral shifting of the vehicle on the test plates and con-

tinually monitor the position of both wheels on the test plates. Should the

wheels move close to the edge of the test plates, stop the test immediately and

reposition the vehicle.

• Periodically check the fastening screws of the test plates for tight fit.

• Service work may be done by authorised service technicians only.

• Turn off and padlock the main switch before doing any repair, maintenance or

setup work.

• Work on the electrical equipment may be done by service technicians or certi-

fied electricians only.

•

with the appropriate regulations.

BA010101-en

Page 8

8

1.8

Safety Instructions for Handling Hydraulic Fluid

CAUTION

• Neutralize hydraulic fluid spills with binder.

• Remove contaminated clothing immediately.

• Inhalation: If symptoms persist, seek medical treatment.

• Skin contact: Wash skin immediately with soap and water. If skin irritation per-

sists, seek immediate medical advice.

• Eye contact: Rinse thoroughly with water and seek medical advice.

• Ingestion: Do not induce vomiting. Seek immediate medical attention.

BA010101-en

Page 9

9

2

Specifications

2.1

PMS Specifications

PMS 3.5

PMS 3/D PIT

PMS 3.5

Double

PMS 3/P PIT

PMS 3/X

PMS 3/XL

Axle load max.

Wheel load max.

TP Dimensions

Installation height incl.

TP

TP height above floor

Thrust per side max.

Movement per side

max.

TP speed (2 TP simultaneously)

Hydraulic pressure

max.

Pneumatic pressure

max.

Hydraulic fluid

Filling quantity of hydraulic unit

Supply voltage

Rated motor power

Fuse

Control voltage of cable

hand lamp

3500 kg 3500 kg 2800 kg 3500 kg 3500 kg

1750 kg 1750 kg 1400 kg 1750 kg 1750 kg

248x550 mm

(left, ApS)

155x460 mm

(left, ExS)

500x550 mm

(right)

625x625 mm

625x625 mm

(FA)

1310x625 mm

(RA)

248x550 mm

(left, 2x)

426x560 mm

500x550 mm

(right)

127.5 mm

(left)

127.5 mm

(left)

148 mm 148 mm 185 mm

92.5 mm

(right)

92.5 mm

(right)

15 mm 15 mm 10 mm --- ---

11 kN 11 kN 10 kN 11 kN 11 kN

100 mm 100 mm 24° 77 mm 77 mm

75 mm 75 mm --- adjustable adjustable

120 bar 120 bar --- 120 bar 120 bar

--- --- 10 bar --- ---

HLPD 32 HLPD 32 --- see Lift see Lift

8.5 ℓ 8.5 ℓ --- see Lift see Lift

3x400 V 3x400 V --- see Lift see Lift

Abbr.: TP = Test Plate(s); FA = Front Axle; RA = Rear Axle;

ApS = Approach Side; ExS = Exit Side

2.5 kW 2.5 kW --- see Lift see Lift

16 A slow 16 A slow --- see Lift see Lift

24 V 24 V --- 24 V 24 V

BA010101-en

Page 10

10

2.2

LMS Specifications

LMS 20.0

LMS 20.0

flush-floor

LMS 20.0 ex-

tended TP

LMS 18/1 MTL

LMS 18/2 MTL

Axle load max.

Wheel load max.

TP Dimensions

Installation height incl. TP

TP height above floor

Thrust per side max.

Movement per side max.

TP speed (2 TP simultaneously)

Hydraulic pressure max.

Hydraulic fluid

Filling quantity of hydraulic unit

Supply voltage

Rated motor power

Fuse

Control voltage of cable hand

lamp

20 000 kg 20 000 kg 20 000 kg 18 000 kg

10 000 kg 10 000 kg 10 000 kg 9000 kg

740x740 mm 740x740 mm 1310x740 mm 712x712 mm

232 mm 232 mm 232 mm 170 mm

15 mm 0 mm 15 mm 20 mm

30 kN 30 kN 30 kN 30 kN

100 mm 100 mm 100 mm 100 mm

60 mm/s 60 mm/s 60 mm/s 30 mm/s

120 bar 120 bar 120 bar 120 bar

Abbr.: TP = Test Plate(s)

HLPD 32 HLPD 32 HLPD 32 HLPD 32

20.3 ℓ 20.3 ℓ 20.3 ℓ 8.5 ℓ

3x400 V 3x400 V 3x400 V 3x400 V

2.5 kW 2.5 kW 2.5 kW 2.5 kW

16 A slow 16 A slow 16 A slow 16 A slow

24 V 24 V 24 V ---

BA010101-en

Page 11

11

3

Transport and Storage

NOTICE

4

Installation and Initial Operation

WARNING

WARNING

Check package to ensure it is complete, in accordance with the order confirmation. Report any transport damage to the carrier immediately.

During loading, unloading and transport always use suitable lifting equipment, material handling equipment (e.g. cranes, forklifts, etc.) and the right load handling

attachments and slings. Always ensure that the parts to be transported are suspended or loaded properly so that they cannot fall, taking into account size,

weight and the centre of gravity.

Store the packages in a covered area, protected from direct sunlight, at a low

humidity and with temperatures between 0...+40 °C (32…104 °F). Do not stack

packages.

When unpacking, take care to avoid any possibility of injury or damage. Keep at a

safe distance when opening the package strapping, do not allow any parts to fall

out.

Installation and initial operation of the equipment may be done only by authorized

and trained service technicians provided by the manufacturer, licensed dealers or

service partners.

Before connecting the power supply, make sure that an external, lockable EMERGENCY-STOP MAIN SWITCH is used. This must be provided by the customer

and installed in the power supply line to the control.

The EMERGENCY-STOP MAIN SWITCH must meet the requirements of

EN ISO 13850.

BA010101-en

Page 12

12

5

Operation

5.1

Main Switch

DANGER

Main switch in position 0

Main switch in position 1

5.2

Preparing for Operation

WARNING

The main switch is used as emergency switch. In case of emergency immediately

turn it to position 0!

Lift is disconnected from power supply

Lift is ready for operation

Examine the danger zone and ensure that warnings are legible. Damaged or illegible warnings and markings must be replaced immediately.

When operating an axle play detector in a mobile test lane, it must be ensured that

all the hydraulic components’ covers are fitted and do not show any signs of

damage that would restrict functionality or signs of poor attachment.

If light conditions vary a great deal between test objects and peripherals (e.g.

when used in mobile test lanes outdoors), sufficient lighting or glare protection

must be provided.

A sufficiently ergonomic positioning option must be provided for performing the

test (particularly for vehicle testing in mobile test lanes).

• Test plates must not be walked on, even when not in use. There is a risk of fall-

ing due to unexpected test plate movements. There is a risk of slipping due to

water or ice on the test plates.

• During operation avoid lateral shifting of the vehicle on the test plates and con-

BA010101-en

tinually monitor the position of both wheels on the test plates. Should the

wheels move close to the edge of the test plates, stop the test immediately and

reposition the vehicle.

Page 13

13

5.3

Operating the Axle Play Detector

WARNING

NOTICE

• The hand lamp must be carried in such a way that eliminates the risk of unin-

tentional operation of the axle play detector. For safety reasons, it is advisable

to stay within the axle play detector’s field of vision and danger zone when using the hand lamp.

• The hydraulic unit must never be left running for longer than absolutely neces-

sary, as the pump can become damaged otherwise.

• The hand lamp must be protected against shocks to ensure that the light bulb

has a long service life.

• Some types of axle play detector are equipped with a synchronisation switch

on the control box which enables control of the plates’ lengthwise and/or

crosswise movement.

• If the plates are moved back and forth in the direction of travel, the brake must

be applied as the turning wheels would otherwise follow the plates’ movements.

• Attempts should always be made to cause the vehicle wheel to slip onto the

plates, as this is the best way to detect incorrect axle play.

1 Switch the test device on at the main switch.

2 Drive the vehicle to be tested onto the test plates at walking speed and secure

it against rolling away, e.g. apply the parking brake or use chocks.

3 The testing plates can be operated using the hand lamp’s push-button

functions.

4 Switch the light and the hydraulic unit off after testing.

5 Drive the vehicle off the test plates.

6 Place the hand lamp in the charging holder to charge.

BA010101-en

Page 14

14

5.4

Operating the Cable Hand Lamp

5.5

Operating the Radio Hand Lamp RHL (Option)

A B C D E

A / B Movement of test plates

C / E Selection of movement (such as switch-over between single, synchronous,

counter or diagonal movement)

D Switch on and off the lamp

See separate operating manual.

BA010101-en

Page 15

15

5.6

Service Mode

Enable Service Mode

Function while Service Mode is Enabled

Quit Service Mode

5.7

Operating Diagrams

To remove the sliding plates, the hydraulic cylinders must be pressure relieved. To

do this, a Service mode was integrated. When this mode is enabled, only the

valves are driven as in the normal operating mode. The hydraulic pump remains

OFF.

• Cable hand lamp: Push and hold rocker buttons A and B together for

10 seconds. The pump switches off. (Simultaneous actuation of A1 and B1 or

A2 and B2).

Once the second button is detected, the valves are switched off. The pump

remains ON until 10 seconds have elapsed. The plates remain in their last posi-

tion.

• Radio hand lamp: Set to mode LED ON (Manual operating button). To enable

the Service mode, push and hold the operating button for 25 seconds.

During this time period, the valve is ON and the pump is also ON. After

25 seconds the pump switches OFF. The valve remains ON.

When in the Service mode, the valves of the corresponding moving directions can

be driven using the operating buttons, and the plates can be moved by hand.

On the MAH CAN RP circuit board the Service mode is indicated by the yellow

LED of VD20.

• Cable hand lamp: Push and hold rocker buttons A and B together for

10 seconds. The output for the pump switches ON and the Service mode is

quit.

• Radio hand lamp: Set to mode LED ON. Push and hold the operating button

for 25 seconds to quit the Service mode. After 25 seconds the pump switches

ON.

Alternatively, the Service mode can be quit by switching off the power supply.

See Annex.

BA010101-en

Page 16

16

6

Maintenance

DANGER

Risk of death or severe personal injury by electric shock

6.1

Maintenance Schedule

and aging,

6.2

Annual Inspection

12 (twelve) months

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

Interval Maintenance Items Procedure

Check fluid level, refill if necessary.

Check hydraulic system for leakages.

3 months Hydraulic system

Check power unit for unusual noise during operation, check fastening screws

for tight fit.

6 months Hydraulic fluid

Check fluid for contamination

replace if necessary.

12 months General inspection Check all components for damage.

6 years Pressure hoses Replace pressure hoses

• The maintenance interval prescribed by the manufacturer is

.

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

• Maintenance work shall be done only by authorized and trained service techni-

cians provided by the manufacturer, licensed dealers or service partners.

• In case of non-compliance the manufacturer's warranty becomes void.

BA010101-en

Page 17

17

6.3

Maintenance by the Operator

NOTICE

6.4

Greasing Points

Relieve the pressure to remove the test plates; activate service mode for this purpose (see section “Operation > Service Mode”).

• Remove the test plates and lubricate the guides with a grease gun or grease

the plastic sliding strips every 200 operating hours, but at least every three

months. In the case of PMS plates installed in lift runways, lubrication can take

place directly from below.

• Check that all the guide rods are secure and tighten them if necessary.

• Check the oil level regularly and top it up if necessary. The oil level must be be-

tween the two marks.

• Change the hydraulic oil every two years. Please see the section entitled “Spec-

ifications” for the filling quantity and specifications.

Lubricating with

a grease gun

PMS plates in lift runways (view: underside of the runways)

Greasing with a brush

BA010101-en

Page 18

18

PMS 3.5

LMS 20.0

LMS 18/1 MTL

LMS 18/2 MTL

BA010101-en

Page 19

19

6.5

Care Instructions

NOTICE

6.6

Spare Parts

6.7

PMS Variants for Installation on Lift Runways

PMS 3/R

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment.

• Periodically clean the equipment and treat it with a care product.

• Repair damage to the paintwork immediately to prevent corrosion.

• Do not use caustic cleaning agents or high pressure and steam jet cleaners to

avoid equipment damage.

To ensure safe and reliable operation, only use original spare parts supplied by the

equipment manufacturer.

BA010101-en

Page 20

20

PMS 3X or PMS 3XL

Prism

PMS 3X

Available with a

pneumatic prism

as an option =

PMS 3XL

B18, B23, B30, B31 for centring in the 10 t option.

The front axle is centred first of all, followed by the rear axle.

Optional:

PMS 3D

BA010101-en

Page 21

21

Prism

PMS 3X

Available with a

pneumatic prism

as an option=

PMS 3XL

Optional:

PMS 3R

BA010101-en

Page 22

22

PMS 3P (Pneumatic)

PMS 3XIE

Prism

Prism

PMS 3P

Standard:

test plate on the

left and right

ATL:

one plate on the

right in the direction of travel only

PMS 3XIE

With two pneu-

matic prisms

BA010101-en

Page 23

23

7

Dismantling

8

Disposal

9

Contents of the Declaration of Conformity

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Type:

Name:

Directives:

Standards:

10

Annex: Operating Diagrams

Decommissioning and dismantling of the equipment may be done only by

specially authorized and trained personnel provided by the manufacturer, licensed

dealers or service partners.

Pay attention to the product and safety data sheets of the lubricant used. Avoid

damage to the environment. Should a disposal of the device be necessary it must

be done in adherence with locally applicable legal regulations regarding

environmental protection. Remove all materials properly sorted out and bring them

to a suitable waste disposal service. Collect operating materials such as grease,

oils, coolant, solvent-based cleaning fluids etc. in suitable containers and dispose

of in an environmentally protective manner.

Alternatively, you may take the equipment to a specialised waste management

plant to ensure that all components and operating liquids are properly disposed

of.

herewith declares as a manufacturer its sole responsibility to ensure that the

product named hereafter meets the safety and health regulations both in design

and construction required by the EC directives stated below.

This declaration becomes void if any change is made to the product that was not

discussed and approved by named company beforehand.

PMS / LMS

3,500 / 20,000 kg

EN 61000-6-3, EN 61000-6-2

See following page(s).

Axle clearance tester for cars and lorries; permissible axle load

2006/42/EC; 2014/30/EU

EN 12100-1/-2; EN 13850, EN 13857, EN 349; EN 60204-1;

BA010101-en

Page 24

A

87

B

C

A2

B2

C2

D

D0

E0

E

LMS 18/2 MTL

300

Büro

100075

F

10

von

1

Blatt

--

Version

A3

87

D0

/

I 0 II

I 0 II

I 0 II

- 0

- 0

Werkstoff

Werkstoffnummer

Änderungsnr.

D1

light on/off

Licht an/aus

Fluid-Plan

right plate

/

left plate

linke Platte / rechte Platte

cable hand lamp

Kabelhandlampe

A2

A1 -

B2

B1

A1

B1

C1

D1

E1

[1/8] PMS 3.5 & LMS 20.0 &

Mindeststreckgrenze Re in N/mm²

Oberfläche

Dokumenttyp

Dokumentnummer

10001022

00

Nettogewicht in kg

Maßstab

E

Schutzvermerk beachten

DIN ISO 2768-mK

nach DIN ISO 16016

0.000

1:1

Benennung

Revision

Fernbedienung PMS/LMS Bedienschema

3000007

Materialnummer

alte Materialnummer

MOBERMAY

Datum, Freigabe

02.09.2019

6

MOBERMAY

Datum, Prüfer

02.09.2019

MOBERMAY

5 6

LED off

/

LED off

/

Size ISO 14405

Allgemeintoleranzen

4

LED flashing

/

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED flashing

/

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

5

Datum, Ersteller

3.6.2019

4

32

right plate

/

left plate

linke Platte / rechte Platte

2 3

radio hand lamp

Funkhandlampe

1

A

Mode

LED off

Mode

LED off

/

/

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

B

C

D

E

F

Page 25

A

10

von

2

Blatt

F

A3

B

C

A2

B2

C2

D0

D

E0

E

300

Büro

87

Werkstoff

Werkstoffnummer

D0

/

I 0 II

I 0 II

I 0 II

- 0

LMS 18/1 MTL

- 0

100075

Änderungsnr.

--

Version

87

D1

light on/off

Licht an/aus

Fluid-Plan

A1

B1

C1

D1

E1

[2] LMS 20.0 ZA &

alte Materialnummer

MOBERMAY

10001022

00

Datum, Freigabe

02.09.2019

6

right plate

/

Mindeststreckgrenze Re in N/mm²

Oberfläche

Dokumenttyp

0.000

Dokumentnummer

Revision

Nettogewicht in kg

MOBERMAY

left plate

linke Platte / rechte Platte

cable hand lamp

A2

Kabelhandlampe

A1 -

5 6

4

B2

B1

LED off

/

E

Size ISO 14405

LED off

/

nach DIN ISO 16016

Schutzvermerk beachten

Allgemeintoleranzen

1:1

Maßstab

DIN ISO 2768-mK

Fernbedienung PMS/LMS Bedienschema

Benennung

Materialnummer

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

4

LED flashing

/

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED flashing

/

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

right plate

/

Mode

left plate

linke Platte / rechte Platte

2 3

radio hand lamp

Funkhandlampe

Mode

LED off

/

LED off

/

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Page 26

A

10

von

3

Blatt

F

A3

B

C

A2

B2

C2

D

D0

E0

E

300

Büro

87

D0

/

D1

light on/off

Licht an/aus

I 0 II

A1

I 0 II

B1

I 0 II

C1

- 0

D1

- 0

E1

[1] LMS 20.0 NZ

Werkstoff

Werkstoffnummer

Mindeststreckgrenze Re in N/mm²

Oberfläche

100075

Änderungsnr.

Fluid-Plan

Dokumenttyp

right plate

/

0.000

--

Version

Dokumentnummer

10001022

00

Revision

87

alte Materialnummer

MOBERMAY

Datum, Freigabe

02.09.2019

6

Nettogewicht in kg

MOBERMAY

left plate

linke Platte / rechte Platte

cable hand lamp

A2

Kabelhandlampe

A1 -

5 6

4

B2

B1

LED off

/

E

Size ISO 14405

LED off

/

nach DIN ISO 16016

Schutzvermerk beachten

Allgemeintoleranzen

1:1

Maßstab

DIN ISO 2768-mK

Fernbedienung PMS/LMS Bedienschema

Benennung

Materialnummer

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

4

LED flashing

/

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED flashing

/

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

right plate

/

Mode

left plate

linke Platte / rechte Platte

2 3

radio hand lamp

Funkhandlampe

Mode

LED off

/

LED off

/

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Page 27

A

10

von

4

Blatt

F

A3

B

C

A2

B2

C2

D

D0

E0

E

300

Büro

87

D0

/

I 0 II

I 0 II

I 0 II

- 0

- 0

[1] PMS 3/D PIT

Werkstoff

Werkstoffnummer

100075

Änderungsnr.

--

Version

87

D1

light on/off

Licht an/aus

Fluid-Plan

Dokumenttyp

0.000

alte Materialnummer

Dokumentnummer

MOBERMAY

10001022

00

Revision

Datum, Freigabe

02.09.2019

6

right plate

/

A1

B1

C1

D1

E1

Mindeststreckgrenze Re in N/mm²

Oberfläche

Nettogewicht in kg

MOBERMAY

left plate

linke Platte / rechte Platte

cable hand lamp

Kabelhandlampe

A2

A1 -

5 6

4

B2

B1

LED off

/

LED off

/

E

nach DIN ISO 16016

Schutzvermerk beachten

Size ISO 14405

Allgemeintoleranzen

1:1

Maßstab

DIN ISO 2768-mK

Fernbedienung PMS/LMS Bedienschema

Benennung

Materialnummer

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

4

LED flashing

/

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED flashing

/

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

right plate

/

Mode

left plate

linke Platte / rechte Platte

2 3

radio hand lamp

Funkhandlampe

Mode

LED off

/

LED off

/

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Page 28

A

10

von

5

Blatt

F

A3

B

C

D

E

300

Büro

87

100075

--

Version

87

right plate

/

Werkstoff

Werkstoffnummer

Änderungsnr.

[2] PMS 3.5 Double (Funk)

left plate

Fluid-Plan

linke Platte / rechte Platte

alte Materialnummer

MOBERMAY

10001022

00

Datum, Freigabe

02.09.2019

6

Mindeststreckgrenze Re in N/mm²

Oberfläche

Dokumenttyp

0.000

Dokumentnummer

Revision

radio hand lamp

Funkhandlampe

E

nach DIN ISO 16016

Schutzvermerk beachten

right plate

/

5 6

Size ISO 14405

Nettogewicht in kg

1:1

Benennung

Maßstab

DIN ISO 2768-mK

Allgemeintoleranzen

Fernbedienung PMS/LMS Bedienschema

Materialnummer

MOBERMAY

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

left plate

linke Platte / rechte Platte

LED off

/

4

LED off

/

4

LED flashing

/

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED flashing

/

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

Mode

2 3

LED off

Mode

LED off

/

/

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Page 29

A

10

von

6

Blatt

F

A3

B

C

D

E

300

Büro

87

right plate

/

Werkstoff

Werkstoffnummer

100075

Änderungsnr.

--

Version

87

[2] PMS 3.5 Double (Kabel)

left plate

Fluid-Plan

linke Platte / rechte Platte

A2

A1 -

C2

B2

B1

C2

Mindeststreckgrenze Re in N/mm²

Oberfläche

Dokumenttyp

0.000

alte Materialnummer

Dokumentnummer

MOBERMAY

10001022

00

Revision

Datum, Freigabe

02.09.2019

6

Vorwahl

preselection

5 6

cable hand lamp

Vorwahl

preselection

E

nach DIN ISO 16016

Schutzvermerk beachten

Size ISO 14405

Nettogewicht in kg

1:1

Benennung

Maßstab

DIN ISO 2768-mK

Allgemeintoleranzen

Fernbedienung PMS/LMS Bedienschema

Materialnummer

MOBERMAY

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

Kabelhandlampe

right plate

/

left plate

linke Platte / rechte Platte

4

A2

B2

-

4

A1 -

C1

Vorwahl

preselection

2 3

B1

C1

Vorwahl

preselection

A2

B2

C2

D0

32

E0

D0

/

I 0 II

I 0 II

I 0 II

- 0

- 0

D1

light on/off

Licht an/aus

A1

1

B1

C1

D1

E1

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Page 30

A

10

von

7

Blatt

F

A3

B

C

A2

B2

C2

D0

D

E0

E

300

Büro

87

100075

D0

/

D1

light on/off

Licht an/aus

I 0 II

I 0 II

I 0 II

- 0

- 0

Werkstoff

Werkstoffnummer

Änderungsnr.

--

Version

87

[6] PMS/LMS + VZ 985021

Fluid-Plan

Dokumenttyp

0.000

alte Materialnummer

Dokumentnummer

MOBERMAY

10001022

00

Revision

Datum, Freigabe

02.09.2019

6

right plate

/

A1

B1

C1

D1

E1

right plate

/

Mindeststreckgrenze Re in N/mm²

Oberfläche

cable hand lamp

Kabelhandlampe

5 6

4

Vorwahl

preselection

left plate

linke Platte / rechte Platte

A2

C1

A1 -

B2

B1

Vorwahl

preselection

left plate

linke Platte / rechte Platte

A2

B2

-

C2

A1 -

LED off

/

B1

E

nach DIN ISO 16016

Schutzvermerk beachten

Size ISO 14405

LED off

/

Allgemeintoleranzen

Nettogewicht in kg

1:1

Maßstab

DIN ISO 2768-mK

Fernbedienung PMS/LMS Bedienschema

Benennung

Materialnummer

MOBERMAY

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

4

right plate

/

LED flashing

/

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

Mode

LED flashing

/

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

left plate

linke Platte / rechte Platte

2 3

LED off

/

radio hand lamp

Mode

LED off

/

Funkhandlampe

1

A

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

Softwareversion: 0.41.001

B

C

D

E

F

Page 31

A

10

von

8

Blatt

F

A3

B

C

D

E

300

Büro

87

right plate

/

100075

--

Version

87

Werkstoff

Werkstoffnummer

Änderungsnr.

left plate

linke Platte / rechte Platte

Fluid-Plan

[7] PMS/LMS + VZ 985023 (Funk)

alte Materialnummer

MOBERMAY

10001022

00

Datum, Freigabe

02.09.2019

6

MOBERMAY

right plate

/

Mindeststreckgrenze Re in N/mm²

Oberfläche

Dokumenttyp

0.000

Nettogewicht in kg

Dokumentnummer

Revision

1:1

Maßstab

left plate

linke Platte / rechte Platte

5 6

radio hand lamp

4

Funkhandlampe

right plate

/

LED off

/

LED flashing

/

E

Schutzvermerk beachten

Size ISO 14405

LED off

/

LED flashing

/

DIN ISO 2768-mK

nach DIN ISO 16016

Allgemeintoleranzen

Fernbedienung PMS/LMS Bedienschema

Benennung

3000007

Materialnummer

Datum, Prüfer

02.09.2019

MOBERMAY

Datum, Ersteller

3.6.2019

5

4

left plate

linke Platte / rechte Platte

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

Mode

2 3

right plate

/

Mode

LED off

/

LED off

/

Shift

LED flashing

left plate

linke Platte / rechte Platte

LED leuchtend / LED aus

LED illuminated

/

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Page 32

A

10

von

9

Blatt

F

A3

B

C

D

E

300

Büro

87

Werkstoff

Werkstoffnummer

C2

Vorwahl

preselection

A2

B2

100075

Änderungsnr.

--

Version

87

-

Fluid-Plan

Dokumenttyp

0.000

alte Materialnummer

Dokumentnummer

MOBERMAY

10001022

00

Revision

Datum, Freigabe

02.09.2019

E0

switch position

Schalterstellung

Vorwahl

preselection

C1

A1 -

A2

B1

B2

B2

und

A1

[7] PMS/LMS + VZ 985023 (Kabel)

Mindeststreckgrenze Re in N/mm²

Oberfläche

-

A1 -

B1

simultaneously

B2

Nettogewicht in kg

6

MOBERMAY

and

manual mode

Manueller Modus

Vorwahl

preselection

5 6

C2

A2

A1 -

B2

B1

Umschalten zwischen Automatik- und manuellem Modus

durch gleichzeitiges Drücken von

A1

E

nach DIN ISO 16016

Schutzvermerk beachten

Size ISO 14405

by pressing

Toggle between automatic and manual mode

Allgemeintoleranzen

1:1

Maßstab

DIN ISO 2768-mK

Fernbedienung PMS/LMS Bedienschema

Benennung

Materialnummer

3000007

Datum, Prüfer

02.09.2019

MOBERMAY

5

Datum, Ersteller

3.6.2019

E1

switch position

Schalterstellung

D0

D1

- 0

E0

4

- 0

E1

C2

B2

A2

4

Vorwahl

preselection

C1

A2

A1 -

B2

B1

D0

/

D1

light on/off

Licht an/aus

I 0 II

A1

I 0 II

B1

I 0 II

C1

32

cable hand lamp

Kabelhandlampe

C2

Vorwahl

preselection

2 3

travel duration 2

//

E0

switch position

0.5 sec // 0.75 sec

A2

0.5 sec // 0.75 sec

B2

E1

switch position

0.5 sec // 0.75 sec

A2

C1

automatic mode

Vorwahl

preselection

travel duration 1

Schalterstellung

1 sec // 1.5 sec

1 sec // 1.5 sec

Schalterstellung

0.5 sec // 0.75 sec

0.5 sec // 0.75 sec

B2

0.5 sec // 0.75 sec

Automatikmodus

Verfahrdauer 1 // Verfahrdauer 2

A1

1

B1

A1

B1

1

A

Softwareversion: 0.41.001

B

C

D

E

F

Page 33

A

B

C

A2

B2

C2

D0

D

E0

E

300

Büro

F

1010

von

A3

Blatt

87

D0

/

I 0 II

I 0 II

I 0 II

- 0

- 0

[A] PMS 3/P PIT

Werkstoff

Werkstoffnummer

100075

Änderungsnr.

--

Version

87

D1

light on/off

Licht an/aus

Fluid-Plan

D1

E1

Mindeststreckgrenze Re in N/mm²

Oberfläche

Dokumenttyp

0.000

Nettogewicht in kg

alte Materialnummer

Dokumentnummer

MOBERMAY

10001022

00

Revision

Datum, Freigabe

02.09.2019

MOBERMAY

6

A2

A1

B1

C1

cable hand lamp

A1 -

Kabelhandlampe

1:1

Maßstab

Fernbedienung PMS/LMS Bedienschema

Benennung

3000007

Materialnummer

Datum, Prüfer

02.09.2019

E

Schutzvermerk beachten

5 6

LED off

/

Size ISO 14405

LED off

/

4

LED flashing

/

LED flashing

/

DIN ISO 2768-mK

nach DIN ISO 16016

Allgemeintoleranzen

MOBERMAY

5

Datum, Ersteller

3.6.2019

4

Licht an/aus

light on/off

LED leuchtend / LED blinkend / LED aus

LED illuminated

LED leuchtend / LED blinkend / LED aus

LED illuminated

activation

Betätigung

32

Mode

2 3

LED off

radio hand lamp

Mode

LED off

/

/

Funkhandlampe

Shift

LED flashing

/

LED leuchtend / LED aus

LED illuminated

1

LED leuchtend / LED blinkend / LED aus

LED illuminated

1

Softwareversion: 0.41.001

A

B

C

D

E

F

Loading...

Loading...