MAGUIRE LPD-30, LPD-200, LPD-100 Maintenance Manual

MAGUIRE PRODUCTS INC.

LPD® Dryer

Models:

• LPD-30

• LPD-100

• LPD-200

LPD®

Low Pressure Dryer ®

INSTALLATION • OPERATION • MAINTENANCE

Copyright © Maguire Products, Inc. 2010

LPD Dryer®

Maguire Products, Inc.

2

Edition: Nov ember 5, 2010

LPD Dryer®

Maguire Products, Inc.

Maguire LPD ® - Low Pressure Dryer ®

Copyright

© 2010 Maguire Products Inc.

The information contained withi n this manual including any translations thereof, is the property of

Maguire Products Inc. and may not be reproduced, or transmitted in any form or by any means

without the express written cons ent of Maguire Products Inc.

To every person concerned with use and maintenance of the Maguire LPD® it is recommended

to read thoroughly these operating instructions. Maguire Products Inc. accepts no responsibility

or liability for damage or malfunction of the equipment arising from non-observance of these

operating instructions.

To avoid errors and to ensure trouble-free operation, it is essential that these operating

instructions are read and understood by all personnel who are to use the equipment.

Should you have problems or difficulties with the equipment, please contact Maguire Products

Inc. or your local Maguire distributor.

These operating instructions only apply to the equipment described within this manual.

Manufacturer’s Contact Information

Maguire Products Inc.

11 Cr oze r v ille R oad

Aston, PA. 19014

Phone: 610.459.4300

Fax: 610.459.2700

Website: http://www.maguire.com

Email: info@maguire.com

Edition: Nov ember 5, 2010

3

LPD Dryer®

Accuracy of this Manual

Maguire Products, Inc.

We make every effort to k eep this manual as correct and current as possibl e.

However, technology and product changes may occur mor e rapi dly then the

reprinting of this manual. Generally, modifications made to the dryer design or to

the operation of t he sof tware are may not reflected in the manual f or sever al

months. The date at the foot er of this manual will indicate approxim ately how

current this manual is. Likewise, your Dryer may have been produced at an

earlier time and the information in this manual may not accurately describe your

Dryer since this manual is written for the current line of Dryers in pr oduc tion (as of

the date in the footer). We always reserve the right to make these changes

without notice, and we do not guarantee the manual to be entirely accurate. If you

question any information in this manual, or find er r or s, please l et us know so that

we may make the requir ed correc tions or provide you with accurate information.

Additionally we will gladly provide you with an updated copy of any manuals you

need at any time. We welcome comment s and suggestions on ways we can

improve this manual.

For additional information, or to download the l atest copy of this manual or any

other Maguir e manual , please visit our website or contact us di r ectly.

On the Web at: www.Maguire.com

Maguire Products Inc.

Main Headquarters

11 Crozerville Road

Aston, PA 19014

Tel: 610.459.4300

Fax: 610.459.2700

Email:

info@maguire.com

Maguire Europe

Tame Park

Tamworth

Staffordshire

B775DY

UK

Tel: + 44 1827 265 850

Fax: + 44 1827 265 855

Email:

info@maguire-europe.com

Maguire Products Asia PTE LTD

Main Office

No. 15 Changi North Street 1

#01-15, I-Lof t s

Singapore 498765

Tel: 65 6848-7117

Fax: 65 6542-8577

magasia@maguire-products.com.sg

Maguire Italy

Via Zancanaro 40

35020 Vigorovea (PD)

Tel: +39 049 970 54 29

Fax: +39 049 971 18 38

Email:

info@maguire-italia.it

Please e-mail c omments and suggestions to: support@maguire.com

4

Edition: Nov ember 5, 2010

LPD Dryer®

Table of Contents

PART 1 GETTING STARTED, READ THIS PAGE 7

1.1 5 Year Warranty and Disclaimers 8

1.2 SAFETY Warnings 9

PART 2 INSTALLATION

2.1 Transport and Setup 10

2.2 Dryer Installation 11

2.2.1 Hopper Installation Series 30 11

2.2.2 Hopper Installation Series 100 / 200 12

2.2.3 Canister Installation Series 200 13

2.2.5 Electrical Connection 14

2.3 Installing Maguire Receiver on Process Machine 15

2.4 Using Your Own Receiver / Loader 16

2.5 Using the Maguire Receiver to load the Dryer 17

2.6 Dual Convey Option 19

PART 3 OPERATION

Maguire Products, Inc.

10

2.2.4 Compressed Air Connection 13

23

3.1 Standard Operation 23

3.2 Recommended Cycle Times 24

3.3 Standard Operating Sequence 25

3.4 Operating Features/Options 26

3.4.1 Convey-Only Mode 27

3.5 Changing Color “On The Fly” 28

3.6 Controls Description

3.6.1 Controller & Operator Station 29

3.6.2 Keypad 34

3.6.3 Star Functions 37

3.6.4 Parameters 50

3.6.5 Changing / Saving Parameters 60

29

Edition: Nov ember 5, 2010

5

LPD Dryer®

Maguire Products, Inc.

PART 4 MAINTENANCE AND SERVICE

4.1 Clean / Replace Air Filter 63

4.2 Cleaning the Vacuum Takeoff Assembly (VTA) 64

4.3 Canister Removal / Cleaning 66

4.4 Fill Hopper and Fill Valve Cleaning 69

4.5 Clean / Inspect the silicone disk seals 71

4.6 Drain and purge Air Filter / Regulator 71

4.7 Adjustments 72

4.8 Check Out Procedure 75

4.9 Temperature and Pressure Verification 76

4.10 Control Panel Removal 77

4.11 Diagnostic / Test Mode 77

4.12 Control Inputs and outputs

4.13 Decommissioning and Disposal 80

63

78

PART 5 TROUBLESHOOTING / SOFTWARE 81

5.1 Alarms – Cause and Solution 81

5.2 Possible Service Issues 84

5.2.1 Loss of Vacuum 84

5.2.2 Damaged Vacuum Disks 84

5.2.3 Heater Safety Switches Tripped 85

5.2.4 Filter Clogged 85

5.3 Print Outputs 86

5.4 Material Not Drying Correctly 87

5.5 Dryer Software – Backup, Restore, Factory Reset 88

PART 6 General Information

6.1 - Models, Model Identification 89

6.2 - LPD Nomenclature / Order Code 90

6.3 - Features 91

6.4 - Our Design Philosophy 92

6.5 - Theory of Operation / Performance 93

6.6 - Warranty 94

6.7 – LPD wiring Diagram & Supplements 95

6.8 - Exploded View and Parts List 109

6.9 - Pneumatic Diagrams 121

6.10 - Technical Support / Contact Information 127

89

6

Edition: Nov ember 5, 2010

LPD Dryer®

1 - Getting Started – READ THIS PAGE

PLEASE READ THIS PAGE

You don't have to read the entire manual....

BUT...

PLEASE READ THE NEXT TEN PAGES.

It will take about 10 minutes.

THESE PAGES COVER:

Maguire Products, Inc.

Warranty and Disclaimers: What we Warranty and

what we ca nn ot pr om i se.

SAFETY Warnings: Safety warnings.

INSTALLATION: Assembly and setup.

OPERATION: What buttons to push.

MAGUIRE "LPD" Dryers are protected by U.S. patent 6,154,980.

Additional U.S. and International patents are pending.

GETTING STARTED:

PROCEED TO: WARRANTY AND DISCLAIMERS NEXT PAGE

Edition: Nov ember 5, 2010

7

LPD Dryer®

1.1 - Warranty – Exclusive 5-Year

MAGUIRE PRODUCTS offers THE MOST COMPREHENSIVE

WARRANTY in the plastics auxiliary equipment industry. We

warrant each MAGUI RE LPD DRYE R manufac tured by us to be

free from defects in material and workmanship under normal use

and service; excl uding only those items listed below as 'excluded

items'; our obli gation under this warranty being limited to making

good at our factory any Dryer which shall, within FIVE (5) YEARS

after deliv ery t o the ori ginal purchaser, be RETURNED intact t o us,

transportation char ges PREPAID, and which our examination shall

disclose to our satisfaction to have been thus defecti ve; this

warranty being expressly in lieu of all other warranties expressed

or implied and of all other obligations or liabilities on our part, and

MAGUIRE PRODUCTS neither assumes nor authorizes any other person s to as sume for it any other

liabilit y in connect ion with the sale of its Dryers.

This warranty shall not apply to equipment repaired or al tered outside MAGUIRE PRODUCTS INC.

factory, unless such repair or alteration was, in our judgment, not responsible for the failure; nor which

has been subject to mi suse, negl igence or accident, incorrect wiring by others,

or installation or use not in accord with instructions furnished by

Maguire Produc ts, Inc.

Our liabilit y under this warranty will extend only to equipment that is returned to our factory in Aston,

Pennsylvania, PREPAID.

Please note that we al ways strive to satisfy our customers in whatever manner is deemed most ex pedient

to overcome any pr oblem s they m ay have in connection with our equipment.

Excluded Items:

The ability of the canisters to hold vacuum will be compromi sed if the vacuum seal edge is damaged from

mishandli ng. W e do not warranty c anisters damaged from improper handl ing. We do, however, warranty

the seals.

Disclaimers – Production of faulty product

This dryer is of a new design. We have had exc ellent results in all tests performed to date, but we have

not tested every m aterial available to the plastics industry. Materials vary widel y throughout the industry.

We have not antici pated all possible materials, proc essing conditions, and requirements. We are not

certain that our equipment will perform properly in all instances. You must observe and v erify the

performance level of this equipment in your pl ant as part of your ov er all manufacturing process. You

must verify t o your own satisfaction that this lev el of performance meets your requirement s. We can not

be responsible f or losses due to produc t not dried correctly, even when due to equipment malfunction or

design incorrec t for your requirements; and/or any consequential losses due to our equipment not drying

material to your r equir em ents.

We will only be responsible to correct, repair, replace, or accept return for full refund, our equipment if it

fails to perform as designed, or we have inadvertently misrepresented our equipment for your appli cation.

If for any reason this disclaimer is not acceptabl e, we will ac c ept return of the equipment for full refund,

including freight costs both ways.

Maguire Products, Inc.

GETTING STARTED:

PROCEED TO: SAFETY WARNINGS NEXT PAGE

8

Edition: Nov ember 5, 2010

LPD Dryer®

1.2 – SAFETY WARNINGS

Maguire Products, Inc.

HOT SURFACES:

As with all dryers, there are HOT SURFACES to avoid. Temperatures

can reach 250F (120C), or 350F, (180C) on high temperature models.

All heated surfac es are contained within the exter nal encl osure.

When the door is opened you can access and touch hot surfaces. Typic ally these

surfaces are not at danger ous temperatures, however all hot surfaces should be

avoided.

Warning Label indicate HOT SURFACES

USE CAUTION when removing and instal li ng canisters.

USE GLOVES.

DO NOT REACH into the dryer enclosure.

INDEXING OF THE MATERIAL CANISTERS:

At the end of each cycle canisters automatically index.

The forces that cause rotation are light. However, the inertia of

already moving c anisters might cause injury. Additionally the

disks above and below each canister close automati c ally and

present a pinch poi nt. For these reasons an interlock on the access door prevents all

operations while the door is open.

DO NOT DEFEAT this in t e rloc k .

DO NOT try to index the canister s by hand, against the force of the positioni ng air

cylinder. They will swing back r apidly when released.

If you disconnect the air supply and then rotate the canisters by hand, rec onnec ting

the air will cause the c anister s to s wing r apidly back to their start position.

When connecting the air supply KEEP hands CLEAR. Have the DOOR CLOSED.

DOOR SAFETY INTERLOCK:

There is a safety interlock switch on the door. If you open the door, all oper ations will

stop. After closing the door, you will need to press START to restart the dryer.

Accumulated cycle time will not be lost.

RISK OF SHOCK:

Disconnect power supply before servicing the Dryer.

GETTING STARTED: PROCEED TO: INSTALLATION - NEXT PAGE

Edition: Nov ember 5, 2010

9

LPD Dryer®

Cut sides and top flaps, unscrew screws and washers from the sides at the skid.

Maguire Products, Inc.

2 - Installation

2.1 – Transport, Unpacking and Setup

To help you identify your Dryer see: LPD Nomenclature / Order Code on page 90.

Unpacking - Removing from Carton

There are 6 screw locations. Remove carton, remove cardboard tray at the top

of the carton. On Series 30 models, cut and remove plastic wire ties from

handles inside the dryer attached to the black frame member. On the Series 100

and 200 models, remove the packing material from around the canisters and

brackets.

Return Shipping Information

Lifting

DANGER OF INJURY!

If the weight is unevenly distributed, the Dryer may tip and injure

people when it is lifted.

Lift the Dryer with a fork truck or suitable equipment. Weights of

Dryer models range from 425 pounds (193 Kg) to 900 pounds (408

Kg). Lift points are between the wheels, oriented from front or rear.

The forks must be closest to the inside of the wheels as possible for

stability.

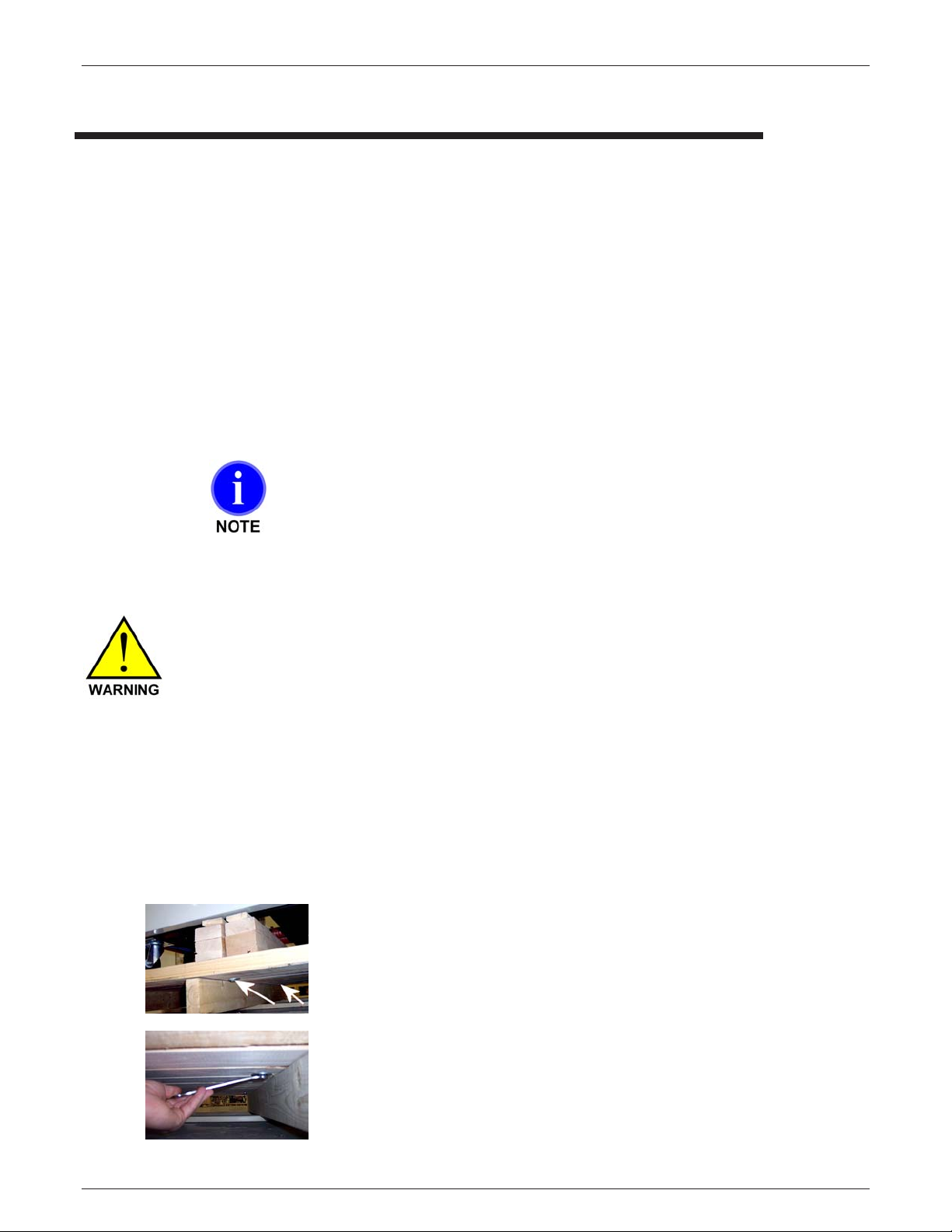

Remove Skid

Save the carton and cardboar d if at all possible, reuse for retur n to

factory. Use strong pl astic wire ties to affix the canister fr om tur ning on

the Series 30 units. On t he Series 100 and 200 models, it is advisable to

use packing material around the canister support br ac kets and ship t he

canisters on a separate skid or c ar ton.

To remove the skid, unbolt the two bolts that secure the

dryer to the skid.

The bolts are located at the bottom of the Dryer and go

through the wooden skid. These bolts can be loosened

while the Dryer and the skid are on the ground. Reverse

procedure to install dryer on the skid.

10

Edition: Nov ember 5, 2010

LPD Dryer®

2.2 – Dryer Installation

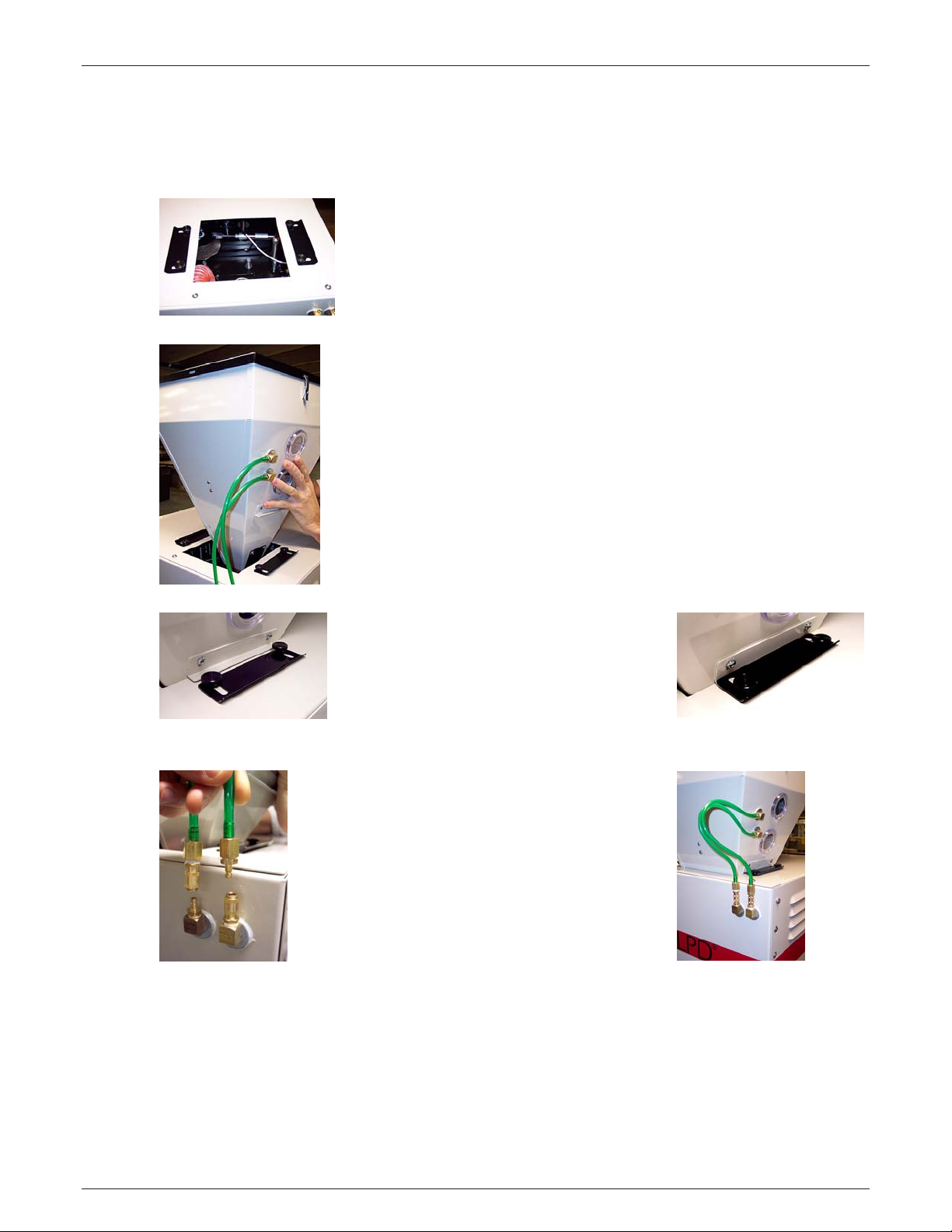

2.2.1 - Hopper Installation on the Series 30 model Dryers

Maguire Products, Inc.

Loosen thumbscrews and slide plates away from opening.

Insert hopper into opening so that air supply hoses are

facing the same side of the Dryer as the fitting they will

attach to.

Slide both lock plates towards

hopper and over hopper flange.

Tighten thumbscrews.

Attach hopper air supply quick

connect fittings.

Edition: Nov ember 5, 2010

11

LPD Dryer®

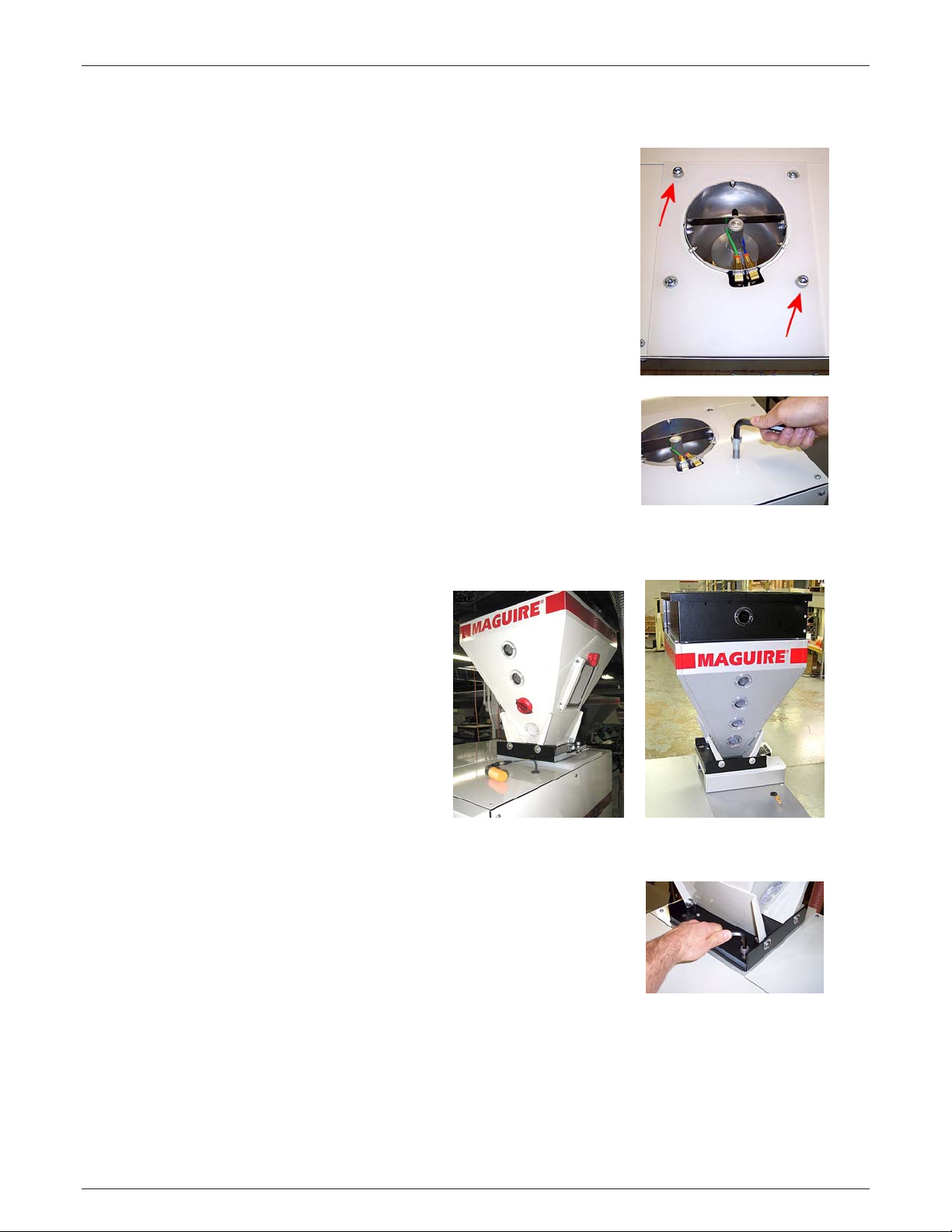

2.2.2 - Hopper Installation on the Series 100, 200, model Dryers

Locate and remove the two ½” SHCS fasteners and

washers on the fill hopper intake plate (on top of the

Dryer) using 3/8” Allen wrench.

Note: Do not remove the two recessed button head

fasteners.

Place the hopper on the dryer intake and line up the two

boltholes in the hopper with the boltholes in the fill

hopper intake plate.

For easy accessibility orientate the hopper so that the

manual slide gate handle and hopper access door are

accessible from the side or rear of the Dryer.

Maguire Products, Inc.

Note: LPD-200 Series is equipped

with a Cleanout Chute. The LPD200 hopper is elevated 2 7/8

inches higher than the LPD-100

hopper). For easy cleanout of the

LPD-200 hopper, orient the

hopper so the manual slide gate

handle is above the chute (right

side of dryer).

LPD-100

Re-install the two ½” SHCS fasteners and washers then

firmly tighten by hand using 3/8” Allen wrench.

LPD-200 Cleanout chute

12

Edition: Nov ember 5, 2010

LPD Dryer®

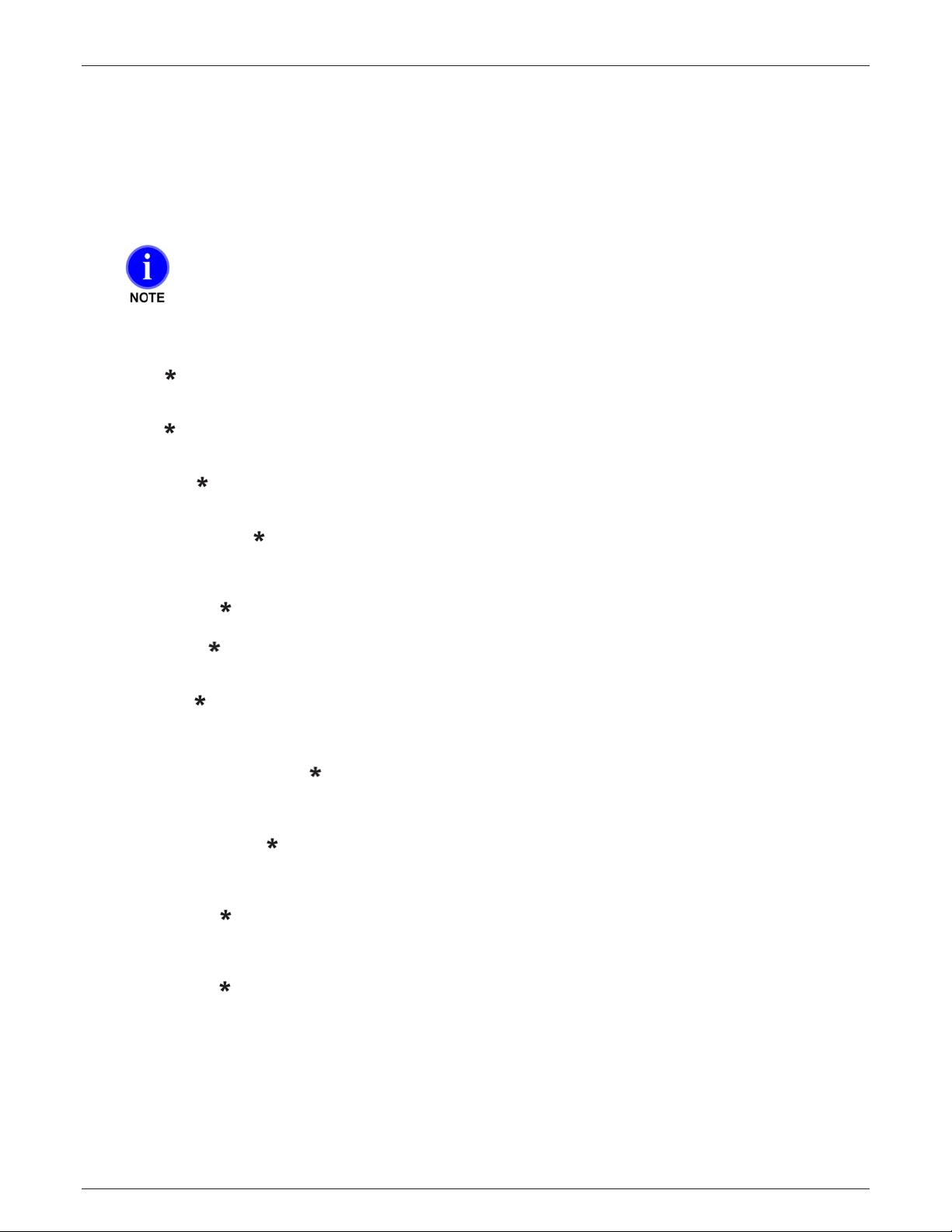

2.2.3 – Installing Canisters on Series 200 model Dryers

Maguire Products, Inc.

With 200 Series Dryers, the canisters are packaged separate from the Dryer

itself. To install the Canisters into the Dryer, follow these steps.

Do not damage the edge of the canister . Always rest the

canisters on a rubber mat or thick cardboard and take care

not to damage the edge of the canisters.

After unpacki ng the canisters, rest the canisters on a rubber

mat to protect the c anister edge. Open the Dryer door and

rotate the “Cani ster Hanger A ssembly” around to an empty

station. Grip the t wo handles of the canister firmly and lift the

canister up i nto t he Dryer, and hang the upper supports into

the “Canister Hanger A ssembly”, then swing the lower

supports back to t he lower l atches.

Hook the canister latch on each side of the canister by pushing the cani ster

back to the latch, securing the canister.

Note: Each canister hangs in one of three posi tions in the “Canister Hanger

Assembly”. These three P osi tions are labeled 1,2 and 3. The number identif ies

the canisters posit ion in the assembly.

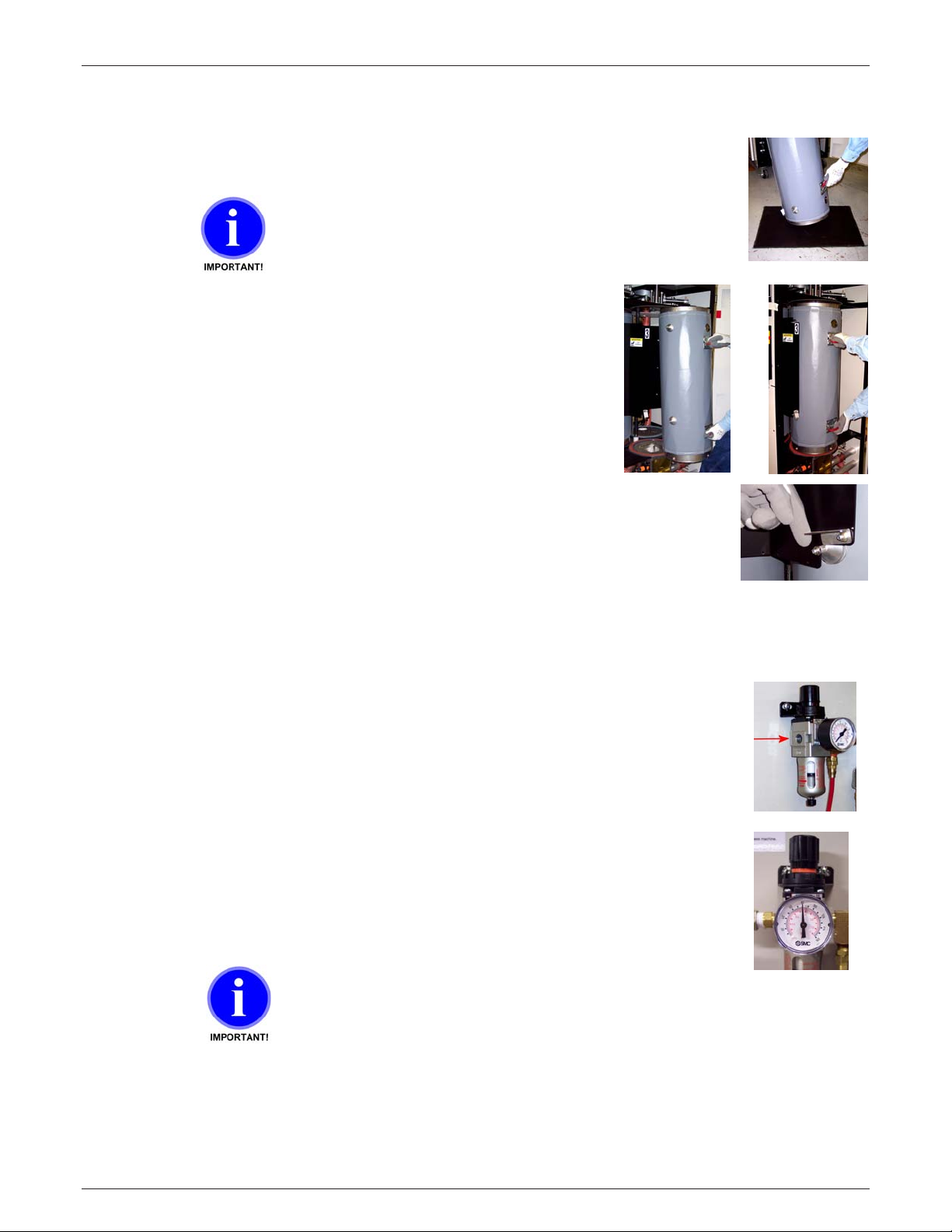

2.2.4 - Compressed Air Connection

Connect an air suppl y to the ai r regulator’s IN port using a male ¼” NPT fitti ng.

An operating air pressure of 80 psi (5.5 bar) while the vacuum generator

is running is required for proper operation of the Dryer.

Note: The Vacuum Generate ru ns for the first few minutes of every cycle.

If your air supply has oil in it add an oil separator filter.

Oil in the air will combine with dust drawn from the canisters formi ng a paste

inside the vac uum generat or . It will stop working and require cleaning.

Observe the air pressure gauge t o be sure t he pr es sure maintains 80 psi (5. 5

bar) while the v acuum generator is running or activ ate the bl ow gun rel easing

air as you check and adjust t he r egulator. If pressure drops below 80 psi,

adjust the regulator. If the pressure cannot maintain 80 psi (5.5 bar) while the

vacuum generator is running, then the air supply line is not adequate.

Do not supply Dryer with a lubricated air supply. Damage to

Dryer may result. Use only a clean, dry , oil-free air supply.

Edition: Nov ember 5, 2010

13

LPD Dryer®

Maguire Products, Inc.

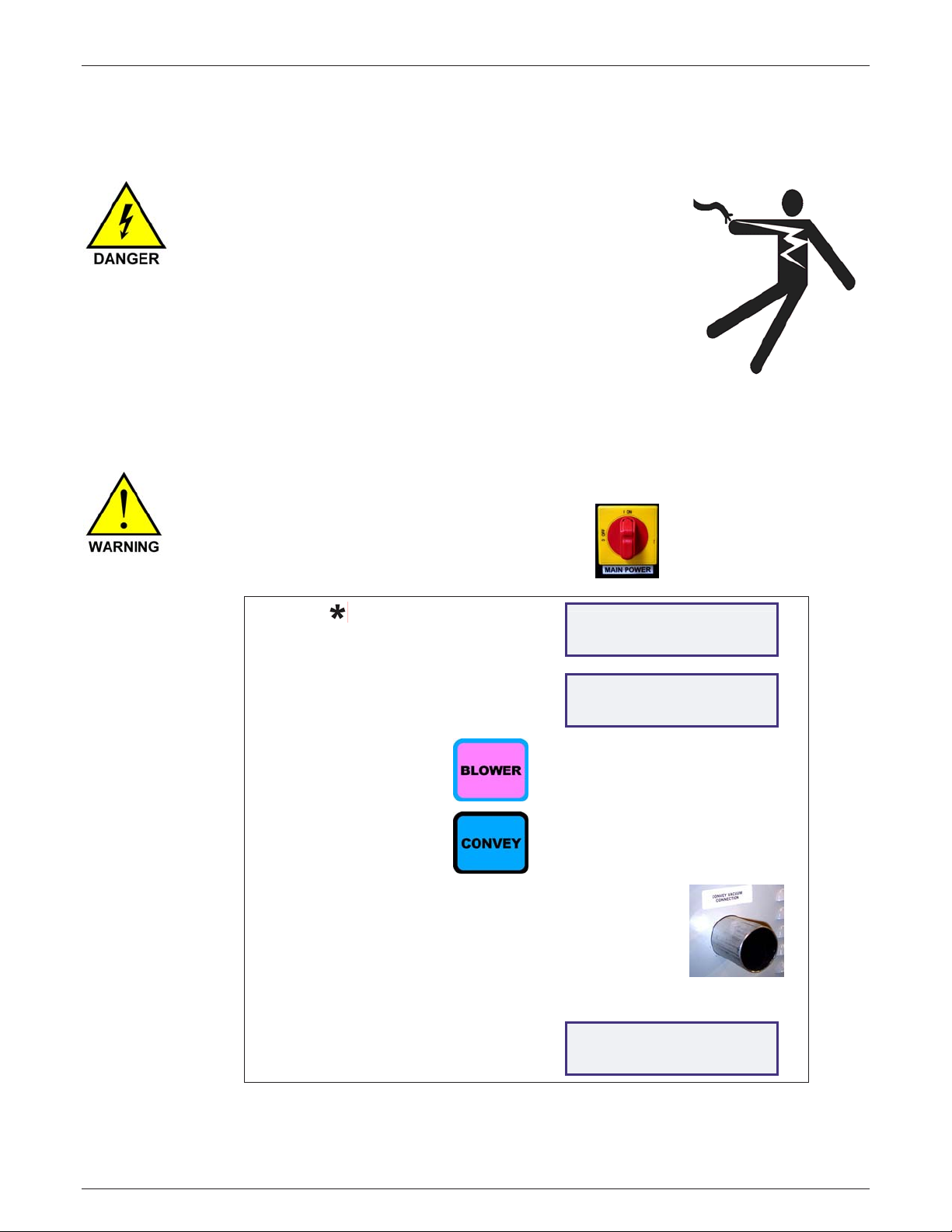

2.2.5 - Electrical Connection

To help you identify your Dryer see: LPD Nomenclature / Order Code on page 90.

RISK OF INJURY! Only qualified technicians should

make electrical connections.

Connect power to a properl y fused disconnect.

Voltage and amp ratings are speci fied on the serial num ber pl ate.

THREE PHASE UNITS are: 60 cycle 230 volts

60 cycle 480 volts

50 cycle 400 volts

or

See Wiring Diagrams on page 95 for wiring details.

Confirm Correct Blower Rotation

On THREE PHASE units CONFIRM CORRECT BLOWER ROTATION by following these instructions:

Turn power on using main power switc h.

Press:

Display will say:

ENTER FIV E DI GI T

PASSWORD _ _ _ _ _

Press:

Press:

Press:

Place hand over the CONVEY VACUUM CONNECTION port

located on the right side of the Dryer. If there is VACUUM,

that indicates the c or r ec t rotation.

If air is blowing OUT, this is NOT correct.

Reverse any two power leads (not ground) to correct rotat ion.

Press:

22222

BLOWER

CONVEY

EXIT

Display will say:

Display will say:

TEMP=63°F v=0in

MODE=PROGRAM CAN=2

TEMP=63°F v=0in

MODE=AUTO CAN=2

14

Edition: Nov ember 5, 2010

LPD Dryer®

2.3 – Installin g th e Maguir e Re cei ver on a pr oc es s ma ch in e

If you intend to use the Maguir e Rec eiver to load your process

machine, foll ow these i nstr uc tions.

Attach the Magui re Receiver to the your process machine using the

four bolt holes located at the base of the Maguire Receiver.

Maguire Products, Inc.

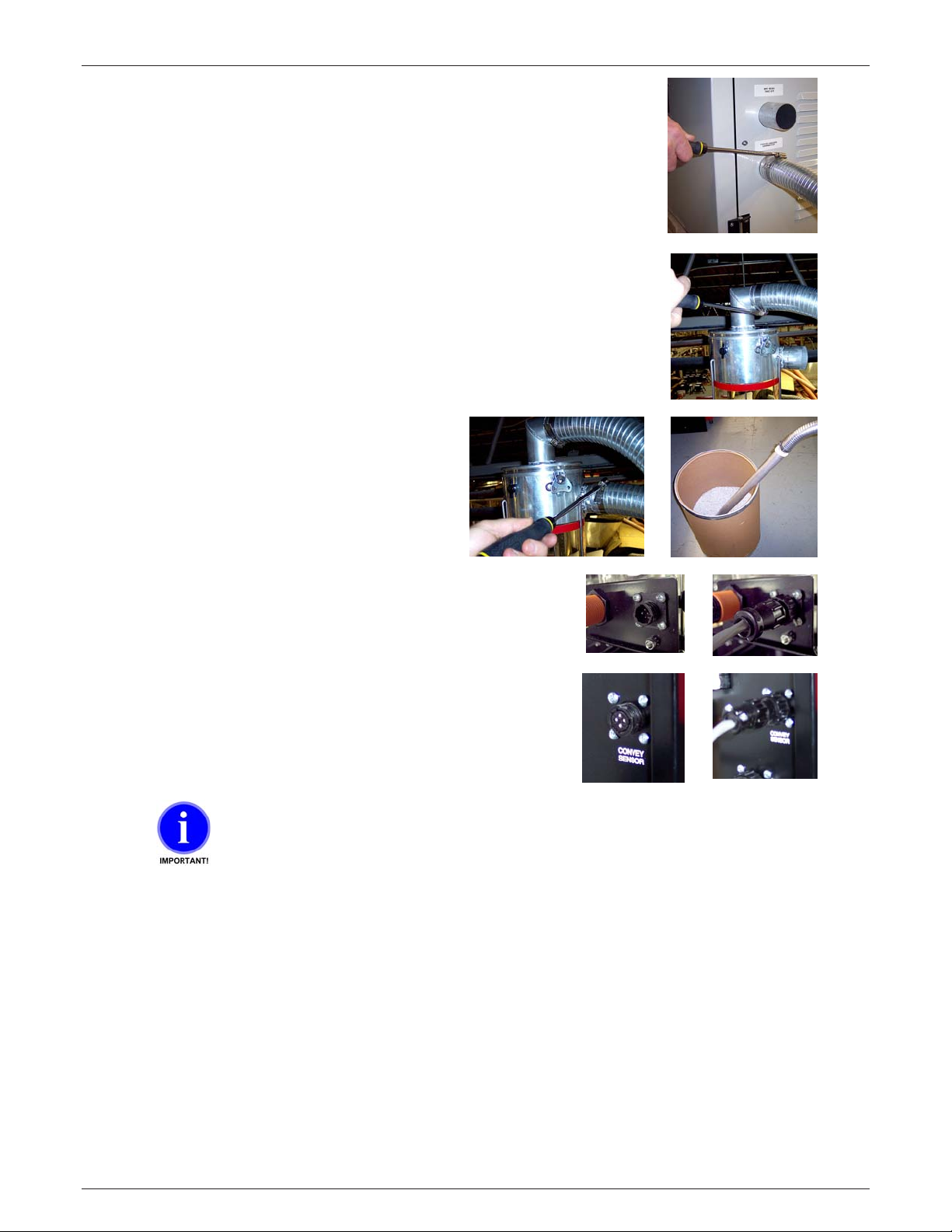

At the lower, right si de of t he Dryer ar e two ports. T he “Dry Resi n

Takeoff” port and the “ Convey Vacuum Connection” port. Using a hose

clamp, attach one end of the 2-inch vacuum line to the “Convey Vacuum

Connection” port.

Attach the other end of the 2-inch vacuum line to the port located on t op

of the Maguire Receiv er (vacuum), again using a hose clamp. Orient the

top port to face the right side of the Dryer by loosening the two clamps

and rotating it t o face the ri ght side if the Dryer for better access to the

“Convey Vacuum Connection” port.

Next, attach the mat eri al c onv ey line to the Maguire Receiver’s lower

port (materi al c onv ey ) using a hose clamp.

Next attach the ot her end of your Material Convey line to the “Dry Resin

Takeoff” port on the Dr y er .

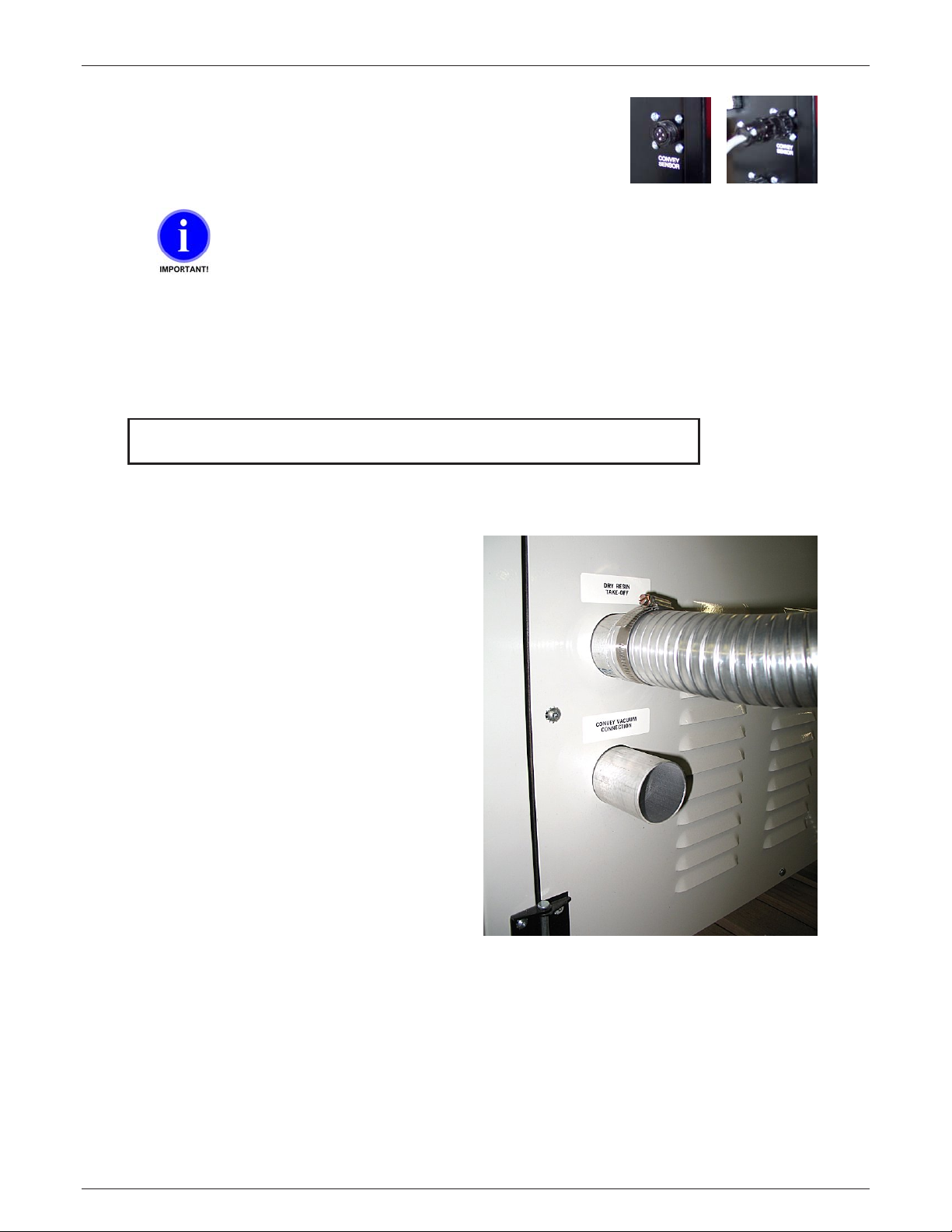

Attach one end of the Convey Sensor Cable to the cable

port located at the base of the Maguire Receiver.

Edition: Nov ember 5, 2010

15

LPD Dryer®

Maguire Products, Inc.

Attach the other end of the Convey Sensor Cable to the

Convey Sensor port l oc ated on the left side of the Dryer’s

controller.

DO NOT wire tie the SENSOR cabl e to the MATERIAL hose. This will induce

static spik es i nto t he pr oc essor. Keep them separated.

2.4 – Using Your Own Receiver / Loa ding System on a proc es s ma ch in e

If you have installed our receiver: PROCEED TO: OPERATION

If you use your own Receiver / Loading

System:

Attach your Material Convey line to the “Dry

Resin Takeoff” port on the Dryer.

16

Edition: Nov ember 5, 2010

LPD Dryer®

2.5 - Using the Maguire Receiver to load the Dryer

If you have your own receiver/ lo ader: Proceed to the next section: OPERATION

If you intend to use the Maguire Rec eiver to load the Dryer, follow

these instructions.

Configuring the Dryer Sof tware t o u se M aguire Receiver to load

the Dryer

If you want to load the Dryer usi ng a Magui r e Rec eiv er see

the Star Functi ons section, page 42 and select the Convey Mode:

“CONVEY TO DRYER”.

Along with the Maguire Dryer, you will have been provided a Hopper

and a Hopper Lid, which incl udes a Hopper Lid Blank. The Hopper

Lid Blank will need to hav e the necessary mounting holes drilled into

it to mount the Maguir e Rec eiv er . Depending on the Maguire

Receiver you have, you will use one of two patterns to drill out the

necessary holes in t he Hopper Lid Blank. Note: The Hopper Lid

Blank can be supplied pr e- dr illed if requested. Patter ns are for

ADR-1 or ADR-4 and are located in this manual on page 119.

39 in

Maguire Products, Inc.

First remove t he two retaining screws from the Hopper Lid Blank, then using the appropriate

pattern, mark and dri ll the holes in the Hopper Lid Blank. Then re-attac h the Hopper Lid Blank to

the Hopper Lid.

Attach the Magui re Receiver to the Hopper

Lid before installing the Hopper Lid onto the

Hopper. Using the 4 bolthol es at the base of

the Receiver, install four ¼ inch bolts and

locknuts. See pi ctur e to t he ri ght.

After the Maguire Receiver has been attached

to the Hopper Lid, plac e the Hopper Lid on top

of the Hopper. Be sure to align t he exi sting

screw holes in the Hopper Lid with the screw

holes in the hopper. Secure the Hopper Lid to

the Hopper by installing 2 screws into the

screw holes. See pictur e to the right.

Edition: Nov ember 5, 2010

17

LPD Dryer®

At the lower, right si de of t he Dryer ar e two ports. T he “Dry Resi n

Takeoff” port and the “ Convey Vacuum Connection” port. Using a hose

clamp, attach one end of the 2-inch vacuum line to the “Convey Vacuum

Connection” port.

Attach the other end of the 2-inch vacuum line to the port located on t op

of the Maguire Receiv er (vacuum), again using a hose clamp. Orient the

top port to face the right side of the Dryer by loosening the two clamps

and rotating it t o face the ri ght side if the Dryer for better access to the

“Convey Vacuum Connection” port.

Maguire Products, Inc.

Next, attach the mat erial convey line to the

Maguire Receiver’s lower port (material

convey) using a hose clam p. The other end

of the material convey line will attach to

your material source such a s a Mat er ial

Pick-Up Lances as pictur ed to the right.

Attach one end of the Convey Sensor Cable to the cable

port located at the base of the Maguire Receiver.

Attach the other end of the Convey Sensor Cable to the

Convey Sensor port l oc ated on the left side of the Dryer’s

controller.

DO NOT wire tie the SENSOR cabl e to the MATERIAL hose. This will induce

static spik es i nto t he pr oc essor. Keep them separated.

18

Edition: Nov ember 5, 2010

LPD Dryer®

2.6 - Dual Convey Option

The Dual Convey Option all ows for one Dryer to supply material to two processes using two

Maguire Receivers. Using Dual convey requires the purchase of the Dual Convey Kit, which

includes:

• Dual Convey Receiv er Selector Control

• Dual Convey Solenoid

• Dual Convey Shifti ng Valve

• Y Resin Takeoff Pipe

• Nylon Air line

• NP T ¼” T fitting with Nylon Quick Connect

The following instr uc tions describe the installation of the Dual Convey Option on LPD 100 and

LPD 200 Series Dryers.

Maguire Products, Inc.

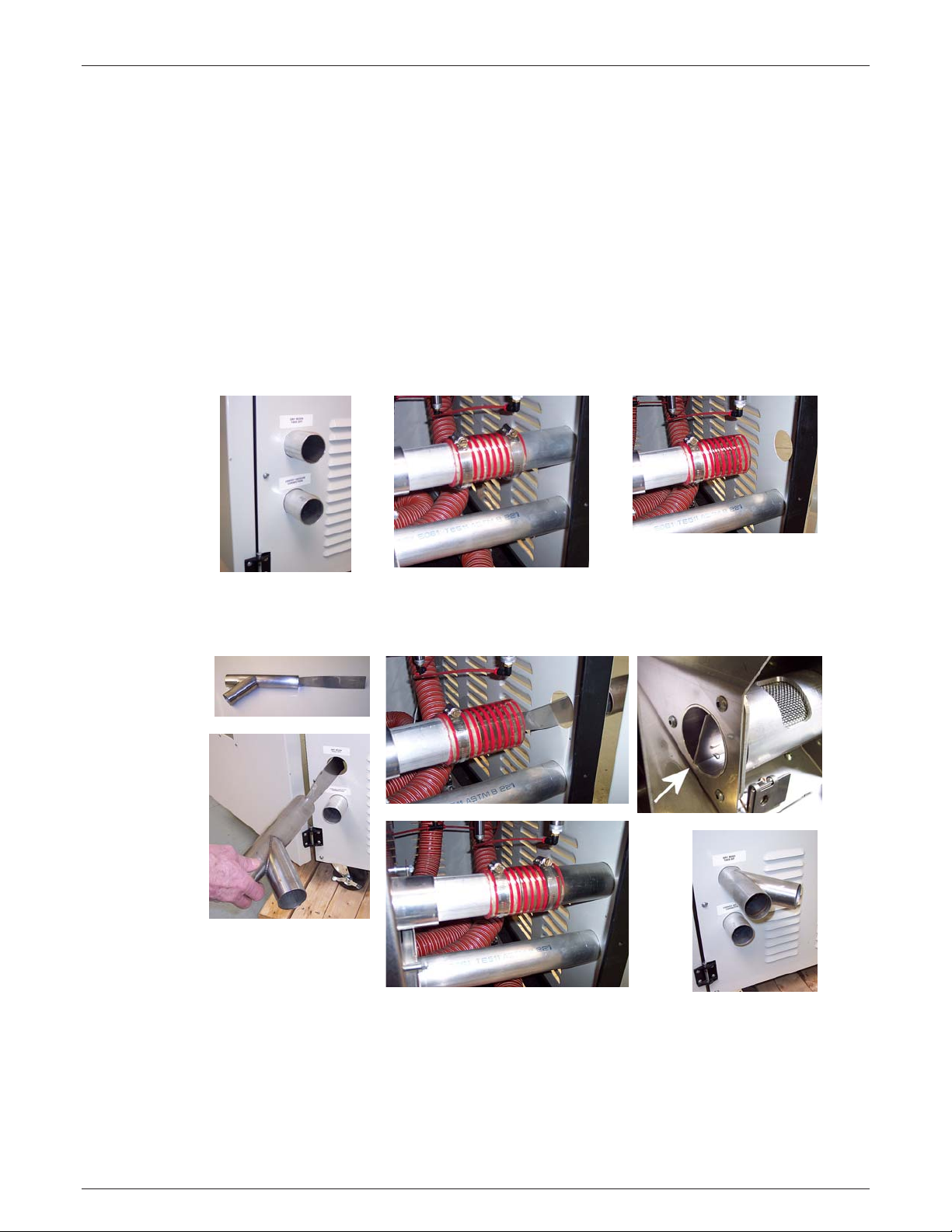

1. Open the front access door of the Dryer, loosen the hose clamp that secures the short

pipe labeled Dry Resi n Takeoff Pi pe ( top pipe). Remove the short stock pipe as shown

above.

2. Insert the “Y Resin Takeoff Pi pe” into the short connector hose and into the V ac uum

takeoff Assembl y (VT A ). Fitment may be tight, use a rubber mallet or block of wood to

gently tap the new “Y Resin Takeoff Pipe” into the Vacuum takeoff Assembly. The flange

of the Y Resin takeoff Pi pe shoul d c om e to t he end of the pipe wit hin the VTA.

CAUTION: Do Not stri k e a steel hammer directly on the Y Pipe as this may damage the

pipe.

Edition: Nov ember 5, 2010

19

LPD Dryer®

Maguire Products, Inc.

3.

Install the “Dual Conv ey

Receiver Selector Control

Box” below the air regulator.

You will have to drill four

holes in the panel of the

Dryer.

Caution: Remove the rear

panel of the dryer and

visually inspect to ensure

clearance befo re drilling

any holes in the cabinet

wall.

If you have been supplied a hole pattern, you may use the pattern, otherwise, center

punch the holes using the holes in the control box. Locati on of the up per left hole

should be approximately: On 200 Series Dryers - 2 inch in from the lef t edge of the

panel and 41 inches up fr om the bott om of t he panel. On 100 Series Dryers - 2 inch in

from the left edge of t he panel and 37 inc hes up fr om the bottom of t he panel.

4. Usi ng the supplied pipe clam p, secure the “Dual Convey Shifting V alv e” to the Convey

Vacuum Connection pipe located below the “Y” pipe (installed previously).

5. Remove the blowgun air hose from the ¼ inc h NPT “T ” fitti ng and install the new “T”

fitting as shown above. Re-install the blowgun facing out and t he Nyl on Quick Connect

facing down. Use Teflon thread tape to seal the threads. Connect a short lengt h of

nylon airli ne from the Nylon Quick Connect on the air supply down to the rear Nyl on

Quick Connect on the “Dual Convey Receiver Selector Control Box”. See image above

and image with Step 6.

20

Edition: Nov ember 5, 2010

LPD Dryer®

Maguire Products, Inc.

6. Route a nylon airline from t he top nylon quick

disconnect on the “D ual Convey Receiver Selector

Control Box” through the Dryer to the opposite side to

the “Dual Convey Shif ting Valve” as described below:

a. Insert on end of a long nylon airli ne in the front

nylon quick disconnect . This line will be run

though the Dryer. See im age to the right.

b. Route the nylon airli ne

up to the louver located to

the left of the air manifold

and run the line into the

lo uver.

e. Route the airline out

bottom louver to the “Dual

Convey Shifting Valve” as

pictured to the right.

f. Connect the nylon airl ine to the nylon quick disconnect on the

“Dual Convey Shifting Valve”. See image to the right.

c. With the back, upper panel

removed, rout e the airline along

with the existi ng air lines and

wires. Run the airline through

the existing wire loops to hold

the airline in place.

d. Route the airline down the

inside corner, through the

access hole. Route the

airline insi de the Dryer

towards the front and out t he

lower louver.

Edition: Nov ember 5, 2010

21

LPD Dryer®

Maguire Products, Inc.

7. Loc ated on the side of the “Dual Convey Receiv er Selector

Control Box” is a Conv ey Sensor cable. Connect that cable

to the Convey Sensor port located on the left side of the

Dryer’s controller.

8. Loc ated on the front of the “Dual Convey Receiver Selector

Control Box” is 2 ports for 2 Conv ey Sensor cables. A

Convey Sensor cable will run to each Maguire Receiver on

your process.

9. Run a m aterial convey line from each of the two outlets of

the Y tube at the Dry Resin takeoff por t to each of the two

Maguire Receivers on the process machines.

10. Run a Vac uum Convey Line from each of the Maguire

Receivers on the proc ess mac hines to the appropriate

Receiver Vacuum port on the Dual Convey Shifting Valve.

The assigned number (Rec eiver, Receiver 2) depends on

how you want to refer to and assign your rec eivers. Note:

Be sure that you run the BOTH the Convey S ensor cable

(for Receiver 1 and Receiver 2) and the Vacuum Convey

Lines to the same Receiver.

Usage: To supply material to a Maguire Receiver (Receiver 1, Receiver 2), turn the Receiver

Switch on the “Dual Conv ey Rec eiv er Sel ector Control Box” in the ON position. The “Dual

Convey Receiver S elec tor Control Box” will automatically supply material on demand t o the

Maguire Receivers.

PROCEED TO: OPERATION NEXT PAGE

22

Edition: Nov ember 5, 2010

LPD Dryer®

3 - Operation

3.1 - Standar d Operation

For a detailed descri ption of Dryer controls see “Controls Description” on page 29.

To help you identify your Dryer see: LPD Nomenclature / Order Code on page 90.

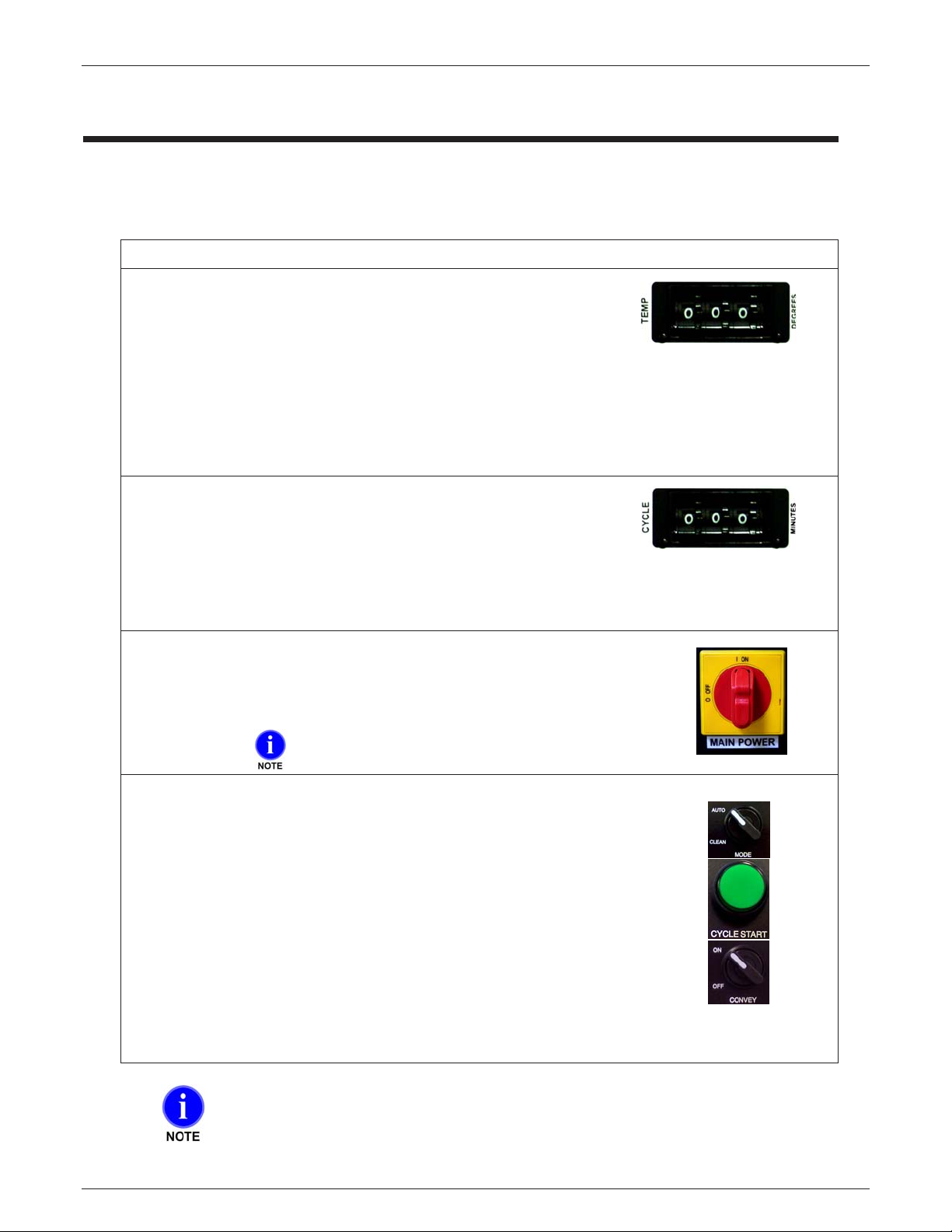

1. Fill the hopper on top of the dryer with material.

2. Set the TEMPERATURE - (TEMP thumbwheel switches)

USE THE SAME temperature setting recommended by the

resin manuf actur er for conventional desicc ant dry er s.

DO NOT exceed the manufactur er s recom m ended dr y ing temperature unl ess you are

sure the materi al will not soften and stick together.

Standard heat models can be set as high as 250 f (120c).

High heat models can be set to 300f (150c).

3. Set the CYCLE TIME - (CYCLE thumbwheel switc hes)

See RECOMMENDED CYCLE TIMES, next page.

These are suggested start ing points only. Run moisture t ests

to determine cor r ect c y cl e times, or submit your material to us for determinati on. See form on

page 87 for material testing.

Maguire Products, Inc.

4. OPERATOR STATION - Left Side

On the POWER box:

a. Turn MAIN POWER on. (RED switch)

On power up, the cani ster s will index to a starting

position based on the position when last shut down.

On the CONTROLLER:

b.

c.

d.

Turn MODE switch to AUTO.

Press CYCLE START.

Two timed cycles must be completed before material is

availabl e to be conv e y e d. When mat er ial is av ail a bl e, tur n

the CONVEY switch to the ON position (if applicable).

For a more indepth ex plaination of the operating sequence, please see Standard Operati ng

Sequence on page 25.

If you ever run material that does not require drying, set both Temperature and Cycle

time to 000. This keeps the heater off and allows indexing as required.

Edition: Nov ember 5, 2010

23

LPD Dryer®

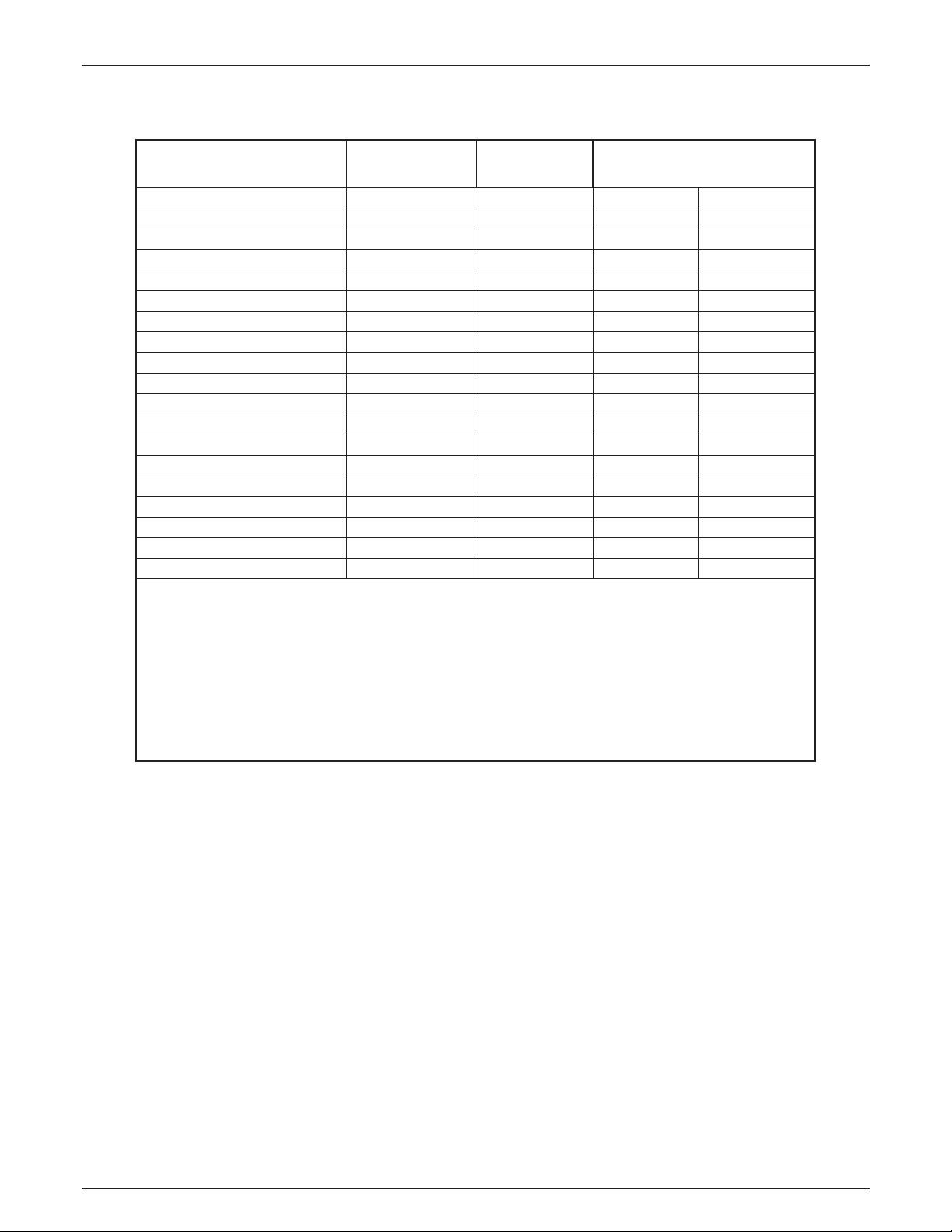

DRYING TEMPERATURE***

3.2 – Recommended Cycle Times

MATERIAL

FINAL

MOISTURE % *

CYCLE TIME

(MINUTES)**

Maguire Products, Inc.

ºC ºF

ABS

ABS/PC

LCP

PA

PBT

PC

PC/PBT

PEEK

PEI

PES

PET (Mold ing Grade)

PET (Preform, Extrusion)

PMMA (Acrylic)

POM (Acetal)

PPO

PPS

PUR

PSU

SAN

* Final moisture c ontent as recommended by the raw material manufacturer.

** Recommended cycle time is based on average initial moisture content. For high initial

moisture cont ent cycle time should be extended 5 minutes. When in doubt contact Maguire

Service.

0.10 20 - 25 80 - 85 180 – 190

0.02 25 - 30 100 210

0.02 20 - 50 150 300

0.20 - 0.10 20 - 30 80 - 85 180 – 190

0.02 20 - 25 120 250

0.02 20 - 25 125 250

0.02 20 - 25 125 250

0.20 - 0.10 25 - 30 150 300

0.02 30 - 40 150 300

0.05 - 0.02 25 - 30 150 300

0.010 30 - 35 150 300

0.005 30 - 35 150 300

0.02 - 0.04 30 85 185

0.20 - 0.10 25 80 - 110 180 – 230

0.02 25 100 - 120 210 – 250

0.02 25 150 300

0.02 25 125 - 140 260 – 280

0.02 25 - 30 150 300

0.20 - 0.10 20 - 40 80 180

*** Drying temperature as recommended by the material manufacturer.

Drying is accomplished when all material reaches the proper temperature, and is then

placed under s u fficient vacuum for a suffici e nt per i od o f time.

Measurement of moisture content of material, both prior to and after drying, is

accomplished by using a moisture analyzer such as one manufactured by Arizona

Instruments.

If you are not obtaining the results you want or if you would like us to test your material

to determine the optimal drying cycle time, please see form on page 87 for material

testing.

24

Edition: Nov ember 5, 2010

LPD Dryer®

3.3 – Standard Operating Sequence

This section will help you understand what the dryer is doi ng as i t runs.

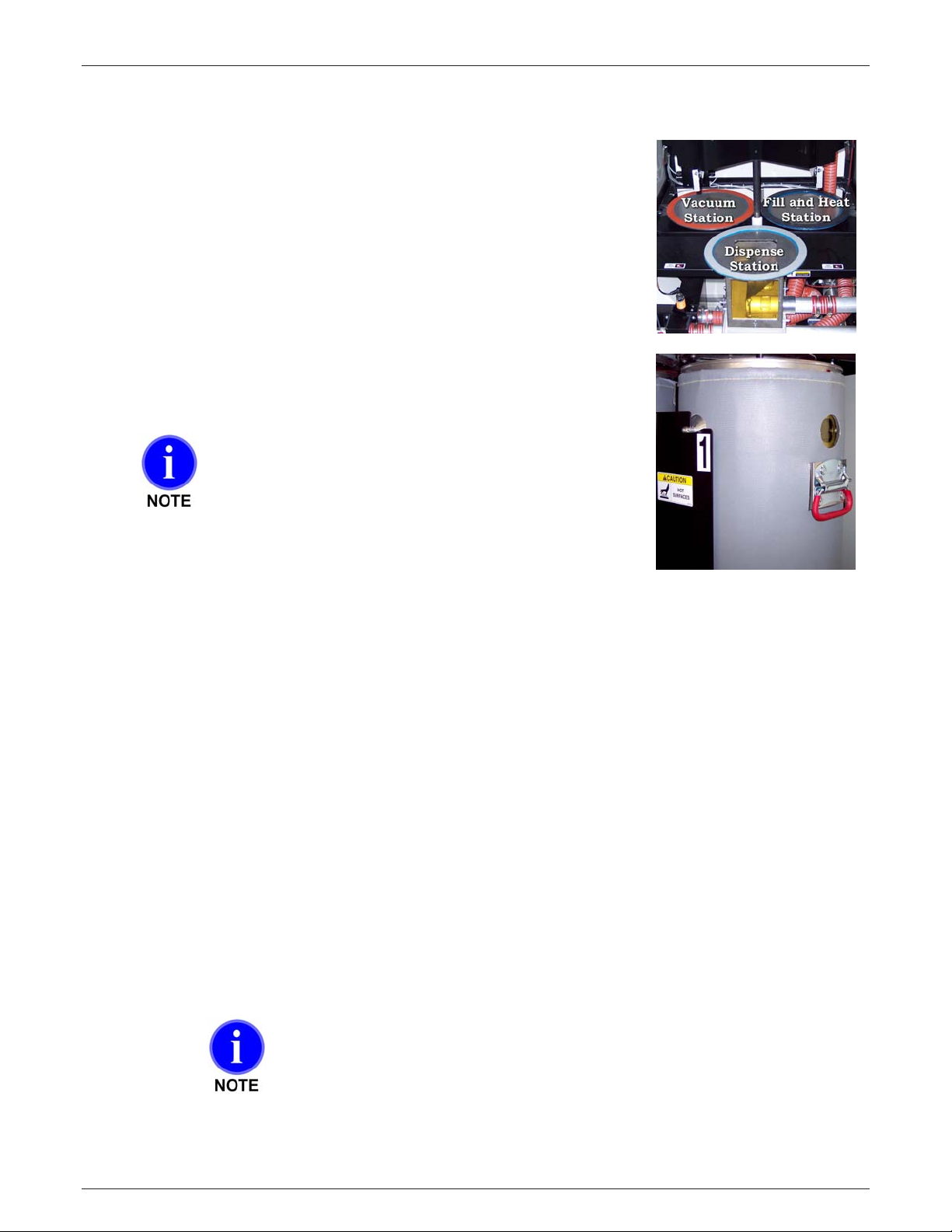

Inside the dryer encl osure are three identical m aterial cani ster s, whi c h

rotate through 3 st ations:

Fill and Heat Station (right rear)

•

Vacuum Station (left rear)

•

Dispense Station (front)

•

Each canister hangs i n one of t hr ee posi tions in the “Canister Hanger

Assembly”. These three posi tions are labeled 1,2 and 3. T he num ber

identifies the canisters position in t he assembly .

With the material in the hopper above the Fill and Heat station, press

CYCLE START to begin the sequence.

On power up, the cani ster s will index to a starting

position based on the position when last shut down.

"Operation" means the following actions occur:

1. The disks above and below each canister close.

2. The Blower turns on.

3. The vacuum generator turns on.

4. The air cylinder over the Disp ense Station extends to open the canister dispense valve located

inside the canister at the bottom, to deliver material to the process. If the bottom sensor was not

uncovered at the time of indexing, the fill valve will delay opening until the sensor becomes

uncovered.

5. The canister fill valv e ov er the Fill and Heat Station opens, filling the canister. A sensor located

under the Fill and Heat S t ation confirms the canister is in place before the fill valve will open.

6. The heater turns on.

7. With the opening of the Fill valve, the canister in the F ill and Heat Statio n begins to fill. Hot air

enters the canister to heat the material as it fills. The heati ng pr oc ess continues for the cycle time

set on the Cycle Time thumbwheel. At the same time, a vacuum is pulled on the canis ter in the

Vacuum Station.

8. After the cycle time elapses, the cycle ends and the canisters index count erclockwise to t he nex t

station. The heated material that was in the Fill and Heat Station has now moved to the

Vacuum Station. Here the vacuum dries the full charge of heated material.

The CYCLE TIMER only count s tim e when the heat ed air temper ature is within 20

degrees of target, and the vacuum has reached 25 inches. Therefor e, t he first

minute or so of each cycle does not count toward cycle time.

Maguire Products, Inc.

Edition: Nov ember 5, 2010

25

LPD Dryer®

9. After the cycle time elapses, the cycle ends and the canisters index counterclockwise again to the

next station. The dried m aterial that was in the Vacuum Station has now mov ed to t he

Dispense Station. Two cycles have passed and the dried material is ready for production.

From now on, indexing oc c ur s at the end of eac h cycl e time. This is the standard mode,

"advance on time". if you have sel ected the "advance when empty" opti on, then indexing occurs

only when the level sensor below the Di spense Station indi c ates the dispensing canister is

empty.

If you are using "advance when empty" option you have the ability to set a short fill time. If the time to use

the material in the canister is more then double the mini mu m cycle time set on the cycle time thu mbwheel,

we suggest you decrease the Fill time so that the canister does not hold so much material. Excessively long

cycle times may allow dried material to begin to re-absorb moisture.

Maguire Products, Inc.

3.4 – Operating Features/Options

Auto Start 22 - Allows for entry of a date/time to automatically start the dryer heating and vacuum cycle.

Aut o Stop

Material Alarm

Index Complete Alarm

Cycle Time Alarm

Convey Options

Convey Alarm

Advance Options Time/Empty

Dispense Valve Option s

Fill Valve Options

Hopper Fill Alarm

Key Functions - See the Keypad description of func tions on page 34 for more information.

See Star Functions on page 37 for more information.

24 - Allows for entry of a date/time to automatically stop the dry er heating and vacuum cycle.

See Star Functions on page 37 for more information.

33 - Alarm to alert an operator that dry material is ready to be conveyed after a cold start

of the dryer. See Star Functions on page 37 for more information.

34 – Alarm after every index and continue running. Thi s is int ended for lab

environment s where som eone has to m anually empty the canisters after each index. See Star

Functions on page 37 for mor e information.

36 – Alarm to alert an operat or that m aterial has run out before end of cycle.

39 – Material convey options are “Standard Convey”, “Convey and Purge” and “Convey

to Dryer”. See Star Functions on page 37 for more informati on.

40 - After initial fill ing of the Maguire receiver, the dryer will alarm if the Maguire receiver

conveying mat erial to your process does not fill on the 3rd attempt. See Star Functions on page

37 for more information.

44 - "Advance on Time" will adv anc e the canisters (index) when the cycl e timer

times out, even if canister is not empty. "Advance on Empty" will advance only after the canister

is empty. See Star Functi ons on page 37 for more information.

52 - Options for dispensing the front canister. Choose between “Enabled”, “Disabl ed”

and “Pulsed”. Enabled for normal operation, disable will not dispense, and pulsed will pulse the

dispense valve on and off when dispensing. See Star Functions on page 37 for more information.

53 - Options for filli ng the canister. Choose between “Enabled” and “D isabled”.

Enabled for normal operation, disable will not fill the canister automatically. See Star Functions on

page 37 for more information.

74 - When enabled, the Dryer alarms if the Hopper fails to fill withi n the time specified.

See Star Functions on page 37 for more information.

Empty key - Manually opens the bott om v alv e at t he “Dispense Station” to empty a canister.

Fill key - Manually opens the fill valve, above the “FILL and HEAT stati on”.

Convey Key – Manuall y shif t hot air flow v alv es to c onv ey mat eri al.

26

Edition: Nov ember 5, 2010

LPD Dryer®

Maguire Products, Inc.

3.4.1 – Convey-Only Mode

In this convey-only mode, the LPD dos not heat, pressurize, fill, or index. This mode will only

convey material to a Maguire ADR (Maguire Dryer Receiver).

To use this mode:

Remove the material hose from the dryer and insert into a container of material. A material

lance is recommended.

Set the temperature thumbwheel set to 000

Set the time thumbwheel to 999

Set the Convey Switch to ON.

Pressing the start button will activate this mode.

Press and hold the “Set Convey Time” button to set the convey time. When conveying starts,

immediately press the "convey time" button and hold until the desired level in the receiver is

reached; then release. This load time will be saved by the software.

Once started, the LPD will only process convey requests from the convey signal/sensor on the

ADR.

Exit convey-only mode, press the STOP button and reset the thumbwheels.

Auto-start and auto-stop functions will work, as well as pausing the mode by opening the door

(closing the door resumes where it left off).

If no convey signal is seen for 10 minutes the blower is turned off. The blower will be turned

back on before starting the next convey request.

Edition: Nov ember 5, 2010

27

LPD Dryer®

cycle. Canisters always wait until the canisters are empty, sensor uncovered.

3.5 – Changin g Col or s “On T he Fl y” U sin g th e Clean Mode

Canisters and surrounding parts may be hot. Use of gloves

is recommended.

To CHANGE COLORS without stopping production:

PLAN AHEAD!

If your canister s are f ull, you have at least ONE hour of material in the pipe li ne. So, you must plan far

enough ahead to allow time to consume this material. So....

ONE hour before the change is required:

1. S et the MODE switch to "CLEAN". In this mode, canisters DO NOT INDEX automatically.

2. S hut off your feed system and clean t he dr y er hopper and t he r ec eiver or blender supplying

material. Be sure to clear the fill valve area under the dryer hopper. The fill v alv e is accessible

and removable by r em ovi ng one bolt f r om the hopper base and rotating the hopper out of

position.

Perform a full clean out and colo r change up to this point, the fill point above the canister.

See section 4.13, Canister Removal / Cleaning on page 66 under the Maintenance and

Service section.

In the CLEAN mode CANISTERS DO NOT INDEX at the end of the cycle. The ALARM sounds

and the display says ( CLEAN ).

When the ALARM sounds:

1. P r ess "Al arm Silence" to preserve your sanity.

2. Remove, clean, and repl ac e the cani ster ; close door.

3. P r ess the INDE X button.

4. After Indexing occurs, begin the filling of the newly cleaned cani st er with the new color blend.

Repeat these 4 steps as each of the remaining canisters empt y.

After the final canister is cleaned:

1. Clear the conveying line t o the proc ess m ac hine.

2. B egin conveying the new color blend to the process.

In the CLEAN mode, canister s do not advance on the time out of the TIME

Maguire Products, Inc.

If the time exceeds double t he normal cycle time, the alarm will sound. Either

silence, or press advance if you are concerned that material may be picking

up moisture.

28

Edition: Nov ember 5, 2010

LPD Dryer®

3.6 – Controls Description

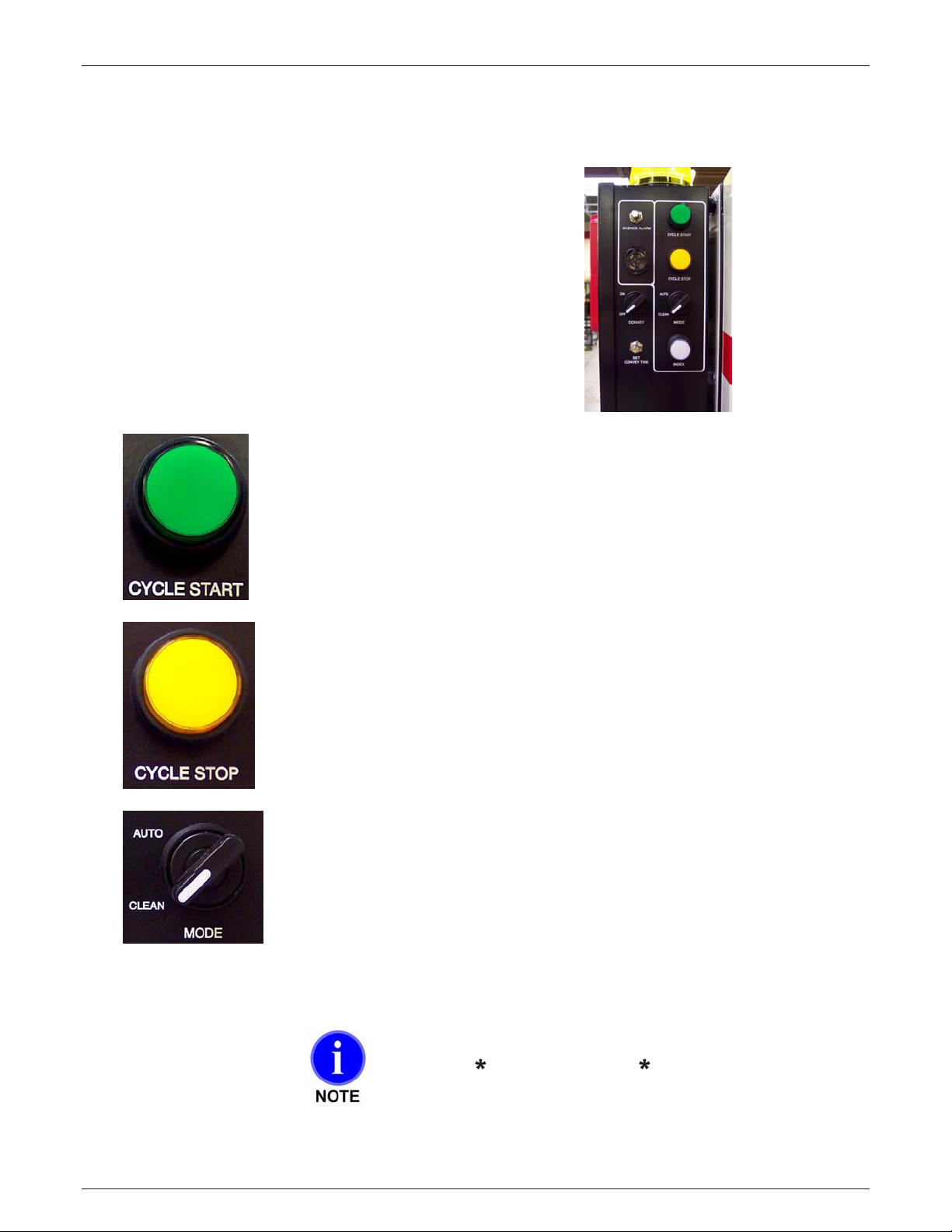

3.6.1 – Controller & Operator Station

Controller - Right Side

• CYCLE START

• CYCLE STOP

• MODE

• INDEX

• SILENCE ALAR M

• CONVEY: ON /OFF

• SET CONVEY TIME

CYCLE START

Press to START the cycle.

Lights when the unit is running automatically.

Maguire Products, Inc.

CYCLE STOP

Press to STOP the cycle.

Lights when the unit has been stopped by t he oper ator or has stopped

between cycles in the "clean out" mode.

MODE - AUTO / CLEAN

Select AUTO for norm al automatic indexing of canisters.

Select CLEAN to PREVENT AUTOMATIC INDEXING.

This is for COLOR CHANGES. INDEXING will NOT occur

automatic all y . Instead the A LA RM wil l sound, and the operator

knows to CLEAN OUT the empty cani ster for the next color.

With a CLEANED CANISTER in place, the door is closed and the

INDEX button is pressed to restart the cycle.

When in Clean Mode, the cycle will continue until the

time set in

information. Star Functions begin on page 37.

Edition: Nov ember 5, 2010

37 has elapsed. See 37 for more

29

LPD Dryer®

Maguire Products, Inc.

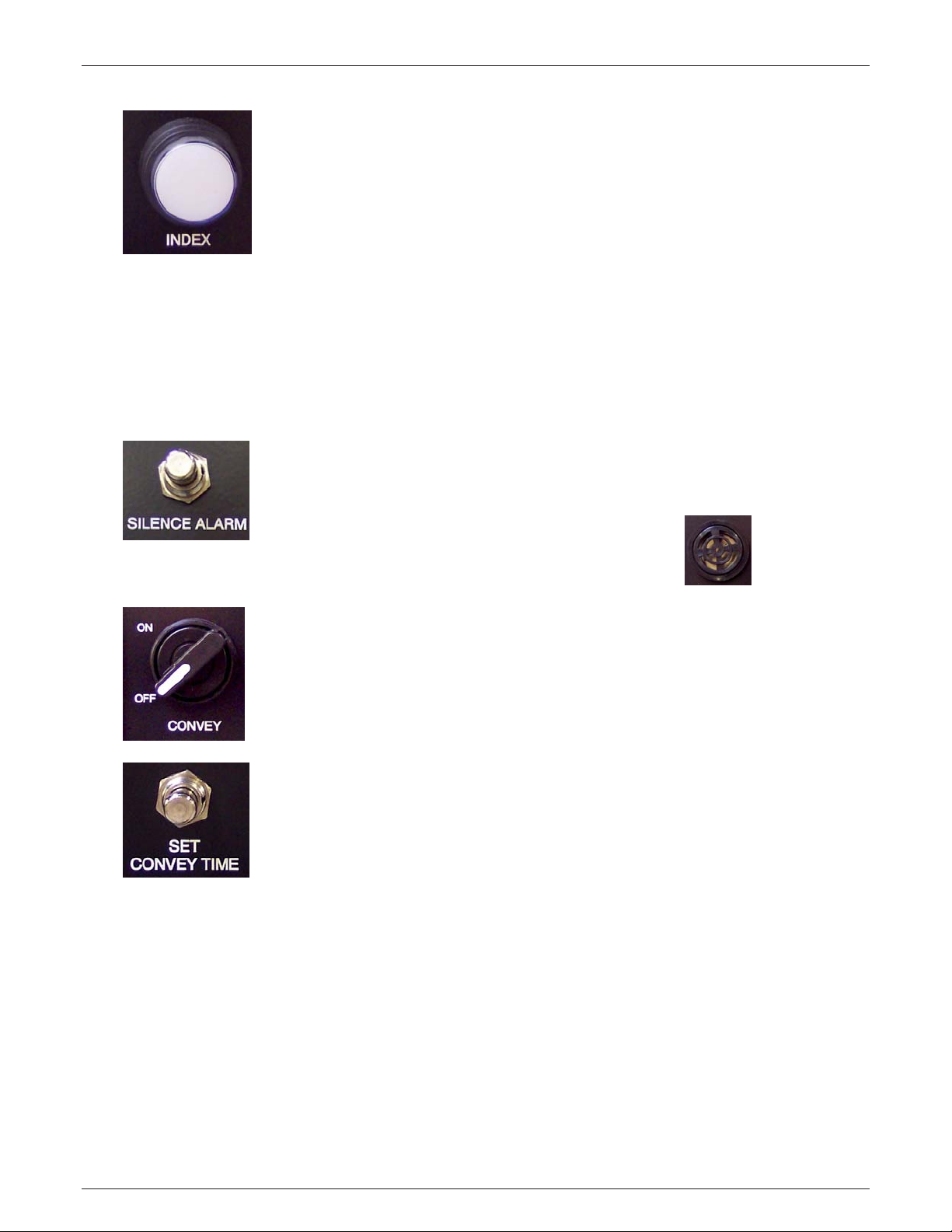

INDEX

Press to MANUALLY ADVANCE the canisters (with Dryer stopped).

In the CLEAN mode,

you must press the INDEX button t o adv anc e the canisters. The next

cycle starts as soon as INDEXING is complete.

In the AUTO mode,

the index button does not work unless you press CYCLE

STOP first. INDEX then serv es to m anually advance the canisters. After

INDEXING, press CYCLE START to start the next cycle.

When blinking in combination with the GREEN Cycle Start Button:

Cycle has stopped in t he "clean" mode, the operator must press the

INDEX button to advanc e the canisters after cleaning.

SILENCE ALARM

This button sil enc es the STROBE and BEEPER ALARMS, but does not

remedy the cause of t he alarm.

ALARM SPEAKER

CONVEY: ON/OF F

Operates only if a Maguir e v ac uum receiver is connected to the Dryer

controls. Turn ON to enable conveying of dried material to your process

machine.

SET CONVEY TIME

Operates only if we provi de a v ac uum receiver connected to the dryer

controls. Press and hold to set the convey time. When conveying star ts,

immediately pr ess the "convey time" button and hold until the desi r ed

level in the receiver is reached; then release. This load time will be

saved by the software. The minimum possible time, as well as initi al

default setti ng, is two seconds.

30

Edition: Nov ember 5, 2010

Loading...

Loading...