Maguire Products VBD-1000 Maintenance Manual

MAGUIRE PRODUCTS INC.

Vacuum Batch Dryer - VBD-1000

Touchscreen Controller

INSTALLATION OPERATION MAINTENANCE

Rev. March 5, 2018

VBD-1000

Vacuum Batch Dryer

Touch Screen Controller

Copyright Maguire Products, Inc. 2018

VBD

- Vacuum Dryer

Maguire Products, Inc.

2

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Maguire Products, Inc.

VBD-1000 - Vacuum Dryer

This document is the Original Instructions manual of the Maguire VBD-1000 Vacuum Dryer

equipped with the Touchscreen Controller.

Copyright 2018 Maguire Products Inc.

The information contained within this manual including any translations thereof, is the property of

Maguire Products Inc. and may not be reproduced, or transmitted in any form or by any means

without the express written consent of Maguire Products Inc.

To every person concerned with use and maintenance of the Maguire VBD-1000 it is

recommended to read thoroughly these operating instructions. Maguire Products Inc. accepts no

responsibility or liability for damage or malfunction of the equipment arising from non-observance

of these operating instructions.

To avoid errors and to ensure trouble-free operation, it is essential that these operating

instructions are read and understood by all personnel who are to use the equipment.

Should you have problems or difficulties with the equipment, please contact Maguire Products

Inc. or your local Maguire distributor.

These operating instructions only apply to the equipment described within this manual.

Manufacturer’s Contact Information

Maguire Products Inc.

11 Crozerville Road

Aston, PA. 19014

Phone: 610.459.4300

Fax: 610.459.2700

Website: http://www.maguire.com

Email: info@maguire.com

Rev. March 5, 2018 – VBD-1000 Touchscreen

3

VBD

- Vacuum Dryer

Accuracy of this Manual

Maguire Products, Inc.

We make every effort to keep this manual as correct and current as possible.

However, technology and product changes may occur more rapidly then the

reprinting of this manual. Generally, modifications made to the dryer design or to

the operation of the software are may not reflected in the manual for several

months. The date at the footer of this manual will indicate approximately how

current this manual is. Likewise, your Dryer may have been produced at an

earlier time and the information in this manual may not accurately describe your

Dryer since this manual is written for the current line of Dryers in production (as of

the date in the footer). We always reserve the right to make these changes

without notice, and we do not guarantee the manual to be entirely accurate. If you

question any information in this manual, or find errors, please let us know so that

we may make the required corrections or provide you with accurate information.

Additionally, we will gladly provide you with an updated copy of any manuals you

need at any time. We welcome comments and suggestions on ways we can

improve this manual.

For additional information, or to download the latest copy of this manual or any

other Maguire manual, please visit our website or contact us directly.

On the Web at: www.maguire.com

Maguire Products Inc.

Main Headquarters

11 Crozerville Road

Aston, PA 19014

Tel: 610.459.4300

Fax: 610.459.2700

info@maguire.com

Maguire Europe

Tame Park

Tamworth

Staffordshire

B775DY

UK

Tel: + 44 1827 265 850

Fax: + 44 1827 265 855

info@maguire-europe.com

Maguire Products Asia PTE LTD

15 Changi North Street 1

#01-15, I-Lofts

Singapore 498765

Tel: 65 6848-7117

Fax: 65 6542-8577

magasia@maguire-products.com.sg

Maguire Imea Fzco India, Middle East & Africa

Lobby 18, Floor 7, Office 6

JAFZA View 18Jebel Ali Downtown

PO Box 17493, Dubai, UAE

Tel: +971 4 881 6700

info@maguire-imea.com

Maguire Canada

299 Basaltic Road, Unit 1

Vaughan, Ontario L4K 4W8,

CANADA

Toll Free: 866-441-8409

Tel: 905-879-1100

Fax: 905-879-1101

info@maguirecanada.com

Please e-mail comments and suggestions to: support@maguire.com

4

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Maguire Products, Inc.

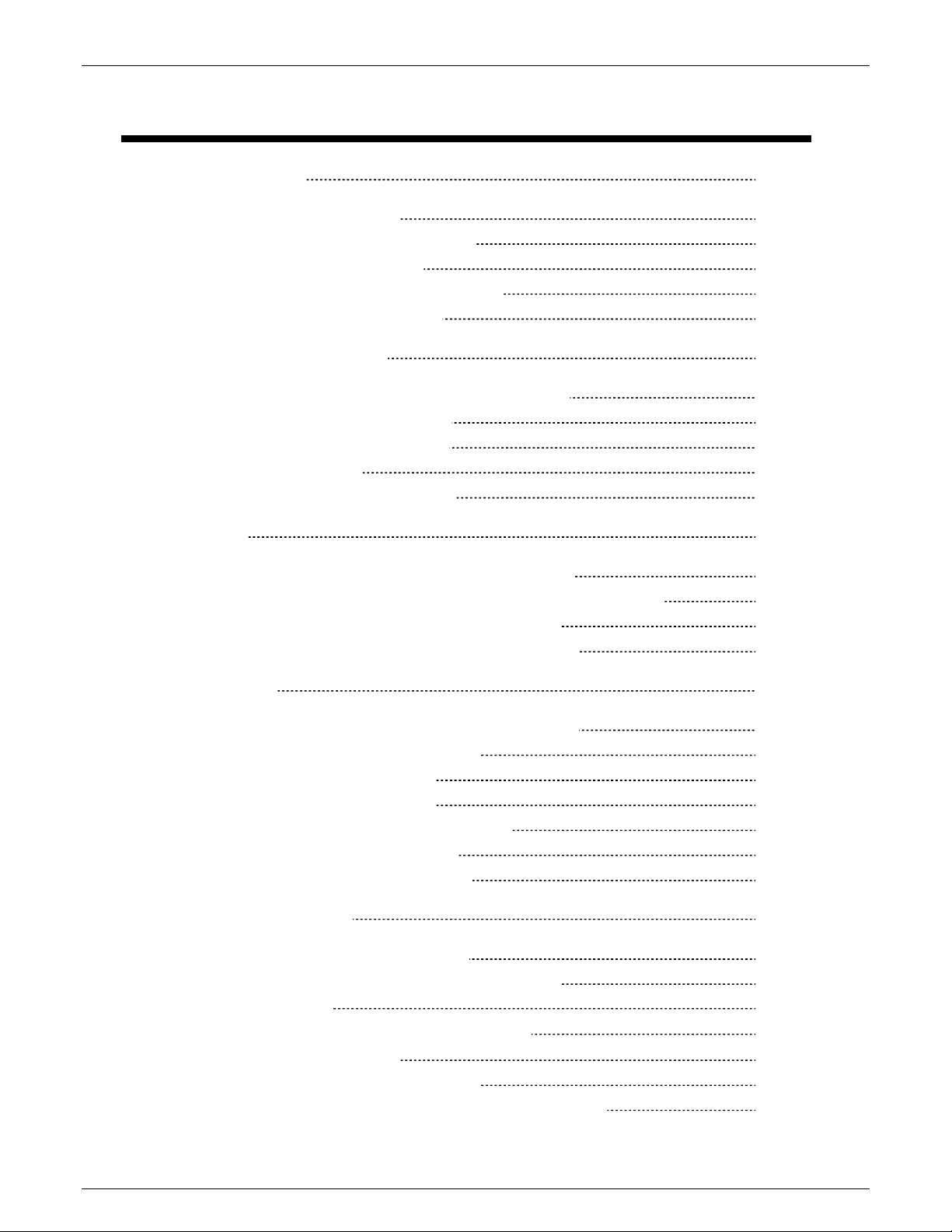

Table of Contents

INSTALLATION 8

Dryer Assembly 12

Engaging the Load Cells 15

Dryer Connections 19

Compressed Air Connection 19

Electrical Connection 20

Home Screen Overview 22

Setup Menu Map -Brief Explanation 30

Parameters Explained 41

Changing Parameters 49

Batch Mode 50

Communication Setup 51

Operation 23

Start Up and Operation Instructions 23

What is happening when the Dryer is Running 25

Shutdown – Immediate or Planned 26

Recommended Drying Temperatures 29

Maintenance 53

Drain and purge Air Filter / Regulator 53

Air Pressure Adjustments 53

Cleanout Procedure 57

Loadcell Calibration 54

Alarms - Cause and Solution 61

Logs and Print Outputs 67

Dryer Firmware Updates 73

General Information 74

Technical Specifications 77

Theory of Operation / Performance 77

Warranty 78

Recommended Spare Parts List 79

Wiring Diagrams 80

Declaration of Conformity 84

Technical Support / Contact Information 85

Rev. March 5, 2018 – VBD-1000 Touchscreen

5

VBD

- Vacuum Dryer

Warranty – Exclusive 5-Year

MAGUIRE PRODUCTS OFFERS THE MOST

COMPREHENSIVE WARRANTY in the plastics

auxiliary equipment industry. We warrant each

MAGUIRE VBD Vacuum Dryer manufactured by us to

be free from defects in material and workmanship under

normal use and service; excluding only those items

listed below as 'excluded items'; our obligation under

this warranty being limited to making good at our

factory any Dryer which shall, within FIVE (5) YEARS

after delivery to the original purchaser, be RETURNED

intact to us, transportation charges PREPAID, and

which our examination shall disclose to our satisfaction

to have been thus defective; this warranty being expressly in lieu of all other warranties

expressed or implied and of all other obligations or liabilities on our part, and MAGUIRE

PRODUCTS neither assumes nor authorizes any other persons to assume for it any

other liability in connection with the sale of its Dryers.

This warranty shall not apply to equipment repaired or altered outside MAGUIRE

PRODUCTS INC. factory, unless such repair or alteration was, in our judgment, not

responsible for the failure; nor which has been subject to misuse, negligence or

accident, incorrect wiring by others,

or installation or use not in accord with instructions furnished by

Maguire Products, Inc.

Our liability under this warranty will extend only to equipment that is returned to our

factory in Aston, Pennsylvania, PREPAID.

Please note that we always strive to satisfy our customers in whatever manner is

deemed most expedient to overcome any problems they may have in connection with

our equipment.

Maguire Products, Inc.

GETTING STARTED:

PROCEED TO: SAFETY WARNINGS NEXT PAGE

6

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

SAFETY WARNINGS

Maguire Products, Inc.

HOT SURFACES:

As with all dryers, there are HOT

SURFACES to avoid. Temperatures can

reach 350F, (180C).

Typically, these surfaces are not at dangerous

temperatures, however all hot surfaces should be avoided.

Warning Label indicate:

HOT SURFACES

USE CAUTION when removing

and installing canisters.

USE GLOVES

DO NOT REACH into the dryer

enclosure.

RISK OF SHOCK:

Disconnect power supply before

servicing the Dryer.

GETTING STARTED: PROCEED TO: INSTALLATION - NEXT PAGE

Rev. March 5, 2018 – VBD-1000 Touchscreen

7

VBD

- Vacuum Dryer

material to be convey from the base of the VBD Dryer.

Maguire Products, Inc.

Installation

Transport and Setup

Shipment

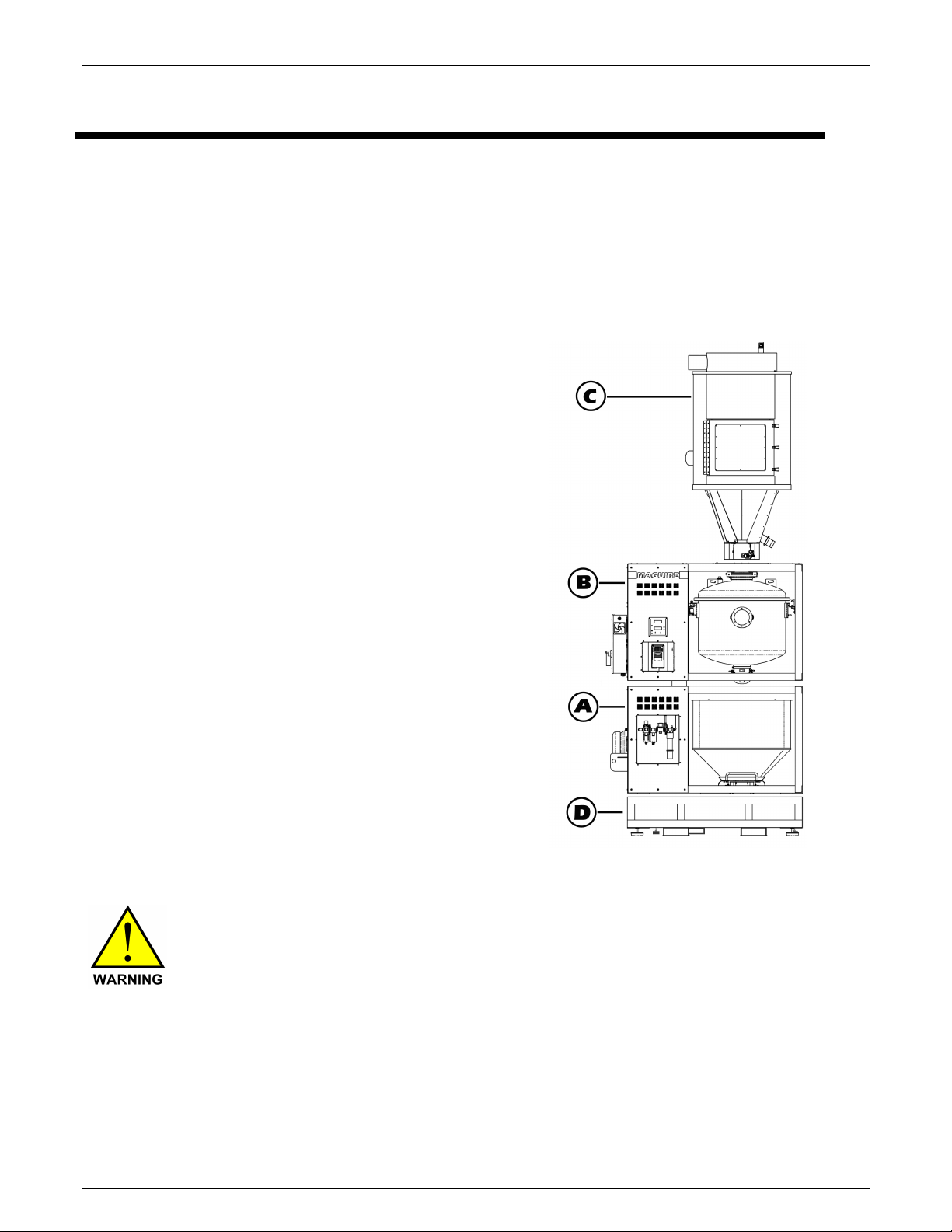

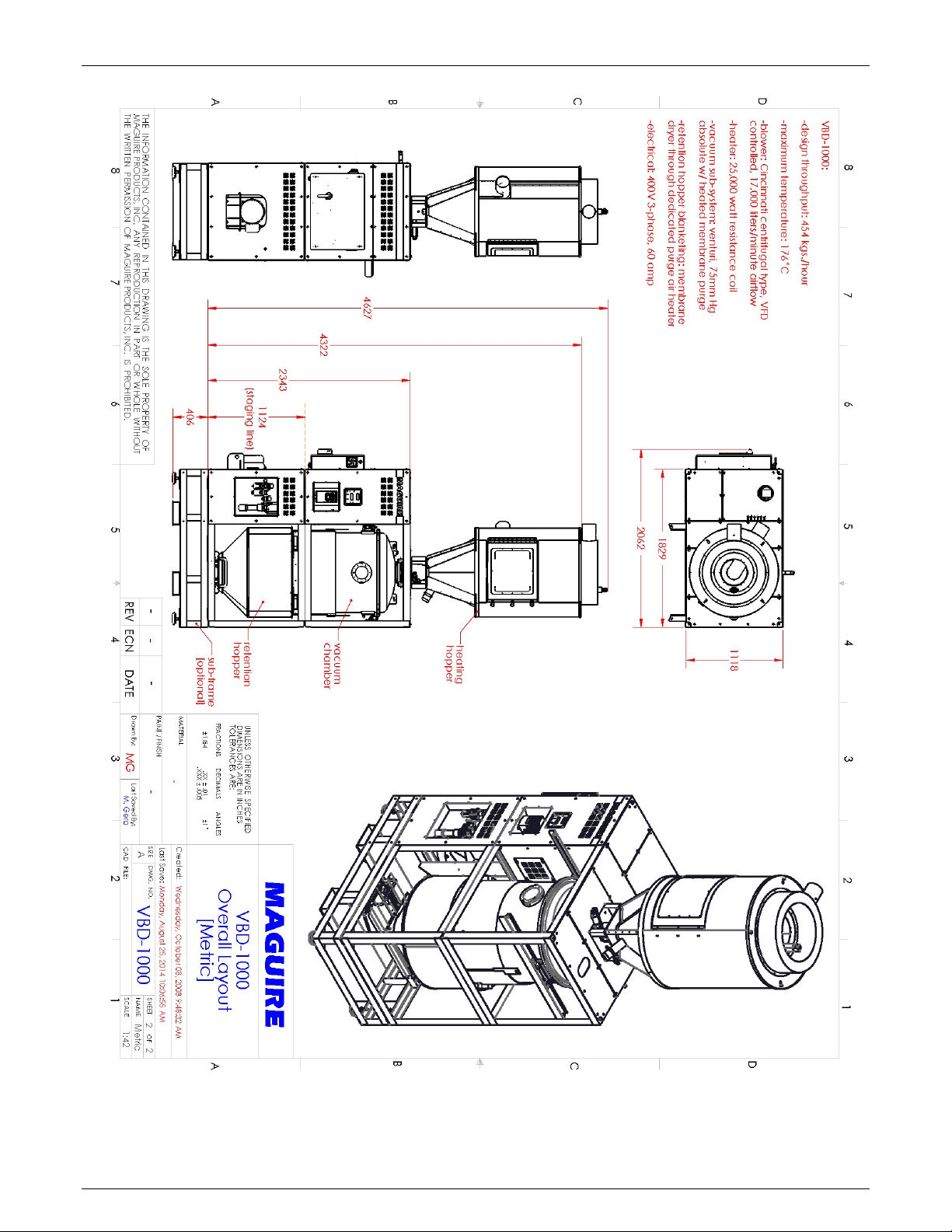

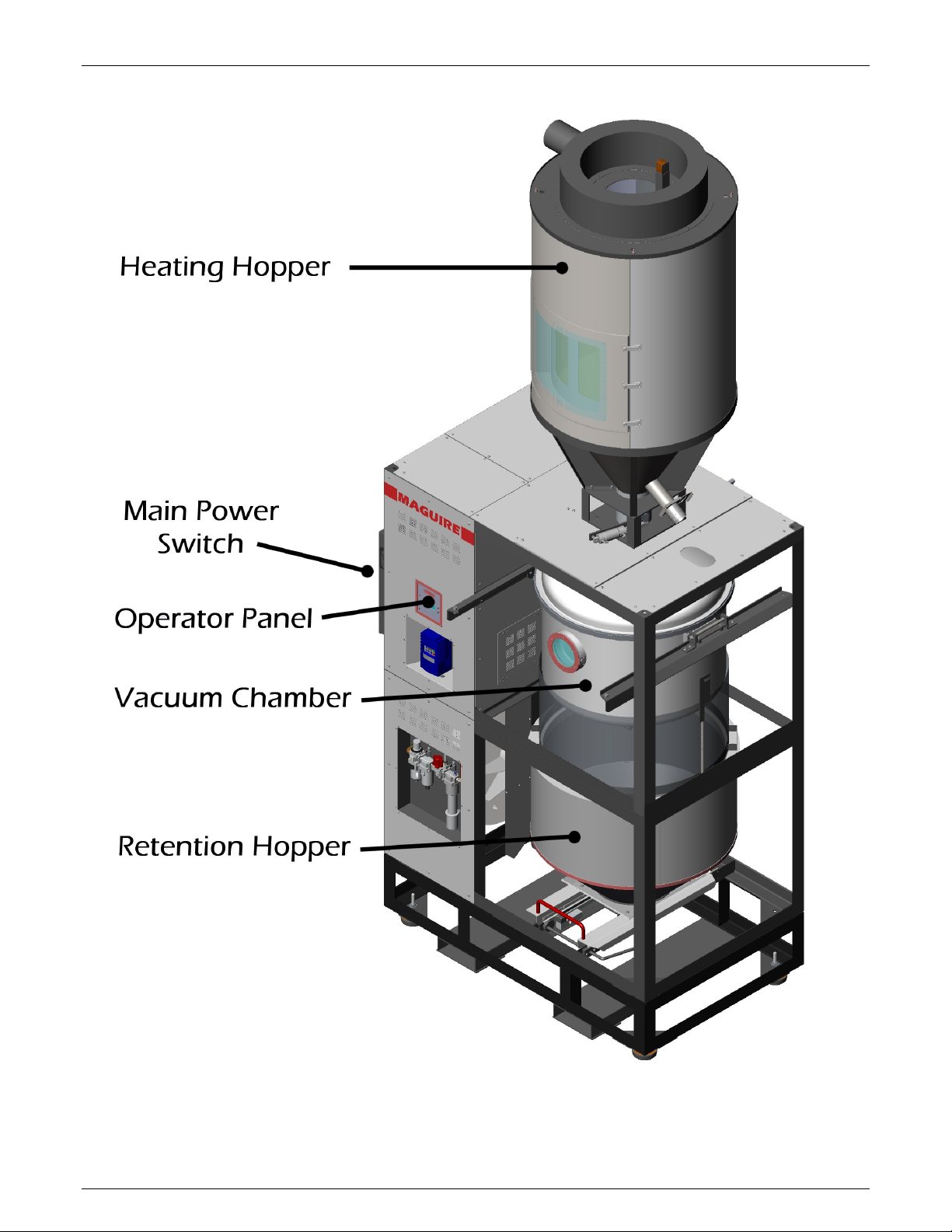

The VBD-1000 Dryer is shipped as separate components that require re-assembly.

The 3 main sections are:

Retention Hopper Assembly (A) – Identified by the

recessed pneumatics cabinet on the front panel and

the removable Retention Hopper on the lower slide

rail. Weight is 1920 lb (871 kg)

Vacuum Chamber Assembly (B) – Identified by the

control panel on the front panel, the electrical cabinet

on the left side and the hanging vacuum chamber.

Weight is 1920 lb (871 kg).

Heating Hopper Assembly (C) – Identified as a tall

heating hopper. Weight is 350 lb (159 kg)

Optional Base Frame (D) – a sub frame that elevates

the Retention Hopper Assembly 16 inch allowing

Weight of the Base Frame is 1303 lb (591 kg)

Other smaller components will be included. An

optional mounting base section may be included.

Lifting and Moving components of the Dryer

Ensure your lifting equipment is rated to lifting the weight

of the individual sections of the VBD-1000.

The three main sections of the VBD-1000 Dryer are shipped with Forged Eye Bolts to be

used specifically as lifting points. When lifting the Retention Hopper Assembly (A) and the

Vacuum Chamber Assembly (B), utilize all 4 Forged Eye Bolts to distribute the weight

evenly. The Retention Hopper Assembly uses two Forged Eye Bolts and should be lifted

using both Forged Eye Bolts. The Forged Eye Bolts must be removed from the

Retention Hopper Assembly (A) BEFORE lowering the Vacuum Chamber Assembly (B)

into place.

8

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

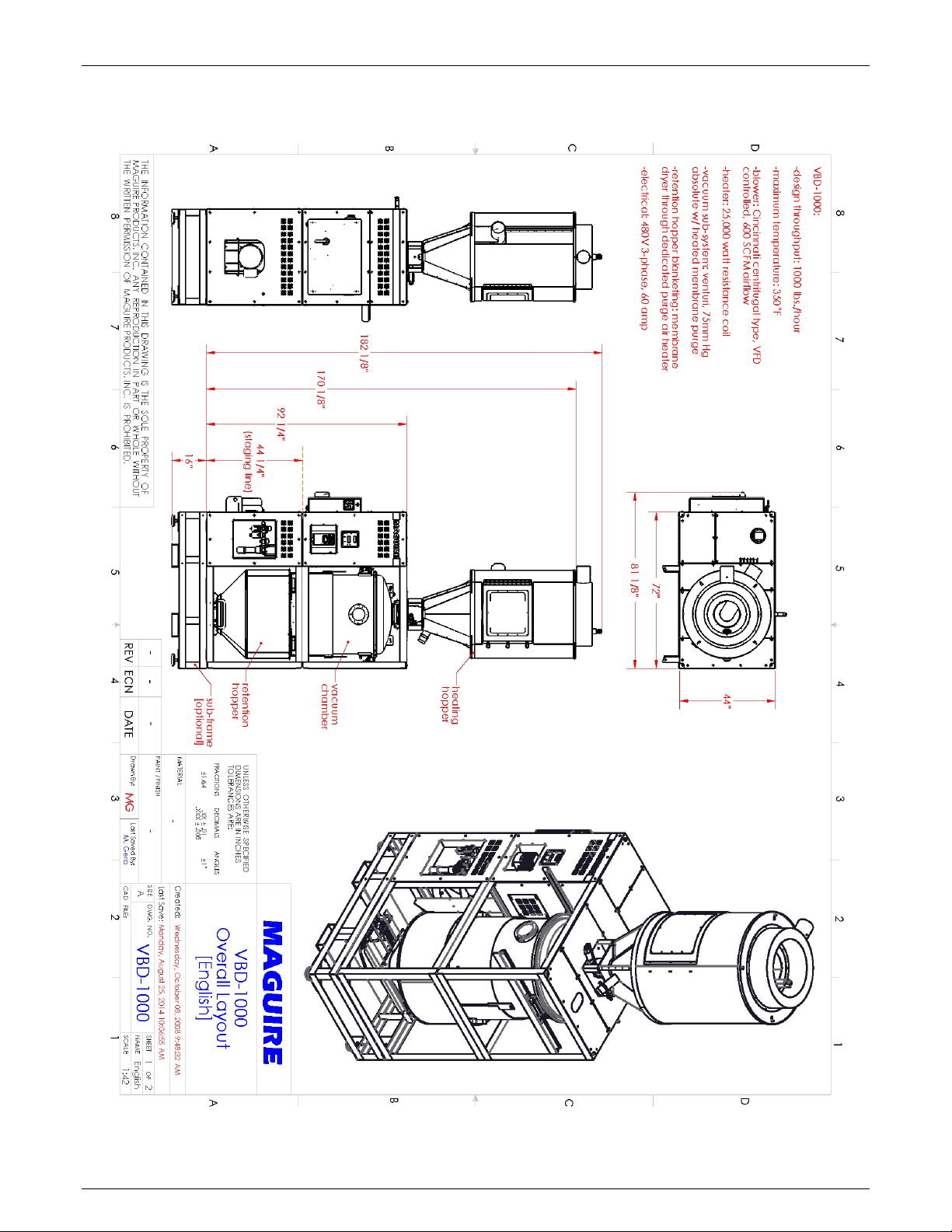

Overall layout and Dimensions

Maguire Products, Inc.

Rev. March 5, 2018 – VBD-1000 Touchscreen

9

VBD

- Vacuum Dryer

Maguire Products, Inc.

10

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Maguire Products, Inc.

Rev. March 5, 2018 – VBD-1000 Touchscreen

11

VBD

- Vacuum Dryer

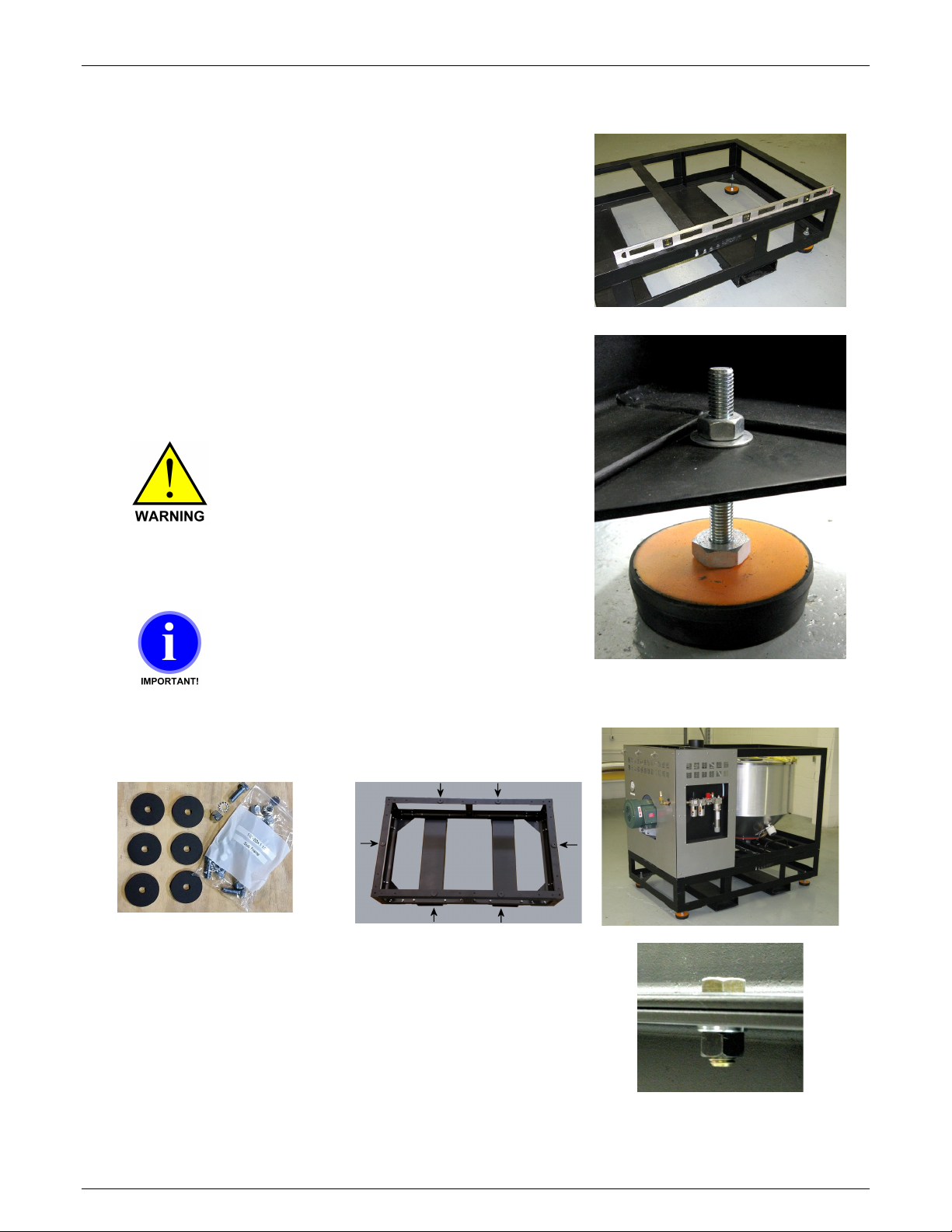

Dryer Assembly

Optional Base Frame

The Base Frame is used to raise VBD’s Retention

Hopper off of the floor. Weight of the Base Frame is

1303 lb (591 kg). Note: If the VBD is to be installed so

that material is gravity fed out of the bottom of the

Dryer, then this Base Frame is not necessary.

Level the Base Frame - If the Base Frame is to be used,

it must be leveled at the installation location. The Base

Frame of the VBD 1000 can be leveled two different

ways. Leveled using the 4 leveling feet or by shimming

the frame to the floor.

If using the leveling feet, make sure

the surface that the VBD 1000 will

be install on can support the weight

of the VBD at 4 corners. If the floor

cannot support this weight in 4

small footprints, use leveling shims

on the frame, not the leveling feet.

When adjusting the leveling feet,

keep the frame as close to the floor

as possible. Over extending the

threads below the frame is not

recommended for stability reasons.

Maguire Products, Inc.

Installing Retention Hopper Assembly (Section A)

Set the 6 spacers at the locations shown below.

If using the Base Frame, lower the Retention Hopper

Assembly onto the Base Frame. Secure the Retention

Hopper Assembly to the Base Frame using the supplied

hardware. The Retention Hopper Assembly is secured

to the Base Frame using (10) 1/2-13 grade 8 bolts.

If the Base Frame is not used – Lower the Retention

Hopper Assembly (Section A) into place. The

Retention Hopper Assembly must be leveled BEFORE

installing the next section.

12

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Installing Vacuum Tank Assembly

(Section B)

Lower the Vacuum Tank Assembly (Section B) onto

the Retention Hopper Assembly. Align the enclosed

side of each section (as shown in image at right). Align

the bolt holes of each section.

Remove the rear panels of Retention Hopper Assembly

(A) and Vacuum Tank Assembly (B) to gain access to

the connections that need to be made within the

enclosure. Install the 10 1/2-13 grade 8 bolts and

tighten.

Install the Heating Hopper

Raise the Heating Hopper on top of section B of

the VBD dryer.

Position the Hopper so that the front hatch faces

the same side of the dryer as the VBD’s control

panel.

Install the 10 1/2-13 grade 8 bolts and tighten.

Maguire Products, Inc.

Connect RTD Sensors and Air Lines

After installing the Heating Hopper,

located the upper sheet metal panel

with the slotted holes. Remove the

button head screws and bring the three

air lines and 3 sensor cables through

the slotted holes. Each sensor cable is

labeled for the specific slots. Air lines

are labeled yellow, white and blue.

Also bring the rubber grommets

through the sheet metal and install the

grommets in the slot to protect the

wires and air lines. Connect the air

lines, Connect the sensor cables and

reinstall the sheet metal panel.

Rev. March 5, 2018 – VBD-1000 Touchscreen

13

VBD

- Vacuum Dryer

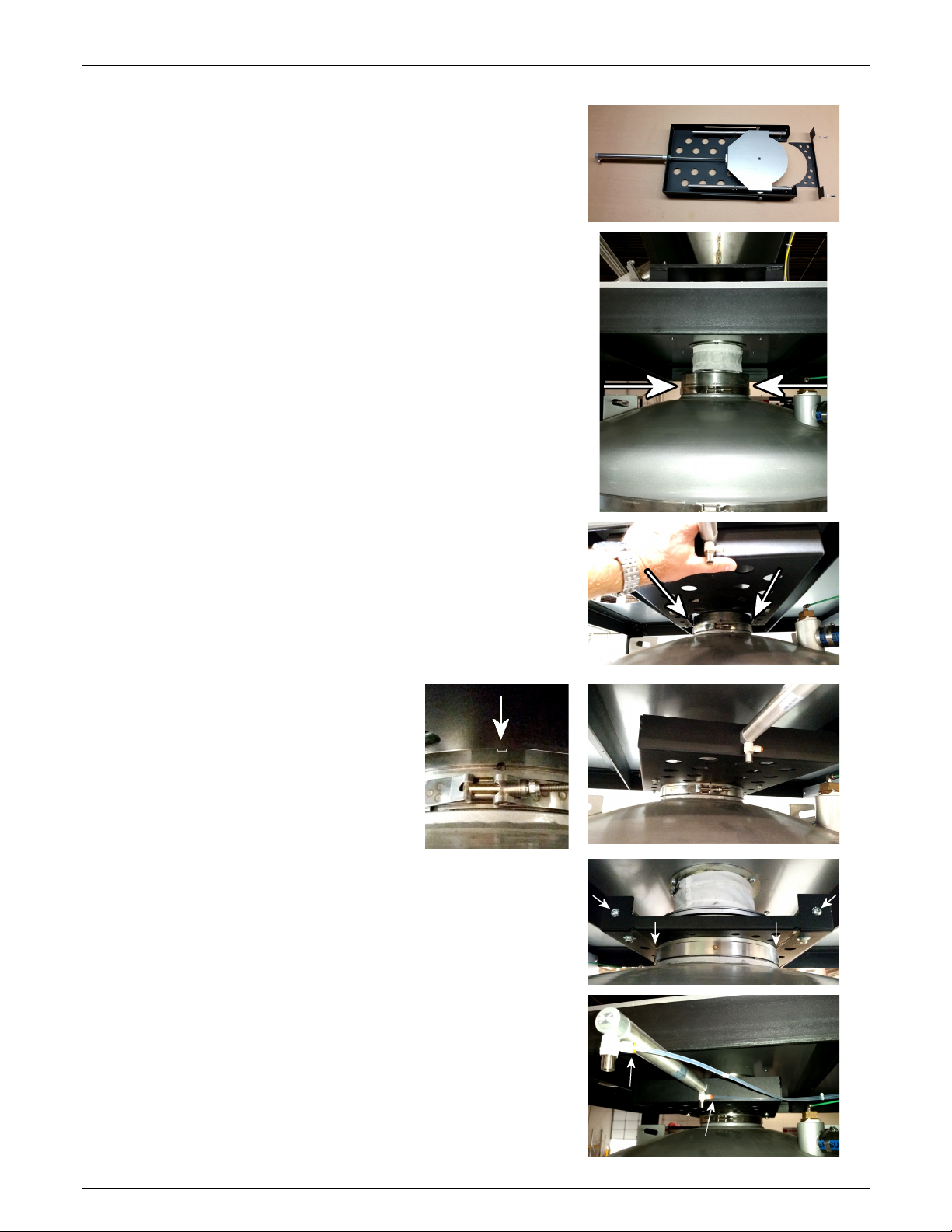

Installing the Upper Vacuum Gate

Note: If your Upper Vacuum Slide Gate is already

installed from factory, skip this step.

If the VBD-1000 Upper Vacuum Gate was shipped

detached from the VBD-1000 it must be installed

after the Heating Hopper is installed.

Items with this assembly:

Upper Vacuum Gate

Retainer Bracket

two 1/4-20 1/2" button head screws

The Upper Vacuum Gate will install from the rear

of the Dryer. Locate the slot on the mount ring at

the very top of the Vacuum Tank. See photo at

right.

Maguire Products, Inc.

With the Slide Gate facing up, slide the Upper

Vacuum Gate assembly into the slot on the mount

ring as shown in the photo to the right. Slide the

Upper Vacuum Gate onto the mount ring until it

fully seats into the slot. It may be helpful to slide

the Upper Vacuum Gate left and right as it is

installed.

Note: To fully seat the Vacuum

Gate onto the mount ring, the tab

in the inner arch of the Upper

Vacuum Gate must go into the

recessed hole of the mount ring

on the Vacuum Chamber.

From the front side of the Dryer, install the

Retaining Bracket onto the Upper Vacuum Gate

and fully into the slot on the mount ring and

secure it using the two 1/4-20 1/2" button head

screws.

Install the two 5/32 (4mm) airlines onto the Upper

Vacuum Gate air cylinder. The shorter line will

connect to the air cylinder fitting closest to the

slide gate.

14

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Engaging the Load Cells

The Load cells are disengaged for shipping and must be engaged for

proper operation of the VBD-1000 Dryer. There are two sets of load cells:

the Vacuum Chamber load cell and the Retention Hopper load cell pair.

Vacuum Chamber Load Cell

The Vacuum Chamber load cell is

located between the Vacuum

Chamber and the Vacuum Chamber

Assembly (B).

To engage the load cell, turn the load

cell lifting bolt down until it engages

the load cell located below. Continue

turning until the Vacuum Chamber

hanger is lifted 1/4 inch (6mm) off of

the sliding rail.

Maguire Products, Inc.

Retention Hopper Load Cell Pair

The Retention Hopper load cell pair is located

in front of and below the Retention Hopper.

To engage the Retention Hopper load cell pair,

remove the packaging straps from the

Retention Hopper Lifting Lever. Lower the

Retention hopper onto the load cell by pressing

the lever back and down. This will engage the

Retention Hopper lower frame onto the load

cell pair.

When the Retention Hopper Lifting Lever is in

its upright position, the lever's cams lift the

weigh off of the load cell pair and allow the

Retention Hopper to be pulled out for servicing

and cleaning purposes.

Lifting bolt, 1/4" (6mm) gap

Engage load cell

Rev. March 5, 2018 – VBD-1000 Touchscreen

15

VBD

- Vacuum Dryer

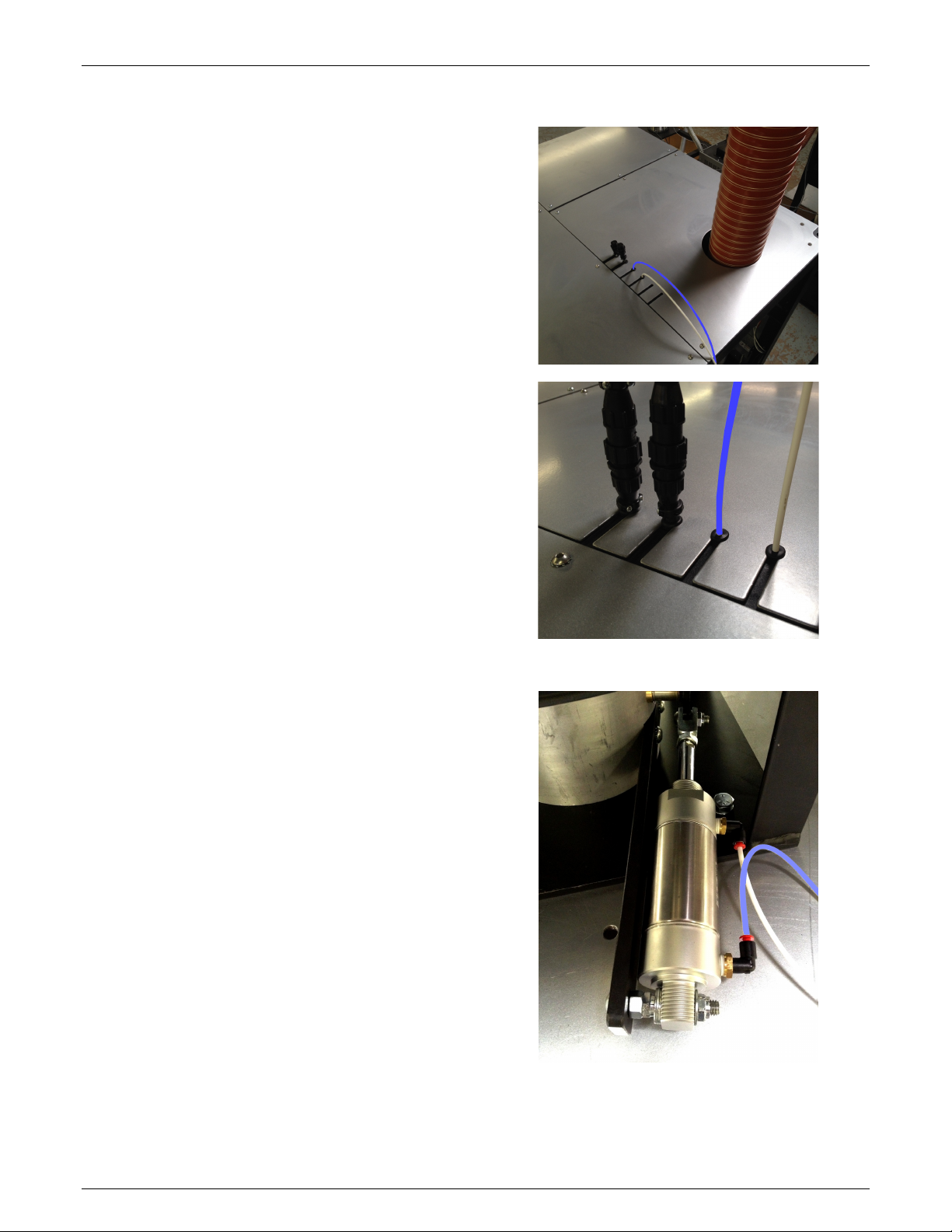

Heating Hopper Dump Valve Air Lines

There is one white and one blue 5/32 inch air

line, two RTD thermometer cables and one

sensor wire (not pictured) bundled within the

VBD-1000 enclosure for safety during

shipping of the VBD-1000. The air lines and

cables must be brought through the enclosure

using the predrilled slotted keyholes. in the

top panel.

To install remove the top panel and locate the

air lines and RTD thermometer cables. On

each air line and wire is a rubber grommet.

Slide the rubber grommet into the slotted

keyhole in the sheet metal, then re-install the

top panel.

Maguire Products, Inc.

Test air line orientation: connect air supply

to VBD-1000. With the VBD power turned off,

the air cylinder should be extended as shown

in photo to the right. Air cylinder is extended

closing the butterfly valve inside the base of

the hopper.

16

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

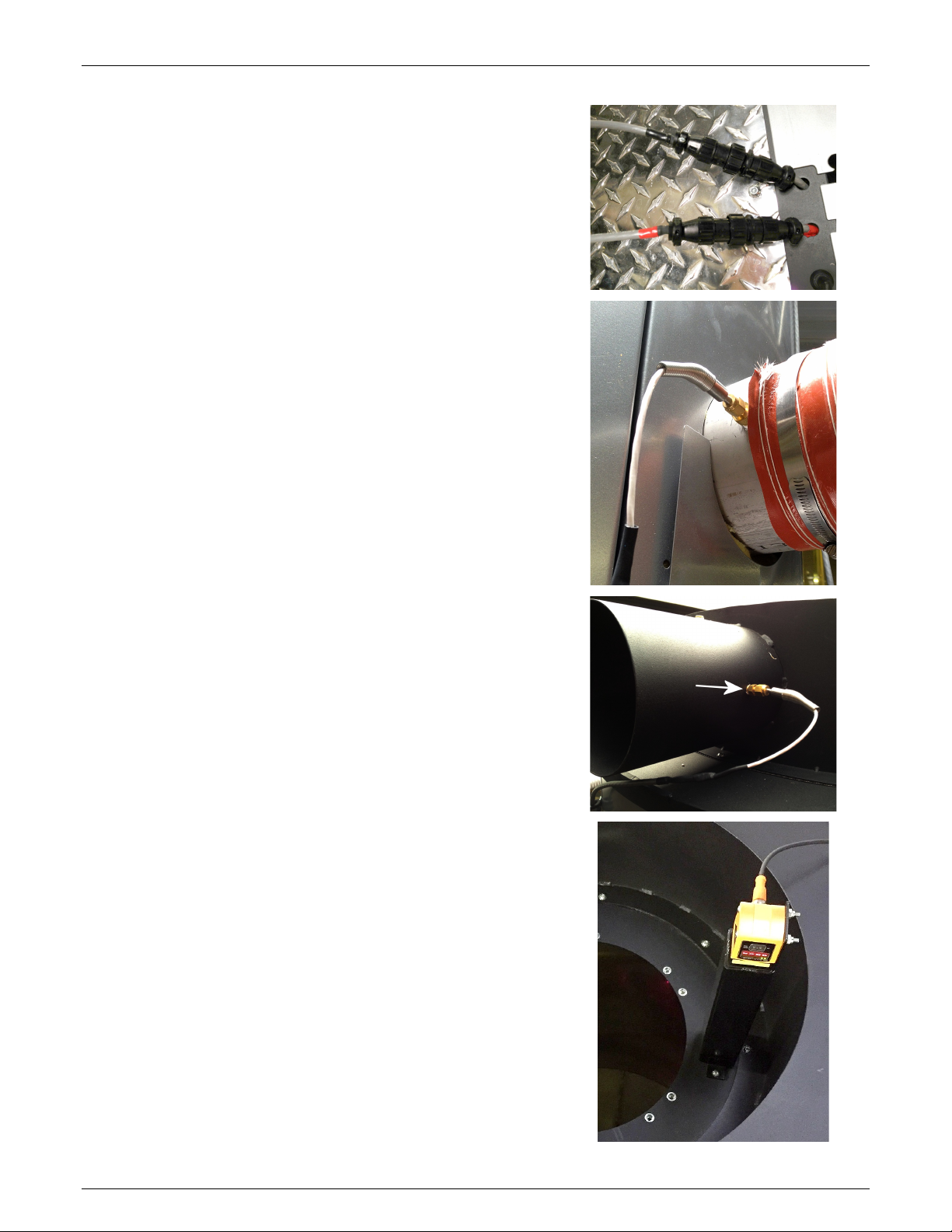

Connect RTD Thermometers

The RTD thermometer cables are terminated on one

end with a CPC connector. The Inlet RTD cable is

marked with a red band. This is the shorter of the two

cables. Connect the cables as shown with the red

banded cable connecting to the CPC connector with

the matching red band.

Secure the Heating Hopper Inlet RTD thermometer to

the side heat inlet of the heating hopper. Secure the

cable to frame of the heating hopper.

Maguire Products, Inc.

Route the longer RTD thermometer cable up to the

exhaust port on the top of the heating hopper and

secure the RTD thermometer as shown. Secure the

cable to frame of the heating hopper.

Install Heating Hopper Level Sensor and Bracket

Install the Heating Hopper bracket and sensor on top

of Heating Hopper (as shown). Located the sensor

cable that exits the top of the VBD Heating Hopper

and attach the sensor cable to the sensor.

Rev. March 5, 2018 – VBD-1000 Touchscreen

17

VBD

- Vacuum Dryer

Maguire Products, Inc.

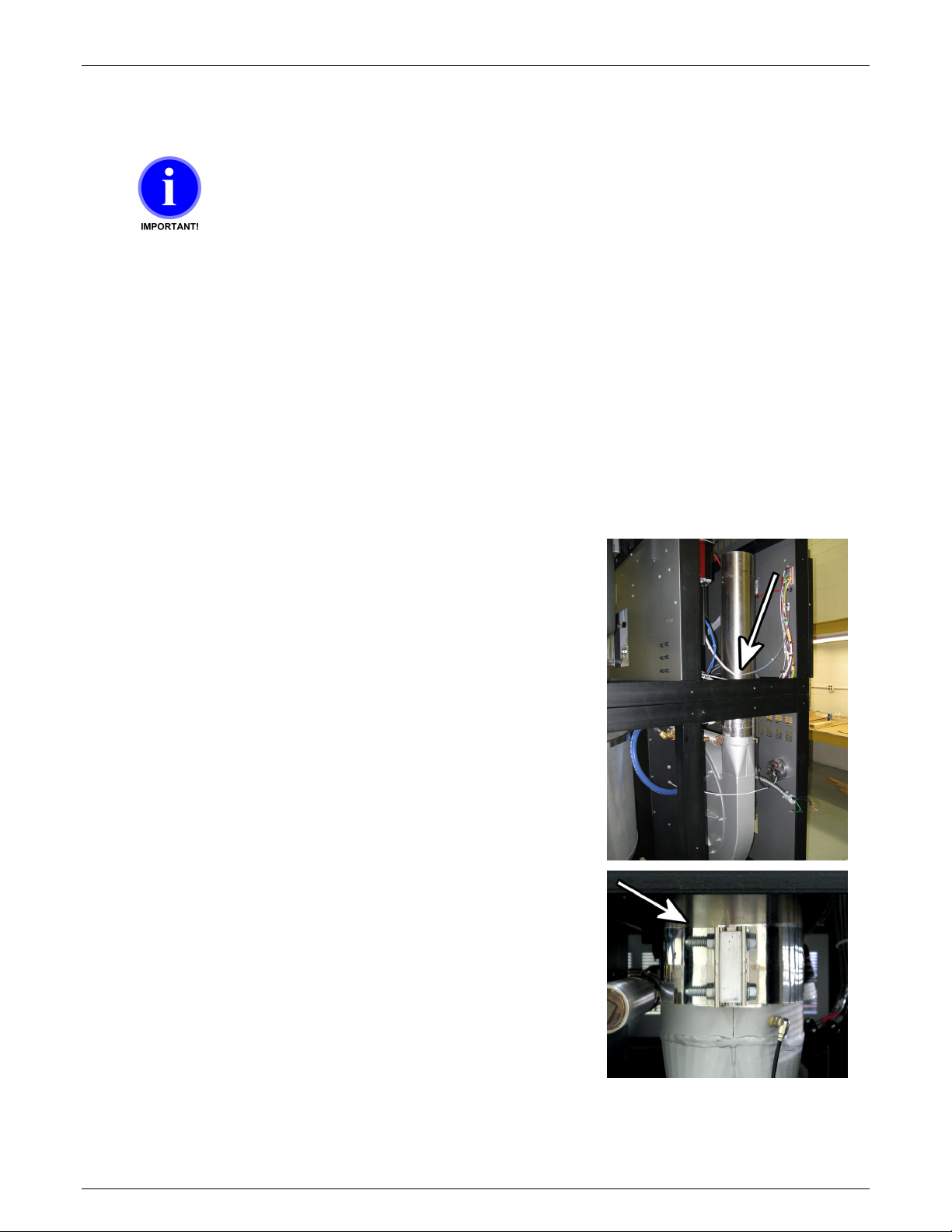

Dryer Internal Assembly

If your Dryer has been shipped with the Retention Hopper Assembly and

the Vacuum Tank Assembly together as one shipment (sections A and B

in the diagrams), then the Dryer Internal Assembly instructions are not

necessary as they are pre-assembled.

Remove the rear panels of Retention Hopper Assembly (A) and Vacuum Tank Assembly

(B) to gain access to the connections that need to be made within the enclosure.

Summary of internal connections:

Heating Hopper Heater connected to blower outlet.

Power Junction Box Plug

Purge Air Solenoid Valve Electrical Plug

Electrical Field Joints (Color Coded)

¾ inch Purge Line

5/32 inch air lines

Install the Heating Hopper Heater

The Heater a polished steel 6-inch cylinder that is prewired and secured within the cabinet during shipping.

This heater must be attached to the outlet of the blower

using the attached 6-inch clamp. First loosen the clamp

attached to the blower’s output. Leave the clamp on the

blower. Then remove the shipping material securing the

Heating Hopper Heater.

Carefully rest the Heater on top of the blower output so

that the heater rests directly on the blower’s 6-inch

output. Tighten the clamp firmly to secure the Heater to

the blower.

18

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Maguire Products, Inc.

Dryer External Connections

Once assembled, installation requires electrical, pneumatic air line connection and intake and

output material lines to be connected.

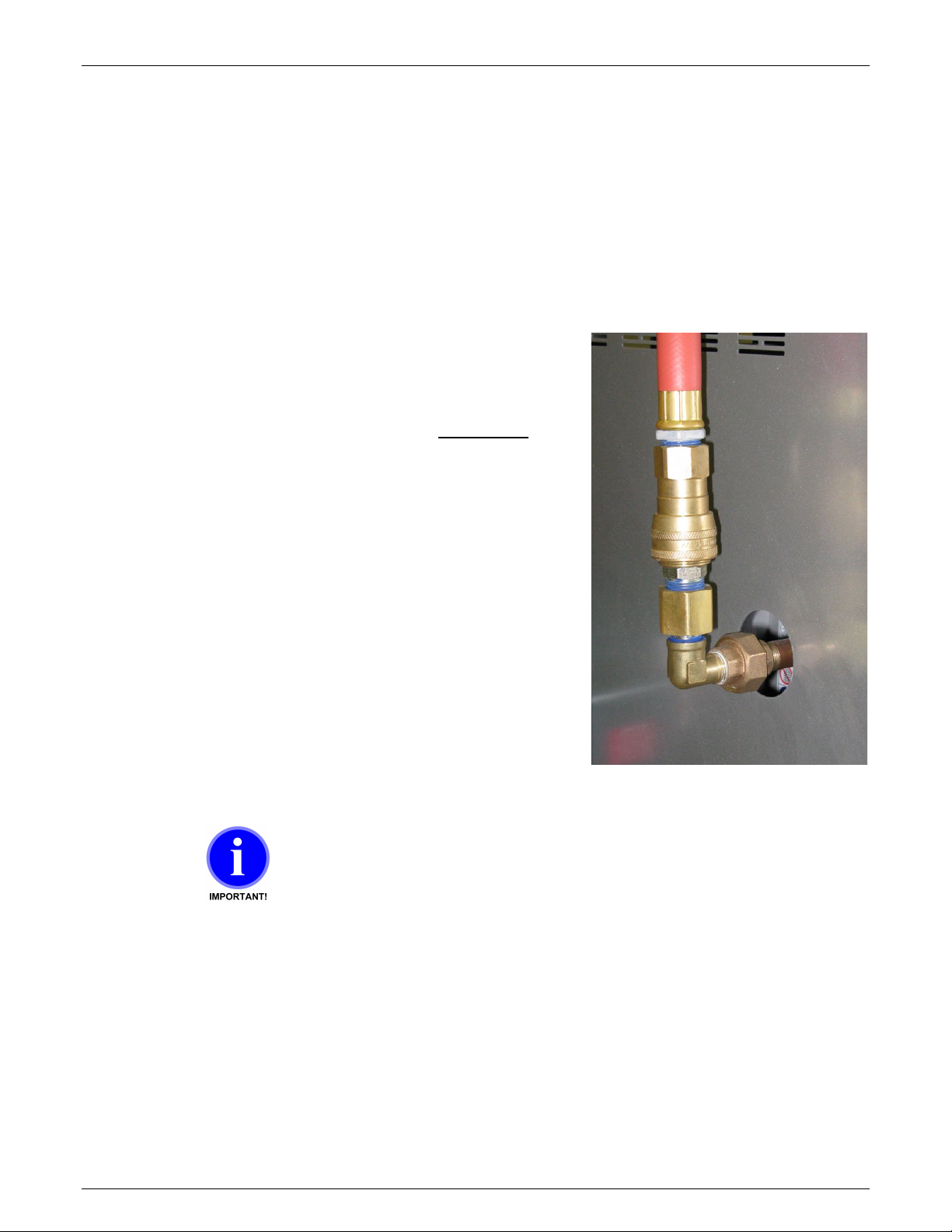

Compressed Air Connection

Connect an air supply to the air regulator’s IN

port using a male 1/2 ” NPT fitting.

An operating air pressure of 80 psi (5.5 bar)

while the vacuum generator is running is

required for proper operation of the Dryer.

If your air supply has oil in it, add an oil

separator (coalescing filter).

Oil in the air will combine with dust drawn from

the vacuum tank forming a paste inside the

vacuum generator. It will stop working and

require cleaning.

Observe the air pressure gauge to be sure the

pressure maintains 80 psi (5.5 bar) while the

vacuum generator is running as you check and

adjust the regulator. If pressure drops below

80 psi, adjust the regulator. If the pressure

cannot be maintained at 80 psi (5.5 bar) while

the vacuum generator is running, then the air

supply line is not adequate.

Do not supply Dryer with a lubricated air supply.

Damage to Dryer may result. Use only a clean,

dry, oil-free air supply.

Rev. March 5, 2018 – VBD-1000 Touchscreen

19

VBD

- Vacuum Dryer

or

Electrical Connection

Maguire Products, Inc.

RISK OF INJURY!

Only qualified

technicians should

make electrical

connections.

Connect Main Power

The electrical cable located on the left side of the Dryer on the power

box supplies the power to the Dryer. Within the cable is four wires.

Three of the wires are black and labeled with a number: 1, 2, and 3.

The fourth wire is a green/yellow wire and is the ground wire.

Connect power to a properly fused disconnect.

See page 81 for the High Voltage Wiring Diagram

THREE PHASE: 60 cycle 480 volts

50 cycle 400 volts

Confirm Correct 3-Phase Electrical Connection

THREE PHASE Unit - CONFIRM proper 3-Phase power connection

by following these instructions:

Turn power on using

main power switch.

On the outside of the electrical

box below the power switch is

a red 3-Phase indicator light.

If 3-Phase power is correctly

connected, the controller will

power up and the red indicator

light will NOT be lit.

20

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

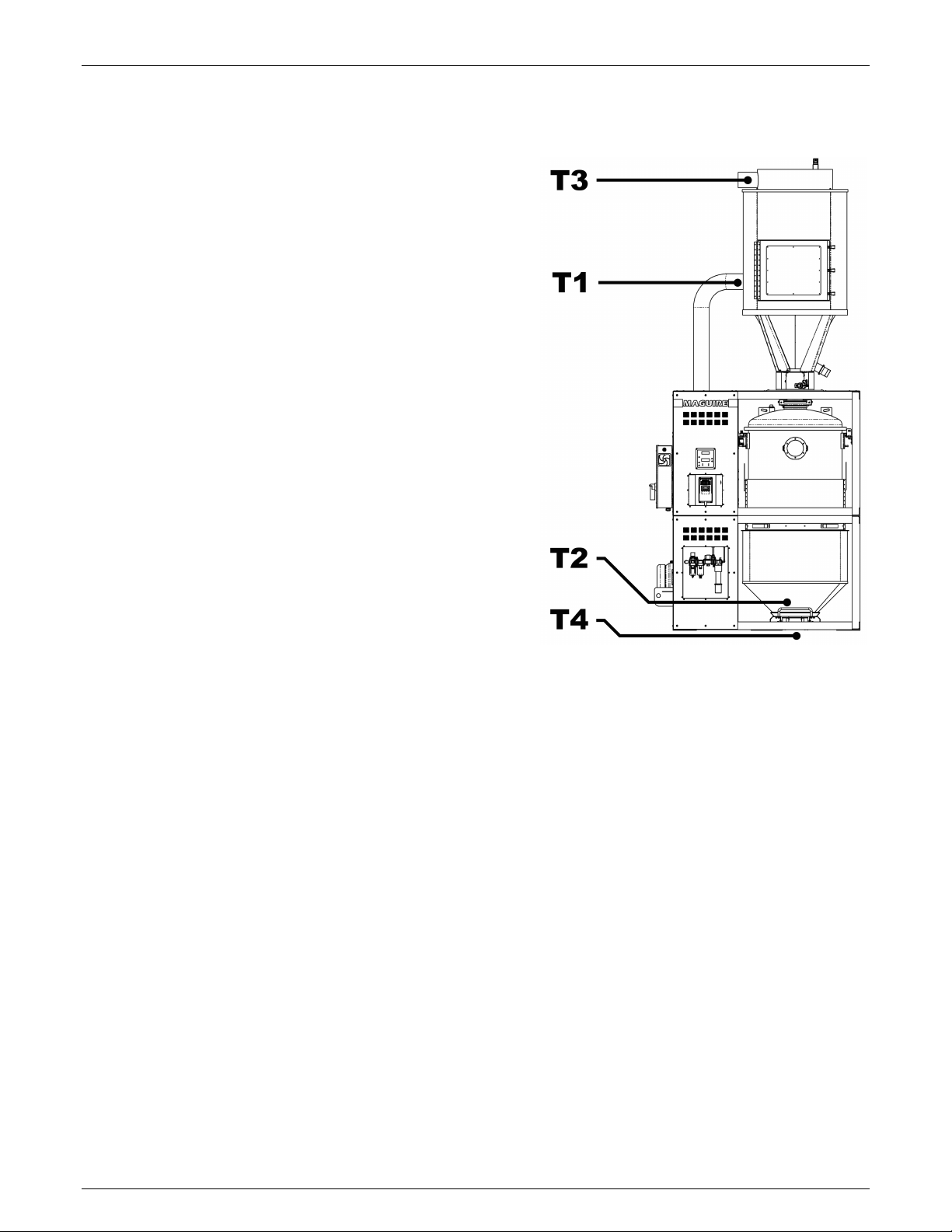

Temperature Sensor Locations

T1 – Heating Hopper Air Inlet

T1s – Heating Hopper Air Inlet Temperature Setting

T1a – Heating Hopper Air Inlet Temperature Actual

T2 – Dry Purge Air Temperature

T2s – Dry Purge Air Temperature Setting

T2a – Dry Purge Air Temperature Actual

T3 – Heating Hopper Air Outlet Temperature

T3s – Heating Hopper Air Outlet Temperature Setting

T3a – Heating Hopper Air Outlet Temperature Actual

T4 – Material Outlet Temperature (optional)

T4s – Material Outlet Temperature Setting

T4a – Material Outlet Temperature Actual

Maguire Products, Inc.

Rev. March 5, 2018 – VBD-1000 Touchscreen

21

VBD

- Vacuum Dryer

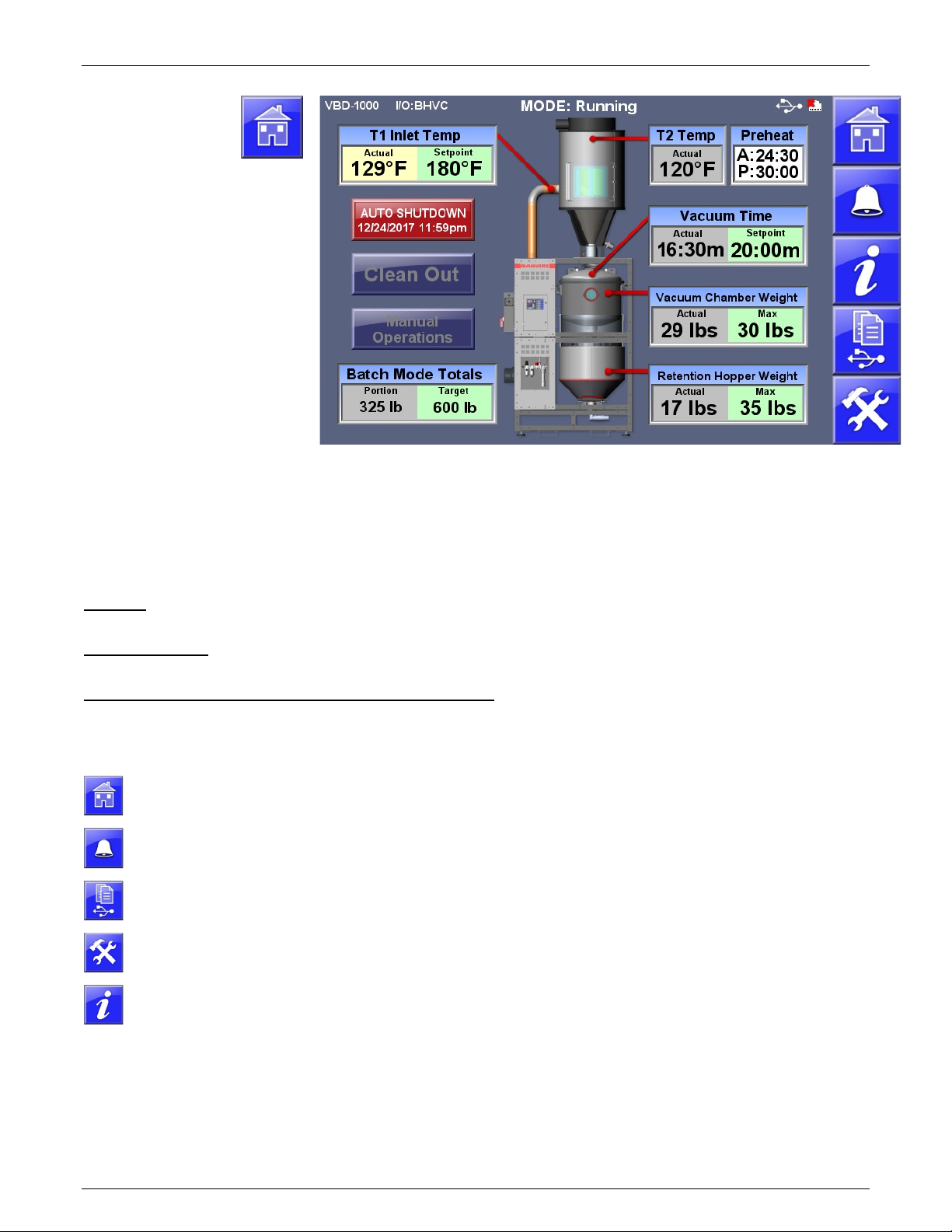

Home Screen

Maguire Products, Inc.

Overview

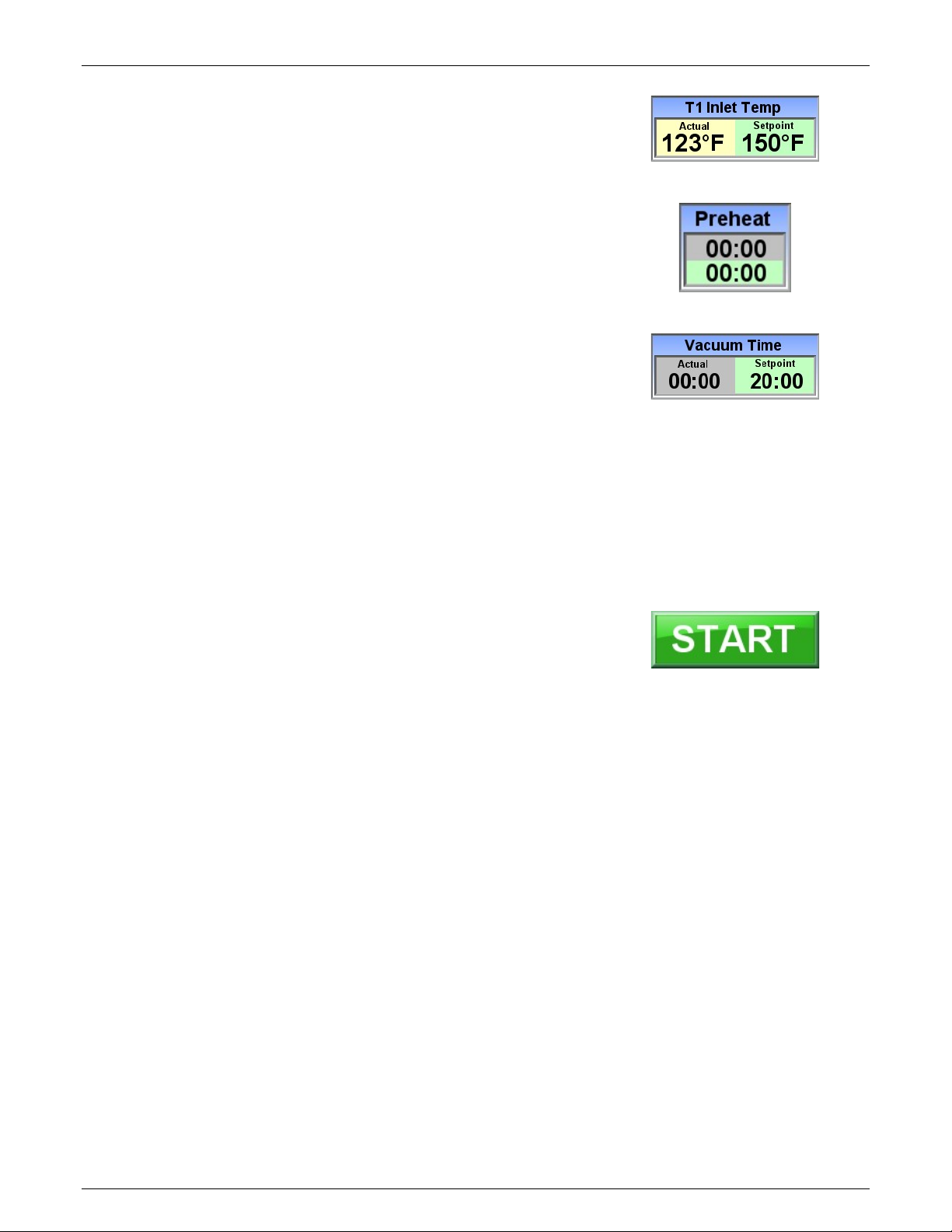

Shown with enabled options:

Auto Shutdown, Batch Mode,

and Preheat, VBD-1000 screen

T1 Actual - Actual Heating

Hopper inlet air temperature

T1 Setpoint - Heating Hopper

inlet air temperature Setpoint.

Touch to adjust.

T2 Temp – Actual Heating

Hopper temperature

Vacuum Time – Vacuum Time

Actual and Vacuum Time

Setpoint. Touch to adjust.

Vacuum Chamber Weight

Vacuum Chamber Actual and

Maximum Weight

Retention Hopper Weight

Actual and maximum weight

Preheat – Preheat Time Actual and Preheat Time Setpoint. Touch to adjust.

Info (i) - Access to advance information.

Additional information can be accessed by touching the Heating Hopper, Vacuum

Chamber and the Retention Hopper.

Title Bar - Located across the top of the screen, the title bar displays Model, ID, I/O status, current operating mode,

date and time, Ethernet and USB status.

Navigation Menu - Located along the right side of the screen, these buttons allow quick navigation to frequently used

and top level screens. The middle three buttons are soft buttons that can be changed or removed.

Start / Shutdown (Auto Shutdown shown above) Button - Main Start Stop Control Button of the Dryer.

Navigation Menu

Home Screen Pressing the Home Screen button from any other screen will return the

Alarm and

Event

Print Center A menu screen of print related options including Totals, Parameters,

Setup Login Password protected access to advanced Dryer and System configuration

Info Screen System Information including firmware versions, IP and MAC address

Run Dryer - See page 23

Clean Out – See page 57

Manual Operations - See page 30

Top Level Menu:

operator to the main Home Screen.

Alarm and Event Log displays a history of alarms and other events with a

date and time stamps and description.

Alarm History, Events, Cycle History, Diagnostics. See page 67.

information.

and machine operating tags.

22

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Maguire Products, Inc.

Start Up and Operation

This section will help you understand what the dryer is doing during operation from a cold start.

There are 3 concurrent operations. Heating, Vacuum and, Retention. Cold startup begins with

Preheat. Preheat only occurs before the first cycle of the dryer’s initial startup, otherwise each

cycle begins with material heating. The vacuum operation pulls and holds a vacuum on the

material for at least the Vacuum Time Set-point (or longer if material remains in the Retention

Hopper). The Retention operation holds the dried material in the Retention Hopper, blanketing

the material with hot, dry air, until the material is conveyed away.

Important: Inspect the VBD, verify that machine is clear of all material from all tanks, heating

hopper, Vacuum Chamber and Retention Hopper. To facilitate a Clean Out, use the Clean Out

function accessible from the home screen.

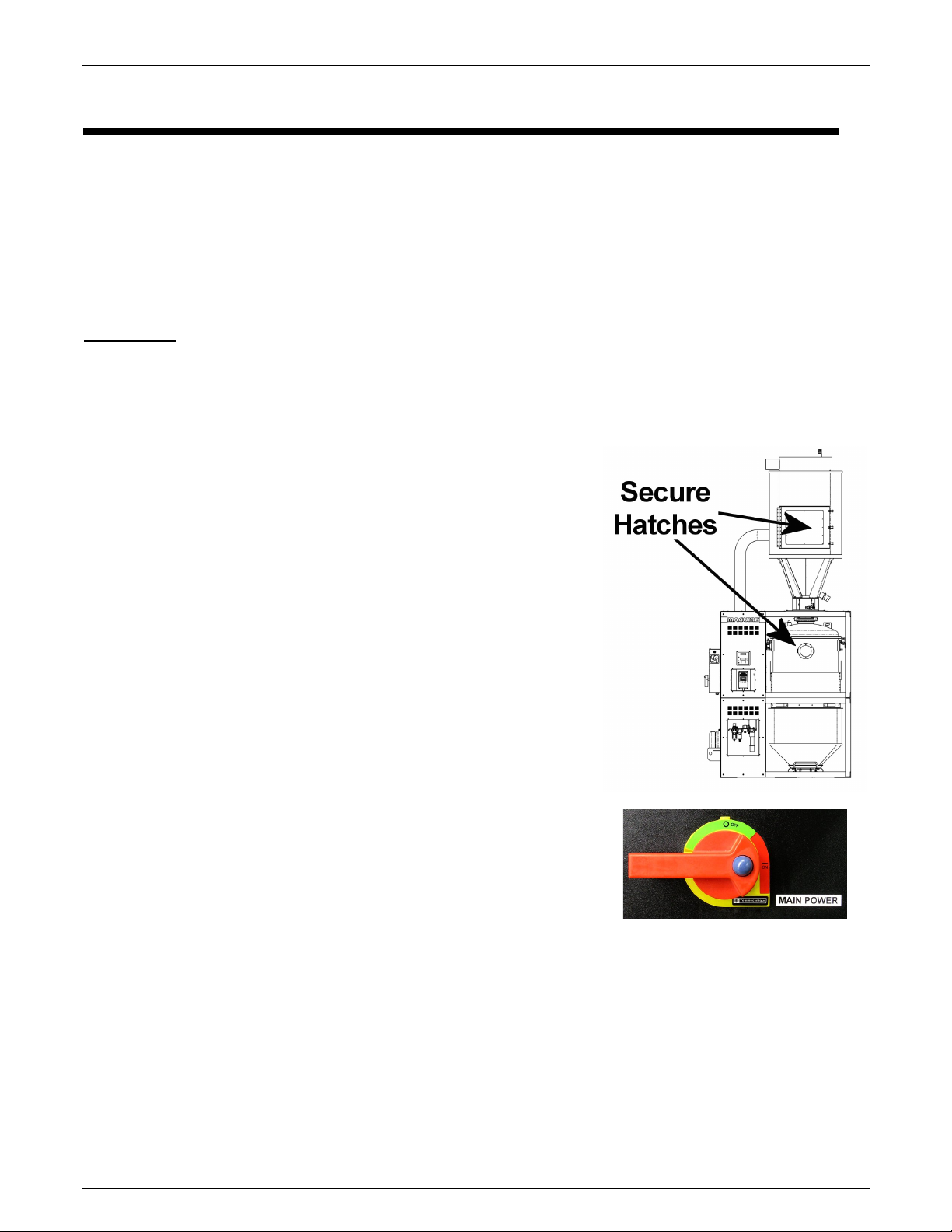

Startup and Operation Instructions

1. ENSURE HATCH IS CLOSED. There is a hatch

located on the upper Heating Hopper. Ensure all 3

latches are closed. Also be sure the removable

Lower Retention Hopper is in place.

2. Load material into the Upper Heating Hopper.

Wait for the Heating Hopper to fill with material before

starting the Dryer.

3. Turn on Main Power by rotating the 60 AMP Main

Disconnect Handle to the Red ON position. This

powers up the VBD-1000 Dryer.

On initial power up of the VBD, the Control Panel

powers ON automatically. If the main power is ON

but the Control Panel is OFF, press and hold the Red

Power Button located on the Control Panel for 2

seconds. (Note: The VBD’s Control Panel can be

powered OFF without powering down the Main Power

by pressing and holding the Red Power button for 4

seconds).

Rev. March 5, 2018 – VBD-1000 Touchscreen

23

VBD

- Vacuum Dryer

Maguire Products, Inc.

4. On the Home Screen:

T1 Inlet Temp Setpoint – This is heat hopper inlet

temperature. By the end of the preheat cycle time, all

material in the Heating Hopper will be heated to this

temperature. By default, the Setpoint temperature is

set to 150°F. Contact the material manufacturer for

temperature recommendations.

Preheat Time – This is the duration of heating from a

cold start.

Vacuum Time – This is the minimum duration of a

vacuum cycle. Actual vacuum cycle times will vary

according to the throughput. The default vacuum

time is 20 minutes. In the vast majority of drying

operations, this time is adequate and does not need

to be adjusted. Special circumstances may require

different vacuum times. Please consult a Maguire

Dryer Technical for additional information.

Press the setpoint field to adjust the setting. Use the

on-sceen keypad to enter the setpoint and press the

green check to complete the setting adjustment.

5. Press the START button to start the dryer.

6. The display will show that the dryer is running in

PREHEAT

mode and display the following:

T1 Actual - Actual Heating Hopper inlet air

temperature

T1 Setpoint - Heating Hopper inlet air temperature

Setpoint.

T2 Temp – Actual Heating Hopper temperature

Vacuum Time – Vacuum Time Actual and Vacuum

Time Setpoint.

Vacuum Chamber Weight - Vacuum Chamber

Actual/Maximum Weight.

7.

24

Rev. March 5, 2018 – VBD-1000 Touchscreen

VBD

- Vacuum Dryer

Maguire Products, Inc.

What is happening when the dryer is running:

During the Pre-heat operation material in the heating hopper is brought up to temperature

(T1s). Preheat time is determined by the specified Preheat Time on the Pre-Start screen

(timed preheat, default 60 minutes) or by the Preheat Setup Auto option, which sets an inlet

to outlet temperature delta and a minimum preheat time.

After pre-heat, approximately one third of the material in the heating hopper is dispensed

into vacuum chamber, and the first vacuum cycle begins. Each vacuum cycle has a

minimum vacuum time, set on the Pre-start screen, or the main run screen (VTs). (default

is 20 minutes).

The loader loads the Heating Hopper with new material as the Vacuum Chamber receives

the heated material and heating cycle begins concurrent to vacuum cycle (the first vacuum

cycle is timed). The new batch of material in the upper portion of the heating hopper will

take less time to heat. Minimum time in the heating is dictated vacuum time.

After first vacuum cycle, material is then dispensed into retention hopper ready for use.

Material in the retention hopper is blanketed with dry air.

The rate of consumption of dried material from the retention hopper ultimately dictates the

amount of time that the material will be preheated and under vacuum. Examples: If it

takes 30 minutes to deplete the retention hopper, the vacuum cycle will run past its 20

minute setpoint (pre-start screen) to 30 minutes. This is normal operation. However if the

retention hopper is depleted in 15 minutes and the vacuum time is set to 20 minutes, there

will be a 5 minute window where no material is available. This indicates that the throughput

of the dryer has been exceeded. If the Throughput Alarm is enabled (Alarm Setup), a

Throughput Alarm (Alarm Code 20) will be triggered.

Rev. March 5, 2018 – VBD-1000 Touchscreen

25

VBD

- Vacuum Dryer

Shutdown – Immediate or Planned

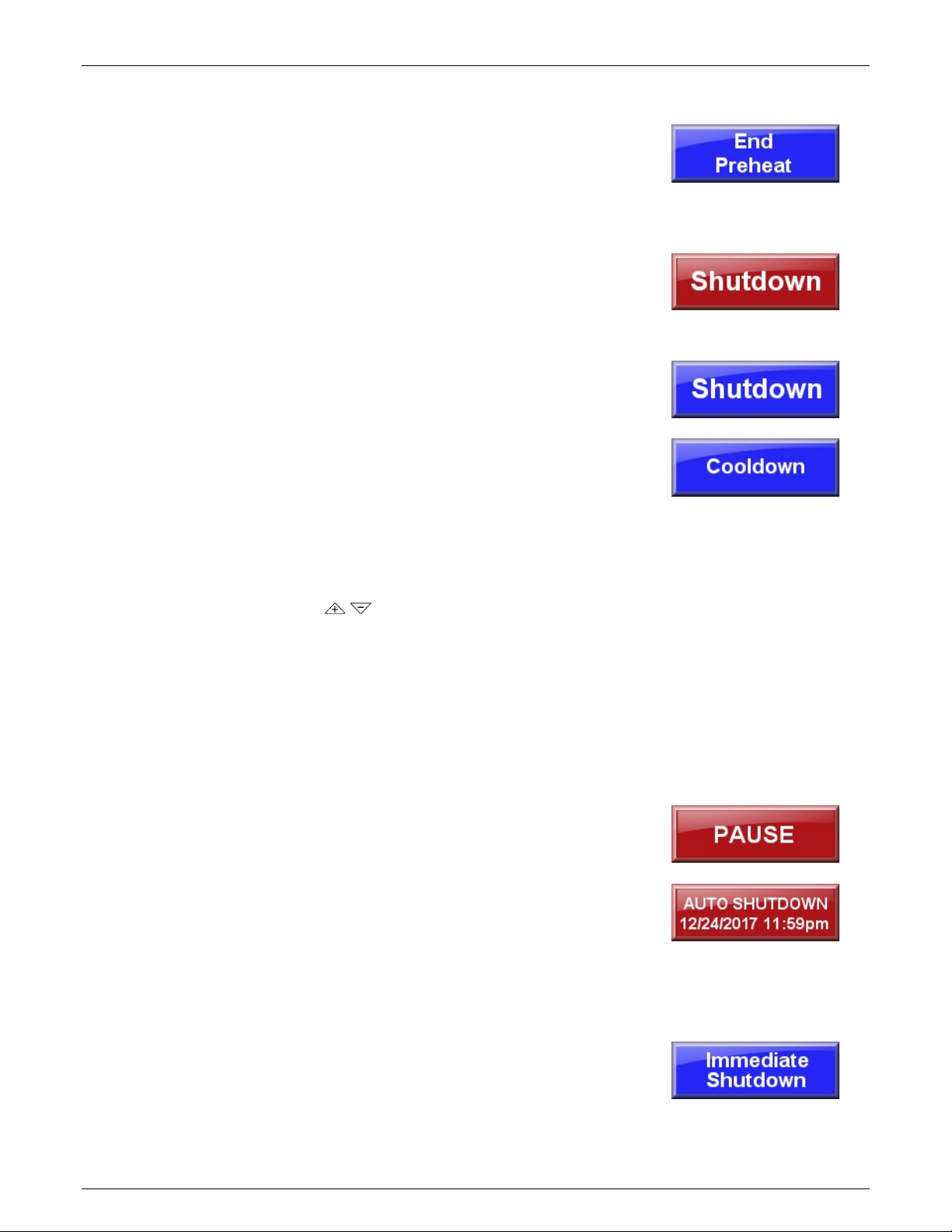

End Preheat - (shown only if in a preheat cycle)

Skips the preheat allowing material to immediately pass down

to the Vacuum Chamber (example: material has already been

heated and dryer has been taking offline briefly and powered

back on).

At any point during the preheat cycle or standard operation

(operation after initial preheat cycle), pressing the red

Shutdown button will bring up the Shutdown Options screen

with the following shutdown options:

Shutdown – Shutdown will continue to run the dryer and

process the material in the Vacuum Chamber and the

Retention Hopper until they are empty. Selecting Planned

Shutdown will display the Cooldown option.

Cooldown (ON/OFF) – When enabled Cooldown will

gradually bring down the temperature of the material in the

heating hopper to the specified temperature (Cooldown

Temp) over the specified time period (Cooldown Time).

To adjust the Cooldown Temperature and Cooldown Time

use the arrow buttons to adjust the setting. Press

ENTER to advance through the digits and to complete the

setting adjustment.

Press the Shutdown button to shutdown.

Pressing the red power button during a Planned Shutdown

will display the Immediate Shutdown Screen allowing

initiation of an immediate shutdown of the dryer.

Maguire Products, Inc.

Pause – Press the Vacuum Chamber will display the Vacuum

Chamber Setup screen. Pause is the red button at the bottom

of the screen. Pauses the vacuum timer indefinitely. To

restart after a pause, press RESUME.

Auto Shutdown – Initiates a shutdown (see above) at

specified date and time. For further explanation on how to set

the Auto Stop date and time see page 27.

Immediate Shutdown – Fast but controlled shutdown of the

heater, blower, the vacuum system and the purge system.

Cancel - Exits the shutdown prompt screen, doing nothing.

26

Rev. March 5, 2018 – VBD-1000 Touchscreen

Loading...

Loading...