Page 1

Air Stream Fan

AIR

for Dynamometers

Original Operating Instructions

D1 1301BA1-GB03

Page 2

AIR

EDITION

Version 3 dated 14.08.2003

D1 1301BA1-GB03

© MAHA GMBH & CO. KG.

All rights reserved. Any reproductions of this document, partial or complete, are only allowed with

prior consent of MAHA GmbH & Co. KG.

All rights reserved in cases of patent granting or registration of design.

The contents of this version have been checked with great care. However, errors cannot be fully

excluded. Please contact MAHA should you find errors of any kind.

Subject to technical change without notice.

These instructions are intended for users with previous technical knowledge in the field of vehicle

testing technology as well as basic computer knowledge and MS-Windows operating system

application.

Windows and Windows for Workgroups is a registered trademark of the Microsoft-Corporation.

MANUFACTURER

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

Hoyen 20

D-87490 Haldenwang/Allgäu

Telephone: 08374 / 585-0

Telefax: 08374/ 585-499

Internet: http://www.maha.de

e-mail: maha@maha.de

SERVICE

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

- Service dept. Hoyen 20

D-87490 Haldenwang/Allgäu

Hotline: 08374 / 585 + extension

260 for brake testers, test lanes

280 for lifting technology

290 for performance testers, exhaust and air condidioning service equipment

Service: 08374 / 585-110 bis - 113, - 115

Telefax: 08374 / 585-491

II D1 1301BA1-GB03

Page 3

AIR

TABLE OF CONTENTS

1 General Information .................................................................................................. 1

1.1 Preliminary Information .................................................................................................................. 1

1.2 Safety Instructions .......................................................................................................................... 1

1.3 Technical Specification .................................................................................................................. 2

1.4 Noise Emission .............................................................................................................................. 3

2 Installation and Operations ...................................................................................... 5

2.1 Installation ...................................................................................................................................... 5

2.1.1 Air Stream Fan AIR 1 and AIR 2 .................................................................................... 5

2.1.2 Air Stream Fan AIR 5 and AIR 7 .................................................................................... 6

2.2 Preparations before Starting the Fan ............................................................................................. 8

2.3 Switching On the Air Stream Fan ................................................................................................... 8

2.3.1 Cooling Fan with ON/OFF Switch ................................................................................... 8

2.3.2 Cooling Fan with Cable Remote Control ........................................................................ 9

2.3.3 Air Stream Fan with Infrared Remote Control .............................................................. 10

2.3.4 Air Stream Fan with 2 Increment-Air Flow Adjustment ................................................. 11

2.3.5 Air Stream Fan with Infinitely Variable Air Flow Adjustment ........................................ 11

2.4 Additional Fan .............................................................................................................................. 12

3 Troubleshooting ...................................................................................................... 13

D1 1301BA1-GB03 III

Page 4

Page 5

AIR

1 General Information

1.1 Preliminary Information

The air stream fan simulates the air stream that is normally produced during driving simulation of

motor vehicles during performance tests on roller dynamometers.

The air cooling fan blows cool air via a low-lying, large exhaust passage on the engine cooler and

under the vehicle. The engine temperature of the tested vehicles is thus maintained at normal

operational temperature. The heat accumulation underneath the vehicle is blown off, avoiding

damage to the corrosion protection of the automobile body and overheating of the the drive unit

and tires.

1.2 Safety Instructions

Read the standard operating procedures and user’s manual carefully before operating

the cooling air fan! MAHA will not accept any claims for damage or service costs occurred

due to non-compliance with these operating instructions.

The accident prevention rules and regulations of the Professional Association, the Workplace

Directive and the Reich Garage Directive, as well as the latest relevant VDE (Association of

German Engineers) regulations shall apply to the operation of the air cooling fan.

The official accident prevention regulations must be complied with at all times.

All work done on electrical parts of the equipment is to be carried out by trained, qualified

electricians or service technicians only. Before any kind of service or repair work is done,

disconnect the cooling air fan from all power supply and turn off the main switch, if

necessary!

The air cooling fan should be operated by trained personnel only!

Protect all parts of the installation from humidity and moisture!

The air cooling fan is only to be used for its intended purpose as described in the operating

instructions (Simulating the airstream which occurs during normal driving conditions while

conducting performance tests on roller dynamometers)!

Make sure that the cooling fan is properly and firmly positioned before starting operation!

Do not deposit any parts (tools, vehicle parts etc.) on the cooling fan!

Never insert any objects into the guard grilles of the cooling fan!

The noise emission value created when the air cooling fan is in operation is more than 70 dB

(A) in the work area of the operational personnel. Ear protection should be worn. The

protection should be approved for noise levels of up to 120 dB(A).

D1 1301BA1-GB03 1

Page 6

AIR General Information

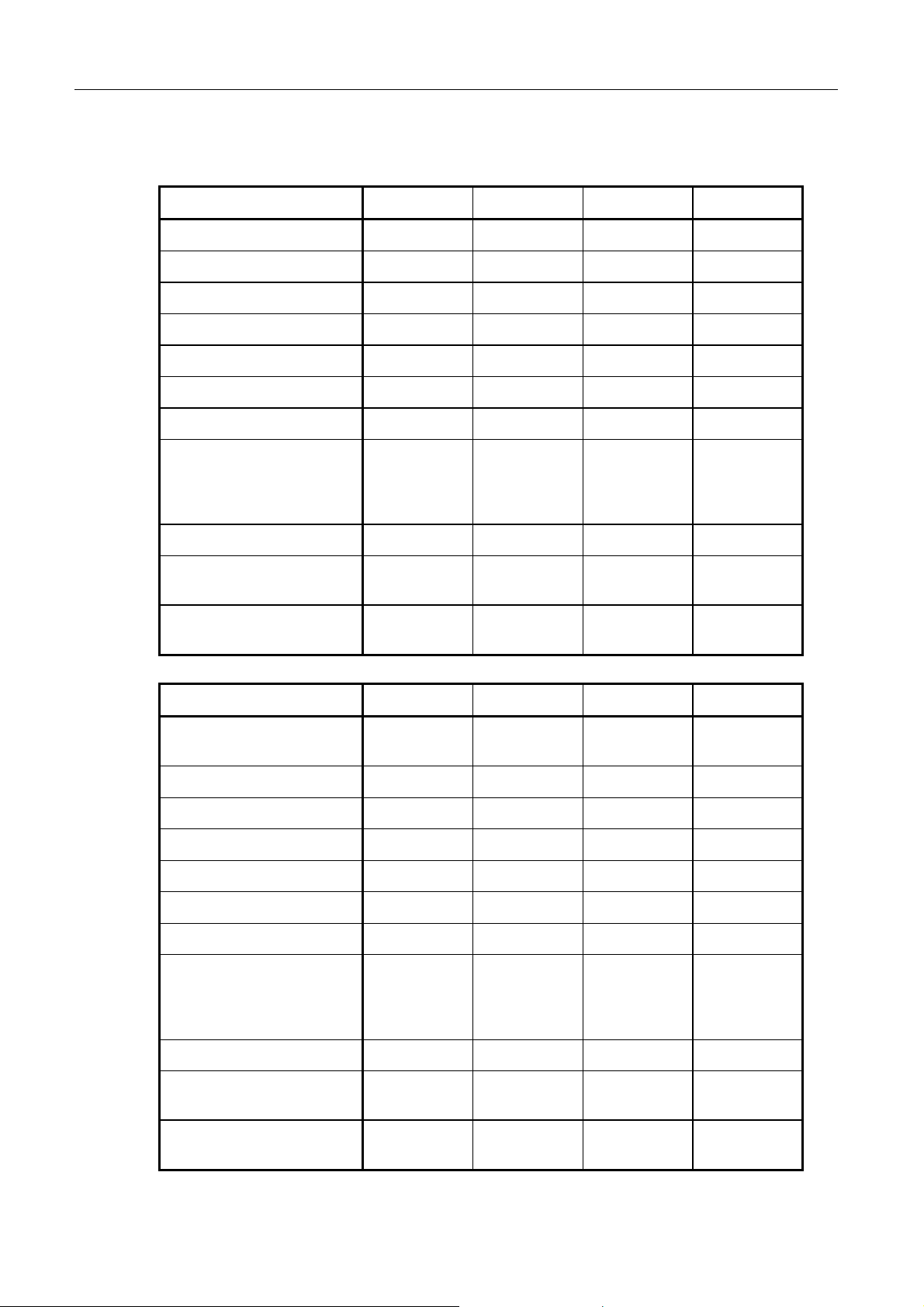

1.3 Technical Specification

Model Air 1 Air 2 Air 5 Air 7

Air output [m3/h] 6200 16500 21000 26500

Air stream [km/h] 70 70 78 98

Motor power [KW] 0,4 1,1 2,2 5,5

Fuse [A] 10 10 16 25

Power connection [V] 230 400 400 400

Version axial axial radial radial

Control Condensor Contactor Contactor Star/Delta

Dimensions

Depth [mm]

Width [mm]

Height [mm]

Weight [kg] 100 100 280 280

Swinging diameter [mm]

Depth [mm] with air flow

scoop

Model Air 7/1 Air 7/2 Air 5/5 Air 7/5

Air output [m3/h] 26500

Air stream [km/h] 98 78/98 0 - 78 0 - 98

Motor power [KW] 7,5 2,5/6 2,2 5,5

Fuse [A] 35 35 25 35

Power connection [V] 400 400 400 400

440

830

960

700

- - 995 995

710

1120

1054

890

21000/

26500

700

1665

960

-

0 - 21000 0 - 26500

1665

700

960

-

Version radial radial radial radial

Control Star/Delta Dalander Regulation Regulation

Dimensions

Depth [mm]

Width [mm]

Height [mm]

Weight [kg] 280 280 280 280

Swinging diameter [mm]

Depth [mm] with air flow

scoop

2 D1 1301BA1-GB03

700

1665

960

-

995 995 995 995

700

1665

960

-

700

1665

960

-

700

1665

960

-

Page 7

General Information AIR

1.4 Noise Emission

The noise emission value created when the air stream fan is in operation is more than 70 dB (A)

in the work area of the operational personnel.

Ear protection should be worn !

The ear protection should be approved for noise levels of up to 120 dB(A).

D1 1301BA1-GB03 3

Page 8

AIR General Information

4 D1 1301BA1-GB03

Page 9

AIR

2 Installation and Operations

2.1 Installation

2.1.1 Air Stream Fan AIR 1 and AIR 2

Air stream fan AIR 1

A: Air exhaust

B: Handle to swing around the fan

The air stream fan AIR 1 is equipped with a power-supply plug (D) for 230 V mains supply. The

ON/OFF switch is situated on the back side of the fan.

The air stream fan AIR 2 must be connected to 400 V three-phase mains. The air stream fan is

equipped with 4 rollers and can therefore easily be moved to the intended point of use. To ensure

a stable position during operation, two of the rollers are equipped with a locking brake. Normally,

a cable remote control is used to switch on and off the cooling fan. If, however, a MAHA

dynamometer is used, the air stream fan can be operated with the dynamometer's remote control.

D1 1301BA1-GB03 5

C: Lever to lock the fan

D: Power-supply plug

Page 10

AIR Installation and Operations

2.1.2 Air Stream Fan AIR 5 and AIR 7

Air stream fan AIR 5 and 7

A: Electro box

B: ON/OFF switch, rotary switch

(depending on model and equipment)

C: Connection to LPS

D: Power-supply plug for 400V three-

phase mains

F: Air entry

G: Lashings for the air flow scoop

H: Three-phase motor

I: Locking brake for guidance rollers

J: Air exhaust

E: Cable holder

The air stream fan AIR 5 is available in two different versions. The AIR 5 blows with a constant air

speed and is turned on and off via the dynamometer's remote control. The AIR 5/5 offers a

infinitely variable air flow adjustment which can be regulated manually via a rotary switch situated

on the cooling fan or automatically via the roller RPM of the dynamometer.

6 D1 1301BA1-GB03

Page 11

Installation and Operations AIR

The air cooling fan AIR 7 is available in three different versions:

Model Air-output control

AIR 7, AIR 7/1 1 increment

AIR 7/2 2 increments

AIR 7/5 infinitely variable

The air stream fan AIR 7 and AIR 7/1 start up with reduced power and automatically change over

to full power approx. 10 seconds after switch-on.

The air flow of the air stream fan AIR 7/2 can be adjusted in two increments via a selector switch.

Air stream fan AIR 7/2

A: Switch /selector switch on position 'OFF'

B: Position 'low air flow' (21000 m

3

/h)

C: Position 'OFF'

D: Position 'high air flow' (26500 m

3

/h)

The air stream fan AIR 7/5 can be controlled either manually or automatically, just as the AIR 5/5,

but offers higher motor power.

D1 1301BA1-GB03 7

Page 12

AIR Installation and Operations

2.2 Preparations before Starting the Fan

Before commencing the performance test, set up the cooling fan approx. 1.5 m - 2 m in front of

the vehicle to be tested. The test vehicle must be positioned with its driving axle or axles (4wd) on

the roller set of the dynamometer (LPS). Secure the guidance rollers of the cooling fan with the

locking brake (I) (Fig. 2-2) to ensure a stable and firm position during operation.

Up to three steps are necessary to connect the cooling fan:

Connection of the remote control cable to the LPS (AIR is switched on via remote control)

Connection of the control cable to the LPS (air flow adjustment via LPS)

Connection of the mains cable to the plug box (power supply).

Ear protection must be worn when the cooling fan is in operation!

AIR 1 and AIR 2 (Fig. 2-1):

The blower position of the AIR 1 and AIR 2 can be adjusted. To to that, loosen the two levers (C)

and use the handle (B) to adjust the fan in such a way that the air flow is directed at the engine

cooler of the vehicle. Now retighten the adjusting levers (C) manually.

AIR 5 and AIR 7 (Fig. 2-2):

For all AIR 5 / AIR 7 models, air flow scoops are optionally available in various versions. To install

the air flow scoop, use the lashings (G).

2.3 Switching On the Air Stream Fan

Depending on model and version determines how the air stream fan is switched on:

via a switch/push button on the electric box (Fig. 2-2)

and/or via remote control (e.g. remote control of the dynamometer)

via the keyboard of the dynamometer.

2.3.1 Cooling Fan with ON/OFF Switch

The ON/OFF switch (B) is located on the electro box. To put the cooling fan into operation, follow

the steps listed below:

a) Drive vehicle with its driven axle onto the roller set of the LPS

b) Position the cooling fan approx. 1.5 m - 2 m in front of the engine cooler

c) Lock the guidance rollers

d) Connect the mains cable

e) Turn switch to position ''

f) To switch off the fan, turn switch to position '0'

8 D1 1301BA1-GB03

Page 13

Installation and Operations AIR

2.3.2 Cooling Fan with Cable Remote Control

The standard version of the air stream fan (except AIR 1) is equipped with a cable remote control.

A toggle- or rotary switch on the cable remote control facilitates easy operation of the cooling fan

directly from the vehicle.

If, however, a MAHA dynamometer of the 'old generation' is used, the air stream fan can be

operated via the dynamometer's remote control (included in the delivery volume). To do that, the

respective connection cable must be connected to the electro control cabinet of the

dynamometer. Proceed as follows to put the air stream fan into operation:

a) Drive vehicle with its driven axle onto the roller set of the LPS

b) Position the cooling fan approx. 1.5 m - 2 m in front of the engine cooler

c) Lock the guidance rollers

d) Connect the mains cable

e1) Connect the remote control to the control cable

e2) Connect the remote control connection cable to the LPS

f) Press the "air stream fan" key on the remote control

g) To turn off the fan, press the "air stream fan" key on the remote control again

Cable remote control

To turn on the air stream fan, set the toggle

switch (A) to position ''. To turn off the fan, set

switch (A) to position '0'.

The basic cable remote control model is

equipped only with a rotary- or toggle switch to

operate the air stream fan.

LPS 23/2 cable remote control

D1 1301BA1-GB03 9

Page 14

AIR Installation and Operations

2.3.3 Air Stream Fan with Infrared Remote Control

If a MAHA dynamometer of the 'new generation' is used, the air stream fan can either be turned

on and off via the dynamometer's infrared remote control (included in the delivery volume) or via

the keyboard by using the function key 'F5'.

In order to operate the air stream fan via infrared remote control or keyboard, the respective

connection cable must be connected to the electro control cabinet of the dynamometer. Proceed

as follows to put the air stream fan into operation:

a) Drive vehicle with its driven axle onto the roller set of the LPS

b) Position the cooling fan approx. 1.5 m - 2 m in front of the engine cooler

c) Lock the guidance rollers

d) Connect the mains cable

e) Connect the remote control connection cable to the LPS

f) Press the "air stream fan" key on the remote control or the 'F5' -key on the keyboard

g) Press the "air stream fan" key on the remote control or the 'F5' -key on the keyboard again

to turn off

Infrared remote control

To turn on the air stream fan, press the key

with the symbol

infrared remote control once. Press this key

again to turn off the fan.

(A) on the LPS 2000

LPS 2000 remote control

(infrared)

10 D1 1301BA1-GB03

Page 15

Installation and Operations AIR

2.3.4 Air Stream Fan with 2 Increment-Air Flow Adjustment

The air speed of the air stream fan AIR 7/2 can be adjusted in two increments (low/high air flow)

via a selector switch (see fig. 2-3). In order to switch over from low to high air flow, turn the rotary

switch first to position 'OFF'.

Proceed as follows to operate the fan :

a) Drive vehicle with its driven axle onto the roller set of the LPS

b) Position the cooling fan approx. 1,5 m - 2 m in front of the engine cooler

c) Lock the guidance rollers

d) Connect the mains cable

e1) Turn rotary switch to position (D) (Fig. 2-3) for high air flow

e2) Turn rotary switch to position (B) (Fig. 2-3) for low air flow

f) Turn rotary switch to position (C) (Fig. 2-3) to turn the fan 'OFF'

2.3.5 Air Stream Fan with Infinitely Variable Air Flow Adjustment

The air flow of the fans AIR 5/5 and AIR 7/5 is infinitely variable. There are two possibilities to

adjust the air flow:

manually

automatically

The air flow can be adjusted manually (between 0 and max.output) via a rotary switch which is

located on the electro box.

For the automatic air flow adjustment, the respective control cable must be connected to the

dynamometer. The air flow generated by the cooling fan is determined by the roller RPM of the

LPS. The generated air flow increases with the roller RPM.

Proceed as follows to put the cooling fan into operation:

a) Drive vehicle with its driven axle onto the roller set of the LPS

b) Position the cooling fan approx. 1.5 m - 2 m in front of the engine cooler

c) Lock the guidance rollers

d) Connect the mains cable

e) Turn switch to position '' to start the cooling fan

f) Adjust the air flow ('0' - 'max') with the rotary switch

g) To switch off the fan, turn switch to position '0'

D1 1301BA1-GB03 11

Page 16

AIR Installation and Operations

2.4 Additional Fan

A

B

C

D

E

F

A: Handle to swing the fan

B: On-/Off switch

C: Cable holder

D: Plug for 400 V-rotary current

Fig.2-6: Additional fan

E: Air inlet

F: Locking device for guidance rollers

G: Air outlet

H: Bracket

H

A

G

B

The additional fan has a power supply plug (D) for the 400 V-rotary power supply. The On/Off

switch is on the backside of the unit.

The unit is equipped with 4 wheels and can be easily driven to where it is to be used. Two wheels

can be locked to guarantee that the unit sits securely during operation.

12 D1 1301BA1-GB03

Page 17

AIR

3 Troubleshooting

Malfunction Possible cause Remedy

Cooling fan does not start

up

Fuse of control circuit has

Cooling fan cannot be

controlled via remote

control.

Accu of the remote control

Cooling fan does not start

up again

Motor protection switch

AUS/OFF

triggered

Control cable for remote

control not connected or

defective

decharged or defective

Thermal-lag switch has

triggered

Press motor protection switch

again;

enable fan via switch or

remote control.

Attention:

Drive motor may be damaged.

Replace fuse

Connect or check control

cable

Place remote control in

charging box or replace accu

Fan motor needs to cool

down.

Attention:

Drive motor may be damaged.

D1 1301BA1-GB03 13

Loading...

Loading...