Page 1

MODEL MT-215232

RS-232 INSERTION READER

TECHNICAL REFERENCE MANUAL

Manual Part Number 99821504 Rev 6

APRIL 2003

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

Copyright© 1996-2005

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

REVISIONS

Rev Number Date Notes

2 5/3/96 Previous versions not assigned Rev Numbers

3 4/28/98 Changed Warranty to 90 days. Added Tech Support

Phone Number.

4 01/01/01 Added MagTek Web address. Changed copyright

date. Changed Warranty to one year. Added Agency

Approvals.

5 07/29/02 Sec 1: First paragraph, adds AAMVA and CDL reads

Trk 2 only; Configurations, deletes all current P/Ns

and adds 2 new P/Ns; Specs, replaces Sprague with

TI; Changes output driver OFF value from 30 to 50 V,

Changed weight from 6 to 5 oz, Table 1-2, editorial.

Sec 2: Switch Setting SWA, Table 2-1, added 150 to

Baud Rate. Sec 3: Table 3-3 broken into 2 tables for

clarity, Clarified signals and power and connectors,

Clarified LED connections and indicators, Clarified

user drivers. Sec 4: removed.

6 08 Apr 03 Front Matter: added ISO line to logo, changed Tech

Support phone number, changed to new warranty,

changed warranty from 90 days to 1 year.

ii

Page 3

LIMITED WARRANTY

MagTek warrants that the products sold to Reseller pursuant to this Agreement will perform in accordance with

MagTek’s published specifications. This warranty shall be provided only for a period of one year from the da

of the shipment of the product from MagTek (the “Warranty Period”). This warranty shall apply only to the

original purchaser unless the buyer is aut

shall apply only to the first repurchase.

horized by MagTek to resell the products, in which event, this warranty

te

During the Warranty Period, should this product fail to conform to MagTek’s specifications, MagTek wi

option, repair or replace this product at no additional charge except as set forth below. Repair parts and

replacement products will be furnished on an exchange basis and will be either reconditioned or new. All rep

parts and products become the property of MagTek. This limited warranty does not include service to repair

damage to the product resulting from accident, disaster, unreasonable use, misuse, abuse, customer’s negligenc

Reseller’s negligence, or non-MagTek modification of the product. MagT

alleged defective goods to determine whether the warranty is applicable.

Without limiting the generality of the foregoing, MagTek specifically disclaims any liability or warranty for

goods resold in other than MagTek’s original packages, and for goods modified, altered, or treated by customers

Service may be obtained by delivering the product during the warranty period to MagTek (1710 Apollo Court,

Seal Beach, CA 90740). If this product is delivered by mail or by an equivalent shipping carrier, the customer

agrees to insure the product or assume the risk of loss or damage in transit, to prepay shipping charges to the

warranty service location and to use the original shipping container or equivalent. MagTek will return the produc

prepaid, via

all returns.

MAGTEK MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAGTEK DISCLAIMS AN

WARRANTY OF ANY OTHER KIND, INCLU

FITNESS FOR A PARTICULAR PURPOSE.

EACH PURCHASER UNDERSTANDS THAT THE MAGTEK PRODUCT IS OFFERED AS IS. IF THIS

PRODUCT DOES NOT CONFORM TO MAGTEK’S SPECIFICATIONS, THE SOLE REMEDY SHALL BE

REPAIR OR REPLACEMENT AS PROVIDED ABOVE. MAGTEK’S LIABILITY, IF ANY, TO RESELLER

OR TO RESELLER’S CUSTOMERS, SHALL IN NO EVENT EXCEED THE TOTAL AMOUNT PAID TO

MAGTEK BY RESELLER UNDER THIS AGREEMENT. IN NO EVENT WILL MAGTEK BE LIABLE T

THE RESELLER OR THE RESELLER’S CUSTOMER FOR ANY DAMAGES, INCLUDING ANY LOST

PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OF OR INABILITY TO USE SUCH PRODUCT, EVEN IF MAGTEK HAS BEEN A

HE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

T

LIMITATION ON LIABILITY

a three (3) day shipping service. A Return Material Authorization (RMA) number must accompany

DING ANY WARRANTY OF MERCHANTABILITY OR

ek reserves the right to examine the

ll, at its

laced

e,

Y

O

DVISED OF

.

t,

EXCEPT AS PROVIDED IN THE SECTIONS RELATING TO MAGTEK’S LIMITED WARRANTY,

MAGTEK’S LIA

PRODUCTS.

MAGTEK MAKES NO OTHER WARRANTIES WITH RESPECT TO THE PRODUCTS, EXPRESSED OR

IMPLIED, EXCEPT AS MAY BE STATED IN THIS AGREEMENT, AND MAGTEK DISCLAIMS A

IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION ANY IM

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MAGTEK SHALL NOT BE LIABLE FOR CONTINGENT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES TO PERSONS OR PROPERTY. MAGTEK FURTHER LIMITS ITS LIABILITY OF ANY

WITH RESPECT TO THE PRODUCTS, IN

CONTRACT PRICE FOR THE GOODS.

MAGTEK’S SOLE LIABILITY AND BUYER’S EXCLUSIVE REMEDIES ARE

AND IN THE SECTION RELATING TO MAGTEK’S LIMITED WARRANTY.

BILITY UNDER THIS AGREEMENT IS LIMITED TO THE CONTRACT PRICE OF THE

NY

PLIED WARRANTY OF

KIND

CLUDING ANY NEGLIGENCE ON ITS PART, TO THE

STATED IN THIS SECTION

iii

Page 4

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 Of The FCC Rules. Operation of this device is subject to the following two

conditions: (1) This device may not cause harmful interference. And (2) This device must accept any interference

received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de las classe A prescrites dans le Réglement sur le brouillage radioélectrique édicté par les

ministère des Communications du Canada.

CE STANDARDS

Testing for compliance to CE requirements was performed by an independent laboratory. The unit under test was

found compliant to Class A.

UL/CSA

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

iv

Page 5

TABLE OF CONTENTS

CTION 1. FEATURES AND SPECIFICATIONS--------------------------------------------------------------------- 1

SE

FEATURES--------------------------------------------------------------------------------------------------------------------- 1

M

ODES OF OPERATION -------------------------------------------------------------------------------------------------- 2

Unbuffered Mode..................................................................................................................................2

Buffered Mode......................................................................................................................................2

CONFIGURATIONS---------------------------------------------------------------------------------------------------------- 3

SPECIFICATIONS------------------------------------------------------------------------------------------------------------ 4

PIN LIST AND I/O SIGNALS----------------------------------------------------------------------------------------------- 6

SECTION 2. IN

MOUNTING -------------------------------------------------------------------------------------------------------------------- 7

SW

ITCH SETTINGS ---------------------------------------------------------------------------------------------------------9

Switch SWA..........................................................................................................................................9

Switch SWB........................................................................................................................................10

SE

CTION 3. COMMANDS, FORMATS, TIMING-----------------------------------------------------------------------13

HOST TO READER COMMANDS---------------------------------------------------------------------------------------13

RE

ADER TO HOST FORMATS------------------------------------------------------------------------------------------13

Successful Card Read........................................................................................................................14

Unsuccessful Card Read....................................................................................................................15

No Card Read.....................................................................................................................................16

IN

TERFACE WIRE LIST FOR MT-215232----------------------------------------------------------------------------17

Control Signals ...................................................................................................................................17

Power and Connector Mating.............................................................................................................17

LED Connections................................................................................................................................19

TIMING -------------------------------------------------------------------------------------------------------------------------20

INDICATORS -----------------------------------------------------------------------------------------------------------------20

USER DRIVERS -------------------------------------------------------------------------------------------------------------21

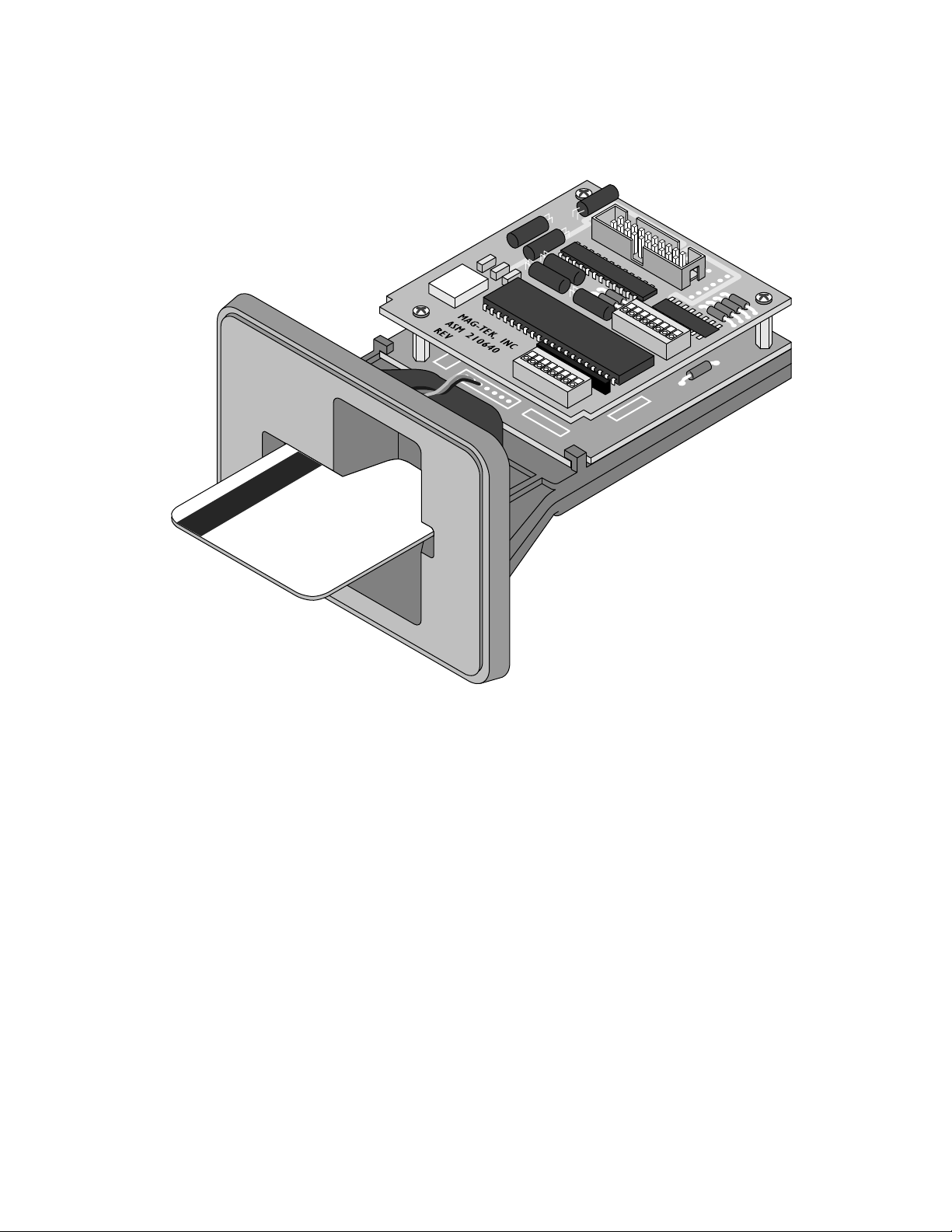

Figure 1-1. RS-232 Insertion Reader ---------------------------------------------------------------------------------------vi

Figure 1-2. Dimensions---------------------------------------------------------------------------------------------------------5

Figure 2-1. Switches and Connector---------------------------------------------------------------------------------------- 7

Figure 2-2. Mounting Dimensions-------------------------------------------------------------------------------------------- 8

Figure 3-1. Successful Card Read------------------------------------------------------------------------------------------14

Figure 3-2. Unsuccessful Card Read --------------------------------------------------------------------------------------15

Figure 3-3. No Card Read ----------------------------------------------------------------------------------------------------16

F

igure 3-4. Transmission Timing--------------------------------------------------------------------------------------------20

Table 1-1. Specifications------------------------------------------------------------------------------------------------------- 4

Table 1-2. J2 Connector Signals--------------------------------------------------------------------------------------------- 6

Table 2-1. Baud Rate Setting ------------------------------------------------------------------------------------------------- 9

Table 2-2. Parity Setting-------------------------------------------------------------------------------------------------------- 9

Table 3-1. Commands and Responses - I and R Commands -------------------------------------------------------13

Table 3-2. Commands and Responses – Auxiliary Driver Commands--------------------------------------------13

Table 3-3. D9 Without Control Signals ------------------------------------------------------------------------------------18

Table 3-4. D25 Without Control Signals-----------------------------------------------------------------------------------18

Table 3-5. D9 With Control Signals-----------------------------------------------------------------------------------------19

T

able 3-6. D25 With Control Signals---------------------------------------------------------------------------------------19

STALLATION ------------------------------------------------------------------------------------------------ 7

ILLUSTRATIONS

TABLES

v

Page 6

Figure 1-1. RS-232 Insertion Reader

vi

Page 7

SECTION 1. FEATURES AND SPECIFICATIONS

The Model MT-215232 Insertion Reader is a magnetic

ual tracks of alphanumeric or numeric data in formats established by the credit card industry.

d

For AAMVA and CDL, the Reader reads track 2 only.

The Reader is compatible with the PC AT/PS2 series of perso

ith an RS-232 interface. The MT-215 will read cards that meet the standards defined by ISO

w

7810, 7811-1, 7811-2, 7811-3, 7811-4, 7811-5, and 7811-6.

card is inserted all the way into the reader and withdrawn with a steady motion. A read

A

attempt is made during insertion and removal of the card.

Two blocks of eight switches each select the RS-232 pro

aming characters. The switches also select buffered and unbuffered modes of operation and

fr

enable comma

FEATURES

Major features of the Insertion Reader are as follows:

nd selection from the Host to the Reader.

• Hardware compatible with PC or any computer with an RS-23

• Switch selectable buffered o

• Switch selectable baud ra

r unbuffered modes of operation

te

• Switch selectable parity

On/off switches for STX (Start of Text), ETX (End of Text), and ESC (ESCAPE) framing

•

characters.

• On/off switch for CR (Carriage Return)

• Magnetic stripe read dur

ing insertion and removal of card

• ASCII message format

• Two auxiliary drivers for Reader status, or to actuate devices such as solenoids, or relays

stripe card reader, which reads single or

nal computers or any computer

tocol including baud rate, parity, and

2 interface.

1

Page 8

MT-215232 Insertion Reader

MODES OF OPERATION

The Reader can operate in either unbuffered or buffered mode. The descriptions are as follows:

Unbuffered Mode

When a card is inserted and removed, a read attempt is made during both insertion and removal.

Upon removal of the card if the read is successful, data (including the two sentinel characters) is

sent to the Host. The data is transmitted immediately and not retained in the Reader.

When operating in the unbuffered mode, the Reader does not need to received commands from

the Host in order to transmit data or status characters; however, the Reader does respond to an

“Inquiry Command” by sending status characters. The inquiry command that requests the

transmission of status characters is the ESCAPE (ESC) character followed by the ASCII

character “I”.

The Reader must be turned off before selecting the operating mode. Refer to Section 2 for

switch settings.

Note

The insertion and removal of the card must be done in a

continuous motion. If not, the Reader may not read the encoded

data properly. In that case, the Reader responds by either

transmitting the ASCII character “E” representing an error, or by

not transmitting any character, which indicates that the Reader

has not detected data and the card was not completely inserted.

Buffered Mode

When a card is inserted and removed, a read attempt is made during both insertion and removal.

Upon removal of the card if the read is successful, data (including the two sentinel characters) is

stored in a memory buffer on the Reader and is not transmitted until the Reader receives an

“Inquiry Command” from the Host. This command is the ESCAPE character followed by the

ASCII “I”. The Reader cannot read another card until the buffer is cleared. To clear the buffer,

the Host must transmit the ESCAPE character followed by The ASCII “R”.

The Reader must be turned off before selecting the operating mode. Refer to Section 2 for

switch settings

2

Page 9

Section 1. Features and Specifications

Note

The insertion and removal of the card must be done in a

continuous motion. If not, the Reader may not read the encoded

data properly. In that case, the Reader responds to an inquiry

command by either transmitting the ASCII character “E””

representing an error, or by just transmitting status characters,

which indicates that the Reader has not detected any data and the

card was not completely inserted.

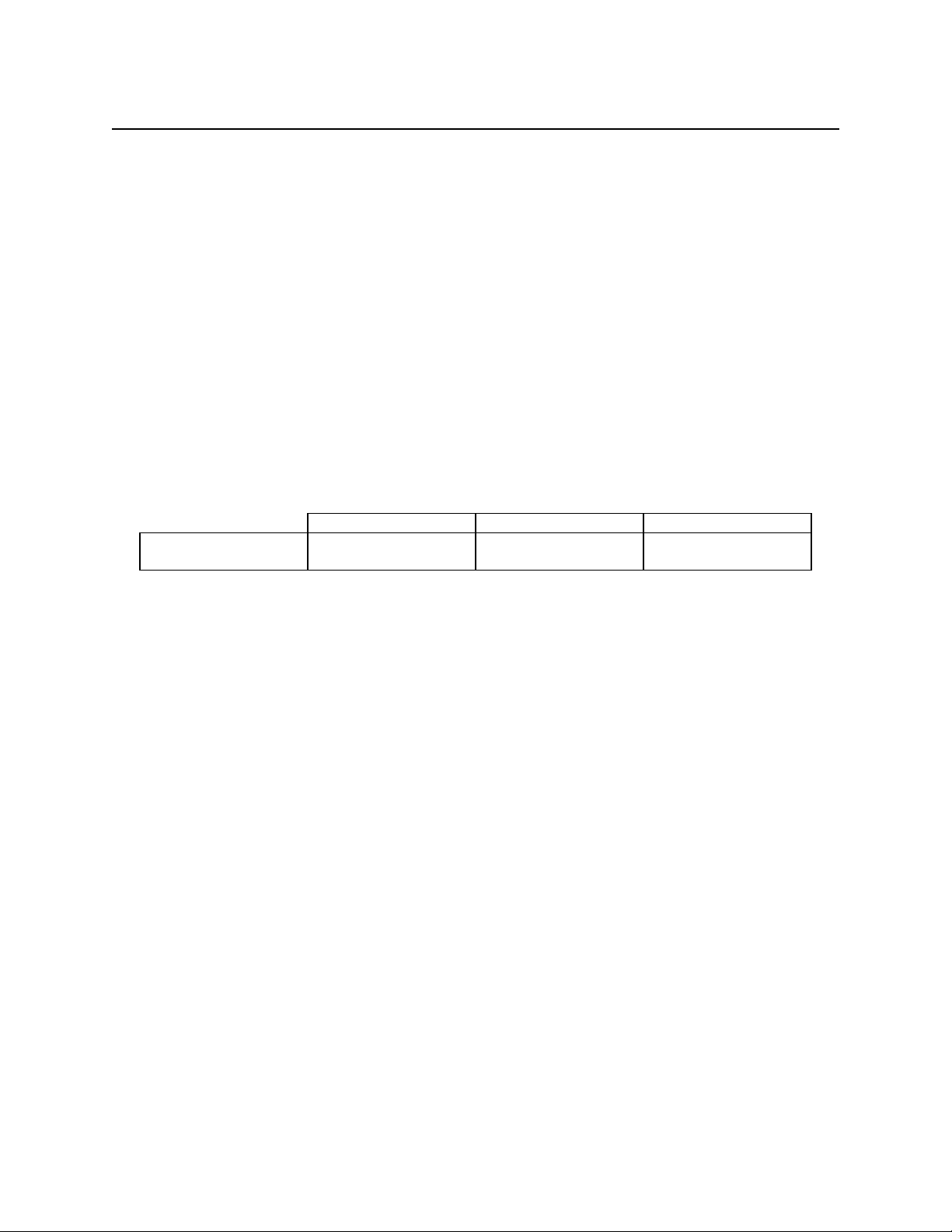

CONFIGURATIONS

The following list includes part numbers and available track configurations:

Part Number Read Bezel

Multiple Tracks

21065127

21065132

Tracks 1, 2

Tracks 1, 2

No Bezel

Flat Face Bezel

3

Page 10

MT-215232 Insertion Reader

SPECIFICATIONS

Table 1-1 lists the specifications for the RS-232 Insertion Reader.

Table 1-1. Specifications

OPERATING

Reference Standards ANSI/ISO

Power Input +5V DC - Requires +4.75 V DC to +5.25 V DC @ 0.045 A

Power Consumption 0.225 WATTS

Auxiliary Drivers 1 and 2 Open Collector outputs, capable of driving visual indicators, solenoids,

relays, etc. Outputs driven by Texas Instruments ULN 2003AN. Any

use of these drivers must meet the following: ON = 0.8V @ 0.2 amps

max. OFF = 50.0V max. (See Texas Instruments Data Sheet for

parameters.)

Interface Signal RS-232E

Message Format ASCII (7 Data Bits + Parity Bit)

Track Card Speed TRK 1 or 3: 3 to 50 IPS (127 cm) at 210 BPI.

TRK 2: 3 to 50 IPS (127 cm) at 75 BPI

MTBF Electronics: 120,000 hours

Head: 1,000,000 passes (500,000 insertion cycles)

MECHANICAL

Dimensions (with Bezel)

Length

Width

Height

Bezel Thickness

Weight 5.42 oz. (154 g.)

Temperature

Operating 0oC to 70oC (32oF to 158oF)

Storage -40oC to 80oC (-40oF to 176oF)

Humidity

Operating 10% to 90% noncondensing

Storage 0% to 100% noncondensing

Altitude

Operating 0-10,000 ft. (0-3,048 m.)

Storage 0-50,000 ft. (0-15,240 m.)

4.58 “ (11.63cm)

4” (10.16 cm)

3” (7.62 cm)

0.31” (0.79 cm)

ENVIRONMENTAL

4

Page 11

Section 1. Features and Specifications

Figure 1-2. Dimensions

5

Page 12

MT-215232 Insertion Reader

PIN LIST AND I/O SIGNALS

Table 1-2 lists the pin numbers, signals, and descriptions for connector J2 on the Reader. See

Section 3 for the Interface Wire List for the MT215232.

Table 1-2. J2 Connector Signals

Pin

Number

1,2 +5v

3,4 GND

5 DSR

6

7 DTR

8* AUX 1

9 CTS

10* AUX 2

11 RTS

12

13 RD

14***

15 TD

16*** BUSY

17** N/C

18*** READY

19** N/C

20*** ERROR

*These signals are open collector outputs, capable of driving visual indicators, solenoids, relays, etc. The

outputs are driven by a Texas Instruments ULN 2003AN. Any use of these drivers must meet the

following specifications: ON = 0.8V @0.2 amps max. OFF = 50.0V max.

**The 5V to +12V/-12V conversion is now being done on the processor board. Pins 17 and 19 (which

formerly transmitted the +12V/-12V) now have no connection so that the new version of the Reader can

be used interchangeably with the old version of the Reader.

***See Section 3 for details and mating connectors.

Signal Description

Either one or both pins can be connected to a +5V power supply. See Specifications,

Section 1 for ratings.

Either one or both pins can be used as circuit ground.

Data Set Ready, RS-232E signal. Indicates to the Reader that the Host is active.

Used for factory testing only.

Data Terminal Ready, RS-232 signal. Indicates to the Host that the Reader is active.

Auxiliary driver 1. Operated by commands from the Host.

Clear to sent, RS-232C signal. Signal from the Host to the Reader allowing data to be

transmitted.

Auxiliary driver 2. Operated by commands from the Host.

Request to send, RS-232E signal. The Reader transmits the signal to the Host

indicating the Reader is ready to transmit data.

CARD

PRESENT Used for factory testing only.

Received data, RS-232E signal. Reader receives data sent from the Host.

REAR

SENSOR

BLOCKED

Indicates the presence of a card when it is fully inserted in the reader.

Transmitted data, RS-232E signal. Transmits data from the Reader to the Host.

Used for factory testing only.

In previous versions of the Reader this pin was used for -12V.

Indicates the unit is ready to accept a card.

In previous versions of the Reader this pin was used for +12V.

Indicates an unsuccessful read attempt. This signal remains active for 2.0 seconds.

6

Page 13

SECTION 2. INSTALLATION

The installation consists of mounting the Reader, connecting the cable, and settings the switches.

Other considerations such as commands, responses, formats and timing are given in Section 3.

The switches and the connector are shown in Figure 2-1. The pin list for the connector is

presented in Section 1 under Specifications. The illustration in Section 1 also shows clearance

dimensions of the Reader.

Figure 2-1. Switches and Connector

MOUNTING

Figure 2-2 shows dimensions for mounting considerations.

7

Page 14

MT-215232 Insertion Reader

8

Figure 2-2. Mounting Dimensions

Page 15

Section 2. Installation

SWITCH SETTINGS

The switch positions and orientations are shown in Figure 2-1. The switches must be set while

power is off to ensure that the switch settings are properly loaded. As shown in the illustration

and designated on the printed circuit board, the switches are SWA and SWB. Set the switches as

described below.

Switch SWA

On SWA switches 1, 2 and 3 set the baud rate. This is the rate at which data is transmitted and

received between the Reader and the Host. The switch settings are shown in Table 2-1.

Table 2-1. Baud Rate Setting

BAUD RATE SWA1 SWA2 SWA3

150 ON ON ON

300 OFF ON ON

600 ON OFF ON

1200 OFF OFF ON

2400 ON ON OFF

4800 OFF ON OFF

9600 ON OFF OFF

19200 OFF OFF OFF

On SWA switches 4 and 5 set the parity as shown in Table 2-2.

Table 2-2. Parity Setting

PARITY SENT SWA4 SWA5 RECEIVED

PARITY CHECK

ODD ON ON ODD

EVEN OFF ON EVEN

ONE (MARK ) ON OFF IGNORED

ZERO (SPACE) OFF OFF IGNORED

SWA6:

Sets the Start of Text (STX) framing character. This character is optional. Set SW6 to ON if

STX is required and to OFF if it is not.

9

Page 16

MT-215232 Insertion Reader

SWA7:

Sets the ESCAPE character. This character is optional. Set SW7 to ON if ESCAPE is

implemented and OFF if it is not.

SWA8:

Sets the End of Text (ETX) framing character. This character is optional. Set SW8 to ON if

ETX is implemented and OFF if it is not.

Switch SWB

SWB1:

Sets the Carriage Return (CR). This character is optional. Set SWB1 to ON if CR is to be

implemented and OFF if it is not.

SWB2:

Sets the operating mode of Buffered or Unbuffered. Set SWB2 to ON for Buffered or OFF for

Unbuffered.

SWB3:

Two open collector auxiliary drivers are available to the user. The status of these drivers is

reported by the bytes of information following the transmitted card data. If the drivers are not

used, these status bytes may be suppressed by setting the switch to OFF. The status bytes are

transmitted if the switch is set to ON.

SWB4:

Factory set to ON for “I” and “R”, OFF for “+” and “-” See Section 3, Operation, under Host to

Reader Commands.

SWB5:

Factory set to OFF (must not be changed).

10

Page 17

Section 2. Installation

SWB6:

Factory set to OFF (for the most reliable operation should not be changed). Reader will read

upon insertion and withdrawal. If set to the ON position, the Reader will read on Insert only.

Data is transmitted upon contact of the rear sensor.

SWB7:

Set to the ON position to jumper the control signals RTS-CTS. Set to OFF is these signals are

implemented by the Host.

SWB8:

Set to the ON position to jumper the control signals DSR-DTR. Set to OFF is these signals are

implemented by the Host.

Notes:

1. In previous versions of the Reader, a switch was used to enable reading either a 5-bit

data format or a 7-bit data format. In this version the function of reading a 7- or 5-bit

format is performed automatically by the firmware.

2. Switches that are factory set must be set in the position indicated when used by the

customer. The Reader is one of a series of products using the same microcontroller. The

factory set switches make the microcontroller function properly in the Reader.

11

Page 18

MT-215232 Insertion Reader

12

Page 19

SECTION 3. COMMANDS, FORMATS, TIMING

This section includes commands from the Host to the Reader, Reader to Host message formats,

transmission timing, and possible uses of drivers.

HOST TO READER COMMANDS

All commands transmitted from the Host to the Reader must be preceded by the ASCII “ESCAPE”

character. These command messages may contain other framing characters, which are ignored by the

Reader. Table 3-1 describes I and R commands, a switch selectable option for the ASCII command

character and the Reader response to the Host. Table 3-2 describes the second character commands

Table 3-1. Commands and Responses - I and R Commands

HOST COMMANDS READER RESPONSES

ASCII “ESCAPE”

CHARACTER

(1B hex)

<ESC> I + Inquiry command causes the

<ESC> R - Release command causes the

Table 3-2. Commands and Responses – Auxiliary Driver Commands

ASCII “ESCAPE”

CHARACTER

(1B hex)

READER TO HOST FORMATS

The following diagrams represent the formats of the data transmitted after a successful card read, an

unsuccessful card read, and no card read which is the response if the Host inquires and the buffer is

empty.

SWITCH SELECTABLE ASCII

CHARACTER - SWB4

ON OFF

Reader to transmit data, error, or

status message.

Reader to clear its memory buffer of

any data present. This command

works only in the Buffered mode.

ASCII SECOND

CHARACTER

<ESC> 0 Deactivates both user drivers 1 and

<ESC> 1 Activates user driver 1.

<ESC> 2 Activates user driver 2.

<ESC> 3 Deactivates user driver 1.

<ESC> 4 Deactivates user driver 2

READER RESPONSES

2.

13

Page 20

MT-215232 Insertion Reader

Successful Card Read

<STX> <ESC> SS CARD

DATA

ES USER DRIVER

STATUS

CARD SENSOR

STATUS

<CR> <ETX>

End of Text

Character,

(03 Hex)

Optional.

Set SWA # 8

to ON

Carriage Return

Character (OD Hex)

Optional. Set SWB #1

to ON.

ASCII “0” = No Card is in the Reader

ASCII “1” = Card present in the Reader

ASCII”0” = Drivers 1 and 2 OFF

ASCII”1” = Driver 1 ON

ASCII”2” = Driver 2 ON

ASCII”3” = Drivers 1 and 2 ON

Set SWB #3 ON

End Sentinel Character ASCII “?”

Card Data in ASCII Track Order

i.e., Tk 1 and 2 for a Tk 1 and 2 device, or

Tk 2 and 3 for a Tk 2 and 3 device

Start Sentinel Character

ASCII “%” for Track 1

ASCII “;” for Tracks 2 and 3

Escape character, optional

(1B hex), set SWA #7 to ON

Start of Text Character, optional (02 hex),

Set SWA #6 to ON

Notes: 1. Optional characters are used to frame the data.

2. The LRC character is not transmitted.

3. The optional Hex characters are shown with the parity bit as zero (“0”).

Figure 3-1. Successful Card Read

14

Page 21

Section 3. Commands, Formats, and Timing

Unsuccessful Card Read

<STX> <ESC> ERROR USER DRIVER

STATUS

CARD SENSOR

STATUS

<CR> <ETX>

End of Text

Character,

(03 Hex)

Optional.

Set SWA # 8

to ON

Carriage Return

Character (OD Hex)

Optional. Set SWB #1

to ON.

ASCII “0” = No Card is in the Reader

ASCII “1” = Card present in the Reader

ASCII”0” = Drivers 1 and 2 OFF

ASCII”1” = Driver 1 ON

ASCII”2” = Driver 2 ON

ASCII”3” = Drivers 1 and 2 ON

Set SWB #3 ON

ASCII “E” represents error. If both tracks fail

on a dual track reader, an “EE” will be transmitted.

If one of two tracks fails on a dual track reader, it

will be replaced with an “E”. On a dual track reader,

the higher density track will be transmitted first.

If a card is inserted so the oxide is not in contact with the head,

the unit outputs a single “E” no matter whether it is a single or

dual track unit.

Escape character, optional

(1B hex), set SWA #7 to ON

Start of Text Character, optional (02 hex),

Set SWA #6 to ON

Notes: 1. Optional characters are used to frame the data.

2. The optional Hex characters are shown with the parity bit as zero (“0”).

Figure 3-2. Unsuccessful Card Read

15

Page 22

MT-215232 Insertion Reader

No Card Read

The No Card Read is the response if the Host inquires (Esc I) and the buffer is empty.

<STX> <ESC> USER DRIVER

STATUS

CARD SENSOR STATUS <CR> <ETX>

End of Text

Character,

(03 Hex)

Optional.

Set SWA # 8

to ON

Carriage Return

Character (OD Hex)

Optional. Set SWB #1

to ON.

ASCII “0” = No Card is in the Reader

ASCII “1” = Card present in the Reader

ASCII”0” = Drivers 1 and 2 OFF

ASCII”1” = Driver 1 ON

ASCII”2” = Driver 2 ON

ASCII”3” = Drivers 1 and 2 ON

Optional Set SWB #3 ON

Escape character, optional

(1B hex), set SWA #7 to ON

Start of Text Character, optional (02 hex),

Set SWA #6 to ON

Notes: 1. Optional characters are used to frame the data.

2. The optional Hex characters are shown with the parity bit as zero (“0”).

Figure 3-3. No Card Read

16

Page 23

Section 3. Commands, Formats, and Timing

INTERFACE WIRE LIST FOR MT-215232

The interface wire list describes the unit with and without control signals in the buffered and unbuffered

modes, D9 and D25 connectors, and LED connections.

Control Signals

The control signals are defined as: DSR, pin 5; DTR, pin 7; CTS, pin 9; RTS, pin 11.

Without control signals in the unbuffered mode, the card reader will transmit the data immediately upon

removal of the card.

Without control signals in the buffered mode, the card reader will transmit the data upon removal of the

card and immediately after the Host has polled the card reader.

With control signals connected in the unbuffered mode, the unit will signal the Host (RTS goes positive)

when it has a message and wait for the Host to signal that it is ready to accept the data. The Host raises

CTS to a positive level to receive the data, and RTS will return to negative after data has been

transmitted.

With control signals connected in the buffered mode, after the card is removed and polled by the Host,

and the Host signals that it is ready to accept data, the data will be transmitted.

Note

Normally this last configuration is not used if the Host has full command of

the control signals

Power and Connector Mating

The +5 VDC ± 5% at 0.045 Amps power can be obtained from an external power supply or from the Host

(not available on the "D" COM port connector).

The reader mates to a 20 pin connector (P2), and the Host has a "D type" connector (P3) which is

normally designated as Com 1 or Com 2.

Part numbers for the 3M interface: Connector 3421-6000; Flat gray cable 3365-20; or Flat multi-color

cable: 3302-20.

Tables 3-2 through 3-5 describe the correct wiring schemes for 25- and 9-pin “D’’ connectors with and

without control signals.

17

Page 24

MT-215232 Insertion Reader

Table 3-3 is used when the Host has a 9-pin “D” connector without control signals.

Note

Switches SWB7 and SWB8 must be ON for this configuration.

Table 3-3. D9 Without Control Signals

READER HOST

P2-1 TO +5 VDC POWER

P2-3 TO POWER SUPPLY GROUND (RETURN)

P2-4 TO P3-5

P2-13 TO P3-3

P2-15 TO P3-2

P3-7 TO P3-8

P3-1 TO P3-4 TO P3-6

Table 3-4 is used when the Host has a 25-pin “D” connector without control signals.

Note

Switches SWB7 and SWB8 must be ON for this configuration.

Table 3-4. D25 Without Control Signals

READER HOST

P2-1 TO +5 VDC POWER

P2-3 TO POWER SUPPLY GROUND (RETURN)

P2-4 TO P3-7

P2-13 TO P3-2

P2-15 TO P3-3

P3-4 TO P3-5

P3-6 TO P3-8 TO P3-20

Table 3-5 is used when the Host has a 9-pin “D” connector with control signals.

18

Page 25

Section 3. Commands, Formats, and Timing

Note

Switches SWB7 and SWB8 must be OFF for this configuration.

Table 3-5. D9 With Control Signals

READER CONNECT TO HOST

P2-1 TO +5 VDC POWER

P2-3 TO POWER SUPPLY GROUND (RETURN)

P2-4 TO P3-5

P2-5 TO P2-9 TO P3-4

P2-7 TO P3-6 TO P3-8

P2-11 TO P3-1

P2-13 TO P3-3

P2-15 TO P3-2

Table 3-6 is used when the Host has a 25-pin “D” connector with control signals.

Table 3-6. D25 With Control Signals

Note

Switches SWB7 and SWB8 must be OFF for this configuration.

READER CONNECT TO HOST

P2-1 TO +5 VDC POWER

P2-3 TO POWER SUPPLY GROUND (RETURN)

P2-4 TO P3-7

P2-5 TO P2-9 TO P3-20

P2-7 TO P3-6 TO P3-5

P2-11 TO P3-8

P2-13 TO P3-2

P2-15 TO P3-3

LED Connections

It may be desirable to have a visual indication of the reader's status at the reader.

By adding two to three LED's (Light Emitting Diodes) to any of the above cables, this can be

accomplished. Connect the anode of all LED's to +5 VDC.

19

Page 26

MT-215232 Insertion Reader

Connect the cathode of a green LED to pin P2-18. This LED will illuminate when the card reader is

READY to accept a card.

Connect the cathode of a red LED to pin P2-20. This LED will illuminate when the card reader has

detected an ERROR. It will glow for 2 seconds after the card has been withdrawn if there was an error in

reading any track.

The BUSY indicator is not very useful since it is on only when the ready LED is out.

To use this LED, connect a yellow LED's cathode to P2-16.

Normally the anode is the longer lead on an LED to be connected to +5 VDC. The circuit has a built-in

220 ohm resistor to limit LED current on pins J2-14, J2-16, and J2-18.

TIMING

The Reader is capable of bidirectional communication with the Host. Transmission timing is shown in

Figure 3-4. Each ASCII character is transmitted with 1 start bit, 7 data bits, 1 parity bit, and 1 stop bit.

Logic levels conform to standard RS-232 levels; logic levels are “true” or “1” if the level is low (-9 VDC

(quiescent state)) and “false” or “0” if the level is high (+9 VDC).

Figure 3-4. Transmission Timing

INDICATORS

There are three drivers in the Reader that may function as status indicators. They are:

REAR SENSOR (Pin J2-14): Indicates the presence of a card when it is fully inserted in the

Reader.

ERROR (Pin J2-20): Indicates an unsuccessful read attempt. This indicator remains active for 2.0

seconds.

READY (Pin J2-18): Indicates that the unit is ready to accept a card.

See LED connections above.

20

Page 27

Section 3. Commands, Formats, and Timing

USER DRIVERS

There are two user drivers activated or deactivated by commands from the Host, which can be defined in

the Host system as indicators to prompt the operator. For Example, if the Reader sent a message to the

Host indicating that it was not ready to read a card, the Host can turn one driver off. When the Host has

completed a card read process, the driver would be turned back on, and a new transition could occur.

Further applications of the two drivers include such functions as operating solenoids or relays. Ratings

for the two drivers are listed in Section 1 under Specifications. For complete specifications, visit

www.ti.com. Search ULN2003AN. Commands to activate or deactivate these drivers are shown in

Table 3-2.

21

Page 28

MT-215232 Insertion Reader

22

Loading...

Loading...