Magtrol 5210-2 User Manual

Model 5210-2 Power Supply

1.0 INTRODUCTION

The Model 5210-2 is a current-regulated power supply and display that is designed for use with

Magtrol’s Dial Weight Dynamometers. With regulated current, torque drift caused by temperature

changes within the brake coil is eliminated.

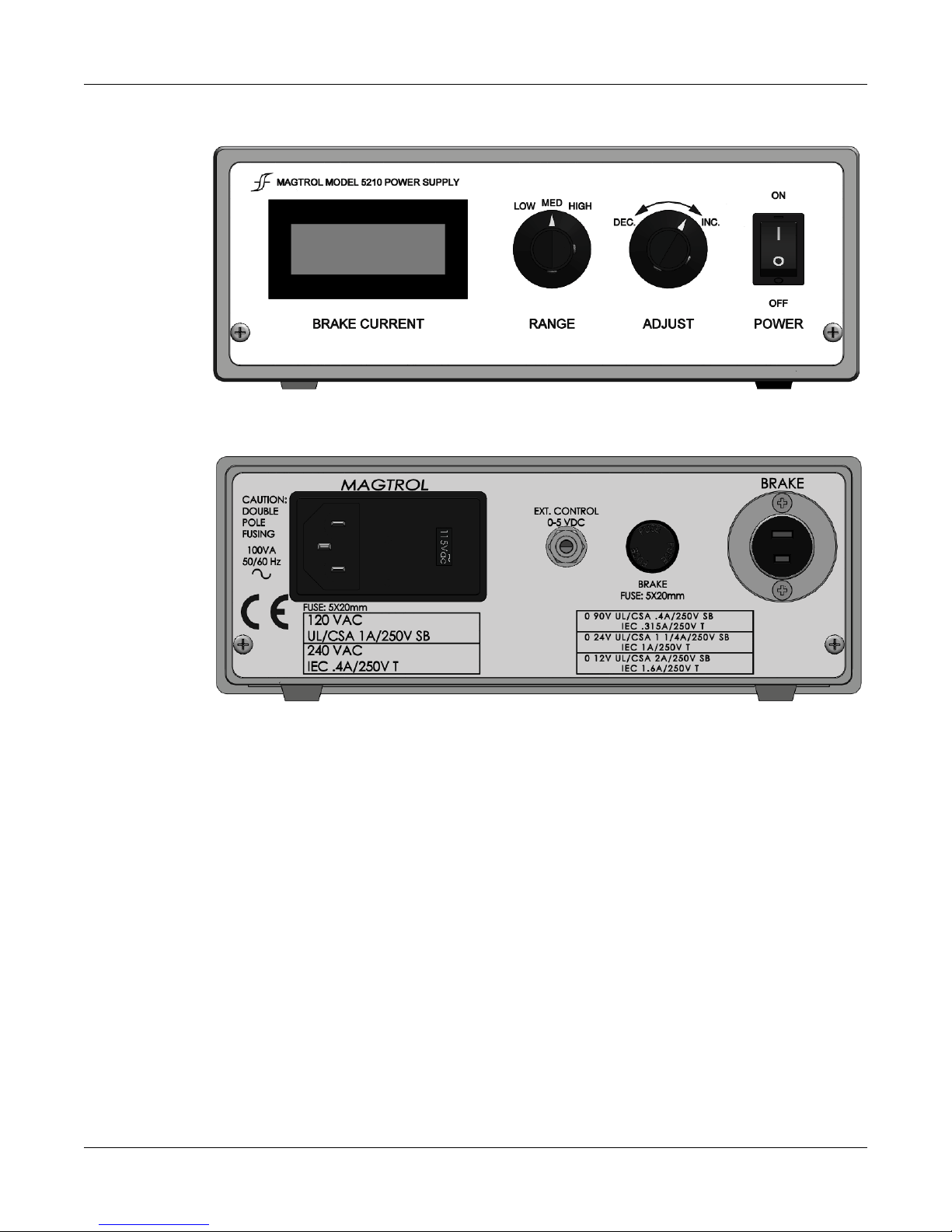

The 5210 is a solid-state control that provides smooth application of current from zero to maximum.

Braking power can be controlled manually from either the 10-turn potentiometer and adjustment

knob on the front panel, or externally from the 0–5 V DC input when remote operation is desired.

An LCD readout conveniently displays the applied braking current.

Note: Magtrol offers three different models of the 5210 Power Supply,

1.1 SpecificationS

each with a different maximum voltage output. The 5210-1 is 90

volts, 5210-2 is 24 volts, and the 5210-3 is 12 volts. All Magtrol

Dial Weight Dynamometers are designed with a 24 volt coil.

Therefore, the 5210-2 is the only power supply that should be used

with a dial weight dynamometer. The 5210-1 and 5210-3 are for

use with Magtrol brakes and clutches only.

Brake Voltage

CURRENT RANGES:

Low Scale

Medium Scale

High Scale

Current Regulation

Braking Control

Brake Fuse (5 × 20 mm)

Line Fuse (5 × 20 mm)

Power Requirements

Voltage Requirements

0 to 24 V DC

0 to 200 mA

0 to 500 mA

0 to 1000 mA

± 1% Full Scale

10-turn potentiometer (internal) or

0–5 V DC input (external)

UL/CSA 1.25 A 250 V SB

IEC 1.00 A 250 V T

120 V: UL/CSA 1.0 A 250 V SB

240 V: IEC 0.4 A 250 V T

100 VA

120/240 V AC 50/60 Hz

1

1.2 front and rear panel

Magtrol Model 5210-2 Power SupplyUser’s Manual

1.3 circuit deScription

Functionally, the circuit is a closed loop, current feedback amplifier regulating the output current at

the value set by the front panel controls.

DC current from the internal 35 volt power supply passes through the dynamometer coil connected

at the BRAKE connector J6, through the insulated gate field effect transistor Q1 (HEXFET), and

through a current sense resistor R13, R14 or R15 (selected by the RANGE control). The voltage

drop across the current sense resistor is amplified by Operational Amplifier U1b and applied to the

non-inverting differential input of Operational Amplifier U1a. Amplifier U1a amplifies the difference

between the conditioned current signal from the sense resistor and the voltage from the front panel

current ADJUST potentiometer, R6. This amplified error voltage is applied to the gate of transistor

Q1 to control its channel resistance and thereby regulates the output current at the value set by the

ADJUST control.

2

Loading...

Loading...