MAGUIRE PRODUCTS INC.

LoPro

TM

Receiver

TM

TM

LoPro

LoPro

LoProLoPro

TMTM

Receiver

Receiver

ReceiverReceiver

INSTRUCTION MANUAL

Copyright Maguire Products, Inc. 2019

L o P r o R e c e i v e r

Maguire Products Inc.

Maguire Products Inc.

Maguire Products Inc.Maguire Products Inc.

M A G U I R E P R O D U C T S , I N C .

Model

Table of Contents

Model LPR

Model Model

LPR----A7 & LPR

A7 & LPR----A12

LPRLPR

A7 & LPRA7 & LPR

A12 LoPro Receiver

LoPro Receiverssss

A12A12

LoPro ReceiverLoPro Receiver

Principle of Receiver Operation __________________________________________ 4

Principle of Controller Operation ________________________________________ 4

Description of Controls _________________________________________________ 6

Installing the LoPro Receiver ____________________________________________ 7

Filter Cleaning or Replacement __________________________________________ 9

MCP & 3rd Party Pump _________________________________________________10

Wiring Diagrams _____________________________________________________ 11

Dimensional Drawings ________________________________________________ 14

Warranty ___________________________________________________________ 12

Technical Support and Contact Information ______________________________ 13

2

Rev: January 15, 2019

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

Copyright 2019 Maguire Products Inc.

The information contained within this manual including any translations thereof, is the property of

Maguire Products Inc. and may not be reproduced, or transmitted in any form or by any means

without the express written consent of Maguire Products Inc.

To every person concerned with use and maintenance of the Maguire LoPro Receiver it is

recommended to read thoroughly these operating instructions. Maguire Products Inc. accepts no

responsibility or liability for damage or malfunction of the equipment arising from non-observance of

these operating instructions.

To avoid errors and to ensure trouble-free operation, it is essential that these operating instructions

are read and understood by all personnel who are to use the equipment.

Should you have problems or difficulties with the equipment, please contact Maguire Products Inc.

or your local Maguire distributor.

These operating instructions only apply to the equipment described within this manual.

Accuracy of this Manual

We make every effort to keep this manual as correct and current as possible. However, technology

and product changes may occur more rapidly then the reprinting of this manual. Generally,

modifications made to the pump design or to the operation of the software are may not reflected in

the manual for several months. The date at the footer of this manual will indicate approximately how

current this manual is. Likewise, your pump may have been produced at an earlier time and the

information in this manual may not accurately describe your pump since this manual is written for

the current line of pumps in production (as of the date in the footer). We always reserve the right to

make these changes without notice, and we do not guarantee the manual to be entirely accurate. If

you question any information in this manual, or find errors, please let us know so that we may make

the required corrections or provide you with accurate information. Additionally, we will gladly provide

you with an updated copy of any manuals you need at any time. We welcome comments and

suggestions on ways we can improve this manual. For additional information, or to download the

latest copy of this manual or any other Maguire manual, please visit our website or contact us

directly.

Manufacturer’s Contact Information

Maguire Products Inc.

11 Crozerville Road

Aston, PA. 19014

Phone: 610.459.4300

Fax: 610.459.2700

Website: http://www.maguire.com

Email: info@maguire.com

Rev: January 15, 2019

3

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

Principles of Receiver Operation

The LoPro is a material conveying receiver. Being that of a receiver, this unit requires the

addition of a stand-alone vacuum pump. The Maguire MCP pump is specially designed for this

purpose. A third-party pump control (part #: OPL-LPR-AVB) is also offered, so LoPro receivers

can be used with larger vacuum pump systems as well.

The LoPro will also require a regulated, non-lubricated 80 psi (5.5 Bar) compressed air

supply. This model incorporates a pneumatic vacuum shift valve, and filter clearing blow-off which

rely on this air supply.

A unique feature of this LoPro unit is the vertical height. While many other material loaders

and receivers can protrude 2 to 3 feet out the top of a hopper lid, the LoPro stands only 7-5/8”

(193 mm) out of a hopper lid. Despite its low clearance, it maintains a respectable capacity.

Another unique feature of the LoPro are their large opening for material discharge. This

large opening helps to provide fast, effective flow of any type of material from the receiver.

Principle of Controller Operation

The LoPro is powered with 24 VDC, which is supplied exclusively from the pump which it

is connected to via its signal cable. Multiple LoPro units can be wired to other each other so that

they all share a single pump (depending on throughput, on average up to 8 units, per pump).

The controller logic works off a first-in, first-out priority order. Adding receivers requires no

additional programming sequence or setup. Operators simply attach the next receiver’s input

connector to any other receiver’s output connector using a signal cable.

The LoPro receiver obtains its demand signal from the positioning of its counter-weighted

dump flap via a magnetic sensor. When a hopper is empty, the dump flap of the receiver will

swing shut, telling the it to run a loading cycle. When a LoPro has filled the hopper, the material

inside the hopper will hold the dump flap open, indicating not to run.

Alarm Routine

If a LoPro is running and material is not successfully being conveyed, an alarm will sound

indicating this to the operator. The receiver is able to detect this by observing the signal from

the dump flap sensor. At the end of the loading cycle, material should flow out of the receiver

causing the dump flap to temporarily swing open. The controller will see this happen; thus,

verifying material was successfully conveyed.

If the LoPro detects that material is not conveyed 5 consecutive times, the receiver will

enter an alarm routine to alert the operator. The alarm routine consists of 5 more loading

attempts with the alarm (buzzer) active, followed by a 2 min wait period. This sequence will

repeat until LoPro detects material being conveyed, or the alarm routine is exited by the

operator.

While the receiver is alarming, an operator can manually exit the alarm routine by

pressing the “set time” pushbutton twice (1st to silence the alarm, 2nd to exit the alarm routine

completely). Whether the alarm routine is exited naturally or manually, the LoPro will then

resume its standard operating procedure.

4

Rev: January 15, 2019

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

Set Time

The “Set Time” pushbutton is primarily used to set the duration of time that the LoPro will

convey material for during a loading cycle. The time is defaulted to 25 seconds, but can be set

anywhere from 5 to 45 seconds. Depending on the material’s density, an operator may want a

duration which is longer, or shorter. Adjusting this time interval is very easy. Simply wait until the

loader begins conveying material normally. While it is doing this, press and hold the “Set Time”

pushbutton. After the desired time duration has passed, let go of the “Set Time” pushbutton.

The new conveying duration will be from when the LoPro began loading initially, to when you

released the “Set Time” pushbutton. The LoPro will save this duration even after power has

been cycled. An operator can adjust this as many times as they feel necessary.

Operational Modes

Out of the box, the Lopro receiver is set to run anytime a demand signal is present. This

demand signal is determined by the hanging position of the dump flap. For conveying

applications where material may not always available (such as regrind), the operator may want

to set the receiver to one of the 4 additional non-continuous, or “regrind” modes.

These additional modes differ from the standard operating mode such that a delay is

incorporated in between loading cycles. Additionally, the alarm routine is disabled when set to

any of the 4 regrind modes.

Properly using one of these modes can help to prevent unnecessary vacuum motor

operation.

Directions on how to set, or exit regrind mode in the Lopro are as follows:

1) Power Lopro controller off (rocker switch on front panel switched down)

2) While holding the “SET TIME” button down, turn controller power on.

3) Continue to hold the “SET TIME” button down until the status LED blinks once, then

immediately let go of the “SET TIME” button.

4) LED blinks once after a few seconds.

5) Release set time button.

6) Immediately press set time button 1 through 5 times to enter one of the 5 different

modes. Here is a list of what operating parameters are associated with:

(Pressed 1 time) - Exit Regrind mode (default, alarm active, zero delay)

(Pressed 2 times) - 2 min delay after each cycle (alarm disabled)

(Pressed 3 times) - 4 min delay after each cycle (alarm disabled)

(Pressed 4 times) - 8 min delay after each cycle (alarm disabled)

(Pressed 5 times) - 16 min delay after each cycle (alarm disabled)

After the set time button has been pressed the desired amount of times, there will be a pause

for several seconds, and then the receiver’s status light will blink back what was just set

(example: 3 blinks for 3 button presses).

Following this, nothing else is required from the operator. The receiver will boot up in the mode

that was just set. The receiver will remember this setting if power is cycled. An operator can

adjust this as many times as they feel necessary.

Rev: January 15, 2019

5

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

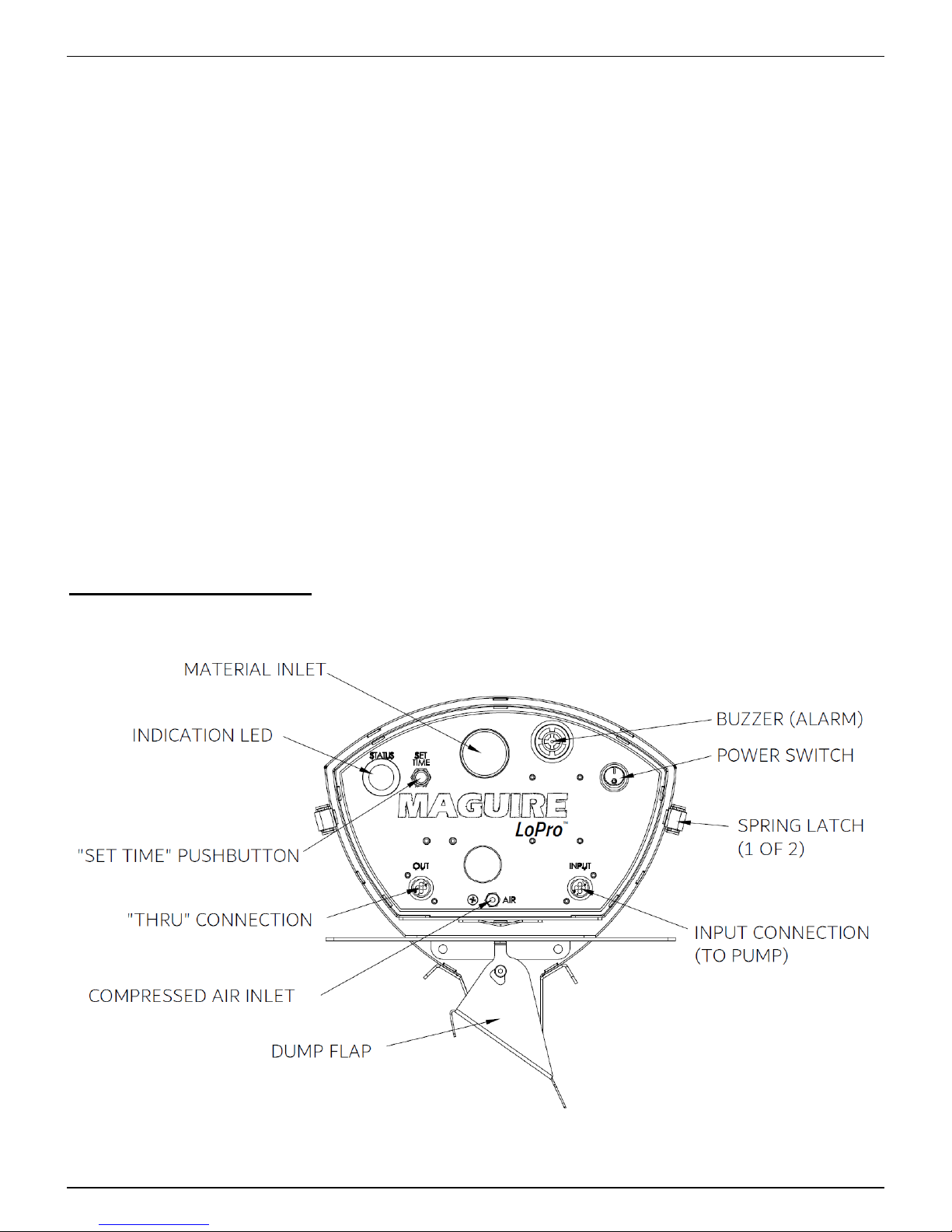

Status Indicator

The LoPro’s status indicator is a green LED located on the front panel of the controller.

Primarily, this is used to indicate if the unit is powered up, but also serves several other

purposes. As mentioned earlier, the status indicator is an integral part of setting the LoPro’s

running mode.

The status indicator will provide information about the LoPro during standard operation.

This can be a useful tool for troubleshooting. At any point when the LoPro is turned on, the

status indicator should be displaying 1 of 4 conditions. The following list describes each, and

explains what each one means:

• Constantly Illuminated: Satisfied. Not calling for material, presumably hopper full.

• 1-Second flash rate: Waiting. Calling for material, but line is currently in use by

another receiver.

• ¼ Second flash rate: Loading. In the process of conveying material.

• Rapid (1/20th second) flash rate: Alarming. Could be anywhere within the alarm

routine (see description on page 4).

Description of Controls

6

Rev: January 15, 2019

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

Installing the LoPro Receiver

1. Install flexible hose, secured with hose clamps at both ends, from feed tube to material inlet tube on

the front of loader (same side as controller).

2. Install flexible hose, secured with hose clamps at both ends, from vacuum pump to vacuum inlet of

receiver (opposite side as material inlet).

3. Install 5/32” (4 mm) air line into the fitting and connect to clean, dry 80 psi (5.5 bar) compressed air

supply. DO NOT apply direct air pressure to the LoPro fitting. Damage or an air leak could result.

A compressed air filter (sold separately) is recommended for protection of pneumatic components.

4. Connect the 4-pin power/signal cable to the receptacle labeled “INPUT” on the front panel of the

Lopro. Connect other end of cable to pump (or another LoPro’s “OUT” receptacle that has already

been attached to a pump).

5. Attach pump (shown with Maguire MCP) to electrical power source (120 or 230 volts AC depending

on model), then turn on.

6. Rotate the feed tube ring for the best air to material mixture. The best mixture of air and material

will allow material to flow efficiently, with the right proportion of conveying air, without clogging and

without rapid hose wear.

Rev: January 15, 2019

7

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

Filter Cleaning or Replacement

1) Turn off power on loader.

2) Disconnect the material line, signal cable, and compressed air.

3) Release spring latches, and remove controller portion.

4) Remove / replace filter (Maguire part #: ashffd4). Dome side of filter facing toward the material

portion.

5) When reinstalling the controller portion of the receiver, make sure that the material inlet is lined up

and slides in smoothly into the respective grommet. Then, fasten the 2 spring latches.

8

Rev: January 15, 2019

L o P r o R e c e i v e r

Accessing electronics, valves for service

To access the electronics of the Lopro receiver, remove the (7) sheetmetal screws holding in the

front panel. Remove only the front panel.

M A G U I R E P R O D U C T S , I N C .

Replacement Parts:

Part Description

4.5” dia. Dacron filter with foam gasket

Solenoid, 3-way, 24 VDC

Circuit Board

“Status” Indicator LED, 22mm, 24V Green

“ON/OFF” Rocker Switch

Piezo Alarm Buzzer, 24VDC

Maguire Part Number

ashffd4

nv91

eab-LPL-R

ehl-24G

eswr06

ehb-2

Rev: January 15, 2019

9

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

MCP Pump & 3rd Party Control Options

Maguire MCP

The MCP pump is a simple, compact vacuum system specifically designed for LoPro recieivers systems.

• Features a brushless motor which last 4 to 5 times as

long as equivalent motors with brushes.

• Capable of providing vacuum power for systems up to

1,000 lbs/hr.

• Hinged lid for quick cleanout.

• 1-1/2” Vacuum inlet

• Available in both 120V and 230V models.

3rd Party Pump Control Module

LoPro receivers can be run with a 3rd party pump by using the 3rd party pump control module.

Part number: LPR-PC-O

This module can be used to run most vacuum pumps.

It will interfaces using 24 Vdc outputs to operate a motor contactor and vacuum bypass valve.

10

Rev: January 15, 2019

L o P r o R e c e i v e r

Wiring Diagrams

LPR Controller

M A G U I R E P R O D U C T S , I N C .

Rev: January 15, 2019

11

L o P r o R e c e i v e r

MCP Pump

M A G U I R E P R O D U C T S , I N C .

12

Rev: January 15, 2019

L o P r o R e c e i v e r

3rd Party Pump Control Module

M A G U I R E P R O D U C T S , I N C .

Rev: January 15, 2019

13

L o P r o R e c e i v e r

Dimensional Drawings

M A G U I R E P R O D U C T S , I N C .

14

Rev: January 15, 2019

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

Rev: January 15, 2019

15

L o P r o R e c e i v e r

M A G U I R E P R O D U C T S , I N C .

WARRANTY - Exclusive 5-Year

MAGUIRE PRODUCTS offers one of the MOST

COMPREHENSIVE WARRANTIES in the plastics

equipment industry. We warrant each Pump

manufactured by us to be free from defects in

material and workmanship under normal use and

service; our obligation under this warranty being

limited to making good at our factory any Feeder

which shall within FIVE (5) YEARS after delivery to

the original purchaser be returned intact to us,

transportation charges PREPAID, and which our

examination shall disclose to our satisfaction to have

been thus defective; this warranty being

expressly in lieu of all other warranties expressed or implied and of all other

obligations or liabilities on our part, and MAGUIRE PRODUCTS neither assumes

nor authorizes any other persons to assume for it any other liability in connection

with the sale of its products.

This warranty shall not apply to any Feeder which shall have been repaired or

altered outside MAGUIRE PRODUCTS factory, unless such repair or alteration was,

in our judgment, not responsible for the failure; nor which has been subject to

misuse, negligence or accident,

incorrect wiring by others, or installation or use not in accord with instructions

furnished by Maguire Products.

Our liability under this warranty will extend only to Feeders that are returned to our

factory in Aston, Pennsylvania PREPAID.

It should be noted, however, that we strive to satisfy our customers in whatever

manner is deemed most expedient to overcome any problems they may have in

connection with our equipment.

16

Rev: January 15, 2019

L o P r o R e c e i v e r

Technical Support and Contact Information

Maguire Products Inc.

11 Crozerville Road

Aston, PA 19014

Tel: 610.459.4300

Fax: 610.459.2700

Email: info@maguire.com

Web: www.maguire.com

Maguire Europe

Tame Park

Tamworth

Staffordshire

B775DY

UK

Tel: + 44 1827 265 850

Fax: + 44 1827 265 855

Email: info@maguire-europe.com

M A G U I R E P R O D U C T S , I N C .

Maguire Products Asia PTE LTD

Main Office

15 Changi North Street 1

#01-15, I-Lofts

Singapore 498765

Tel: 65 6848-7117

Fax: 65 6542-8577

E-mail: magasia@maguire-products.com.sg

Rev: January 15, 2019

17

Loading...

Loading...