Magtrol HD-505, HD-700, HD-500, HD-705, HD-710 User Manual

...

HD and ED Series

Hysteresis Dynamometers

User’s Manual

Purchase Record

Please record all model numbers and serial numbers of your

Magtrol equipment, along with the general purchase information.

The model number and serial number can be found on either

a silver identification plate or white label affixed to each unit.

Refer to these numbers whenever you communicate with a

Magtrol representative about this equipment.

Model Number: _____________________________

Serial Number: _____________________________

Purchase Date: _____________________________

Purchased From: _____________________________

While every precaution has been exercised in the compilation of this document to ensure

the accuracy of its contents, Magtrol, Inc./Magtrol SA assumes no responsibility for

errors or omissions. Additionally, no liability is assumed for any damages that may result

from the use of the information contained within this publication.

COPYRIGHT

Copyright ©2002-2018 Magtrol, Inc. All rights reserved.

Copying or reproduction of all or any part of the contents of this manual without the

express permission of Magtrol is strictly prohibited.

TRADEMARKS

LabVIEW™ is a trademark of National Instruments Corporation.

Microsoft® is a registered trademark of Microsoft Corporation.

National Instruments™ is a trademark of National Instruments Corporation.

Windows® is a registered trademark of Microsoft Corporation.

4th Edition, revision O – May 2018

CAUTION

BRAKE SURFACES MAY BECOME HOT

CAUTION

LIFTING BY BRAKE ASSEMBLY

MAY CAUSE DAMAGE TO

TORQUE SENSOR

Safety Precautions

Several warning labels are affixed directly to the dynamometer. These warnings are discussed in

further detail below. Please take the time to read this page thoroughly before connecting and using

your dynamometer.

1. Make sure that all Magtrol dynamometers and electronic products are earth-grounded, to ensure

personal safety and proper operation.

2. Check line voltage before operation on any dynamometer that uses AC input power.

3. Make sure that dynamometers are equipped with a protective cover to prevent contact with the

rotating shaft and coupling. The protective cover must be equipped with a safety interlock to

disable the test motor if the cover is removed.

4. Make sure that all motors under test are equipped with appropriate safety guards.

5. Use caution with exposed brake surfaces. They have a tendency to become very hot during long

periods of operation.

6. Do not lift the unit by the brake assembly, as it may cause damage to the torque sensor.

7. When operating dynamometers with blowers, hearing protection must be worn.

i

Revisions To This Manual

The contents of this manual are subject to change without prior notice. Should revisions be necessary, updates to all

Magtrol User’s Manuals can be found at Magtrol’s web site at www.magtrol.com/support/manuals.htm.

Please compare the date of this manual with the revision date on the web site, then refer to the manual’s Table of

Revisions for any changes/updates that have been made since this edition.

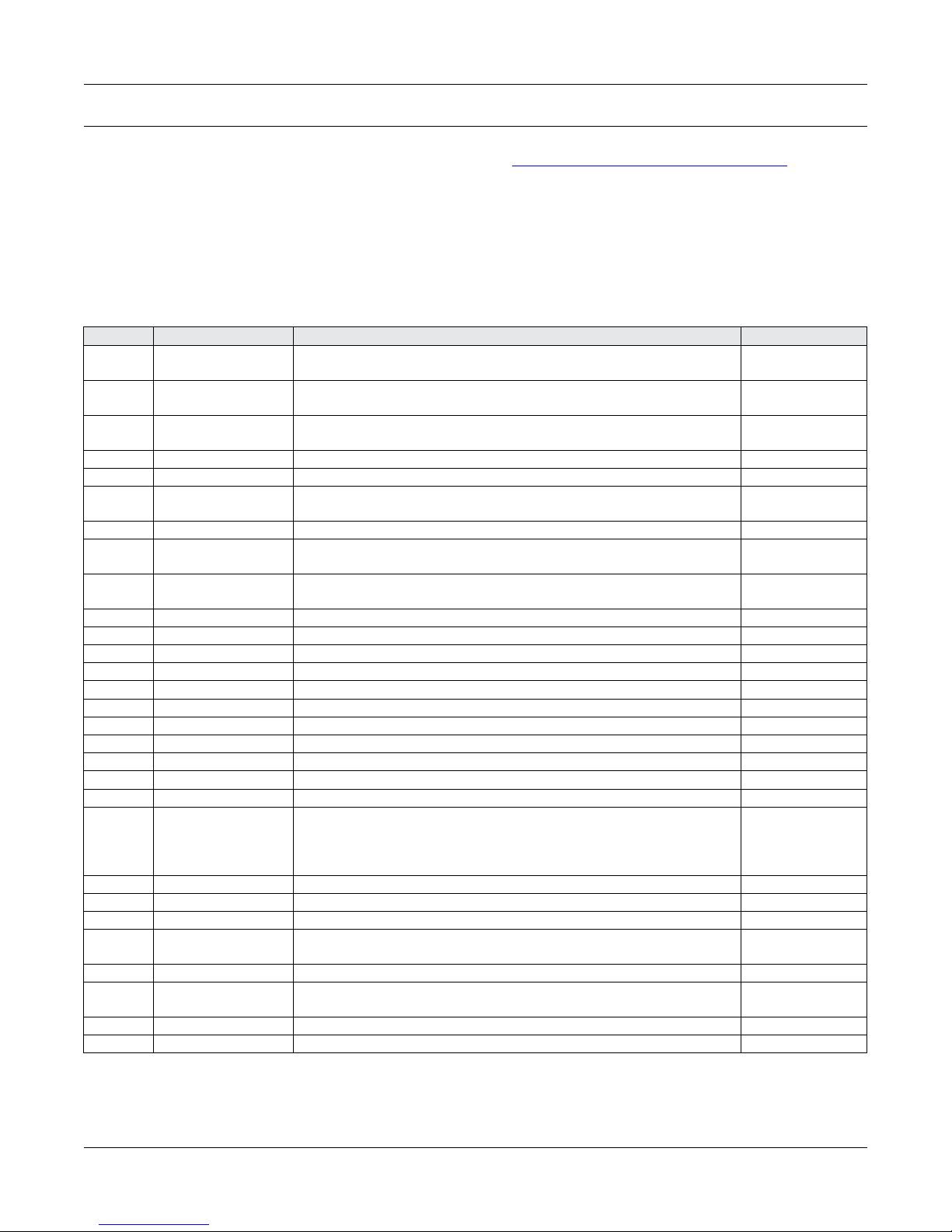

REVISION DATE

4th Edition, revision O – May 2018

TABLE OF REVISIONS

Date Edition Change Section(s)

05/22/18 4th Edition - rev. O

02/18/16 4th Edition - rev. N

06/11/15 4th Edition - rev. M

05/11/15 4th Edition - rev. L Compressed air regulator setting changed for HD-800 dynamometer. 1.3, 4.1.3.2.1

09/04/14 4th Edition - rev. K Updated description of booster power amplier. 5.6.1

06/09/14 4th Edition - rev. J

02/26/14 4th Edition - rev. I All referneces to DSP6001 changed to DSP7000 throughout manual

06/01/12 4th Edition - rev. H

05/21/12 4th Edition - rev. G

10/07/08 4th Edition - rev. F Temperature conditions for maximum power absorption 4.1.3.1

08/31/07 4th Edition - rev. E Updated electrical power and fuse ratings 1.3

08/31/07 4th Edition - rev. E New resistance and current values for HD-106 8.1.3.1, 8.1.3.2

08/31/07 4th Edition - rev. E Added note about circuitry between connector and brake coil 8.1.3.1

06/11/07 4th Edition - rev. D Deleted: Analog Outputs 7.2, 1.3

03/12/07 4th Edition - rev. C Updated calibration drawings and procedure 6.4

03/12/07 4th Edition - rev. C Added new section: "Calibration Beams and Weights" 6.2

02/02/07 4th Edition - rev. B New "A", "P" and "Q" dimensions for HD-700 series dynamometers 1.3

02/02/07 4th Edition - rev. B Change in torque, speed and power ratings. 1.3, 4.1.3.1

06/28/06 4th Edition - rev. A Change in power and speed ratings for HD-805. 1.3, 4.1.3.1

01/23/06 4th Edition All HD and ED data sheets condensed to one single data sheet. 1.3

01/23/06 4th Edition HD-515 (compressed air cooled) dynamometer added to product line.

01/23/06 4th Edition New resistance and current values for HD-500 and HD-505 8.1.3.1, 8.1.3.2

10/12/05 3rd Edition - rev. D Note to "call factory" for HD-805 power and speed ratings 1.3.3, 4.1.3.1

10/12/05 3rd Edition - rev. D Change in power rating (5 minutes) for HD-800 1.3.3, 4.1.3.1

02/24/05 3rd Edition - rev.C Hearing safety warnings added

12/09/04 3rd Edition - rev.B Electrical power and fuse ratings added to data sheets 1.3.1–1.3.4

03/11/04 3rd Edition - rev. A

12/08/03 3rd Edition HSD Series High Speed Dynamometers discontinued throughout manual

10/27/03 2nd Edition - rev. E Change in maximum torque rating for HSD-710-8N 1.3.5, 4.1.3.1

6510e/6530 Power Analyzer references changed to 7500 Series

Power Analyzer.

HD-805 Dynamometer regulator setting updated for maximum air ow

cooling.

Speed sensor board schematic added for 2015 and later

dynamometers.

Note added concerning operation at continuous power rating for long

intervals and high temperatures.

Dimensions were updated on the data sheet for the HD-800 and HD810 model dynamometers

Part number for the 88M007 and 88M070 cables was changed to

88M007-0150 and 88M070-0150

5410 Torque/Speed Readout and 5200/5210 Power Supply removed

from manual/open-loop test system congurations

throughout manual

4.1.3.2.1

B.2

4.3.1

1.3

1.3, 3.3.1, 3.3.2

1.3, 2.2, 3.3.3,

3.3.3.2, 4.1.3.1,

4.1.3.2.1, 8.1.3.1,

8.1.3.2

2.2, 3.3.3.1, 4.1.1,

4.1.3.2.2

1.3.1–1.3.4, 3.3.1

ii

10/27/03 2nd Edition - rev. E Added short base plate option 1.3.1–1.3.3

10/27/03 2nd Edition - rev. E Change in speed encoder options 1.3.1–1.3.4

10/02/03 2nd Edition - rev. D New dimensions for HD-700 series dynamometers 1.3.2

09/25/03 2nd Edition - rev. C New "B" dimension for HD-400 1.3.1

09/25/03 2nd Edition - rev. C New "B" and "E" dimensions for HD-106 1.3.1

08/19/03 2nd Edition - rev. B New schematic drawing for HD-800–815 Brake Control Supply B.4

03/17/03 2nd Edition - rev. A New "F" dimension for HSD-610M 1.3.5

03/17/03 2nd Edition - rev. A New Dynamometer Table added to System Options and Accessories 1.3.1–1.3.5

01/03/03 2nd Edition

Added more information about air cooling – air ow sensor now

standard

3.3.3

01/03/03 2nd Edition Inserted new chapter about optional features chapter 7

01/03/03 2nd Edition HSD High Speed Dynamometer information added throughout manual

iii

Table of Contents

SAFETY PRECAUTIONS .........................................................................................................................I

REVISIONS TO THIS MANUAL ...............................................................................................................II

TABLE OF CONTENTS ......................................................................................................................... IV

TABLE OF FIGURES ........................................................................................................................................................ VI

PREFACE ............................................................................................................................................... VI

PURPOSE OF THIS MANUAL ........................................................................................................................................VI

WHO SHOULD USE THIS MANUAL .............................................................................................................................VI

MANUAL ORGANIZATION ............................................................................................................................................ VI

CONVENTIONS USED IN THIS MANUAL ..................................................................................................................VII

1. INTRODUCTION ................................................................................................................................1

1.1 UNPACKING YOUR HYSTERESIS DYNAMOMETER ...........................................................................................1

1.2 FEATURES OF THE HYSTERESIS DYNAMOMETER ............................................................................................ 2

1.2.1 HD SERIES ..................................................................................................................................................... 2

1.2.2 ED SERIES ..................................................................................................................................................... 2

1.3 DATA SHEET ................................................................................................................................................................ 3

2. INPUTS/OUTPUTS ...........................................................................................................................16

2.1 REAR PANEL ............................................................................................................................................................. 16

2.2 REAR PANEL INPUTS AND OUTPUTS.................................................................................................................. 16

3. INSTALLATION/CONFIGURATION ..................................................................................................18

3.1 REMOVAL OF THE LOAD CELL SHIPPING/RESTRAINING BOLT .................................................................. 18

3.1.1 HD-100, -400 AND -500 SERIES ................................................................................................................ 18

3.1.2 HD-700 SERIES ........................................................................................................................................... 19

3.1.3 HD-800 SERIES ........................................................................................................................................... 19

3.1.4 ED-715 .......................................................................................................................................................... 19

3.1.5 ED-815 .......................................................................................................................................................... 19

3.2 EARTH GROUND ...................................................................................................................................................... 20

3.3 SYSTEM CONFIGURATIONS ..................................................................................................................................21

3.3.1 MANUAL TEST SYSTEMS ........................................................................................................................ 21

3.3.2 PC-BASED TEST SYSTEMS ...................................................................................................................... 22

3.3.3 AIR COOLING ............................................................................................................................................. 23

4. TESTING ...........................................................................................................................................25

4.1 TESTING CONSIDERATIONS .................................................................................................................................25

4.1.1 SAFETY ........................................................................................................................................................ 25

4.1.2 ACCURACY ................................................................................................................................................. 25

4.1.3 POWER DISSIPATION ................................................................................................................................ 26

4.1.4 FIXTURES AND COUPLINGS ................................................................................................................... 38

4.1.5 WINDAGE .................................................................................................................................................... 38

4.1.6 FRICTION .................................................................................................................................................... 39

4.1.7 VIBRATION ................................................................................................................................................. 39

4.1.8 COGGING .................................................................................................................................................... 40

4.1.9 EDDY CURRENTS ...................................................................................................................................... 40

iv

Magtrol Hysteresis Dynamometers

4.1.10 TEMPERATURE RISE ................................................................................................................................ 41

Table of Contents

5. OPERATING PRINCIPLES ...............................................................................................................42

5.1 SPEED ......................................................................................................................................................................... 42

5.2 TORQUE ..................................................................................................................................................................... 42

5.3 TORQUE SIGNAL AMPLIFICATION ...................................................................................................................... 43

5.4 DECIMAL POINT CONTROL .................................................................................................................................. 43

5.5 DAMPER CYLINDER ............................................................................................................................................... 44

5.6 BRAKE CONTROL POWER ..................................................................................................................................... 44

5.6.1 HD-800/815 AND ED-815 ........................................................................................................................... 44

5.6.2 HD-825 .......................................................................................................................................................... 44

6. CALIBRATION ..................................................................................................................................45

6.1 INITIAL CALIBRATION ........................................................................................................................................... 45

6.2 CALIBRATION BEAMS AND WEIGHTS ............................................................................................................... 45

6.3 CALIBRATION PREPARATION ............................................................................................................................... 46

6.4 CALIBRATION PROCEDURE .................................................................................................................................. 46

6.5 CALIBRATION FREQUENCY.................................................................................................................................. 48

7. OPTIONAL FEATURES ....................................................................................................................49

7.1 SPEED ENCODER ..................................................................................................................................................... 49

8. TROUBLESHOOTING .......................................................................................................................50

8.1 TORQUE READOUT PROBLEMS ........................................................................................................................... 50

8.1.1 NEW DYNAMOMETER ............................................................................................................................. 50

8.1.2 ZERO BALANCE ......................................................................................................................................... 50

8.1.3 FULL SCALE TORQUE .............................................................................................................................. 51

8.1.4 MECHANICAL (ROTATIONAL) ALIGNMENT ....................................................................................... 53

8.2 SPEED READOUT PROBLEMS ............................................................................................................................... 54

APPENDIX A: CALIBRATION RECORD .............................................................................................55

APPENDIX B: SCHEMATICS ...............................................................................................................56

B.1 TORQUE AMPLIFICATION BOARD ....................................................................................................................... 56

B.2 SPEED SENSOR BOARD ......................................................................................................................................... 57

B.3 LOAD CELL SCHEMATIC........................................................................................................................................ 58

B.4 HD-800–815 BRAKE CONTROL SUPPLY .............................................................................................................. 59

B.5 HD-825 BRAKE CONTROL SUPPLY ...................................................................................................................... 60

INDEX .....................................................................................................................................................61

SERVICE INFORMATION ......................................................................................................................63

RETURNING MAGTROL EQUIPMENT FOR REPAIR AND/OR CALIBRATION ..................................................... 63

RETURNING EQUIPMENT TO MAGTROL, INC. (UNITED STATES) ................................................................ 63

RETURNING EQUIPMENT TO MAGTROL SA (SWITZERLAND) ..................................................................... 63

v

Magtrol Hysteresis DynamometersTable of Contents

TABLE OF FIGURES

2. INPUTS/OUTPUTS

Figure 2–1 Rear Panel ..............................................................................................................................................16

Figure 2–2 Dynamometer Brake Input .....................................................................................................................16

Figure 2–3 Dynamometer Connector .......................................................................................................................16

Figure 2–4 Calibration Potentiometers.....................................................................................................................17

Figure 2–5 Speed Encoder Switch ............................................................................................................................17

Figure 2–6 Blower Input ...........................................................................................................................................17

Figure 2–7 Compressed Air Input .............................................................................................................................17

3. INSTALLATION/CONFIGURATION

Figure 3–1 HD 100–500 Series Shipping/Restraining Bolt Location .......................................................................18

Figure 3–2 HD-700 Series Shipping/Restraining Bolt Location ..............................................................................19

Figure 3–3 ED-715 Shipping/Restraining Bolt Location .........................................................................................19

Figure 3–4 HD 100–500 Series Top View ................................................................................................................20

Figure 3–5 HD-800 Series Top View .........................................................................................................................20

Figure 3–6 Dynamometer with 6200 Controller .......................................................................................................21

Figure 3–7 Dynamometer with DSP7001 Controller and M-TEST Software ...........................................................22

Figure 3–8 Dynamometer with 6510e Power Analyzer, DSP7001 Controller and M-TEST Software .....................22

Figure 3–9 Air Flow Sensor Schematic ....................................................................................................................23

Figure 3–10 Dynamometer with Blower Connection ...............................................................................................24

Figure 3–11 Dynamometer with Compressed Air Connection .................................................................................24

4. TESTING

Figure 4–1 Power Absorption Curve Parameters .....................................................................................................27

Figure 4–2 HD 106 Power Absorption Curve ...........................................................................................................28

Figure 4–3 HD 100 Power Absorption Curve ...........................................................................................................28

Figure 4–4 HD 400 Power Absorption Curve ...........................................................................................................29

Figure 4–5 HD 500 Power Absorption Curve ..........................................................................................................29

Figure 4–6 HD 510 Power Absorption Curve ...........................................................................................................30

Figure 4–7 HD 505 Power Absorption Curve ...........................................................................................................30

Figure 4–8 HD 515 Power Absorption Curve ...........................................................................................................31

Figure 4–9 HD 700 Power Absorption Curve ...........................................................................................................31

Figure 4–10 HD 710 Power Absorption Curve .........................................................................................................32

Figure 4–11 HD 705 Power Absorption Curve .........................................................................................................32

Figure 4–12 HD 715 Power Absorption Curve .........................................................................................................33

Figure 4–13 HD 800 Power Absorption Curve .........................................................................................................33

Figure 4–14 HD 810 Power Absorption Curve .........................................................................................................34

Figure 4–15 HD 805 Power Absorption Curve .........................................................................................................34

Figure 4–16 HD 815 Power Absorption Curve .........................................................................................................35

Figure 4–17 HD 825 Power Absorption Curve .........................................................................................................35

Figure 4–18 ED 715 Power Absorption Curve .........................................................................................................36

Figure 4–19 ED 815 Power Absorption Curve .........................................................................................................36

Figure 4–20 Dynamometer with Compressed Air Connection .................................................................................37

Figure 4–21 Dynamometer with Blower Connection ...............................................................................................37

Figure 4–22 Examples of Possible Shaft Misalignment ............................................................................................38

Figure 4–23 Hysteresis Brake Cross-Section ............................................................................................................40

5. OPERATING PRINCIPLES

Figure 5–1 Mechanical Layout of a Load Cell .........................................................................................................42

6. CALIBRATION

Figure 6–1 Calibration Label ...................................................................................................................................45

Figure 6–2 Calibration Setup ...................................................................................................................................46

Figure 6–3 Calibration Potentiometers.....................................................................................................................47

Figure 6–4 Calibration Calculation .........................................................................................................................47

7. OPTIONAL FEATURES

Figure 7–1 Speed Encoder Schematic.......................................................................................................................49

8. TROUBLESHOOTING

Figure 8–1 Damper Connection ...............................................................................................................................53

vi

PURPOSE OF THIS MANUAL

This manual contains all the information required for the setup and general use of Magtrol’s Hysteresis

Dynamometers. To achieve maximum capability and ensure proper use of the dynamometer, please

read this manual in its entirety before operating. Keep the manual in a safe place for quick reference

whenever a question should arise.

WHO SHOULD USE THIS MANUAL

This manual is intended for those operators who are planning to use any of Magtrol’s Hysteresis

Dynamometers.

MANUAL ORGANIZATION

This section gives an overview of the structure of the manual and the information contained within it.

Some information has been deliberately repeated in different sections of the document to minimize

cross-referencing and to facilitate understanding through reiteration.

The structure of the manual is as follows:

Chapter 1: INTRODUCTION – Contains the technical data sheets for Magtrol’s Hysteresis

Dynamometers, which describe the units and provide detailed technical

characteristics.

Preface

Chapter 2: INPUTS/OUTPUTS – Description of the elements located on the rear panel of the

dynamometer.

Chapter 3: INSTALLATION/CONFIGURATION – Provides information needed for setup of

the dynamometer. This includes load cell shipping/restraining bolt removal, earth

ground instruction and configurations for manual, computer-controlled and aircooled test setups.

Chapter 4: TESTING – Provides information on how to run a test along with considerations

that should be taken when operating the dynamometer.

Chapter 5: OPERATING PRINCIPLES – Information pertaining to theory of operation including

speed, torque, torque signal amplification, decimal point control, damper cylinder

and brake control power.

Chapter 6: CALIBRATION – Provides recommended calibration schedules along with step-

by-step instructions for the calibration procedure.

Chapter 7: OPTIONAL FEATURES – Provides information regarding various optional features

available to enhance the capability of Magtrol’s Hysteresis Dynamometers including

speed encoders and analog outputs.

Chapter 8: TROUBLESHOOTING – Solutions to common problems encountered during setup

and testing.

Appendix A: CALIBRATION RECORD – Data sheet for tracking calibration results.

Appendix B: SCHEMATICS – For the torque amplification board, speed sensor board, load cell

and brake control power supplies.

vi

Magtrol Hysteresis Dynamometers

CONVENTIONS USED IN THIS MANUAL

The following symbols and type styles may be used in this manual to highlight certain parts of the

text:

Preface

Note: This is intended to draw the operator’s attention to complementary

information or advice relating to the subject being treated. It

introduces information enabling the correct and optimal function

of the product.

Caution: this is used to draw the operator’s attention to information,

direCtives, proCedures, etC. whiCh, if ignored, may result in damage

to the material being used. the assoCiated text desCribes the

neCessary preCautions to take and the ConsequenCes that may

arise if these preCautions are ignored.

WARNING! THIS INTRODUCES DIRECTIVES, PROCEDURES,

PRECAUTIONARY MEASURES, ETC. WHICH MUST

BE EXECUTED OR FOLLOWED WITH THE UTMOST

CARE AND ATTENTION, OTHERWISE THE PERSONAL

SAFETY OF THE OPERATOR OR THIRD PARTY MAY

BE AT RISK. THE READER MUST ABSOLUTELY

TAKE NOTE OF THE ACCOMPANYING TEXT, AND

ACT UPON IT, BEFORE PROCEEDING FURTHER.

WHEN HEARING PROTECTION IS REQUIRED, THE STOP

SIGN IS REPLACED WITH THE EAR MUFF SYMBOL.

vii

1. Introduction

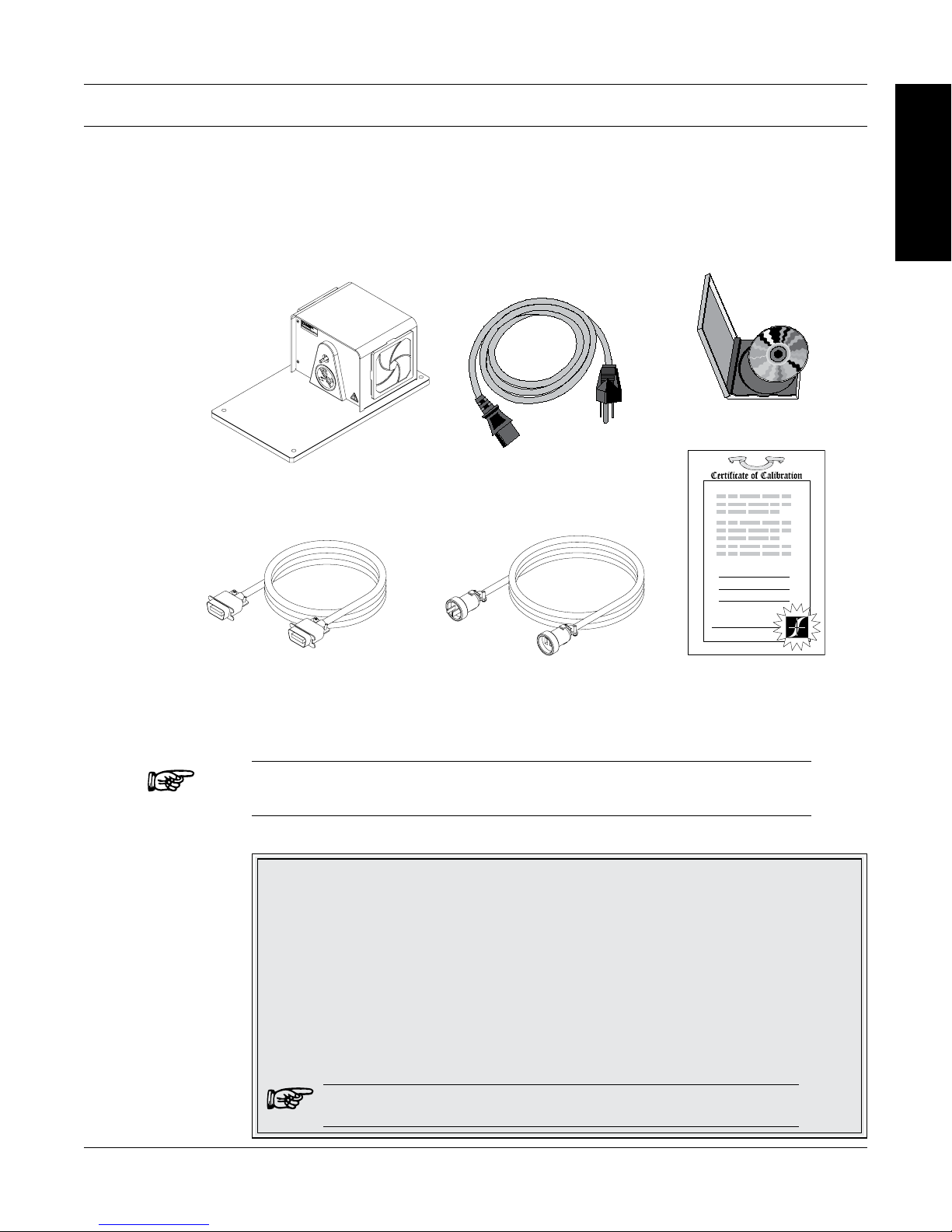

1.1 UNPACKING YOUR HYSTERESIS DYNAMOMETER

Your Hysteresis Dynamometer was packaged in reusable, shock resistant packing material that will

protect the instrument during normal handling.

1. Make sure the carton contains the following:

INFORMATION

GENERAL

Magtrol User Manual CD-Rom

Hysteresis Dynamometer

2. Inspect the contents for any evidence of damage in shipping. In the event of shipping damage,

immediately notify the carrier and Magtrol’s Customer Service Department.

Note: Save all shipping cartons and packaging material for reuse when

returning the instrument for calibration or servicing.

3. Remove the Shipping Bolt

Before proceeding any further, you will need to remove the load cell shipping/restraining

bolt if you have just unpacked a new:

PLEASE TAKE NOTICE!

Line Cord

(not included with 700

series or HD-825)

Brake Cable14-Pin Instrument Cable

Calibration Certificate

HD-100 HD-500 HD-515 HD-710

HD-106 HD-505 HD-700 HD-715

HD-400 HD-510 HD-705 ED-715

This does not apply to HD-800, HD-805, HD-810, HD-815, HD-825 or ED-815

Dynamometers. For further instruction see Section 3.1 Removal of the Load Cell

Shipping/Restraining Bolt.

Note: Retain the shipping/restraining bolt for future use when

moving or shipping your Magtrol Dynamometer.

8

Magtrol Hysteresis Dynamometers

Chapter 1 – Introduction

1.2 FEATURES OF THE HYSTERESIS DYNAMOMETER

All Magtrol Hysteresis Dynamometers (HD and ED Series) feature the following:

• Hysteresis Braking System: The dynamometers do not require speed to create torque, and

therefore can provide a full motor ramp from free-run to locked rotor along with precise

torque loading.

• Air Flow Sensor: Any Magtrol Hysteresis Dynamometer that is internally ported for

compressed air and/or blower cooling contains an air flow sensor that provides protection

against overheating and operator error

• Standard Torque Units: English, metric and SI are available.

• Easy Calibration

Unique features of each series are listed below.

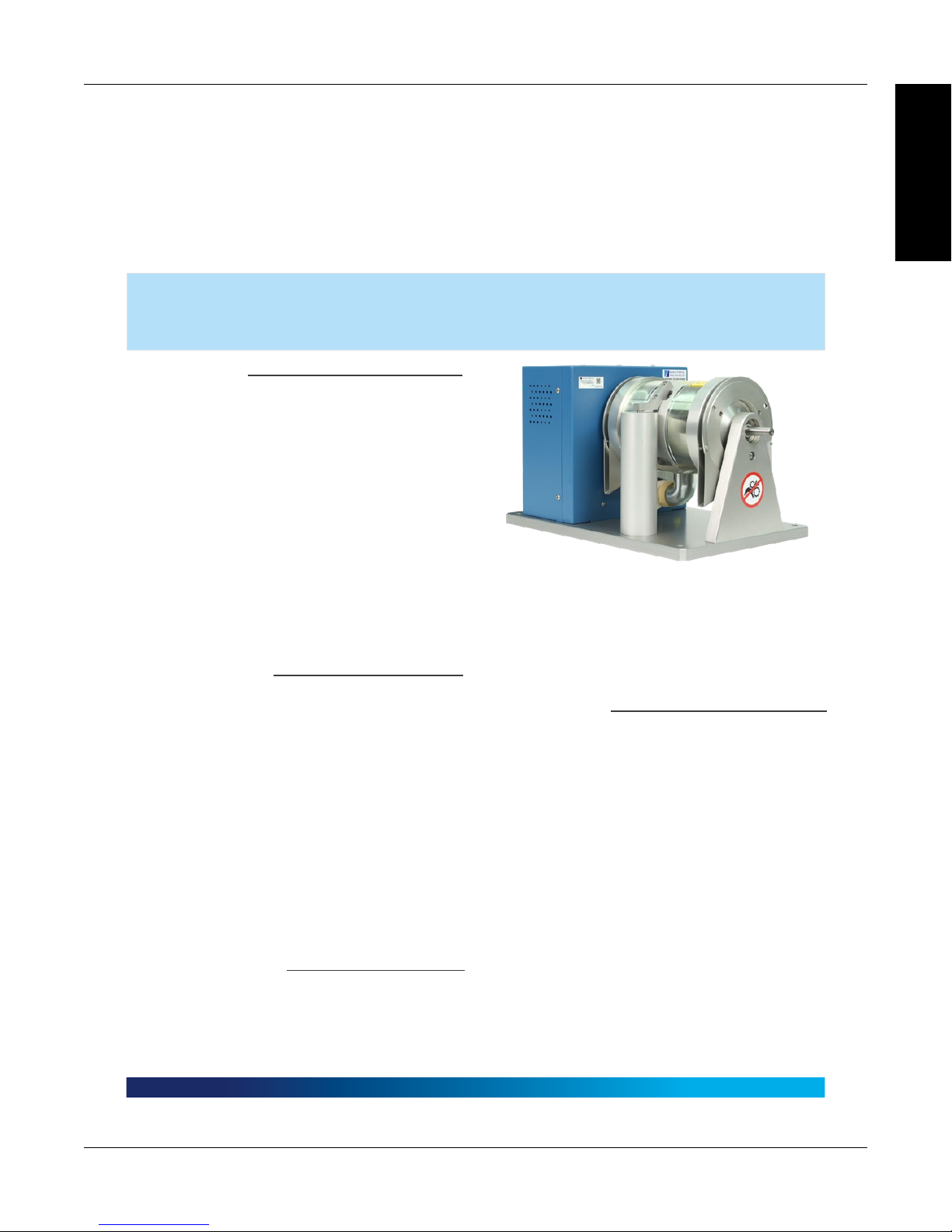

1.2.1 HD SerieS

Magtrol’s HD Series Dynamometers are versatile and ideal for testing in low to medium power

ranges. Features include:

• Accuracy: ±0.25% to ±0.5% full scale, depending on size and system configuration.

• Custom Dynamometers: For special torque and speed requirements.

• Encoder Switch: Optional feature that allows the user to switch between a 60 and 600-bit

encoder or a 60 and 6000-bit encoder.

INFORMATION

GENERAL

1.2.2 eD SerieS

Magtrol’s ED Series Dynamometers are high performance dynamometers specifically designed to

address the severe, high vibration conditions inherent in internal combustion engine testing. Features

include:

• Accuracy: ±0.25% full scale.

• High Speed Capabilities: 12,000 to 25,000 rpm, depending on model.

• Rugged Stainless Steel Shaft: Larger shaft for additional strength.

• Specially Reinforced Load Cell: Stainless steel pin used at contact point to prevent

premature wear from excess vibration.

• Gusseted Pillow Blocks: Adds additional front and rear support.

• Brake Cooling: Blower cooled to maximize heat dissipation.

9

Magtrol Hysteresis DynamometersChapter 1 – Introduction

www.magtrol.comDATASHEET

Page 1 / 16

© 2016 MAGTROL | Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

HD

SERIES

HD

SERIES

HYSTERESIS DYNAMOMETERS

HD FEATURES

▪ 16 Standard Models with Maximum Torque from

2.5 oz·in to 500 lb·in (18 mN·m to 56.5 N·m)

▪ Hysteresis Braking System: provides precise

torque loading independent of shaft speed

▪ Motor Testing: from no load to locked rotor

▪ Standard Torque Units: English, Metric and SI

▪ Accuracy: ±0.25% to ± 0.5% (full scale)

▪ Air Flow Sensor: For protection against

overheating and operator error

▪ Base Plates: available in long or short versions

▪ Custom Dynamometers: for special torque and

speed requirements

▪ Easy Calibration

Fig.1 : HD-700 Series Hysteresis Dynamometer

HD DESCRIPTION

Hysteresis Brake Dynamometers (HD Series) are versatile and

ideal for testing in the low to medium power range (maximum

14 kW intermittent duty). With a Hysteresis Braking system,

the Dynamometers do not require speed to create torque, and

therefore can provide a full motor ramp from free-run to locked

rotor. Brake cooling is provided by convection (no external

source), by compressed air or by dedicated blower, depending

on the model. All Magtrol Hysteresis Dynamometers have

accuracy ratings of ± 0.25% to ± 0.5% full scale — depending

on size and system configuration.

To better integrate dynamometers into systems, Magtrol offers

both long and short base plates. The shorter base plate

facilitates easier motor mounting when used with T-slot tables

and Magtrol Adjustable Motor Fixtures, where as the long base

plates are better suited for table top testing.

HD APPLICATIONS

Magtrol motor test systems can be found in test labs, at

inspection stations, and on the manufacturing floors of most of

the world’s leading manufacturers, users and certifiers of small

to medium sized electric, pneumatic and hydraulic motors, as

ED FEATURES

▪ Maximum Torque: from 55 lb·in to 250 lb·in

(6.5 N·m to 28 N·m)

▪ Hysteresis Braking System

▪ Motor Testing: from no load to locked rotor

▪ Standard Torque Units: English, Metric & SI

available

▪ Accuracy: ±0.25% (full scale)

▪ Blower Cooled: to maximize heat dissipation

▪ Air Flow Sensor: for protection against overheating

and operator error

▪ Specially Reinforced Load Cell: stainless steel pin at

contact point prevents premature wear from excess

vibration

▪ Larger Shaft: for additional strength

▪ Gusseted Pillow Blocks: for additional front and

rear support

▪ Easy Calibration

Magtrol offers three types of dynamometer brakes to absorb load: Hysteresis, Eddy Current and Magnetic Powder. Each type

of Dynamometer has advantages and limitations and choosing the correct one will depend largely on the type of testing to be

performed. With over 50 models to choose from, Magtrol Sales professionals are readily available to assist in selecting the

proper Dynamometer to meet your testing needs.

well as internal combustion engines. Magtrol supplies motor

test systems for a wide array of industries including: Appliance,

Automotive, Aviation, Computer, HVAC, Lawn and Garden,

Medical and Dental, Electric Motor, Office Equipment and

Power Tools.

1.3 DATA SHEET

10

INFORMATION

GENERAL

Magtrol Hysteresis Dynamometers

FIELD COIL

R

(Drag Cup)

Chapter 1 – Introduction

INFORMATION

GENERAL

HD SERIES

ED DESCRIPTION

With Magtrol’s Engine Dynamometers, high performance

motor testing is available to manufacturers and users of small

engines. Magtrol’s Engine Dynamometers have been designed

to address the severe, high vibration conditions inherent in

internal combustion engine testing.

Magtrol’s Engine Dynamometers are highly accurate (± 0.25%

of full scale) and can be controlled either manually or via a PC

based Controller. For a small engine test stand, Magtrol offers

a full line of controllers, readouts and software.

As with all Magtrol Hysteresis Dynamometers, engine loading is

provided by Magtrol’s Hysteresis Brake, which provides: torque

independent of speed, including full load at 0 rpm; excellent

repeatability; frictionless torque with no wearing parts (other

than bearings); and long operating life with low maintenance.

ED APPLICATIONS

The Engine Dynamometers are ideally suited for emissions

testing as set forth in CARB and EPA Clean Air Regulations. The

Dynamometers will offer superior performance on the production

line, at incoming inspection or in the R&D lab.

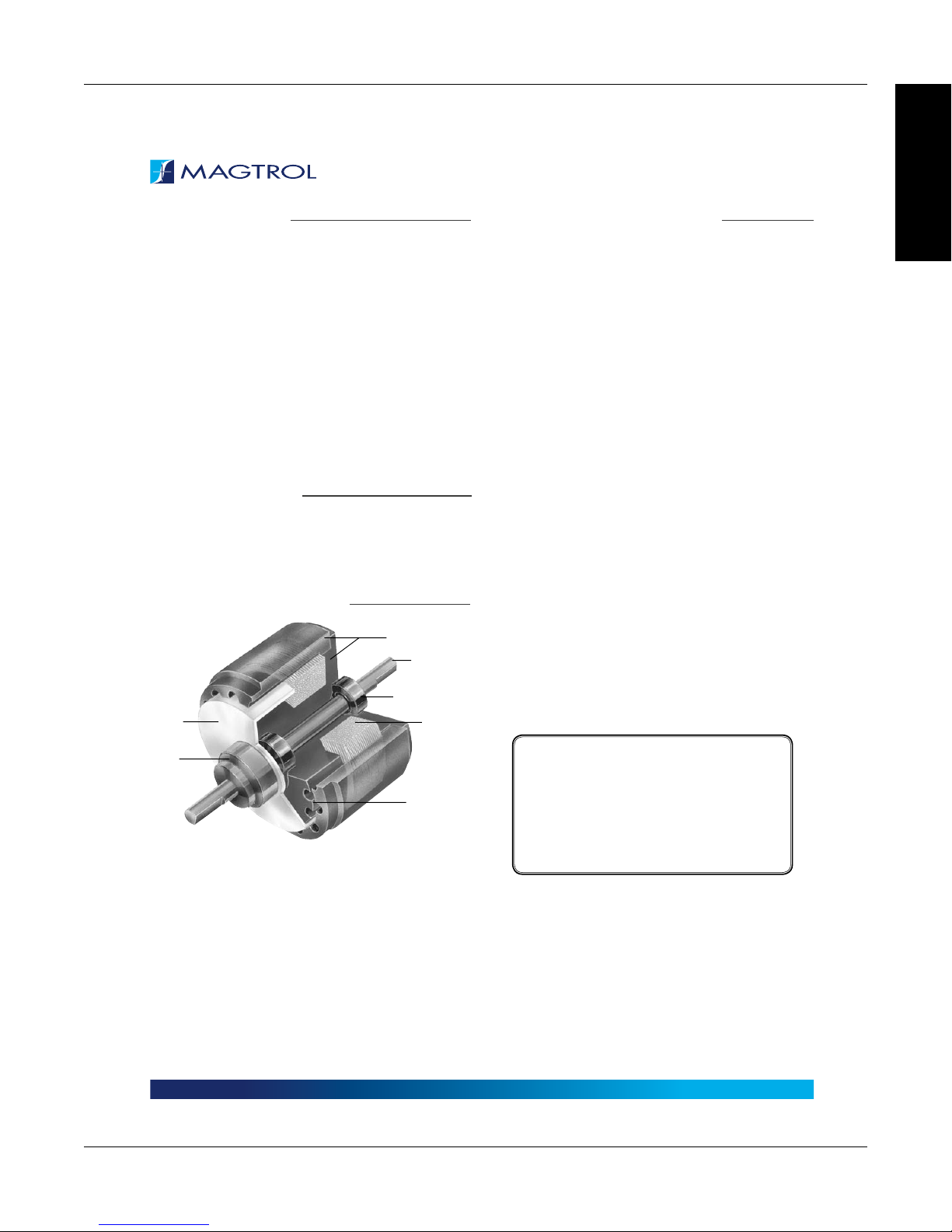

OPERATING PRINCIPLES

POLE STRUCTURE

SHAFT

BALL BEARINGS

OTOR

HUB

AIR GAP

Magtrol Hysteresis Dynamometers absorb power with a

unique Hysteresis Braking System which provides frictionless

torque loading independent of shaft speed. The Hysteresis

Brake provides torque by the use of two basic components—a

reticulated pole structure and a specialty steel rotor/shaft

assembly—fitted together but not in physical contact. Until the

pole structure is energized, the drag cup can spin freely on its

shaft bearings. When a magnetizing force from the field coil is

applied to the pole structure, the air gap becomes a flux field

and the rotor is magnetically restrained, providing a braking

action between the pole structure and rotor.

DYNAMOMETER SELECTION

Magtrol’s Hysteresis Dynamometers cover a wide range of

Torque, Speed and Mechanical Power ratings. To select the

appropriate size Dynamometer for your motor testing needs,

you will need to determine the Maximum Torque, Speed and

Power applied to the Dynamometer.

MAXIMUM TORQUE

The Magtrol Hysteresis Absorption Dynamometer will develop

braking torque at any speed point, including low speed and stall

conditions (“0” rpm). It is important to consider all torque points

that are to be tested, not only rated torque, but also locked

rotor and breakdown torque. Dynamometer selection should

initially be based on the maximum torque requirement, subject

to determining the maximum power requirements.

MAXIMUM SPEED

This rating is to be considered independent of torque and

power requirements, and is the maximum speed at which the

Dynamometer can be safely run under free-run or lightly loaded

conditions. It is not to be considered as the maximum speed at

which full braking torque can be applied.

MAXIMUM POWER RATINGS

These ratings represent the maximum capability of the

Dynamometer Braking System to absorb and dissipate heat

generated when applying a braking load to the motor under

test. The power absorbed and the heat generated by the

Dynamometer is a function of the Torque (T) applied to the motor

under test, and the resulting Speed (n) of the motor. This is

expressed in these power (P) formulas:

SI: P (watts) = T (N·m) × n (rpm) × (1.047 × 10

English: P (watts) = T (lb·in) × n (rpm) × (1.183 × 10

Metric: P (watts) = T (kg·cm) × n (rpm) × (1.027 × 10

All of Magtrol’s controllers, readouts and software

calculate horsepower as defined by 1 hp = 550 lb·ft / s.

Using this definition:

hp = P (watts) / 745.7

The Dynamometer’s ability to dissipate heat is a function of

how long a load will be applied. For this reason, the maximum

power ratings given are based on continuous operation under

load, as well as a maximum of 5 minutes under load.

To safely dissipate heat and avoid Dynamometer failure, the

maximum power rating is the most important consideration

in selecting a Dynamometer.

-1

)

-2

)

-2

)

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 2 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

11

Magtrol Hysteresis DynamometersChapter 1 – Introduction

HD SERIES

COMPLETE PC CONTROL

Magtrol’s M-TEST 7 Software is a state-of-the-art motor testing program for Windows®-based data acquisition. Used with a Magtrol

Programmable Dynamometer Controller, Magtrol M-TEST 7 Software provides the control of any Magtrol Dynamometer and runs test

sequences in a manner best suited to the overall accuracy and efficiency of the Magtrol Motor Test System. The data that is generated

by Magtrol’s Motor Testing Software can be stored, displayed and printed in tabular or graphic formats, and can be easily imported into

a spreadsheet.

Written in LabVIEW™, M-TEST 7 has the flexibility to test a majority of motor types in a variety of ways. Because of LabVIEW’s

versatility, obtaining data from other sources (e.g. thermocouples), controlling motor power and providing audio/visual indicators

is relatively easy.

Magtrol’s M-TEST 7 Software is ideal for simulating loads, cycling the unit under test and motor ramping. Because it is easy to gather

data and duplicate tests, the software is ideal for use in engineering labs. Tests can be programmed to run on their own and saved

for future use allowing for valuable time savings in production testing and incoming/outgoing inspection.

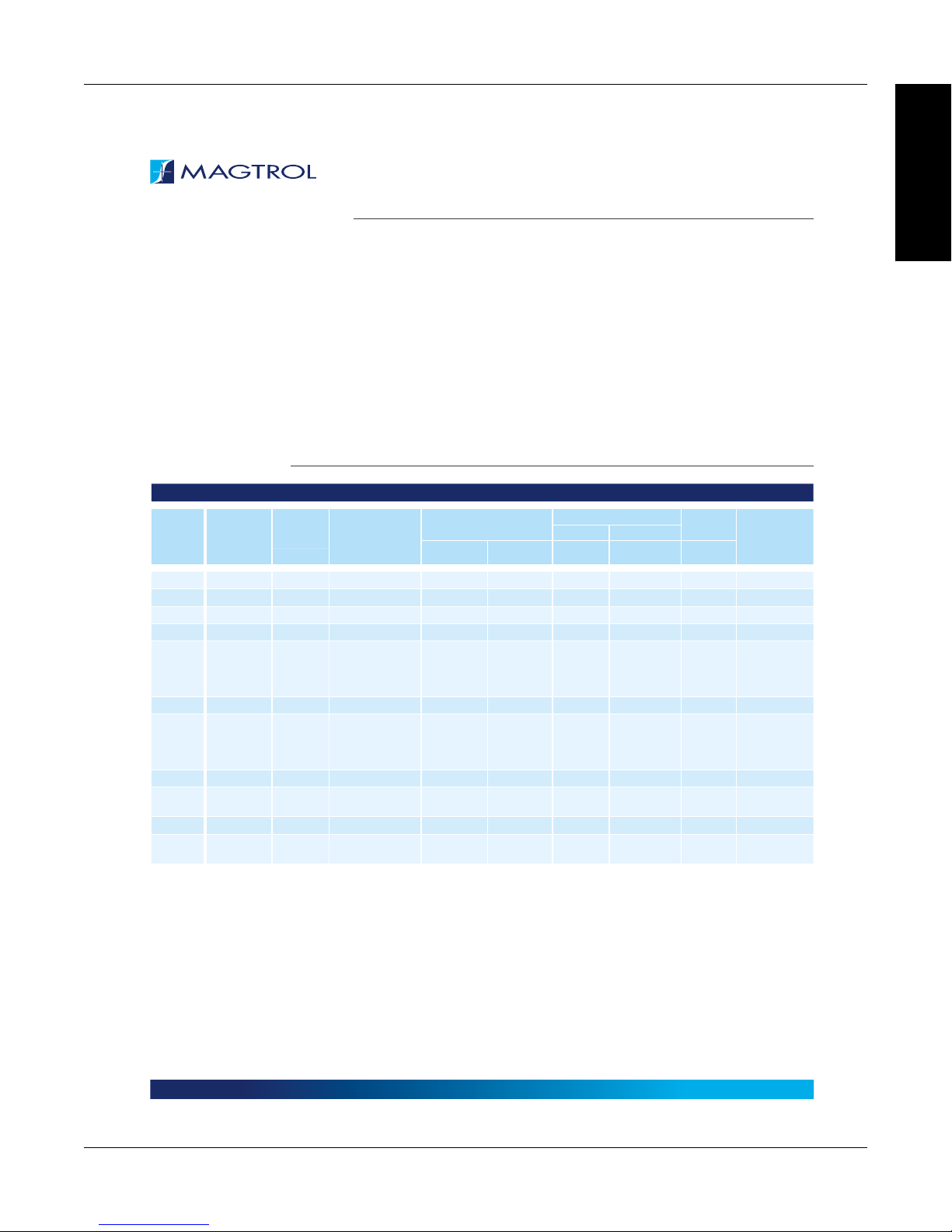

SPECIFICATIONS

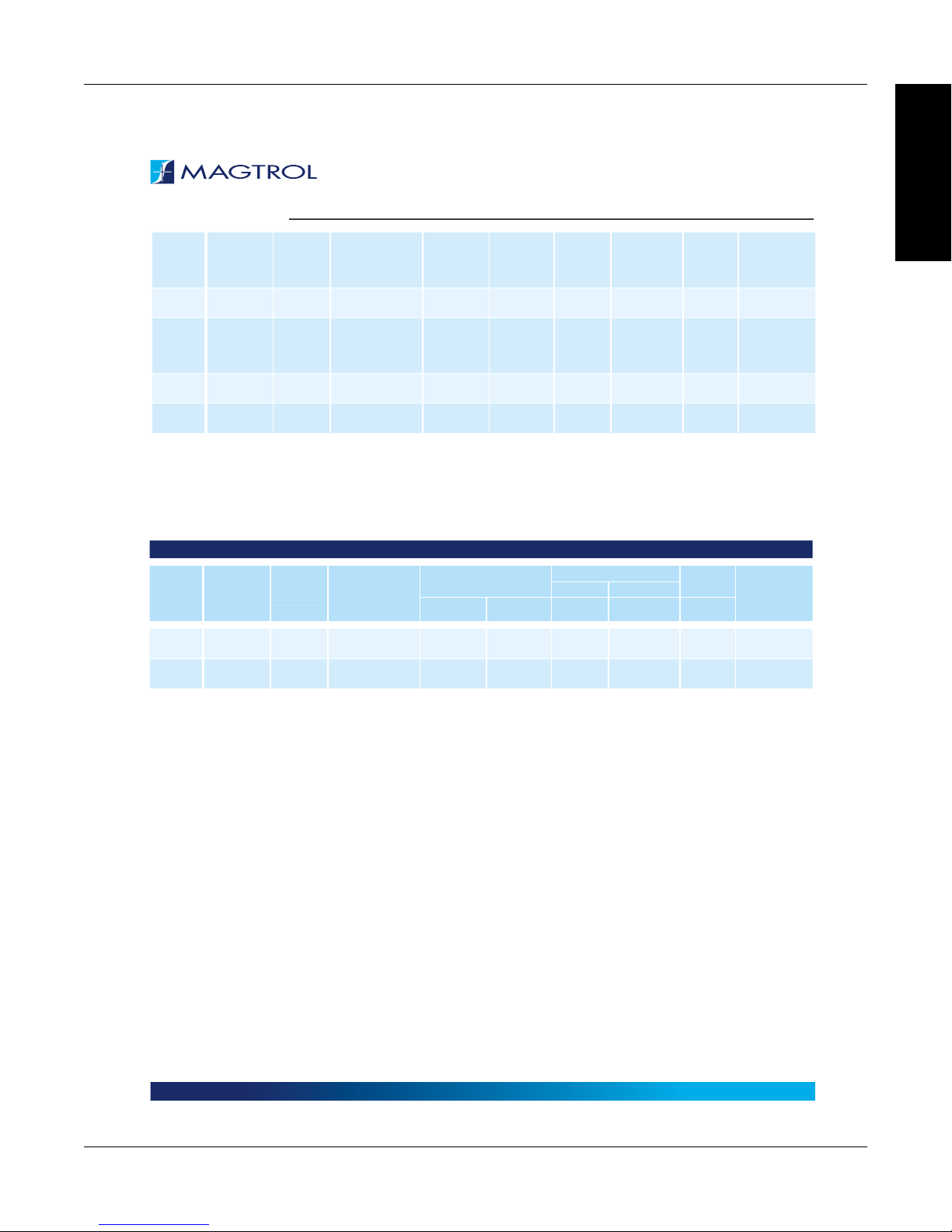

HD HYSTERESIS DYNAMOMETER RATINGS

MODEL

TORQUE

MEASURE

UNIT CODE

HD-106 5N

HD-100

HD-400

HD-500

HD-510

HD-505

HD-515

HD-700

HD-710

HD-705

HD-715

a) All -5N(A) dynamometers are 5 Volt Output. Contact Magtrol for 6N (English), 7N (Metric) and 8N (SI) Specications.

b) Note: Operating at the continuous power rating for periods of up to 4 hours is acceptable. However, operating for extended periods at high temperatures will

result in premature component and bearing failure. Limiting the length of the cycle and the component temperatures will guard against premature failure. Where

continuous duty is desired for longer time intervals, component temperatures should be maintained less than 100°C; monitoring the outside brake surface

temperature is a sufcient reference.

c) Requires air cooling provided by user. Regulator and lter package is provided as standard equipment on these units.

5N

5N

5N

5N

5N

5N

5N

5N

5N

5N

MAXIMUM

TORQUE

RANGE

a)

N·m

0.018 0.056 mN·m 7.04 × 10-79.54 × 10

0.08 0.64 mN·m 3.40 × 10-64.61 × 10

0.28 2 mN·m 1.55 × 10-52.10 × 10

0.85 5 mN·m 8.05 × 10-51.09 × 10

0.85 5 mN·m 8.05 × 10-51.09 × 10

1.70 10 mN·m 1.61 × 10-42.18 × 10

1.70 10 mN·m 1.61 × 10-42.18 × 10

3.10 0.013 N·m 5.51 × 10-47.47 × 10

3.10 0.013 N·m 5.51 × 10-47.47 × 10

6.20 0.023 N·m 1.10 × 10-31.49 × 10

6.20 0.023 N·m 1.10 × 10-31.49 × 10

DRAG TORQUE

DE-ENERGIZED AT

1,000 RPM

NOMINAL INPUT INERTIA

2

lb·ft·s

kg·m

MAX. POWER RATINGS

5 MINUTE CONTINUOUS

2

W W

-7

35 7

-6

75 20 25,000

-5

200 55 25,000

-4

400 80 25,000

-4

750 375 25,000

-4

800 160 25,000

-4

1,500 900 25,000

-4

700 150 25,000

-4

1,500 935 25,000

-3

1,400 300 25,000

-3

3,400 3,000 25,000

MAXIMUM

b)

SPEED

30,000

RPM

BRAKE

COOLING

METHOD

Convection

Convection

Convection

Convection

Compressed

c)

Air

(7 CFM @

1.75 PSI)

Convection

Compressed

c)

Air

(10 CFM @

4 PSI)

Convection

Blower

(included)

Convection

Blower

(included)

INFORMATION

GENERAL

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 3 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

12

Magtrol Hysteresis Dynamometers

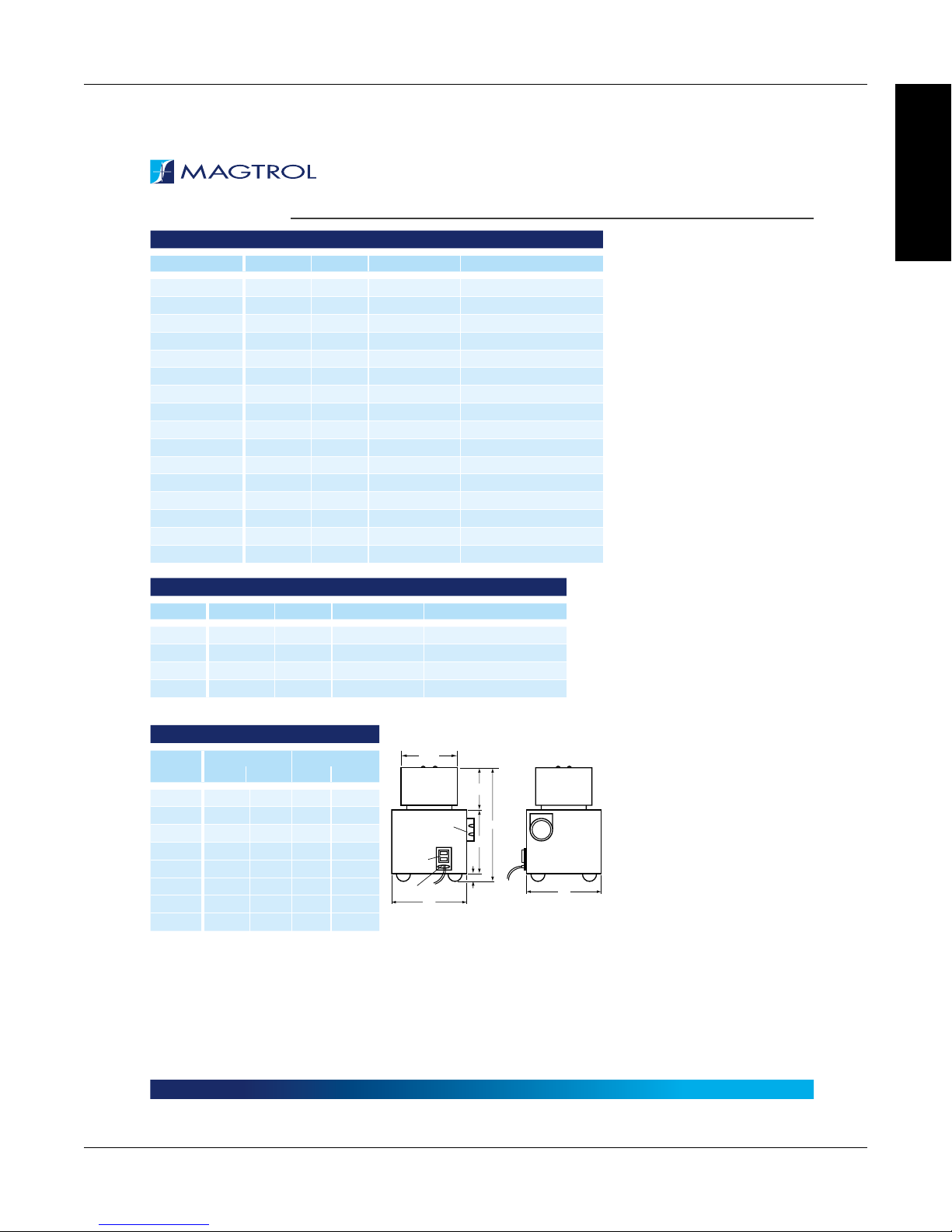

SPECIFICATIONS

HD-800

HD-810

HD-805

HD-815

HD-825

a) All -5N(A) dynamometers are 5 Volt Output. Contact Magtrol for 6N (English), 7N (Metric) and 8N (SI) Specications.

b) Note: Operating at the continuous power rating for periods of up to 4 hours is acceptable. However, operating for extended periods at high temperatures will

result in premature component and bearing failure. Limiting the length of the cycle and the component temperatures will guard against premature failure. Where

continuous duty is desired for longer time intervals, component temperatures should be maintained less than 100°C; monitoring the outside brake surface

temperature is a sufcient reference.

c) Requires air cooling provided by user. Regulator and lter package is provided as standard equipment on these units.

5N

5N

5N

5N

5N

14.00 0.10 N·m 4.43 × 10-36.01 × 10

14.00 0.10 N·m 4.43 × 10-36.01 × 10

28.00 0.14 N·m 8.81 × 10-31.19 × 10

28.00 0.14 N·m 8.81 × 10-31.19 × 10

56.50 0.22 N·m 1.85 × 10-22.51 × 10

-3

2,800 1,800 12,000

-3

3,500 3,000 12,000

-2

5,300 3,000 12,000

-2

7,000 6,000 12,000

-2

14,000 12,000 8,000

Chapter 1 – Introduction

HD SERIES

Compressed

c)

Air

(13 CFM @

10 PSI)

Blower

(included)

Compressed

c)

Air

(15 CFM @

14 PSI)

Blower

(included)

Blower

(included)

INFORMATION

GENERAL

ED ENGINE DYNAMOMETER RATINGS

MAXIMUM

TORQUE

a)

RANGE

N·m

MODEL

TORQUE

MEASURE

UNIT CODE

ED-715 5N

ED-815

a) All -5N(A) dynamometers are 5 Volt Output. Contact Magtrol for 6N (English), 7N (Metric) and 8N (SI) Specications.

b) Note: Operating at the continuous power rating for periods of up to 4 hours is acceptable. However, operating for extended periods at high temperatures will

result in premature component and bearing failure. Limiting the length of the cycle and the component temperatures will guard against premature failure. Where

continuous duty is desired for longer time intervals, component temperatures should be maintained less than 100°C; monitoring the outside brake surface

temperature is a sufcient reference.

c) The maximum speed will depend on what type of keyway (if any) is used on the shaft. Unless specied, the dynamometer shaft will be made without a keyway.

5N

28.0 0.14 N·m 9.61 × 10-31.30 × 10

DRAG TORQUE

DE-ENERGIZED AT

1,000 RPM

NOMINAL INPUT INERTIA

2

lb·ft·s

kg·m

6.20 0.035 N·m 1.27 × 10-31.72 × 10

MAX. POWER RATINGS

5 MINUTE CONTINUOUS

2

W W

-3

3,400 3,000

-2

7,000 6,000 12,000

MAXIMUM

b)

SPEED

25,000

RPM

c)

BRAKE

COOLING

METHOD

Blower

(included)

Blower

(included)

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 4 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

13

SPECIFICATIONS

Ø A

ELECTRICAL POWER AND FUSES

MODEL

HD-1XX-XN

HD-1XX-XNA

HD-4XX-XN

HD-4XX-XNA

HD-5XX-XN

HD-5XX-XNA

HD-800-XN

HD-800-XNA

HD-810-XN

HD-810-XNA

HD-805-XN

HD-805-XNA

HD/ED-815-XN

HD/ED-815-XNA

HD-825-XN

HD-825-XNA

VOLTAGE VA

120 V 30 UL/CSA 300 mA 250 V SB

240 V 30 IEC 125 mA 250 V T

120 V 30 UL/CSA 300 mA 250 V SB

240 V 30 IEC 125 mA 250 V T

120 V 30 UL/CSA 300 mA 250 V SB

240 V 30 IEC 125 mA 250 V T

120 V 65 UL/CSA 800 mA 250 V SB

240 V 65 IEC 315 mA 250 V T

120 V 65 UL/CSA 800 mA 250 V SB

240 V 65 IEC 315 mA 250 V T

120 V 130 UL/CSA 1.25 A 250 V SB

240 V 130 IEC 630 mA 250 V T

120 V 130 UL/CSA 1.25 A 250 V SB

240 V 130 IEC 630 mA 250 V T

120 V

240 V

Magtrol Hysteresis DynamometersChapter 1 – Introduction

INFORMATION

GENERAL

HD SERIES

STYLE RATING

N/A N/A N/A

N/A N/A N/A

BLOWER POWER AND FUSES

MODEL

BL-001

BL-001A

BL-002

BL-002A

VOLTAGE VA

120 V

240 V

120 V

240 V

1,000

1,000

600

500

BLOWER DIMENSIONS

MODEL

Ø A 6 152

A 11 279

B 6 152

C 8 203

D 4 102

E 8 203

F 1 25

Weight 8.5 lb 3.9 kg

BL-001

in mm in mm

11

15

12

18 lb

BL-002

6

6

4

1

STYLE RATING

6.3 A 250 V SB

3.15 A 250 V T

15 A 250 V SB

6.3A 250 V T

Air Filter

Dyno. Brake

Air Outlet

On/Off

Switch

D

152

279

152

381

102

302

25

8.1 kg

UL/CSA

IEC

UL/CSA

IEC

120 VAC 60 Hz

▪ Models HD-710, HD-715, HD-810 and

ED-715 include the BL-001 blower.

▪ Models HD-815 and ED-815 include the

BL-002 blower.

▪ Model HD-825 uses two BL-002 blowers

for cooling its two brake sets.

Allow approximately 6 in to 8 in

E

(152 mm to 203 mm) between rear

of dynamometer base plate and

B

C

blower for connection hardware.

Required hardware is supplied with

the dynamometer.

BL-002 Blower has two filter elements.

FG

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 5 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

14

Magtrol Hysteresis Dynamometers

F

D

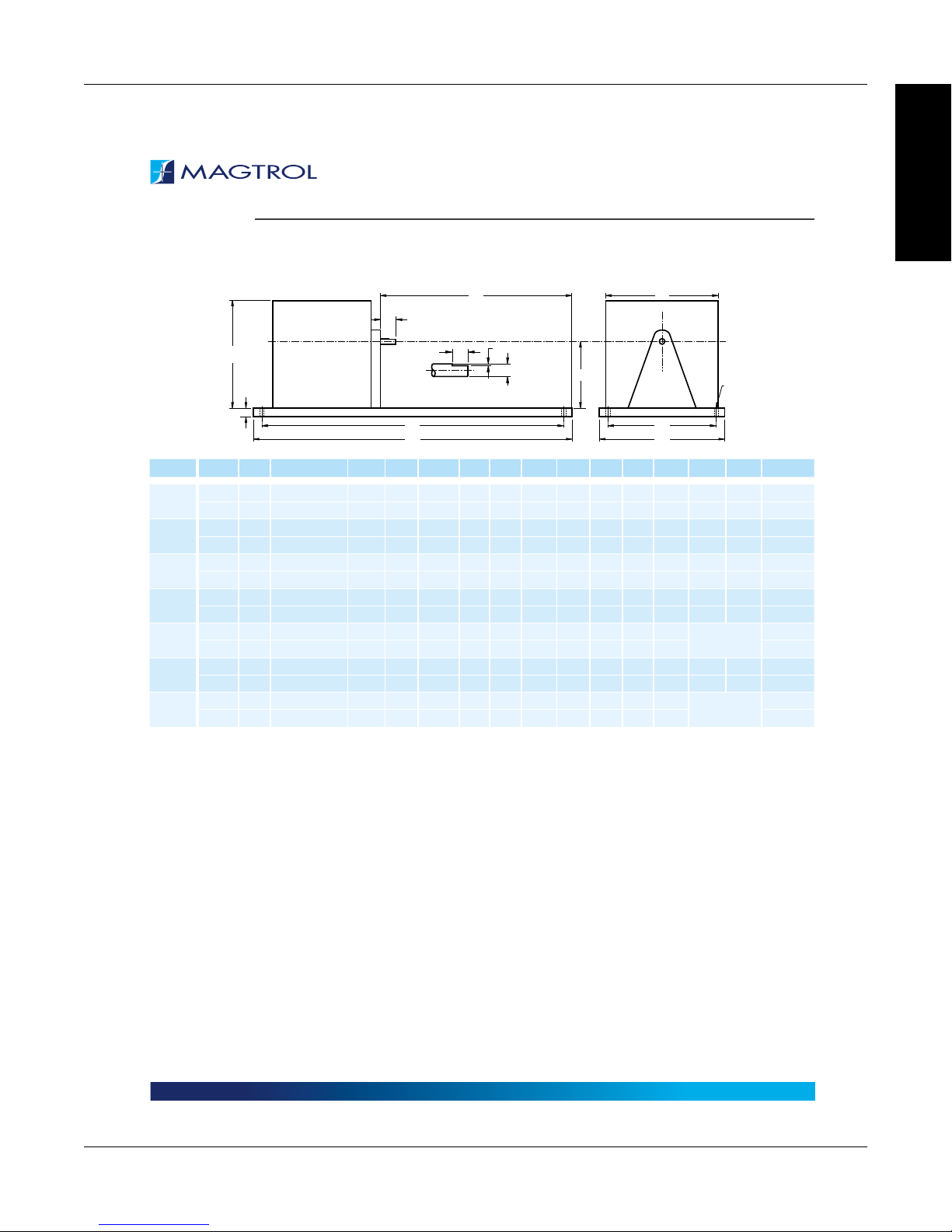

DIMENSIONS

NOTE: Original dimensions are in English units. Dimensions converted to Metric units have been rounded and are for reference only.

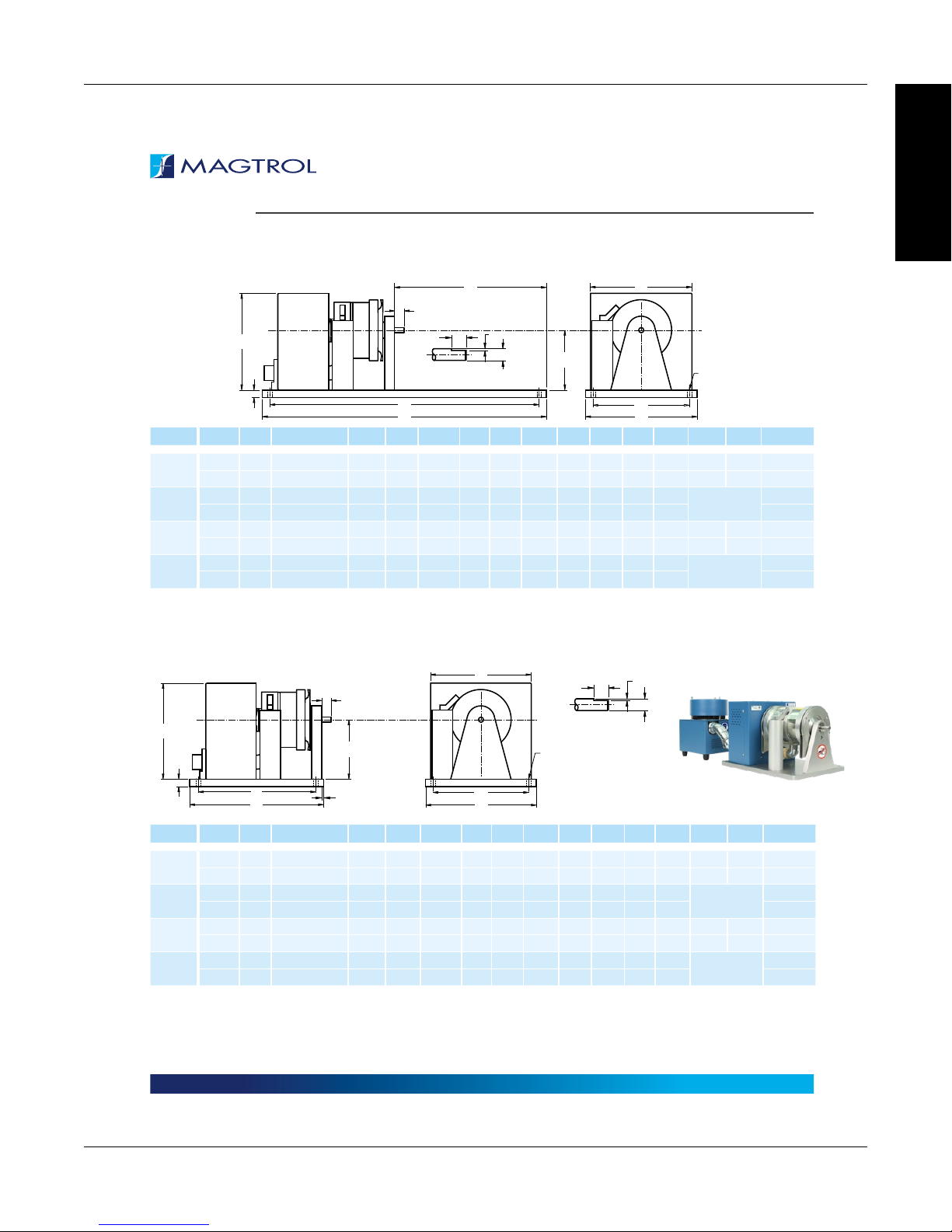

HD-100/400/500 SERIES WITH LONG BASE PLATE

Chapter 1 – Introduction

INFORMATION

GENERAL

HD SERIES

E

A

(FLAT)

P

ØB

C

a)Ma)

H

G

B

MODEL UNITS A

in

HD-106

HD-100

HD-400

HD-500

HD-510

HD-505

HD-515

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

0.50 0.1245/0.1247 3.5 17 9.38 10 0.5 6.3 8.5 15.5 8.5 0.37 0.015 0.375

mm

12.7 3.162/3.167 88.9 432 238.3 254 12.7 159 216 394 216 9.4 0.38 9.53

in

0.75 0.1870/0.1875 3.5 17 9.13 10 0.5 6.3 8.5 15.5 8.5 0.37 0.025 0.375

mm

19.1 4.750/4.763 88.9 432 231.9 254 12.7 159 216 394 216 9.4 0.64 9.53

in

0.67 0.2495/0.2497 3.5 17 9.13 10 0.5 6.3 8.5 15.5 8.5 0.37 0.03 0.438

mm

17.0 6.337/6.342 88.9 432 231.9 254 12.7 159 216 394 216 9.4 0.76 11.13

in

0.88 0.3745/0.3750 4.0 17 9.13 10 0.5 6.3 8.5 15.5 8.5 0.37 0.047 0.375

mm

22.2 9.512/9.525 101.6 432 231.9 254 12.7 159 216 394 216 9.4 1.19 9.53

in

0.88 0.3745/0.3750 4.0 17 9.13 10 0.5 6.3 8.5 15.5 8.5 0.37

mm

22.2 9.512/9.525 101.6 432 231.9 254 12.7 159 216 394 216 9.4

in

0.88 0.3745/0.3750 4.0 20 9.64 10 0.5 6.3 8.5 18.5 8.5 0.37 0.05 0.375

mm

22.2 9.512/9.525 101.6 508 244.9 254 12.7 159 216 470 216 9.4 1.27 9.53

in

0.88 0.3745/0.3750 4.0 20 9.64 10 0.5 6.3 8.5 18.5 8.5 0.37

mm

22.2 9.512/9.525 101.6 508 244.9 254 12.7 159 216 470 216 9.4

Ø

C D E F G H J L

Q

SHAFT END DETAIL (2:1)

L

J

M

Ø N

ØN

P Q WEIGHT

12.0 lb

5.4 kg

12.5 lb

5.7 kg

15.0 lb

6.8 kg

16.0 lb

7.3 kg

N/A

N/A

16.0 lb

7.3 kg

18.0 lb

8.1 kg

18.0 lb

8.1 kg

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 6 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

15

Magtrol Hysteresis DynamometersChapter 1 – Introduction

HD SERIES

DIMENSIONS

NOTE: Original dimensions are in English units. Dimensions converted to Metric units have been rounded and are for reference only.

HD-100/400/500 SERIES WITH SHORT BASE PLATE

INFORMATION

GENERAL

J

A

H

C

G

L

D

MODEL UNITS A

in

HD-106

HD-100

HD-400

HD-500

HD-510

HD-505

HD-515

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

0.50 0.1245/0.1247 3.5 7.0

mm

12.7 3.162/3.167 88.9 177.8

in

0.75 0.1870/0.1875 3.5 7.0

mm

19.1 4.750/4.763 88.9 177.8

in

0.67 0.2495/0.2497 3.5 7.0

mm

17.0 6.337/6.342 88.9 177.8

in

0.88 0.3745/0.3750 4.0 7.0

mm

22.2 9.512/9.525 101.6 177.8

in

0.88 0.3745/0.3750 4.0 8.0

mm

22.2 9.512/9.525 101.6 203.2

in

0.88 0.3745/0.3750 4.0 9.5

mm

22.2 9.512/9.525 101.6 241.3

in

0.88 0.3745/0.3750 4.0 10.25

mm

22.2 9.512/9.525 101.6 260.4

E

B

Ø

C D E F G H J L

0.33 11

8.4 279.4

0.08 11

2.1 279.4

0.08 11

2.1 279.4

0.08 11

2.1 279.4

0.13 11

3.2 279.4

0.10 11

2.6 279.4

0.10 11

2.6 279.4

M

F

0.5 6.3 8.5

12.7 159 216

0.5 6.3 8.5

12.7 159 216

0.5 6.3 8.5

12.7 159 216

0.5 6.3 8.5

12.7 159 216

0.5 6.3 8.5

12.7 159 216

0.5 6.3 8.5

12.7 159 216

0.5 6.3 8.5

12.7 159 216

Q

SHAFT END DETAIL (2:1)

ØN

152.4 250 9

152.4 250 9

152.4 250 9

152.4 250 9

177.8 250 9 5.7 kg

215.9 250 9

9.25 9.84 0.35

234.9 250 9 5.9 kg

P

(FLAT)

a)Ma)

6.0 9.84 0.35

6.0 9.84 0.35

6.0 9.84 0.35

6.0 9.84 0.35

7.0 9.84 0.35

8.5 9.84 0.35

ØB

Ø N

P Q WEIGHT

0.015 0.375

0.38 9.53

0.025 0.375

0.64 9.53

0.03 0.438

0.76 11.13

0.047 0.375

1.19 9.53

N/A

0.05 0.375

1.27 9.53

N/A

7.5 lb

3.4 kg

8.0 lb

3.6 kg

11.0 lb

5.0 kg

12.0 lb

5.4 kg

12.5 lb

13.0 lb

5.9 kg

13.0 lb

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 7 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

16

Magtrol Hysteresis Dynamometers

F

D

F

D

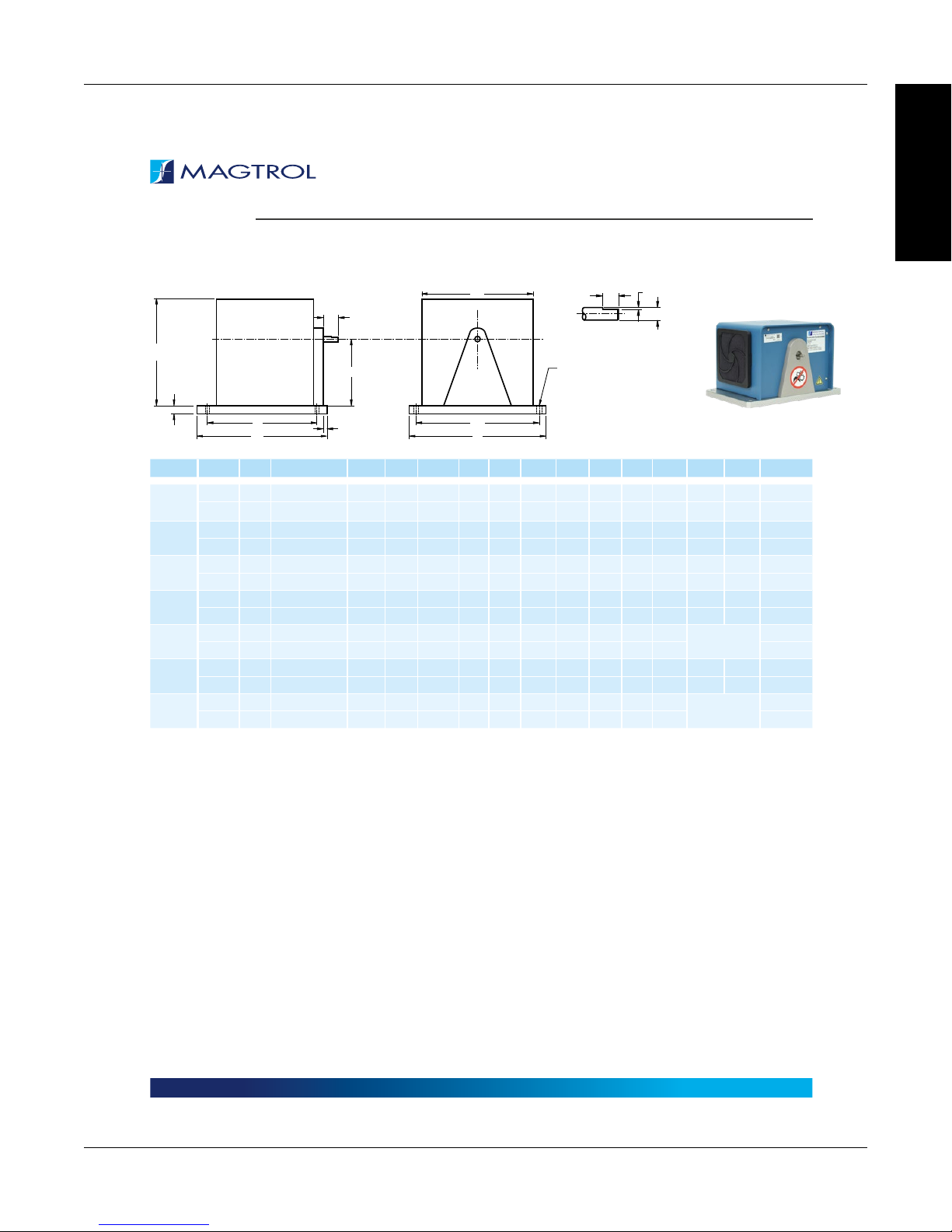

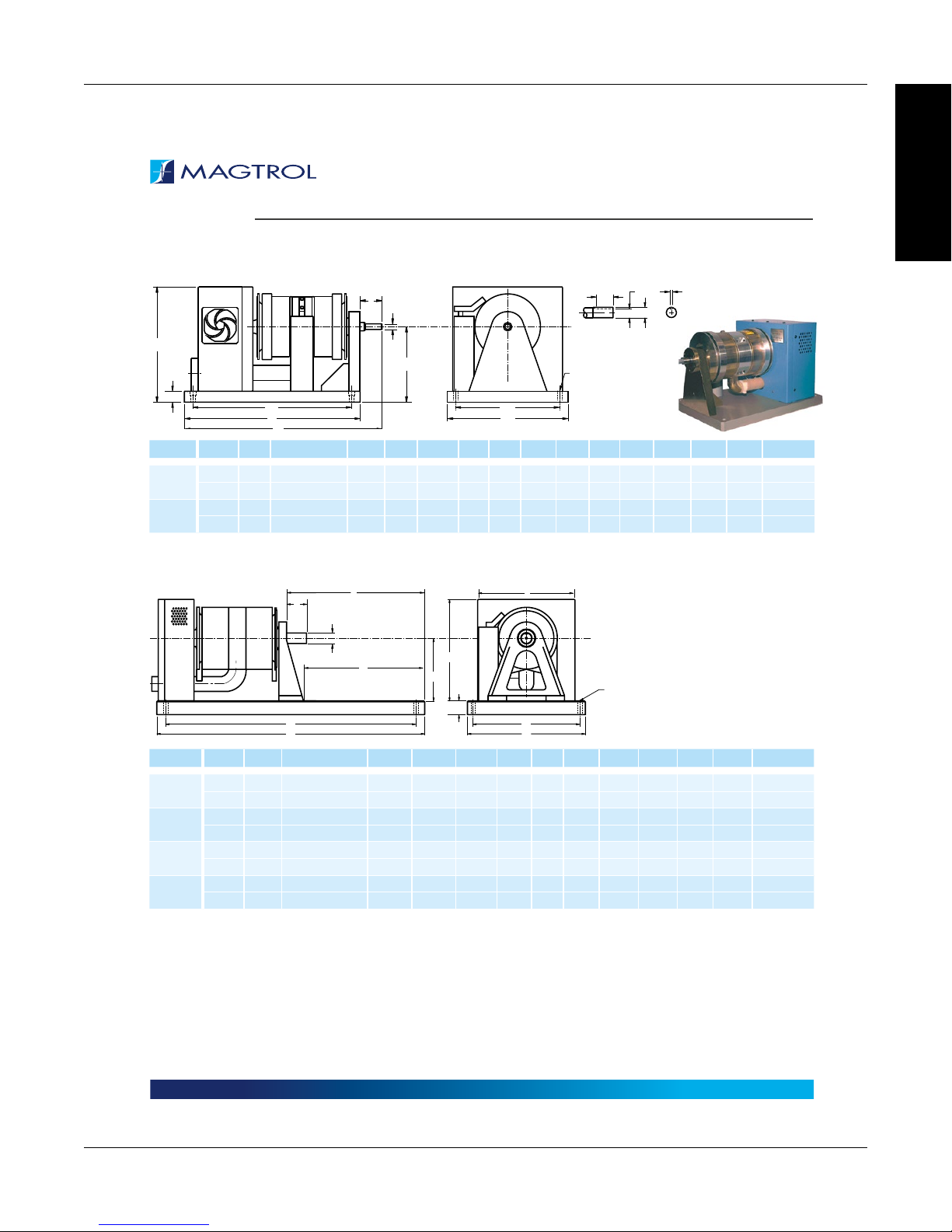

DIMENSIONS

NOTE: Original dimensions are in English units. Dimensions converted to Metric units have been rounded and are for reference only.

HD-700 SERIES WITH LONG BASE PLATE

H

G

E

A

Q

SHAFT END DETAIL (2:1)

(FLAT)

L

Chapter 1 – Introduction

INFORMATION

GENERAL

HD SERIES

J

P

ØB

C

ØN

M

B

MODEL UNITS A

HD-700

HD-710

HD-705

HD-715

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

in 1.25 0.4995/0.4999 5.875 24 12.75 11 0.625 9.5 10 22.5 723.9 0.375 0.06 0.63 39 lb

mm 31.8 12.687/12.692 149.2 609.6 323.9 279.4 15.9 241.3 254 571.5 241.3 9.5 1.6 15.9 17.63 kg

in 1.25 0.4995/0.4999 5.875 26 13.59 11 0.625 9.5 10 24.5 9.5 0.375

mm 31.8 12.687/12.692 149.2 660.4 345.2 279.4 15.9 241.3 254 622.3 241.3 9.5 20.30 kg

in 1.25 0.4995/0.4999 5.875 28 13.62 11 0.625 9.5 10 26.5 9.5 0.375 0.06 0.63 52 lb

mm 31.8 12.687/12.692 149.2 711.2 346.0 279.4 15.9 241.3 254 673.1 241.3 9.5 1.6 15.9 23.50 kg

in 1.25 0.4995/0.4999 5.875 30 14.29 11 0.625 9.5 10 28.5 9.5 0.375

mm 31.8 12.687/12.692 149.2 762.0 363.0 279.4 15.9 241.3 254 723.9 241.3 9.5 26.60 kg

Ø

C D E F G H J L

a)Ma)

HD-700 SERIES WITH SHORT BASE PLATE

J

A

H

C

G

L

MODEL UNITS A

HD-700

HD-710

HD-705

HD-715

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

in 1.25 0.4995/0.4999 5.875 11.34 0.09 11 0.625 9.5 10 9.84 9.84 0.375 0.06 0.63 30 lb

mm 31.8 12.687/12.692 149.2 288.0 2.2 279.4 15.9 241.3 254 250.0 250 9.5 1.6 15.9 13.6 kg

in 1.25 0.4995/0.4999 5.875 12.50 0.09 11 0.625 9.5 10 11.00 9.84 0.375

mm 31.8 12.687/12.692 149.2 317.5 2.2 279.4 15.9 241.3 254 279.5 250 9.5 16.3 kg

in 1.25 0.4995/0.4999 5.875 14.45 0.09 11 0.625 9.5 10 12.95 9.84 0.375 0.06 0.63 43 lb

mm 31.8 12.687/12.692 149.2 367.0 2.2 279.4 15.9 241.3 254 329.0 250 9.5 1.6 15.9 19.5 kg

in 1.25 0.4995/0.4999 5.875 15.75 0.09 11 0.625 9.5 10 14.25 9.84 0.375

mm 31.8 12.687/12.692 149.2 400.0 2.2 279.4 15.9 241.3 254 362.0 250 9.5 22.7 kg

E

B

Ø

C D E F G H J L

M

Q

SHAFT END DETAIL (2:1)

ØN

P

ØB

(FLAT)

a)Ma)

Ø N

P Q WEIGHT

Ø N

P Q WEIGHT

N/A

N/A

N/A

N/A

45 lb

59 lb

36 lb

50 lb

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 8 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

17

Magtrol Hysteresis DynamometersChapter 1 – Introduction

E

J

ØN

F

D

HD SERIES

DIMENSIONS

NOTE: Original dimensions are in English units. Dimensions converted to Metric units have been rounded and are for reference only.

ED-SERIES ENGINE DYNAMOMETERS

A

H

G

B

C

Q

SHAFT END DETAIL (2:1)

ØN

P

(SQUARE KEY)

R

ØB

INFORMATION

GENERAL

L

D

B

MODEL UNITS A

ED-715

ED-815

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

in 1.72 0.7490/0.7495 6.87 16.00 18.13 11.00 1.00 10.50 14.50 9.50 0.37 0.64 1.00 0.187 75 lb

mm 43.7 19.025/19.037 174.5 406.4 460.5 279.4 25.4 266.7 368.3 241.3 9.4 16.35 25.4 4.83 34 kg

in 3.02 1.4995/1.5000 11.00 23.00 23.27 17.00 2.00 16.63 20.80 15.00 5/8-11 1.287 2.00 0.375 285 lb

mm 76.7 38.087/38.100 279.4 584.2 591.1 431.8 50.8 422.4 528.3 381.0 THD 32.7 50.8 9.53 129.3 kg

Ø

C D E F G H L

M

F

a)Ma)

Ø N

HD-800 SERIES WITH LONG BASE PLATE

A

ØB

K

L

B

MODEL UNITS A

HD-800

HD-810

HD-805

HD-815

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

in 2.13 0.9995/1.0000 9 38.5 23.81 17 2 14.6 14 36.5 15 0.53 237.0 lb

mm 54 25.387/25.400 228.6 978 605 432 50.8 371 356 927 381 13.5 107.2 kg

in 2.05 0.9995/1.0000 9 38.5 23.09 17 2 14.6 14 36.5 15 0.53 233.0 lb

mm 52 25.387/25.400 228.6 978 587 432 50.8 371 356 927 381 13.5 105.3 kg

in 2.13 0.9995/1.0000 9 38.5 20.57 17 2 14.6 14 36.5 15 0.54 287.0 lb

mm 54 25.387/25.400 228.6 978 522 432 50.8 371 356 927 381 13.7 129.7 kg

in 2.12 0.9995/1.0000 9 38.5 18.19 17 2 14.6 14 36.5 15 0.54 288.0 lb

mm 54 25.387/25.400 228.6 978 462 432 50.8 371 356 927 381 13.7 130.1 kg

Ø

C D E F G H J L

H

C

G

M

NOTE: For detailed dimension

drawings of dynamometers with

the T-slot base plate option, visit

Magtrol’s Web site.

P Q R WEIGHT

a)Ma)

Ø N

WEIGHT

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

www.magtrol.comDATASHEET

Page 9 / 16© 2016 MAGTROL

18

Magtrol Hysteresis Dynamometers

ØN

F

D

F

D

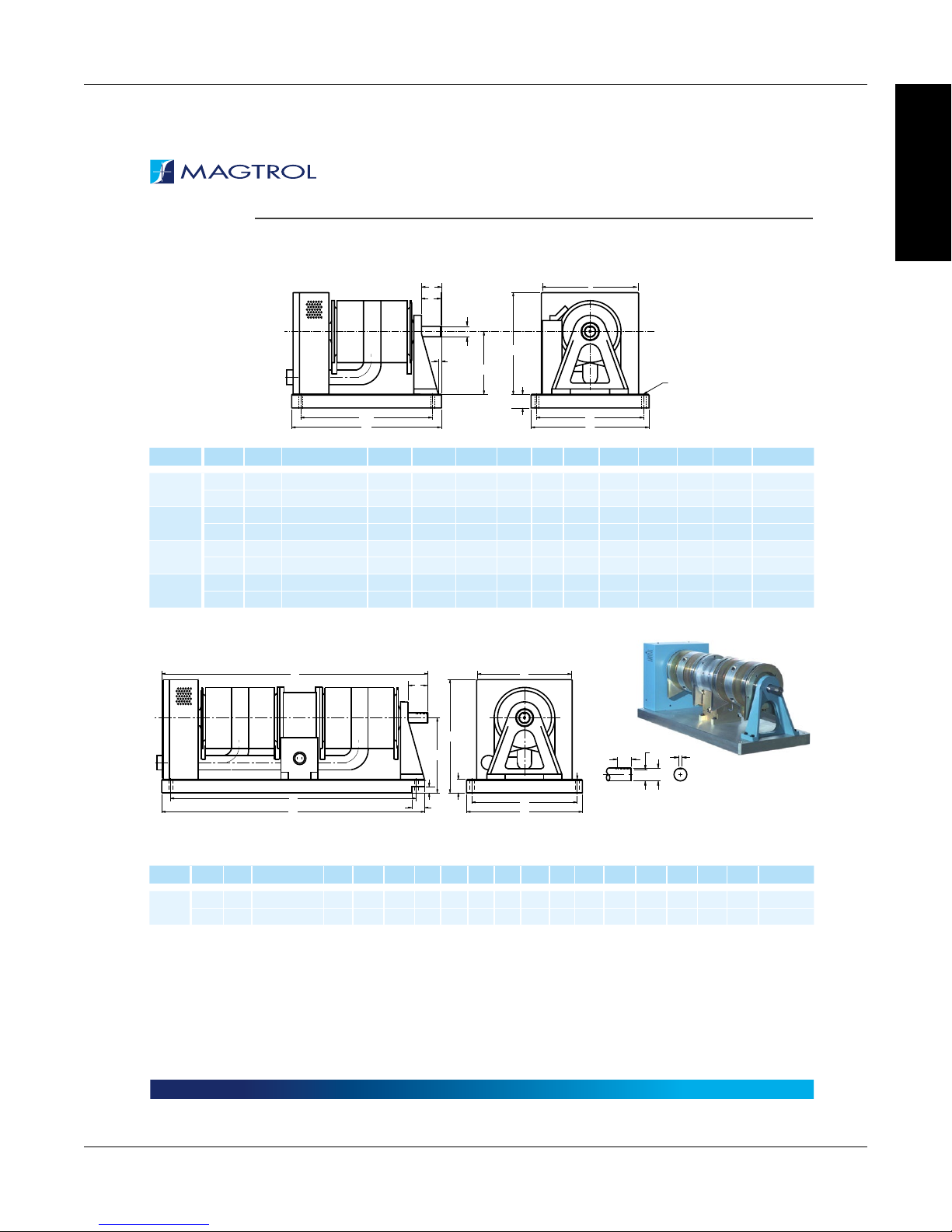

DIMENSIONS

NOTE: Original dimensions are in English units. Dimensions converted to Metric units have been rounded and are for reference only.

HD-800 SERIES WITH SHORT BASE PLATES

Chapter 1 – Introduction

INFORMATION

GENERAL

HD SERIES

E

A

ØB

J

K

L

B

MODEL UNITS A

HD-800

HD-810

HD-805

HD-815

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

in 2.13 0.9995/1.0000 9 17.25 2.56 17 2 14.6 14 13.78 15.75 0.35 168.0 lb

mm 54 25.387/25.400 228.6 438 65 432 50.8 371 356 350 400 9 76.2 kg

in 2.05 0.9995/1.0000 9 18.00 2.59 17 2 14.6 14 14.06 15.75 0.35 164.0 lb

mm 52 25.387/25.400 228.6 457 66 432 50.8 371 356 357 400 9 74.4 kg

in 2.13 0.9995/1.0000 9 20.50 2.57 17 2 14.6 14 15.75 15.75 0.35 228.0 lb

mm 54 25.387/25.400 228.6 520 65 432 50.8 371 356 400 400 9 103.4 kg

in 2.12 0.9995/1.0000 9 23.00 2.59 17 2 14.6 14 19.09 15.75 0.35 236.0 lb

mm 54 25.387/25.400 228.6 584 66 432 50.8 371 356 485 400 9 107.0 kg

Ø

E

L

C D E F G H J L

A

H

C

G

T

S

H

C

G

J

M

M

Q

ØN

SHAFT END DETAIL (2:1)

(SQUARE KEY)

a)Ma)

P

ØB

Ø N

WEIGHT

R

An HD-825 Dynamometer with long base plate is available if ordered with the accompanying dynamometer table (TAB 0825L).

Contact Magtrol for details.

MODEL UNITS A

B

Ø

C D E F G H J L

a)Ma)

Ø N

P Q R S T WEIGHT

HD-800

a) These dimensions represent the distance between mounting holes. There are four (4) mounting holes on each base plate.

in 2.83 1.4995/1.5000 11 38.5 38.93 17 2 16.6 14 36.5 15 0.54 1.287 2 0.376 2 1 400.0 lb

mm 72 38.087/38.100 279.4 978 989 432 50.8 422 356 927 381 13.7 32.69 50.8 9.53 50.8 25.4 181.4 kg

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 10 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

19

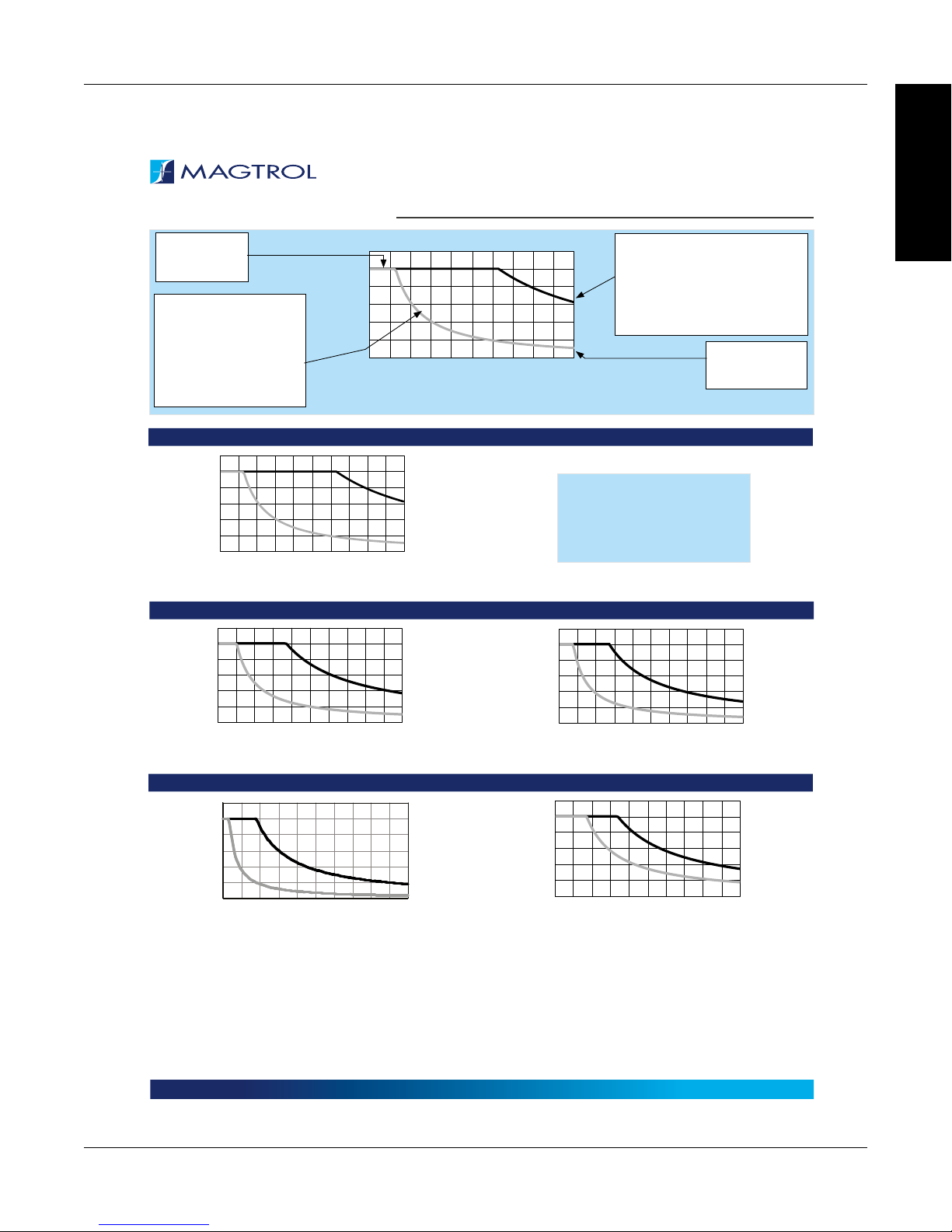

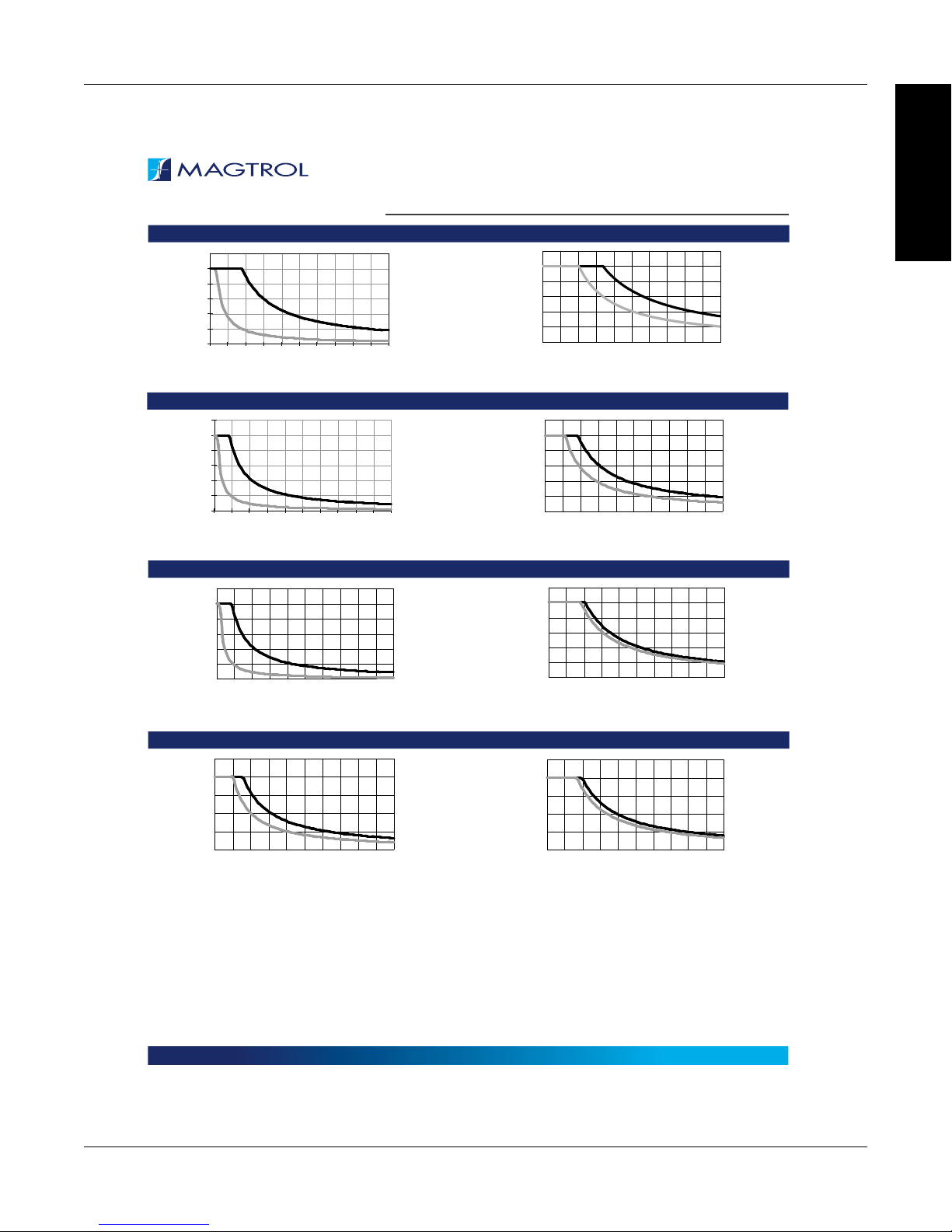

POWER ABSORPTION CURVES

Magtrol Hysteresis DynamometersChapter 1 – Introduction

INFORMATION

GENERAL

HD SERIES

Maximum Rated

Speed for

Dynamometer

Maximum Kinetic

Power Rating Curve for

Continuous Duty: Area

under curve equals the

maximum speed and

torque combinations for a

continuous duty motor test.

36000

30000

24000

18000

12000

SPEED (rpm)

6000

0

000.5

3.617.2

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

002.2164.4326.6488.86411

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0024

170483407251096680

36000

30000

24000

18000

12000

SPEED (rpm)

6000

0

000.5

3.617.2

1.5

10.8214.4

2.5

18

Maximum Kinetic Power Rating

Curve for Less Than Five Minutes:

Area under curve equals the

maximum speed and torque

combinations for a motor test of

less than five minutes.

(oz·in)

(mN·m)

TORQUE

HD-106

The power absorption curves

represent the maximum power

(heat) that the dynamometer can

dissipate over time.

10.8214.4

TORQUE

1.5

2.5

18

(oz·in)

(mN·m)

HD-100 HD-400

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0

085616112241683222440280

TORQUE

TORQUE

80

(oz·in)

(mN·m)

HD-500 HD-510

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0024

170483407251096680

TORQUE

TORQUE

120

850

(oz·in)

(mN·m)

Maximum Torque

for Dynamometer

(oz·in)

(mN·m)

(oz·in)

120

(mN·m)

850

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

Page 11 / 16© 2016 MAGTROL

www.magtrol.comDATASHEET

20

Magtrol Hysteresis Dynamometers

POWER ABSORPTION CURVES

HD-505 HD-515

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0048

34096680

TORQUE

HD-700 HD-710

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0088

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0011

176

0.62

1.24

TORQUE

HD-705 HD-715 AND ED-715

1.24222.48333.72444.96556.20

TORQUE

144

1020

264

1.86

192

1360

352

2.48

240

1700

440

3.10

(oz·in)

(mN·m)

(oz·in)

(N·m)

(lb·in)

(N·m)

30000

30000

25000

25000

20000

20000

15000

15000

10000

10000

SPEED (rpm)

5000

5000

0

0

0048

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0088

30000

25000

20000

15000

10000

SPEED (rpm)

5000

0

0011

Chapter 1 – Introduction

144

34096680

TORQUE

176

0.62

1.24

TORQUE

1.24222.48333.72444.96556.20

TORQUE

1020

264

1.86

192

1360

352

2.48

1700

HD SERIES

240

(oz·in)

(mN·m)

(oz·in)

440

(N·m)

3.10

(lb·in)

(N·m)

INFORMATION

GENERAL

15000

12000

9000

6000

SPEED (rpm)

3000

0

0025

|

Due to continual product development, Magtrol reserves the right to modify specifications without forewarning.

HD-800 HD-810

2.8505.6758.4

TORQUE

100

11.2

125

14.0

(lb·in)

(N·m)

21

15000

12000

9000

6000

SPEED (rpm)

3000

0

0025

2.8505.6758.4

TORQUE

100

11.2

www.magtrol.comDATASHEET

125

14.0

(lb·in)

(N·m)

Page 12 / 16© 2016 MAGTROL

Loading...

Loading...