TM 300 Series

Via Paolo Uccello 4 - 20148 Milano

Tel +39 02 48 009 757 Fax +39 02 48 002 070 info@dspmindustria.it www.dspmindustria.it

In-Line Torque Transducers

User’s Manual

Purchase Record

Please record all model numbers and serial numbers of your

Magtrol equipment, along with the general purchase information.

The model number and serial number can be found on either

a silver identification plate or white label affixed to each unit.

Refer to these numbers whenever you communicate with a

Magtrol representative about this equipment.

Model Number: _____________________________

Serial Number: _____________________________

Purchase Date: _____________________________

Purchased From: _____________________________

While every precaution has been exercised in the compilation of this document to ensure

the accuracy of its contents, Magtrol, Inc./Magtrol SA assumes no responsibility for

errors or omissions. Additionally, no liability is assumed for any damages that may result

from the use of the information contained within this publication.

COPYRIGHT

Copyright ©2006–2008 Magtrol, Inc. All rights reserved.

Copying or reproduction of all or any part of the contents of this manual without the

express permission of Magtrol is strictly prohibited.

TRADEMARKS

LabVIEW™ is a trademark of National Instruments Corporation.

Microsoft® is a registered trademark of Microsoft Corporation.

National Instruments™ is a trademark of National Instruments Corporation.

Windows® is a registered trademark of Microsoft Corporation.

1st English Edition, rev. G– June 2011

Safety Precautions

Warning! in order to minimize risks, it is of utmost

importance to respect the current safety

standards When planning, configuring and

operating the torque measurement drive

train.

1. Make sure that all Magtrol electronic products are earth-grounded, to ensure personal safety

and proper operation.

2. Check line voltage before operating electronic equipment.

3. Make sure that all rotating parts are equipped with appropriate safety guards.

Note: Detailed information regarding safety guards can be found in Section

2.5 – Protective Systems.

4. Periodically check all connections and attachments.

5. Always wear protective glasses when working with rotating elements.

6. Never wear a necktie or baggy clothes when standing close to rotating elements.

7. Never stand too close or bend over the rotating drive chain.

i

Revisions to this Manual

The contents of this manual is subject to change without prior notice.

REVISION DATE

First English edition, revision G – June 2011

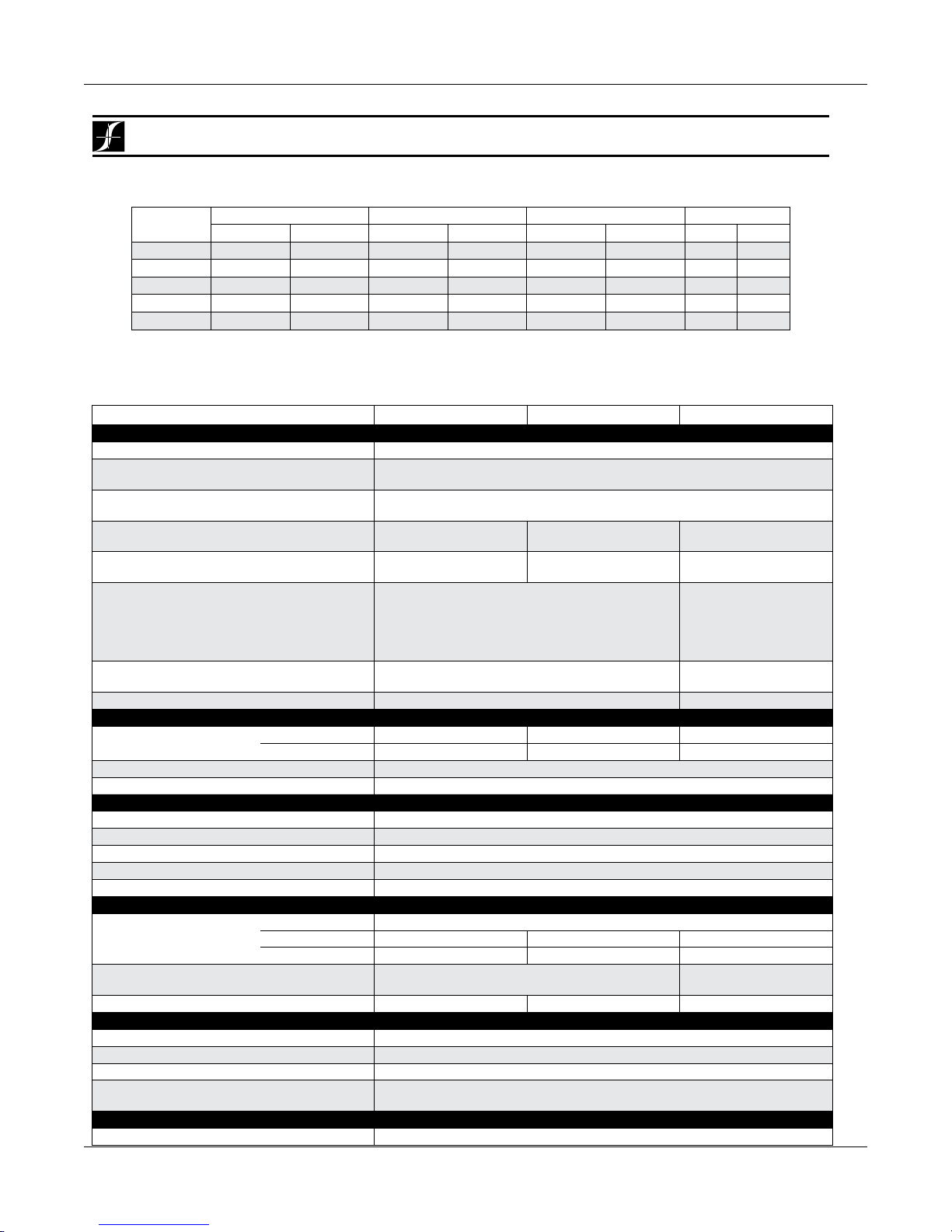

Date Edition Change Section(s)

20.06.11 1st Edition - rev. G Accuracy update for TMB 301 to 313

26.05.11 1st Edition - rev. F Overload limit updated

04.10.10 1st Edition - rev. E Added information regarding vertical installation of a TM/TMB 2.1.3

28.07.09 1st Edition - rev. D Added information regarding connection to an differential amplifier 2.7.3

10.09.08 1st Edition - rev. C Updated: Figure 2–3 Parastic Forces 2.2

12.18.07 1st Edition - rev. B New transducer model: TM 309

01.10.07 1st Edition - rev. A Added information regarding connection to non-Magtrol electronics. 2.7.3

1.3.1, 1.3.2

1.3.1, 1.3.2, 1.3.3

1.3.2, 2.2.1, 2.2.2

and 2.4.3

ii

Table of Contents

SAFETY PRECAUTIONS .........................................................................................................................I

REVISIONS TO THIS MANUAL ...............................................................................................................II

REVISION DATE .................................................................................................................................................................II

TABLE OF REVISIONS ......................................................................................................................................................II

TABLE OF CONTENTS ..........................................................................................................................III

TABLE OF FIGURES ........................................................................................................................................................ IV

PREFACE ................................................................................................................................................ V

PURPOSE OF THIS MANUAL ......................................................................................................................................... V

WHO SHOULD USE THIS MANUAL .............................................................................................................................. V

MANUAL ORGANIZATION ............................................................................................................................................. V

1. INTRODUCTION .................................................................................................................................1

1.1 GENERAL INFORMATION ........................................................................................................................................ 1

1.2 DESCRIPTION ............................................................................................................................................................. 1

1.3 DATA SHEETS ............................................................................................................................................................. 2

1.3.1 TM 301 – TM 308 ........................................................................................................................................... 2

1.3.2 TM 309 – TM 313 ........................................................................................................................................... 6

1.3.3 TM 314 – TM 317 ......................................................................................................................................... 12

2. INSTALLATION / CONFIGURATION ................................................................................................17

2.1 MOUNTING POSSIBILITIES ................................................................................................................................... 17

2.1.1 Suspended Installation .................................................................................................................................. 17

2.1.2 Supported Installation ................................................................................................................................... 17

2.1.3 TM/TMB in Vertical Installation ................................................................................................................... 18

2.2 PARASITIC FORCES ................................................................................................................................................. 18

2.2.1 Radial Forces (Bending) ............................................................................................................................... 19

2.2.2 Axial Forces (Thrust) .................................................................................................................................... 20

2.3 MEASURING SHAFT VIBRATIONS .......................................................................................................................21

2.3.1 Permitted Vibrations on Measuring Shaft ..................................................................................................... 21

2.3.2 Torque Signal Conditioning Electronic Circuit ............................................................................................. 23

2.4 MOUNTING LIMITS ................................................................................................................................................. 24

2.4.1 Dynamic Torque ............................................................................................................................................ 24

2.4.2 Natural Frequency of Drive Train ................................................................................................................. 24

2.4.3 Natural Measuring Shaft Torsional Frequency ............................................................................................. 26

2.4.4 Maximum Dynamic Amplitude..................................................................................................................... 27

2.5 PROTECTIVE SYSTEMS .......................................................................................................................................... 27

2.6 ELECTRONIC SIGNAL PROCESSING .................................................................................................................... 29

2.6.1 Model 3410 Torque Display .......................................................................................................................... 29

2.6.2 Model 6400 Torque Transducer Display ....................................................................................................... 30

2.6.3 Model DSP6001 Programmable Dynamometer Controller .......................................................................... 31

2.7 ELECTRICAL CONNECTIONS ............................................................................................................................... 32

2.7.1 Grounding ..................................................................................................................................................... 32

2.7.2 Connecting Cable .......................................................................................................................................... 33

2.7.3 Connection to Non-Magtrol Electronics ....................................................................................................... 34

3. OPERATING PRINCIPLES ...............................................................................................................36

3.1 TORQUE TRANSDUCER ARCHITECTURE .......................................................................................................... 36

iii

Table of Contents Magtrol TM Series In-Line Torque Transducers

3.1.1 Differential Transformer ............................................................................................................................... 37

3.2 SPEED CONDITIONING CHAIN ............................................................................................................................. 37

3.3 BUILT-IN SELF-TEST CIRCUIT .............................................................................................................................. 37

4. MAINTENANCE / REPAIR ................................................................................................................38

4.1 MAINTENANCE ........................................................................................................................................................ 38

4.2 REPAIR ....................................................................................................................................................................... 39

SERVICE INFORMATION ......................................................................................................................40

RETURNING MAGTROL EQUIPMENT FOR REPAIR AND/OR CALIBRATION ..................................................... 40

Returning Equipment to Magtrol, Inc. (United States) ............................................................................................... 40

Returning Equipment to Magtrol SA (Switzerland) .................................................................................................... 40

TABLE OF FIGURES

1. INTRODUCTION

Figure 1–1 TMB 313 In-Line Torque Transducer .......................................................................................................1

2. INSTALLATION / CONFIGURATION

Figure 2–1 Suspended Installation ...........................................................................................................................17

Figure 2–2 Supported Installation ............................................................................................................................18

Figure 2–3 Parasitic Forces ......................................................................................................................................18

Figure 2–4 Radial Displacement ..............................................................................................................................21

Figure 2–5 Vibratory Acceleration ............................................................................................................................22

Figure 2–6 SW1 – SW12 Micro-switches and Offset Adjustment Potentiometer ......................................................23

Figure 2–7 Simplified Drive Train Model .................................................................................................................24

Figure 2–8 Frequency Response Graph ....................................................................................................................25

Figure 2–9 Admissible Dynamic Load ......................................................................................................................27

Figure 2–10 Example of Protective System...............................................................................................................28

Figure 2–11 Model 3410 Torque Display .................................................................................................................29

Figure 2–12 PC-Based System Configuration with Model 3410 Display .................................................................29

Figure 2–13 Model 6400 Torque Transducer Display ..............................................................................................30

Figure 2–14 PC-Based System Configuration with Model 6400 Display .................................................................30

Figure 2–15 Model DSP6001 Programmable Dynamometer Controller .................................................................31

Figure 2–16 PC-Based System Configuration with Model DSP6001 Controller .....................................................31

Figure 2–17 Common Grounding .............................................................................................................................32

Figure 2–18 6-pin Souriau Connector Configuration ...............................................................................................33

Figure 2–19 14-pin Centronics Connector Configuration ........................................................................................33

Figure 2–20 Wiring Diagram for Connection to Non-Magtrol Electronics ..............................................................34

Figure 2-21 ER 107 Pin Configuration .....................................................................................................................35

3. OPERATING PRINCIPLES

Figure 3–1 TM Torque Transducer Principal Elements ............................................................................................36

iv

PURPOSE OF THIS MANUAL

This manual contains information required for the installation and general use of Magtrol’s TM

Series In-Line Torque Transducers. To achieve maximum capability and ensure proper use, please

read this manual in its entirety before operating the unit. Keep the manual in a safe place for quick

reference whenever a question should arise.

WHO SHOULD USE THIS MANUAL

This is written for operators installing a torque transducer as part of a test system that meausres the

torque on transmission chains. The operator is assumed to have the necessary technical training in

electronics and mechanical engineering enabling him to install the in-line torque transducer without

risk.

MANUAL ORGANIZATION

This section gives an overview of the structure of the manual and the information contained therein.

Some information has been deliberately repeated in different sections of the document to minimize

cross-referencing and to facilitate understanding through reiteration.

Preface

The structure of the manual is as follows:

Chapter 1 : INTRODUCTION – Contains the technical data sheets for Magtrol’s TM In-Line

Torque Transducers, which describe the units and provide detailed technical

characteristics.

Chapter 2 : INSTALLATION / CONFIGURATION – Provides information needed for the setup

of the TM Transducers in a test system, and their integration with Magtrol electronic

control units.

Chapter 3 : OPERATING PRINCIPLES – Information pertaining to theory of operation

including details about the transducer's architecture, speed conditioning chain and

built-in self-test circuit.

Chapter 4 : MAINTENANCE / REPAIR – Provides information on maintenance and repair

procedures, should the need arise.

v

Magtrol TM Series In-Line Torque TransducersPreface

CONVENTIONS USED IN THIS MANUAL

The following symbols and type styles may be used in this manual to highlight certain parts of the

text:

Note: This is intended to draw the operator’s attention to complementary

information or advice relating to the subject being treated. It

introduces information enabling the correct and optimal functioning

of the product to be obtained.

Caution : this is used to draw the operator's attention to information,

direCtives, proCedures, etC. whiCh, if ignored, may result in damage

being Caused to the material being used. the assoCiated text

desCribes the neCessary preCautions to take and the ConsequenCes

that may arise if the preCautions are ignored.

Warning! thi s in t roduces dire c t i ves, proced u r e s,

precautionary measures, etc. Which must Be

eXecuted or folloWed With the utmost care

and attention, otherWise the personal safety

of the operator or third parties may Be put

at risk. the reader must aBsolutely take note

of the accompanying teXt, and act upon it,

Before proceeding further.

vi

1. Introduction

1.1 GENERAL INFORMATION

The TM Series In-Line Torque Transducers represent the new generation of high-precision torque

sensors with integrated electronic processing circuitry developed by Magtrol. The TM Series

transducers are available in three versions: TMB, TM and TMHS. TMB for all standard applications,

TM for high-precision applications and TMHS for high-speed applications.

The TM 300 Series includes transducers with the following torque ratings: 0.1 N·m, 0.2 N·m, 0.5

N·m, 1 N·m, 2 N·m, 5 N·m, 10 N·m, 20 N·m, 50 N·m, 100 N·m, 200 N·m, 500 N·m, 1 000 N·m,

2 000 N·m, 5 000 N·m and 10 000 N·m.

The TM Series In-Line Transducers, together with Magtrol's New TF Series Torque Flange

Transducers, offer a wide range of torque measurement requirements for the most demanding

applications.

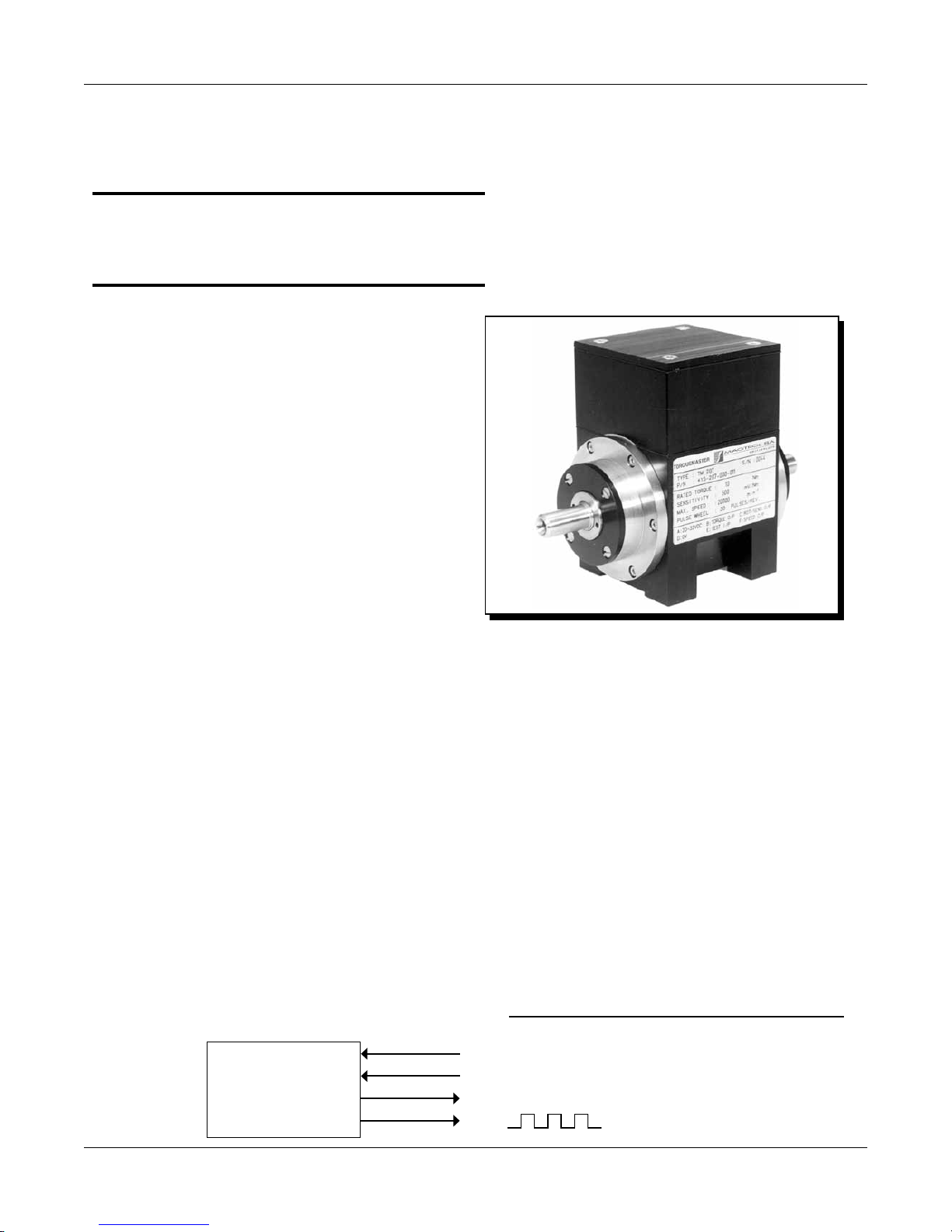

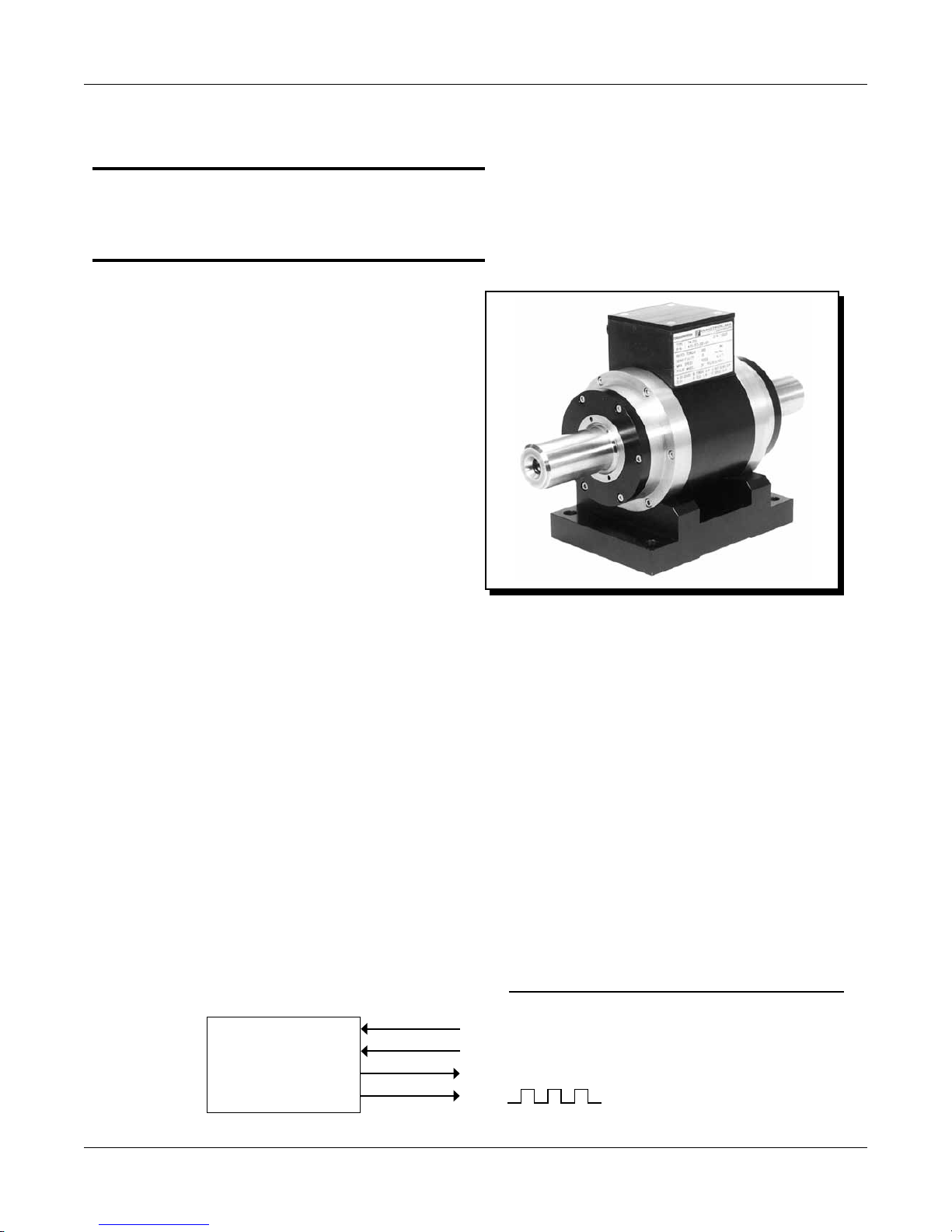

1.2 DESCRIPTION

All TM Series In-Line Torque Transducers consist of a torque measuring shaft and built-in signal

processing electronics. These elements, along with two sealed bearings having lifelong lubrication,

are all contained in an aluminium housing which also supports the shaft.

The upper part of the unit contains the built-in electronics. This part is sealed according to the

IP44 standard and offers protection against splashed water. A Souriau connector allows the torque

transducer to be connected to an external signal processing unit—such as the Magtrol 3410 Torque

Display—via a special cable assembly.

Figure 1–1 TMB 313 In-Line Torque Transducer

TM Torque Transducers perform the following main functions:

1. Measurement of static and dynamic torque and detection of torque direction.

2. Measurement of the shaft's rotational speed and detection of rotational direction.

3. Self-check.

The transducer's integrated electronic circuitry filters the torque signal and its built-in self-test

function checks the operation of the measuring chain. Each transducer also has a built-in temperature

compensation circuit. This assures that the accuracy of the measured torque is maintained regardless

of operating temperature.

1

1.3 DATA SHEETS

TM 301 – TM 308

Data Sheet

1.3.1 TM 301 – TM 308

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

TM 301 – TM 308

In-Line Torque Transducers

FEATURES

• Integrated Torque and Speed Conditioning

• Torque Range: 0.1 N·m to 20 N·m (0.07 lb·ft to 15 lb·ft)

• Accuracy: < 0.1%

• Overload Capacity: 200%

• Overload Limit: 400%

• High Speed Applications: up to 50,000 rpm

• Non-Contact (no sliprings)

• No Electronic Components in Rotation

• High Electrical Noise Immunity

• Single DC Power Supply: 20 VDC to 32 VDC

• Immediate Speed Detection

• Adjustable Torque Signal Frequency Limitation

• Built-in Test Function

• Stainless Steel Shaft

• EMC Susceptibility Conforms to European Standards

DESCRIPTION

Magtrol’s In-Line Torque Transducers provide extremely

accurate torque and speed measurement over a very broad range.

Each model has an integrated conditioning electronic module

providing a 0 to ±10 VDC torque output and an open collector

speed output. Magtrol Torque Transducers are very reliable,

providing high overload protection, excellent long term stability

and high noise immunity.

All transducer models employ our unique non-contact

differential transformer torque measuring technology. This

measuring technology offers many benefits, most notably that

no electronic components rotate during operation.

To provide customers with several price/performance options,

Magtrol offers three torque transducer models: basic accuracy

(TMB series), high accuracy (TM series) and high speed with

high accuracy (TMHS).

Each transducer consists of a hardened stainless steel shaft with

smooth shaft ends, an anodized aluminium housing containing

the guide bearings and

an electronic measurement conditioner.

Model TM 307

Torque Transducer

The integrated electronic circuit, supplied by single DC voltage,

provides torque and speed signals without any additional

amplifier. Connections are made by means of a 6-pole male

connector mounted on the housing, and fixed mounting is

enabled by mounting holes located on the transducer.

APPLICATIONS

TM, TMB and TMHS Series Torque Transducers provide

dynamic torque and speed measurement of:

• Propellers - aerospace, marine and helicopter

• Windshield wipers, electrical windows, starters,

generators and brakes in automobile industry

• Pumps - water and oil

• Reduction gears and gearboxes

• Clutches

• Motorized valves

• Drills, pneumatic tools and other machine tools

BASIC SYSTEM CONFIGURATION

TORQUE

TRANSDUCER

TM 301 – TM 308

Power Supply 20 to 32 VDC / 100 mA max.

Test

Torque 0 to ±10 VDC (max.)

Speed

2

Magtrol TM Series In-Line Torque Transducers

in series), max. 30 VDC, protected against short-circuits

Chapter 1 – Introduction

Specifications

TM 301 – TM 308

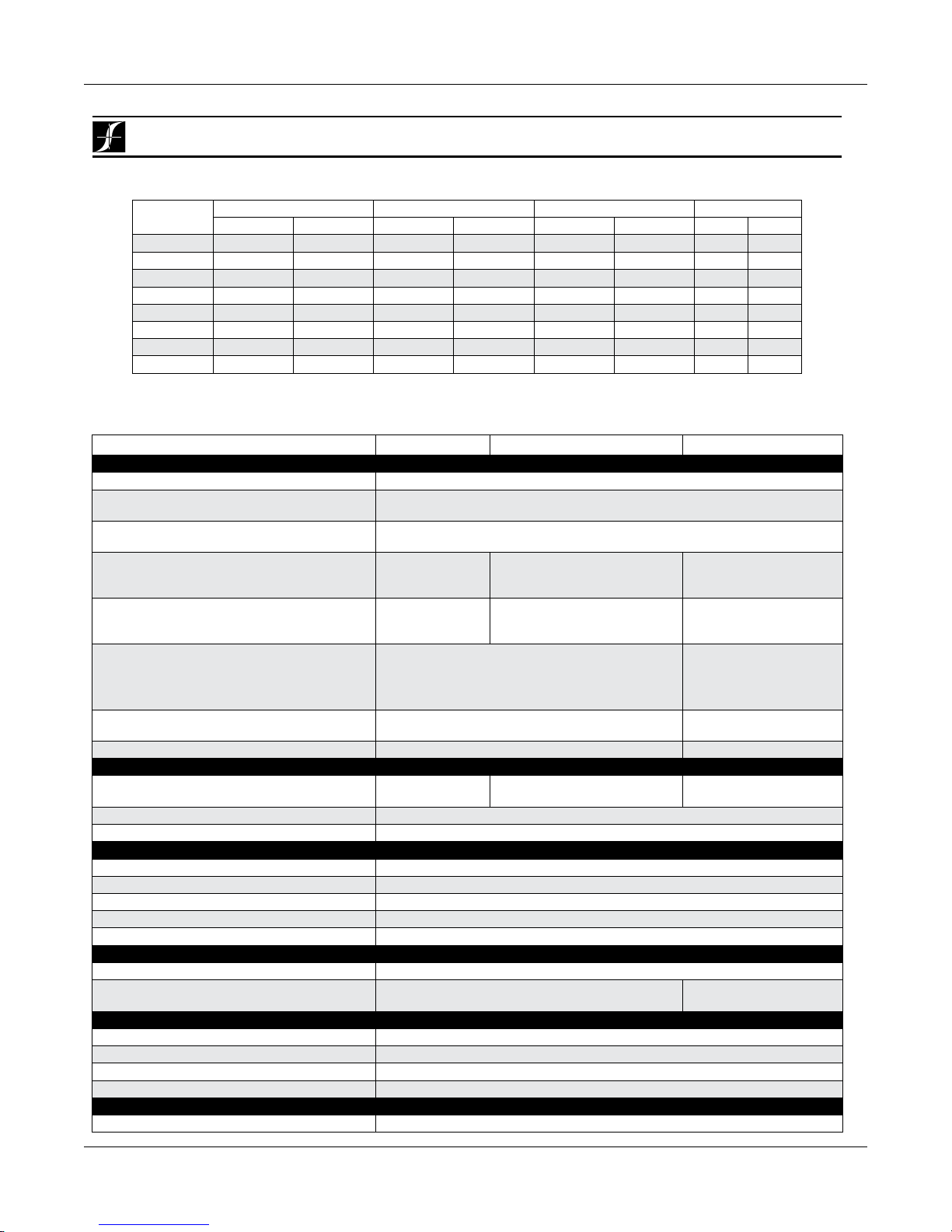

moDel ratings

The ratings in the following table apply to all Torque Transducer series (TM, TMHS and TMB).

Model

301 * 0.1 0.07 29 21 2.50 × 10

302 * 0.2 0.15 29 21 2.50 × 10

303 0.5 0.37 66 48 2.55 × 10

304 1 0.7 145 107 2.82 × 10

305 2 1.5 290 214 2.91 × 10

306 5 3.7 725 535 3.08 × 10

307 10 7.4 1450 1069 2.63 × 10

308 20 15 2900 2139 2.66 × 10

* Models 301 and 302 available in TM Series only.

Nominal Rated Torque Torsional Stiffness Moment of Inertia Weight

N·m lb·ft N·m/rad lb·ft/rad kg·m² lb·ft·s² kg lb

-5

-5

-5

-5

-5

-5

-5

-5

1.84 × 10

1.84 × 10

1.88 × 10

2.07 × 10

2.14 × 10

2.27 × 10

1.94 × 10

1.96 × 10

-5

-5

-5

-5

-5

-5

-5

-5

1.1 2.43

1.1 2.43

1.1 2.43

1.2 2.65

1.2 2.65

1.2 2.65

1.2 2.65

1.2 2.65

series ratings

The ratings in the following table apply to all standard Torque Transducer models 301–308, unless otherwise noted.

Stand ard Ve rsi on TM Se ries TMHS Ser ies TMB S eries

TORQUE MEASUREMENT

Rated Torque (RT) 0 to ±100% of RT

Maximum Dynamic Torque Peak Value

(Overload Capacity)

Maximum Dynamic Torque Without Damage

(Overload Limit)

Combined Error of Linearity and

Hysteresis

to 100% of RT

Combined Error of Linearity and

Hysteresis from 100% to 200% of RT

< ±0.1% of RT

(0.2% for TM 301)

< ±0.1% of

measured value

(0.2% for TM 301)

Temperature Influence on the Zero/

Sensitivity:

• In the Compensated Range +10 °C to +60 °C < ±0.1% of RT/10K < ±0.2% of RT/10K

• In the Compensated Range -25 °C to +80 °C < ±0.2% of RT/10K < ±0.4% of RT/10K

Influence of Speed on the Zero Torque

Signal

< ±0.01% of RT/1000 rpm < ±0.02% of RT/1000 rpm

Long-term Stability of Sensitivity < ±0.05% of RT/year < ±0.1% of RT/year

SPEED MEASUREMENT

Rated Range of Use 1 to 20,000 rpm

TMHS 303: 1 to 40,000 rpm

TMHS 304-308: 1 to 50,000 rpm

Number of Teeth 60 Z

Minimum Speed Detection 1 rpm

ENVIRONMENT

Storage Temperature Range -40 °C to +100 °C

Operating Temperature Range -40 °C to +85 °C

Mechanical Shock according to IEC 68.2.27 / Class D3

Vibration according to IEC 68.2.6 / Class D3

Protection Class IP 44

MECHANICAL CHARACTERISTICS

Shaft Ends smooth

Balancing Quality G1 according to ISO 1940

INPUT AND OUTPUT SIGNALS

Power Supply (max. voltage / current) 20 to 32 VDC / 100 mA

Torque Output (rated / max.) ±5 / ±10 VDC

Filter Cutoff (frequency) 5000, 2500, 1000, 500, 200, 100, 40, 20, 10, 5, 2, 1 Hz

Speed Output (frequency)

open collector (15 Ω

CONNECTORS

Counter Connector (female) optional (P/N 957.11.08.0081)

0 to ±200% of RT

0 to ±400% of RT

< ±0.1% of RT < ±0.1% of RT

< ±0.1% of

measured value

< ±0.15% of

measured value

1 to 6,000 rpm

G2.5 according to

ISO 1940

3

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

Specifications

operating principles

The measuring system, based on the principle of a variable,

torque-proportional transformer coupling, consists of two

concentric cylinders shrunk on the shaft on each side of the

shaft’s deformation zone, and two concentric coils attached

to the housing.

Both cylinders have a circularly disposed coinciding row of

slots and rotate with the shaft inside the coils. An alternating

current with the frequency of 20 kHz flows through the primary

coil. When no torque is applied, the slots on the two cylinders

fail to overlap. When torque is applied, the deformation zone

undergoes an angular deformation and the slots begin to

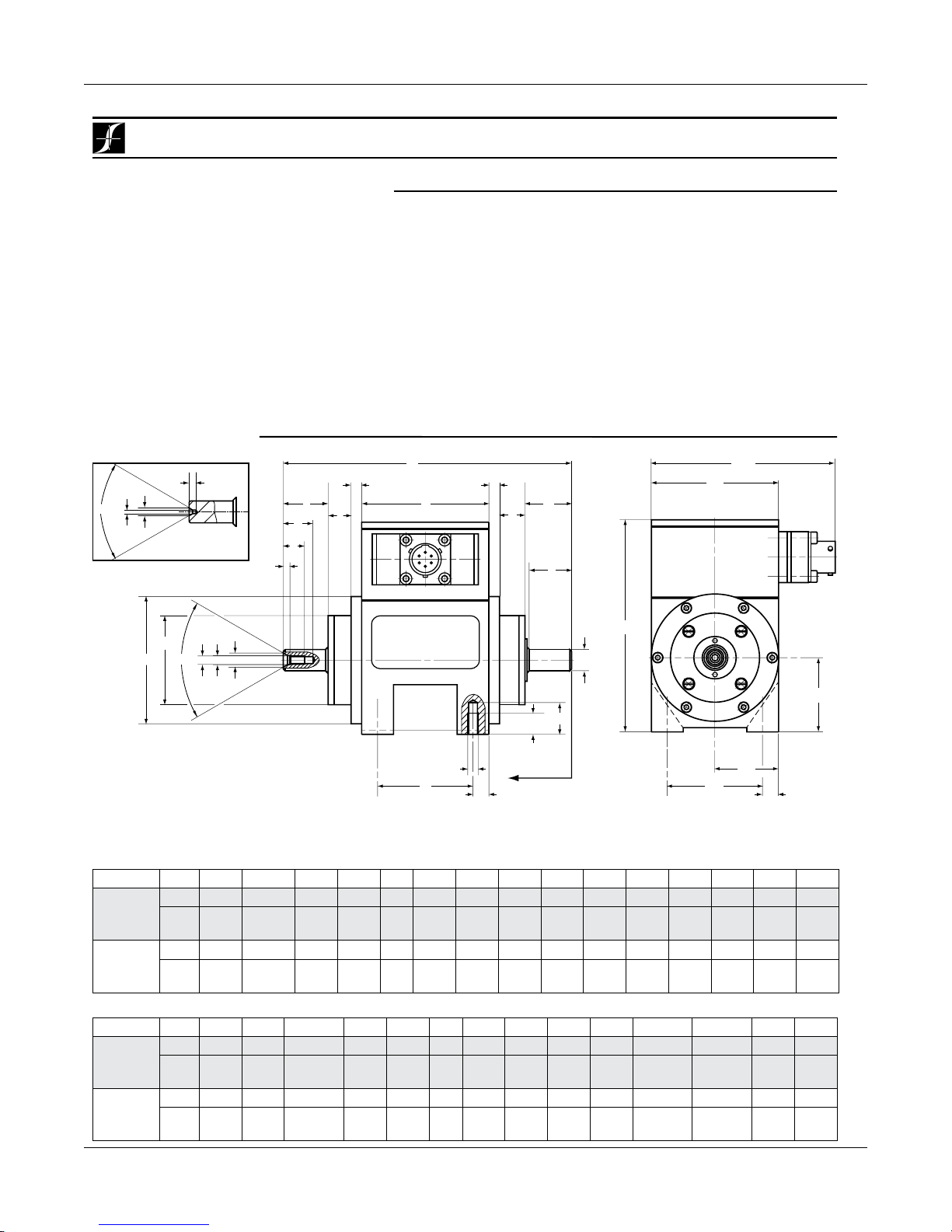

Dimensions

M CC

60°

D

C

TM 301–303

Shaft Detail

F

J

H

G

F

L P

K

N

A

BCF

E

D

TM 301 – TM 308

overlap. Thus a torque-proportional voltage is on the secondary

coil. The conditioning electronic circuit incorporated in the

transducer converts the voltage to a nominal torque signal

of 0 to ±5 VDC. A low-pass filter (Butterworth/2nd order),

adjustable from 5 kHz to 1 Hz, allows tuning of the torque

signal frequency limitation.

An optical sensor reads the speed on a toothed path machined

directly on the measuring system. The electronic conditioner

outputs a frequency signal proportional to the shaft rotational

speed. An active circuit compensates the zero and sensitivity

temperature drifts within a tolerance of 0.1% / 10 K.

N

R

Q

S

CAUTION!

C

E

B

A

D

60°

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

U

V

W

Y GG

Permitted

X FF

Axial Thrust

AA

T

EE

NOTE:

Dimensions are the same for every series (TM, TMHS, TMB).

Original dimensions are in Metric units. Dimensions converted to English have been rounded up to 3 or 4 decimal places.

Model units Ø A Ø B Ø C Ø D E F G H J K L M N P Q

60 42g6 2.12 0.1 --- 1.9 --- --- 13.2 7.8 5 114 60 5 9

2.362

1.6533

1.6526

0.083 0.004 --- 0.075 --- --- 0.520 0.307 0.197 4.488 2.362 0.197 0.354

60 42g6 6.7 4.3 M4 3.2 10 14 21.2 10.8 5 136 60 5 12

2.362

1.6533

1.6526

0.264 0.169 M4 0.126 0.394 0.551 0.835 0.425 0.197 5.354 2.362 0.197 0.472

301–303

304–308

mm

in

mm

in

Model units R S Ø T U V W X Y AA CC DD EE FF GG

0

(

-0.05

1.3779

1.3760

0

(

-0.05

1.3779

1.3760

)

30 7.5 45

1.181 0.295 1.772

)

30 ±0.02 7.5 45

1.1819

1.1803

0.295 1.772

301–303

304–308

mm

in

mm

in

14 12 6h6 15 10 M5 7.5 45 100 87 35

0.551 0.472

0.2362

0.2359

0.591 0.394 M5 0.295 1.772 3.937 3.425

22 20 10h6 15 10 M5 7.5 45 100 87 35

0.866 0.787

0.3937

0.3933

0.591 0.394 M5 0.295 1.772 3.937 3.425

DD

4

Magtrol TM Series In-Line Torque Transducers

Chapter 1 – Introduction

Specifications

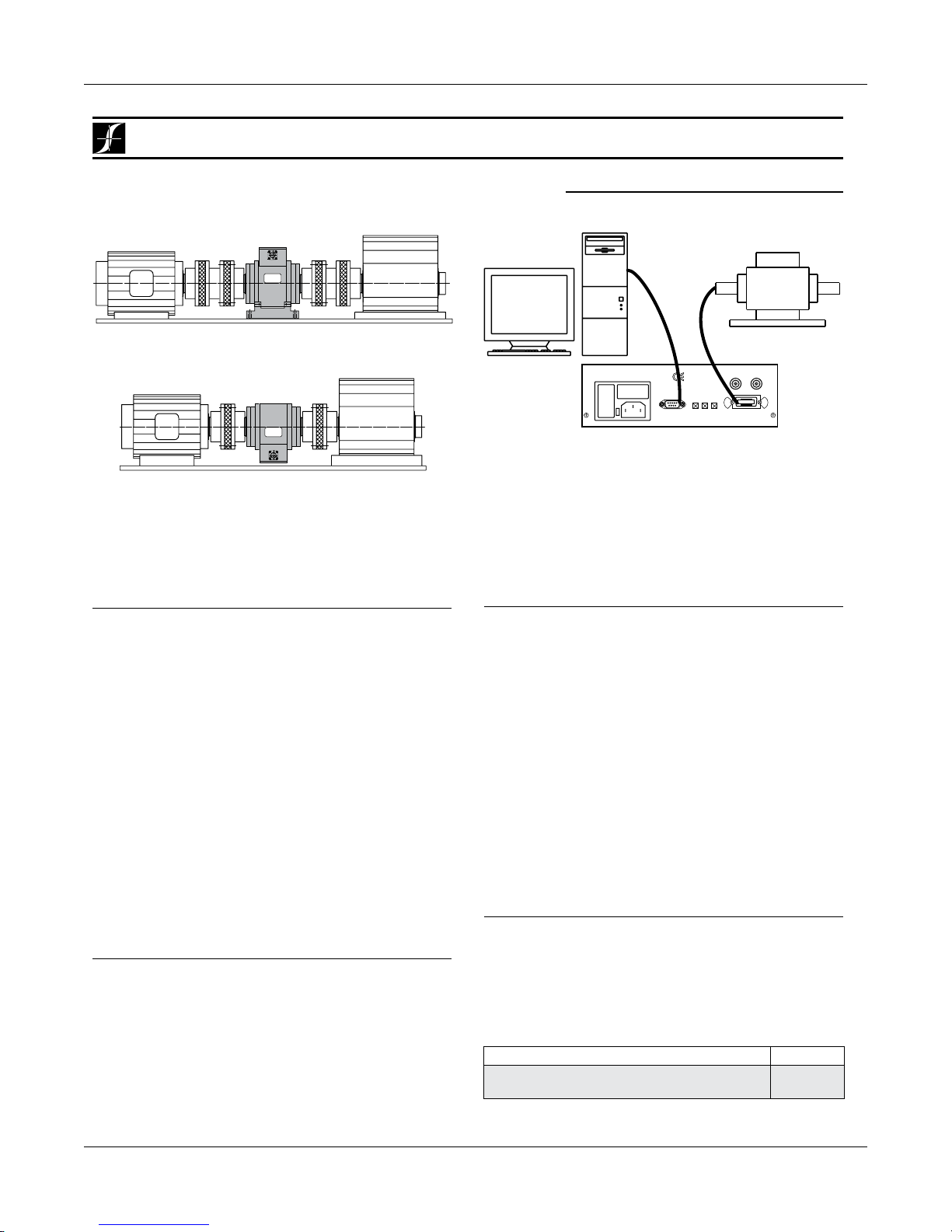

system options anD accessories

TM SERIES

Unit Under Test

Mandatory for high speed applications.

Unit Under Test

For low speed applications only, uses single-element

couplings to create a shorter drive train.

TORQUE TRANSDUCER

A

B C F

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

Coupling Coupling

Supported Installation

TM SERIES

TORQUE TRANSDUCER

MAINTENANCE.

PERFORMING

STOP SYSTEM BEFORE

IN OPERATION.

ROTATING PARTS

CAUTION!

D

Coupling Coupling

E

BCF

A

Suspended Installation

TM 301 – TM 308

PC

Torque 1.0

Software

RS-232C

MAGTROL

Model 3410

Torque Display

PC-Based System Configuration

Torque Transducer with Model 3410 Display

and Torque 1.0 Software

Torque Transducer

SYSTEM

SELECT

TARE

TRANSDUCER

TM Series

SPEED TORQUE

Couplings

When Magtrol TMB, TM and TMHS Series Torque Transducers

are to be mounted in a drive train, double-element miniature

couplings are the ideal complement, although single-element

couplings can be used for low speed applications. Several

manufacturers provide adequate couplings for both supported

and suspended drive train installations. The criteria for selecting

appropriate couplings for torque measurement is as follows:

• High torsional spring rate: Ensures a high torsional

stiffness and angular precision (should be greater than

three times the torque transducer stiffness)

• Clamping quality (should be self-centering and of

adequate strength)

• Speed range

• Balancing quality (according to speed range)

• Alignment capability

The higher the speed of the application, the more care is required in

selecting the coupling and assembling (alignment and balancing)

the drive train configuration. Your Magtrol sales representative

can assist you in choosing the right coupling for your transducer.

Torque Speed Box

Magtrol’s TSB Torque Speed Box allows data acquisition

from two torque transducers simultaneously and provides the

torque’s analog signal output and speed’s TTL signal output.

Torque Transducer Displays

Magtrol offers two different Torque Displays (Models 3410 and

6400) which supply power to any TM/TMHS/TMB Transducer

and display torque, speed and mechanical power. Features

include:

• Adjustable English, metric and SI torque units

• Large, easy-to-read vacuum fluorescent display

• Built-in self-diagnostic tests

• Overload indication

• Tare function

• RS-232 interface

• Torque and speed outputs

• Closed-box calibration

• Includes Magtrol Torque 1.0 Software

The Model 6400 Display has the following additional features:

• Pass/fail torque-speed-power testing capabilities

• RS-232 and IEEE-488 interface

• Auxiliary analog input

Torque 1.0 Software

Magtrol’s Torque 1.0 Software is an easy-to-use Windows

®

executable program, used to automatically collect torque, speed

and mechanical power data. The data can be printed, displayed

graphically or quickly saved as a Microsoft

®

Excel spreadsheet.

Standard features of Torque 1.0 include: peak torque capture,

multi-axes graphing, measured parameter vs. time, adjustable

sampling rates and polynomial curve fitting.

Accessories Model #

Torque Transducer Connector Cable (5/10/20

m)

ER 113

5

1.3.2 TM 309 – TM 313

TM 309 – TM 313

Data Sheet

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

TM 309 – TM 313

In-Line Torque Transducers

FEATURES

• Integrated Torque and Speed Conditioning

• Torque Rating: 20 N·m to 500 N·m (37 lb·ft to 369 lb·ft)

• Accuracy: < 0.1%

• Overload Capacity: 200%

• Overload Limit: 400%

• High Speed Applications: up to 32,000 rpm

• Non-Contact (no sliprings)

• No Electronic Components in Rotation

• High Electrical Noise Immunity

• Single DC Power Supply: 20 VDC to 32 VDC

• Immediate Speed Detection

• Adjustable Torque Signal Frequency Limitation

• Built-in Test Function

• Stainless Steel Shaft

• EMC Susceptibility Conforms to European Standards

DESCRIPTION

Magtrol’s In-Line Torque Transducers provide extremely

accurate torque and speed measurement over a very broad range.

Each model has an integrated conditioning electronic module

providing a 0 to ±10 VDC torque output and an open collector

speed output. Magtrol Torque Transducers are very reliable,

providing high overload protection, excellent long term stability

and high noise immunity.

All transducer models employ our unique non-contact

differential transformer torque measuring technology. This

measuring technology offers many benefits, most notably that

no electronic components rotate during operation.

To provide customers with several price/performance options,

Magtrol offers three torque transducer models: basic accuracy

(TMB series), high accuracy (TM series) and high speed with

high accuracy (TMHS).

Each transducer consists of a hardened stainless steel shaft with

smooth or splined shaft ends, an anodized aluminium housing

containing the guide bearings

conditioner. The integrated electronic circuit, supplied by single

and an electronic measurement

Model TM 313

Torque Transducer

DC voltage, provides torque and speed signals without any

additional amplifier. The transducer is a stand-alone measuring

chain. Connections are made by means of a 6-pole male

connector mounted on the housing. A removable aluminium

base—delivered as standard with TM and TMHS models, and

as an option for TMB transducers—allows fixed mounting of

the transducer.

APPLICATIONS

TM, TMB and TMHS Series Torque Transducers provide

dynamic torque and speed measurement of:

• Propellers - aerospace, marine and helicopter

• Windshield wipers, electrical windows, starters,

generators and brakes in automobile industry

• Pumps - water and oil

• Reduction gears and gearboxes

• Clutches

• Motorized valves

• Drills, pneumatic tools and other machine tools

BASIC SYSTEM CONFIGURATION

TORQUE

TRANSDUCER

TM 309 – TM 313

Power Supply 20 to 32 VDC / 100 mA max.

Test

Torque 0 to ±10 VDC (max.)

Speed

6

Magtrol TM Series In-Line Torque Transducers

Chapter 1 – Introduction

Specifications

TM 309 – TM 313

moDel ratings

The ratings in the following table apply to all Torque Transducer series (TM, TMHS and TMB).

Model

309 20 15 2.4 × 10

310 50 37 5.7 × 10

311 100 74 1.14 × 10

312 200 148 3.82 × 10

313 500 369 9.58 × 10

* The weight for TMB series transducers ordered without an optional foot mount is slightly lower.

Nominal Rated Torque Torsional Stiffness Moment of Inertia Weight *

N·m lb·ft N·m/rad lb·ft/rad kg·m² lb·ft·s² kg lb

3

1.770 × 1031.49 × 10-41.03 × 10

3

4.204 × 1031.52 × 10-41.12 × 10

4

8.408 × 1031.55 × 10-41.14 × 10

4

2.82 × 1044.85 × 10-43.57 × 10

4

7.07 × 1045.16 × 10-43.80 × 10

-4

-4

-4

-4

-4

2.5 5.51

2.5 5.51

2.5 5.51

4.1 9.04

4.4 9.70

series ratings

The ratings in the following table apply to all standard Torque Transducer models 309–313, except where specifically noted.

Stand ard Versi on TM S eri es TMHS Ser ies TMB S eri es

TORQUE MEASUREMENT

Rated Torque (RT) 0 to ±100% of RT

Maximum Dynamic Torque Peak Value

(Overload Capacity)

Maximum Dynamic Torque Without Damage

(Overload Limit)

Combined Error of Linearity and Hysteresis

to 100% of RT

Combined Error of Linearity and Hysteresis

from 100 to 200% of RT

Temperature Influence on the Zero/

Sensitivity:

• In the Compensated Range +10 °C to +60 °C < ±0.1% of RT/10K < ±0.2% of RT/10K

• In the Compensated Range -25 °C to +80 °C < ±0.2% of RT/10K < ±0.4% of RT/10K

Influence of Speed on the Zero Torque

Signal

Long-term Stability of Sensitivity < ±0.05% of RT/year < ±0.1% of RT/year

SPEED MEASUREMENT

Rated Range of Use

Number of Teeth 60 Z

Minimum Speed Detection 1 rpm

ENVIRONMENT

Storage Temperature Range -40 °C to +100 °C

Operating Temperature Range -40 °C to +85 °C

Mechanical Shock according to IEC 68.2.27 / Class D3

Vibration according to IEC 68.2.6 / Class D3

Protection Class IP 44

MECHANICAL CHARACTERISTICS

Shaft Ends

Balancing Quality G1 according to ISO 1940

Foot Support (Base Mount) included included optional

INPUT AND OUTPUT SIGNALS

Power Supply (max. voltage / current) 20 to 32 VDC / 100 mA

Torque Output (rated / max.) ±5 / ±10 VDC

Filter Cutoff (frequency) 5000, 2500, 1000, 500, 200, 100, 40, 20, 10, 5, 2, 1 Hz

Speed Output (frequency)

CONNECTORS

Counter Connector (female) optional (P/N 957.11.08.0081)

models 309–311 1 to 10,000 rpm 1 to 32,000 rpm 1 to 4,000 rpm

models 312–313 1 to 10,000 rpm 1 to 24,000 rpm 1 to 4,000 rpm

model 309 smooth

models 310–311 smooth smooth keyway

models 312–313 smooth or splined smooth or splined keyway

< ±0.1% of RT < ±0.1% of RT < ±0.1% of RT

< ±0.1% of

measured value

< ±0.01% of RT/1000 rpm < ±0.02% of RT/1000 rpm

open collector (15 Ω in series), max. 30 VDC, protected against short-

0 to ±200% of RT

0 to ±400% of RT

< ±0.1% of

measured value

circuits

< ±0.15% of

measured value

G2.5 according to ISO

1940

7

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

M CC

Dimensions

TM 309 – TM 313

operating principles

The measuring system, based on the principle of a variable, torqueproportional transformer coupling, consists of two concentric

cylinders shrunk on the shaft on each side of the shaft’s deformation

zone, and two concentric coils attached to the housing.

Both cylinders have a circularly disposed coinciding row of

slots and rotate with the shaft inside the coils. An alternating

current with the frequency of 20 kHz flows through the primary

coil. When no torque is applied, the slots on the two cylinders

fail to overlap. When torque is applied, the deformation zone

undergoes an angular deformation and the slots begin to overlap.

Thus a torque-proportional voltage is on the secondary coil. The

conditioning electronic circuit incorporated in the transducer

converts the voltage to a nominal torque signal of 0 to ±5 VDC. A

low-pass filter (Butterworth/2nd order), adjustable from 5 kHz to

1 Hz, allows tuning of the torque signal frequency limitation.

An optical sensor reads the speed on a toothed path machined

directly on the measuring system. The electronic conditioner

outputs a frequency signal proportional to the shaft rotational

speed. An active circuit compensates the zero and sensitivity

temperature drifts within a tolerance of 0.1% / 10 K.

transDucers with smooth shaFt

N

AA

DD

KK

LL

GG

HH

FF

EE

H

* Centering Seat

B

60°

A*

C

G

F

D

E

NOTE:

Original dimensions are in Metric units.

Dimensions converted to English have

been rounded up to 3 or 4 decimal places.

J

K

L

N

A

BCF

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

W

Y

Z

X

R

S

Q

T

Permitted

P

Axial Thrust

U

V

JJ

Model units Ø A Ø B Ø C Ø D E F G H J K L M N P Q R S Ø T

82g6 64 9.6 6.4 M6 5.0 16 21 26.2 16.8 86 170.4 60 20 15 26.4 25 20h6

309/X11

310/X11

311/X11

312/X11

313/X11

mm

in

mm

in

mm

in

mm

in

mm

in

3.2283

3.2270

3.2283

3.2270

3.2283

3.2270

3.7791

3.7782

3.7791

3.7782

2.52 0.378 0.252 M6 0.197 0.63 0.827 1.031 0.661 3.386 6.709 2.362 0.787 0.591 1.039 0.984

82g6 64 9.6 6.4 M6 5.0 16 21 36.2 16.8 86 190.4 60 20 15 36.4 35 20h6

2.52 0.378 0.252 M6 0.197 0.63 0.827 1.425 0.661 3.386 7.496 2.362 0.787 0.591 1.433 1.378

82g6 64 9.6 6.4 M6 5.0 16 21 41.2 16.8 86 200.4 60 20 15 41.4 40 20h6

2.52 0.378 0.252 M6 0.197 0.63 0.827 1.622 0.661 3.386 7.89 2.362 0.787 0.591 1.63 1.575

96g6 78 14.9 10.5 M10 7.5 22 30 46.4 22.8 91 228.0 60 25 21 46.8 45 30h6

3.071 0.587 0.413 M10 0.295 0.866 1.181 1.827 0.898 3.583 8.976 2.362 0.984 0.827 1.842 1.772

96g6 78 14.9 10.5 M10 7.5 22 30 56.4 22.8 91 248.0 60 25 21 56.8 55 30h6

3.071 0.587 0.413 M10 0.295 0.866 1.181 2.22 0.898 3.583 9.764 2.362 0.984 0.827 2.236 2.165

0.7874

0.7869

0.7874

0.7869

0.7874

0.7869

1.1811

1.1806

1.1811

1.1806

Model units U V W X Y Z AA CC DD EE FF GG HH Ø JJ KK LL

29.4 12 76 10 110 130 74 87

309/X11

310/X11

311/X11

312/X11

313/X11

mm

1.157 0.472 2.992 0.394 4.331 5.118 2.913 3.425

in

39.4 12 76 10 110 130 74 87

mm

in

mm

in

mm

in

mm

in

1.551 0.472 2.992 0.394 4.331 5.118 2.913 3.425

44.4 12 76 10 110 130 74 87

1.748 0.472 2.992 0.394 4.331 5.118 2.913 3.425

53.8 18 83 10 119 139 80 87

2.118 0.709 3.268 0.394 4.685 5.472 3.15 3.425

63.8 18 83 10 119 139 80 87

2.512 0.709 3.268 0.394 4.685 5.472 3.15 3.425

60

2.3622

2.3603

60

2.3622

2.3603

60

2.3622

2.3603

75

2.9527

2.9508

75

2.9527

2.9508

8

0

45±0.025 8 74 90±0.05 6.6 M5×10 20

(

)

-0.05

1.7726

0.315 2.913

1.7707

0

45±0.025 8 74 90±0.05 7 M5×10 20

(

)

-0.05

1.7726

0.315 2.913

1.7707

0

45±0.025 8 74 90±0.05 7 M5×10 20

(

)

-0.05

1.7726

0.315 2.913

1.7707

0

50±0.025 10 80 100±0.05 9 M6×8 26

(

)

-0.05

1.9695

0.394 3.15

1.9675

0

50±0.025 10 80 100±0.05 9 M6×8 26

(

)

-0.05

1.9695

0.394 3.15

1.9675

3.5453

0.260 M5×0.394 0.787

3.5413

3.5453

0.276 M5×0.394 0.787

3.5413

3.5453

0.276 M5×0.394 0.787

3.5413

3.9390

0.354 M6×0.315 1.024

3.9350

3.9390

0.354 M6×0.315 1.024

3.9350

Magtrol TM Series In-Line Torque Transducers

AA

DD

Chapter 1 – Introduction

Dimensions

TM 309 – TM 313

transDucers with splineD shaFt

M CC

KK

N

LL

GG

HH

EE

H

G

* Centering Seat

B

60°

A*

F

C

D

E

NOTE:

Original dimensions are in Metric

units. Dimensions converted to

English have been rounded up to

3 or 4 decimal places.

J

K

L

N

A

B C F

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

W

Y

Z

Q

P

X

R

S

MM

NN

PP

Permitted

Axial Thrust

U

V

QQ - Splines

according to

DIN 5481

January 1952

* Centering

Seat

RR*

T*

QQ

JJ

Model units Ø A Ø B Ø C Ø D E F G H J K L M N

96g6 78 14.9 10.5 M10 7.5 22 30 40.4 22.8 91 216 60

312/X21

313/X21

mm

in

mm

in

3.7791

3.7782

3.7791

3.7782

3.071 0.587 0.413 M10 0.295 0.866 1.181 1.591 0.898 3.583 8.504 2.362

96g6 78 14.9 10.5 M10 7.5 22 30 52.4 22.8 91 240 60

3.071 0.587 0.413 M10 0.295 0.866 1.181 2.063 0.898 3.583 9.449 2.362

FF

Model units P Q R S Ø T U V W X Y Z AA CC

312/X21

313/X21

mm

in

mm

in

25 21 40.8 39 22h6 47.8 18 83 10 119 139 80 87

0.984 0.827 1.606 1.535

0.8661

0.8656

1.882 0.709 3.268 0.394 4.685 5.472 3.15 3.425

25 21 52.8 51 22h6 59.8 18 83 10 119 139 80 87

0.984 0.827 2.079 2.008

0.8661

0.8656

2.354 0.709 3.268 0.394 4.685 5.472 3.15 3.425

Model units DD EE FF GG HH Ø JJ KK LL MM NN PP QQ Ø RR

0

312/X21

313/X21

mm

in

mm

in

75

75

50±0.025 10 80 100±0.05 9 M6×8 26 35 24 4 26×30 31h6

(

)

-0.05

2.9527

2.9508

0

(

-0.05

2.9527

2.9508

1.9695

1.9675

50±0.025 10 80 100±0.05 9 M6×8 26 47 36 4 26×30 31h6

)

1.9695

1.9675

0.394 3.15

0.394 3.15

3.9390

3.9350

3.9390

3.9350

0.354 M6×0.315 1.024 1.378 0.945 0.157 26×30

0.354 M6×0.315 1.024 1.850 1.417 0.157 26×30

options

Flanges

Flanges are optional for torque transducers with splined shaft

ends. Flange drawing is available on request.

Description Model P/N

Flange for Model 312/X21 FTM 212 415-212-960-011

Flange for Model 313/X21 FTM 213 415-213-960-011

1.2205

1.2198

1.2205

1.2198

9

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

AA

Di mensions

TM 309 – TM 313

tmB transDucers with Keyway

M CC

N

UU

SS

KK

LL

* Centering Seat

A*

NOTE:

J

H

G

F

C

D

B

60°

E

K

L

N

A

BCF

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

W

Q

P

R

S

BB

Permitted

Axial Thrust

T

Original dimensions are in Metric units. Dimensions converted to

English have been rounded up to 3 or 4 decimal places.

Model units Ø A Ø B Ø C Ø D E F G H J K L M P

82g6 64 9.6 6.4 M6 5.0 16 21 36.2 16.8 86 190.4 20

310/431

311/431

312/431

313/431

mm

3.2283

in

3.2270

82g6 64 9.6 6.4 M6 5.0 16 21 41.2 16.8 86 200.4 20

mm

3.2283

in

3.2270

96g6 78 14.9 10.5 M10 7.5 22 30 46.4 22.8 91 228.0 25

mm

3.7791

in

3.7782

96g6 78 14.9 10.5 M10 7.5 22 30 56.4 22.8 91 248.0 25

mm

3.7791

in

3.7782

2.52 0.378 0.252 M6 0.197 0.63 0.827 1.425 0.661 3.386 7.496 0.787

2.52 0.378 0.252 M6 0.197 0.63 0.827 1.622 0.661 3.386 7.89 0.787

3.071 0.587 0.413 M10 0.295 0.866 1.181 1.827 0.898 3.583 8.976 0.984

3.071 0.587 0.413 M10 0.295 0.866 1.181 2.22 0.898 3.583 9.764 0.984

Model units N Q R S Ø T W AA BB CC KK LL SS UU

310/431

311/431

312/431

313/431

mm

mm

mm

mm

60 15 36.4 35 20h6 76 74 32 87 M5×10 20 25 6h9

2.362 0.591 1.433 1.378

in

0.7874

0.7869

2.992 2.913 1.26 3.425 M5×0.394 0.787 0.984

60 15 41.4 40 20h6 76 74 37 87 M5×10 20 25 6h9

2.362 0.591 1.63 1.575

in

0.7874

0.7869

2.992 2.913 1.457 3.425 M5×0.394 0.787 0.984

60 21 46.8 45 30h6 83 80 42 87 M6×8 26 36 8h9

2.362 0.827 1.842 1.772

in

1.1811

1.1806

3.268 3.15 1.653 3.425 M6×0.315 1.024 1.417

60 21 56.8 55 30h6 83 80 52 87 M6×8 26 36 8h9

2.362 0.827 2.236 2.165

in

1.1811

1.1806

3.268 3.15 2.047 3.425 M6×0.315 1.024 1.417

options

Foot Mount

For foot mount dimensions, ref er to U–Z and DD– JJ

dimensions of the smooth shaft transducer.

5

Description Model P/N

Foot mount for models 310–311 PTM 310 415-309-950-011

Foot mount for models 312–313 PTM 312 415-312-950-011

10

0.2362

0.2350

0.2362

0.2350

0.3150

0.3135

0.3150

0.3135

Magtrol TM Series In-Line Torque Transducers

TM SERIES

Chapter 1 – Introduction

System Options

system options anD accessories

Unit Under Test

Mandatory for high speed applications.

Unit Under Test

For low speed applications only, uses single-element

couplings to create a shorter drive train.

Couplings

When Magtrol TMB, TM and TMHS Series Torque Transducers

are to be mounted in a drive train, double-element miniature

couplings are the ideal complement, although single-element

couplings can be used for low speed applications. Several

manufacturers provide adequate couplings for both supported

and suspended drive train installations. The criteria for selecting

appropriate couplings for torque measurement is as follows:

• High torsional spring rate: Ensures high torsional

stiffness & angular precision (should be > 3 times the

torque transducer stiffness)

• Clamping quality (should be self-centering & of

adequate strength)

• Speed range

• Balancing quality (according to speed range)

• Alignment capability

The higher the speed of the application, the more care is required in

selecting the coupling and assembling (alignment and balancing)

the drive train configuration. Your Magtrol sales representative

can assist you in choosing the right coupling for your transducer.

Torque Speed Box

Magtrol’s TSB Torque Speed Box allows data acquisition

from two torque transducers simultaneously and provides the

torque’s analog signal output and speed’s TTL signal output.

TORQUE TRANSDUCER

A

B C F

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

Coupling Coupling

Supported Installation

TM SERIES

TORQUE TRANSDUCER

MAINTENANCE.

PERFORMING

STOP SYSTEM BEFORE

IN OPERATION.

ROTATING PARTS

CAUTION!

D

Coupling Coupling

E

BCF

A

Suspended Installation

TM 309 – TM 313

PC

Torque 1.0

Software

TM Series

Torque Transducer

SPEED TORQUE

RS-232C

SYSTEM

SELECT

TARE

MAGTROL

Model 3410

Torque Display

PC-Based System Configuration

Torque Transducer with Model 3410 Display

and Torque 1.0 Software

Torque Transducer Displays

Magtrol offers two different Torque Displays (Models 3410 and

6400) which supply power to any TM/TMHS/TMB Transducer

and display torque, speed and mechanical power. Features

include:

• Adjustable English, metric and SI torque units

• Large, easy-to-read vacuum fluorescent display

• Built-in self-diagnostic tests

• Overload indication

• Tare function

• RS-232 interface

• Torque and speed outputs

• Closed-box calibration

• Includes Magtrol Torque 1.0 Software

The Model 6400 Display has the following additional features:

• Pass/fail torque-speed-power testing capabilities

• RS-232 and IEEE-488 interface

• Auxiliary analog input

Torque 1.0 Software

Magtrol’s Torque 1.0 Software is an easy-to-use Windows

executable program, used to automatically collect torque, speed

and mechanical power data. The data can be printed, displayed

graphically or quickly saved as a Microsoft

Standard features of Torque 1.0 include: peak torque capture,

multi-axes graphing, measured parameter vs. time, adjustable

sampling rates and polynomial curve fitting.

TRANSDUCER

®

Excel spreadsheet.

®

Accessories Model #

Torque Transducer Connector Cable (5/10/20

m)

11

ER 113

1.3.3 TM 314 – TM 317

TM 314 – TM 317

Data Sheet

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

TM 314 – TM 317

In-Line Torque Transducers

FEATURES

• Integrated Torque and Speed Conditioning

• Torque Rating: 1000 to 10,000 N·m (737 to 7375 lb·ft)

• Accuracy: < 0.1% (depending on model)

• Overload Capacity: 200%

• Overload Limit: 400% (TM 317 up to 280%)

• High Speed Applications: up to 16,000 rpm

• Non-Contact (no sliprings)

• No Electronic Components in Rotation

• High Electrical Noise Immunity

• Single DC Power Supply: 20 VDC to 32 VDC

• Immediate Speed Detection

• Adjustable Torque Signal Frequency Limitation

• Built-in Test Function

• Stainless Steel Shaft

• EMC Susceptibility Conforms to European Standards

DESCRIPTION

Magtrol’s In-Line Torque Transducers provide extremely

accurate torque and speed measurement over a very broad range.

Each model has an integrated conditioning electronic module

providing a 0 to ±10 VDC torque output and an open collector

speed output. Magtrol Torque Transducers are very reliable,

providing high overload protection, excellent long term stability

and high noise immunity.

All transducer models employ our unique non-contact

differential transformer torque measuring technology. This

measuring technology offers many benefits, most notably that

no electronic components rotate during operation.

To provide customers with several price/performance options,

Magtrol offers two torque transducer models: high accuracy

(TM series) and high speed with high accuracy (TMHS).

Each transducer consists of a hardened stainless steel shaft

with smooth or splined shaft ends, an anodized aluminium

housing containing the

measurement conditioner. The integrated electronic circuit,

guide bearings and an electronic

Model TM 316

Torque Transducer

supplied by single DC voltage, provides torque and speed

signals without any additional amplifier. The transducer is

a stand-alone measuring chain. Connections are made by

means of a 6-pole male connector mounted on the housing.

A removable aluminium base, delivered as standard, allows

fixed mounting of the transducer.

APPLICATIONS

TM and TMHS Series Torque Transducers provide dynamic

torque and speed measurement of:

• Propellers - aerospace, marine and helicopter

• Windshield wipers, electrical windows, starters,

generators and brakes in automobile industry

• Pumps - water and oil

• Reduction gears and gearboxes

• Clutches

• Motorized valves

• Drills, pneumatic tools and other machine tools

BASIC SYSTEM CONFIGURATION

TORQUE

TRANSDUCER

TM 314 – TM 317

Power Supply 20 to 32 VDC / 100 mA max.

Test

Torque 0 to ±10 VDC (max.)

Speed

12

Magtrol TM Series In-Line Torque Transducers

Chapter 1 – Introduction

Specifications

TM 314 – TM 317

moDel ratings

The ratings in the following table apply to both Torque Transducer series (TM and TMHS).

Model

314 / X21

314 / X31

315 / X21

315 / X31

316 / X21

317 / X21

Nominal Rated Torque Torsional Stiffness Moment of Inertia Weight

N·m lb·ft N·m/rad lb·ft/rad kg·m² lb·ft·s² kg lb

1,000 737 3.28 × 10

2,000 1,475 6.56 × 10

5,000 3,687 1.94 × 10

10,000 7,375 2.26 × 10

5

2.419 × 1063.01 × 10-32.21 × 10

5

4.838 × 1063.30 × 10-32.43 × 10

6

1.4 × 1079.95 × 10-37.32 × 10-320.0 44.1

6

1.7 × 1071.18 × 10-28.66 × 10-322.3 49.2

9.2 20.3

-3

9.9 21.8

10.1 22.3

-3

10.8 23.8

series ratings

The ratings in the following table apply to all standard Torque Transducer models 314–317.

Stand ard Ve rsi on Model TM Se ries TMHS Ser ies

TORQUE MEASUREMENT

Rated Torque (RT) 314–317 0 to ±100% of RT

Maximum Dynamic Torque Peak Value

(Overload Capacity)

Maximum Dynamic Torque Without Damage

(Overload Limit)

Combined Error of Linearity and Hysteresis

to 100% of RT

Combined Error of Linearity and Hysteresis

from 100 to 200% of RT

Temperature Influence on the Zero/Sensitivity:

• In the Compensated Range +10 °C to +60 °C 314–317 < ±0.1% of RT/10K

• In the Compensated Range -25 °C to +80 °C < ±0.2% of RT/10K

Influence of Speed on the Zero Torque Signal 314–317 < ±0.01% of RT/1000 rpm

Long-term Stability of Sensitivity 314–317 < ±0.05% of RT/year

SPEED MEASUREMENT

Rated Range of Use

Number of Teeth 314–317 60 Z

Minimum Speed Detection 314–317 1 rpm

ENVIRONMENT

Storage Temperature Range 314–317 -40 °C to +100 °C

Operating Temperature Range 314–317 -40 °C to +85 °C

Mechanical Shock 314–317 according to IEC 68.2.27 / Class D3

Vibration 314–317 according to IEC 68.2.6 / Class D3

Protection Class 314–317 IP 44

MECHANICAL CHARACTERISTICS

Shaft Ends

Balancing Quality 314–317 G1 according to ISO 1940

Foot Support (Base Mount) 314–317 included

INPUT AND OUTPUT SIGNALS

Power Supply (max. voltage / current) 314–317 20 to 32 VDC / 100 mA

Torque Output (rated / max.) 314–317 ±5 / ±10 VDC

Filter Cutoff (frequency) 314–317 5000, 2500, 1000, 500, 200, 100, 40, 20, 10, 5, 2, 1 Hz

Speed Output (frequency) 314–317

CONNECTORS

Counter Connector (female) 314–317 optional (P/N 957.11.08.0081)

314–317 0 to ±200% of RT

314–316

317

314–316 < ±0.1% of RT

317 < ±0.15% of RT

314–316 < ±0.1% of measured value

317 < ±0.15% of measured value

314–315 1 to 7,000 rpm 1 to 16,000 rpm

316–317 1 to 5,000 rpm 1 to 12,000 rpm

314–315 splined or keyway

316–317 splined

open collector (15 Ω in series), max. 30 VDC,

0 to ±400% of RT

0 to ±280% of RT

protected against short-circuits

13

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

Dimensions

TM 314 – TM 317

operating principles

The measuring system, based on the principle of a variable, torqueproportional transformer coupling, consists of two concentric

cylinders shrunk on the shaft on each side of the shaft’s deformation

zone, and two concentric coils attached to the housing.

Both cylinders have a circularly disposed coinciding row of

slots and rotate with the shaft inside the coils. An alternating

current with the frequency of 20 kHz flows through the primary

coil. When no torque is applied, the slots on the two cylinders

fail to overlap. When torque is applied, the deformation zone

undergoes an angular deformation and the slots begin to overlap.

Thus a torque-proportional voltage is on the secondary coil. The

conditioning electronic circuit incorporated in the transducer

converts the voltage to a nominal torque signal of 0 to ±5 VDC. A

low-pass filter (Butterworth/2nd order), adjustable from 5 kHz to

1 Hz, allows tuning of the torque signal frequency limitation.

An optical sensor reads the speed on a toothed path machined

directly on the measuring system. The electronic conditioner

outputs a frequency signal proportional to the shaft rotational

speed. An active circuit compensates the zero and sensitivity

temperature drifts within a tolerance of 0.1% / 10 K.

tm anD tmHs transDucers witH Keyway sHaFt

M CC

* Centering Seat

B

60°

A*

J

H Q

G

F

C

D

E

K

L

N

A

BCF

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

R

S

MM

UU

T

TT

N

AA

SS

U

NOTE:

Original dimensions are in Metric

units. Dimensions converted to

English have been rounded up to

3 or 4 decimal places.

Model units Ø A Ø B Ø C Ø D E F G H J K L M N Q R S Ø T U

125g6 106 23 17 M16 12 36 45 67.7 26.8 106 294 80 25 68.5 65 50h6 79.5

314/X31

315/X31

Model units V X Y Z AA CC DD EE FF GG HH Ø JJ MM SS TT UU

314/X31

315/X31

mm

4.9207

in

mm

in

mm

in

mm

in

4.173 0.906 0.669 M16 0.472 1.417 1.772 2.665 1.055 4.173 11.575 3.150 0.984 2.697 2.559

4.9197

125g6 106 23 17 M16 12 36 45 87.7 26.8 106 334 80 25 88.5 85 50h6 99.5

4.9207

4.173 0.906 0.669 M16 0.472 1.417 1.772 3.453 1.055 4.173 13.150 3.150 0.984 3.484 3.346

4.9197

18 10 134 154 98 93

0.709 0.394 5.276 6.063 3.858 3.661

18 10 134 154 98 93

0.709 0.394 5.276 6.063 3.858 3.661

Y

Z

90

(

3.5433

3.5414

90

(

3.5433

3.5414

0

-0.05

0

-0.05

)

)

X

V

JJ

60 ±0.025 10 100 120 ±0.05 11 60.0 9h11 57 14h9

2.3632

0.394 3.937

2.3612

60 ±0.025 10 100 120 ±0.05 11 59.7 9h11 57 14h9

2.3632

0.394 3.937

2.3612

4.7264

4.7224

4.7264

4.7224

0.433 2.362

0.433 2.350

GG

HH

0.3543

0.3508

0.3543

0.3508

EE

1.9685

1.9679

1.9685

1.9679

2.244

2.244

DD

FF

3.130

3.917

0.5512

0.5495

0.5512

0.5495

14

Magtrol TM Series In-Line Torque Transducers

AA

DD

Chapter 1 – Introduction

Dimens ions

TM 314 – TM 317

tm anD tmHs transDucers witH splineD sHaFt

M CC

R

S

MM

NN

PP

U

X

V

QQ - Splines

according

to DIN 5481

January 1952

* Centering

T*

QQ

Seat

RR*

JJ

H Q

G

* Centering Seat

B

60°

A*

F

C

D

E

NOTE:

Original dimensions are in Metric

units. Dimensions converted to

English have been rounded up to

3 or 4 decimal places.

J

K

L

N

A

B C F

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

W

Y

Z

P

Model units Ø A Ø B Ø C Ø D E F G H J K L M N P Q R S Ø T U V

125g6 106 23 17 M16 12 36 45 50.7 26.8 106 260 80 32 25 51.5 48 44h6 62.5 18

314/X21

315/X21

316/X21

317/X21

mm

4.9207

in

mm

in

mm

in

mm

in

4.173 0.906 0.669 M16 0.472 1.417 1.772 1.996 1.055 4.173 10.236 3.150 1.260 0.984 2.028 1.890

4.9197

125g6 106 23 17 M16 12 36 45 70.7 26.8 106 300 80 32 25 71.5 68 44h6 82.5 18

4.9207

4.173 0.906 0.669 M16 0.472 1.417 1.772 2.784 1.055 4.173 11.811 3.150 1.260 0.984 2.815 2.677

4.9197

155g6 135 28.4 21 M20 15 42 53 82.7 25.8 124 340 80 33 24 83.5 80 55h6 94.5 18

6.1018

5.315 1.118 0.827 M20 0.591 1.654 2.087 3.256 1.016 4.882 13.386 3.150 1.299 0.945 3.287 3.150

6.1008

155g6 135 28.4 21 M20 15 42 53 107.7 25.8 124 390 80 33 24 108.5 105 60h6 119.5 18

6.1018

5.315 1.118 0.827 M20 0.591 1.654 2.087 4.240 1.016 4.882 15.354 3.150 1.299 0.945 4.272 4.134

6.1008

KK

LL

GG

HH

N

FF

EE

1.7323

2.461 0.709

1.7317

1.7323

3.248 0.709

1.7317

2.1654

3.721 0.709

2.1646

2.3622

4.705 0.709

2.3615

Model units W X Y Z AA CC DD EE FF GG HH Ø JJ KK LL MM NN PP QQ Ø RR

92 10 134 154 98 93

314/X21

315/X21

316/X21

317/X21

mm

3.622 0.394 5.276 6.063 3.858 3.661

in

92 10 134 154 98 93

mm

3.622 0.394 5.276 6.063 3.858 3.661

in

106 10 150 170 113.5 93

mm

4.173 0.394 5.905 6.693 4.468 3.661

in

106 10 150 170 113.5 93

mm

4.173 0.394 5.905 6.693 4.468 3.661

in

options

Flanges

Flanges are optional for torque transducers with splined shaft

ends. Flange drawing is available on request.

90

90

105

105

0

60±0.025 10 100 120±0.05 11 M8×10 36 42 28 8 45×50 52h6

(

)

-0.05

3.5433

2.3632

3.5414

0

(

-0.05

3.5433

3.5414

0

(

-0.05

4.1338

4.1319

0

(

-0.05

4.1338

4.1319

)

)

)

0.394 3.937

2.3612

60±0.025 10 100 120±0.05 11 M8×10 36 62 48 8 45×50 52h6

2.3632

0.394 3.937

2.3612

80±0.025 10 140 160±0.05 11 M8×10 50 70 50 8 60×65 70h6

3.1506

0.394 5.512

3.1486

80±0.025 10 140 160±0.05 11 M8×10 50 95 80 8 65×70 72h6

3.1506

0.394 5.512

3.1486

4.7264

4.7224

4.7264

4.7224

6.3012

6.2972

6.3012

6.2972

0.433

0.433

0.433

0.433

M8×

1.417 1.654 1.102 0.315 45×50

0.394

M8×

1.417 2.441 1.890 0.315 45×50

0.394

M8×

1.968 2.756 1.968 0.315 60×65

0.394

M8×

1.968 3.740 3.150 0.315 65×70

0.394

Description Model P/N

Flange for Model 314/X 21 FTM 214 415-214-960-011

Flange for Model 315/X 21 FTM 215 415-215-960-011

Flange for Model 316/X 21 FTM 216 415-216-960-011

Flange for Model 317/X 21 FTM 217 415-217-960-011

15

2.0472

2.0465

2.0472

2.0465

2.7559

2.7552

2.8346

2.8339

Magtrol TM Series In-Line Torque TransducersChapter 1 – Introduction

TM SERIES

System Options

system options anD accessories

Unit Under Test

Mandatory for high speed applications.

Unit Under Test

For low speed applications only, uses single-element

couplings to create a shorter drive train.

Couplings

When Magtrol TMB, TM and TMHS Series Torque Transducers

are to be mounted in a drive train, double-element miniature

couplings are the ideal complement, although single-element

couplings can be used for low speed applications. Several

manufacturers provide adequate couplings for both supported

and suspended drive train installations. The criteria for selecting

appropriate couplings for torque measurement is as follows:

• High torsional spring rate: Ensures high torsional

stiffness & angular precision (should be > 3 times the

torque transducer stiffness)

• Clamping quality (should be self-centering & of

adequate strength)

• Speed range

• Balancing quality (according to speed range)

• Alignment capability

The higher the speed of the application, the more care is required in

selecting the coupling and assembling (alignment and balancing)

the drive train configuration. Your Magtrol sales representative

can assist you in choosing the right coupling for your transducer.

Torque Speed Box

Magtrol’s TSB Torque Speed Box allows data acquisition

from two torque transducers simultaneously and provides the

torque’s analog signal output and speed’s TTL signal output.

TORQUE TRANSDUCER

A

B C F

E

D

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

Coupling Coupling

Supported Installation

TM SERIES

TORQUE TRANSDUCER

MAINTENANCE.

PERFORMING

STOP SYSTEM BEFORE

IN OPERATION.

ROTATING PARTS

CAUTION!

D

Coupling Coupling

E

BCF

A

Suspended Installation

TM 314 – TM 317

PC

Torque 1.0

Software

TM Series

Torque Transducer

SPEED TORQUE

RS-232C

SYSTEM

SELECT

TARE

MAGTROL

Model 3410

Torque Display

PC-Based System Configuration

Torque Transducer with Model 3410 Display

and Torque 1.0 Software

Torque Transducer Displays

Magtrol offers two different Torque Displays (Models 3410 and

6400) which supply power to any TM/TMHS/TMB Transducer

and display torque, speed and mechanical power. Features

include:

• Adjustable English, metric and SI torque units

• Large, easy-to-read vacuum fluorescent display

• Built-in self-diagnostic tests

• Overload indication

• Tare function

• RS-232 interface

• Torque and speed outputs

• Closed-box calibration

• Includes Magtrol Torque 1.0 Software

The Model 6400 Display has the following additional features:

• Pass/fail torque-speed-power testing capabilities

• RS-232 and IEEE-488 interface

• Auxiliary analog input

Torque 1.0 Software

Magtrol’s Torque 1.0 Software is an easy-to-use Windows

executable program, used to automatically collect torque, speed

and mechanical power data. The data can be printed, displayed

graphically or quickly saved as a Microsoft

Standard features of Torque 1.0 include: peak torque capture,

multi-axes graphing, measured parameter vs. time, adjustable

sampling rates and polynomial curve fitting.

TRANSDUCER

®

Excel spreadsheet.

®

Accessories Model #

Torque Transducer Connector Cable (5/10/20

m)

ER 113

16

2. Installation / Configuration

2.1 MOUNTING POSSIBILITIES

Magtrol TM Series Torque In-Line Torque Transducers must, above all, be considered precision

measuring instruments and not torque transmission components. The transducer model and the

alignment precision highly influence the measuring precision as well as the operating life of the

transducer, especially of the bearings and couplings.

There are two different ways of mounting TM Torque Transducers: suspended and supported

installation.

2.1.1 SuSpended InSTallaTIon

Both the measuring shaft and torque transducer housing are supported by the driving and driven

machine shafts via couplings (see figure 2–1). In this configuration, couplings offering only one

degree of freedom are adequate to avoid a hyperstatic mounting.

STOP SYSTEM BEFORE

!

CAUTION!

ROTATING PARTS

IN OPERATION.

PERFORMING

MAINTENANCE.

BAF

E

C

D

2.1.1.1 Advantages

• Single-element couplings are less expensive than double-element couplings.

• Shorter drive train leading to a higher torsional resonance frequency (as compared to doubleelement couplings).

2.1.1.2 Disadvantages

• Increase of radial play as the torque transducer is not directly fixed to the test bench.

Consequently, the critical speed is lower than with a supported installation.

Note: The low friction torque generated by the bearings, as well as the

2.1.2 SupporTed InSTallaTIon

The measuring shaft is supported by the torque sensor housing, which itself is fixed to the test bench

frame by means of a support unit (see Figure 2–2). Here, couplings with two degrees of freedom

must be used in order to avoid hyperstatic mountings.

Figure 2–1 Suspended Installation

weight of the built-in electronic housing, results in only the shaft

being driven by the rotating system.

17

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

D

C

B

A

F

E

!

2.1.2.1 Advantages

F

r

F

r

F

a

F

a

CAUTION!

ROTATING PARTS

IN OPERATION.

STOP SYSTEM BEFORE

PERFORMING

MAINTENANCE.

D

C

B

A

F

E

!

F

F

F

F

• Increased critical speed due to less shaft bending.

2.1.2.2 Disadvantages

• Longer overall length of the test bench due to the use of double-element couplings.

• Increased price due to the higher price of double-element couplings.

Magtrol TM Series In-Line Torque TransducersChapter 2 – Installation / Configuration

Figure 2–2 Supported Installation

Note : Supported installations are required when larger misalignments

between the different elements of the system are a possibility, as

well as with high rotational speeds.

High-performance couplings can be realized by mounting flanges directly onto a splined torque

transducer shaft. (Not available on all models.)

2.1.3 TM/TMB In VerTIcal InSTallaTIon

a

F

r

F

B

C

A

D

PERFORMING

IN OPERATION.

MAINTENANCE.

F

E

ROTATING PARTS

CAUTION!

STOP SYSTEM BEFORE

!

r

F

2.2 PARASITIC FORCES

Correct!

Electronic and connector left

from shaft when looking into the

connector!

Caution: Please refer to

manuals for max. acceptable Fa

force!

Wrong!

F

r

!

STOP SYSTEM BEFORE

CAUTION!

ROTATING PARTS

E

F

MAINTENANCE.

IN OPERATION.

PERFORMING

D

A

C

B

F

r

F

a

Incorrectly mounted torque transducers can generate parasitic forces on the measuring shaft in radial

(F

and axial direction (Fa) (see Figure 2–3).

r )

F

a

r

Suspended Installation Supported Installation

STOP SYSTEM BEFORE

!

CAUTION!

ROTATING PARTS

IN OPERATION.

PERFORMING

MAINTENANCE.

D

C

E

BAF

r

F

a

Figure 2–3 Parasitic Forces

18