Page 1

PORT POWERED

SWIPE READER

TECHNICAL REFERENCE MANUAL

Manual Part Number 99875094 Rev 17

JUNE 2010

REGISTERED TO ISO 9001:2008

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

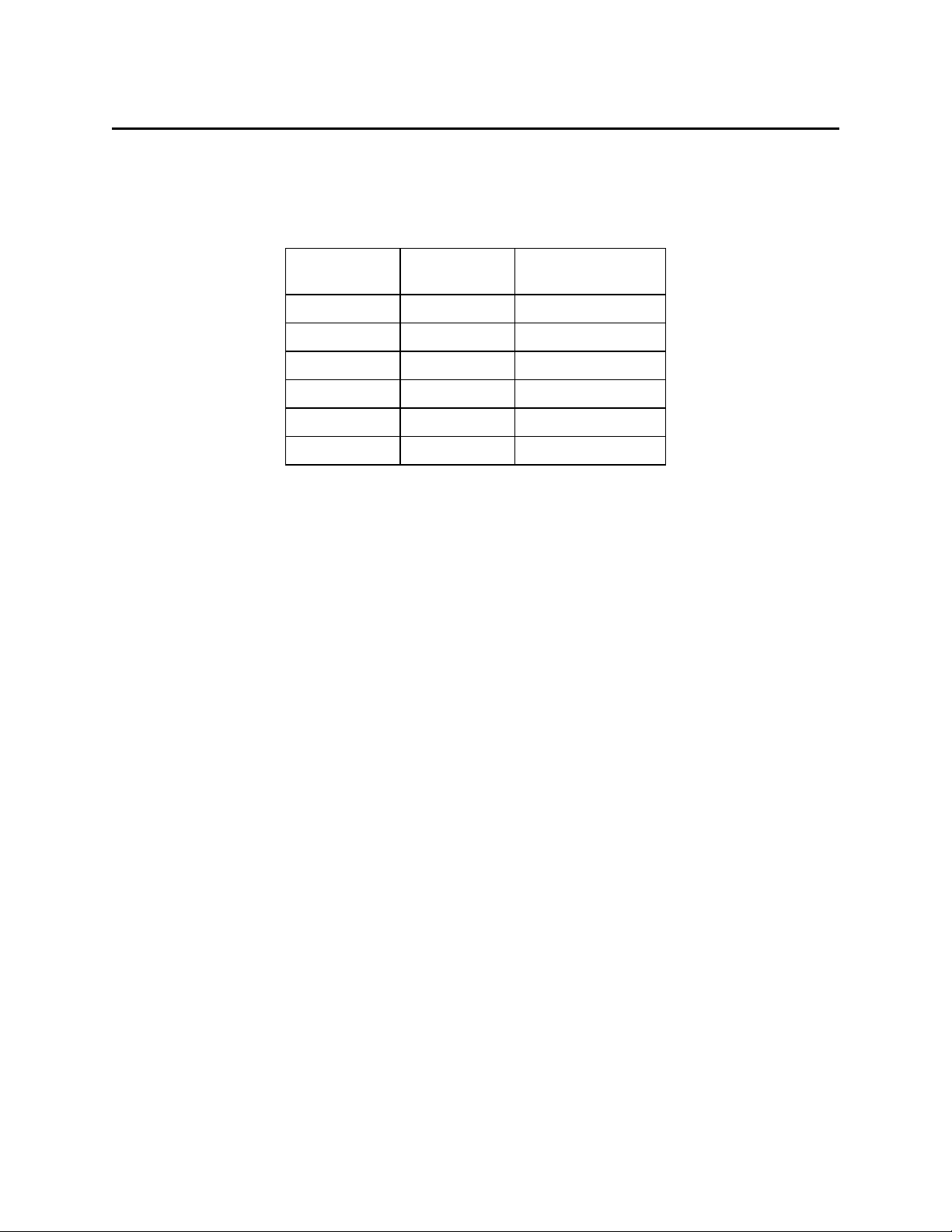

Rev

Number

Date

Notes

1

11 Dec 97

Initial Release

2

18 Dec 97

Sec 1 Changed spec Dimensions; Sec 1, 3 Changed illustrations for clarity.

3

11 May 98

Sections 1, 2, and 3 revised to reflect latest firmware revisions. Sec 4 deleted.

4

15 Jun 98

Two part numbers added.

configurations to 3-2.

6

14 Jun 99

Title change, Removed MT-211 and RS-232; Sec 1, Table 1-1, added Pin List for

Net; Sec 3, Clarified Fig 3-1, Described firmware P/Ns and revisions.

7

1 Dec 99

Section 1: Added P/N 21040084, Updated table for 9- and 25-pin connectors; Section

3: Added P/N 21040084 to Sign-on table.

8

21 Sep 00

Editorial changes throughout. Sec 1: Configuration list expanded and moved to Sec 3;

configurations.

“Track 3 – 7 bit” line from Table 3-1. Added 094 and 096 configurations in Table 3-2.

10

25 Jul 01

Front Matter: Agency Approvals: Corrected Class B for CE and Corrected UL and

11

24 Apr 03

Front Matter: added ISO line to logo, changed Tech Support phone number, added

new warranty statement; Sec 3: added 2 new part numbers at the end of Table 3-2.

12

23 Jun 03

Editorial throughout. Section 3: Removed the following parts from Table 3-2:

21040073, 21040077, 21040084, 21040089.

13

11 May 04

Sec 1: Specifications, corrected cable length.

modification of properties (Section 4).

15

23 Feb 06

Sec 3: Timing for Sign-on ID changed from 150 to a range from 150 to 330ms. Sec 4:

Sending of <CR> when using Reset Device Command follows SB switch setting.

16

2 Feb 07

Clarified port powered operation

PN 21040088.

Copyright© 1997-2010

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

REVISIONS

5 1 Mar 99 Sec 1, Added 3 part numbers, changed specs, Changed Dimensions Figure 1-3,

removed Figure 1-4, Mounting Dimensions, added MagTek Windows Drivers; Added

note to Table 1-1. Section 2, added mounting instructions and Figure 2-1, Mounting

Dimensions. Section 3, added 3 track symbols to Table 3-1 and 3 sign-on

Cable 21040077, added RS-232 Communication; Sec 2, added Demo Program from

Specification weight changed from 5.9 oz to 5.8oz, Converted symbols to Metric

System [SI]. Sec 3: Added 5 new part numbers with firmware, tracks, and

9 09 Mar 01 Front Matter: Corrected Agency Approvals to include Class B for FCC and Class B

for CE. Changed RMA Warranty address to 20801 S. Annalee. Sec ti on 3: Rem ov ed

CUL. Copyright 2001 added.

14 10 Jan 06 Updated specifications to reflect new models. Added commands to support

17 1 Jun 10 Formatting changes and updated Limited Warranty & Agency Appro vals. Removed

ii

Page 3

LIMITED WARRANTY

MagTek warrants that the products sold pursuant to this Agreement will perform in accordance with MagTek’s

published specifications. This warranty shall be provided only for a period of one year from the date of the

shipment of the product from MagTek (the “Warranty Period”). This warranty shall apply only to the “Buyer”

(the original purchaser, unless that entity resells the product as authorized by MagTek, in which event this

warranty sha ll apply only to the first repurchaser).

During the Warranty Period, should this product fail to conform to MagTek’s specifications, MagTek will, at its

option, repair or replace this product at no additional charge except as set forth below. Repair parts and

replacement products will be furnished on an exchange basis and will be either reconditioned or new. All replaced

parts and products become the property of MagTek. This limited warranty does not include service to repair

damage to the product resulting from accident, disaster, unreasonable use, misuse, abuse, negligence, or

modification of the product not authorized by MagTek. MagTek reserves the right to examine the alleged

defective goods to determine whether the warranty is applicable.

Without limiting the generality of the foregoing, MagTek specifically disclaims any liability or warranty for

goods resold in other than MagTek’s original packages, and for goods modified, altered, or treated without

authorization by MagTek.

Service may be obtained by delivering the product during the warranty period to MagTek (1710 Apollo Court,

Seal Beach, CA 90740). If this product is delivered by mail or by an equivalent shipping carrier, the customer

agrees to insure the product or assume the risk of loss or damage in transit, to prepay shipping charges to the

warranty service location, and to use the original shipping container or equivalent. MagTek will return the

product, prepaid, via a three (3) day shipping service. A Return Material Authorization (“RMA”) number must

accompany all returns. Buyers may obtain an RMA number by contacting Technical Support at (888) 624-8350.

EACH BUYER UNDERSTANDS THAT THIS MAGTEK PRODUCT IS

OFFERED AS IS.

MAGTEK MAKES NO OTHER WARRANTY , EXPRESS OR

IMPLIED, AND MAGTEK DISCLAIMS ANY WARRANTY OF ANY OTHER

KIND, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

IF THIS PRODUCT DOES NOT CONFORM TO MAGTEK’S SPECIFICATIONS, THE SOLE REMEDY

SHALL BE REPAIR OR REPLACEMENT AS PROVIDED ABOVE. MAGTEK’S LIABILITY, IF ANY,

SHALL IN NO EVENT EXCEED THE TOTAL AMOUNT PAID TO MAGTEK UNDER THIS

AGREEMENT. IN NO EVENT WILL MAGTEK BE LIABLE TO THE BUYER FOR ANY DAMAGES,

INCLUDING ANY LOST PROFITS, LOST SAVINGS, OR OTHER INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THE USE OF, OR INABILITY TO USE, SUCH PRODUCT, EVEN IF

MAGTEK HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY

ANY OTHER PARTY.

LIMITATION ON LIABILITY

EXCEPT AS PROVIDED IN THE SECTIONS RELATING TO MAGTEK’S LIMITED WARRANTY,

MAGTEK’S LIABILITY UNDER THIS AGREEMENT IS LIMITED TO THE CONTRACT PRICE OF THIS

PRODUCT.

MAGTEK MAKES NO OTHER WARRANTIES WITH RESPECT TO THE PRODUCT, EXPRESSED OR

IMPLIED, EXCEPT AS MAY BE STATED IN THIS AGREEMENT, AND MAGTEK DISCLAIMS ANY

IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MAGTEK SHALL NOT BE LIABLE FOR CONTINGENT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES TO PERSONS OR PROPERTY. MAGTEK FURTHER LIMITS ITS LIABILITY OF ANY KIND

WITH RESPECT TO THE PRODUCT, INCLUDING ANY NEGLIGENCE ON ITS PART, TO THE

CONTRACT PRICE FOR THE GOODS.

MAGTEK’S SOLE LIABILITY AND BUYER’S EXCLUSIVE REMEDIES ARE STATED IN THIS SECTION

AND IN THE SECTION RELATING TO MAGTEK’S LIMITED WARRANTY.

iii

Page 4

FCC WARNING STATEMENT

This equipment has been tested and was found to comply with the limits for a Class B digital device pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a residential environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference with radio communications. However, there is no guarantee that interference will not occur

in a particular installation.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class B limits for radio noise from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de la classe B prescrites dans le Réglement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numériqué de la classe B est conformé à la norme NMB-003 du Canada.

CE STANDARDS

Testing for compliance with CE requirements was performed by an independent laboratory. The unit under test

was found compliant with s tandards established for Class B devices.

UL/CSA

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

RoHS STATEMENT

When ordered as RoHS compliant, this product meets the Electrical and Electronic Equipment (EEE) Reduction

of Hazardous Substances (RoHS) European Directive 2002/95/EC. The marking is clearly recognizable, either as

written words like “Pb-free”, “lead-free”, or as another clear symbol ( ).

iv

Page 5

TABLE OF CONTENTS

SECTION 1. FEATURES AND SPECIFICATIONS ---------------------------------------------------------------------- 1

MAGTEK DEVICE DRIVERS FOR WINDOWS ------------------------------------------------------------------------ 1

FEATURES ---------------------------------------------------------------------------------------------------------------------- 2

CONFIGURATION ------------------------------------------------------------------------------------------------------------ 2

SPECIFICATIONS ------------------------------------------------------------------------------------------------------------- 4

SECTION 2. INSTALLATION ------------------------------------------------------------------------------------------------- 7

REQUIREMENTS ------------------------------------------------------------------------------------------------------------- 7

MOUNTING --------------------------------------------------------------------------------------------------------------------- 7

INSTALLATION AND TEST ------------------------------------------------------------------------------------------------- 8

SECTION 3. OPERATION ---------------------------------------------------------------------------------------------------- 11

LED INDICATOR ------------------------------------------------------------------------------------------------------------ 11

CARD READ ------------------------------------------------------------------------------------------------------------------ 11

READER TO HOST MESSAGE FORMAT ---------------------------------------------------------------------------- 11

TIMING FOR ID SIGN ON ------------------------------------------------------------------------------------------------- 12

SECTION 4. PROPERTIES AND COMMANDS ------------------------------------------------------------------------ 15

SENDING COMMANDS --------------------------------------------------------------------------------------------------- 15

XON/XOFF -------------------------------------------------------------------------------------------------------------------- 15

RESET DEVICE -------------------------------------------------------------------------------------------------------------- 16

VERSION REQUEST ------------------------------------------------------------------------------------------------------- 16

UPLOAD COMMAND ------------------------------------------------------------------------------------------------------- 16

CONFIGURATION COMMANDS ---------------------------------------------------------------------------------------- 17

Switch A -------------------------------------------------------------------------------------------------------------------- 18

Switch B -------------------------------------------------------------------------------------------------------------------- 19

Switch C -------------------------------------------------------------------------------------------------------------------- 20

Sentinel Definitions ------------------------------------------------------------------------------------------------------- 20

FIGURES AND TABLES

Figure 1-1. Port-Powered Swipe Reader ---------------------------------------------------------------------------------- vi

Figure 1-2. Reader Cable and Optional Adapter -------------------------------------------------------------------------- 2

Table 1-1. 9-Pin Connectors and 25-Pin Adapter ------------------------------------------------------------------------- 3

Table 1-2. Specifications -------------------------------------------------------------------------------------------------------- 4

Figure 1-3. Dimensions --------------------------------------------------------------------------------------------------------- 5

Figure 2-1. Mounting Hole Dimensions for Surface ---------------------------------------------------------------------- 8

Table 3-1. SS and ES Track Symbols ------------------------------------------------------------------------------------- 11

Figure 3-1. Timing For ID Sign-on and Transmission Bursts (Old version). -------------------------------------- 12

Table 3-2. Sign-on ID for Configurations ---------------------------------------------------------------------------------- 13

Table 4-1. Switch A ------------------------------------------------------------------------------------------------------------ 18

Table 4-2. Switch B ------------------------------------------------------------------------------------------------------------ 19

Table 4-3. Switch C ------------------------------------------------------------------------------------------------------------ 20

Table 4-4. Start and End Sentinels ----------------------------------------------------------------------------------------- 20

v

Page 6

vi

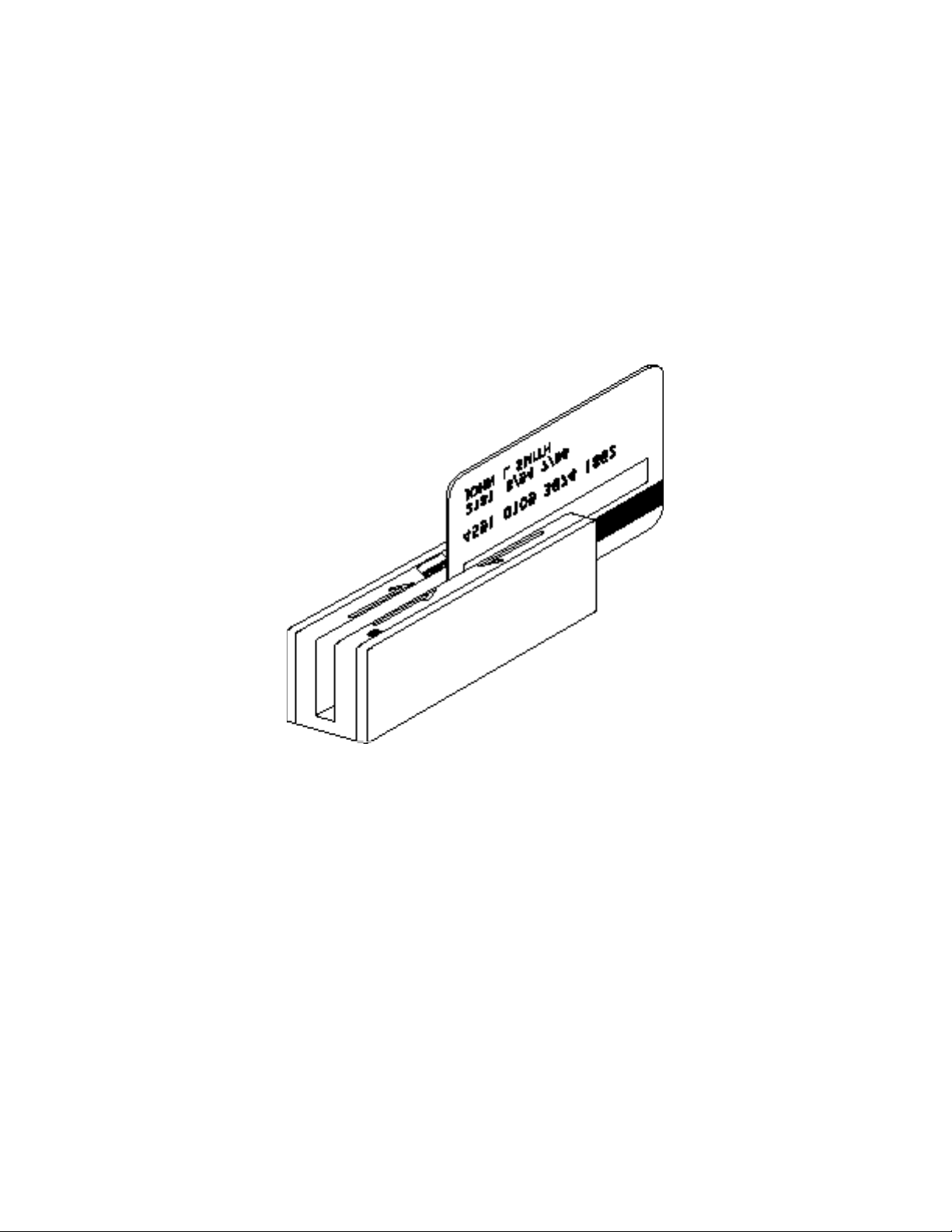

Figure 1-1. Port-Powered Swipe Reader

Page 7

SECTION 1. FEATURES AND SPECIFICATIONS

The Port Powered Swipe Reader is a compact magnetic stripe card reader which conforms to

ISO/ANSI standards. The Reader is compatible with the PC series of personal computers or any

device with a serial RS-232 interface. A card is read by sliding it, stripe down and facing the

LED side, through the slot either forward or backward.

A green/red LED (Light Emitting Diode) indicator on the Reader panel provides the operator

with continuous status of the Reader operations.

When power is applied, the Reader transmits a sign-on ID message. About 150 to 330

milliseconds after DTR is applied, the Reader sends the part number of the firmware in the

following form: 210888xxAnn<CR>. The first 8 characters indicate the firmware number; the

letter is the revision, which is followed by a revision sublevel of 01 to 99. The <CR> indicates

carriage return (0x0D). The sign-on messages for part numbers are listed in Section 3. Timing

is also shown in Section 3.

Note

Additional features have been incorporated into the new version of

the Port Powered Swipe Reader (generally available after March

2006). In the new version, the firmware part number will be

reported as 21088838. The enhancements included in this new

version are identified within this document with the word “new”.

Since the input voltage is supplied by a relatively low source of power, the Reader depends on its

input capacitor to maintain proper charge during all operations. In the old model, in order to

reduce the drain on this internal power source during data transmission, the output data is

transmitted in 5 to 6 millisecond bursts with a 10-millisecond gap between bursts to allow the

capacitor to recharge. The PC software should be able to tolerate this 10-millisecond space

between characters. The Timing is shown is Section 3, Figure 3-1. In the new version, with its

lower current draw, the data is transmitted continuously since there is no need to transmit in

bursts. Configurations, including part numbers, firmware, tracks, and unit configuration, are

listed in Section 3, Table 3-2.

MAGTEK DEVICE DRIVERS FOR WINDOWS

The MagTek Device Drivers for Windows may be used with the Port Powered Swipe Reader.

They are available on a CD (Part Number 30037385) or from the MagTek web site (Part Number

99510013). When these drivers are used, refer to MagTek Device Driver for Windows,

Programming Reference Manual, Part Number 99875125.

1

Page 8

Port Powered Swipe Reader

FEATURES

Major features of the Swipe Reader are as follows:

• Powered through the RS-232 serial port – no external power supply required

• Hardware Compatible with PC or any computer or terminal with an RS-232 interface

• Software Compatible with the MagTek MTD Windows Device Drivers or any RS-232

communications program

• Bidirectional card readi n g

• Reads encoded data that meets ANSI/ISO/AAMVA standards

• Green/Red LED for status

CONFIGURATION

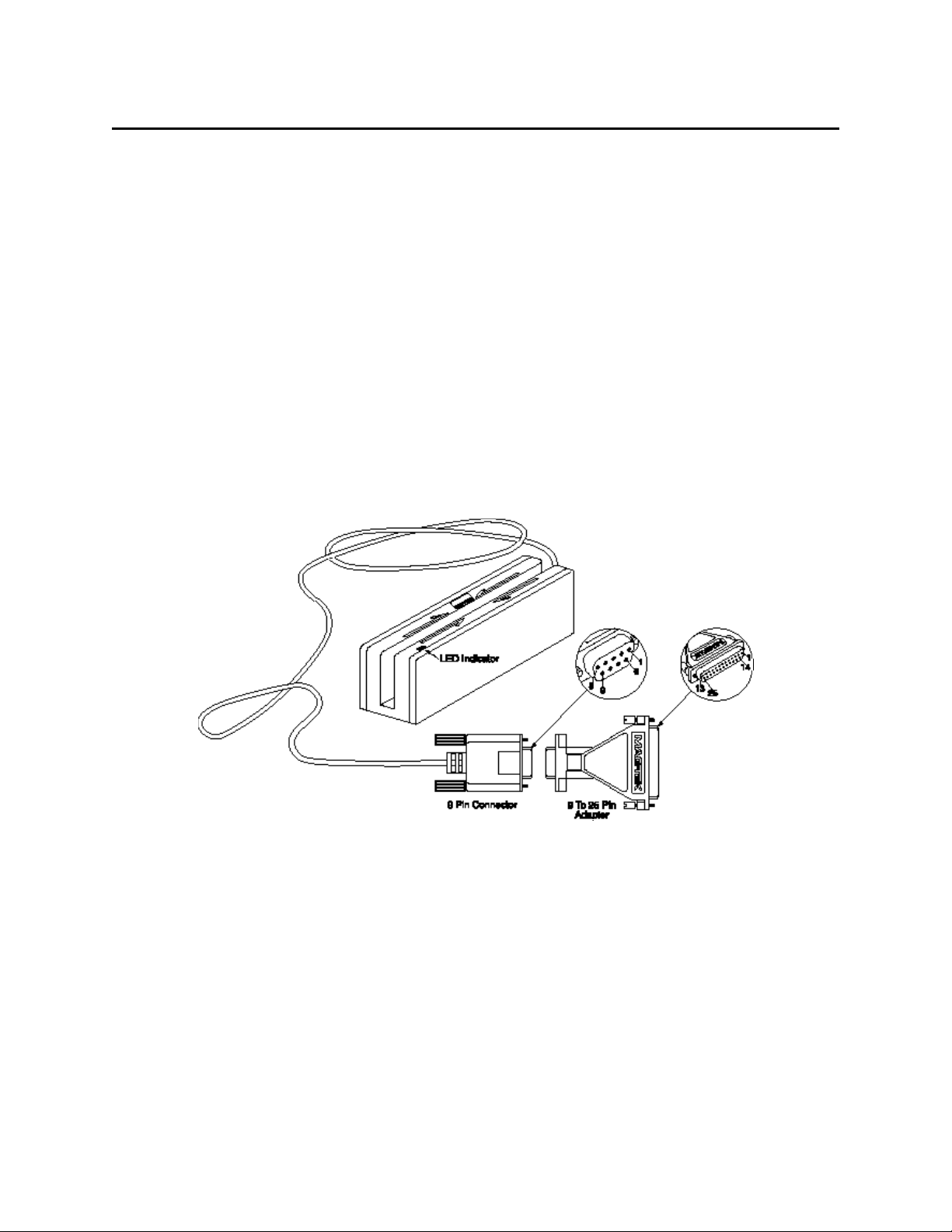

The Reader, LED Indicato r, pin numbers for the 9-pin connector and the 25-pin adapter are

shown in Figure 1-2.

2

Figure 1-2. Reader Cable and Optional Adapter

Page 9

Section 1. Features and Specifications

25-pin

DE9-pin

Signal

3

2

RXD (to PC)

2

3

TXD** (from PC)

20

4

DTR (from PC)

-

6-9

NC*

Pin numbers and signal descriptions for the 9-pin (DE9) cable and 25-pin (DB25) adapter shown

in the illustration are listed in Table 1-1.

Table 1-1. 9-Pin Connectors and 25-Pin Adapter

Adapter

- 1 NC*

7 5 GND

* No Connection

** Pin must be connected to TXD (or DTR if TXD not available).

Connector

3

Page 10

Port Powered Swipe Reader

OPERATING

Reference Standards

ISO/ANSI/AAMVA*

Power Input

From RS-232 interface

Recording Method

Two-frequency coherent phase (F2F)

Message Format

ASCII

Card Speed

3 to 60 in/s (7.6 to 152.4 cm/s) – forward or reverse

Head Life

1,000,000 passes

ELECTRICAL

Old Version

New Version

DTR Voltage

5 to 15 VDC

4 to 15 VDC (+/-24 VDC absolute max )

Current

Peak at Power On

12 mA

Limited by source (~50 µF load)

RS-232 Communication

9600 bps 8N1

Adjustable (default 9600 bps 8N1)

MECHANICAL (STANDARD PRODUCT)

Dimensions

Length: 3.94” (100.0 mm)

Height: 1.23” (31.3 mm)

Weight

Reader 5.8 oz. (165 gr.)

Cable length

See Table 3-2

Connector

9 pin D female

ENVIRONMENTAL

Temperature

Old Version

New Version

Operating

32oF to 131oF (0oC to 55oC)

32oF to 158oF (0oC to 70oC)

Storage

-22oF to 158oF (-30oC to 70oC)

-22oF to 158oF (-30oC to 70oC)

Humidity

Operating

10% to 90% noncondensing

10% to 90% noncondensing

Storage

10% to 90% noncondensing

10% to 90% noncondensing

SPECIFICATIONS

Table 1-2 lists the specifications for the Port Powered Swipe Reader. Figure 1-3 shows the

dimensions for the standard product. Other sizes are available by special order.

Table 1-2. Specifications

Quiescent

Transmit/Read

* ISO (International Standards Organization), ANSI (American National Standards Institute), and

AAMVA (American Association of Motor Vehicle Administrators).

1 to 2 mA typical (continuous)

8 to 9 mA typical (5 ms duration)

Width: 1.28” (32.5 mm)

7 mA max imum (continuous)

11 mA maximum

4

Page 11

Section 1. Features and Specifications

Figure 1-3. Dimensions

5

Page 12

Port Powered Swipe Reader

6

Page 13

SECTION 2. INSTALLATION

The hardware installation consists of plugging the cable into the PC and optional 25-pin adapter,

if required, Com Port setup, and testing the Reader.

REQUIREMENTS

• Port Powered Swipe Reader

• Optional 9- to-25-pin Adapter, P/N 78200018

• PC with Serial RS-232 Com Port

• MagTek Windows Drivers or any RS-232 communications program

MOUNTING

1. The Reader can be mounted on a surface in three ways:

• By two screws through the surface attached to the bottom of the unit and running the

cable on the top of the surface

• By two screws through the surface attached to the bottom of the unit and by drilling a

hole in the surface for the cable and running the cable through the hole

• By attaching the unit to the surface with 3M™ Dual Lock™ fasteners (or equivalent) and

running the cable on the top of the surface

Note

The two mounting inserts are 3 mm diameter; 0.5 mm pitch; 6.4

mm deep. The length of the screws used depends on the mounting

surface thickness and the thickness of washers (if used).

The mounting dimensions are shown in Figure 2-1. Determine the method of mounting

required.

2. Ensure the Reader is positioned on a flat, accessible surface with at least 4 inches

clearance on either end for room to swipe a card. Orient the Reader so the side with the

LED is facing the direction of intended use.

If fastening tape is to be used, clean the area that the Reader will be mounted on with

isopropyl alcohol. Remove the adhesive protective cover on the fastening tape, and

position the Reader and push down firmly.

7

Page 14

Port Powered Swipe Reader

Figure 2-1. Mounting Hole Dimensions for Surface

3. Mount the Reader.

INSTALLATION AND TEST

To install the Swipe Reader, perform the following steps:

1. Connect the Swipe Reader cable connector into a 9-pin serial Com Port on the PC. If a

25-pin Adapter is required, plug the 9-pin connector on the Reader into the Adapter and

the adapter into the PC.

2. Open a communications program such as the MagTek Encoder/Reader Demonstration

Program, which may be obtained from the Internet at www.magtek.com. Navigate to the

Demo Programs and select Encoder/Reader Demo.

3. On the program, select the Com Port the Reader is connected to.

4. If the Com Port selected is correct, the green LED on the Reader will light; if the wrong

Com Port is selected, the LED will not light.

5. Select the baud rate of 9600.

8

Page 15

Section 2. Installation

6. Select 8 data bits, no parity, 1 stop bit. (With the new version, this setting can be

adjusted as required.)

7. With the LED on, swipe a card. The data on the screen will show Track 1 beginning with

“%” and ending with “?”. Track 2 begins with “;” and ends with “?”. Track 3 begins

with “+” (normal) or "!" (CDL) and ends with “?”. The following is an example:

%B123^Smith/Joann^9812101000?;112222333333444444444?<0x0D>

If a track cannot be read, an E will appear in place of the track data; for example, if Track

2 is bad and Tracks 1 and 3 are good, the display will be similar to the following:

%11111111111111111111?;E?+3333333333333333333?<0x0D>

If Tracks 1 and 3 are bad and Track 2 is good, the display will be similar to the following:

%E?;22222222222222222222?+E?<0x0D>

8. If the data on the screen is not numeric or alphanumeric similar to the above, check the

communications rate. If the alphanumeric characters are similar to the above, the unit is

ready for operation.

9

Page 16

Port Powered Swipe Reader

10

Page 17

SS

CARD DATA

ES

CR

Start Sentinel

End Sentinel

Description

%

?

Track 1 ; ?

Track 2 + ?

Track 3 - ISO

#

?

Track 3 - AAMVA

Start Sentinel

Card Data or "E" (for Error)

Carriage

SECTION 3. OPERATION

Included in this section are Indicator, Card Read, Reader to Host Message Format, and a timing

diagram of sign-on ID.

LED INDICATOR

A green/red LED indicator on the panel gives the operator the status of the Reader. If the

cabling is correct and the correct Com Port is selected, the indicator will show green. If the

indictor does not come on, check the cabling and the Com Port. The LED is turned off while the

unit is transmitting. If an error has been detected while reading the card, the LED will

momentarily show red.

CARD READ

A card may be swiped through the Reader slot when the green LED is lit. The magnetic stripe

must face toward the front (the side with the LED) and may be swiped in either direction.

READER TO HOST MESSAGE FORMAT

Track data is sent in the following order: SS, Card Data, ES.

The format in which data is transmitted (in track order) after a card is read successfully is as

follows:

End Sentinel

Table 3-1 lists the default Start Sentinel and End Sentinel symbols.

Table 3-1. SS and ES Track Symbols

11

Page 18

Port Powered Swipe Reader

10 ms

TIMING FOR ID SIGN ON

Timing for the ID Sign-on and transmission bursts (5 ms with 10 ms between bursts) are shown

in Figure 3-1.

Note

The “Transmission Burst” timing shown in Figure 3-1 only applies

to the old version of the Reader. The new version does not apply

the 10 ms gap between transmission bursts but rather transmits the

full message without any delays. The Sign-on ID delay is in the

range between 150 to 330 milliseconds.

DTR

150 - 330 ms

Sign-on ID

Transmission

Burst

5 ms

Figure 3-1. Timing For ID Sign-on and Transmission Bursts (Old version).

The firmware controls the operation of Sign-on ID and Transmission bursts in the following

format:

210888xxLnn<CR>

Where:

the first 8 digits are the firmware part number

xx represents the Swipe Reader series

L is the alpha revision

nn is the number sub-revision

<CR> (Carriage Return) is 0x0D

12

Page 19

Section 3. Operation

Part

Number

Firmware

(Old)

Firmware

(New)

Track

Configuration

Configuration*

21040071

21088811

21088838

1,2

Pearl White

21040074

21088817

21088838

1,2,3

Pearl White

21040075

21088814

n/a

2

Pearl White

21040079

21088811

21088838

1,2

Black

21040080

21088814

n/a

2

Black

21040081

21088811

21088838

1,2

Black, 150 mm cable

21040082

21088817

21088838

1,2,3

Black

21040091

21088811

21088838

1,2

Black, No Cover, 5.9" Cable, 4-pin

21040092

21088817

21088838

1,2,3

Pearl White, 5 m cable

21040094

21088811

21088838

1,2

Pearl White, No Cover

21040096

21088811

21088838

1,2

Black, 4” Cable, 4-pin

21040097

21088811

21088838

1,2

Pearl White, 150 mm cable, 4-pin

21040231

21088817

21088838

1,2,3

Black, Teflon wires, 4’ Cable, no connector

Table 3-2 lists the available part number, firmware, and configuration.

Table 3-2. Sign-on ID for Configurations

*All cables are 6' DE9 unless otherwise specified.

13

Page 20

Port Powered Swipe Reader

14 15

Page 21

SECTION 4. PROPERTIES AND COMMANDS

A full set of properties and commands have been incorporated into the new version of the Port

Powered Swipe Reader. This section describes the function and operation of each of these

properties, and shows how to implement the commands.

SENDING COMMANDS

The Reader will operate from 2400 to 115200 bps but each command sent to the Reader must

match the communication parameters of the Reader. The default communication parameters are

9600 bps with 8 bits, no parity and 1 stop bit (8N1). If the Reader fails to respond after a

command has been transmitted, the application should modify the transmission parameters until

a response is received.

Commands, as described below, must be preceded by an Escape (<ESC> – 0x1B) character and

be terminated by a Carriage Return (<CR> – 0x0D). All commands are case sensitive—that is,

they must all use upper case characters.

After a valid command has been received, the Reader will respond with an Acknowledge

(<ACK> – 0x06) within one character time. If a message is started but not completed within 2

seconds, a No-acknowledge (<NAK> – 0x15) will be transmitted; also, if the baud rate or other

communication settings are incorrect, the Reader will transmit a NAK using its current

communication parameters. An unrecognized command will also return a NAK.

XON/XOFF

The Reader can be placed into a “silent” mode so that it will not transmit or receive anything

until requested to do so. This may be useful with interrupt-driven applications where the Reader

should be disabled. The default for the Reader after a reset is XON.

After an XOFF (0x13) has been received and after completing any transmission that may be in

progress, the Reader will respond with an ACK and then hold card data in buffer. The data will

not be transmitted until an XON has been received. In this mode, only the most recent card

swipe will be available; any prior card swipes will be erased. Additionally, when in the XOFF

mode, all commands will be ignored (until an XON is received or until a hardware reset).

When an XON (0x11) has been received, the Reader will transmit an ACK followed by the data

in the buffer (from the last swiped card) if available. The buffer will be cleared after the data has

been transmitted. If the buffer is empty, only an ACK will be transmitted.

Page 22

Port Powered Swipe Reader

RESET DEVICE

The Reader will always be reset when power (DTR) is applied (hardware reset). It can also be

reset programmatically with a Reset (RS) command. This command can be used after changing

the setting to activate the new values:

<ESC>RS<CR>

After sending the <ACK>, the Reader will perform a soft reset and, if the function is enabled

(SA-6), will transmit the sign-on ID message:

<ACK>21088838A00<CR>

Note that the carriage return (CR) will be included in this response only if the function is enabled

(SB-0).

VERSION REQUEST

In order to determine which device is connected, the application can send a Version Request

(VR) command to the Reader:

<ESC>VR<CR>

The Reader will respond with an ACK and then will transmit the firmware part number and the

corresponding version in a format like this:

<ACK>21088838A00<CR>

Note that the carriage return (CR) will be included in this response only if the function is enabled

(SB-0).

UPLOAD COMMAND

The Upload (UP) command is used to move any modified properties from temporary storage into

the flash memory. This only needs to be done once after all changes have been made.

This method of updating the programmable settings allows all parameters to be modified in

anticipation of the next reset. Thus, a series of switch commands (including the sentinel values

described below) can be sent to the Reader without affecting any operation. The set of

configuration commands should be followed by an Upload (UP) command to transfer all settings

into flash. Finally, the Reset (RS) command can be sent to validate that all changes have taken

place. After the RS command, any changes to communication parameters will be effective.

16

Page 23

Section 4. Properties and Commands

CONFIGURATION COMMANDS

The configuration properties are stored in three separate bytes (referred to as switches). The

switch settings are modified with three separate commands, one for each switch. The switch

names, bits and corresponding properties are shown in the tables below.

The command to interrogate or modify a switch is of the form:

<ESC>Sn<CR>

where “n” is “A”, “B” or “C”.

For example, to interrogate the values of switch B, send the command:

<ESC>SB<CR>

The response will look like this:

<ACK><ESC>SB00000001<CR>

In order to change any switch settings, send a command like this:

<ESC>SA11100010<CR>

which will set switch A to the default value. The Reader will respond with an ACK if the

command is formatted properly. The change in settings will NOT take place until after the

Upload and Reset commands have been sent:

<ESC>UP<CR>

<ESC>RS<CR>

The Upload (UP) command moves the new setting(s) into flash memory. The new setting(s),

however, will not be used until the device has been reset—either with a power reset or with the

soft Reset (RS) command.

17

Page 24

Port Powered Swipe Reader

Command position

1 2 3 4 5 6 7 8

Byte Position

7 6 5 4 3 2 1 0 Description

0 0 0 Baud rate 2400

0 0 1 Baud rate 4800

0 1 0 Baud rate 9600

0 1 1 Baud rate 14400

1 0 0 Baud rate 19200

1 0 1 Baud rate 38400

1 1 0 Baud rate 57600

1 1 1 Baud rate 115200

0 0 No parity

0 1 Even parity

1 0 Odd parity

1 1 Mark (Parity = 1 all the time)

0 7 bits data length

1 8 bits data length

0 Send ID at power on: No

1 Send ID at power on: Ye s

0 Transmit SS and ES: No

1 Transmit SS and ES: Yes

Switch A

Switch A, Table 4-1, is primarily used to define the communication settings. The default for

Switch A is:

11100010 9600, no parity, 8 bits, send ID at power on, transmit SS & ES

Table 4-1. Switch A

18

Page 25

Section 4. Properties and Commands

Command position

1 2 3 4 5 6 7 8

Byte Position

7 6 5 4 3 2 1 0 Description

0 Send CR after messages: No

1 Send CR after messages : Yes

0 Send STX before data: No

1 Send STX before data: Yes

0 Send ETX before data: No

1 Send ETX before data: Yes

0 Send ESC before data: No

1 Send ESC before data: Yes

0 Send LRC with track data: No

1 Send LRC with track data: Yes

X Reserved

X Reserved

X Reserved

Switch B

Switch B, Table 4-2, is used to define the bracketing characters that are used in the messages.

The default for Switch B is:

00000001 Send CR after messages but don’t send STX, ETX, ESC, LRC

Table 4-2. Switch B

19

Page 26

Port Powered Swipe Reader

Command position

1 2 3 4 5 6 7 8

Byte Position

7 6 5 4 3 2 1 0 Description

0 0 Track 1 Disabled

0 1 Track 1 Enabled

1 1 Track 1 is required*

0 0 Track 2 Disabled

0 1 Track 2 Enabled

1 1 Track 2 is required*

0 0 Track 3 Disabled

0 1 Track 3 Enabled

1 1 Track 3 is required*

0 Decode ISO/ABA tracks only

1 Decode ISO/ABA & custom tracks

X Reserved

Value

Name

Default

(hex)

Default

(ASCII)

%

S3

2B

+

Start Sentinel ISO/ABA Track 3

@

&

SE

3F

?

End Sentinel for all tracks all type

Switch C

Switch C, Table 4-3, is used to define the way a card is read. The default for Switch C is:

01010101 Enable (but don’t require) tracks 1, 2 & 3; decode all types of tracks

Table 4-3. Switch C

* If a track is required but does not exist, the Reader will indicate an error for that track.

Sentinel Definitions

The start and end sentinels values can individually be specified by commands. The default

settings are shown in the Table 4-4.

Note

Changing the value of any of the sentinels does not actually

change the encoded value on the magnetic track; it merely

represents the sentinel in a unique way to help distinguish

differently formatted tracks.

Table 4-4. Start and End Sentinels

Definition

S1 25

S2 3B

S4 40

S5 26

S6 23

;

#

Start Sentinel ISO/ABA Track 1

Start Sentinel ISO/ABA Track 2

SS Non-standard (7bits) Track 2

SS Non-standard (7bits) Track 3

SS AAMVA track 3

20

Page 27

Section 4. Properties and Commands

As with the switch settings, the sentinel parameters can be discovered by sending the

corresponding command for that value immediately followed by a CR. For instance, in order to

determine the present setting of the 7-bit track 3 start sentinel, send the following command:

<ESC>S5<CR>

The Reader will respond with the value, in nibbles:

<ACK><ESC>S526<CR>

Any ASCII character from 0x00 to 0x7F can be used as a sentinel. To change the value of the 7bit track 3 start sentinel to “!” (0x21), send the following command:

<ESC>S521<CR>

Again, as with the switch commands described above, send the Upload (UP) command followed

by the Reset (RS) command to complete the transaction.

21

Page 28

Port Powered Swipe Reader

22

Loading...

Loading...