Page 1

I/O INTERFACE FOR TTL

MAGNETIC STRIPE READERS

TECHNICAL REFERENCE MANUAL

Manual Part Number 99875148 Rev-6

DECEMBER 2003

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

Copyright© 1999-2003

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

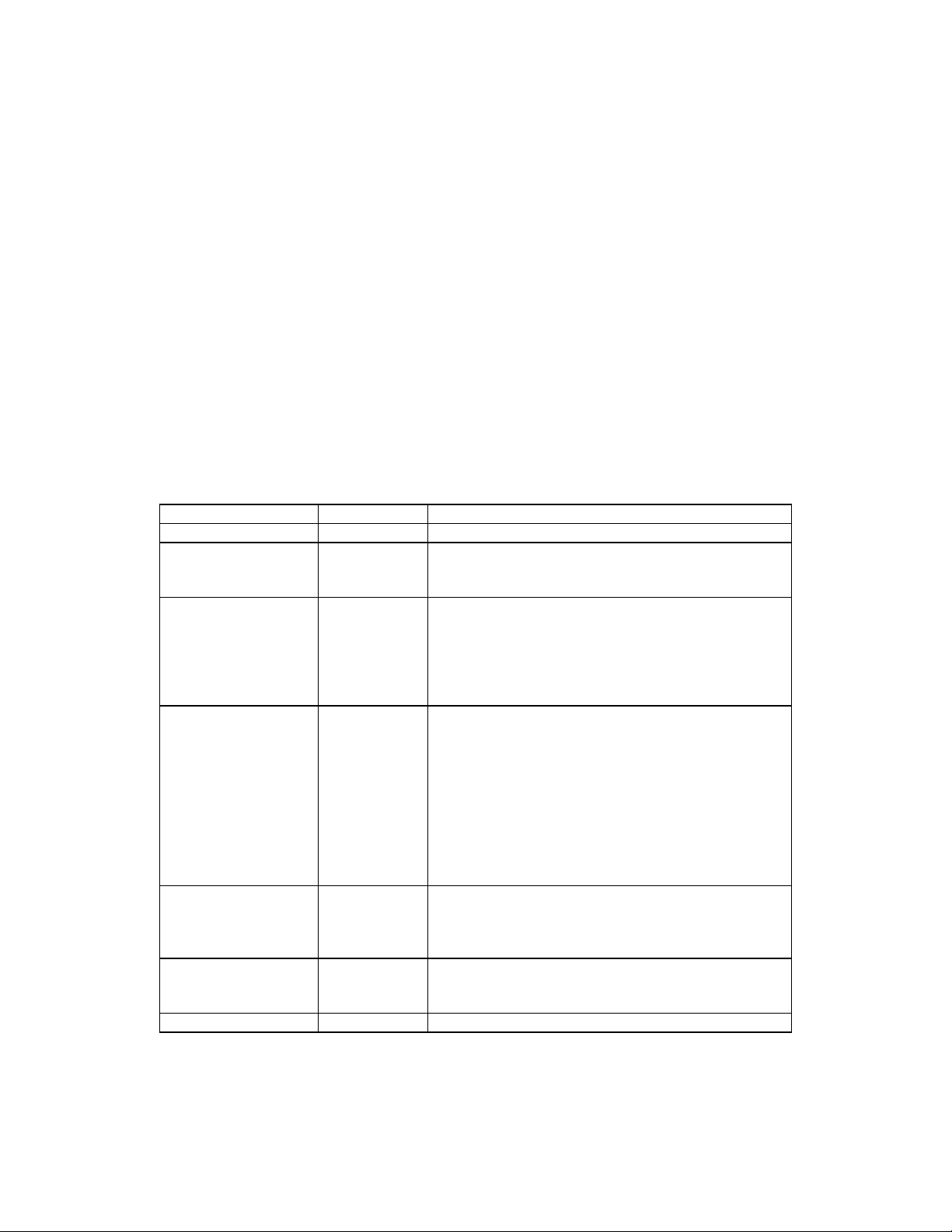

REVISIONS

Rev Number Date Notes

1 22 Oct 99 Initial Release

2 12 Jun 00 Table of Contents corre cte d; Appendix A,

Applications Note, Character Conversion

99875065-2 replaced -1 as update.

3 24 Jun 02 Sec 1: Updated MagTek Documents.

Sec 4: Corrected Error Checking, Track 2; added

Insertion Reader.

Appendix A: Replaced 99875065-2 with –3.

Appendix B: Replaced 99821066-8 with –10.

Appendix C: Editorial corrections.

4 06 Aug 02 Front Matter: Title change; Sec 1, MagTek

Documents, deleted Rev numbers and updated

P/N 210065015/16 to /16 only, added 8 manuals

to Reference Documents; Sec 2: corrected Error

Checking, Track 2, added Insertion Readers; Sec

4: added Insertion Readers subsection; Appendix

A : corrected character ]ND and bumped rev;

Appendix B: removed DIP IC 15, bumped rev;

Appendix C: changed ANSI address, and

dimensions on Trks 1, 2, 3.

5 07 Aug 03 Editorial and format corrections throughout. Front

Matter: added ISO line to logo, changed Tech

Support phone number. Sec 2: added note to

Figure 2-2.

6 17 Dec 03 Appendix C, Standards, Card Data Format –

Track 1: extended Data Character line to include

Format Code (FC).

ii

Page 3

TABLE OF CONTENTS

SECTION 1. DECODING READER OUTPUT.............................................................................................1

REFERENCE DOCUMENTS ...................................................................................................................2

MAGTEK DOCUMENTS INCLUDED IN THIS MANUAL.........................................................................2

TRACK 1 DATA FORMAT........................................................................................................................3

TRACKS 2 AND 3 DATA FORMAT..........................................................................................................4

SECTION 2. ENCODING............................................................................................................................. 7

TIMING ...................................................................................................................................................10

DATA ......................................................................................................................................................10

STROBE.................................................................................................................................................10

CARD PRESENT....................................................................................................................................10

SECTION 3. LRC CALCULATION............................................................................................................13

SECTION 4. ERROR CHECKING.............................................................................................................15

ERROR CHECKS BY A TYPICAL READER .........................................................................................15

ERROR CHECKING, TRACK 2, WITH AN INTEL 8751........................................................................16

INSERTION READERS..........................................................................................................................18

SECTION 5. BIDIRECTIONAL READING AND AMPLITUDE VARIATIONS..........................................19

READING IN ONE DIRECTION VERSES BOTH DIRECTIONS........................................................... 19

CARD READBACK AMPLITUDE VARIATIONS....................................................................................20

APPENDIX A. CHARACTER CONVERSION........................................................................................... 21

TRACK 1 CHARACTER SET.................................................................................................................21

TRACK 2 AND 3 CHARACTER SET .....................................................................................................21

APPENDIX B. READ IC 21006516 SPEC SHEET ................................................................................... 23

APPENDIX C. STANDARDS ....................................................................................................................27

APPENDIX D. CARD READER INTERFACE........................................................................................... 29

INTERFACING THE CARD READER TO A MICROPROCESSOR......................................................29

SINGLE - BIT INPUT PROGRAMMING.................................................................................................29

USART....................................................................................................................................................29

DETECTING START SENTINEL............................................................................................................30

BIDIRECTIONAL READING................................................................................................................... 30

CONVERTING CARD DATA TO ASCII DATA ....................................................................................... 30

TRACK 1.................................................................................................................................................30

TRACK 2 & 3 ..........................................................................................................................................30

FIGURES

Figure 2-1. Bit Cell - Flux Transition -----------------------------------------------------------------------------------------8

Figure 2-2. Card Coding --------------------------------------------------------------------------------------------------------9

Figure 2-3. Timing--------------------------------------------------------------------------------------------------------------10

iii

Page 4

iv

Page 5

SECTION 1. DECODING READER OUTPUT

The usual way to gather card data from a TTL (Transistor Transistor Logic) swipe magnetic card

reader is as follows:

1. Connect the strobe line to an interrupt port on the CPU tha t is programmed to interrupt on

the falling edge of the strobe.

2. Connect the data line to an ordinary CPU port pin.

3. Connect the card present line to another ordinary CPU port pin.

All three of the above signals are quiescently high (Vcc). When a card is swiped , the f i rst s ign al to

go low (active) is Card Present. It will go low after 14 to 15 head flux reversals have been read.

These initial strobes are not output on the strobe line. After Card Present goes low, the strobes are

output on the strobe line. Normally, storing data is not begun until the data line goes low (indicating

a one) and the strobe line falls. When this occurs, the CPU starts to store the data in RAM (Random

Access Memory) until the strobes stop because the card has cleared the head. Approximately

150ms later, Card Present returns to V

checks for parity errors and LRC (Longitudinal Redundancy Check or check sum) error. If no

errors are detected, the CPU outputs the data in some useful form, such as ASCII (American

Standard Code for Information Interchange) or Keyboard Scan Code.

There are two methods of storing data, one way is to put each character into its own byte in RAM.

The advantage of this method is that it is easy to debug the software. The disadvantages are that

some bits are not used (wasted) and the card can only be read in the forward direction. The second

method is to stor e all b its f rom the ca rd in to RAM (no unused bits). The only disadvantage to this

method is that it is difficult to debug your software code. The reason being, in the case of Track 2

(5 bits per character), the first byte of RAM has the first character (5 bits) and 3 bits of the second

character. The second byte of ram has 2 bits of the second character, 5 bits of the third character,

and 1 bit from the fourth character, etc. When using In-Circuit Emulation (ICE) to decode the data

in RAM, it is difficult to figure out what you have. Also, with both methods the data is read in

backwards (Least Sign ific ant Bit F irs t).

If you run out of interrupts, one way to create another interrupt is to set a counter to all one's. When

the strobe falls, the cou nter increm ents cau sing a counter interrupt which can be used to collect the

data bit and reset the counter to all one's again.

When this occurs, the CPU analyzes the data in RAM and

cc.

1

Page 6

I/O Interface for TTL Magnetic Stripe Readers

REFERENCE DOCUMENTS

43-millimeter Compatible, Swipe Reader, Technical Reference Manual, P/N 99875148

90-millimeter Compatible, Swipe Reader, Technical Reference Manual, P/N 99831083

100-millimeter Compatible, Swipe Reader, Technical Reference Manual, P/N 99831012

101-millimeter Compatible, Swipe Reader, Technical Reference Manual, P/N 99821101

Slim Profile Card Guide, Swipe Reader, Technical Reference Manual, P/N 99875147

MT-215, TTL, Half Card Insertion Reader, Technical Reference Manual, P/N 99875009

Model MT-215, TTL, Insertion Reader, Technical Reference Manual, P/N 99875042

IntelliStripe 50 Manual Insertion Reader Tech Reference Manual, P/N 99875079

Model MT-215 TTL, Single or Dual Head, Insertion Reader Technical Reference Manual,

P/N 99875113

IntelliStripe 60, TTL Insertion Reader, Technical Reference Manual, P/N 99875135

Petrol (P-Series), TTL, Insertion Readers, Technical Reference Manual, P/N 99875139

Model MT-215, TTL, Single Head, 3-Track, Insertion Reader Technical Reference Manual,

P/N 99875157

MAGTEK DOCUMENTS INCLUDED IN THIS MANUAL

The following MagTek documents are included as appendices in this manual:

Appendix A. Character Conversion, P/N 99875065

Appendix B. Read IC 21006516 Spec Sheet, P/N 99821066

Appendix C. Magnetic Stripe Card Standards, P/N 99800004

Appendix D. Card Reader Interface, P/N 99875063

2

Page 7

Section 1. Decoding Reader Output

TRACK 1 DATA FORMAT

The following is typical for Track 1 data.

The Track 1 data format includes the following items:

1. Approximately 62 leading clocking zeros

2. The Start Sentinel "%"

3. Up to 76 alphanumeric characters selected by the user

4. The end sentinel "?"

5. The LRC (longitudinal redundancy check character)

6. Trailing clocking zeros (minimum of 62) to the end of the card

Each data character is in a 7-bit (6 plus parity) alphanumeric format. The data is in the format

"parity, 32, 16, 8, 4, 2, 1". Parity is odd (an odd number of "one's" in each character).

The character is written "backwards" on the card starting with the least significant digit and

ending with the parity bit. The card data format is "1, 2, 4, 8, 16, 32, parity".

See Appendix C for ATM and credit card formats.

Example: The data message "AT3" is encoded on the card as follows:

1. "000..00" leading clocking zeros (approximately 62)

2. "1010001" the Start Sentinel "%" (1000101)

3. "1000011" the character "A"* (1100001)

4. "0010110" the character "T"* (0110100)

5. "1100100" the character "3" (0010011)

6. "1111100" the End Sentinel "?" (0011111)

7. "0011100" the character "<"** (0011100) the LRC (check digit)

8. "000..00" trailing clocking zeros (minimum of 62) to end of the card

*Use capital letters only.

**The character "<" is not defined by credit card standards but is a legitimate LRC character.

The binary values of all card data can be found in the MagTek publication, Application Note Character Conversion, Part Number 99875065, see Appendix A.

See Appendix C for ATM and Credit Card Formats.

3

Page 8

I/O Interface for TTL Magnetic Stripe Readers

Calculating odd parity and LRC, for the message AT3:

P 32 16 8 4 2 1 Hex Value, Decimal Value

Less Parity Less Parity

Start sentinel % 1 0 0 0 1 0 1 05 hex 05 (4+1)

A 1 1 0 0 0 0 1 21 hex 33 (32+1)

T 0 1 1 0 1 0 0 34 hex 52 (32+16+4)

3 0 0 1 0 0 1 1 13 hex 19 (16+2+1)

End sentinel: ? 0 0 1 1 1 1 1 1F hex 31 (16+8+4+2+1)

___________ ___ __

LRC < 0 0 1 1 1 0 0 1C hex 28 (16+8+4)

Calculating odd parity: scan each horizontal row and enter a zero or one In the P column so that

each row has an odd number of one's.

To find the LRC: disregard the parity bits, scan up each vertical column, and make sure that each

column has an even number of one's in it. Enter a zero or one in the LRC position, so that it

does. If you are using a computer to calculate the LRC, use the "Exclusive OR" function. Next,

calculate odd parity for the LRC character, in the horizontal direction.

TRACKS 2 AND 3 DATA FORMAT

The following is typical for Track 2 and Track 3 data.

The Track 2 and 3 data formats include the following items:

1. Leading clocking zeros: Approximately 22 (Track 2) or 62 (Track 3)

2. The start sentinel (hexadecimal "B")

3. Up to 37 (track 2) or 104 (track 3) hexadecimal numeric characters selected by the user

4. The end sentinel (hexadecimal "F")

5. The LRC (longitudinal redundancy check character)

6. Trailing clocking zeros: A minimum of 22 (track 2) or 62 (track 3)

to the end of the card

Each data character is in a 5-bit (4 plus parity) numeric format. The data is in the format "parity,

8, 4, 2, 1". Parity is odd (an odd number of one's in each character).

The character is written "backwards" on the card starting with the least significant bit and ending

with the parity bit. The card data format Is "1, 2, 4, 8, parity".

Example: The data message "123" is encoded on the card as follows:

4

Page 9

Section 1. Decoding Reader Output

1. "00.00" leading clocking zeros Approximately 22 (tk2) or 62 (tk3)

2. "11010" the character "hex B" (01011) the Start Sentinel

3. "10000" the character "1" (00001)

4. "01000" the character "2" (00010)

5. "11001" the character "3" (10011)

6. "11111" the character "hex F" (11111) the End Sentinel

7. "00100" the character "4" (00100) the LRC (check digit)

8. "00.00" trailing clocking zeros A minimum of 22 (Tk2) or 62 (tk3)

to the end of the card

Calculating odd parity and LRC for the message 123:

P 8 4 2 1 Hex Value Decimal Value

Less Parity Less Parity

Start Sentinel: B 0 1 0 1 1 B 11 (8+2+1)

1 0 0 0 0 1 1 1

2 0 0 0 1 0 2 2

3 1 0 0 1 1 3 3 (2+1)

End Sentinel: F 1 1 1 1 1 F 15 (8+4+2+1)

___________ __

LRC 4 0 0 1 0 0 4 4

Calculating odd parity: scan each horizontal row and enter a zero or one In the P column so that

each row has an odd number of one's.

To find the LCR: disregard the parity bits, scan up each vertical column, and make sure that each

column has a even number of one's in it. Enter a zero or one in the LCR position, so that it does.

If you are using a computer to calculate the LCR, use the "exclusive or" function. Next, calculate

odd parity for the LCR character, in the horizontal direction.

The Hex characters are usually displayed in their ASCII equivalent: Hex B as a ";" semicolon,

Hex D as an "=" equal sign, and Hex F as a "?" question mark.

5

Page 10

I/O Interface for TTL Magnetic Stripe Readers

6

Page 11

SECTION 2. ENCODING

There are several schemes used to record or encode ones and zeros in the computer industry.

(We use the term record and encode synonymously.) In the card industry the International

Organization for Standardization (ISO) has defined F2F as the encoding scheme for cards. F2F

stands for frequency - double frequency, or for the purist - two frequency coherent phase

recording. F2F encoding provides for self-clocking data. That is, the serial data stream

consisting of one and zero bits provides the timing information for the reader to determine which

bit is which.

The key feature of self-clocking data is that the data bits can be extracted from the serial data

stream without the need to control the speed of the magnetic media past the encoding head.

Thus, card swipe readers, where a human hand is passing the card through the read slot can work

regardless of how fast or slow the card is passing through the slot. Serial data merely means that

the one and zero bits, that form the desired characters, are stored on the same track, one bit after

the next bit.

F2F is an encoding technique which places flux transitions on the magnetic stripe separated by a

defined distance for zero bits and one half that distance for one bits.

The defined distance for Track 1 and Track 3 is 0.0047619 inches for zero bits. This value is the

reciprocal of the bit density of Track 1 - 210 bits per inch. For one bits - 0.0023809 (1/2 the zero

bit distance.)

The defined distance for Track 2 is 0.013333 inches for zero bits. This value is the reciprocal of

the bit density of Track 2 - 75 bits per inch. for one bits - 0.0066665 inches (1/2 the zero bit

density.)

Figure 2-1 illustrates this concept.

7

Page 12

I/O Interface for TTL Magnetic Stripe Readers

Figure 2-1. Bit Cell - Flux Transition

The encoding device has the responsibility to separate the flux transitions at the proper distance.

Variations in the proper distance between flux transitions is what is commonly referred to as

jitter.

Before the desired information can be stored (encoded) on the card, many things must happen.

The information itself (the alphanumeric characters for Track 1 and the numeric characters for

Tracks 2 and 3) needs to be coded. That is, the information must be converted to one and zero

bits. The one and zero bit code for each character can be found in the Coded Character Set tables

in ISO/IEC 7811-2, see Appendix A. These tables define the pattern of the one and zero bits for

each character. There is a special bit that is added to each character code for the purpose of error

detection. This special bit is called a parity bit. The parity bit is either a zero bit or a one bit

depending on whether the number of one bits in the character is an even number or and odd

number. The ISO standard has defined that for all tracks odd parity is maintained on each

character.

This means that if the character has an odd number of one bits in the character code for that

character, the parity bit is then a zero bit. On the other hand, if the character has an even number

of one bits in the character code for that character, the parity bit is a one bit causing the total

number of one bits to be odd. Thus the term odd parity.

8

Page 13

Section 2. Encoding

Before the first character (or more specifically, the first series of bits that define the desired first

character) can be encoded, a Start Sentinel character needs to be encoded. The Start Sentinel is a

defined series of bits, which signal the start of the data bits. Track 1 Start Sentinel consists of

seven bits (as all characters on Track 1). Track 2 and 3 Start Sentinel consists of five bits (as all

characters on Track 2). As an example, the Track 2 Start Sentinel code is: 11010.

After the last data character is encoded, an End Sentinel must be encoded. The End Sentinel is a

defined series of bits, which signal the end of the data bits. Immediately after the End Sentinel, a

special error checking character is also encoded. This error checking character is called the LRC

- Longitudinal Redundancy Check character. For further details see Section 3.

Before the Start Sentinel character and after the LRC character, “clocking bits” are encoded.

These clocking bits provide card readers with timing to start their synchronization process before

encountering the start sentinel (or end sentinel for reverse reading). Figure 2-2 illustrates the

relative location of all the characters previously discussed.

This means that if the character has an odd number of one bits in the character code for that

character, the parity bit is then a zero bit. On the other hand, if the character has an even number

of one bits in the character code for that character, the parity bit is a one bit causing the total

number of one bits to be odd. Thus the term odd parity.

Figure 2-2. Card Coding

Note: In this example, Start Sentinel is Hex B, End Sentinel is Hex F, and LRC is Hex F.

Note that as you look at the diagram, while not to scale, the encoded information does travel

from right to left along the length of the magnetic stripe. See Appendix A.

9

Page 14

I/O Interface for TTL Magnetic Stripe Readers

TIMING

The timing for Card Present, Strobe, and Data is as shown in Figure 2-3.

CARD PRESENT

DATA

0 0 0 0

1 1 1 0 0 0 0 0 1 1 0

STROBE

Notes:

1. Time out of the CARD PRESENT signal occurs approximately 150 ms after the last strobe transition.

Bit

Time

STROBE WIDTH APPROXIMATELY

25-50% OF BIT TIME

2. DATA is valid 1.0μ sec before the negative edge of STROBE.

Figure 2-3. Timing

DATA

The Data signal is valid while the strobe is low. If the Data signal is high, the bit is a zero. If the

Data signal is low, the bit is a one.

STROBE

The Strobe signal indicates when Data is valid. It is recommended that Data be loaded by the

user with the leading edge (negative) of the Strobe.

CARD PRESENT

Card Present will go low after 14/15 flux reversals from the head. Card Present will return high

150 milliseconds after the last flux reversal.

10

Page 15

Section 2. Encoding

When no card is being moved through the unit, the Data, Strobe, and Card Present signals are

high. The signal timing diagram shown above represents the data along with other signals that

are generated during the reading process.

11

Page 16

I/O Interface for TTL Magnetic Stripe Readers

12

Page 17

SECTION 3. LRC CALCULATION

The formula for calculating LRC below uses Track 2 as an example. Perform the following:

1. Write the value for each character (see examples below and Appendix A).

2. Do not use the odd parity bit (P) in the formula for calculating LRC calculation.

3. Count the number of one bits in each of the 4 vertical columns.

4. Enter a zero or one in the LRC position so that each vertical column has a even number

of ones (not the parity column {P}).

5. After all 4 vertical columns have their LRC bit affixed, affix odd parity to the LRC

character itself.

Examples:

P 8 4 2 1 P 8 4 2 1 P 8 4 2 1

B 0 1 0 1 1 B 0 1 0 1 1 B 0 1 0 1 1

0 1 0 0 0 0 0 1 0 0 0 0 0 1 0 0 0 0

F 1 1 1 1 1 1 0 0 0 0 1 1 0 0 0 0 1

_______ F 1 1 1 1 1 2 0 0 0 1 0

4 0 0 1 0 0 _______ 3 1 0 0 1 1

Where: 5 1 0 1 0 1 F 1 1 1 1 1

"B" is the start sentinel _______

"F" is the end sentinel 4 0 0 1 0 0

The LRC is under the line

13

Page 18

I/O Interface for TTL Magnetic Stripe Readers

Calculation of LRC for an encoder, using a Micro Processor (Intel 8751), is as follows:

START:

MOV R2,#0 ;ZERO REGISTER 2 (LRC ACCUMULATOR)

MOV R0,#START_SEN ;POINT AT FIRST CARD CHARACTER (START SENTINEL)

LOOP1:

MOVX A,@R0 ;PUT A CARD CHARACTER INTO THE ACCUMULATOR

ANL A,#0FH ;MASK OFF THE PARITY BIT

XCH A,R2 ;EXCHANGE THE ACCUMULATOR & REG 2

XRL A,R2 ;"EXCLUSIVE OR" ACC WITH R2

XCH A,R2 ;RUNNING TOTAL OF LRC IS NOW IN REG 2, CARD CHARACTER IN ACC.

INC R0 ;POINT AT THE NEXT CHARACTER

CJNE A,0FH,LOOP1 ;COMPARE, JUMP TO LOOP1 IF NOT EQUAL TO A END SENTINEL.

;WHEN THE PROGRAM FALLS THROUGH THE ABOVE INSTRUCTION THE FINAL LRC IS

;IN REGISTER 2, WE CALL THE ODD PARITY ROUTINE TO AFFIX ODD PARITY TO THE

;LRC AND WE ARE READY TO WRITE THE LRC ON A CARD.

14

Page 19

SECTION 4. ERROR CHECKING

This section describes error checking by a typical single track reader and with and Intel 8751

CPU on a typical Track 2 reader.

ERROR CHECKS BY A TYPICAL READER

The following error checking is performed by a typical card reader:

1. While the card is being swiped no error checking is done. All of the micro processor unit

(MPU) time is being devoted to storing the data being read off the card into memory

(RAM). Normally the strobe output from the card reader is connected to an interrupt

input on the MPU. The MPU is set so that the interrupt is triggered on the falling edge of

the strobe. The data output line from the card reader goes to a normal MPU port input

pin. On each Falling edge of the strobe, one bit of data is collected from the data input

line and the interrupt routine is exited. The 'Card Present' output from the card reader

goes to a normal MPU port Input pin. All outputs from the card reader are quiescently

high (Vcc).

2. When 'card present' returns to high again the MPU knows that the card has cleared the

read head and error checking can begin. The MPU now checks each character that it

collected in step 1 for the following:

A. Checks to ensure the first character is a 'Start Sentinel'. This will be a hex B (01011)

for Track 2 or Track 3. For Track 1 it will be a percent sign (1000101).

B. Checks each character for odd parity (an odd number of one bits).

C. Updates the LRC total as each character is checked.

D. Checks to see if the current character is an 'End Sentinel' (11111, 0011111). If no

'End Sentinel' is found, this is an error. When the 'end sentinel' is found, the MPU

inputs the next character (LRC), checks its parity, and updates the LRC total. It

then checks that the LRC total is zero. If it is not zero it is an error.

3. Some readers keep count of the number of characters checked, and if this number

exceeds the maximum allowed, will give an error. The maximum allowed is: track 1 =

79; track 2 = 40; track 3 = 107.

4. If for some reason you do not have enough interrupts available to use the preceding

method, MagTek can provide an application note on how to do it without using

interrupts. This is done by using a "USART" for each track along with an MPU. See

Appendix D.

15

Page 20

I/O Interface for TTL Magnetic Stripe Readers

ERROR CHECKING, TRACK 2, WITH AN INTEL 8751

Example of error checking in a Track 2 reader, using an Intel 8751 CPU:

; INITAILIZE REGISTERS AND FLAG BITS.

CHECK: MOV R2,#0 ;ZERO REGISTER 2 (LRC ACCUMULATOR)

CLR PARITY_FLAG ;CLEAR THE PARITY ERROR FLAG

MOV R0,#START_SEN ;POINT AT FIRST CARD CHARACTER IN RAM (START SENTINEL)

; START PARITY AND LRC CHECK (LONGITUDINAL REDUNDANCY CHECK CHARACTER).

CK0: CALL CK1 ;GO TEST A CHARACTER

CJNZ A,0FH,CK0 ;COMPARE ACCUMULATOR TO END SENTINEL, GO TO CK0 IF NOT ES

;IF IT'S A END SENTINEL THE PROGRAM DROPS THROUGH

CALL CK1 ;GO UPDATE THE LRC CHARACTER

MOV A,R2 ;MOVE REGISTER 2 TO THE ACCUMULATOR, GET THE LRC SUM

JNZ ERROR ;IF LRC SUM IS NOT ZERO, THIS EQUALS AN ERROR

JB PARITY_FLAG,ERROR ;SKIP TO ERROR IF PARITY FLAG IS SET

NOP ;IF THIS POINT IS REACHED THE CARD WAS READ CORRECTLY

;END OF TEST

; CK1--LRC SUBROUTINE

; THIS ROUTINE KEEPS THE RUNNING SUM OF THE LRC IN REGISTER 2

CK1: MOVX A,@R0 ;PUT A CARD CHARACTER FROM RAM INTO THE ACCU MULATOR

CALL PARITY_CK ;CHECK FOR ODD PARITY

MOVX A,@R0 ;GET THE SAME CHARACTER AGAIN

ANL A,#0FH ;ZERO THE FIRST 4 BITS, INCLUDING THE PARITY BIT

XCH A,R2 ;EXCHANGE ACCUMULATOR AND REGISTER 2

XRL A,R2 ;"EXCLUSIVE OR" THE ACCUMULATOR WITH REGISTER 2

XCH A,R2 ;EXCHANGE ACCUMULATOR AND REGISTER 2

INC R0 ;POINT AT THE NEXT CHARACTER

RET ;RETURN, AT THIS TIME THE RUNNING LRC IS IN REGISTER 2

16

Page 21

Section 4. Error Checking

; PARITY--PARITY SUBROUTINE

; COUNTS THE NUMBER OF 'ONES' IN THE ACCUMULATOR.

; SETS THE 'PARITY ERROR FLAG' IF IT FINDS A CHARACTER WITH AN EVEN NUMBER OF ONE BITS.

PARITY_CK:

MOV R4,#0 ;INITIALIZE THE 'ONES' BIT COUNTER TO ZERO

PARITY1: CLR C ;CLEAR THE CARRY

PARITY2: JZ PARITY3 ;SKIP TO PARITY3 IF ACC U MULATOR ZERO, DONE, GO TO PARITY3

RRC A ;ROTATE THE ACCUMULATOR RIGHT, THROUGH THE CARRY

JNC PARITY2 ;IF THE CARRY IS 'ZERO', GO TO PARITY2

INC R4 ;OTHERWISE INCREMENT THE '1' COUNTER & GO TO PARITY1

JMP PARITY1 ;GO TO PARITY1 AND CONTINUE

PARITY3: MOV A,R4 ;PUT THE 'ONES' COUNT INTO THE ACCUMULATOR

JB ACC.0 PARITY4 ;IF BIT 0 IS A 1 (ODD), CHARACTER IS OK, RETURN

SETB PARITY_FLAG ;PARITY IS EVEN, SO SET ERROR FLAG

PARITY4: RET ;RETURN

ERROR: ;THE READ ERROR ROUTINE IS ENTERED AT THIS POINT.

17

Page 22

I/O Interface for TTL Magnetic Stripe Readers

INSERTION READERS

While it is possible for the card reader to read data on either the insertion or withdrawal stroke, it

should be noted that card reading is most reliable during the card withdrawal stroke. For this

reason MagTek recommends that customer’s software be designed to emphasize data capture

during the card withdrawal stroke.

For the most reliable operation:

1. Read the card upon insertion. When the card hits the backstop (Card Present will go

high), check the data for errors.

2. If the data contains no errors, output that data, start sentinel first, after the card has been

withdrawn.

3. If an error was detected, clear that data and get ready to read the card again upon

withdrawal.

4. After the card is removed (Card Present will go high), check the data for errors.

5. If no errors are found, output that data, start sentinel first.

6. If an error is detected, indicate to the host that an error was detected, indicate to the

customer to insert the card again.

18

Page 23

SECTION 5. BIDIRECTIONAL READING AND AMPLITUDE

VARIATIONS

READING IN ONE DIRECTION VERSES BOTH DIRECTIONS

1. The simplest way to read a card is in one direction only, with the Start Sentinel read first.

If this method is chosen, normally each character is stored in one byte of memory.

During the debug operation this Is a simple and clear method to see what is happening

using 'In Circuit Emulation' (ICE).

2. If reading in both directions is desired, the normal method is to scan the data in the

forward direction and if no errors are found, then the data is sent. If an error is found,

then the scan is done in the reverse direction. And if no error is found the data is sent in

the forward direction (Start Sentinel first). If an error is found in both directions, then an

error is Reported.

3. To be able to process the data in both directions, it is necessary to pack the data into

RAM without any unused bits between characters. In the case of 5 bit data, the first byte

will have the first character plus 3 bits of the Second character. The second byte will

have 2 bits of the second character, 5 bits of the third character and one bit of the fourth

character, etc. With the data not being on byte boundaries, it can be difficult to decode it

and especially difficult when looking at the data using ICE.

4. When a card is read in the forward direction, the Start Sentinel is first, and the Start

Sentinel was chosen so that the first bit would be a one. This makes it simple to tell when

you have reached the end of leading clocking zeros and the first data bit. It also allows

for the first bit to be on a Byte boundary.

When a card is read in the reverse direction, there is no way to tell the boundary between

the trailing zeros (which are now acting as the leading zeros) and the LRC character. For

example, if the LRC is 1 (00001), then the first one bit will be encountered as the fifth bit

of the message, and there is no easy way to tell when the trailing zeros stop and the LRC

starts:

B 5 F 1

000000000,11010,10101,11111,10000,00000000

which really looks like this:

0000000001101010101111111000000000000

As you can see if you are scanning right to left, it is not easy to tell where the clocking zeros stop

and the message begins.

19

Page 24

I/O Interface for TTL Magnetic Stripe Readers

It is necessary to write a program that will:

1) go through memory, starting from the end that has the start sentinel, and

2) decode the characters (which may be forward or backwards depending on which way the card

was swiped and not on a byte boundary), and

3) check for errors then transmit the characters forward back To the host.

Another problem is that the LRC will assume the same value as the Start Sentinel some of the

time, and when it does, then the character adjacent to it has to be tested to see if it is an end

sentinel. If it is an end sentinel, then this character is an LRC otherwise it is a Start Sentinel. In

this way you can make sure which end is really the beginning. See Appendix D, Bidirectional

Reading.

CARD READBACK AMPLITUDE VARIATIONS

Causes of readback amplitude variations are as follows:

• Speed of the card - the faster, the more amplitude

• Head contact, head pressure, smoothness of stripe, bumps

• Quality of oxide

• Orientation of oxide (polarization)

• Thickness of oxide

• Type of oxide, low or high coercivity

To check the amplitude variations, connect a scope between ground (pin 5) and drive or gain set

(pin 9 or 11), on the F2F read/decode IC. Swipe an encoded card, and check the scope for the

variations above.

The waveshape should be similar to Figure 2-1. For pin locations refer to Appendix B,

Connection diagram (Pin Outs).

20

Page 25

APPENDIX A. CHARACTER CONVERSION

TRACK 1 CHARACTER SET

Card Data ASCII Card Data ASCII

Character P B6 B5 B4 B3 B2 B1 P0 P1 EP OP Character P B6B5 B4 B3 B2B1P0 P1 EP OP

Space 1 0 0 0 0 0 0 20 A0 A0 20 @ (ND) 0 1 0 0 0 0 0 40 C0 C0 40

! (ND) 0 0 0 0 0 0 1 21 A1 21 A1 A 1 1 0 0 0 0 1 41 C1 41 C1

" (ND) 0 0 0 0 0 1 0 22 A2 22 A2 B 1 1 0 0 0 1 0 42 C2 42 C2

# (OG) 1 0 0 0 0 1 1 23 A3 A3 23 C 0 1 0 0 0 1 1 43 C3 C3 43

$ 0 0 0 0 1 0 0 24 A4 24 A4 D 1 1 0 0 1 0 0 44 C4 44 C4

% (SS) 1 0 0 0 1 0 1 25 A5 A5 25 E 0 1 0 0 1 0 1 45 C5 C5 45

& (ND) 1 0 0 0 1 1 0 26 A6 A6 26 F 0 1 0 0 1 1 0 46 C6 C6 46

' (ND) 0 0 0 0 1 1 1 27 A7 27 A7 G 1 1 0 0 1 1 1 47 C7 47 C7

( 0 0 0 1 0 0 0 28 A8 28 A8 H 1 1 0 1 0 0 0 48 C8 48 C8

) 1 0 0 1 0 0 1 29 A9 A9 29 I 0 1 0 1 0 0 1 49 C9 C9 49

* (ND)

+ (ND)

, (ND)

- 0 0 0 1 1 0 1 2D AD 2D AD M 1 1 0 1 1 0 1 4D CD 4D CD

. 0 0 0 1 1 1 0 2E AE 2E AE N 1 1 0 1 1 1 0 4E CE 4E CE

/ 1 0 0 1 1 1 1 2F AF AF 2F O 0 1 0 1 1 1 1 4F CF CF 4F

0 0 0 1 0 0 0 0 30 B0 30 B0 P 1 1 1 0 0 0 0 50 D0 50 D0

1 1 0 1 0 0 0 1 31 B1 B1 31 Q 0 1 1 0 0 0 1 51 D1 D1 51

2 1 0 1 0 0 1 0 32 B2 B2 32 R 0 1 1 0 0 1 0 52 D2 D2 52

3 0 0 1 0 0 1 1 33 B3 33 B3 S 1 1 1 0 0 1 1 53 D3 53 D3

4 1 0 1 0 1 0 0 34 B4 B4 34 T 0 1 1 0 1 0 0 54 D4 D4 54

5 0 0 1 0 1 0 1 35 B5 35 B5 U 1 1 1 0 1 0 1 55 D5 55 D5

6 0 0 1 0 1 1 0 36 B6 36 B6 V 1 1 1 0 1 1 0 56 D6 56 D6

7 1 0 1 0 1 1 1 37 B7 B7 37 W 0 1 1 0 1 1 1 57 D7 D7 57

8 1 0 1 1 0 0 0 38 B8 B8 38 X 0 1 1 1 0 0 0 58 D8 D8 58

9 0 0 1 1 0 0 1 39 B9 39 B9 Y 1 1 1 1 0 0 1 59 D9 59 D9

: (ND)

; (ND)

< (ND) 0 0 1 1 1 0 0 3C BC 3C BC \ (ND) 1 1 1 1 1 0 0 5C DC 5C DC

= (ND) 1 0 1 1 1 0 1 3D BD BD 3D ] (ND) 0 1 1 1 1 0 1 5D DD DD 5D

> (ND)

? (ES) 0 0 1 1 1 1 1 3F BF 3F BF _ (ND) 1 1 1 1 1 1 1 5F DF 5F DF

1 0 0 1 0 1 0 2A AA AA 2A J 0 1 0 1 0 1 0 4A CA CA 4A

0 0 0 1 0 1 1 2B AB 2B AB K 1 1 0 1 0 1 1 4B CB 4B CB

1 0 0 1 1 0 0 2C AC AC 2C L 0 1 0 1 1 0 0 4C CC CC 4C

0 0 1 1 0 1 0 3A BA 3A BA Z 1 1 1 1 0 1 0 5A DA 5A DA

1 0 1 1 0 1 1 3B BB BB 3B [ (ND) 0 1 1 1 0 1 1 5B DB DB 5B

1 0 1 1 1 1 0 3E BE BE 3E ^ (FS) 0 1 1 1 1 1 0 5E DE DE 5E

TRACK 2 AND 3 CHARACTER SET

Card Data ASCII Card Data ASCII

Character P B4 B3 B2 B1 P0 P1 EP OP Character P B4B3B2B1 P0 P1 EP OP Hex Character

0 1 0 0 0 0 30 B0 30 B0 8 0 1 0 0 0 38 B8 B8 38

1 0 0 0 0 1 31 B1 B1 31 9 1 1 0 0 1 39 B9 39 B9

2 0 0 0 1 0 32 B2 B2 32 : (AS) 1 1 0 1 0 3A BA 3A BA A

3 1 0 0 1 1 33 B3 33 B3 ; (SS) 0 1 0 1 1 3B BB BB 3B B

4 0 0 1 0 0 34 B4 B4 34 < (ND) 1 1 1 0 0 3C BC 3C BC C

5 1 0 1 0 1 35 B5 35 B5 = (FS) 0 1 1 0 1 3D BD BD 3D D

6 1 0 1 1 0 36 B6 36 B6 > (ND) 0 1 1 1 0 3E BE BE 3E E

7 0 0 1 1 1 37 B7 B7 37 ? (ES) 1 1 1 1 1 3F BF 3F BF F

P = Parity

EP = Even Parity

OP = Odd Parity

P0 = Parity bit set to 0

P1 = Parity bit set to 1

SS = Start Sentinel

ES = End Sentinel

FS = Field Separator

AS = Account Separator (Track 3 only)

ND = Character Not Defined by Credit Card Standards

= Optional Graphic

OG

REGISTERED TO ISO 9001:2000

1710 Apollo Court, Seal Beach, CA 90740

Phone: (562) 546-6400, Help Line (651) 415-6800

Fax (562) 546-6301 http://www.magtek.com

P/N 99875065-4, 4/03Copyright 2000-2003, Mag-Tek

®

, Inc

21

Page 26

I/O Interface for TTL Magnetic Stripe Readers

22

Page 27

APPENDIX B. READ IC 21006516 SPEC SHEET

21006516 SMD (SOIC)

General Information

The F/2F Read/Decode Integrated Circuit in intended for use in recovering F/2F encoded data received fro m a

magnetic head.

Features

• 150 to more than 12,000 F/2F bits per second.*

• Low power: Full operation from 2.7 to 5.5 volts. Current below 2.0 mA.

• Recovers Data with as much as 30% dropout of amplitude.*

• Acce pts amplitudes from below 20% of ISO reference voltage to more than 250% of ISO reference voltage.*

• Meets or exceeds the requirement for:

IEC 1000-4-2 ESD (Electro Static Discharge)

IEC 1000-4-3 Radiated EMC Field (2x requirement)

IEC 1000-4-4 Electrical Fast Transient Burst requirement (transmissions on I/O cable)

* When used with MagTek read heads and recommended circuit.

Functional Block Diagram

Magnetic Stripe

F/2F Read/Decode

Integrated Circuit

Functional Description

The F/2F Read/Decode I.C. will recover clock and data signals from an F/2F data stream generated from a magnetic

head. The I.C. will function for data rates from 150 to more than 12,000 bits per second. Acquisition and tracking of

the data within this range is automatic. The F/2F Read/Decode I.C. is composed of three functional sections:

• Signal Conditioning and Detection

• Bit Recovery

• Enable/Disable Counters

The signal conditioning and detection section amplifies and filters the signal from the magnetic head, rejects common

mode noise, and detects the signal peaks. Other features include protection against certain waveform distortions that

may be present in the signal.

The enable/disable counters provide initialization for the recovery section. These counters initi alize both the bit

recovery and the signal conditioning and detection sections.

The Bit Recovery section locks onto the data rate and performs the recovery of individual bits from the F/2F data

stream.

23

Page 28

I/O Interface for TTL Magnetic Stripe Readers

Absolute Maximum Ratings (Non-Operating)

Supply Voltage .........................7.0 Volts

Voltage Input Range.................0 to VCC

Output Sink Current..................10 mA

Internal Power Dissipation........100 mW

Storage Temperature Range....-55 to 150°C

Lead Soldering (10 Sec.)..........260°C

Electrical Characteristics

Unit operates from 2.7 to 5.5 Volts (VCC) and -30° to 70°C

Test conditions: VCC = 5.00 Volts, Ambient Temperature = 25°C

Table 1: Electrical Characteristics.

Parameter Condition Min. Max. Typ. Units

Device Current 2 mA

Logic Low Out (VOL) at +2.0 mA 1 0.4 Volts

Logic High Out (VOH) at -2.0 mA 1 VCC - 0.5 Volts

Oscillator Frequency (2) 1.2 MHz

Notes:

1. TTL/CMOS compatible. Outputs covered include the following: Card Present, Read Data, Strobe and F/2F.

2. Frequency measured using R2 and C3 component values. Refer to recommended circuit for required values.

Signal Timing Diagram

Notes:

1. Card Present, Data, and Strobe are negative true logic.

2. Card Present goes low after 14-15 head flux reversals.

3. Card Present returns to high level approximently 150mS after the last flux transition.

4. Data is valid 1.0µS (min.) before the leading negative edge of strobe and remains valid until approximently 1.0µS

before the next STROBE.

DATA

The DATA signal is valid while the STROBE is low. If the DATA signal is high, the bit is a zero. If the DATA signal is

low, the bit is a one.

STROBE

The STROBE signal indicates when DATA is valid. It is recommended that DATA be loaded by the user with the

leading negative edge of the STROBE.

CARD PRESENT

CARD PRESENT will go low after 14-15 flux reversals from the head. It will return high if Reset or about 150

milliseconds after the last flux reversal. The CARD PRESENT signal can be tied together with other card present

signals from more than one IC, however use only one pull-up resistor (R4). E.g., if this is a 3 track reader, all 3 CARD

PRESENTS would be tied together using a single 10K resistor.

24

Page 29

Read IC 21006516 Spec Sheet

When no card is being moved through the unit, the DATA, STROBE and CARD PRESENT signals are high.

The signal timing diagram shown above represents the data along with other signals that are generated during the

reading process.

Reset Feature

In normal operation, the I.C. resets itself approximately 150 milliseconds after the last flux reversal from the magnetic

head. Reset may be forced by applying a pulse of 1.0 to 100 microseconds to the RESET pin. The positive edge of

the pulse will reset the I.C.

Connection Diagram (Pin Outs)

Recommended Circuit

This circuit is intended for use in systems employing F/2F data such as ID cards that conform to ISO 7811-2 or 7811-6.

21006516

VCC May be +2.7V to +5.5V

Tolerances: Resistors ±5%; C1, C3 ±5% NPO; other capacitors non-critical.

* R3 has different values for Rev B and Rev G. The table bellow shows the value of R3.

Table 2: Value of R3.

Rev B Rev G Rev

H

R3 470K 1.5M 1.5M

Printed Circuit Board Layout Requirements

The I.C. is a combined digital and analog system. The analog signal pins are very low level. Good layout pra ctice

requires that there be a separation of head and other analog signals from the digital outputs. The digital signals are:

DATA, STROBE, CARD PRESENT, F/2F OUT, OSC-OUT and OSC-IN. The analog signals in order of sensitivity are

HEAD in 1&2, SUM, DRIVE, GSR and BIAS. The digital signals must not pass near the first four analog signals. The

layout below illustrates the requirements.

25

Page 30

I/O Interface for TTL Magnetic Stripe Readers

Caution

Keep Data, Strobe, and Card Present signals away from Head 1 and Head 2 signals.

SOIC Physical Dimensions

REGISTERED TO ISO 9001:2000

1710 Apollo Court, Seal Beach, CA 90740

Phone: (562) 546-6400, Help Line (651) 415-6800

Fax (562) 546-6301

http://www.magtek.com

P/N 99821066-11, 6-24-03, Copyright© 1998 -2003,

MagTek, Inc.

26

Page 31

APPENDIX C. STANDARDS

DIMENSIONS − FINANCIAL TRANSACTION CARDS

ISO 7810 Physical Characteristics of Credit

Card Size Document

7811-1 Embossing

7811-2 Magnetic Stripe - Low Coercivity

7811-3 Location of Embossed Characters

7811-4 Location of Tracks 1 and 2

7811-5 Location of Track 3

7811-6 Magnetic Stripe - High Coercivity

7813 Financial Transaction Cards

For Copies of Specifications contact:

AMERICAN NATIONAL STANDARDS INSTITUTE

25 W. 43rd Street, New York, New York 10036

(212) 642-4900

MAGNETIC STRIPE ENCODING − FINANCIAL TRANSACTION CARDS

0.223" RECORDING DENSITY CHARACTER CONFIGURATION INFORMATION CONTENT

(bits per inch) (including parity bit) (including control characters)

0.100" Track 1 IATA 210BPI 7 BITS PER CHARACTER 79 APHANUMERIC CHARACTERS

0.100" Track 2 ABA 75BPI 5 BITS PER CHARACTER 40 NUMERIC CHARACTERS

0.100" Track 3 Thrift 210BPI 5 BITS PER CHARACTER 107NUMERIC CHARACTERS

CARD DATA FORMAT - TRACK 1

76 ALPHANUMERIC DATA CHARACTERS

SS FC PAN FS NAME FS ADDITIONAL DATA DISCRETIONARY DATA ES LRC

Primary Account Name No. of Characters No. of Characters

Number (19 (26 alphanumeric Expiration Date (YYMM) 4 *PVKI 1

digits max.) characters Max.) Service Code 3 *PVV 4

*CVV or *CVC 3

Some or all of the above fields

may be found within the

Discretionary Data.

Control Characters:

SS = Start Sentinel %

FS = Field Separator ^ FC = Format Code *(PKIV) = PIN Verification Key Indicator

ES = End Sentinel ? LRC = Longitudinal Redundancy

Check Character *(CVV) = Card Verification Value

MAGNETIC STRIPE

EMBOSSED

INFORMATION

3.375"

Thick

0.030"

*(PVV) = PIN Verification Value

*(CVC) = Card Validation Code

2.125"

27

Page 32

I/O Interface for TTL Magnetic Stripe Readers

CARD DATA FORMAT − TRACK 2

37 NUMERIC DATA CHARACTERS

SS PAN FS ADDITIONAL DATA DISCRETIONARY DATA ES LRC

Primary Account Number

(19 digits Max.)

No. of Characters

Expiration Date (YYMM) 4

Service Code 3

*PVKI 1

*PVV or Offset 4

*CVV or CVC 3

Some of the above fields may

be found within the Discretionary

Data.

No. of Characters

SS = Start Sentinel Hex B ; ES = End Sentinel Hex F ?

Indicator

*(PKIV) = PIN Verification Key

FS = Field Separator Hex D = Longitudinal Redundancy *(PVV) = PIN Verification Value

Check Character *(CVV) = Card Verification Value

*(CVC) = Card Validation code

CARD DATA FORMAT − TRACK 3 (ISO 4909)

104 NUMERIC DATA CHARACTERS

SS PAN FS USE AND SECURITY DATA ADDITIONAL DATA ES LRC

Primary Account Number No. of Characters No. of Characters

(19 digits Max.) Country Code (opt.) 3

Currency Code 3 First Subsidiary

Currency Exponent 1 Account Number (opt.)

Amount Authorized per Cycle 4

Amount Remaining this Cycle 4 Second Subsidiary

Cycle Begin (Validity Date) 4 Account Number (opt.)

Cycle Length 2

Retry Count 1 Relay Marker 1

PIN Control Parameters (opt.) 6

Interchange Control 1 Cryptographic 6

PAN Service Restriction 2 Check Digit (opt.)

SAN-1 Service Restriction 2

Expiration Date (opt.) 4 Discretionary Data

Card Sequence Number 1

Card Security Number (opt.) 9

A Field Separator (FS) must be encoded if an optional field is not used.

SS = Start Sentinel Hex B ; FC = Format Code (2 digits)

FS = FS = Field Separator Hex D = LRC = Longitudinal Redundancy Check Character

ES = End Sentinel Hex F ?

This section is derived from P/N 99800004. Copies may be

obtained from MagTek.

*(PKIV) = PIN Verification Key

The track formats used in this

document are based on ISO

Standards, however, other

formats may be used. Contact

your card issuer for your exact

requirements.

28

Page 33

APPENDIX D. CARD READER INTERFACE

INTERFACING THE CARD READER TO A MICROPROCESSOR

The Mag-Tek Card Reader may be interfaced to a

microprocessor unit (MPU) in a number of ways.

Selection of the most suitable method will depend on the

system requirements and the MPU capabilities. The two

most common methods are:

1. Single-bit input programming.

2. USART (Universal Synchronous/Asynchronous

Receiver - Transmitter such as NEC 82C51).

SINGLE - BIT INPUT PROGRAMMING

This method of interface does not require any external

chip to implement serial data communication between

the Card Reader and an MPU. This function is done

through a software program that allows the MPU to

transmit and receive data. This process requires some

very time-critical programming. A disadvantage of this

approach is that, while the processor is receiving data

serially, it must totally dedicate itself to the task.

Accurate timing can only be maintained if the program

remains in a tight wait loop without being diverted to

other functions. When programming the MPU, the timing

loops required for receiving data cannot exceed the time

period of the incoming data bits. Table 1 shows the data

rates at card speed of 50 inches per second (ips).

TK1 TK2 TK3

Bit Rate (bits/sec.) 10,500 3,750 10,500

Character Rate (char/sec.) 1,500 750 2,100

Table 1 data rates @ 50ips

USART

The primary advantage of the USART method is that the

MPU is relieved of the critical time-dependent

programming.

The CARD PRESENT signal can be connected to an

input pin on the USART. The DSR input of the USART is

suggested as an input of the CARD PRESENT signal to

the MPU. The serial data input (RXD) of the USART

receives data from the Card Reader. The clock input

(RXC) of the USART is connected to the read STROBE

output of the Card Reader. The USART must be set up

to operate in the synchronous mode with a single sync

character. This sync character must be equivalent to the

Start Sentinel character of the track that is being read.

When reading Track 1, the user may set the parity on

the USART to ON or OFF. If parity is set to Enabled,

then the word size must be set to 6 bits. In this case the

USART checks the character for parity error. If the user

prefers the parity to be checked by the MPU and not the

USART then parity must be set to Disabled and word

size must be set to 7 bits. When reading Track 2 or

Track 3, parity must be set to OFF. This is because data

characters encoded on these two tracks are in 5 bit

words, including parity. The USART is limited to a

minimum word size of 5 bits only when parity is OFF. In

this case, the USART treats the parity bit just like any

other data bit, and the MPU should check for correct

parity on each character.

In operation, the USART remains inactive until it

recognizes the Start Sentinel character. Then it becomes

active and collects the data characters, frames the data,

and presents it to the MPU. (In some applications, this

may not be suitable for reliable Start Sentinel detection;

see the Detecting Start Sentinel discussion below.)

When using either method, after the CARD PRESENT

signal indicates that the card is gone, the MPU should

perform error detection by checking both the parity of

each character and of the Longitudinal Redundancy

Check (LRC) character. To perform the LRC calculation,

each bit of each character excluding the parity bit should

be exclusive ORed with the respective bit of all

characters, including Start Sentinel and End Sentinel.

Exclusive ORing the parity bit of all characters does not

generate the parity bit for the LRC character; it is the

parity bit for the LRC character.

The Start Sentinel and the End Sentinel characters

frame data. The first bits encountered by the Card

Reader are the leading zeros. They indicate to the

Reader the presence of an encoded magnetic stripe

card, and allow the Reader to synchronize itself with the

incoming data bits. The leading zeros are followed by

the Start Sentinel character, which indicates the

beginning of data on a track. The characters following

the Start Sentinel represent the data. The End Sentinel

Character indicates the end of data. After the End

Sentinel is the Longitudinal Redundancy Check (LRC)

character. Trailing zeros follow the LRC and fill the

remainder of the track.

NOTE: Characters are encoded on the magnetic stripe

with the least significant bit recorded first. The Start

Sentinel character on Track 2 is recorded as 11010. The

bit pattern is B

is the most significant bit. P is the parity bit. As

B

3

0 B1 B2 B3

P. The least significant bit is B0.

defined in the ANSI x4.16 1983, ODD parity is required.

The conventional representation of the Start Sentinel

would be 01011 (P B

3 B2 B1 B0

) or 0Bh (hex).

29

Page 34

I/O Interface for TTL Magnetic Stripe Readers

Notes:

1. Card Present, Data, and Strobe are negative true

logic.

2. Card Present goes low after 14-15 head flux

reversals.

3. Card Present returns to high level approximately

150mS after the last flux transition.

4. Data is valid 1.0µS (min.) before the leading

negative edge of strobe and remains valid until

approximately 1.0µS before the next STROBE.

DETECTING START SENTINEL

In some cases, random noise on a blank track

(especially High Coercivity media) may be detected as a

Start Sentinel. If a Start Sentinel is erroneously detected

then parity and/or LRC checking would undoubtedly

indicate that the track, although blank, actually has an

error on it. For this reason, it is suggested that some

number of the leading zeros be included in the detection

of Start Sentinel. The location of the Start Sentinel and

the number of zeros required to synchronize the read

circuitry determine the number of detectable zeros prior

to the Start Sentinel. In the worst case, there may be no

more than four leading zeros on track 2 and no more

than nine on tracks 1 and 3. In other words, the Start

Sentinel on track 2 should be considered as a 9-bit

value: 4 bits of zero and 5 bits of Start Sentinel.

BIDIRECTIONAL READING

In many of today’s magnetic stripe card applications,

reading the card in both directions is necessary.

Programming for bidirectional reading has its own

special requirements. First, the data acquired from the

reader must be treated in memory as a collection of bits

(see note below). Since the direction is not known, the

program must search the bits looking for the Start

Sentinel. If the first character is not the Start Sentinel,

then you must move to the other end of the memory and

begin searching the bits in reverse order for the Start

Sentinel. However, if a Start Sentinel is found, it is

possible that the character is LRC. You may check for

this by determining if the next character is the End

Sentinel. If the next character is the End Sentinel, then

you must move to the other end of memory and begin

searching the bits in the reverse order as discussed

above. The important point is to realize that the LRC

could appear to be a false Start Sentinel.

If the message does not meet the requirements for a

correct recording (the sentinels, party & LRC) then try to

interpret the message in the other direction. The card is

unreadable only after the software has tried both

directions.

Note: For bidirectional reading, a USART cannot be

used to identify the Start Sentinel. The USART must be

programmed to begin capturing data based on the first

binary 1 that is found. Set the word length to one byte (8

bits) and disable parity checking; for track 2, the word

size should be no more than 5 bits.

CONVERTING CARD DATA TO ASCII DATA

The data transmitted or received by the user’s device is

in ASCII. The data encoded on the cards, however, is in

a different format called Card Data. All RS-232 Mag-Tek

equipment automatically converts transmitted and

received data from ASCII to Card Data. The procedure

for converting ASCII to Card Data is described bellow.

TRACK 1

Card data on Track 1 consists of six binary bits and an

odd parity bit for each character. A method for

converting ASCII characters to six-bit Card Data (the

parity bit is not included in the calculation) is to subtract

20h (hex) from the equivalent 0 parity ASCII character

(see Character Conversion Chart). For example, the

ASCII character that represents the percent sign (%) is

25h. Subtract 20h from 25h and the result is 05h, which

represents the six-bit portion of the card data code for

the percent sign. An odd parity bit must be added to the

six-bit portion of the character to complete the Card Data

code. A method for converting card data to ASCII

characters is to remove the parity bit from the Card Data

code, then add 20h to the remaining six-bit portion of the

character. The result will be the 0 parity ASCII character.

TRACK 2 & 3

Card data on Track 2 & 3 consists of four binary bits and

an odd parity bit for each character. A method for

converting ASCII characters to four-bit Card Data (again

the parity bit is not included in the calculation) is to

subtract 30h from the equivalent ASCII character. For

example, the ASCII character that represents the

number 7 is 37h. Subtract 30h from 37h and the result is

07h, which represents the four-bit portion of the card

data code for the number 7. An odd parity bit must be

added to the four-bit portion of the character to complete

the Card Data code. A method for converting card data

to ASCII characters is to remove the parity bit from the

Card Data code, then add 30h to the remaining four-bit

portion of the character. The result will be the 0 parity

ASCII character.

REGISTERED TO ISO 9001:2000

1710 Apollo Court, Seal Beach, CA 90740

Phone: (562) 546-6400, Help Line (651) 415-6800

Fax (562) 546-6301

http://www.magtek.com

P/N 99875063-4, 4/03 Copyright 1997-2003, Mag-Tek

30

Loading...

Loading...