Maguire Products GRAVIMETRIC AUGER FEEDER MGF-ST Instruction Manual

MAGUIRE PRODUCTS INC.

GRAVIMETRIC AUGER FEEDER

MAGUIRE

GRAVIMETRIC AUGER FEEDER

Original Instructions Manual

Revision Date: December 4, 2018

Model MGF-ST

Touch Screen Controller

INSTRUCTION MANUAL

Copyright Maguire Products, Inc. 2018

G R A V I M E T R I C A U G E R F E E D E R

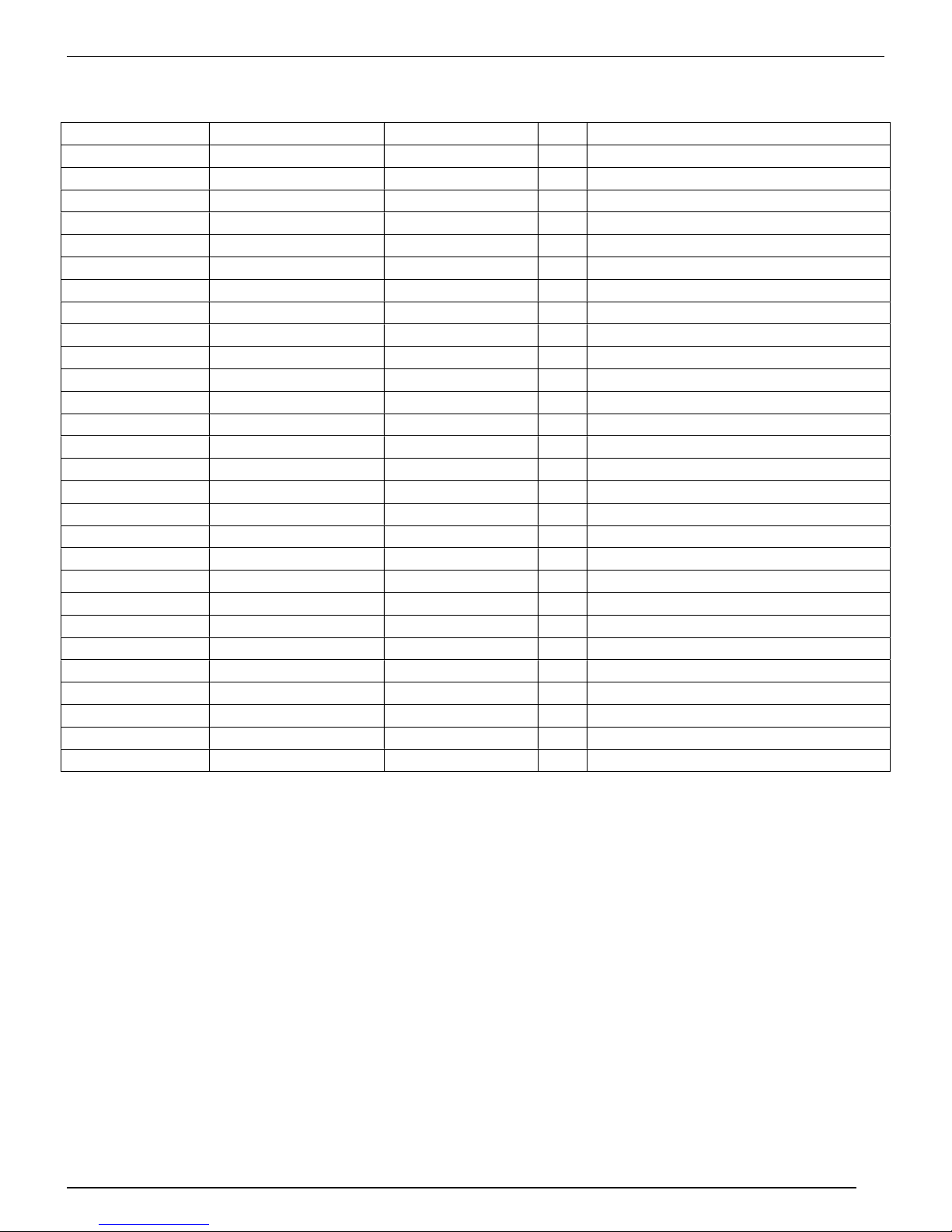

Use this space to record information about your Maguire Machines:

M A G U I R E P R O D U C T S , I N C .

Serial Number Date of Purchase Model Number ID IP Address

Notes:

2

G R A V I M E T R I C A U G E R F E E D E R

M A G U I R E P R O D U C T S , I N C .

Maguire MGF-ST

This document is the Original Instructions manual of the Maguire MGF-ST with the Touchscreen

controller.

Copyright 2018 Maguire Products Inc.

The information contained within this manual including any translations thereof, is the property of

Maguire Products Inc. and may not be reproduced, or transmitted in any form or by any means

without the express written consent of Maguire Products Inc.

To every person concerned with use and maintenance of the Maguire MGF-ST it is recommended

to read thoroughly these operating instructions. Maguire Products Inc. accepts no responsibility or

liability for damage or malfunction of the equipment arising from non-observance of these operating

instructions.

To avoid errors and to ensure trouble-free operation, it is essential that these operating instructions

are read and understood by all personnel who are to use the equipment.

Should you have problems or difficulties with the equipment, please contact Maguire Products Inc.

or your local Maguire distributor.

Manufacturer’s Contact Information

Maguire Products Inc.

11 Crozerville Road

Aston, PA. 19014

Phone: 610.459.4300

Fax: 610.459.2700

Website: http://www.maguire.com

Email: info@maguire.com

3

G R A V I M E T R I C A U G E R F E E D E R

Table of Contents

EC Declaration of Conformity ____________________________________________ 5

Safety Notifications and Safety Hazards ___________________________________ 6

Features _____________________________________________________________ 7

Assembly and Installation Instructions ___________________________________ 8

Description of Controls ________________________________________________ 9

Touchscreen Overview _______________________________________________ 10

Software Setup (First Time Setup) ______________________________________ 11

Startup Instructions __________________________________________________ 13

Normal Operation ____________________________________________________ 14

Alarms and Troubleshooting ___________________________________________ 15

Troubleshooting Loss of Color _________________________________________ 17

M A G U I R E P R O D U C T S , I N C .

MGF Menu Navigation and Overview ____________________________________ 18

Troubleshooting Controller Problems ___________________________________ 18

Settings Menu Explained ______________________________________________ 18

Password Management _______________________________________________ 20

Weight Units ________________________________________________________ 20

Volumetric Mode _____________________________________________________ 21

Print Center _________________________________________________________ 22

Parameters _________________________________________________________ 28

Updating the MGF Firmware ___________________________________________ 32

Rate Adjust Reset ____________________________________________________ 33

View / Reset Totals ___________________________________________________ 33

MGF Defaults _______________________________________________________ 33

Optional Loader Installation ___________________________________________ 34

AGL Loader Diagram _________________________________________________ 35

MGF Wiring Diagram _________________________________________________ 39

Parts diagram / Dimensions ___________________________________________ 42

Principle of Feeder Operation __________________________________________ 45

Principle of Controller Operation _______________________________________ 45

Warranty ___________________________________________________________ 46

Technical Support and Contact Information ______________________________ 47

4

G R A V I M E T R I C A U G E R F E E D E R

M A G U I R E P R O D U C T S , I N C .

5

G R A V I M E T R I C A U G E R F E E D E R

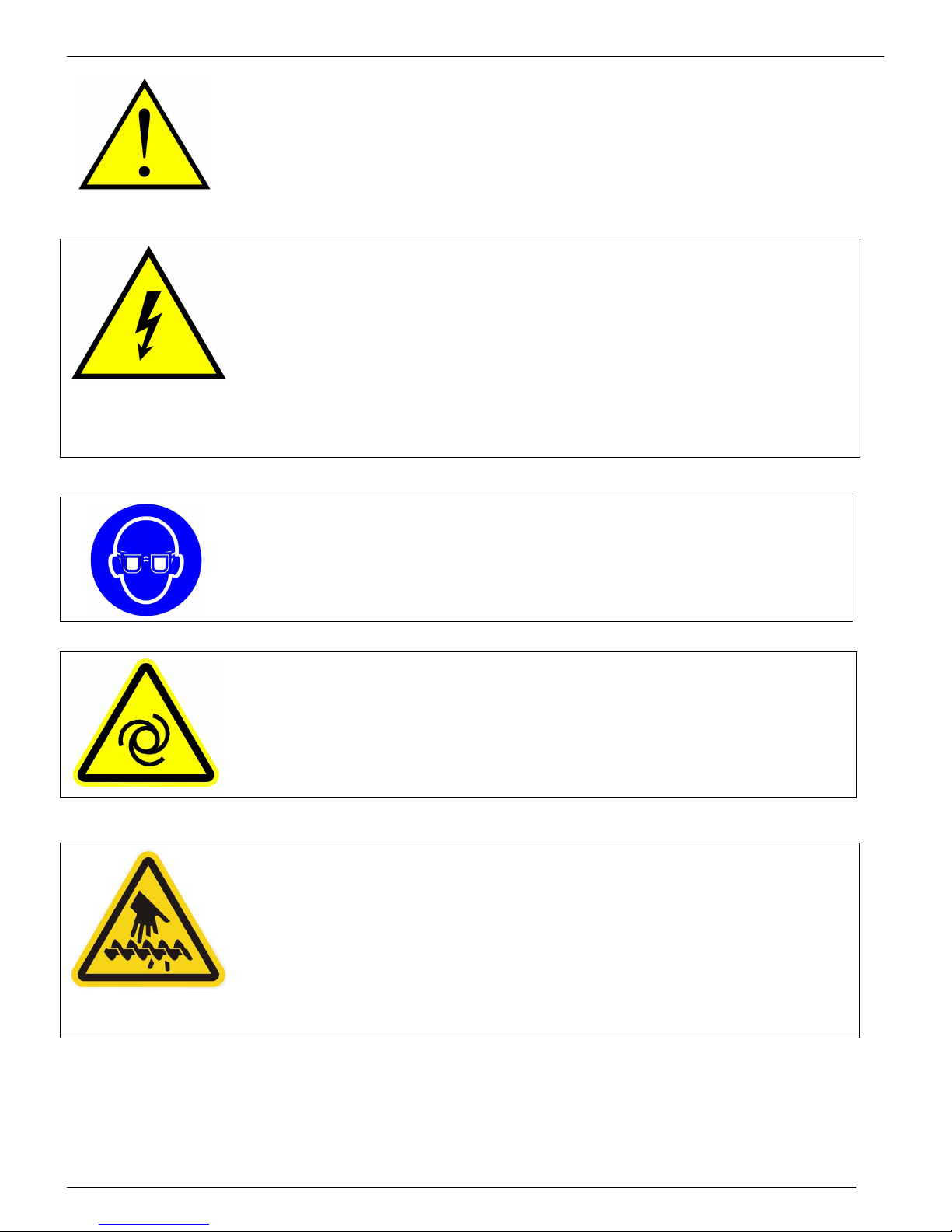

Safety Notifications

HAZARD - ELECTRICAL

Only qualified electrical technicians should make

electrical connections. Disconnect and lockout power

supply before servicing Blender.

Disconnect electric before opening or servicing. Use

Power Lockout Tagout.

M A G U I R E P R O D U C T S , I N C .

CAUTION - Always wear safety glasses when using this

equipment.

HAZARD - AUTOMATIC STARTUP

WARNING - Feeder may start automatically without warning.

HAZARD - ROTATING AUGER

The auger is driven with substantial Torque.

Never place your hand in the MGF while the auger is rotating.

SERIOUS INJURY WILL RESULT

ALWAYS keep fingers clear of rotating shaft and auger.

NEVER use your fingers to clear an obstruction.

NEVER touch a rotating shaft or auger.

6

G R A V I M E T R I C A U G E R F E E D E R

Maguire MGF-ST Features

MGF-ST

Gravimetric

Feeder

Throughput capacity:

Injection molding –

Up to 40.0 lb/hr

(18 kg/hr)

Extrusion –

Up to 120.0 lb/hr

(55 kg/hr)

Full function gravimetric

feeder for the price of a

volumetric model.

M A G U I R E P R O D U C T S , I N C .

Eliminate Waste of Colorants and Additives

This compact loss-in-weight additive feeder precisely measures the amount of additive

that is fed directly into the machine throat to eliminate costly waste.

Standard features:

3 Standard Modes of Operation

Cyclical, Continuous and Extrusion Following

Modes. Rate (volumetric) also available.

Reduces Input Error

The easiest setup procedure in the industry: enter

let-down ratio and either shot weight or lb/hr

output and press start. Feeder automatically

adjusts to screw recovery time and extruder

output.

Fine Metering Resolution

100 rpm Stepper Motor advances at 200

increments per revolution. In combination with

digital control, the 200-step rotation achieves fine

metering resolution of ± 0.2%.

Automatic Re-calibration Ensures

Continuous Accuracy

Automatic adjustments guarantee that feed rate is

held to within ± 0.2% of desired let-down ratio.

Dual Load Cells

Balanced load readings improve accuracy.

Torque-limiting Drive Coupling

Protects drive motor in case of jammed auger.

Easy-to-Use Microprocessor Controller Saves

Time

User-friendly controller has intuitive setup

procedure.

USB Port

Allows data download, data printout and

software update capability.

Detailed Material Usage Documentation

Microprocessor control allows data collection via

G2 networking software, or MLAN protocol via

Ethernet.

Eliminates Downtime Associated with Color

Change

Feeder automatically re-calibrates to new color,

so no additional setup required. Spare hoppers

available for faster color changes.

Exclusive 5-Year Warranty

7

G R A V I M E T R I C A U G E R F E E D E R

M A G U I R E P R O D U C T S , I N C .

ASSEMBLY AND INSTALLATION INSTRUCTIONS

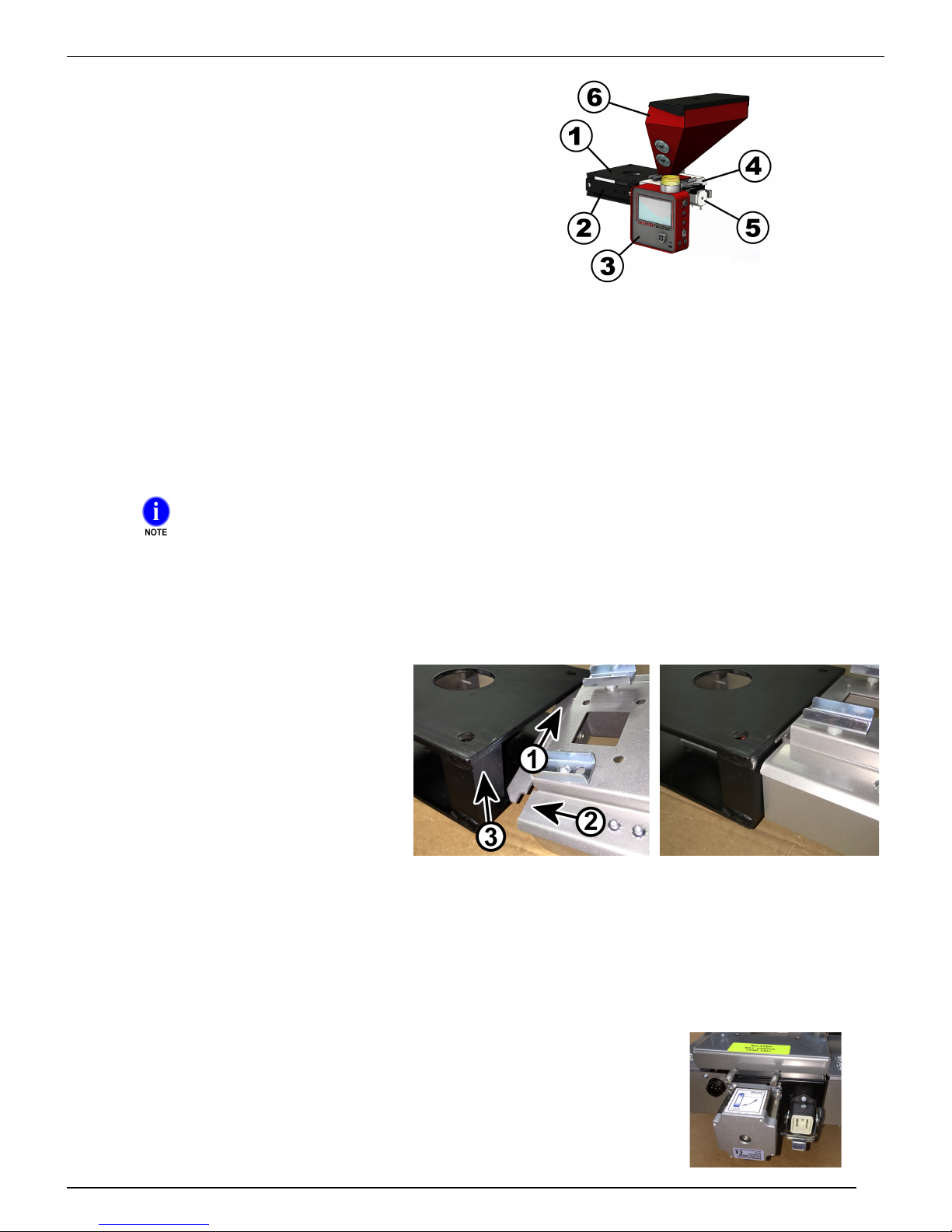

The MGF consists of these assemblies:

1. The Adaptor Frame Assembly

2. The Bar Assembly (for the Controller).

3. The Controller

4. The Load Cell Assembly

5. The Auger Tube Assembly

6. The Hopper Assembly

MOUNT THE ADAPTOR FRAME

1. The ADAPTOR frame mounts directly to the throat under your current natural material hopper.

For proper ORIENTATION, consider the following:

• Orient the Auger Tube Assembly at 90° to the machine barrel.

• Clearance and ease of access for removing the hopper.

• Easy viewing and access to the controller.

• The feeder will hang from the side of the adapter that has the opening into the flow chamber.

2. Locate and drill the proper bolt patterns (top and bottom of the adapter frame). This frame will be bolted

directly to the feed throat of your process machine and the natural material hopper will be bolted on top.

The TOP plate has the ROUND hole.

The BOTTOM plate has the SQUARE hole.

MOUNT THE CONTROLLER

3. The CONTROLLER will be mounted to a bar that bolts on the left side of the adaptor frame. You may also

mount the controller in a remote location and use optional extension cords to connect the motor and load cell.

Be sure that the mounting screws are tight.

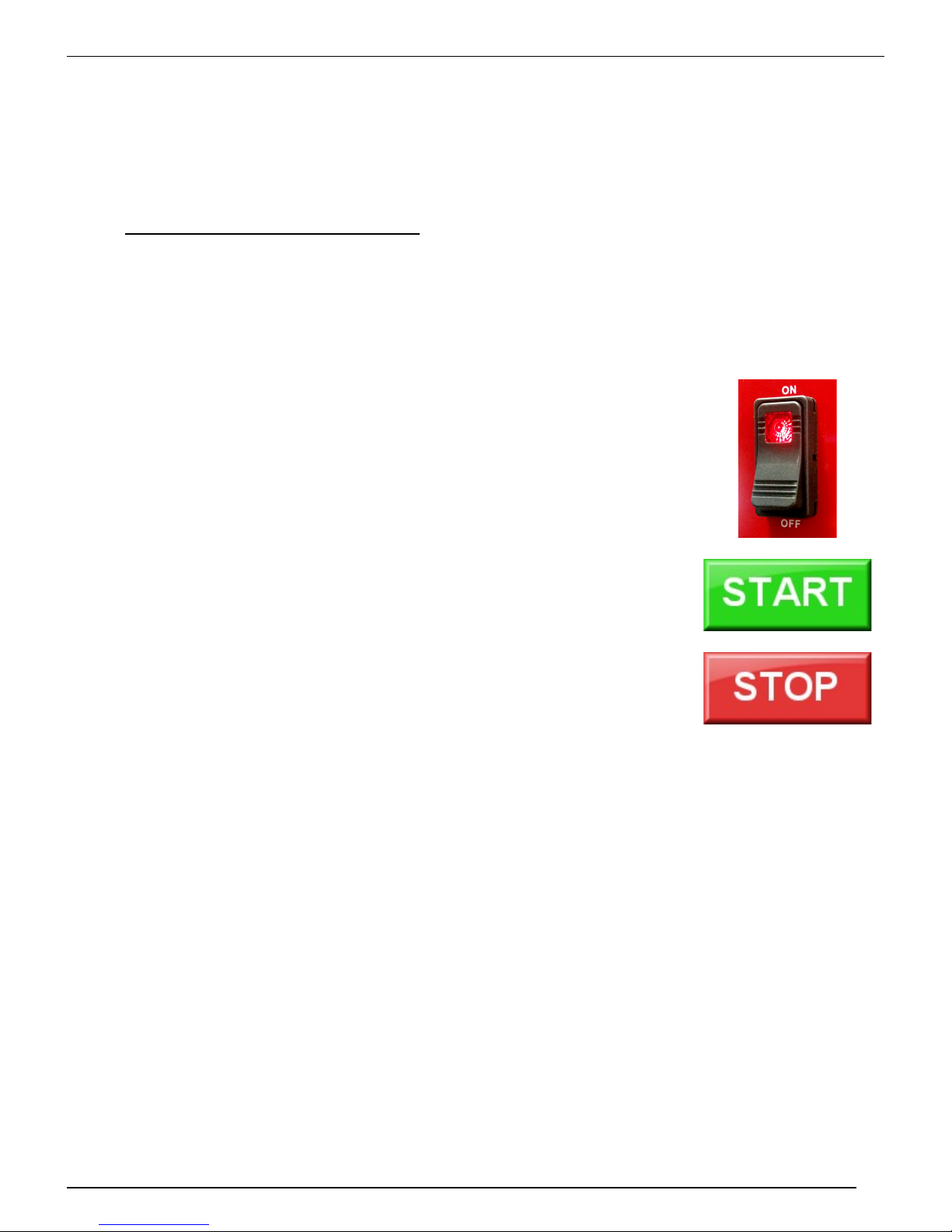

HANG THE LOAD CELL ASSEMBLY

4. Hang the Load Cell Assembly from the

side of the frame with the opening into

the chamber. (See photo) Tilt unit. (1)

Slip upper ear behind the corner post.

(2) Slip the lower ear behind the other

corner post. (3) Raise the lower ear up

and rest the load cell assembly into

frame as shown.

INSTALL AUGER TUBE ASSEMBLY

5. Insert the Auger Tube Assembly into Load Cell Assembly and hang onto the two bolt heads.

INSTALL HOPPER ASSEMBLY

6. Place the hopper assembly on the load cell assembly and secure with the hold downs.

PLUG IN ALL CORDS

7. Plug the motor and load cell cables into the Load Cell Assembly.

8. Plug the black power cable into a standard 120-volt (EURO, 230 VAC) outlet.

8

G R A V I M E T R I C A U G E R F E E D E R

CONNECT SIGNAL CABLE

9. Standard equipped for contact closure applications only, your controller will be equipped with the supplied

cable lead and 5-pin connector. You will also have a 20’ length of cable with a mating 5-pin connector. This

cable will connect to the MGF controller using the connector, and the open end will be wired to your

equipment. The open ends leads should be wired to the screw signal normally open contact closure. When

the screw is retracting contacts will close and then open at the end of the retract. The time closed is used by

the MGF to adjust output. This 5-pin connector is also used with an extrusion following 0-10 volt signal.

See the MGF wiring diagram on page 39.

M A G U I R E P R O D U C T S , I N C .

10. If optionally ordered with 24 to 120 VDC or VAC plug the "SIGNAL" (gray) cord will be plugged into outlet that

is energized only when the screw is turning. Signal voltage can be from 24 to 120 VDC or VAC. The screw

signal on-time can not be less then 1 second. INJECTION time or CLAMP CLOSE time are options.

Description of Controls

1. POWER ON / OFF SWITCH - Turns power on or off. Switch light

is illuminated when MGF is powered ON.

2. START / STOP on-screen button - This on-screen button

provides a run signal to the circuit board. For the MGF feeder to

run, a screw turning signal MUST be present, providing power to

the screw signal cord, AND the RUN switch must be in the RUN

position. The only exception is when the PRIME feature is

selected. This will operate the auger without any Run signal.

9

G R A V I M E T R I C A U G E R F E E D E R

Prime Auger

Run Loader

Title Bar

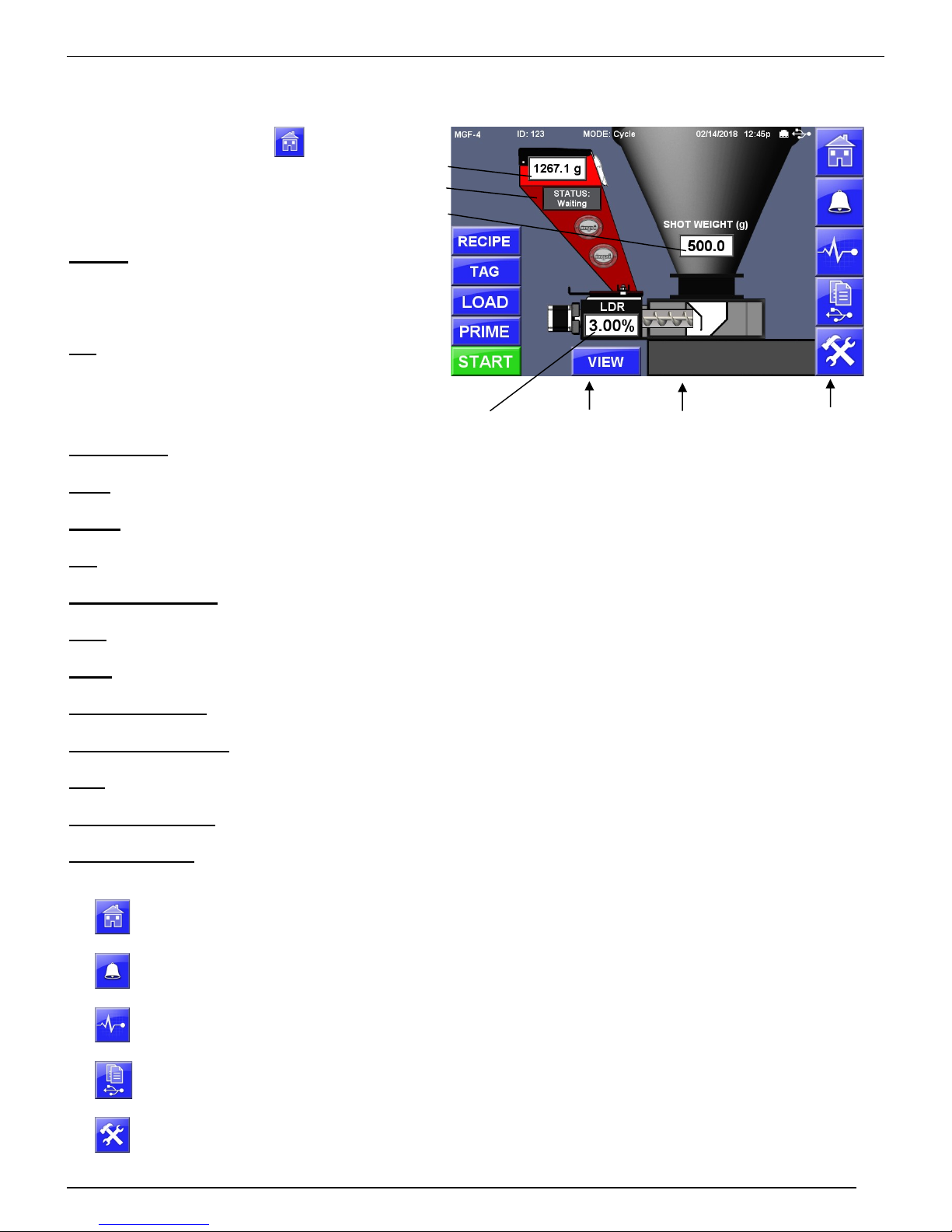

Touchscreen Overview

M A G U I R E P R O D U C T S , I N C .

Home Screen

The Home Screen contains

several fields and buttons:

Title Bar - Located across the top of the

screen, the title bar displays Model, ID,

current operating mode, date and time,

Ethernet and USB status.

Info - The i (info) button displays

information about the MGF including

firmware and serial number.

Actual Weight – The actual weight of material currently in the hopper.

Mode – Displays current configuration. Cycle, Continuous or Extrusion Following mode.

Recipe – Screen to set, save and load preconfigured MGF settings.

Tag – Screen to set material tag information. Operator, Recipe and Work Order tags. Used in communications.

Shot Weight or Rate – Displayed setting based on selected Mode. Metering Rate or Shot Weight. See page 11.

Load – On/Off button (if enabled) activates the loader. See page 27.

Prime – Primes and calibrates the MGF - See page 14.

Start / Stop Button – Main Start / Stop Control Button of the MGF.

Let Down Ratio (LDR) – Let Down Ratio, Percent. See page 11.

View – Screen to view, clear or save: MGF ID, date/time, totals, cycles, work order, recipe, operator. See page 33

Injection / Recovery –Cycle Mode only. Displays the state of the cycle, Injection or Recovery.

Navigation Menu - Located along the right side of the screen, these buttons allow quick navigation to frequently

used and top-level screens. The middle three buttons are soft buttons that can be changed or removed.

Home Screen

Pressing the Home Screen button from any other screen will return the operator to the main

Home Screen.

Actual Weight

MGF Status

Shot Weight

or Rate

Start / Stop

Let Down Ratio

View Totals Injection/Recovery Navigation Menu

Alarm and Event

Live Diagnostics

Print Center

Setup

Alarm and Event Log displays a history of alarms and other events with a date and time

stamps and description.

Live Diagnostics displays a cycle summary of detailed diagnostics information scrollable

back through a history of cycles printable to USB.

A menu screen of print related options including Totals, Parameters, Alarm History, Events,

Cycle History, Diagnostics.

Password protected area to access the MGF settings. See page 18.

10

G R A V I M E T R I C A U G E R F E E D E R

SOFTWARE SETUP - FIRST TIME ONLY

Select Mode of Operation – CYCLE, CONTINUOUS, EXTR FLLW

Press

Display will prompt for a password. (default: 22222)

M A G U I R E P R O D U C T S , I N C .

Then press:

Press

Press

Press

Display will show the System Configuration categories.

Mode of Operation Select the Mode of Operation:

Cycle, Continuous or Extrusion Following

Select CYCLE...

for injection molding, where the MGF auger turns on and

off with each cycle. In this mode the first step is to enter

the SHOT WEIGHT of the part on the main screen. Next

set the LDR (Let Down Ratio) on the main screen. In

CYCLE mode your MGF will dispense the calculated rate

(shot weight x LDR) during the length of screw recover

time.

Select CONTINUOUS...

for extrusion, where the MGF auger runs continuously. In

this mode the first step is enter LBS (or KILOS) / HOUR

of the extruder on the main screen. Next set the LDR

(Let Down Ratio) on the main screen. In CONTINUOUS

mode your MGF will run continuously at the calculated

rate (lbs/hr x LDR). Auger speed will adjust automatically

to maintain dispense rate.

Select Extrusion Following

for extrusion, where the MGF auger runs continuously by

following the 0-10 volt reference voltage of the extruder

screw. In this mode the first step is to set the XMO

parameter. Setting XMO will automatically calculate

extruder throughput on the main screen based on a 0-10

volt reference. See page 28 for XMO. Next set the LDR

(Let Down Ratio) on the main screen. In Extrusion

Following mode your MGF will run continuously at the

calculated rate (lbs/hr x LDR). Auger speed will adjust

automatically to maintain dispense rate.

To save the Changes.

11

G R A V I M E T R I C A U G E R F E E D E R

Select Units – Pounds, Grams or Kilograms

Press

Display will prompt for a password. (default: 22222)

M A G U I R E P R O D U C T S , I N C .

Then press:

Press

Press

Press

Preferences

Weight Units

Press

Set Date and Time

Press

Press

Press

Press

Preferences

Date and Time

Press

Display will show the System Configuration categories.

Display will show the System Preferences categories.

Select the Weight Units:

Pounds, Grams or Kilograms.

To save the Changes.

Display will prompt for a password. (default: 22222)

Display will show the System Configuration categories.

Display will show the System Preferences categories.

Using the keypad, set the date, time and date format.

To save the Changes.

Then press:

12

G R A V I M E T R I C A U G E R F E E D E R

M A G U I R E P R O D U C T S , I N C .

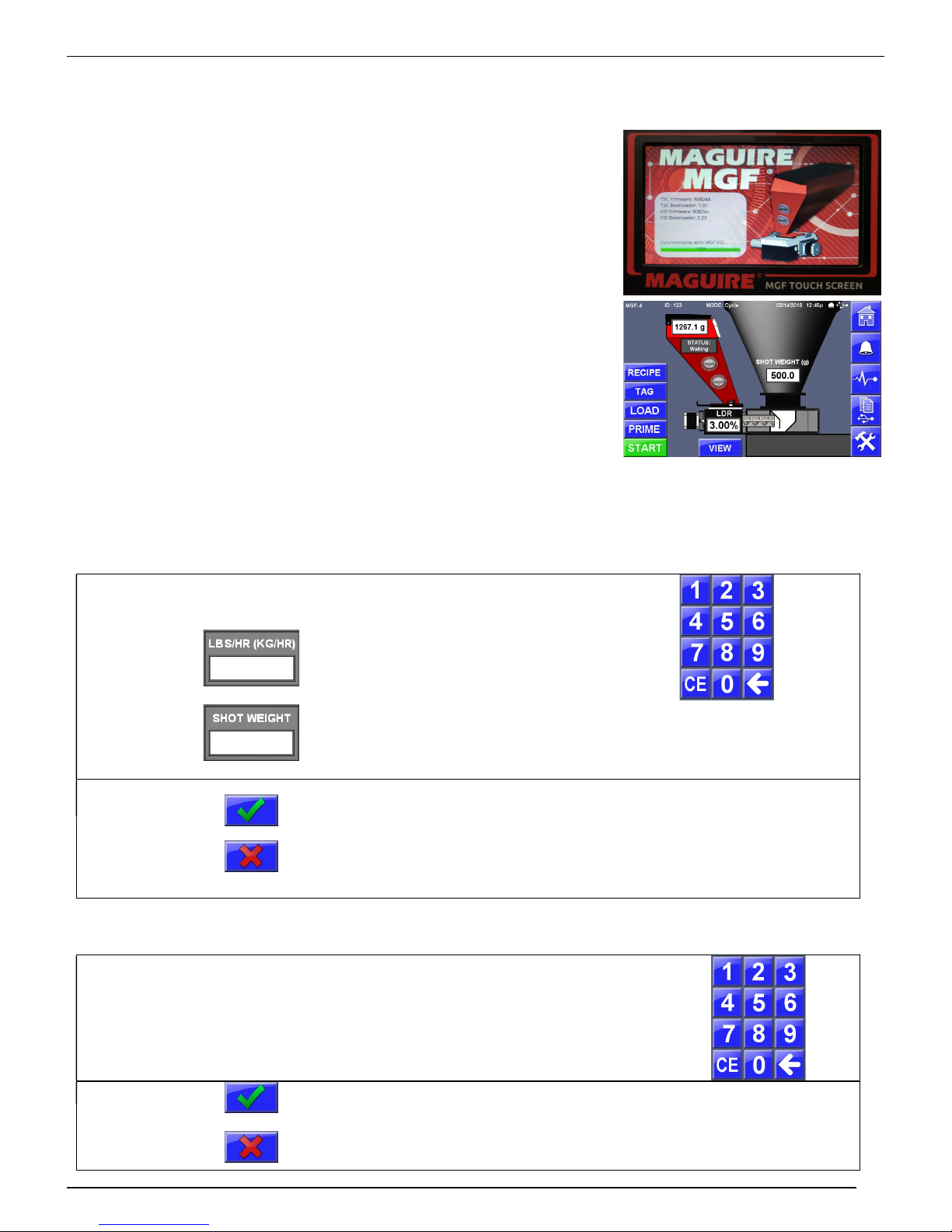

Start Up Procedure

1. Turn POWER ON:

The opening screen displays for 5 seconds and shows

your current firmware and bootloaders software versions

for the touchscreen controller and I/O, in the information

window.

The display then shows the Main Home Screen of the

MGF. Depending on your Mode of Operation, the Main

screen will either display Shot Weight (grams) for Cycle

Mode or Pounds or Kilograms per hour for Continuous

Mode.

Adjustments

Depending on your selected Mode, the display will show SHOT/WT or LBS/HR (KG/HR).

To adjust this value, follow these instructions:

Press field LBS/HR (KG/HR)

or

Display will show the Per Hour

Rate or Show Weight Screen

showing the current setting. Use

the keypad to set a new rate or

shot weight.

Press

Press

LDR – Let Down Ratio - To adjust this value, follow these instructions:

Press field

(Let Down Ratio)

Press

Press

LDR

Saves and loads new setting and return to Home.

Cancels the new setting, revert to original settings and

returns to the Home Screen.

Display will show the Let Down Ratio

screen showing the current LDR setting.

Use the keypad to set a new LDR. The

decimal is hard coded to 100

ths

of a %.

Saves and loads new LDR setting, return to Home.

Cancels the new setting, revert to original settings and

returns to the Home Screen.

13

G R A V I M E T R I C A U G E R F E E D E R

M A G U I R E P R O D U C T S , I N C .

Prime the MGF Auger / Calibrate

It may be necessary to prime the auger prior to running. Prime will allow the MGF to run without a

signal from the process machine. Run time is automatically limited to ONE minute. After one

minute the display will read “PRIME TIMED OUT”. During the Prime, the MGF automatically

calibrates the flow rate of the material. To Prime, follow these instructions:

Press

Display will show animated movement on the auger. A 60-second

counter will begin to count down. During this time the MGF will selfcalibrate and display CALIBRATED indicating that it has learned the

flow rate of your specific material and has adjusted the motor factor

accordingly. After CALIBRATED has displayed, the prime function can

be ended by pressing the BACK button, otherwise prime will continue

to run for 60 seconds, then timeout and alarm, displaying “PRIME

TIMED OUT”.

Press

To stop the prime function.

When the MGF settings are adjusted and the MGF is primed

with material, it is ready for operation.

Press the START button run the MGF.

What happens during NORMAL OPERATION

The software uses the information you have entered, lbs/hr (or shot wt) and Let Down Ratio, plus

the motor factor, to determine a correct percentage off-time between steps for the motor to control

speed.

Two 10K load cells detect the loss of weight after each dispense. Based on this feedback,

adjustments are made to the percentage off-time to maintain the correct metering rate.

In the CONTINUOUS mode the percentage off-time, (motor speed) is adjusted to hold the correct

loss in weight of the hopper.

In the CYCLE mode the speed is adjusted to meter the correct amount over the full screw signal

cycle time. A change in process screw signal time will result in an adjustment to motor speed.

Speed adjustment is based on the previous screw return time. If screw return time is SHORTER

then the PREVIOUS time, the auger motor will continue past the end of the run signal for 1

additional second. It will run faster on the next dispense to end in time.

14

G R A V I M E T R I C A U G E R F E E D E R

Alarms and Troubleshooting

NO METERING - ALARM CODE:48

This alarm indicates that no loss in weight has been detected during the last

several cycles. After clearing the alarm, metering will continue, however the

alarm will not re appear until after you have remedied the problem.

The following conditions are required to generate the NO METERING ALARM

a. Before this alarm is checked, the system needed to have been running for at least 24

seconds.

b. If the MGF is in continuous or extrusion follow mode, the target rate needs to be more

than 7.5 g/min.

c. If the MGF is in cycle mode, the target rate needs to be more than 2 grams / cycle.

If the above conditions (a and (b or c)) are met, then the MGF will compare the current bin weight

with a captured value from 24 seconds ago.

d. If the MGF is in continuous or extrusion following mode, the difference between the two

weights need to greater than 10 times the target rate.

e. If the MGF is in cycle mode, the difference between the two weights needs to be greater

than 5 times the target rate.

If the above condition (d or e) fails, then a counter is incremented

If the above condition (d or e) passes, then the counter is reset to 0.

If the counter gets incremented past 3, then the NO METERING alarm is triggered.

In cycle mode, the NO METERING alarm is checked only at the start of every cycle.

In continuous or extrusion following mode, the NO METERING alarm is checked every RTU

update.

M A G U I R E P R O D U C T S , I N C .

LOADING TOO SLOWLY - ALARM CODE:49

If the loading feature is enabled and it takes more than LAT (Loader Alarm Time)

seconds to fill the bin to LHF (Loader High Level) grams then this alarm is

triggered.

PRIME ALARM - ALARM CODE:50

This alarm indicates that the 60-second Prime cycle time has ended. The Prime

function is used to prime the feeder and is accessible from the main menu. It

operates by running the feeder auger for one minute to prime the feeder then

alarms to alert the operator that the prime cycle has ended.

LOW WEIGHT ALARM - ALARM CODE:51

If the bin weight falls below the LWA (Low Weight Alarm) setting (Default 400g)

then this alarm will be triggered. If the bin weight rises above the LWA

parameter, then the alarm will shut off.

15

Loading...

Loading...