MAGUIRE PRS-20 Maintenance Manual

MAGUIRE PRODUCTS INC.

Purging Recovery System

®

MAGUIRE

Purging Recovery System

INSTALLATION • OPERATION • MAINTENANCE

Copyright © Maguire Products, Inc. 2012

Maguire Purging Recovery System

Maguire Products, Inc.

2

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

Maguire Products, Inc.

Maguire Purging Recovery System

Copyright

© 2012 Maguire Products Inc.

The information contained within this manual including any translations thereof, is the property of

Maguire Products Inc. and may not be reproduced, or transmitted in any form or by any means

without the express written consent of Maguire Products Inc.

To every person concerned with use and maintenance of the Maguire Purging Recovery System

it is recommended to read thoroughly these operating instructions. Maguire Products Inc.

accepts no responsibility or liability for damage or malfunction of the equipment arising from nonobservance of these operating instructions.

To avoid errors and to ensure trouble-free operation, it is essential that these operating

instructions are read and understood by all personnel who are to use the equipment.

Should you have problems or difficulties with the equipment, please contact Maguire Products

Inc. or your local Maguire distributor.

These operating instructions only apply to the equipment described within this manual.

Manufacturer’s Contact Information

Maguire Products Inc.

11 Crozerville Road

Aston, PA. 19014

Phone: 610.459.4300

Fax: 610.459.2700

Website: http://www.maguire.com

Email: info@maguire.com

Edition: June 20, 2012 – PRS-20

3

Maguire Purging Recovery System

Accuracy of this Manual

We make every effort to keep this manual as correct and current as possible.

However, technology and product changes may occur more rapidly then the

reprinting of this manual. Generally, modifications made to the Maguire Purging

Recovery System design or to the operation of the software are may not reflected

in the manual for several months. The date at the footer of this manual will

indicate approximately how current this manual is. Likewise, your Maguire

Purging Recovery System may have been produced at an earlier time and the

information in this manual may not accurately describe your Maguire Purging

Recovery System since this manual is written for the current line of Maguire

Purging Recovery System in production (as of the date in the footer). We always

reserve the right to make these changes without notice, and we do not guarantee

the manual to be entirely accurate. If you question any information in this manual,

or find errors, please let us know so that we may make the required corrections or

provide you with accurate information. Additionally we will gladly provide you with

an updated copy of any manuals you need at any time. We welcome comments

and suggestions on ways we can improve this manual.

For additional information, or to download the latest copy of this manual or any

other Maguire manual, please visit our website or contact us directly.

On the Web at: www.Maguire.com

Maguire Products Inc.

Main Headquarters

11 Crozerville Road

Aston, PA 19014

Tel: 610.459.4300

Fax: 610.459.2700

Email:

info@maguire.com

Maguire Products, Inc.

Maguire Europe

Tame Park

Tamworth

Staffordshire

B775DY

UK

Tel: + 44 1827 265 850

Fax: + 44 1827 265 855

Email:

info@maguire-europe.com

Maguire Products Asia PTE LTD

45 Kallang Pudding Road

#01-02 Alpha Building

Singapore 349317

Tel: +65 6848 7117

Fax: +65 6744 3370

Email:

magasia@maguire-products.com.sg

Please e-mail comments and suggestions to: support@maguire.com

Maguire Italy

Via Zancanaro 40

35020 Vigorovea (PD)

Tel: +39 049 970 54 29

Fax: +39 049 971 18 38

Email:

info@maguire-italia.it

4

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

Table of Contents

PART 1 GETTING STARTED, READ THIS PAGE

1.1 5 Year Warranty and Disclaimers

1.2 SAFETY Warnings

1.3 Purging Recovery System Terminology

1.4 Concept and Principle of Operation

PART 2 INSTALLATION

2.1 Transport and Setup 13

2.2 Purging Recovery System Installation / Wiring

2.3 Final Checks Before Operation

PART 3 OPERATION

3.1 Standard Operation 17

3.2 Starting / Stopping the PRS-20 19

PART 4 MAINTENANCE AND SERVICE

4.1 General Maintenance 20

4.2 Preventative Maintenance Checklist

4.3 Installing New Shredder Rotor Knives

4.4 Adjustment of Lower Granulator Knife Gaps

4.5 Clearing a Jam 26

4.6 Drain and purge Air Filter / Regulator

4.7 Adjustments

4.8 Cleaning the PRS-20 28

PART 5 TROUBLESHOOTING

5.1 Troubleshooting - Symptoms/Cause

5.2 Clearing a Material Jam due to Plastic Melt

5.3 Cutting Chamber Hardware Diagram

5.4 PRS-20 Wiring Diagrams

PART 6 General Information 45

Our Design Philosophy

Warranty

Technical Support / Contact Information

Maguire Products, Inc.

7

8

9

10

12

13

14

16

17

20

21

22

24

27

27

30

30

32

34

36

45

46

47

Edition: June 20, 2012 – PRS-20

5

Maguire Purging Recovery System

Maguire Products, Inc.

6

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

1 - Getting Started – READ THIS PAGE

PLEASE READ THIS PAGE

You don't have to read the entire manual....

BUT...

PLEASE READ THE NEXT TEN PAGES.

It will take about 10 minutes.

THESE PAGES COVER:

Maguire Products, Inc.

Warranty and Disclaimers: What we Warranty and

what we cannot promise.

SAFETY Warnings: Safety warnings.

INSTALLATION: Assembly and setup.

OPERATION: What buttons to push.

MAGUIRE Shuttle Granulators are protected by U.S. patent 6,405,949.

Other U.S. and International patents are pending.

GETTING STARTED:

PROCEED TO: WARRANTY AND DISCLAIMERS NEXT PAGE

Edition: June 20, 2012 – PRS-20

7

Maguire Purging Recovery System

Maguire Products, Inc.

1.1 - Warranty – Exclusive 5-Year

MAGUIRE PRODUCTS offers THE MOST COMPREHENSIVE

WARRANTY in the plastics auxiliary equipment industry. We

warrant each MAGUIRE PRS-20 manufactured by us to be free

from defects in material and workmanship under normal use and

service; excluding only those items listed below as 'excluded

items'; our obligation under this warranty being limited to making

good at our factory any PRS-20 which shall, within FIVE (5)

YEARS after delivery to the original purchaser, be RETURNED

intact to us, transportation charges PREPAID, and which our

examination shall disclose to our satisfaction to have been thus

defective; this warranty being expressly in lieu of all other

warranties expressed or implied and of all other obligations or

liabilities on our part, and MAGUIRE PRODUCTS neither assumes nor authorizes any other persons to

assume for it any other liability in connection with the sale of its PRS-20.

This warranty shall not apply to equipment repaired or altered outside MAGUIRE PRODUCTS INC.

factory, unless such repair or alteration was, in our judgment, not responsible for the failure; nor which

has been subject to misuse, negligence or accident, incorrect wiring by others,

or installation or use not in accord with instructions furnished by

Maguire Products, Inc.

Our liability under this warranty will extend only to equipment that is returned to our factory in Aston,

Pennsylvania, PREPAID.

Please note that we always strive to satisfy our customers in whatever manner is deemed most expedient

to overcome any problems they may have in connection with our equipment.

Excluded Items:

REPLACEMENT PARTS such as rotor knives, bed knives, belts, their associated hardware and

removable screen ring or other "wear surfaces" etc.

Disclaimers – Production of faulty product

We will only be responsible to correct, repair, replace, or accept return for full refund, our equipment if it

fails to perform as designed, or we have inadvertently misrepresented our equipment for your application.

If for any reason this disclaimer is not acceptable, we will accept return of the equipment for full refund,

including freight costs both ways.

8

GETTING STARTED:

PROCEED TO: SAFETY WARNINGS NEXT PAGE

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

1.2 – SAFETY WARNINGS

SHARP EDGES:

It is advisable to wear gloves and use a block of

wood to move and "block" the rotor, or when

attempting to remove partially ground product or

service the PRS-20 blades.

Knives Are Extremely Sharp!! Use extreme

caution when placing your fingers or hands near

the rotor knives.

Maguire Products, Inc.

DOOR SAFETY INTERLOCK:

There are 4 safety interlocks switches on the front and rear doors

as well as one safety interlock switch on the PRS-20’s containment

chamber. If you open any of the doors or containment chamber,

all operations will stop. After closing the doors, you will need to

restart the PRS-20 properly. If Operation is abruptly stopped a

possible material jam may occur. See Clearing a Jam for more

information.

RISK OF SHOCK:

Disconnect power supply before servicing the

PRS-20.

DO NOT OPEN electrical box without disconnecting

power.

GETTING STARTED: PROCEED TO: INSTALLATION - NEXT PAGE

Edition: June 20, 2012 – PRS-20

9

Maguire Purging Recovery System

Maguire Products, Inc.

1.3 – Purging Recovery System Terminology

Bed Guides

Bed Knife

Blower

Containment Chamber Hopper in which parts are placed & contained during processing

Cylinders

Discharge Chute

Follower Plate

Front of Machine

Granulator

Grip Latches

Home Position

Jack Screw Block

Lifting Channels

Limit Switches

Lower Table

White polypro strips running along the outside of the PRS-20’s

tables. These strips provide minimal clearance from the bottom of

the containment chamber to the guide preventing material from

leaking out during processing.

2nd Stage Adjustable knife determining gap (clearance) to rotor

knife. All four edges of this knife are sharpened for maximum life.

Material movement system positioned below grinder

(1) pneumatic, (1) hydraulic that move containment chamber &

monitor pressure changes for protection against jamming

Chute which material drops into after being cut by R- Nine

Polypropylene plate that lowers onto scrap parts being processed.

Keeps material close to shredder rotor for efficient processing

Hinged doors in center. (drive motors are on back of machine)

Machine designed to size reduce material to chips/granulate

(1) located on each side on front of containment chamber keeping

cover securely closed.

Containment chamber is stopped over upper table & in contact with

table limit stop

White polypro blocks located on exterior lower right comers of

containment chamber. These blocks have a jam nut and a socket

head set screw in them. When wheel assemblies are loosened,

these blocks provide hopper clearance adjustment over bed guides.

Two rectangular slot in front face of sound enclosure. These slots

allow forklift access so machine can be moved.

Switches, which immediately terminate electrical current upon

activation. (Located on sound enclosure doors & containment

chamber cover)

Located to left of rotor when viewed from front of machine

10

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

Maguire Products, Inc.

Regulator

Allows compressed air line to be connected. Regulates air pressure

to pneumatic cylinders. (Do not adjust from factory setting of 90 psi

without consulting Maguire Products

Reversing Circuit

Monitors resistance encountered during containment chamber

travel. When resistance is met, unit reverses travel preventing

overfeeding or jamming.

Lower Radial Granulator Performs 2nd stage of grinding (located under tables)

Rotor

Machined cutter with mounted knives

Rotor Knife

Fixed (non-adjustable) knife that is bolted to rotor

Screen Ring

Removable ring with drilled holes, which dictate particle size

(located in Lower Radial Granulator)

Sensing Switch

Switch mounted between hydraulic cylinder inlet/outlet. This switch

monitors hydraulic fluid movement. When no movement of fluid is

detected for 2 seconds, (i.e. a "jam" condition) hopper will reverse

direction.

Shredder

Process where rotor performs 1st stage of grinding (located

between upper & lower tables)

Shuttle

Describes "Back & forth" movement of containment chamber

Sound Enclosure

Sound dampened panels mounted to machine minimizing DBA

level.

Stripper Plate

Machined plate mounted to lower bed with scalloped design.

Prevents long pieces of processed parts from making their way into

transition discharge.

Timer

Adds additional runtime after Shuttle Empty Alarm.

Transition Discharge

Removable chute that directs shredded material into Lower

Granulator.

Upper Table

Located to right of shredder rotor when viewed from front of

machine

Wiper Blades

Adjustable aluminum strips mounted to bottom of containment

chamber. Prevents material from escaping containment chamber &

keeps upper & lower tables free of debris.

Edition: June 20, 2012 – PRS-20

11

Maguire Purging Recovery System

Maguire Products, Inc.

Purging Recovery System Concept

The Maguire Purging Recovery System is a low cost alternative to

conventional size-reduction of any large parts or purgings. This

completely new type of plastics granulator automatically transforms

large reject parts, purgings and other bulky or difficult-to-handle scrap

into high-quality regrind but costs substantially less than conventional

equipment. Until now, size-reducing large parts has meant buying a

massive heavy-duty granulator, using a shredder in combination with a

standard granulator, or cutting the parts with a saw before granulation.

The PRS-20 is a two-stage system that in the first stage literally planes

reject parts into small pieces. In this “planing” stage the scrap or reject

part is automatically shuttled back and forth over a table surface that is

split into two levels like a carpenter’s plane. Mounted in between the two

levels is a staggered knife rotor that turns at 1750 rpm. This rotor

reduces the scrap into small pieces and propels them into the hopper of a Radial Granulator. This

Radial Granulator is positioned directly below the planer and performs the second stage by size

reducing the pieces into highly uniform regrind meeting the particle size requirement of your operation.

The final particle is then removed from the discharge chute by the Maguire Blower system & conveyed

to a gaylord for storage.

PRINCIPLES OF OPERATION

•

The operator places the plastic part or bulk scrap into the containment chamber, or hopper,

which is parked, at the home position at the upper level table. The containment chamber has

two cylinders mounted to it. The first cylinder is pneumatic and solely provides the movement of

the containment chamber. The second cylinder is hydraulic and has a switch mounted in-line,

which monitors the movement of the fluid in the cylinder. If there is no movement of fluid, such

as a jam condition, the switch senses this and reverses the hoppers direction of movement. The

hydraulic cylinder also provides excellent shock absorbent qualities during the grinding process

and containment chamber movement.

•

Upon push-button activation by the operator, the follower plate releases and applies gentle

pressure on the parts) being ground. The containment chamber shuttles on wheels toward the

lower level table.

•

The scrap then passes over the rotor, which is turning in the same direction as the Shuttle's

movement.

•

When the containment chamber reaches the farthest end of the lower table it is restricted from

moving any further. The hydraulic sensor detects no movement in fluid and reverses the

containment chambers direction. The part is now being fed into the rotor knives, which are

turning into the part.

•

Small pieces produced by the rotor knife are propelled downward into the hopper of the Radial

Granulator for final size reduction.

•

The fine particles are removed from the Radial Granulator discharge chute by the blower. The

particle is conveyed through 3 inch tube into a gaylord container.

•

This shuttling process continues until the Hopper Empty Alarm or the operator manually stops

the machine for reloading.

12

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

2 - Installation

2.1 – Transport, Setup

The PRS-20 is shipped pre-assembled. The PRS-20 frame is designed with forklift fork

tubes and can be lifted using a forklift. The Granulator’s weight is 2500 lbs (1135 kg).

Protective wrap and wood may be attached to the PRS-20 and must be removed prior

to use.

Remove the crating surrounding your granulator.

The Granulator is bolted to the crate base using lengths of wood running through the

forklift tubes in the frame. Unbolt these boards and remove them.

Remove any strapping, securing tape or plastic wrap from the Granulator.

Your granulator has been equipped with lifting channels that allow forklift access. These

lifting channels are accessed from the front of the granulator.

Make sure all doors are secured closed and move your granulator to the location of your

choice.

Maguire Products, Inc.

Lifting

DANGER OF INJURY!

If the weight is unevenly distributed, the PRS-20 may tip and injure people

when it is lifted.

Lift the PRS-20 with a fork truck or suitable equipment. Weight of PRS-20 is

2500 (1134 kg). Lift points (fork tubes) are between the leveling feet,

oriented from front or rear. The forklift forks must be within the fork tubes

for stability when lifting.

Edition: June 20, 2012 – PRS-20

13

Maguire Purging Recovery System

2.2 – PRS-20 Installation

Electrical Connection

RISK OF INJURY! Only qualified technicians should

make electrical connections.

Connect Motor Power to PRS-20

After initial setup of the Granulator, the power cable must be

connected. The electrical cable is located on the left side of the

Granulator and supplies the power. Within the cable are four

wires. These wires are black, brown, blue and fourth wire is a

green/yellow wire is the ground wire.

WIRING YOUR GRANULATOR AND ASSURING PROPER ROTATION

The following procedure will guide you in supplying power to your granulator. Your

granulators requires a 20amp Breaker & is wired for 60 cycle / 3 phase.

1. Select The Proper Male Cord Cap To Match Your Electrical Supply.

2. Remove Approx. Four Inches Of Rubber Coating On Cord To Expose

Coated Wires.

3. Remove Approx. Y2 Inch Of Plastic Coating From Each Of The Four Leads.

4. Attach your Male Cord Cap as required by local code.

5. Plug Granulator Into Power Supply.

6. Turn the granulator power disconnect to the "ON" position.

Press The Start Button for the Blower, the grinder & 3rd sequence "Shuttle Rotor".

Maguire Products, Inc.

14

Edition: June 20, 2012 – PRS-20

Maguire Purging Recovery System

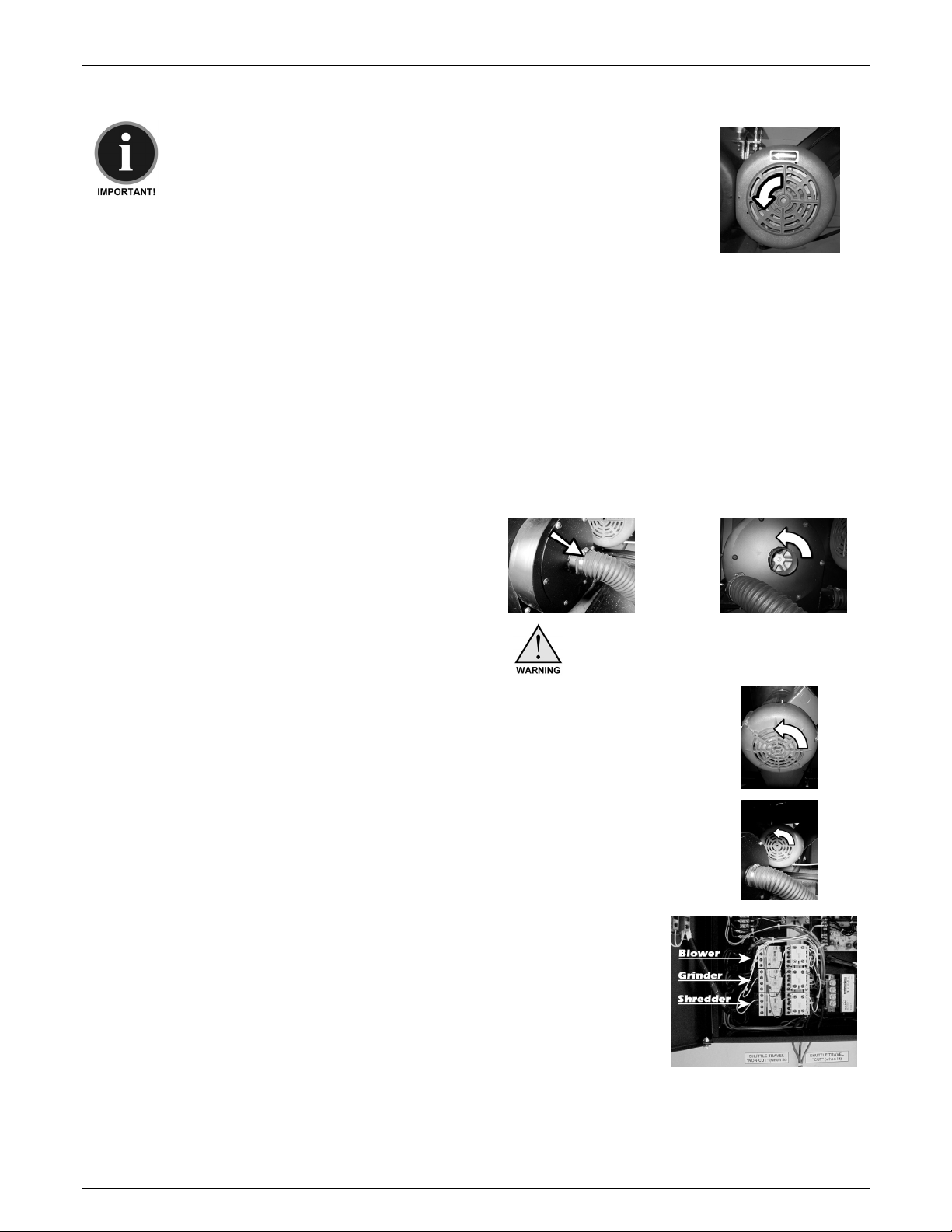

Check The Motors For Proper Rotation

Important: The blower, shredder & second stage motors all use

3-phase. Therefore, it is only necessary to assure that one

motor is turning in the correct direction. From the front of the

granulator, the shredder rotor should be turning in a

"counterclockwise" direction.

If The Motor Is Not Turning In The Correct Direction:

Maguire Products, Inc.

1. Turn Off The Grinder and follow proper lockout/tagout procedures.

2. Remove power cable from the power source.

3. DO NOT REMOVE THE GREEN GROUND WIRE.

4. Swap Any Two (2) Of The Other Three (3) Wires In The Lord Cap And Secure.

5. Reassemble Cord, Connect To Power Supply & Recheck For Proper Rotation.

If Proper Rotation Is Observe:

Supply the granulator with compressed air & assure regulator is set at 90 psi.

Follow this procedure if the PRS-20 has been serviced or it is necessary to check the

rotation of all 3 motors individually:

Blower Motor: The blower motor is located

within the front door below the

bed rails. Remove the black

convey line. Observe the

rotation during operation. It

should rotate in a counterclockwise direction.

DO NOT reach into the blower!

Grinder Motor: The grinder motor is located in the back of the PRS-

20 below the bed rails. Observe the rotation during

operation. It should rotate in a counter-clockwise

direction.

Shredder Motor: From the front of the granulator, the shredder rotor

should be turning in a "counterclockwise" direction.

If any ONE of the three motors are not turning in The Correct

Direction (counter-clockwise), then follow these steps:

1. Turn Off The Grinder, follow proper lockout/tagout procedures.

2. Remove power cable from the power source.

3. Open the Electrical cabinet and locate the motor starter

contactors / overload relays. See labeled photo at right.

4. Located the specific relay that needs to be corrected.

5. Swap any two (2) of the other three (3) wires and secure.

Connect To Power Supply & Recheck For Proper Counter-clockwise Rotation.

Edition: June 20, 2012 – PRS-20

15

Loading...

Loading...