MAGUIRE PRODUCTS INC.

VBD-150® Vacuum Dryer

INSTALLATION • OPERATION • MAINTENANCE

Rev. August 31, 2016

VBD-150®

Maguire Vacuum Dryer

Copyright © Maguire Products, Inc. 2016

®

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

2

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

VBD-150® - Vacuum Dryer ®

Copyright © 2016 Maguire Products Inc.

The information contained within this manual including any translations thereof, is the property of

Maguire Products Inc. and may not be reproduced, or transmitted in any form or by any means

without the express written consent of Maguire Products Inc.

To every person concerned with use and maintenance of the Maguire VBD-150® it is

recommended to read thoroughly these operating instructions. Maguire Products Inc. accepts no

responsibility or liability for damage or malfunction of the equipment arising from non-observance

of these operating instructions.

To avoid errors and to ensure trouble-free operation, it is essential that these operating

instructions are read and understood by all personnel who are to use the equipment.

Should you have problems or difficulties with the equipment, please contact Maguire Products

Inc. or your local Maguire distributor.

These operating instructions only apply to the equipment described within this manual.

Manufacturer’s Contact Information

Maguire Products Inc.

11 Crozerville Road

Aston, PA. 19014

Phone: 610.459.4300

Fax: 610.459.2700

Website: http://www.maguire.com

Email: info@maguire.com

Rev. August 31, 2016 – VBD-150

3

V

BD® - Vacuum Dryer®

Accuracy of this Manual

We make every effort to keep this manual as correct and current as possible.

However, technology and product changes may occur more rapidly then the

reprinting of this manual. Generally, modifications made to the dryer design or to

the operation of the software are may not reflected in the manual for several

months. The date at the footer of this manual will indicate approximately how

current this manual is. Likewise, your Dryer may have been produced at an

earlier time and the information in this manual may not accurately describe your

Dryer since this manual is written for the current line of Dryers in production (as of

the date in the footer). We always reserve the right to make these changes

without notice, and we do not guarantee the manual to be entirely accurate. If you

question any information in this manual, or find errors, please let us know so that

we may make the required corrections or provide you with accurate information.

Additionally we will gladly provide you with an updated copy of any manuals you

need at any time. We welcome comments and suggestions on ways we can

improve this manual.

For additional information, or to download the latest copy of this manual or any

other Maguire manual, please visit our website or contact us directly.

On the Web at: www.maguire.com

Maguire Products Inc.

Main Headquarters

11 Crozerville Road

Aston, PA 19014

Tel: 610.459.4300

Fax: 610.459.2700

Email:

info@maguire.com

Maguire Products, Inc.

Maguire Europe

Tame Park

Tamworth

Staffordshire

B775DY

UK

Tel: + 44 1827 265 850

Fax: + 44 1827 265 855

Email:

info@maguire-europe.com

Maguire Products Asia PTE LTD

15 Changi North Street 1

#01-15, I-Lofts

Singapore 498765

Tel: 65 6848-7117

Fax: 65 6542-8577

magasia@maguire-products.com.sg

Please e-mail comments and suggestions to: support@maguire.com

Maguire Italy

Via Zancanaro 40

35020 Vigorovea (PD)

Tel: +39 049 970 54 29

Fax: +39 049 971 18 38

Email:

info@maguire-italia.it

4

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Table of Contents

INSTALLATION

VBD-150 Dryer Assembly

Dryer Connections

Compressed Air Connection 14

Electrical Connection

Dryer Overview

Operating Station Overview

Controller Overview

Description of Menu Options 25

Setup Menu Options Explained 27

Parameters Explained 32

Changing Parameters

Batch Mode

Communication Setup

Operation

Startup and Operation 19

Recommended Drying Temperatures

Maintenance

Loadcell Calibration

Cleanout Procedure

Vacuum Chamber Removal

Replacing the Vacuum Chamber Flange Seal

Drain and purge Air Filter / Regulator 43

Air Pressure Adjustments

Replacing the Vacuum Chamber Fill Valve Seal

Logs and Print Outputs

Alarms - Cause and Solution

Dryer Firmware Updates

Maguire Products, Inc.

8

10

14

14

17

18

18

40

41

42

19

24

43

43

44

47

49

52

55

60

64

69

General Information 70

Technical Specifications 70

Theory of Operation / Performance 71

Warranty

Diagrams

Recommended Spare Parts List

Bookmark not defined.

Technical Support / Contact Information

72

73

Error!

84

Rev. August 31, 2016 – VBD-150

5

V

BD® - Vacuum Dryer®

Warranty – Exclusive 5-Year

MAGUIRE PRODUCTS offers THE MOST

COMPREHENSIVE WARRANTY in the plastics

auxiliary equipment industry. We warrant each

MAGUIRE VBD – Vacuum Dryer manufactured by us to

be free from defects in material and workmanship under

normal use and service; excluding only those items

listed below as 'excluded items'; our obligation under

this warranty being limited to making good at our

factory any Dryer which shall, within FIVE (5) YEARS

after delivery to the original purchaser, be RETURNED

intact to us, transportation charges PREPAID, and

which our examination shall disclose to our satisfaction

to have been thus defective; this warranty being expressly in lieu of all other warranties

expressed or implied and of all other obligations or liabilities on our part, and MAGUIRE

PRODUCTS neither assumes nor authorizes any other persons to assume for it any

other liability in connection with the sale of its Dryers.

This warranty shall not apply to equipment repaired or altered outside MAGUIRE

PRODUCTS INC. factory, unless such repair or alteration was, in our judgment, not

responsible for the failure; nor which has been subject to misuse, negligence or

accident, incorrect wiring by others,

or installation or use not in accord with instructions furnished by

Maguire Products, Inc.

Our liability under this warranty will extend only to equipment that is returned to our

factory in Aston, Pennsylvania, PREPAID.

Please note that we always strive to satisfy our customers in whatever manner is

deemed most expedient to overcome any problems they may have in connection with

our equipment.

Maguire Products, Inc.

6

GETTING STARTED:

PROCEED TO: SAFETY WARNINGS NEXT PAGE

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

SAFETY WARNINGS

Maguire Products, Inc.

HOT SURFACES:

As with all dryers, there are HOT SURFACES to avoid. Temperatures

can reach 350F, (180C).

Typically these surfaces are not at dangerous temperatures, however

all hot surfaces should be avoided.

Warning Label indicate HOT SURFACES

USE CAUTION when removing and installing canisters.

USE GLOVES.

DO NOT REACH into the dryer enclosure.

RISK OF SHOCK:

Disconnect power supply before servicing the Dryer.

GETTING STARTED: PROCEED TO: INSTALLATION - NEXT PAGE

Rev. August 31, 2016 – VBD-150

7

V

BD® - Vacuum Dryer®

Installation

Transport and Setup

Shipment

The VBD-150 Dryer is shipped on two skids with 4 main sections.

(A) Heating Hopper Assembly

(B) Vacuum Chamber Assembly

(C) Retention Hopper Assembly

(D) Control Panel

Maguire Products, Inc.

Lifting and Moving components of the Dryer

Ensure your lifting equipment is rated to lifting the weight

of the individual sections of the VBD-150.

8

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Overall layout and Dimensions

Maguire Products, Inc.

Rev. August 31, 2016 – VBD-150

9

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

VBD-150 Assembly

Shipment Inventory

The VBD-150 is shipped on two pallets. One pallet holds the main body of the

VBD-150 and two cardboard boxes containing the Vacuum Chamber, the

Retention Hopper, and hardware for assembly. The second pallet holds the

heating Hopper.

Hardware includes: 1 - 2" Hose Clamp, Two RTD Assemblies (RTD Sensor, wire, plug), 4 - ½"

x13x1¼" Button Head bolts, 4 - ½" Lock Nuts, 8 - ½" Star Washers.

Unpacking the VBD-150 Main Body

Remove the two boxes containing the Vacuum Chamber and Retention Hopper from the pallet.

With the VBD-150 pallet on the floor, secure the wheels so

that it will not roll once it is unbolted from the pallet. Two

wheels can be locked. With the wheels secured, locate

the two shipping bolts that attach the VBD-150 to the

pallet. Unbolt the upper visible nuts from the frame and

allow the bolt to drop out of the VBD-150 frame. Remove

the Wood blocks. The VBD-150 is now detached from the

shipping pallet. Use caution.

Do not wheel the VBD-150 directly off of the pallet.

Damage to the VTA can occur. The VBD-150 can be

gently wheeled off of the pallet using stacked 2x4 pieces of

wood. Use two or more people to guide the Dryer off of

the pallet. Make sure enough clearance is given to the

VTA.

Under the Dryer there is a

VTA. Use enough ramp

clearance to prevent contact

with the VTA below Dryer.

Remove all packing material from Dryer

main body.

10

When cutting the zip-tie

located at the top rear of

the dryer, hold the

Vacuum tray and lower it

slowly onto load cell. →

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Heating Hopper Installation

The Heating Hopper is shipped on a separate pallet. The weight of the

Heating Hopper is 115 lbs (52 kg).

It is secured to the pallet with four bolts.

While holding the heating hopper securely remove

these four bolts.

Attaching the Heating Hopper

A forklift can be used to raise the heating hopper onto the VBD150 main body. Lifting points are located below on the lower

black steel ring as shown in photo on right.

Maguire Products, Inc.

Install the Heating Hopper so that the

Heating Hopper Access Door is facing

the front of the Dryer, the same side as

the Control Panel.

To assist with lining up the bolt holes, the

four ½" socket head bolts (13x1¼) can

be installed prior to lowering the Heating

Hopper onto the VBD-150.

Install the four ½" socket head bolts as follows:

Socket head bolt will receive a ½ star washer below the head.

Rev. August 31, 2016 – VBD-150

11

V

BD® - Vacuum Dryer®

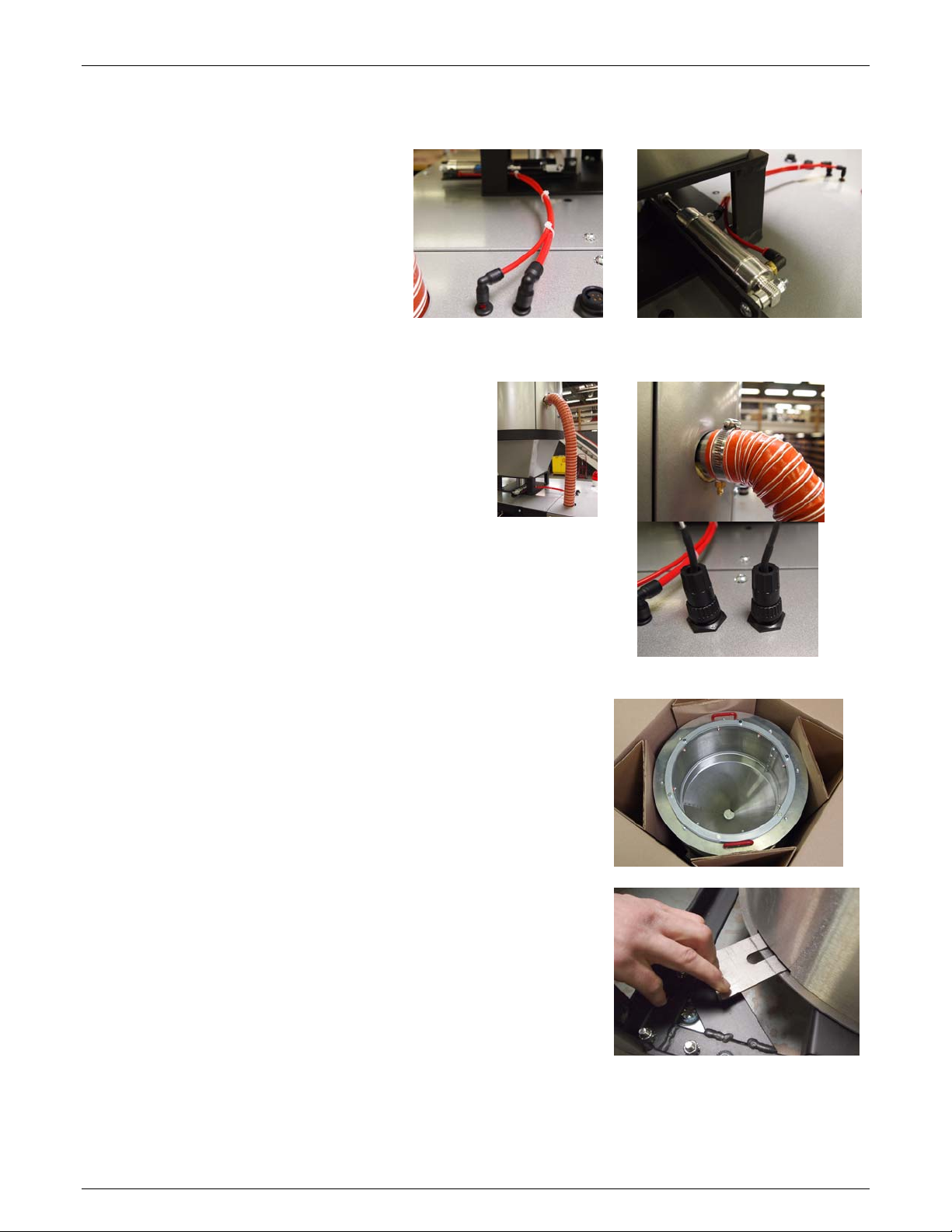

Install Connections

Attach the Heating Hopper

butterfly valve air lines.

The two air lines that connect the

Heating Hopper Air cylinder to the

VBD-150 are different sizes to

prevent an incorrect connection.

Attach the Heating Hopper Hose

Using the 2" Hose Clamp, attached the red Heating Hose

to the Heating Hopper.

Maguire Products, Inc.

Attach the RTD Plugs

The RTD plugs are different sizes and will only install on the

correct outlet.

Installing the Retention Hopper

Unbox the Retention Hopper. The Retention Hopper is

identified by the red handles located on the top of the hopper

(the Vacuum Chamber has red handles on the upper sides).

Close the slide-gate to allow the Retention Hopper to seat

down onto the base of the VBD-150. Once seated open the

slide-gate to allow material to flow.

Install the Retention Hopper so that the Retention Hopper

manual slide-gate is located at the forward right corner of the

Dryer.

12

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

At the base of the Retention Hopper are two slots that must

be aligned with the locator bolts.

Once the locator bolts are aligned, close the press in the

slide-gate to lock the Retention Hopper in place and open the

base for material flow.

Installing the Vacuum Chamber

Unbox the Vacuum Chamber.

Lift the Slider Lock located on the right side of the VBD-150

cabinet. While holding the Slider Lock up, pull the Vacuum

Chamber slider out. Release the Slider Lock, which will rest on

top of the opened slider.

Rest the Vacuum Chamber onto the fully extended Sliders. The

Vacuum Chamber has three resting pins. Orient the side with two

resting pins on the left Slider rail.

Maguire Products, Inc.

Push the Slider rails and Vacuum Chamber

back into the Dryer until the Slider Lock falls

into place.

Connect the air lines. Rotate the locking ring fully clockwise to

secure the air connection.

Slide the Retention Hopper sealing collar up so that the magnets

engage onto the bottom of the Vacuum Chamber.

Rev. August 31, 2016 – VBD-150

13

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

Dryer External Connections

Once assembled, installation requires connection of: pneumatic air line, electrical, intake and

output material lines.

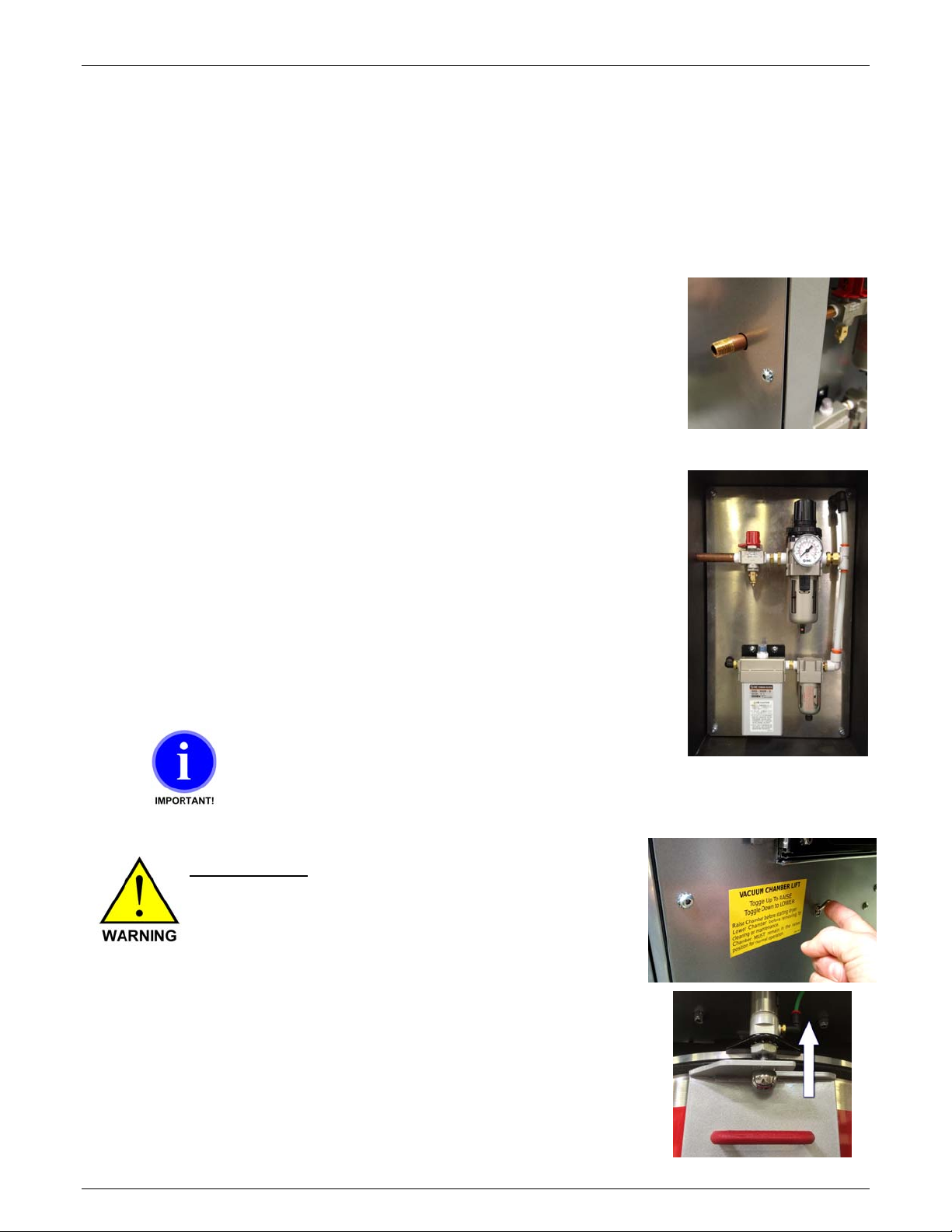

Compressed Air Connection

Connect an air supply to the air regulator’s IN port using a female

1/4” NPT pipe fitting.

An operating air pressure of 80 psi (5.5 bar) while the

vacuum generator is running is required for proper operation

of the Dryer. Setting the air pressure to 85 psi while the

machine is idle will usually attain the desired 80 psi while the

vacuum generator is running.

If your air supply has oil in it, add an oil separator (coalescing

filter). Oil in the air will combine with dust drawn from the

Vacuum Chamber forming a paste inside the vacuum generator.

It will stop working and require cleaning.

Observe the air pressure gauge to be sure the pressure

maintains 80 psi (5.5 bar) while the vacuum generator is running

as you check and adjust the regulator. If pressure drops below

80 psi, adjust the regulator. If the pressure cannot be maintained

at 80 psi (5.5 bar) while the vacuum generator is running, then

the air supply line is not adequate.

Do not supply Dryer with a lubricated air supply.

Damage to Dryer may result. Use only a clean,

dry, oil-free air supply.

Pinch Hazard - Keep fingers clear of seal

deck, the mating surface above the Vacuum

Chamber seal.

When air pressure is turned on and the

Vacuum Chamber Lift Switch is flipped up, air

cylinders lift the Vacuum Chamber off of the

slider rails and up to the seal deck closing the

gap between the top of the Vacuum Chamber

and the seal deck.

KEEP FINGERS CLEAR

14

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

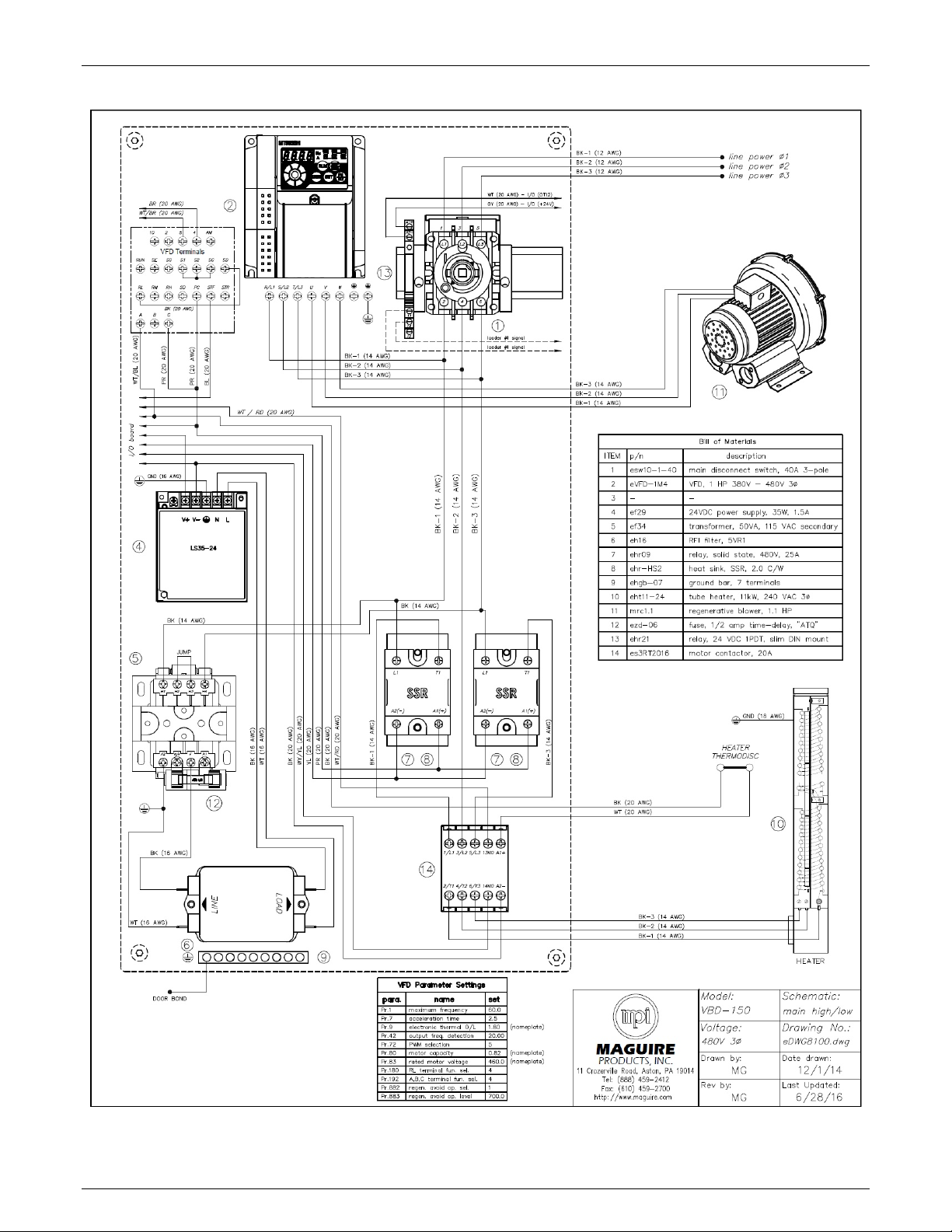

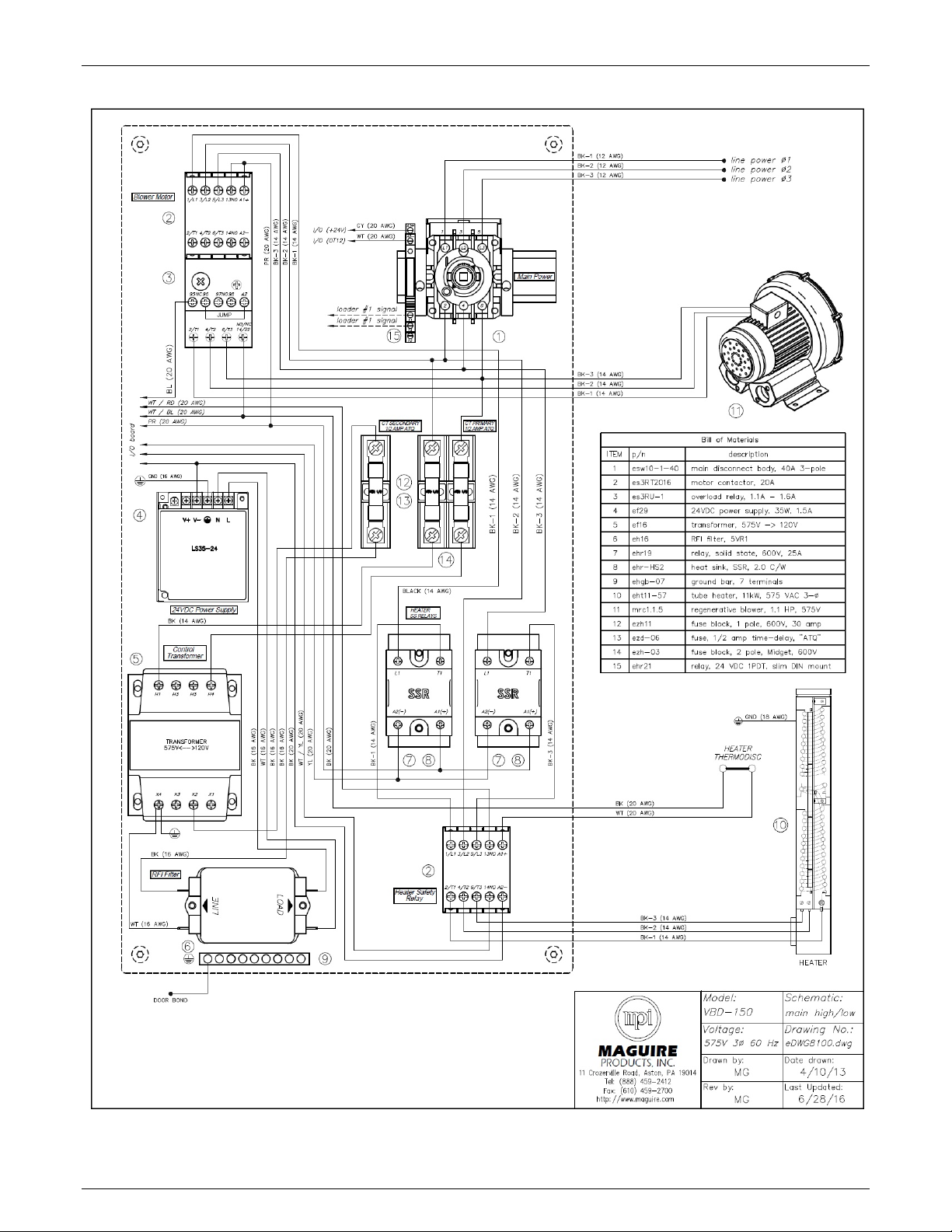

Electrical Connection

RISK OF INJURY!

Only qualified

technicians should

make electrical

connections.

Maguire Products, Inc.

Connect Main Power

The electrical cable

located on the left side of

the Dryer on the power

box supplies the power to

the Dryer. Within the

cable is four wires. Three

of the wires are black and labeled with a number: 1, 2, and 3.

The fourth wire is a green/yellow wire and is the ground wire.

Connect power to a properly fused disconnect.

VBD-150 Fuse / Circuit Breaker Rating Table

Protect the unit with fuses or circuit breakers at the amp ratings shown below:

voltage amps

240 25

400 15

480 15

575 15

See page 73 for the High Voltage Wiring Diagram

Rev. August 31, 2016 – VBD-150

15

V

BD® - Vacuum Dryer®

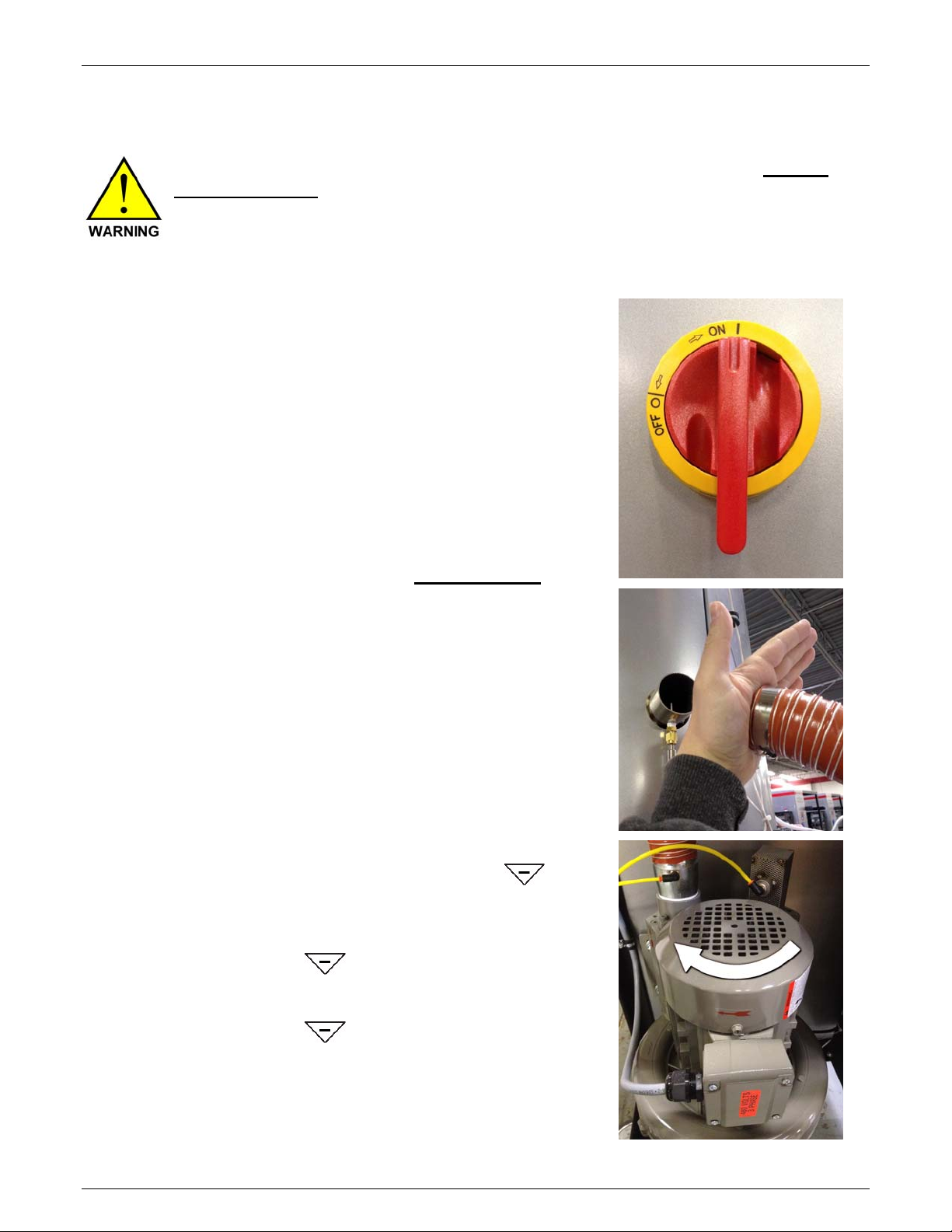

Confirm Correct 3-Phase Electrical Connection

THREE PHASE Unit - CONFIRM proper 3-Phase power connection prior to

loading material. Failure to confirm proper 3-phase connection can result in

reversed blower rotation and damage to blower if the blower sucks in material

from heating hopper rather than blow heated air into heating hopper.

To confirm proper 3-phase connection following these instructions:

Turn power on using main power switch.

There are two methods to confirm proper

3-phase connection:

Incorrect 3-phase connection will result in

reversed blower rotation. Both methods

for checking correct 3-phase connection

involve testing the blower rotation.

Method one requires the disconnecting the

2-inch hot air hose from the heating hopper

and manually turning on the blower. The

air from the blower should blow out of the

2-inch hose. Air should not suck into the

hose. If air does not blow out and sucks in,

the 3-phase connection is NOT correct.

Method two requires the removal of the left

side panel to view the blower and confirm

blower rotation on power up. Rotation

must be clockwise as indicated by the red

arrow.

1. From the Main Screen press

to highlight Manual Operations.

Press ENTER.

2. Press to select Operate

Outputs. Press ENTER.

3. Press

to select Blower. Press

ENTER to start blower. Press

ENTER again to stop blower.

Maguire Products, Inc.

16

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

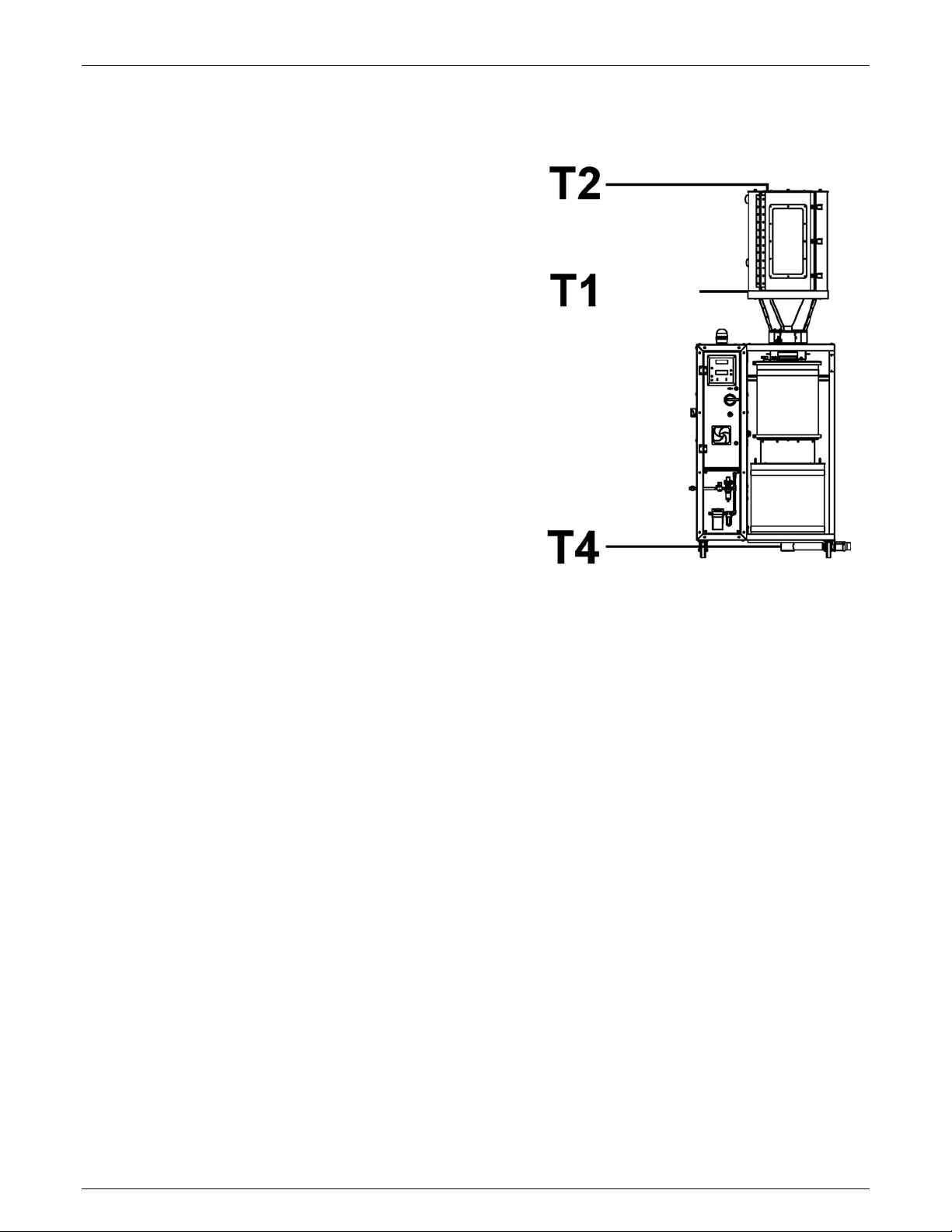

Dryer Overview

T1 – Heating Hopper Inlet Temperature

T1s – Heating Hopper Air Inlet Temperature Setting

T1a – Heating Hopper Air Inlet Temperature Actual

T2 – Heating Hopper Outlet Temperature

T4 – Material Outlet Temperature (optional)

Maguire Products, Inc.

(T1s,T1a)

Rev. August 31, 2016 – VBD-150

17

V

BD® - Vacuum Dryer®

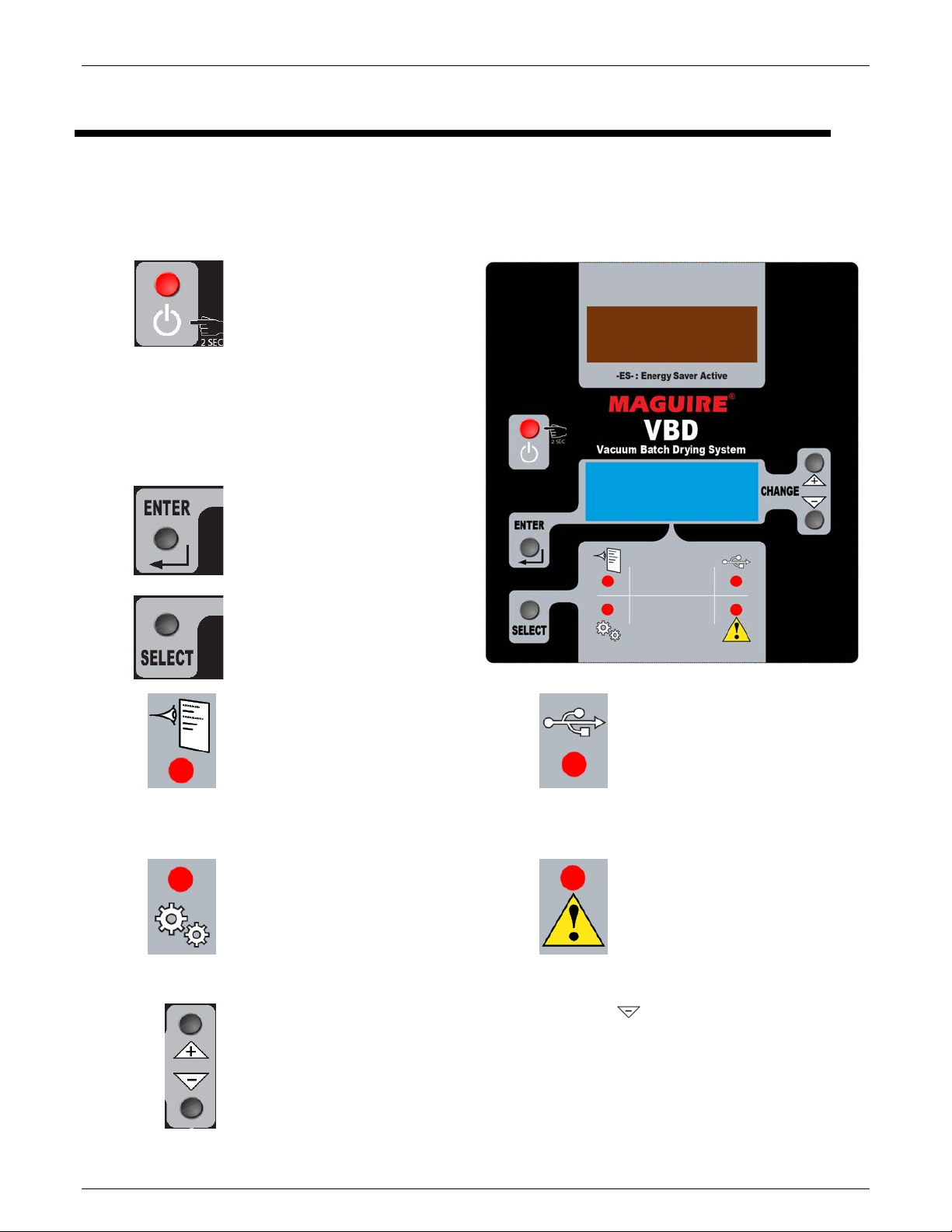

Operating Station Overview

Control Panel Overview

Display Screens – The VBD control panel has two screens. The upper, red display shows Actual

Temperature or Throughput. The lower, blue display shows various running mode information or setup

and configuration information.

Control Panel Power Powers on

the control panel (main power

must be ON.) Also used to exit or

cancel out of any menu option

and return to the top level screen.

Top Level Menu:

• Run Dryer - See page 19

• Run Dryer (Batch) – See page 41

• Clean Out – See page 49

• Manual Operations - See page 25

Enter selects the highlighted

menu option.

Maguire Products, Inc.

Select toggles between 4

different screen sets:

Status Screen

The Status Screen

T1a - Actual Air Temperature into the heating

hopper

T1s - Air Temperature Set-point

VTa – Vacuum Time Actual

VTs – Vacuum Time Set-point

ADV - Access to Advance Mode (page 23)

Setup Mode

Access to advanced set up information.

See Page 27

Displays:

Print Center

For printing reports, logs, and

parameters to a USB flash drive.

See page 60.

Alarm Log

Displays a buffer of 50 of the

most recent alarm logs. Note: A

printed alarm log will print the

history of alarms since the last

clear of alarm logs.

Arrow Buttons – Navigate menus, make adjustments. is also used to silence the

alarm.

Navigating to BACK and pressing ENTER exits the current menu and back one level.

18

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

Startup and Operation

This section will help you understand what the dryer is doing during operation from a cold start.

There are 3 concurrent operations. Heating, Vacuum and, Retention. Cold startup begins with

Preheat. Preheat only occurs before the first cycle of the dryer’s initial startup, otherwise each

cycle begins with material heating. The vacuum operation pulls and holds a vacuum on the

material for at least the Vacuum Time Set-point (or longer if material remains in the Retention

Hopper). The Retention operation holds the dried material in the Retention Hopper, blanketing

the material with hot, dry air, until the material is conveyed away.

Important: Inspect the VBD, verify that machine is clear of all material from heating hopper,

Vacuum Chamber and Retention Hopper. To facilitate a Clean Out, use the Clean Out

function accessible from the home screen.

Startup and Operation Instructions

1. ENSURE HATCH IS CLOSED. There is a hatch located on the upper

Heating Hopper. Ensure all 3 latches are closed. Also be sure the

removable Lower Retention Hopper is in place.

2. Load material into the Upper Heating Hopper. Wait for the Heating

Hopper to fill with material before starting the Dryer.

3. Turn on Main Power by rotating the 25 AMP Main Disconnect Handle

to the Red ON position. This powers up the VBD-150 Dryer.

On initial power up of the VBD, the Control Panel powers ON

automatically. If the main power is ON but the Control Panel is OFF,

press and hold the Red Power Button located on the Control Panel for

2 seconds. (Note: The VBD’s Control Panel can be powered OFF

without powering down the Main Power by pressing and holding the

Red Power button for 4 seconds).

4. After material has been loaded into the Heating Hopper,

select Run Dryer and press the ENTER button.

=== SELECT MODE ====

►Run Dryer

Clean Out

Manual Operations

Rev. August 31, 2016 – VBD-150

19

V

BD® - Vacuum Dryer®

5. The display will show the Pre-Start screen. On this screen is:

Setpoint Temp – This is heat hopper inlet temperature. By the end of

the preheat cycle time, all material in the Heating Hopper will be

heated to this temperature. By default, the Setpoint temperature is set

to 150 °F. See Recommended Heat Temperatures on page 19 for

general temperature recommendations or contact the material

manufacturer.

Preheat Time – This is the duration of heating from a cold start.

Vacuum Time – This is the minimum duration of a vacuum cycle.

Actual vacuum cycle times will vary according to the throughput. The

default vacuum time is 20 minutes. In the vast majority of drying

operations, this time is adequate and does not need to be adjusted.

Special circumstances may require different vacuum times. Please

consult a Maguire Dryer Technical for additional information.

By default, START is selected (location of cursor). If the settings you

desire have been entered previously, simply pressing ENTER once

more will start the machine. Otherwise use the arrow buttons

to navigate to the desired settings for adjustment, then press ENTER.

The display will highlight the adjustable digit.

Use the arrow buttons

advance through the digits and to complete the setting adjustment.

6. When the display is no longer in the Edit Mode (highlighted setting),

press

to toggle the selection to START. With START selected,

press the ENTER button to start the dryer.

to adjust the setting. Press ENTER to

Maguire Products, Inc.

Setpoint Temp.: 150°F

Preheat Time: 35m

►Vacuum Time: 20m

================ START

Setpoint Temp.: 150°F

Preheat Time: 35m

Vacuum Time: 18m

================►START

7. The display will show that the dryer is running in PREHEAT

mode and display the following:

T1a - Actual heating hopper inlet temperature

T1s - Heating Hopper inlet temperature setpoint.

VTa - Elapsed vacuum time.

VTs - Vacuum Time sepoint.

VAC - Actual vacuum chamber pressure.

======= PREHEAT: 35:00

T1a:130°F VTa: 00:00

►T1s:150°F VTs: 18:00

ADV ==== VAC: 760mm

==== AUTO CYCLE ====

T1a:130°F VTa: 00:00

►T1s:150°F VTs: 18:00

ADV ==== VAC: 760mm

20

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

What is happening when the dryer is running:

During the Pre-heat operation material in the heating hopper is brought up to temperature (T1s). Preheat

time is determined by the specified Preheat Time on the Pre-Start screen (timed preheat, default 35 minutes)

or by the Preheat Setup Auto option, which sets an inlet to outlet temperature delta and a minimum preheat

time.

After pre-heat, approximately one third of the material in the heating hopper is dispensed into vacuum

chamber, and the first vacuum cycle begins. Each vacuum cycle has a minimum vacuum time, set on the

Pre-start screen, or the main run screen (VTs). (default is 20 minutes).

The loader loads the Heating Hopper with new material as the Vacuum Chamber receives the heated material

and heating cycle begins concurrent to vacuum cycle (the first vacuum cycle is timed). The new batch of

material in the upper portion of the heating hopper will take less time to heat. Minimum time in the heating is

dictated vacuum time.

After first vacuum cycle, material is then dispensed into retention hopper ready for use. Material in the

retention hopper is blanketed with dry air.

The rate of consumption of dried material from the retention hopper ultimately dictates the amount of time that

the material will be preheated and under vacuum. Examples: If it takes 25 minutes to deplete the retention

hopper, the vacuum cycle will run past its 20 minute setpoint (pre-start screen) to 25 minutes. This is normal

operation. However if the retention hopper is depleted in 15 minutes and the vacuum time is set to 20

minutes, there will be a 5 minute window where no material is available. This indicates that the throughput of

the dryer has been exceeded. If the Throughput Alarm is enabled (Alarm Setup), a Throughput Alarm (Alarm

Code 20) will be triggered.

Rev. August 31, 2016 – VBD-150

21

V

BD® - Vacuum Dryer®

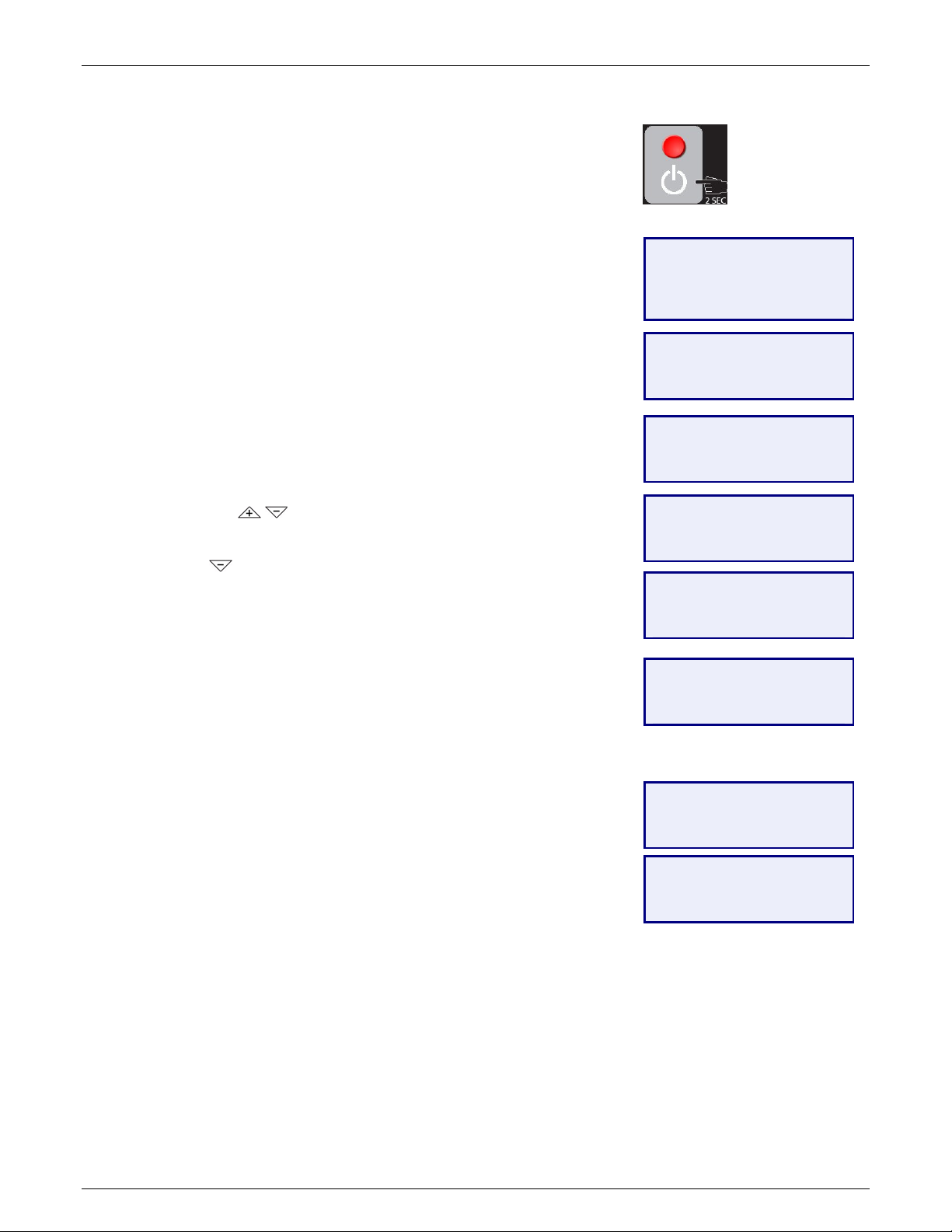

Shutdown, Auto Shutdown, Immediate Shutdown

At any point during the preheat cycle or standard operation

(operation after initial preheat cycle), pressing the red button will

bring up a Shutdown Options screen and display.

Shutdown - Shutdown during post-preheat operation

Pressing the red power button once during post-preheat operation

prompts the operator with these options:

Shutdown – Shutdown will run to run the dryer and process the material

in the Vacuum Chamber and the Retention Hopper until they are empty.

Selecting Planned Shutdown will display the Cooldown option.

Cooldown (ON/OFF) – When enabled Cooldown will gradually bring

down the temperature of the material in the heating hopper to the

specified temperature (Cooldown Temp) over the specified time period

(Cooldown Time).

To adjust the Cooldown Temperature and Cooldown Time use the

arrow buttons

through the digits and to complete the setting adjustment.

Press the

shutdown. Press the ENTER button to proceed with the shutdown.

Pressing the red power button during a Planned Shutdown will display

the Immediate Shutdown Screen allowing initiation of an immediate

shutdown of the dryer.

Auto Shutdown – Initiates a shutdown (see above) as specified date and

time. For further explanation on how to set the Auto Shutdown Date and

Time see page 23.

Immediate Shutdown – Fast but controlled shutdown of the heater,

blower, the vacuum system and the purge system.

Cancel - Exits the shutdown prompt screen, doing nothing.

Skip Preheat (shown only if in a preheat cycle) – Skips the preheat

allowing material to immediately pass down to the Vacuum Chamber

(example: material has already been heated and dryer has been taking

offline briefly and powered back on).

to adjust the setting. Press ENTER to advance

to scroll down to Shutdown to continue with the

Maguire Products, Inc.

====== SHUTDOWN ======

►Shutdown

Auto Shutdown

Immediate Shutdown

Cancel

===== SHUTDOWN ======

Cooldown:OFF

Cancel

►Shutdown

===== SHUTDOWN ======

Cooldown:ON

Cooldown Temp:120°F

►Cooldown Time: 60m▼

===== SHUTDOWN ======

Cooldown:ON

Cooldown Temp:120°F

►Cooldown Time: 30m▼

===== SHUTDOWN ======

Cooldown Temp:120°F

Cooldown Time: 30m

►Cancel ▼

== PLANNED SHUTDOWN ==

Cooldown Time: 30m

Cancel

►Shutdown

== COOLDOWN: 29:58

T1a: 120°F VTa: 14:37

►T1s: 120°F VTs: 20:00

ADV ==== VAC: 82mm

H:OFF B:ON Pabs:752

Shutting Down…

-=- Standby -=-

22

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

ADVANCED (ADV) - Selecting ADV (advanced) will display additional

information such as readings of all RTD thermometers, vacuum time elapsed,

absolute pressure in the Vacuum Chamber, blower drive frequency. ADV also

allows an option to abort preheat and proceed into vacuum cycle. (Aborting the

preheat cycle does not shut down the machine). Advanced scrolls through 4

screens. To move to the next screen, use the

buttons to navigate.

Fill Weight – The desired weight of material to be dispensed into the Vacuum

Chamber.

Bulk Density - Bulk density of the material in either pounds per cubic foot or

kilograms per liter (depending on the weigh unit of measurement in Loadcell

Setup).

Vac Cham. - Current material weight in Vacuum Chamber.

Ret. Hopp. - Current material weight in Retention Hopper.

Thruput - Calculated throughput, weight per hour.

Totalizer - Calculated total of all cycles since last clear of totals.

Last Cycle * - Total time to process a completed batch of dry material.

Cycle Count * - Total number of cycles since start button was pressed.

Fill Time * - Total time to fill the Vacuum Chamber.

T1 - Show actual temperature of the heating hopper inlet. & heating %.

T2 - Show Actual temperature of the heating hopper outlet.

T4 - Show Actual temperature of the retaining hopper.

==== AUTO CYCLE ====

T1a:149°F VTa: 07:57

T1s:150°F VTs: 20:00

►ADV ==== VAC: 78mm

I/O:BHVC ►BACK

Fill Weight: 35LB

Vac. Cham.:+ 35LB

Ret. Hopp.: 27LB▼

I/O:BHVC ►BACK

Thruput: 75LB/HR▲

Totalizer: 778LB

Last Cycle: 21:06▼

I/O:BHVC ►BACK

Cycle Count: 5▲

Fill Time: 18.697

T1:149/150°F H:19% ▼

I/O:BHVC ►BACK

T1:149/150°F H:19% ▲

T2:106°F T4: 145°F

* These advanced menu options can be turned on / off in the DISPLAY SETUP menu.

Auto Shutdown

At any point during the preheat cycle or standard operation (operation after initial preheat cycle),

pressing the red button will bring up a Shutdown Options screen and display.

Press:

to display the shutdown screen.

Use the

button to navigate

down to Auto Shutdown.

Press: The display will show the current date and time

above the Auto-Shutdown date and time. You are

adjusting the Auto-Shutdown date and time. Use

the

buttons to navigate down to the lower

Display

will show:

Display

will show:

====== SHUTDOWN ======

Shutdown

►Auto Shutdown

Immediate Shutdown

AUTO-SHUTDOWN BACK

Mon 10/30/2014 12:30

Mon 10/30/2014 00:00

► Month: 1-12

adjustment field to adjust the date and time for the

Auto-Shutdown to occur.

Press: Use the buttons to adjust the digit and

press ENTER to save that edited field and move to

the next field. When complete (NEXT will display

to indicate you have completed edit of all fields),

Display

will show:

AUTO-SHUTDOWN BACK

Mon 10/30/2014 12:30

Mon 10/30/2014 16:30

►NEXT ================

press ENTER to finish. The Home Screen will now

display "AUTO-SHUTDOWN" at the top to indicate

the dryer is in an Auto-Shutdown mode.

Rev. August 31, 2016 – VBD-150

23

V

BD® - Vacuum Dryer®

Recommended Drying Temperatures

MATERIAL

FINAL

MOISTURE % *

Maguire Products, Inc.

DRYING TEMPERATURE**

ºC ºF

ABS

ABS/PC

LCP

PA

PBT

PC

PC/PBT

PEEK

PEI

PES

PET (Molding Grade)

PET (Preform, Extrusion)

PMMA (Acrylic)

POM (Acetal)

PPO

PPS

PUR

PSU

SAN

* Final moisture content as recommended by the raw material manufacturer.

** Drying temperature as recommended by the material manufacturer.

0.10 80 - 85 180 – 190

0.02 100 210

0.02 150 300

0.20 - 0.10 80 - 85 180 – 190

0.02 120 250

0.02 125 250

0.02 125 250

0.20 - 0.10 150 300

0.02 150 300

0.05 - 0.02 150 300

0.010 150-180 300-350

0.005 150-180 300-350

0.02 - 0.04 79 175

0.20 - 0.10 80 - 110 180 – 230

0.02 100 - 120 210 – 250

0.02 150 300

0.02 125 - 140 260 – 280

0.02 150 300

0.20 - 0.10 80 180

Drying is accomplished when all material reaches the proper

temperature, and is then placed under sufficient vacuum for a sufficient

period of time.

Measurement of moisture content of material, both prior to and after

drying, is accomplished by using a moisture analyzer.

24

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

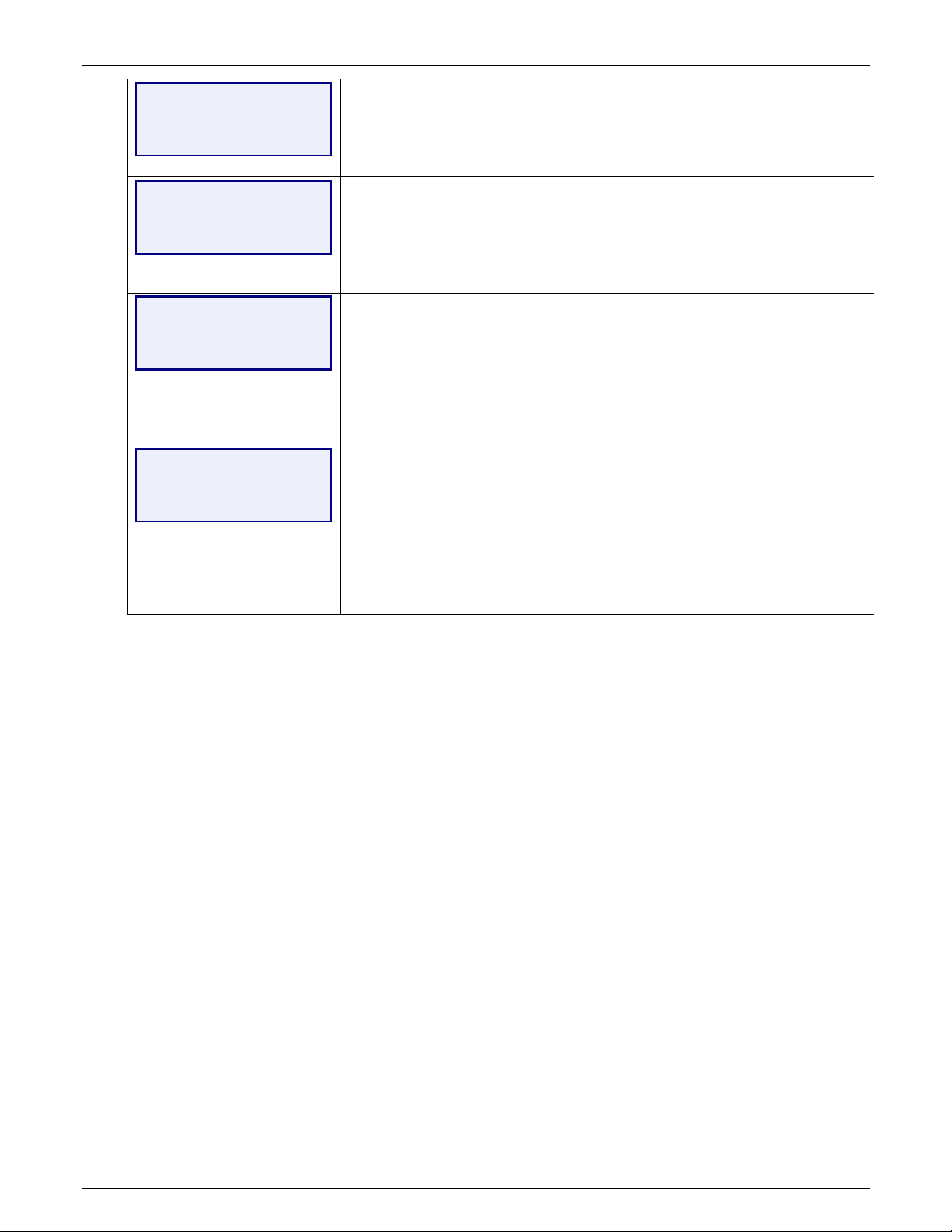

Description of Menu Options

Select Mode (Top Level Menu)

Three modes of operation: Run Dryer, Clean Out and Manual Operations.

Run Dryer - See Operation on page 19.

Clean Out – Clean Out opens all valves and allows for material evacuation and cleanout.

Dump Heat Hopper – Opens the Vacuum Chamber Fill Valve, drains the Heating

Hopper.

Dump Vacuum Chamber – Opens Vacuum Chamber dump valve, draining Vacuum

Chamber

Dump All – Opens both the Vacuum Chamber Fill Valve and Vacuum Chamber dump

valve

Manual Operations – Options that allow direct control over specific outputs.

Operate Outputs

Alarm Audio – OFF/ON – Operates audible alarm.

Alarm Strobe – OFF/ON – Operates strobe.

Dry Purge Supply – CLOSED/OPEN of dry purge supply air valve

Vac Gate Upper – OPEN/CLOSED – Material gate above vacuum chamber.

Vac Gate Lower – OPEN/CLOSED – visible disk shaped gate below vacuum

chamber.

Vac Cham Fill – OPEN/CLOSED - Gate located at the base of the heating

hopper.

Vac Cham Dump – OPEN/CLOSED – Internal gate (not visible) located at the

base of the vacuum chamber.

Vac Gen Supply – OPEN/CLOSED – Vacuum generator supply. When

operating, the vacuum generator supply pulls a vacuum on the vacuum chamber.

Vac Gen Check – OPEN/CLOSED – Vacuum generator check valve located on

the vacuum generator. Holds the vacuum on the vacuum chamber.

Vac Cham Purge – OPEN/CLOSED – Located below the vacuum generator.

When open the vacuum on the vacuum chamber is released.

Heater Test – Operates the heater and blower that supplies heat to the Heating

Hopper.

T1s: Heating Hopper inlet temp setpoint.

T1a: Heating Hopper inlet temp actual.

Start: Starts the heater test. Blower will run during test.

Heater Output: Heater duty cycle expressed in percent

Blower: Status of blower

Control: PID or manual. Controller will modulate the heater as it would during

auto cycle. In manual mode the operator can select a heater duty cycle.

Edit Settings: Easy access to heater control parameters

Blower Test – Operates the blower.

Blower: OFF/ON toggle using ENTER button.

Aux: OFF/ON toggle using ENTER button.

Fail Safe: OFF/ON toggle using ENTER button.

Rev. August 31, 2016 – VBD-150

25

V

BD® - Vacuum Dryer®

T1s: Heating Hopper inlet temp setpoint.

T1a: Heating Hopper inlet temp actual.

Vacuum Test - Tests the Vacuum System

Vac: Vacuum pressure readout

Start Test: Starts the vacuum test. Runs the vacuum generator system.

Evac Time: Amount of time in minutes/seconds to attain the vacuum setpoint

during the current test.

Cycle: Amount of time in minutes/seconds between vacuum generator runs

during a vacuum hold. Used to determine vacuum chamber seal integrity.

Pset: Absolute pressure that the Vacuum Chamber will be evacuated to. See

VPL parameter.

Pdel: The pressure difference above VPL at while the vacuum generator turns

back on. See VPD parameter.

Purge Cham: Enables or disables the dry purge.

Input Status – Shows status of various inputs

Blower – OFF/ON

Level – Heating Hooper Level (0-100%)

Pressure – LOW/OK

VAC – Vacuum chamber absolute pressure (mmHg)

Primary OT – Primary Heater temperature switch - OK/OVERTMP

Purge OT - Purge Heater temperature switch - OK/OVERTMP

HH Rem. Dump – Remote heating hopper dump – ON/OFF

VC LC – Raw counts of the vacuum chamber loadcell

RH LC - Raw counts of the retention hopper loadcell

T1 – Heating hopper inlet temperature

T2 – Heating hopper outlet temperature

T4 – Optional material exit temperature

Timed Dispense – .

Fill: Fill Time of the Vacuum Chamber in milliseconds.

Dump: Dump time of the Vacuum Chamber in milliseconds.

Maguire Products, Inc.

26

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

Setup Menu

The Setup Menu is accessed by pressing the Select button and choosing the Wrench mode.

Press:

to toggle the Mode Selection

to the Wrench Icon.

Enter: the 5-digit password. (Default password is 22222).

Use the

ENTER to move to the next digit and to finish.

Press: the button several times to move down to the desired option.

Press ENTER to select that Setup option for modification.

Setup Menu Option Description / Options

Alarm Setup

buttons to adjust the digit. Press

Material Shortage Alarm

WARN: In the event of a material shortage, activate

SHUTDOWN: In the event of a material shortage, activate

OFF: Disables the Material Shortage alarm

When Material Shortage Alarm is in Warn or Shutdown Mode

Fill Retries are ENABLED. When set to OFF, Fill Retries are

disabled.

Material Ready Alarm - If the Material Ready alarm is enabled, this

alarm will trigger after the first and only first batch of material has

completed a full vacuum cycle. After 15 seconds, the audible

portion of this alarm will automatically silence. The first batch of

material will remain under vacuum indefinitely until this alarm is

cleared. There are two main purposes of this alarm:

1. To alert the operator that dry material is ready for the process.

2. To act as a hold-back, when necessary, giving the operator

additional time to prepare the process.

ON: When the Material Ready Alarm is enabled,

OFF: Disables the Material Ready Alarm

(labeled "Material")

the audible alarm and strobe light but

continue retrying for material.

the audible alarm and strobe light and

automatically initiate a planned shutdown.

Audible alarm with sound for 15 seconds and

the strobe will flash until the dryer is

completely shut down.

the alarm will sound when this alarm is

triggered.

Display

will show:

Display

will show:

SETUP

ENTER PASSWORD

_ _ _ _ _

SETUP

► Alarm Setup

Auto-Start Setup

Blower Setup ▼

Rev. August 31, 2016 – VBD-150

27

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

Material Temperature Alarm - When the Material Temp alarm is

enabled, during any instance where the Heating Hopper is called

upon to dispense material into the vacuum chamber and the T2

(heating hopper exit) temperature is below the ESM parameter

level, this alarm will trigger. Its purpose is to alert the operator that

insufficient heating has occurred, most likely from a process

throughput that exceeds the capacity of the VBD.

ON: When the Material Temperature Alarm is

enabled,.

OFF:

Residence Alarm (labeled “Residence”) -

Disables the Material Temperature Alarm

When the Residence Alarm

is enabled, an alarm will sound if dried material has sat in the

retention hopper too long. The RAL parameter determines when a

residence alarm will occur based on elapsed time and weight of

remaining material in the retention hopper. See the RAL parameter

for more information.

ON: When the Residence Alarm is enabled, the

alarm will sound when this alarm is triggered.

OFF:

Throughput Alarm (labeled "Thruput") -

Disables the Residence Alarm

If the Throughput alarm is

enabled, the alarm will sound if the material in the Retention Hopper

is used faster than the dryer can produce dried material. (Material

level reaches RTL parameter before the Vacuum Time Setting

expires VTS parameter)

ON: If the Throughput alarm is enabled, the alarm

will sound when this alarm is triggered.

OFF: Disables the Throughput alarm

VC Dump (Vacuum Chamber Dump) Alarm -

If the Vacuum Chamber

Dump alarm is enabled, the dispensing of material from the vacuum

chamber into the retention hopper is monitored using the CDR

(Chamber Dump Retries) parameter. CDR’s default settings of

05003 requires that at least 50% of the material that is in the

vacuum chamber be detected in the retention hopper after the

dispense. If it’s under 50% the dispense will retry 3 times before

triggering the alarm. Retries will continue indefinitely until 50% is

satisfied.

ON: If the Vacuum Chamber Dump alarm is

enabled, the alarm will sound when this alarm

28

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

is triggered.

OFF:

Disables both the vacuum chamber dump

alarm and vacuum chamber Dump retries.

Print Alarm Log - Prints the Alarm Log. See page 60.

Clear Alarm Log - Clears the Alarm Log. See page 60.

Auto-Start Setup

Auto-Starts the Dryer at a specified Time and Day(s). Can be set to

Auto-Start the Dryer at one time only or on a repeated schedule.

Auto-Stop Setup

Auto-Stop the Dryer at a specified Time and Day(s). Can be set to

Auto-Stop the Dryer at one time only or on a repeated schedule.

Communications

Communication setup. See page 42.

Convey Setup

Convey Setup - Material Convey Options - Optional - Uses

dedicated outputs on the I/O board that may be used to control

customer supplied Loader(s).

See the I/O Board Wiring Diagram on page 73

• Loader 1 - Off / Auto - Stops loader that supplies the heating

hopper for shutdown sequence.

• Loader 2 - Off / Auto - When material is ready, loader will

convey material away from dryer retention hopper. When

enabled, select Throughput or Weight.

• Reset Totalizer - Resets Weighed totals to zero. Totals are

the amount of material that has been conveyed away from

the dryer since the Totalizer has been reset.

Dispense Setup

Fill Weight – The desired weight of material to be dispensed into

the Vacuum Chamber.

Bulk Density – Bulk density of the material in either pounds per

cubic foot or kilograms per liter (depending on the weigh unit of

measurement in Loadcell Setup).

Fill Wt. Adj (Fill Weight Adjust) – Off / On – When ON the dryer

will automatically adjust the fill weight to be in appropriate proportion

with the throughput. A Low throughput will result in a lower fill

weight.

Display Setup Show / Hide Information and options on the controller screens

Batch Mode - ON/OFF – When ON, the option to dry a batch

of material is displayed on the home screen.

Auto Shutdown - ON/OFF – When ON, the option to initiate

an auto shutdown (shut down at a specified time) is

displayed on the shutdown options screen.

Rev. August 31, 2016 – VBD-150

29

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

I/O Status – ON/OFF – Displays I/O info on main screen.

Cycle Info - ON/OFF – Displays Cycle info on main screen.

Fill Time - ON/OFF – Displays the fill time on main screen.

Residence Time - ON/OFF – When ON, displays a

countdown timer (RAL parameter) indicating when an alarm

will sound alerting that material has sat in the retention

hopper too long.

Display – TEMP/THRUPUT – Sets the upper red display to

show either actual temperature or throughput (lbs or kgs per

hour).

Dry Purge Setup Purge Cham -

ON/OFF

- Supplies membrane dried air to purge the

Vacuum Chamber and blanket the retention hopper. When enabled

the dryer will supplied air all the time even if dryer is in a STOP

mode.

Purge Interval - Interval in seconds between purges.

Purge Duration - Duration in seconds that the purge will occur.

Loadcell Setup

Parameters

Loadcell Setup - See page 44.

Parameters access. See page 32.

Preheat Setup Preheat Mode - Auto or time - Preheat time for the material in the

Material Hopper. Default preheat time is 30 minutes.

Preheat Time - The Preheat Time is the duration of preheat time.

Print Setup

Print Setup - See page 60

• Event Log: Enabled/disabled

• Interval: 60s (temperatures, pressure)

• Content: Standard/Detail

• Print All - Prints parameters, event log, and alarm log.

• Print Parameters - Prints the parameter list to a USB drive

• Print Event Log - Prints the event log to a USB drive

• Print Alarm Log - Prints the Alarm Log

• Clear Event Log - Deletes all entries in the Event Log

•

System

Clear Alarm Log - Deletes all entries in the Alarm Log

Display Firmware - Displays CPU, I/O board, Model, Boot loader.

Language - Select Language

30

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Temperature Setup

Energy Saver

Vacuum Setup

Maguire Products, Inc.

Set Clock - Set time, date and date format.

Memory - Current memory status.

Password - Sets the Setup Menu Password. Default password is

22222. Setting the password to 00000 disables password

protection.

Restore Parameters - Restores all parameters back to factory

defaults

Restore All - Restores Factory Defaults. WARNING: Only apply

Restore All when directed by a Maguire Technician.

Update Firmware - Update VBD-150 Firmware. See page 69.

Units: Fahrenheit (F) or Celsius (C)

Display Precision: “Standard” displays temperature in whole

degrees. “High” displays temperature in 10ths of a degree.

Energy Saver (OFF/ON): On enables Energy Saver Mode. Energy

Saver Mode when enabled minimizes the amount of energy used to

heat the pellets by shutting down the heater and blower when

possible to conserve energy. When the heating hopper’s outlet

temperature has reached the temperature specified in the Energy

Saver Setup (E.S. Temp), the heater and blower will shut down for

the time period specified in Energy Saver Setup (E.S. Time) or until

the cycle ends, which ever comes first.

E.S. Temp (ESM parameter): Default 125 degrees F.

E.S. Time (EST parameter): Default 30 minutes.

Vacuum Time (Tvac): Amount time the vacuum will run.

Pressure Set Point (Pset): 085mmHg Absolute pressure that the

Vacuum Chamber will be evacuated to.

Pressure Delta (Pdelt): (020 mmHg) Vacuum Deadband

Display: ABS/DIFF Air pressure display, Absolute pressure

(referenced from zero or perfect vacuum, differential pressure

referenced from atmosphere.

Unit: Option to display mmHg (Millimeters of mercury) or inHg

(inches of mercury)

Rev. August 31, 2016 – VBD-150

31

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

Parameters

All Maguire VBD controllers operate according to certain internal PARAMETERS.

Because customer requirements vary widely, we have made parameters accessible for

change through the keypad. In most cases, these parameters will never need to be

changed. Some parameters that are routinely adjusted values are adjustable from the

main display. To access and edit the parameters, see Changing Parameters in this

section:

Changing parameters can have an impact on the Dryers performance. It is highly

recommended that a supervisor change the default Program Mode password to protect the

values. Prior to making any changes, make sure you understand what you are doing. If in

doubt contact a Maguire Dryer Technician before making changes to your dryer.

Blower Parameters: Heater Parameters:

BDT Blower Delay Time PTS Preheat Temperature Setting

BLF VFD Low Limit PHT Preheat Time

BHF VFD High Limit PTD Preheat Target Delta

BDF VFD Frequency RTS Run Temperature Set-Point

BZL VFD Zero Level PT1 PD Loop Proportional

BLA VFD Level Adjustment DT1 PD Loop Derivative

BHT VFD Heat Throttle UT1 PD Loop Update Time

Dispensing Parameters:

VCH Vac. Chamber Hi Level NH1 Heat1 No Heat Alarm

VCL Vacuum Chamber Low Level SO1 Heat1 Set-Point Off. Percent

RHH Ret. Hopper Hi Level MP1 Heat1 Max Percent

RHL Retention Hopper Low Level MAX Max Temp Set-Point

BLK Bulk Density ESM Energy Savings Mode

VFR Vacuum Chamber Fill Rate EST Energy Savings Time

VDR Vacuum Chamber Dump Rate RMP Temperature Ramp Settings

VFT Chamber Fill Time CTM Cool-Down Temperature

VDT Chamber Dump Time CTR Cool-Down Timer

FLA Fill Lag Time

DLA Dump Lag Time KDF Loadcell Stable Wt.

VGD Vacuum Gate Delay LST Load Cell Stable Time

VFA Chamber Fill Adjust LCZ Loadcell Zero

HDD Heating Hopper Dump Delay WST Weight Settle Time

VCT Vacuum Chamber Dump Threshold LZ1 Loadcell 1 Zero

CDR Chamber Dump Reties LZ2 Loadcell 2 Zero

RAL Residence Alarm

BCH Batch Size VTS Vacuum Time Setting

LTP Loader Trip Point VPL Vacuum Pressure Low

LTC Loader Thruput Cutoff VPD Vacuum Pressure Delta

HHV Heating Hopper Volume VSO Vacuum Shutdown Offset

HHU Heating Hopper High Level LVT Low Vacuum Timeout

HLA Heating Hopper Level Alarm NVT No Vacuum Timeout

VPT Chamber Purge Timer

VPI Chamber Purge Interval

ATM Atmospheric Pressure

ELT Event Logging Time

OT1 Heat1 Over-Target Alarm

Load Cell Parameters:

Vacuum Parameters:

System Parameters:

32

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Parameter Units

Maguire Products, Inc.

TIMES

PERCENTS

TEMPERATURES

TERM

3-letter

Acronym

Parameter title (units) – default parameter value

Parameter description

Blower Parameters

BDT

BDF

BHF

BLF

BZL

BLA

BHT

Blower Delay Time (Time in seconds) – 02002

The first two digits are the delay in seconds between powering the blower and

powering the heating hopper heater. The last two digits are the delay in seconds

between powering down the blower and powering down the heating hopper heater.

VFD Frequency (Hz) – 00060

The frequency, in Hz, that the VFD will power the blower motor with. The blower

RPMs, as well as the airflow, are directly proportional to this frequency.

VFD High Limit (Hz) – 00060

The maximum VFD frequency, in Hz, that the blower may be set to from the Blower

Setup menu. The maximum settable value for this parameter is 000060.

VFD Low Limit (Hz) – 00025

The minimum VFD frequency, in Hz, that the blower may be set to from the Blower

Setup menu. The minimum settable value for this parameter is 000025.

VFD Zero Level (%) – 00045

The heating hopper level, expressed as a percentage, that triggers the VFD to

reduce speed to the BLA setting.

VFD Level Adjustment (Hz) – 00025

The frequency, in Hz, that the blower will run at if the heating hopper level is at or

below the BZL level. This reduced blower speed eliminates popcorning when the

heating hopper material level is low.

VFD Heat Throttle (%) – 00100

Percentage of adjustment to the heater's on-time at the point when the material has

finished exiting the heat hopper and the blower starts. A reduced heater on-time

percentage (from 100%) reduces the heat exposure to the new material entering

the heat hopper. Activated when the level sensor is below BZL (parameter). Setting

the first digit to a 1 overrides the percent adjustment and effectively turns off the

heater when material is below the BZL threshold.

Are expressed as full seconds or full minutes.

are expressed in full percents.

are expressed in full degrees (Fahrenheit or Celsius).

used to calculate a value.

Rev. August 31, 2016 – VBD-150

33

V

BD® - Vacuum Dryer®

Dispensing Parameters

VCH

VCL

RHH

RHL

BLK

VFR

VDR

VFT

VDT

FLA

Vacuum Chamber High Level – weight - 00035

Amount of material dispensed into the Vacuum Chamber from the heating hopper.

Also known as the “Fill Weight”.

Vacuum Chamber Low Level – weight - 00005

Two conditions are triggered by VTL.

When in Clean Mode, the Vacuum Chamber fill valve will be open when the amount

of material in the Vacuum Chamber is at or below this weight. When starting in

Auto Cycle, the “material in Vacuum Chamber” warning will be triggered when the

amount of material is at or above this level.

Retention Hopper High Level – weight - 00035

Amount of material (the high level) dispensed into the Retention Hopper from the

Vacuum Chamber.

Retention Hopper Low Level – weight - 00005

Three conditions are triggered by RTL.

When in Clean Mode, the Vacuum Chamber dump valve will be open when the

amount of material in the Retention Hopper is at or below this weight. When

starting an Auto Cycle, the “material in Retention Hopper” warning will be triggered

when the amount of material is at or above this level. When in Auto Cycle, the

amount of material in the Retention Hopper must be at or below this level in order

for the Vacuum Chamber to dump.

Bulk Density - Bulk density of the material in either pounds per cubic foot or

kilograms per liter (depending on the weigh unit of measurement in Loadcell

Setup).

Vacuum Chamber Fill Rate – grams/second – 00580

Learned fill rate of the Vacuum Chamber in seconds. Used to calculate a precise

Vacuum Chamber fill time.

Vacuum Chamber Dump Rate – grams/second – 00580

Learned dump rate of the Vacuum Chamber in seconds. Used to calculate a

precise Vacuum Chamber dump time.

Vessel Fill Time (Time in seconds) – 00035

The time in seconds that the Vacuum Chamber fill valve will be open assuming that

the Vacuum Chamber High Level (VTH) is not reached first.

Vessel Dump Time - (Time in seconds) – 00035

The time in seconds that the Vacuum Chamber dump valve will be open assuming

that the Retention Hopper High Level (RTH) is not reached first.

Fill Lag Time (ms) – 00175

The time, in milliseconds, that is added to every vacuum chamber fill valve opening

operation. This compensates for the fill valve opening delay caused by the inherent

lag in any mechanical device.

Maguire Products, Inc.

34

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

DLA

VGD

VFA

HDD

VCT

CDR

RAL

BCH

LTP

Dump Lag Time (ms) – 00100

The time, in milliseconds, that is added to every vacuum chamber dump valve

opening operation. This compensates for the dump valve opening delay caused by

the inherent lag in any mechanical device.

Vacuum Gate Delay (Time in seconds) – 00303

Format: XXXYY - XXX = lower vacuum gate, YY = upper vacuum gate

The amount of time in seconds after a vacuum gates opens before the vacuum

chamber fill or dump valve can open. (Opening of Vacuum Chamber fill valve or

dump valve).

Vacuum Fill Adjust (Retries, percent) – 00310

Two part parameter. The first three digits are the number of retries to fill the

Vacuum Chamber (default 3 retries). Last two digits are the minimum allowable

percent under the targeted maximum fill weight of the Vacuum Chamber (VTH

parameter). After the third failed retry the “Low Batch” alarm is generated while the

VBD continues to retry.

Heat Hopper Dump Delay - Seconds - 0004

Delay in seconds between the heating system shutdown and material dump from

the heating hopper to the Vacuum Chamber. This delay allows time for the blower

to stop.

Vacuum Dump Threshold – grams/second – 00115

During a Vacuum Chamber dump (into the Retention Hopper), the material flow

rate is constantly calculated. When the flow rate reaches VTT, indicating that the

chamber is empty, the Vacuum Chamber dump valve is closed.

Chamber Dump Retries (%/Retries) – 05003

Controls the Vacuum Chamber Dump Alarm.

Format: XXXYY - XXX = percentage, YY = number of retries

When the vacuum chamber dumps material into the retention hopper, if less than

50% of the material that should have dropped is detected in the retention hopper, a

dump retry will occur. After 3 failed retries a VC DUMP alarm will trigger.

Residence Alarm – pounds / minutes - 05120

When the Residence Alarm is enabled, this parameter will determine when a

residence alarm will occur. This parameter contains two variables. The first two

digits are weight (in lbs or kgs) and the last three digits are minutes. For example,

if after 120 minutes there are less than 5 lbs (or kgs) of material removed from the

retention hopper, the Residence Alarm will sound (if enabled, see the Alarm Setup

menu).

Batch Mode – weight (lbs/kgs) – 00000

The amount of material in pounds or kilograms that will be dried during a batch run.

Loader Trip Point – weight (1/10 pound or kilogram) – 00005

If loader 2 (downstream loader) is enabled, and the amount of material in the

retention hopper is at or above this weight, the loader 2 output turns on.

Maguire Products, Inc.

Rev. August 31, 2016 – VBD-150

35

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

LTC

HHV

HHU

HLA

Loader Throughput Cutoff – weight/minute – 00005

When loader 2 (downstream loader) mode is set to “THRUPUT”, and the amount of

material in the Retention Hopper is at or below the LTP parameter, and the

throughput is below this parameter (LTC), turn the loader 2 output off.

Heating Hopper Volume – 10ths of cubic feet or 10ths of liter.

The amount of material that the heating hopper can hold taking into account dead

space at the top and how far the loader hangs into the heating hopper. This

parameter is used to calculate the beginning of an auto shutdown when loader #1 is

set to auto. Installation of an optional heating hopper extension would necessitate

changing this parameter.

Heating Hopper High Level (%) – 00095

The level, expressed as a percentage, that the heating hopper will be filled to when

Loader #1 is set to AUTO (and the heating hopper loader signal cable is wired in

series to the Loader #1 control relay). Note that the deadband is is 5%.

Heating Hopper Level Alarm (%) – 00050

The level, expressed as a percentage, that the Heating Hopper Level Alarm will

trigger if enabled in the Alarm Setup menu. Any heating hopper level at or below

this level will trigger the alarm.

Heater Parameters

PTS

PHT

PTD

RTS

PT1

DT1

Heat1 Temperature Set-Point (Temperature) – 00150

Heating hopper air inlet temperature setting in F° or C°

Preheat Time – Time in Minutes – 00030

Time in Minutes that the material in the heating hopper is heated following a cold

start before normal Run Dryer sequence starts.

Preheat Target Delta – Degrees – 00030

When preheat mode is set to AUTO (not time), the preheat cycle will end when the

temperature of the air exiting the heating hopper (T2) is within PTD degrees of the

air entering the heating hopper (T1).

Run Temperature Setting – Degrees – 00150

The heating hopper air inlet temperature setting in °F or °C. This is the

temperature that the resin is heated to before the vacuum cycle, and is shown as

“T1a” on the status screen.

Heat1 Proportional – Term – 00040

This parameter is used to make adjustments to the heating hopper heat output.

Changes to this parameter should not be made unless directed by a Maguire

Technician. The proportional term (or “gain”) makes a change to the heating

hopper heater output that is proportional to the current error value difference

between set-point and actual temperature.

Heat1 Derivative – Term – 00015

36

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

This parameter is used to make adjustments to the heating hopper heat output.

Changes to this parameter should not be made unless directed by a Maguire

Technician. The rate of change of the process error is calculated by determining

the slope of the error over time (i.e., its first derivative with respect to time) and

multiplying this rate of change by the derivative gain.

UT1

OT1

NH1

SO1

MP1

MAX

ESM

EST

Heat1 Update Time – Time – 00415

This parameter has two parts. The first three digits is the amount of time, in

seconds, between PID updates if the heating hopper inlet temperature, T1a, is

ABOVE setpoint. The last two digits is the amount of time, in seconds, between

PID updates if the heating hopper inlet temperature, T1a, is BELOW setpoint.

Heat1 Over-Temp Alarm – Percent – 06006

The first three digits is the time in seconds by which the actual temperature must be

above the set-point temperature of the heating hopper heater by the value in

degrees represented in the 4th and 5th digits of this parameter before an over-temp

alarm condition occurs.

Heat Hopper No Heat Alarm – Seconds – 120

This is the maximum time limit, in seconds, after the heat cycle begins, during

which one of the following two conditions must be detected: Either the temperature

must climb 20 degrees, or the temperature must move at least 20 percent toward

the target temperature. If neither condition is met the “NO HEAT” alarm will sound.

Such an occurrence would signal a failure of either the heater or the blower. This

parameter protects the heater from burn out in the event the blower fails or airflow

is blocked.

Heat Hopper Set-Point Offset – degrees – 03002

Heating hopper set-point temperature offset. Used for heat control. Offset from the

target in degrees. First 3 digits are the number of seconds to hold the offset

setpoint temperature. 4th and 5th digits are the number of degrees below the target

setpoint.

Heat Hopper Maximum Percent – Percent – 00100

Limits the duty cycle of the heater.

Max Temp Set-Point (Temperature) – 00350

The maximum allowable temperature in whole degrees.

Energy Savings Mode – temperature – 000125

When Energy Saver Mode is enabled, and the temperature of the air exiting the

heating hopper is at or above this level and the Energy Savings Time has elapsed,

trigger Energy Saver Mode.

Energy Savings Time – minutes – 00030

If Energy Savings Mode is enabled and Energy Savings Mode has been activated,

the Energy Saving Time is the time that will elapse before Energy Savings Mode is

reactivated to bring the temperature of the material back up.

Maguire Products, Inc.

Rev. August 31, 2016 – VBD-150

37

V

BD® - Vacuum Dryer®

Maguire Products, Inc.

RMP

CTM

CTR

Temperature Ramp Settings (Increments/Minute/Degrees) – 52036

Format: XYYZZ - X = number of increments, YY = duration of ramp in minutes,

ZZ = temperature delta

For example, with RMP set to 52020: When temperature ramping is turned on, over

the course of 20 minutes, a 20 degree C camp will occur, in 5 increments of 4

degrees C.

Cool-Down Temperature – Degrees - 00120 Fahrenheit or 00050 Celsius

Cool-down target temperature for the heat hopper during the Planned Shutdown.

Cool-Down Timer – Minutes - 00030

Targeted elapsed time to cool-down target temperature (CTM parameter).

Load Cell Parameters

KDF

LST

LCZ

WST

LZ1

LZ2

Loadcell Stable Weight – counts – 00006

Maximum allowable fluctuation in raw loadcell counts to produce a stable weight

reading.

Loadcell Stable Time – milliseconds – 00100

Duration in milliseconds that raw loadcell counts must remain within KDF to

produce a stable loadcell reading.

Loadcell Zero – counts – 01000

Minimal allowable counts when zeroing load cells.

Weight Settle Time – seconds – 00005

Delay time in seconds after the vacuum chamber fill valve closes to allow material

to settle and the dryer to acquire an accurate weigh reading.

Load Cell 1 Zero – counts – 00000

Factory set reference point in counts for retention hopper load cell. This parameter

should not be changed unless directed by a Maguire technician or if load cells are

replaced. If load cells are replaced, instructions will be provided. When this

parameter is set to zero (00000), restriction on loadcell calibration is disabled.

Load Cell 2 Zero – counts – 00000

Factory set reference point in counts for vacuum chamber load cell. This

parameter should not be changed unless directed by a Maguire technician or if load

cells are replaced. If load cells are replaced, instructions will be provided. When

this parameter is set to zero (00000), restriction on loadcell calibration is disabled.

38

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Vacuum Parameters

VTS

VPL

VPD

VSO

LVT

NVT

VPT

VPI

ATM

Vacuum Time Setting (Time in minutes) – 00020

The length of a vacuum cycle in minutes.

Vacuum Pressure Low (mm Hg abs.) – 00080

The pressure (absolute mm, absolute inches, differential mm, differential inches) at

which the vacuum system will attempt to attain before stopping and holding said

pressure. Default shown is absolute mm.

Vacuum Pressure Delta (mm of mercury) – 00020

The pressure difference above VPL at while the vacuum generator turns back on.

This value is the mm of mercury above VPL.

Vacuum Shutdown Offset – Seconds – 00015

Amount of time in seconds before the Vacuum Timer Setting (VTS) expires at

which time Vacuum Chamber equalization will commence.

Low Vacuum Timeout – Seconds – 00120

Time in seconds that the vacuum generator will run before a LOW VACUUM

ALARM is triggered. Vacuum generator continues to attempt to pull a target

vacuum pressure after alarm sounds.

No Vacuum Timeout (retries, time in seconds) – 00345

The first three digits are the number of retries that the vacuum gates will cycle if

vacuum is not achieved. During a retry the vacuum gates are cycled opened and

closed. The last two digits Amount of time in seconds the chamber pressure must

reach 200mm of mercury below atmosphere to not trigger a retry.

Vacuum Purge Timer – seconds – 00005

During equalization of the Vacuum Chamber, this is additional time in seconds

beyond calculated atmospheric pressure, to allow for true pressure equalization.

Vessel Purge Interval – seconds/seconds – 15180

Frequency and duration of dry air purge of the Vacuum Chamber. Default is a

frequency of 3 minutes (180 seconds) for a purge duration of 15 second.

Atmospheric Pressure – mm Hg (absolute) – 00760

The measured ambient atmospheric pressure. This parameter is updated once per

cycle. Do not change this parameter.

System Parameters

ELT

Event Logging Time (Time in seconds) – 00060

Time in seconds between logging data (when logging is enabled).

Maguire Products, Inc.

Rev. August 31, 2016 – VBD-150

39

V

BD® - Vacuum Dryer®

Changing Parameters

Changing parameters can have an impact on the Dryers performance. It is highly

recommended that a supervisor change the default Program Mode password to

protect the parameter values. Prior to making any parameter changes, make sure

you understand what you are doing.

To access the internal parameters you must enter into Setup Mode.

The Setup Mode default password is: 2222

To change a PARAMETER, the machine must be stopped.

Press:

Enter: the 5-digit password. (Default password is 22222).

Use the

ENTER to move to the next digit and to finish.

buttons to adjust the digit. Press

to toggle the Mode Selection

to Setup Mode (Gears Icon).

Display will

show:

Display will

show:

Maguire Products, Inc.

SETUP

ENTER PASSWORD

0_ _ _ _

SETUP

►Alarm Setup

Auto-Start Setup

Change Password ▼

Press: the button several times to move down to the

option “Change Parameters”. Press ENTER to

select Change Parameters.

Press: the button to move through the parameters.

Press ENTER to select a parameter.

Press: When the parameter is selected, the left most digit is

highlighted. Use the

digit. Press ENTER to move to the next digit and to

finish.

Press: When parameter editing is complete, press the

button to move through the parameters to the

bottom of the list the to BACK. With BACK selected,

press ENTER to exit parameters. Pressing the red

power button once will also back out of parameter

editing.

buttons to adjust the

Display will

show:

Display will

show:

Display will

show:

Display will

show:

PARAM. SETUP BACK

Heat1 Proportional

Term PT1

►00040 ▼

PARAM. SETUP BACK

Heat1 Proportional

Term PT1

►00040 ▼

PARAM. SETUP BACK

Heat1 Proportional

Term: PT1

►00040 ▼

PARAM. SETUP ►BACK

Heat1 Proportional

Term: PT1

00040 ▼

40

Rev. August 31, 2016 – VBD-150

V

BD® - Vacuum Dryer®

Batch Mode

Batch Mode, when ON, enables the dryer to dry a predetermined amount of material and then

automatically stop and display a message indicating the batch is complete.

To enable and run the dryer in Batch Mode follow these steps:

Press:

Enter: the 5-digit password. (Default password is 22222).

Use the

ENTER to move to the next digit and to finish.

to toggle the Mode Selection

to the Gears Icon.

buttons to adjust the digit. Press

Display will

show:

Display will

show:

Maguire Products, Inc.

SETUP

ENTER PASSWORD

0_ _ _ _

SETUP

►Alarm Setup

Auto-Start Setup

Change Password ▼

Press: the button several times to move down to the

option “Display Setup”. Press ENTER to select

Display Setup.

Press: the button once to select Batch Mode. Press

ENTER to toggle Batch Mode to ON.

Press: When complete, navigate to BACK and press

ENTER to exit the communication setup.

Press: To return to the home screen.

This displays Run Dryer (Batch) on the home screen.

To start the Dryer in Batch Mode:

Press: the button to move to the home screen selection

to Run Dryer (Batch).

Press: ENTER to run the dryer in Batch Mode. Display will

Display will

show:

Display will

show:

Display will

show:

Display will

show:

show:

DISPLAY SETUP BACK

►Batch Mode: OFF

Auto Shutdown: ON

I/O Status ON▼

DISPLAY SETUP BACK

►Batch Mode: ON

Auto Shutdown: ON

I/O Status ON▼

SETUP

Convey Setup

►Display Setup

Dry Purge Setup ▼

=== SELECT MODE ====

Run Dryer

►Run Dryer (Batch)

Clean Out ▼

BATCH RUN BACK

►Batch Weight: 0

(lbs.)

============== NEXT

Press: ENTER to select the batch weight field. Enter the

weight (lbs or kgs) to dry after which the dryer will

automatically stop. Use the

the digit. Press ENTER to move to the next digit

and to finish.

Press: When complete use the button to navigate down

to NEXT, the press ENTER. From this screen the

Setpoint Temperature, Preheat Time and Vacuum

Time can be adjusted by using the

When complete, select START and press ENTER to

start the drying processes in Batch Mode. When the

Batch Mode has completed the specified weight, the

dryer will automatically stop and display “BATCH

SHUTDOWN”.

buttons to adjust

buttons.

Rev. August 31, 2016 – VBD-150

Display will

show:

Display will

show:

BATCH RUN BACK

►Batch Weight: 0

(lbs.)

============== NEXT

Setpoint Temp.:150F

Preheat Time: 35m

Vacuum Time: 20m

==============►START

41

V

BD® - Vacuum Dryer®

M

M

M

M

M

M

Maguire Products, Inc.

Communications Setup

VBD-150 communications enabled software communication over Ethernet using the MLAN Protocol. For

more information about the MLAN Protocol and the VBD-150 Dryer see the MLAN Protocol manual,

available on the Maguire Products Inc website.

Press:

Enter: the 5-digit password. (Default password is 22222).

Use the

ENTER to move to the next digit and to finish.

Press: the button several times to move down to the

option “Communications”. Press ENTER to select

Communications.

MLAN communication over Ethernet requires an ID number between 001 and 255 and an IP address

including a valid subnet and gateway (if applicable).

Press: the button to move to the MLAN ID. By default

the ID is 001. If you wish to change the ID number

Press ENTER to select the MLAN ID. When the

MLAN ID is selected, the left most digit is

highlighted. Use the

digit. Press ENTER to move to the next digit and to

finish.

buttons to adjust the digit. Press

to toggle the Mode Selection

to the Gears Icon.

buttons to adjust the

Display will

show:

Display will

show:

Display will

show:

Display will

show:

SETUP

ENTER PASSWORD

0_ _ _ _

SETUP

►Alarm Setup

Auto-Start Setup

Change Password ▼

ODE=SETUP BACK

►MLAN ID 001

View MAC Address

View TCP/IP Addr ▼

ODE=SETUP BACK

►MLAN ID 001

View MAC Address

View TCP/IP Addr ▼

Press: When ID editing is complete, press the button to

move to the bottom of the list the to TCP/IP Setup.

Press: ENTER to edit the IP address, subnet, and gateway.

By default the VBD-150 is set to a static IP Address

of 192.168.000.001 with a subnet of 255.255.255.0

and a default gateway of 192.168.000.001. Press

the

buttons to adjust the digit. Press ENTER

Display will

show:

Display will

show:

ODE=SETUP BACK

View MAC Address

View TCP/IP Addr

►TCP/IP Setup

ODE=SETUP BACK

Static IP

►[192.168.000.001]