MAHA AL II, AL II 2.0, AL II 2.0 PH, AL II 2.6 PH, AL II 2.6 PH W Operating Instructions Manual

...Page 1

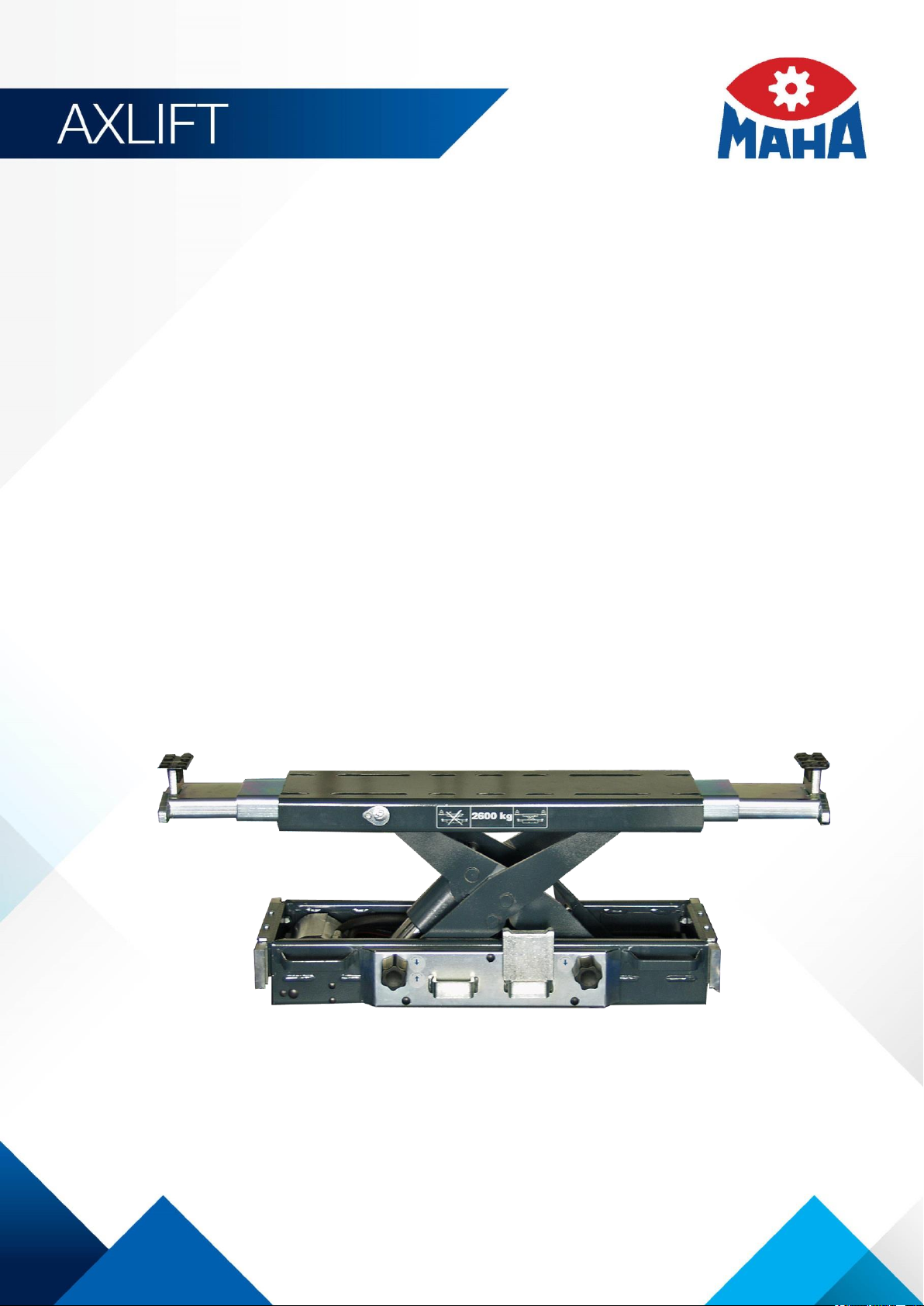

AL II

Axle Jack

Original Operating Instructions

BA082201-en

AL II 2.0

AL II 2.0 PH

AL II 2.6

AL II 2.6 PH

AL II 2.6 PH W

AL II 2.6 PH S

AL II 4.0 PH W

Fehler! Kein Text mit angegebener Formatvorlage im Dokument.Fehler! Kein Text mit angegebener Formatvorlage im Dokument.Fehler!

Kein Text mit angegebener Formatvorlage im Dokument.

Page 2

2

BA082201-en

2018-05-17

© MAHA Maschinenbau Haldenwang GmbH & Co. KG

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without explicit authorization is prohibited. Offenders will be held liable for the payment of damages. All

rights reserved in the event of the grant of a patent, utility model or design.

The contents of this edition have been checked with great care. However, errors cannot be fully excluded. Subject to technical change without notice.

Manufacturer

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20

87490 Haldenwang

Germany

Phone: +49 8374 585 0

Fax: +49 8374 585 590

Mail: maha@maha.de

Web: www.maha.de

Service

MAHA SERVICE CENTER

Maybachstraße 8

87437 Kempten

Germany

Phone: +49 8374 585 100

Fax: +49 8374 585 491

Mail: service@maha.de

Web: www.mahaservicecenter.de

BA082201-en

Page 3

3

Contents

1 Safety .................................................................................................................... 5

1.1 Introduction .............................................................................................................. 5

1.2 Symbols and Signal Words ...................................................................................... 5

1.2.1 Personal Injury .......................................................................................................... 5

1.2.2 Property Damage ..................................................................................................... 5

1.2.3 Information ............................................................................................................... 5

1.3 Intended Use ........................................................................................................... 6

1.4 Inappropriate Use ..................................................................................................... 6

1.5 Requirements on Operating and Service Personnel .................................................. 6

1.6 Safety Instructions for Commissioning ...................................................................... 7

1.7 Safety Instructions for Operation............................................................................... 7

1.8 Safety Instructions for Servicing ................................................................................ 8

1.9 Safety Instructions for Handling Hydraulic Fluid ......................................................... 8

1.10 What to Do in the Event of an Accident .................................................................... 8

2 Transport and Storage ........................................................................................... 9

3 Installation and Initial Operation............................................................................... 9

4 Specifications....................................................................................................... 10

5 Installation Position ............................................................................................... 11

6 Installation Options ............................................................................................... 11

6.1 Installing the Withdrawal Protection Device ............................................................. 12

6.1.1 Two Post Inground Lifts ......................................................................................... 12

6.1.2 Four Post Inground Lifts ......................................................................................... 12

6.1.3 DUO ...................................................................................................................... 13

6.1.4 CARLIFT ................................................................................................................ 13

6.2 Installing the Spiral Hose ........................................................................................ 14

6.2.1 Two Post Inground Lifts ......................................................................................... 14

6.2.2 Four Post Inground Lifts ......................................................................................... 15

6.2.3 DUO ...................................................................................................................... 16

6.2.4 CARLIFT ................................................................................................................ 17

6.3 Park Position .......................................................................................................... 18

6.3.1 Two Post Inground Lifts ......................................................................................... 18

6.3.2 Four Post Inground Lifts ......................................................................................... 19

6.3.3 DUO ...................................................................................................................... 20

7 Installation Procedure ........................................................................................... 23

8 Operation ............................................................................................................. 25

8.1 Operation of AL II 2.0 / 2.6 ..................................................................................... 25

BA082201-en

Page 4

4

8.2 Operation of AL II 2.0 PH / 2.6 PH / 4.0 PH ............................................................ 25

8.3 Operation of AL II 2.6 PH W / 2.6 PH S .................................................................. 26

8.4 After Usage ............................................................................................................ 26

9 Maintenance ........................................................................................................ 27

9.1 Maintenance Schedule ........................................................................................... 27

9.2 Annual Inspection ................................................................................................... 28

9.3 Care Instructions .................................................................................................... 28

9.4 Refilling with Hydraulic Fluid ................................................................................... 29

9.5 Troubleshooting ..................................................................................................... 29

9.6 Spare Parts ............................................................................................................ 29

9.7 Hydraulic Diagram .................................................................................................. 30

10 Service Lifetime .................................................................................................... 31

11 Dismantling .......................................................................................................... 31

12 Disposal ............................................................................................................... 31

13 Contents of the Declaration of Conformity ............................................................. 31

BA082201-en

Page 5

5

DANGER

indicates an immediate hazard which, if not avoided, will result in death or severe

personal injury.

WARNING

indicates a potential hazard which, if not avoided, could result in death or severe

personal injury.

CAUTION

indicates a potential hazard which, if not avoided, could result in moderate or minor personal injury.

NOTICE

indicates a potentially harmful situation which, if not avoided, could result in damage to the equipment or surrounding objects.

indicates important information notes.

1 Safety

1.1 Introduction

Thoroughly read this manual before operating the equipment and comply with the

instructions. Always display the manual in a conspicuous location.

Personal injury and property damage incurred due to non-compliance with these

1.2 Symbols and Signal Words

1.2.1 Personal Injury

safety instructions are not covered by the product liability regulations.

1.2.2 Property Damage

1.2.3 Information

BA082201-en

Page 6

6

WARNING

Any use other than described is inappropriate, for example:

Climbing on the lift supports

Transporting persons on the lift supports

Usage as mobile work platform or for other lifting operations

WARNING

All persons employed in the operation, maintenance, installation, removal and disposal of the device must

be at least 18 years old,

be mentally and physically suited for these activities,

be demonstrably trained and instructed in writing,

have read and understood the operating instructions, especially the instructions

what to do in the event of defects or malfunctions,

be on record as having been instructed in safety guidelines,

have practical experience in working with vehicle lifts and the hazards inherent

in such equipment.

1.3 Intended Use

This axle jack is to be used exclusively for the safe lifting of motor vehicles. Ob-

serve the rated load capacity.

The axle jack shall not be modified without the express written consent of the

manufacturer. In case of non-compliance the declaration of conformity be-

1.4 Inappropriate Use

comes void.

1.5 Requirements on Operating and Service Personnel

BA082201-en

Page 7

7

WARNING

The axle jack must be installed and commissioned by authorized service per-

sonnel only.

The axle jack must be installed only with a suitable running gear on level, stable

and parallel guide rails or working pits. It must be secured against falling out

and derailment.

The standard axle jack version must not be installed and commissioned in the

vicinity of explosives or flammable liquids, outdoors or in moist rooms (e.g. car

wash).

WARNING

Read the detailed operating instructions.

Lift operation by trained personnel over 18 years only.

The load capacity of the axle jack must not exceed 2/3 of the lift load capacity.

Ensure an unobstructed movement of the axle jack.

After raising the vehicle briefly, stop and check the supports for secure contact.

Make sure the vehicle doors are closed during raising and lowering cycles.

Closely watch axle jack and vehicle during raising and lowering cycles.

Before each lifting procedure, check whether the running gear of the axle jack is

correctly placed.

It is the operator’s responsibility to make sure that operation represents no

danger to persons.

The axle jack is to be used as lifting device only. Never transport the load using

the axle jack.

Before working on the vehicle, lower the axle jack to nearest safety notch.

When lifting a vehicle with two axle jack units, they must have a minimum sepa-

ration of 0.85 m.

Do not allow anyone to stay in lift area during raising and lowering cycles.

Do not allow anyone to climb on the raised vehicle.

Comply with the applicable accident prevention regulations.

Do not exceed the rated load capacity as indicated on the type nameplate.

Only use the vehicle manufacturer's recommended lift points.

Do not use the lift for transporting persons.

Keep the axle jack and the working area clean.

1.6 Safety Instructions for Commissioning

1.7 Safety Instructions for Operation

BA082201-en

Page 8

8

Use caution with operating vehicle engines. Danger of poisoning!

WARNING

Service work may be done by authorized service technicians only.

Ensure that ecologically harmful substances are disposed of only in accordance

with the appropriate regulations.

Do not use high pressure or steam jet cleaners.

Use of caustic cleaning agents may damage the axle jack.

Do not replace or override the lift safety devices.

CAUTION

Neutralize hydraulic fluid spills with binder.

Remove contaminated clothing immediately.

Inhalation: If symptoms persist, seek medical treatment.

Skin contact: Wash skin immediately with soap and water. If skin irritation per-

sists, seek immediate medical advice.

Eye contact: Rinse thoroughly with water and seek medical advice.

Ingestion: Do not induce vomiting. Seek immediate medical attention.

1.8 Safety Instructions for Servicing

1.9 Safety Instructions for Handling Hydraulic Fluid

1.10 What to Do in the Event of an Accident

The injured person is to be removed from the danger area. Find out where

dressing and bandages are kept. Seek first-aid.

Provide first-aid (stop bleeding, immobilise injured limbs), report the accident

and seal off the accident site.

Immediately report any accident to your supervisor. Make sure a record is kept

of every occasion first-aid is provided, e.g. in an accident book.

BA082201-en

Remain calm and answer any questions that may arise.

Page 9

9

NOTICE

Check package to ensure it is complete, in accordance with the order confirmation. Report any transport damage to the carrier immediately.

During loading, unloading and transport always use suitable lifting equipment, material handling equipment (e.g. cranes, forklifts, etc.) and the right load handling

attachments and slings. Always ensure that the parts to be transported are suspended or loaded properly so that they cannot fall, taking into account size,

weight and the centre of gravity.

Store the packages in a covered area, protected from direct sunlight, at a low

humidity and with temperatures between 0...+40 °C (32…104 °F). Do not stack

packages.

When unpacking, take care to avoid any possibility of injury or damage. Keep at a

safe distance when opening the package strapping, do not allow any parts to fall

out.

WARNING

Installation and initial operation of the equipment may be done only by authorized

and trained service technicians provided by the manufacturer, licensed dealers or

service partners.

2 Transport and Storage

3 Installation and Initial Operation

BA082201-en

Page 10

10

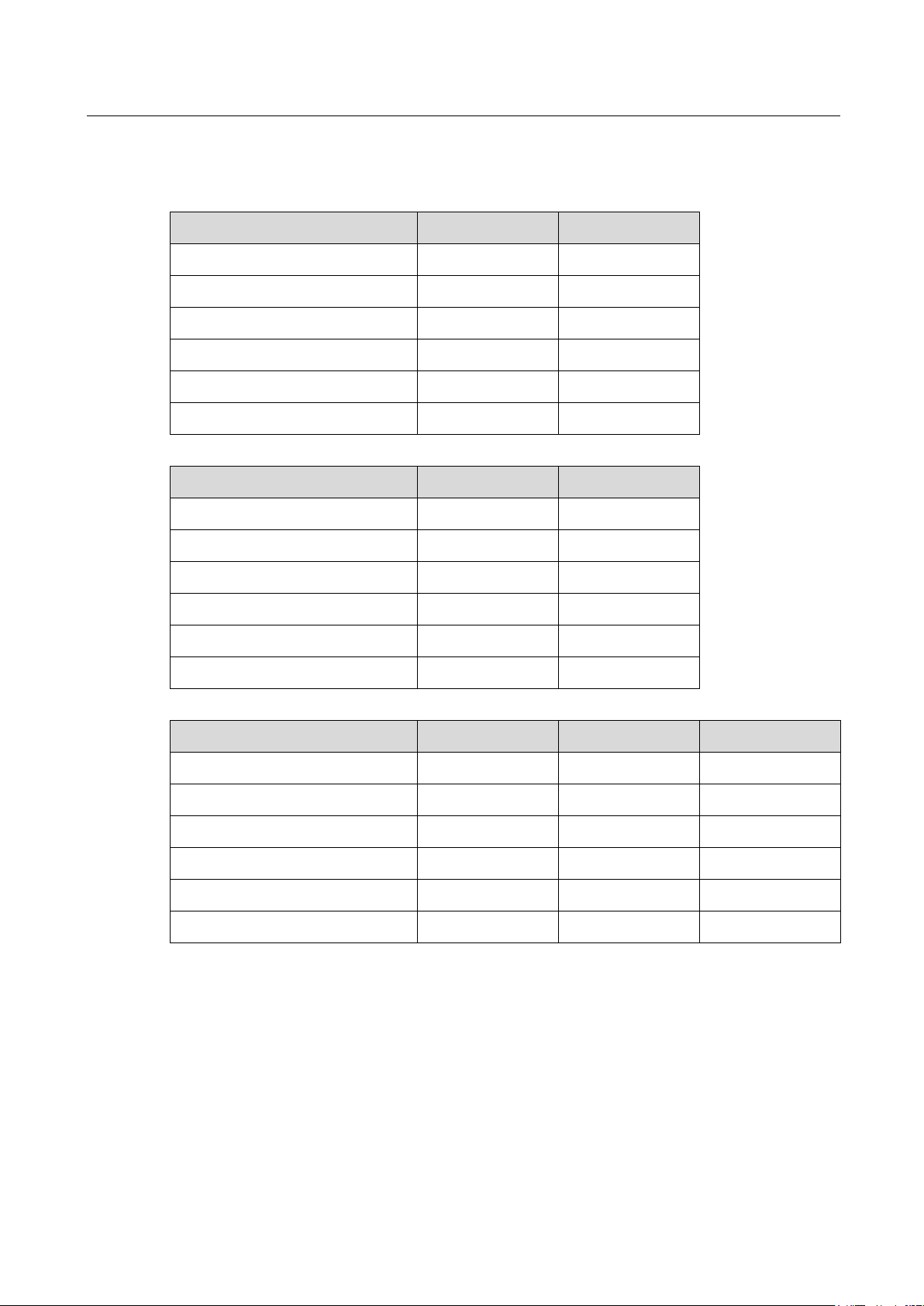

AL II

2.0

2.0 PH

Extension length min…max.

780…1610 mm

780…1610 mm

Working pressure min…max.

---

8,5…12 bar

Full travel

250 mm

250 mm

Minimum air flow

---

500 l/min

Load capacity

2000 kg

2000 kg

Protrusion above runway max.

70 mm

70 mm

AL II

2.6

2.6 PH

Extension length min…max.

780…1610 mm

780…1610 mm

Working pressure min…max.

---

8,5…12 bar

Full travel

250 mm

250 mm

Minimum air flow

---

500 l/min

Load capacity

2600 kg

2600 kg

Protrusion above runway max.

70 mm

70 mm

AL II

2.6 PH W

2.6 PH S

4.0 PH

Extension length min…max.

925…1755 mm

780…1610 mm

796 1650 mm

Working pressure min…max.

8,5…12 bar

8,5…12 bar

8.5…12 bar

Full travel

250 mm

250 mm

250 mm

Minimum air flow

500 l/min

500 l/min

500 l/min

Load capacity

2600 kg

2600 kg

4000 kg

Protrusion above runway max.

70 mm

70 mm

70 mm

4 Specifications

The sound pressure level is lower than 85 dB(A) in the working area of the operator.

BA082201-en

Page 11

11

When the axle lift is in park position, the spiral hose must be contracted in order to

be strain-relieved.

5 Installation Position

A Drill holes in side part of Axle jack, centered in longitudinal direction

C Drill holes in side part of Lift, top

6 Installation Options

Inground Two/Four Post Lifts .................. Variant A

DUO ....................................................... Variant A

CARLIFT ................................................. Variant A, if required: Variant B

BA082201-en

Page 12

12

CAUTION

Risk of personal injury and property damage

The installation of the withdrawal protection devices is absolutely necessary. Oth-

erwise the axle jack may fall out of the running rail.

A

A B B

6.1 Installing the Withdrawal Protection Device

6.1.1 Two Post Inground Lifts

Install the withdrawal protection device (A) and the hose fixture (B).

6.1.2 Four Post Inground Lifts

Install the withdrawal protection device (A) and the hose fixture (B).

BA082201-en

Page 13

13

A

B

6.1.3 DUO

Install the withdrawal protection device (A) and the hose fixture (B).

6.1.4 CARLIFT

Install the withdrawal protection devices (four angles per axle jack) as shown.

BA082201-en

Page 14

14

NOTICE

Risk of property damage

Make sure that the spiral hose is installed without kinks.

A B C

6.2 Installing the Spiral Hose

6.2.1 Two Post Inground Lifts

Slide the spiral hose (A) over the wire rope (B).

Tension the wire rope using the ring bolt (C).

Fasten the hose end to the hose fixture using cable ties.

(Bottom view of runway)

BA082201-en

Page 15

15

A B C

6.2.2 Four Post Inground Lifts

Slide the spiral hose (A) over the wire rope (B).

Tension the wire rope using the ring bolt (C).

Fasten the hose end to the hose fixture using cable ties.

(Bottom view of runway)

BA082201-en

Page 16

16

A C B

6.2.3 DUO

Slide the spiral hose (A) over the wire rope (B).

Tension the wire rope using the ring bolt (C).

Fasten the hose end to the hose fixture using cable ties.

BA082201-en

Page 17

17

A

B

C

6.2.4 CARLIFT

Slide the spiral hose (A) over the wire rope (B).

Tension the wire rope using the ring bolt (C).

Fasten the hose end to the hose fixture using cable ties.

BA082201-en

Page 18

18

A B C

6.3 Park Position

6.3.1 Two Post Inground Lifts

Fasten the switch flag including the withdrawal protection device (A) to the side

piece.

After positioning the limit switch (B), drill holes for the guide rail holding the fix-

ture and the stop screw (C). Then install the rail.

BA082201-en

Page 19

19

A

B

C

2…4 mm

D

6.3.2 Four Post Inground Lifts

Install the stop (A) including the withdrawal protection device to the side piece.

Install the lock (B) and the limit switch (C) to the runway. Then install the prox-

imity switch (D) with a distance of 2 to 4 mm to the switch flag and protect it

against collision.

BA082201-en

Page 20

20

6.3.3 DUO

Required Tools

Drilling machine / Cordless screwdriver

Core hole drill Ø 5 mm (for M6)

Tap M6

Hex key A/F 7

Hex key A/F 10

Hex key A/F 13

Hex key A/F 18

Thread locker

Allen key A/F 3

Allen key A/F 5

Axle Jack Lock

BA082201-en

Page 21

21

Liftout guard

End stop

(L) = Left

(R) = Right

(A) = Stop

(B) = Lock

Left liftout guard, left (L) + Stop (A)

Right liftout guard (R) + Lock (B)

Replacement of the Right liftout guard (R) is necessary only on the side with the

Lock (B)!

a

b

a

b

c

Positioned Axle Jack

Workflow (Initial Installation)

1 Install the lift.

2 Install the floor cover.

3 Mount the axle jack.

4 Replace the Right liftout guard (R) with the liftout guard premounted to the axle

jack; see „Positioned Axle Jack“.

5 Position the premounted Lock (B) and Stop (A) so that the axle jack can be

lowered into the floor cover/foundation without collision.

Open screws (a) Adjust (B) + (A) Tighten screws (a).

BA082201-en

Page 22

22

The rubber buffers of lock (B) and stop (A) must bring the axle jack to a halt as far

as possible simultaneously!

Replacement of the Right liftout guard (R) is necessary on the side with the Lock

(B)!

The rubber buffers of lock (B) and stop (A) must bring the axle jack to a halt as far

as possible simultaneously!

6 Install the proximity switch to the lock (B), connect and adjust it (see circuit

diagram: 299.99.L05308).

7 Functional test.

8 Collision test.

9 Mark the position for screw (b) at the runway, drill and tap holes (M6).

10 Fix lock (B) and stop (A) with screw (b) and secure against loosening using a

thread locker.

11 Secure screws (a) against loosening using a thread locker.

12 Mount the cover on the lock (B) and fix it using a screw and nut (c).

Workflow (Retrofitting)

1 Remove the end stops to be replaced (left + right) and the limit switch.

2 Check: side parts must be installed centrally (symmetrically) to the axle jack.

3 Install Left (L) and Right (R) liftout guard, swap if necessary.

4 Position the premounted Lock (B) and Stop (A) so that the axle jack can be

lowered into the floor cover/foundation without collision.

Open screws (a) Adjust (B) + (A) Tighten screws (a).

5 Install the proximity switch to the lock (B), connect and adjust it (see circuit

diagram: 299.99.L05308).

6 Functional test

7 Collision test

8 Mark the position for screw (b) at the runway, drill and tap holes (M6).

9 Fix lock (B) and stop (A) with screw (b) and secure against loosening using a

thread locker.

10 Secure screws (a) against loosening using a thread locker.

BA082201-en

11 Mount the cover on the lock (B) and fix it using a screw and nut (c).

Page 23

23

NOTICE

The axle jack may only be mounted in a suitable lift. The load capacity of the axle

jack must not exceed 2/3 of the lift load capacity.

NOTICE

The support plate and frame may only be lifted if the axle jack is tied together.

Otherwise, the support plate is not supported by the cylinder and the axle jack will

crash when releasing the safety stop.

CAUTION

Risk of personal injury and property damage

With danger of derailment additional safety measures are needed, especially

with lift types as shown in Fig. C (synchronisation of runways!).

The safety technician must decide about the necessary safety measures for

each individual case.

7 Installation Procedure

1 Lift the axle jack out of the packaging and place it at the desired height on

suitable supports between the runways.

2 Mount the side pieces including roller axles with rollers in the holes so that the

axle jack is at the desired height. There are multiple choices for flange and roller

axle mounting. The height can be varied by 12.5 mm by turning the black

extensions in the axle jack (Fig. A).

3 Oil the roller axles while in mounted position.

4 Position in the guide rail of the runway or in the pit.

5 To secure against collapsing, drill an 8.5 hole on both sides directly outside

the frame and mount with a bolt and nut (Fig. B).

6 Check all screws and nuts for tightness. Retighten if necessary.

BA082201-en

Page 24

24

A B C

BA082201-en

Page 25

25

CAUTION

Risk of personal injury and property damage

Before each lifting procedure, check whether the running gear of the axle jack is

correctly placed.

It is the operator’s responsibility to make sure that operation represents no

danger to persons.

The axle jack is to be used as lifting device only. Never transport the load using

the axle jack.

Before working on the vehicle, lower the axle jack to nearest safety notch.

When lifting a vehicle with two axle jack units, they must have a minimum sepa-

ration of 0.85 m.

8 Operation

8.1 Operation of AL II 2.0 / 2.6

Raising

1 Use the pump lever.

2 After reaching the desired lifting height, turn the left-hand lever to the right to

lower the axle jack to the nearest safety notch.

Lowering

1 Slightly raise the axle jack to release the safety lock.

2 Turn both hand levers to the left.

Left-hand lever is used for operating the trigger valve, right-hand lever for

release of safety lock. Both levers return to the original position after release.

8.2 Operation of AL II 2.0 PH / 2.6 PH / 4.0 PH

Raising

1 Turn the left-hand lever to the left.

2 After reaching the desired lifting height, turn the left-hand lever to the right to

lower the axle jack to the nearest safety notch.

Lowering

1 Slightly raise the axle jack to release the safety lock.

2 Turn both hand levers to the left.

Left-hand lever is used for operating the trigger valve, right-hand lever for

release of safety lock. Both levers return to the original position after release.

BA082201-en

Page 26

26

8.3 Operation of AL II 2.6 PH W / 2.6 PH S

Raising

1 Turn the left-hand operating handle in a clockwise direction.

Lowering

1 Verify that there is no danger of pinching.

2 Actuate button on the box.

Arms are retracted automatically, when axle jack reaches preset height. Height

can be set by adjusting the corresponding valve.

Manual Lowering

1 Turn both operating handles in a counterclockwise direction.

Unloaded arms are retracted automatically, when axle jack reaches preset

8.4 After Usage

height.

1 Lower the axle jack into bottom position.

2 Remove the extenders and hang them up at the holders provided.

3 Move the axle jack to its defined park position in order to avoid damage.

BA082201-en

Page 27

27

DANGER

Risk of death or severe personal injury by electric shock

Before doing any maintenance work, turn off the main switch and protect it

against tampering.

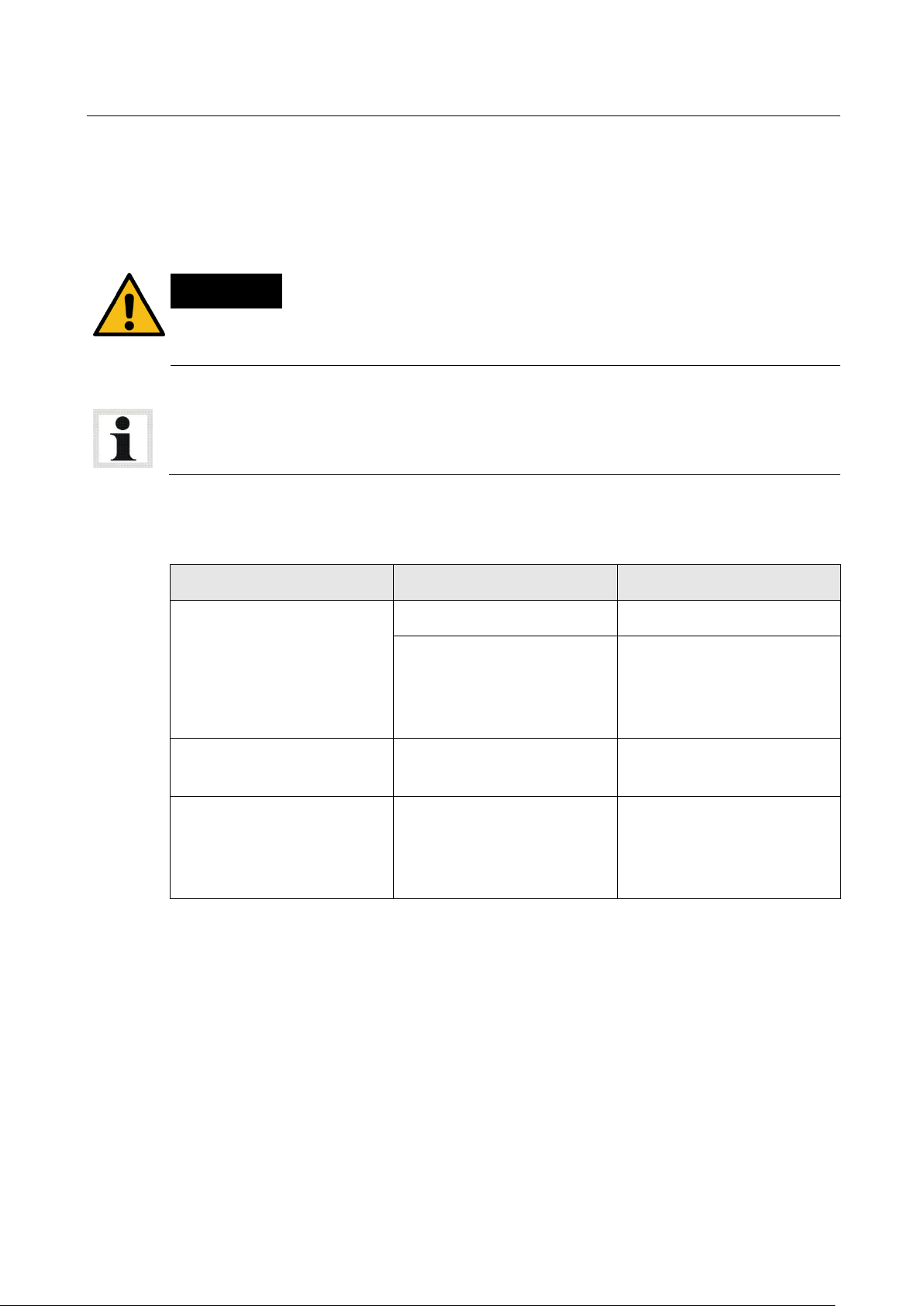

Interval

Maintenance points

Procedure

Daily

Axle jack and supports

Visual check.

Monthly

Mechanical parts

Grease all mechanical parts.

3 months

Hydraulic system

Check fluid reservoir and top up if necessary.

Check hydraulic system for leakage.

Check condition of sealing sleeves, replace if necessary.

Check pump for unusual noise during

operation, check fastening screws for

firm fit.

6 months

Hydraulic fluid

Check fluid for dirt and aging, replace if

necessary.

12 months

General inspection

Check all components for damage.

9 Maintenance

9.1 Maintenance Schedule

BA082201-en

Page 28

28

The maintenance interval prescribed by the manufacturer is 12 (twelve) months.

This maintenance interval refers to normal workshop usage. If the equipment is

used more frequently or under severe operating conditions (e.g. outdoors), the

interval must be reduced accordingly.

Maintenance work shall be done only by authorized and trained service techni-

cians provided by the manufacturer, licensed dealers or service partners.

In case of non-compliance the manufacturer's warranty becomes void.

Regular care and maintenance is the key condition for functionality and long life

expectancy of the equipment!

9.2 Annual Inspection

9.3 Care Instructions

Periodically clean the equipment and treat it with a care product.

Repair damage to the paintwork immediately to prevent corrosion.

Do not use caustic cleaning agents or high pressure and steam jet cleaners to

avoid equipment damage.

BA082201-en

Page 29

29

CAUTION

Do not turn the release lever as long as the filling plug is removed. Fluid reservoir is

put under pressure!

The filling quantity is 0.6 l. Use hydraulic fluid with viscosity ISO VG 15.

Error

Diagnosis

Remedy

Axle jack does not raise to

the desired height.

Fluid level too low.

Re-fill hydraulic fluid.

Axle jack locked.

Check whether the safety

stop lever is in neutral position and can be freely

moved.

Axle jack cannot be completely lowered.

Axle jack damaged or

rough-running.

Check for damage, oil

mechanical parts.

Axle jack continues to

lower although the safety

stop lever has been released.

Air in hydraulic system.

Bleed the hydraulic cylinder in unloaded condition.

9.4 Refilling with Hydraulic Fluid

1 Raise axle jack to maximum height.

2 Remove filling plug.

3 Fill hydraulic fluid up to the hole of the fill screw.

9.5 Troubleshooting

4 Re-attach filling plug.

9.6 Spare Parts

To ensure safe and reliable operation, only use original spare parts supplied by the

equipment manufacturer.

BA082201-en

Page 30

30

9.7 Hydraulic Diagram

AL II 2.0 / 2.6

BA082201-en

AL II 2.0 PH / 2.6 PH / 4.0 PH

Page 31

31

10 Service Lifetime

In its standard version, this product is designed for 22,000 load cycles based on

EN 1493. The maximum period of normal use in relation to the possible product

life expectancy shall be evaluated and scheduled by a qualified person during the

11 Dismantling

annual safety inspection.

Decommissioning and dismantling of the equipment may be done only by

specially authorized and trained personnel provided by the manufacturer, licensed

dealers or service partners.

12 Disposal

If you want to dispose of the equipment, please contact your MAHA dealer or the

following address, indicating equipment type, date of purchase and serial number:

MAHA Maschinenbau Haldenwang GmbH & Co. KG

Hoyen 20 | 87490 Haldenwang | Germany

Phone: +49 (0) 8374 585 0

Fax: +49 (0) 8374 585 500

Email: info@maha.de

Alternatively, you may take the equipment to a specialised waste management

plant to ensure that all components and operating liquids are properly disposed

13 Contents of the Declaration of Conformity

of.

MAHA Maschinenbau Haldenwang GmbH & Co. KG

herewith declares as a manufacturer its sole responsibility to ensure that the

product named hereafter meets the safety and health regulations both in design

and construction required by the EC directives stated below.

This declaration becomes void if any change is made to the product that was not

discussed and approved by named company beforehand.

Model: AL II 2.0 / AL II 2.0 PH

AL II 2.6 / AL II 2.6 PH / AL II 2.6 PH W / AL II 2.6 PH S

AL II 4.0 PH / AL II 2.8 PH W MB / AL II 4.0 PH W MB

Designation: Axle Lift; Rated Load Capacity 2000 / 2600 / 4000 kg

Directives: 2006/42/EC

Standards: EN 1494

BA082201-en

Loading...

Loading...