Page 1

MINI MICR WEDGE

WITH OPTIONAL 3-TRACK MSR

TECHNICAL REFERENCE MANUAL

Manual Part Number: 99875074 Rev 3

APRIL 2003

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

Cop 05

yright© 1997-20

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, e

lectronic or mechanical, for any purpose,

without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

NCR is a registered trademark of National Cash Register, Inc.

IBM, PS/2, and AT are registered trademarks of International Business Machines, Inc.

REVISIONS

Rev Num r D

be ate Notes

1 15 May 97 Initial Release

2 20 Sep 99

3 18 Apr 03

Sec 1: Added EMF and Device Driver

references; Sec 4: Added MICRbase,

Device Drivers, Card Data Message, and

EMF detect; Appendix A: Added formats

7500, 7600, and 7700; Appendix C:

Step 12 to Troubleshooting Guide;

Appendix G: Added ASCII Codes.

Front Matter: added ISO line to logo,

changed Tech Support phone nu

dded new warranty statement.

a

Added

mber,

ii

Page 3

LIMITED WARRANTY

MagTek warrants that the products sold to Reseller pursuant to this Agreement will perform in accordance with

MagTek’s published specifications. This warranty shall be provided only for a period of one year from the da

of the shipment of the product from MagTek (the “Warranty Period”). This warranty shall apply only to the

original purchaser unless the buyer is aut

shall apply only to the first repurchase.

horized by MagTek to resell the products, in which event, this warranty

te

During the Warranty Period, should this product fail to conform to MagTek’s specifications, MagTek wi

option, repair or replace this product at no additional charge except as set forth below. Repair parts and

replacement products will be furnished on an exchange basis and will be either reconditioned or new. All rep

parts and products become the property of MagTek. This limited warranty does not include service to repair

damage to the product resulting from accident, disaster, unreasonable use, misuse, abuse, customer’s negligenc

Reseller’s negligence, or non-MagTek modification of the product. MagT

alleged defective goods to determine whether the warranty is applicable.

Without limiting the generality of the foregoing, MagTek specifically disclaims any liability or warranty for

goods resold in other than MagTek’s original packages, and for goods modified, altered, or treated by customers

Service may be obtained by delivering the product during the warranty period to MagTek (1710 Apollo Court,

Seal Beach, CA 90740). If this product is delivered by mail or by an equivalent shipping carrier, the customer

agrees to insure the product or assume the risk of loss or damage in transit, to prepay shipping charges to the

warranty service location and to use the original shipping container or equivalent. MagTek will return the produc

prepaid, via

all returns.

MAGTEK MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAGTEK DISCLAIMS AN

WARRANTY OF ANY OTHER KIND, INCLU

FITNESS FOR A PARTICULAR PURPOSE.

EACH PURCHASER UNDERSTANDS THAT THE MAGTEK PRODUCT IS OFFERED AS IS. IF THIS

PRODUCT DOES NOT CONFORM TO MAGTEK’S SPECIFICATIONS, THE SOLE REMEDY SHALL BE

REPAIR OR REPLACEMENT AS PROVIDED ABOVE. MAGTEK’S LIABILITY, IF ANY, TO RESELLER

OR TO RESELLER’S CUSTOMERS, SHALL IN NO EVENT EXCEED THE TOTAL AMOUNT PAID TO

MAGTEK BY RESELLER UNDER THIS AGREEMENT. IN NO EVENT WILL MAGTEK BE LIABLE T

THE RESELLER OR THE RESELLER’S CUSTOMER FOR ANY DAMAGES, INCLUDING ANY LOST

PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OF OR INABILITY TO USE SUCH PRODUCT, EVEN IF MAGTEK HAS BEEN A

HE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

T

LIMITATION ON LIABILITY

a three (3) day shipping service. A Return Material Authorization (RMA) number must accompany

DING ANY WARRANTY OF MERCHANTABILITY OR

ek reserves the right to examine the

ll, at its

laced

e,

Y

O

DVISED OF

.

t,

EXCEPT AS PROVIDED IN THE SECTIONS RELATING TO MAGTEK’S LIMITED WARRANTY,

MAGTEK’S LIA

PRODUCTS.

MAGTEK MAKES NO OTHER WARRANTIES WITH RESPECT TO THE PRODUCTS, EXPRESSED OR

IMPLIED, EXCEPT AS MAY BE STATED IN THIS AGREEMENT, AND MAGTEK DISCLAIMS A

IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION ANY IM

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MAGTEK SHALL NOT BE LIABLE FOR CONTINGENT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES TO PERSONS OR PROPERTY. MAGTEK FURTHER LIMITS ITS LIABILITY OF ANY

WITH RESPECT TO THE PRODUCTS, IN

CONTRACT PRICE FOR THE GOODS.

MAGTEK’S SOLE LIABILITY AND BUYER’S EXCLUSIVE REMEDIES ARE

AND IN THE SECTION RELATING TO MAGTEK’S LIMITED WARRANTY.

BILITY UNDER THIS AGREEMENT IS LIMITED TO THE CONTRACT PRICE OF THE

NY

PLIED WARRANTY OF

KIND

CLUDING ANY NEGLIGENCE ON ITS PART, TO THE

STATED IN THIS SECTION

iii

Page 4

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to

terference in which case the user will be required to correct the interference at his own expense.

in

cause harmful

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class A limits for radio noise for

terference Regulations of the Canadian Department of Communications.

In

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de las classe A prescri

inistère des Communications du Canada.

m

tes dans le Réglement sur le brouillage radioélectrique édicté par les

digital apparatus set out in the Radio

SAFETY

This product has been evaluated, tested, and certified by the Canadian Standards Association (CSA 22.2, No. 950

Underwriters Laboratories (UL1950), and TUV Rheinland (TUV/EN60950). In order to insure that it ma

the safety integrity that was designed into the product, and for which it has been evaluated by the Safety

Certification Agencies, compliance with all Installation Instructions and Safety Requirements is essential.

intains

,

iv

Page 5

v

Page 6

TABLE OF CONTENTS

CTION 1. OVERVIEW ------------------------------------------------------------------------------------------------------ 1

SE

FEATURES............................................................................................................................................... 1

ACCESSORIES........................................................................................................................................ 1

SPECIFICATIONS.................................................................................................................................... 2

CTION 2. INSTALLATION ------------------------------------------------------------------------------------------------ 3

SE

REQUIREMENTS..................................................................................................................................... 3

PROCEDURE........................................................................................................................................... 3

CTION 3. OPERATION----------------------------------------------------------------------------------------------------- 5

SE

CHECK READING PROCEDURE ...........................................................................................................5

CARD SWIPE PROCEDURE................................................................................................................... 5

LED INDICATOR......................................................................................................................................6

CTION 4. COMMANDS ---------------------------------------------------------------------------------------------------- 7

SE

INSTA-CHANGE CHECKS ......................................................................................................................7

MICRBASE SETUP PROGRAM FOR WINDOWS.................................................................................. 7

MAGTEK DEVICE DRIVERS FOR WINDOWS....................................................................................... 8

US

ER APPLICATIONS WITHOUT MAGTEK DEVICE DRIVERS........................................................... 8

PC Commands To Enable and Disable Keyboard Wedge.................................................................. 8

PC Timing ............................................................................................................................................8

Keyboard Wedge Port IO Addresses................................................................................................... 8

COMMAND FORMAT ..............................................................................................................................9

DK – DISABLE KEYBOARD ....................................................................................................................9

EK – ENABLE KEYBOARD...................................................................................................................... 9

SWA - SWITCH A COMMAND.................................................................................................................9

SW

A PARAMETERS.............................................................................................................................. 10

Wedge Type.......................................................................................................................................10

Send Data After Error ........................................................................................................................ 10

Keypad Type...................................................................................................................................... 11

SWB - SWITCH B COMMAND...............................................................................................................12

SW

B PARAMETERS.............................................................................................................................. 12

Control Characters and MICR Data...................................................................................................13

<ENTER> Key Options......................................................................................................................13

Send Status After Data ...................................................................................................................... 15

SWC - SWITCH C COMMAND.............................................................................................................. 15

SW

C PARAMETERS .............................................................................................................................16

CMC-7 Character Set ........................................................................................................................16

Card Data Message...........................................................................................................................16

HW - HARDWARE COMMAND ............................................................................................................. 17

HW

PARAMETERS................................................................................................................................17

Disable/Enable Tracks....................................................................................................................... 17

ID Card Decoding .............................................................................................................................. 18

EMF Detect........................................................................................................................................ 18

FC - FORMAT CHANGE COMMAND....................................................................................................18

VR - VERSION COMMAND...................................................................................................................18

SA - SAVE COMMAND.......................................................................................................................... 19

RS - RESET COMMAND .......................................................................................................................19

APPENDIX A. FORMAT LIST---------------------------------------------------------------------------------------------- 21

AP

PENDIX B. CHECK READING----------------------------------------------------------------------------------------- 39

E13-B CHARACTER SET......................................................................................................................39

CMC-7 CHARACTER SET..................................................................................................................... 39

CHECK LAYOUTS................................................................................................................................. 40

MI

CR FIELDS.........................................................................................................................................41

1-Transit Field....................................................................................................................................41

2-On-Us Field.....................................................................................................................................41

3-Amount Field...................................................................................................................................42

vi

Page 7

4-Auxiliary On-Us Field ......................................................................................................................42

AP

PENDIX C. TROUBLESHOOTING GUIDE--------------------------------------------------------------------------43

REQUIREMENTS...................................................................................................................................43

SET-UP...................................................................................................................................................43

PROCEDURE.........................................................................................................................................43

APPENDIX D. PINPAD INTERFACE TO MICR READER-----------------------------------------------------------51

APPENDIX E. INTERFACE CABLE PIN LISTS------------------------------------------------------------------------53

APPENDIX F. ASCII CODES------------------------------------------------------------------------------------------------55

DEX ------------------------------------------------------------------------------------------------------------------------------57

IN

FIGURES

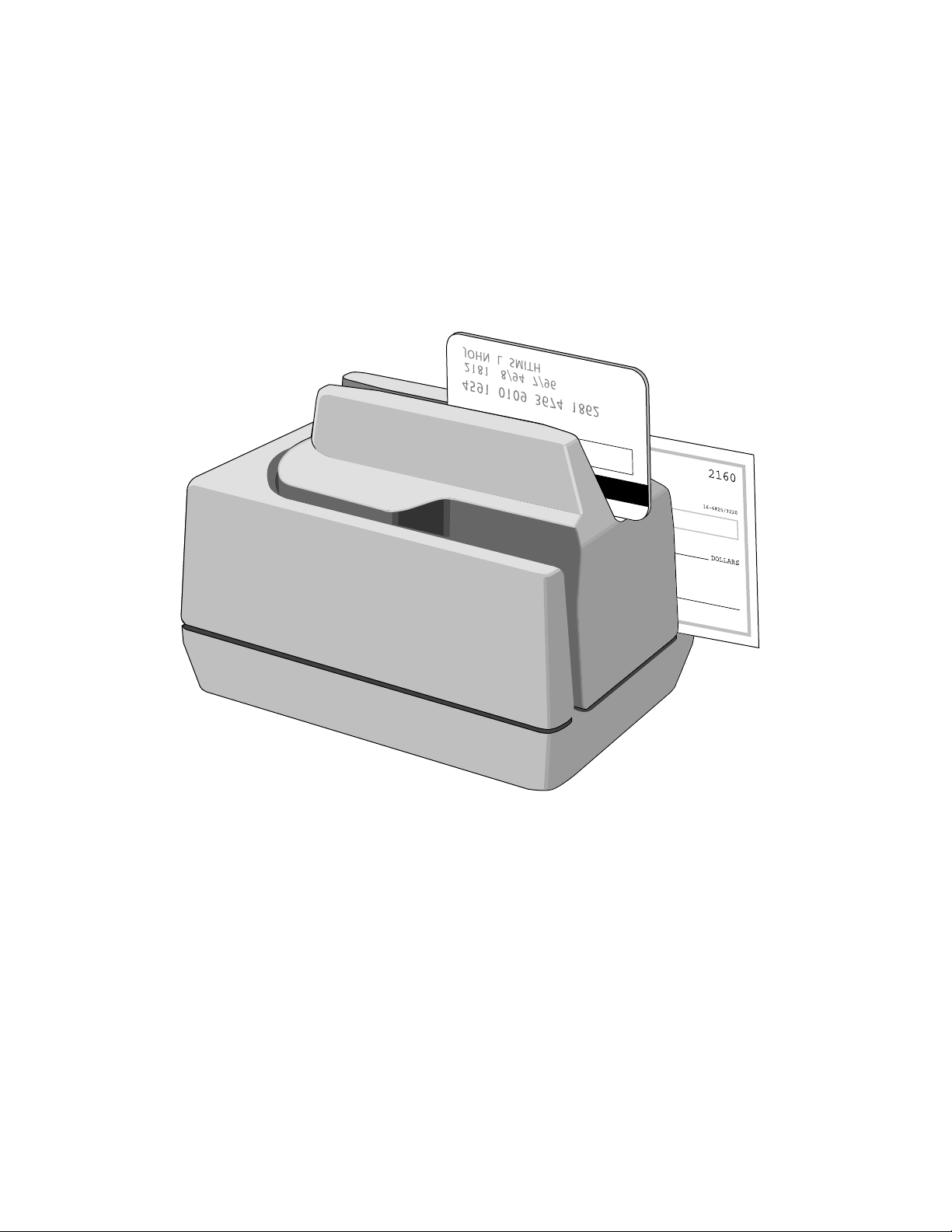

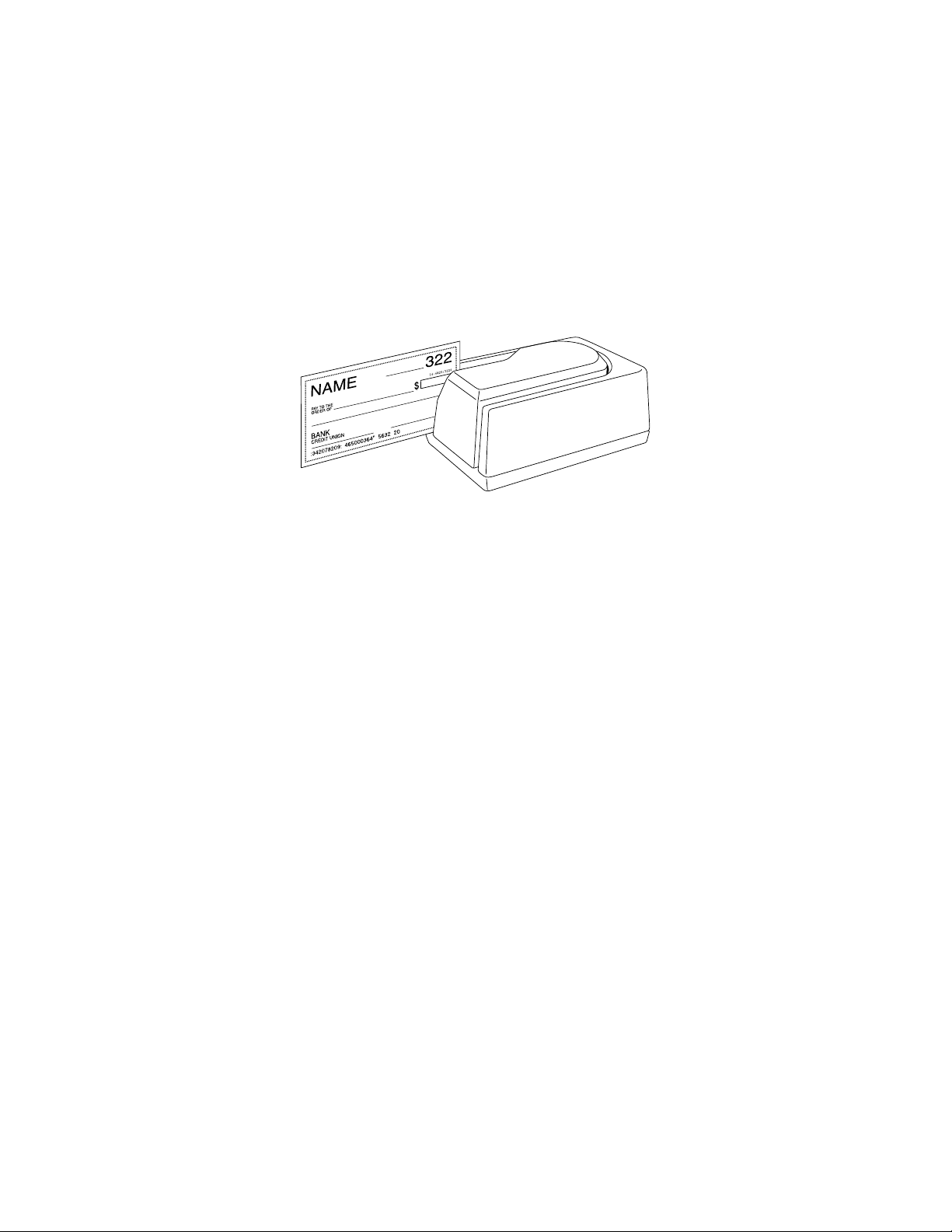

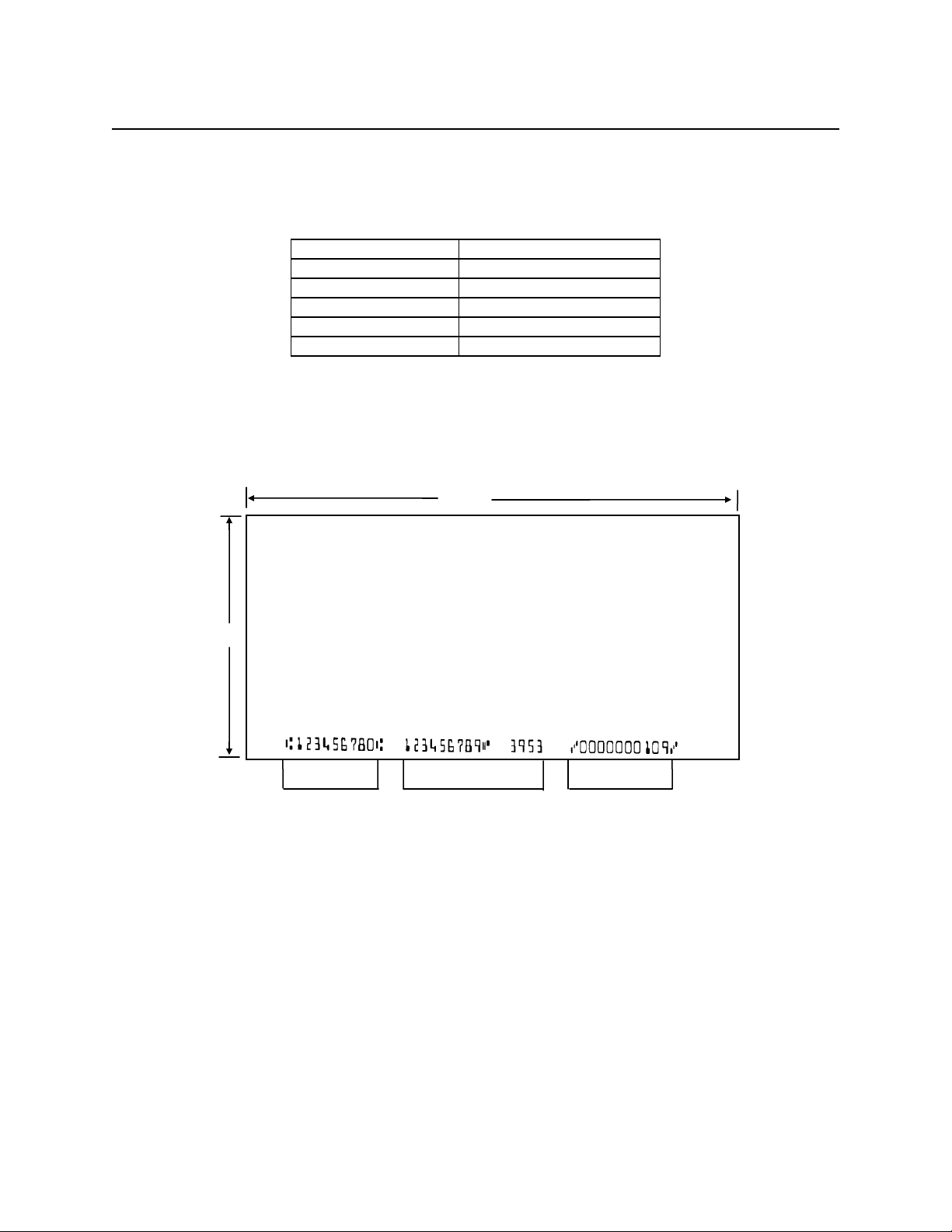

Figure 1-1. MINI MICR WEDGE with 3-Track MSR...................................................................................viii

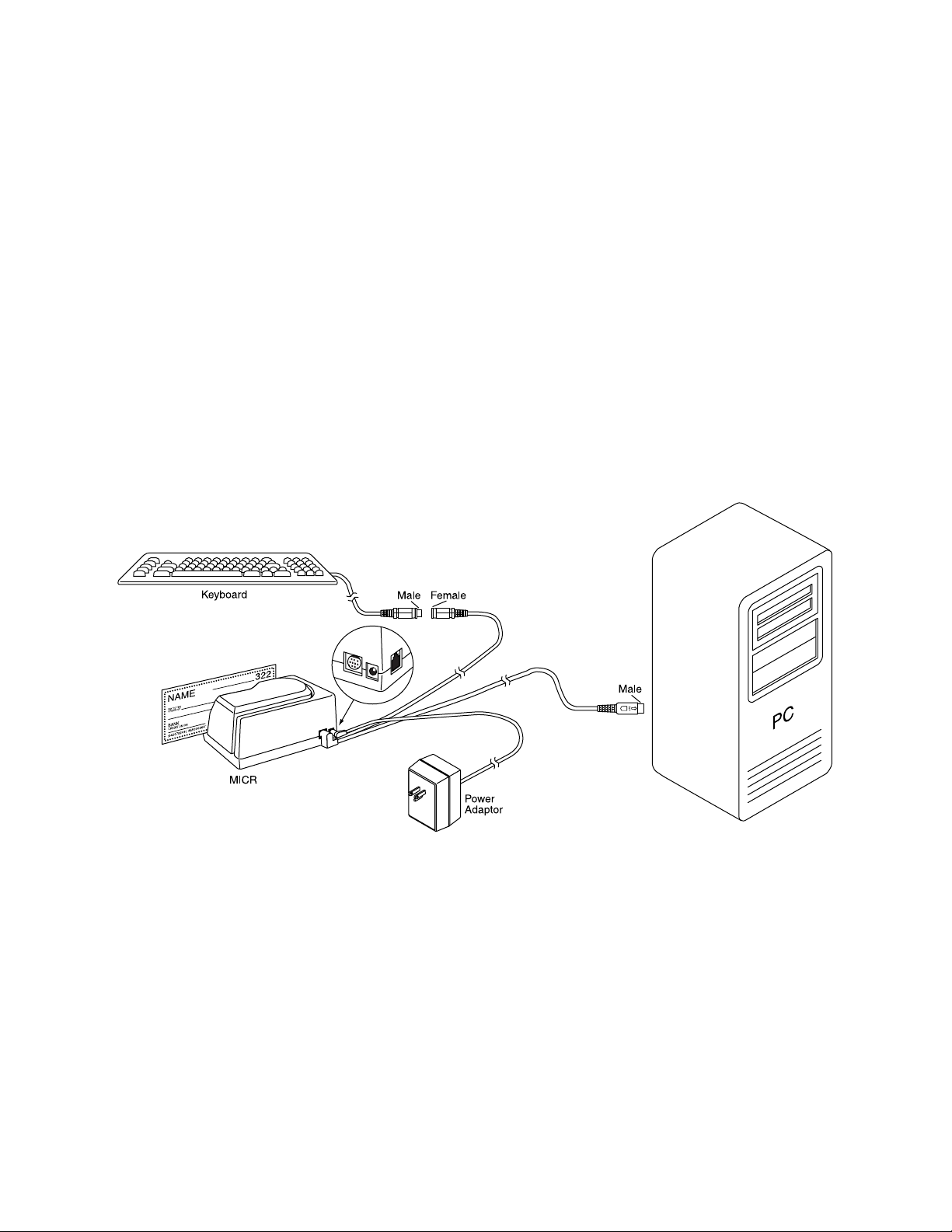

Figure 2-1. MICR Interface Cabling .............................................................................................................3

Figure 3-1. Check Orientation......................................................................................................................5

Figure 4-1. Keypad Types..........................................................................................................................11

Figure 4-2. <Enter> Key Positions.............................................................................................................14

Figure B-1. Personal Checks....................................................................................................................40

Figure B-2. Business Checks.....................................................................................................................41

Figure C-1. Sensor Location......................................................................................................................49

igure D-1. PINPad RJ Socket ..................................................................................................................51 F

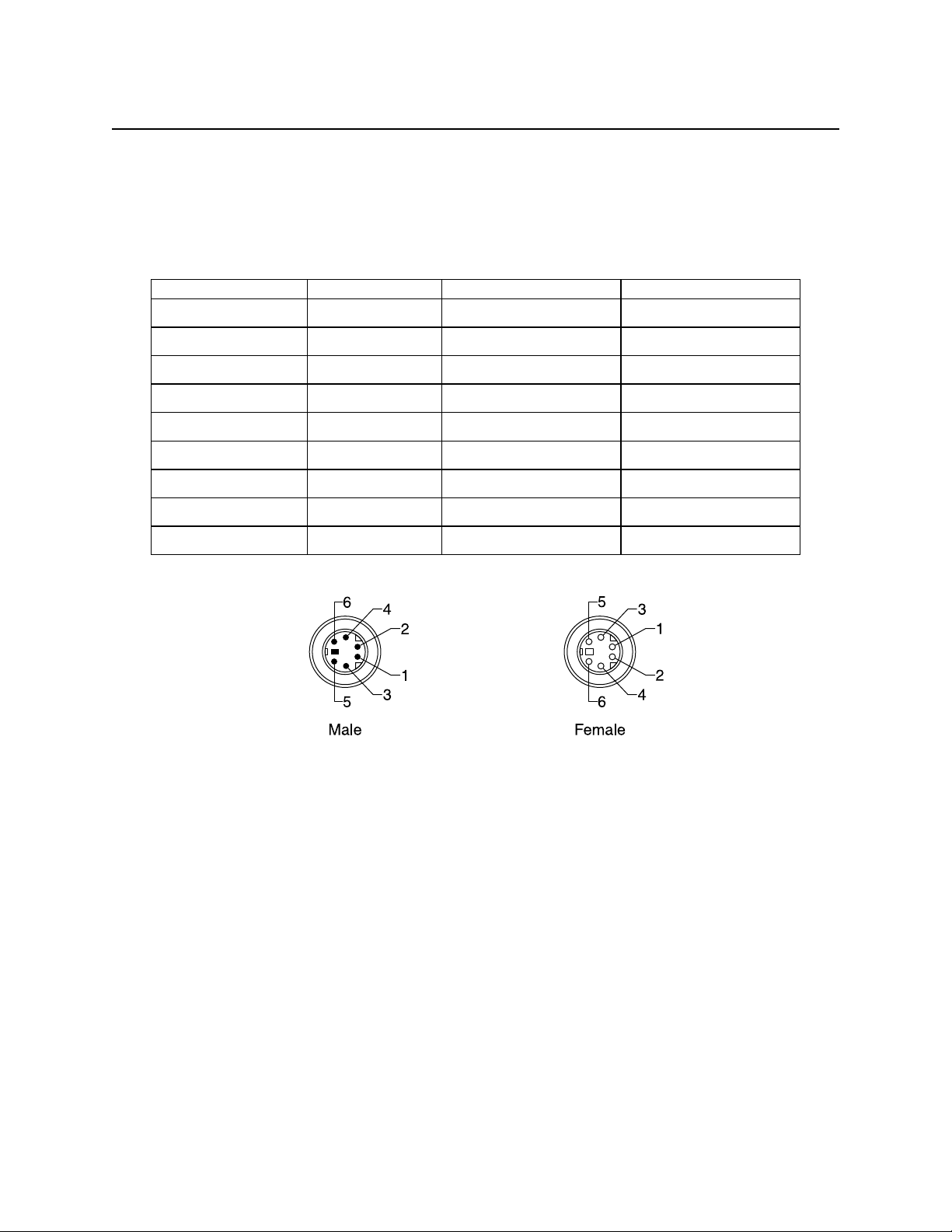

igure E-1. Large DIN 5-Pin Connectors...................................................................................................53

F

Figure E-2. Mini

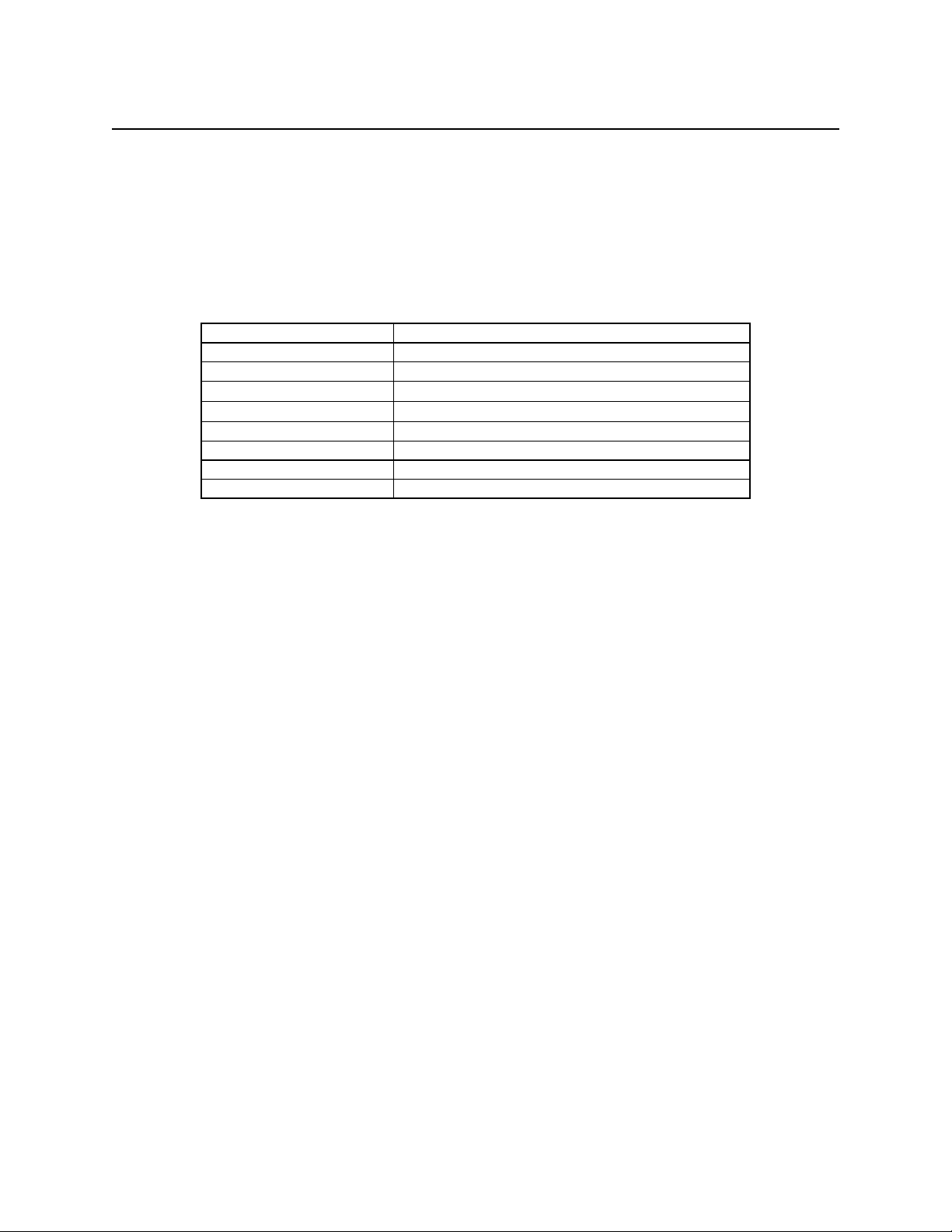

Table 1-1. Specifications..............................................................................................................................2

Table 3-1. LED indicators.............................................................................................................................6

Table 4-1. SWA Command ........................................................................................................................10

Table 4-2. Error and Status Codes ............................................................................................................11

Table 4-3. SWB Command ........................................................................................................................12

Table 4-4. Control Characters....................................................................................................................13

Table 4-5. SWC Command........................................................................................................................16

Table 4-6. HW Command ..........................................................................................................................17

Table B-1. CMC-7 Nonnumeric Characters...............................................................................................40

Table D-1. PINPad RJ Socket.....................................................................................................................52

Table E-1. Large DIN 5-Pin Interface Cable..............................................................................................53

Table E-2. Mini DIN 6-Pin Interface Cable.................................................................................................54

DIN 6-Pin Connectors......................................................................................................54

TABLES

vii

Page 8

viii

Figure 1-1. MINI MICR WEDGE with 3-Track MSR

Page 9

SECTION 1. OVERVIEW

The MINI MICR WEDGE With Optional 3-Track MSR is both a MICR (Magnetic Ink

Character Recognition) Check Reader and an MSR (Magnetic Stripe Reader).

The MICR Reader, in a typical application, reads the magnetic data encoded on the bottom of

checks or magnetic stripe cards and transmits this data to a Host device. The Host device then

uses a specific authorization or verification process to validate a business transaction.

The use of the MICR Reader improves accuracy and speed because there is no manual data

entry; therefore there are no keying errors or unwanted delays.

The MICR Reader will connect between the PC and the keyboard using the split wedge interface

cable. The original connection between the PC and the keyboard is maintained. The MICR

Reader will transmit all data as scan codes and the PC will receive it as if it was entered using

the keyboard.

FEATURES

• Available with MICR Reader only or with 3-Track or 2-Track MSR.

• Three track MSR autodiscriminates different card formats: ISO (International Standards

Organization), CDL (California Drivers License), or AAMVA (American Association of

Motor Vehicle Administrators).

• Small footprint.

• Automatic parsing of MICR fields: transit, account, etc.

• Ability to create custom formats to transmit MICR data, plus an extensive list of built-in

formats.

• Optional error/status reporting for check reading.

• Reads E13-B and CMC-7 MICR fonts.

• EMF noise detection

• In addition to the Wedge interface, the MICR Reader is also available with other interfaces.

ACCESSORIES

Accessories available for the MICR Reader are as follows:

• MagTek Device Drivers for Windows, Part Number 30037385

• MagTek Device Drivers for Windows, Programming Reference Manual, Part Number

99875125

1

Page 10

MINI MICR WEDGE with 3-Track MSR

• MICRbase Program, P/N 22000021

• MICRbase, Setup Program for MICR Readers, Programming Reference Manual, P/N

99875102

• Interface Cable, Mini DIN 6 pin, Part Number 22517501

• Interface Cable, Large DIN 5 pin, Part Number 22517503

• AC Power Adapter with Cable, 120VAC to 12 VAC, 1 Amp, Part Number 64300050

• MICR Reader Cleaning Card, Part Number 96700006

• Sample Checks, Part Number 96530005

• Encrypting PINPad and Cable, Part Number 30015061 (See Appendix D)

• Encrypting PINPad Specification, Part Number 99815042

• Nonencrypting PINPad and Cable, Part Number 30015026 (See Appendix D)

• Nonencrypting PINPad Technical Description, Part Number 99833004

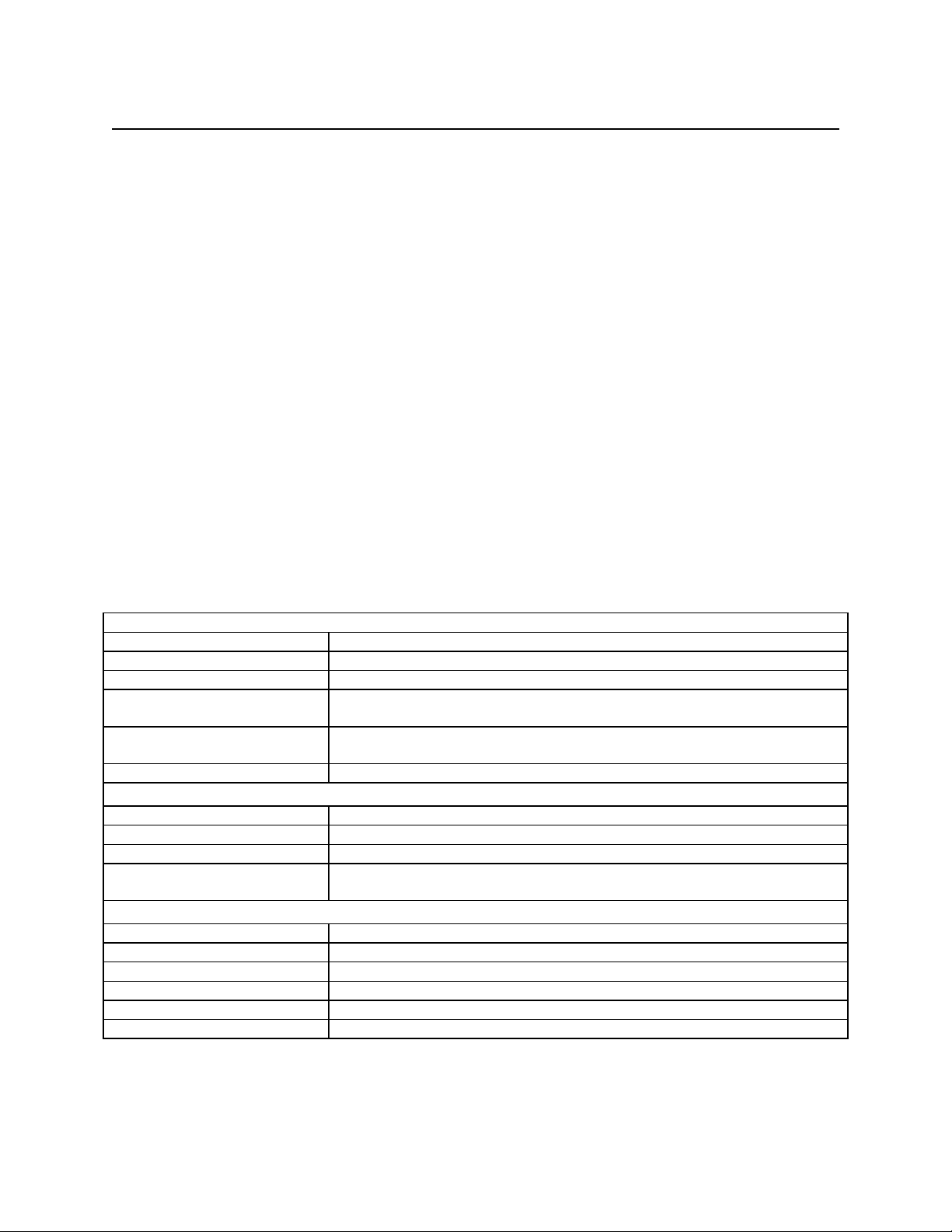

SPECIFICATIONS

Table 1-1 lists the specifications for the MICR Reader.

Table 1-1. Specifications

OPERATING

Reference Standards ISO/CDL/AAMVA

Power Input 120 VAC, 50/60 Hz

Output Signal Levels 12 VAC, 1 Amp

Check Read/Decode/Transit

Time

MICR fonts supported E13-B

MSR supported Tracks 1, 2, and 3; or Tracks 1 and 2

Dimensions Length 6.0”, Width 4.0”, Height 4.25”

Weight: 3.0 lbs. MSR and Adapter included

Cable length 6’

Interface Connectors Large DIN 5-pin

Temperature

Operating 0oC to 50oC (32oF to 122oF)

Storage -30oC to 70oC (-22oF to 158oF)

Humidity

Operating 10% to 90% noncondensing

Storage Up to 100% noncondensing

1 second

CMC-7

MECHANICAL

Mini DIN 6-pin

ENVIRONMENTAL

2

Page 11

SECTION 2. INSTALLATION

The installation for the MICR Reader is as follows:

REQUIREMENTS

The following is required for the Installation:

• MINI MICR WEDGE With Optional 3-Track or 2-Track MSR

• Interface Cable, Mini DIN 6 pin, Part Number 22517501 or

Interface Cable, Large DIN 5 pin, Part Number 22517503

• AC Power Adapter with Cable, 120VAC to 12 VAC, 1 Amp, Part Number 64300050

PROCEDURE

To install the MICR Reader, refer to Figure 2-1 and perform the following steps:

Figure 2-1. MICR Interface Cabling

1. Power off the PC.

2. Disconnect the keyboard from the PC.

3. On the interface cable, connect the 9-pin male DIN connector to the MICR Reader.

3

Page 12

MINI MICR WEDGE with 3-Track MSR

4. On the interface cable, connect female DIN connector to the keyboard cable. Pin lists

and connector illustrations are shown in Appendix E.

5. On the interface cable, connect the male DIN connector to the PC.

6. On the AC power adapter, connect the jack to the plug on the MICR Reader.

7. On the AC power adapter, connect the plug to the wall outlet.

8. Power the PC on. The LED indicator on the MICR Reader should turn on to a steady

green. The LED indicator is located below the slot where the check is first inserted for

reading.

Caution

Do not place the MICR Reader within 6 inches of a computer

monitor or power supply. These devices may cause undesirable

interference with the check reading operation.

4

Page 13

SECTION 3. OPERATION

This section contains check and card reading procedures and LED indicator states.

CHECK READING PROCEDURE

1. Orient the check so the MICR line is down and the printed side faces the center on the

MICR Reader as shown in Figure 3-1.

Figure 3-1. Check Orientation

2. Drop the check so the leading edge is in the open slot.

3. When the MICR Reader detects the presence of the check, the motor will turn on. At this

time gently urge the check forward until the unit grabs the check. When this happens,

release the check. The check will then be transported around the check path and will exit

through the other side.

4. After the check is read, the MICR Reader will transmit the data as specified by the

parameters described in Section 4, Commands.

CARD SWIPE PROCEDURE

The card may be swiped through the MSR in either direction, but the magnetic stripe must be

oriented in only one direction as shown in Figure 1-1. The MICR Reader will transmit raw card

data (“as is” on the card) for all tracks that have been enabled using the HW (Hardware)

command (Section 4, Commands).

The MSR is capable of reading ISO, AAMVA, and CDL encoded cards. The MSR will

autodiscriminate all the card formats when the ID Card Decoding option is enabled using the

HW (Hardware) command (Section 4, Commands).

5

Page 14

MINI MICR WEDGE with 3-Track MSR

LED INDICATOR

Table 3-1 describes the LED indicator conditions for check and card reading operations. The

LED indicator is located below the slot where the check is first inserted for reading.

Table 3-1. LED indicators

LED INDICATOR DESCRIPTION

OFF Power off

SOLID GREEN Ready to read check or card

OFF→ SOLID RED

OFF→ SOLID GREEN

FLASH GREEN Needs initialization*

FLASH RED/GREEN Data sensor blocked (motor does not run)*

FLASH RED Motor sensor blocked (motor does not run)*

FLASH GREEN FAST Monitor mode (factory use only)*

*Refer to “Appendix C. Troubleshooting Guide.”

Check or card read error

Good read

6

Page 15

SECTION 4. COMMANDS

This section describes the use of commands and programmable options available for the MICR Reader.

Note

All options described below can be factory set as specified by the user when

ordering.

The following methods are available to execute MICR commands:

• Insta-change checks

• MICRbase setup program for Windows

• MagTek Device Drivers for Windows

• User application without drivers

INSTA-CHANGE CHECKS

The Insta-Change check is a MICR encoded document that contains commands and options used to

reset the parameters of the MICR Reader. Multiple commands and options may be contained on one

Insta-Change check. When used, the Insta-Change checks are run through the MICR Reader the

same as a standard check, and the options to be used are automatically selected. To obtain InstaChange checks, notify a MagTek representative and specify what options will be used. To operate

Insta-Change checks, install the MICR Reader as described in Section 2, and watch the LED

indicator. When the Insta-Change check is run through the MICR Reader and read successfully, the

LED indicator will blink green. If the LED indicator turns red, the read is not successful. Try again

or use a different Insta-Change check.

MICRBASE SETUP PROGRAM FOR WINDOWS

The MICRbase setup program (P/N 22000021) allows the user to control all the programmable

options available in the MICR Reader.

The program provides a graphical, user-friendly interface that hides the complexities involved in

manually entering MICR commands. The user is no longer required to know the specific commands

or the detailed data associated with each command. However, the program still allows manual entry

of commands for advanced users. For more detailed information refer to the MICRbase Setup

Program Reference Manual (P/N 99875102).

The MICRbase setup program may also be downloaded from the internet at www.magtek.com under

Software/Demo Programs.

7

Page 16

MINI MICR WEDGE with 3-Track MSR

MAGTEK DEVICE DRIVERS FOR WINDOWS

For Windows applications, the MagTek Device Drivers for Windows (P/N 30037385) are available

to simplify the programming of the MICR Reader. The drivers are easy to install, and they facilitate

the execution of MICR Reader commands. For more detailed information, refer to the MagTek

Device Driver for Windows, Programming Reference Manual (P/N 99875125).

The drivers may also be downloaded from the Internet at www.magtek.com

Software/Device

Drivers.

USER APPLICATIONS WITHOUT MAGTEK DEVICE DRIVERS

For applications that communicate directly with the MICR Reader, the following programming

procedures must be considered:

PC Commands To Enable and Disable Keyboard Wedge

Because the system is connected from the PC to the MICR Reader to the PC keyboard, the user must

cut the communication between the MICR Reader and the keyboard. This is accomplished by

sending a Disable Keyboard (DK) command. This command permits the PC to send commands to

the MICR Reader. After the commands have been sent to the MICR Reader, the PC must send an

Enable Keyboard (EK) command to reestablish communication between the PC and the keyboard.

PC Timing

The timing between each character sent to the MICR Reader must be in the range of 5 milliseconds

to 150 milliseconds.

The timing between the last key pressed (from the keyboard) and the first character of the MICR

Reader command should be 500 milliseconds.

Keyboard Wedge Port IO Addresses

For the PC program, the keyboard port IO address is 60 HEX for AT and PS/2 model 50. The

address for all other PS/2 models is 68 HEX.

8

Page 17

Section 4. Commands

COMMAND FORMAT

When the commands are entered manually, they must use the following format:

[COMMAND][DATA] <ENTER>

• [COMMAND] is 2 or 3 alpha characters.

• [Data] is optional as described below for each command.

• <ENTER> is always required.

• All characters are ASCII

• No spaces, brackets, or angle brackets required.

DK – DISABLE KEYBOARD

When a PC program is used, the keyboard must be disabled to allow programming of the MICR

Reader. Commands used for programming the MICR Reader are described below. The command

to disable the keyboard is:

DK <ENTER>

The MICR Reader will execute the command and will reply with lower case 'k'.

EK – ENABLE KEYBOARD

After all commands have been sent to the MICR Reader, communication between the PC and the

keyboard must be established. The command to enable the keyboard is:

EK <ENTER>

The MICR Reader will execute the command and will reply with lower case 'k'.

SWA - SWITCH A COMMAND

The SWA command controls the communication parameters, shown in Table 4-1. The data for

this command consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the SWA command as follows:

SWA 01010101<ENTER> (with data)

or

SWA <ENTER> (without data)

9

Page 18

MINI MICR WEDGE with 3-Track MSR

When sending data, all 8 bits must be provided. The MICR Reader will execute the command but

it will not reply. The SWA options are saved immediately.

If no data is sent, the MICR Reader responds with the current settings for SWA.

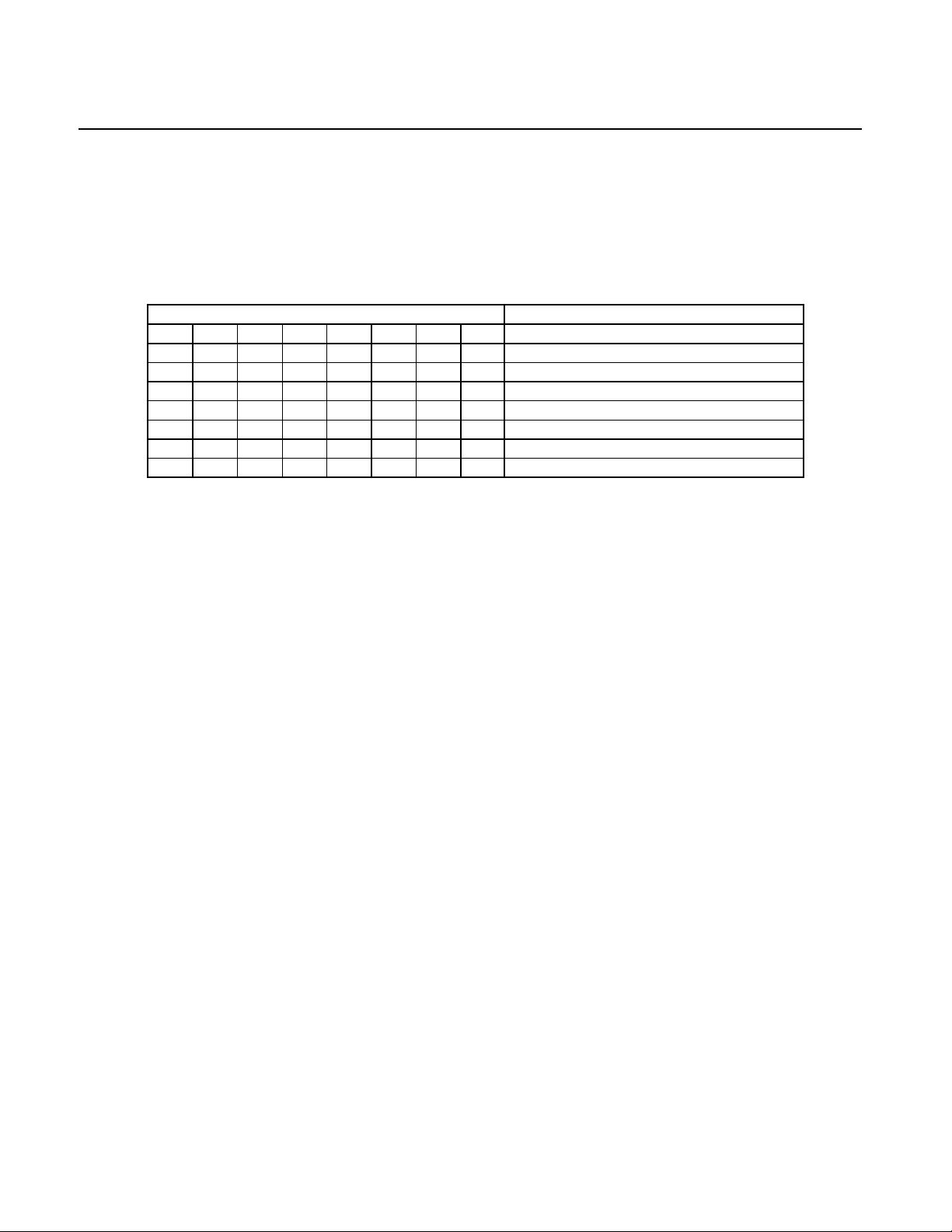

Table 4-1. SWA Command

BITS PARAMETERS

7 6 5 4 3 2 1 0

1 1 0 Wedge AT

0 1 0 Wedge NCR

0 0 Send data after error: Yes

0 1 Send data after error: No

0 Keypad: calculator (Wedge NCR only)

1 Keypad: telephone (Wedge NCR only)

0 0 These bits are always set to 0

SWA PARAMETERS

The SWA functions are listed in Table 4-1 and described below.

Wedge Type

The Wedge type can be for the IBM AT or NCR 7052/7053 cash registers.

Send Data After Error

The request Send Data After Error specifies whether the MICR Reader will return data to the Host

after a read error. If YES is selected and the MICR Reader detects a read error, the MICR Reader

will still send the data back to the Host. If NO is selected and the MICR Reader finds an error, it

will discard the data and nothing will be sent. The error conditions are listed in Table 4-2.

10

Page 19

Section 4. Commands

Table 4-2. Error and Status Codes

PRIORITY CODE TYPE DESCRIPTION

9 01 Error No MICR data: no transit and no account found

8 09 Status Mexican check

7 08 Status Canadian check

6 05 Error Transit error: No transit, bad character, bad length,

bad check digit

5 07 Error Account error: No account, bad character

4 04 Error Check # error: Bad character in check number

4 04 Status No check number

3 03 Status Low MICR signal, good read

2 10 Status Business check

1 11 Status Amount field present

0 00 Status No error, check OK

Notes:

• The LED will turn red on all error conditions.

• The absence of a check number is not considered an error.

• If a multiple error condition occurs, the error or status code with the highest priority is

reported.

• All unreadable MICR characters are transmitted as a “?” ASCII character (hex 3F), except for

Format 00xx (See Appendix A).

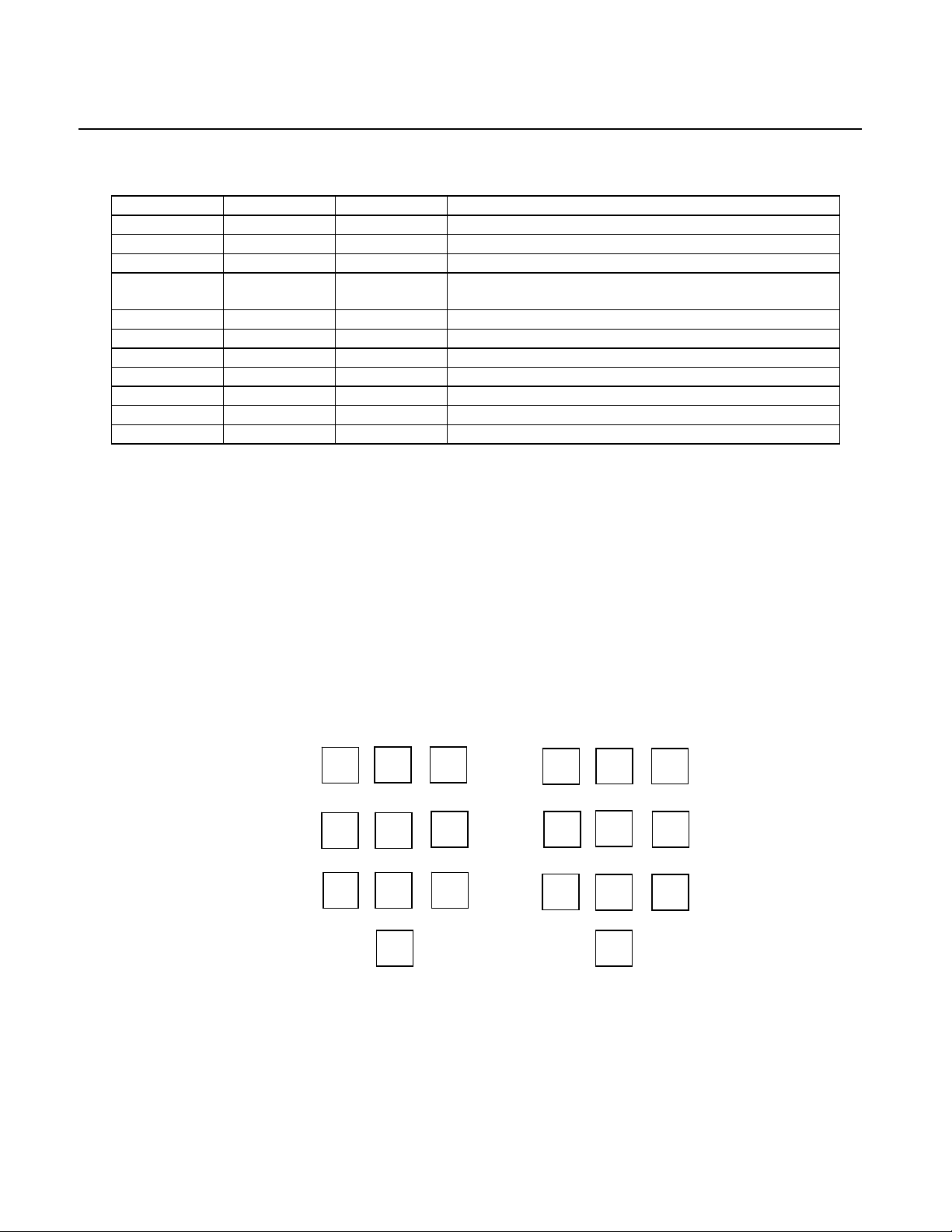

Keypad Type

The Keypad selection is for the Wedge NCR only. The selection is the calculator type of layout or

telephone layout. Both are shown in Figure 4-1.

1

4

7 8 9

2 3

5

0

8

6

4

1

5

2

0

9

6

3

Telephone Calculator

Figure 4-1. Keypad Types

11

Page 20

MINI MICR WEDGE with 3-Track MSR

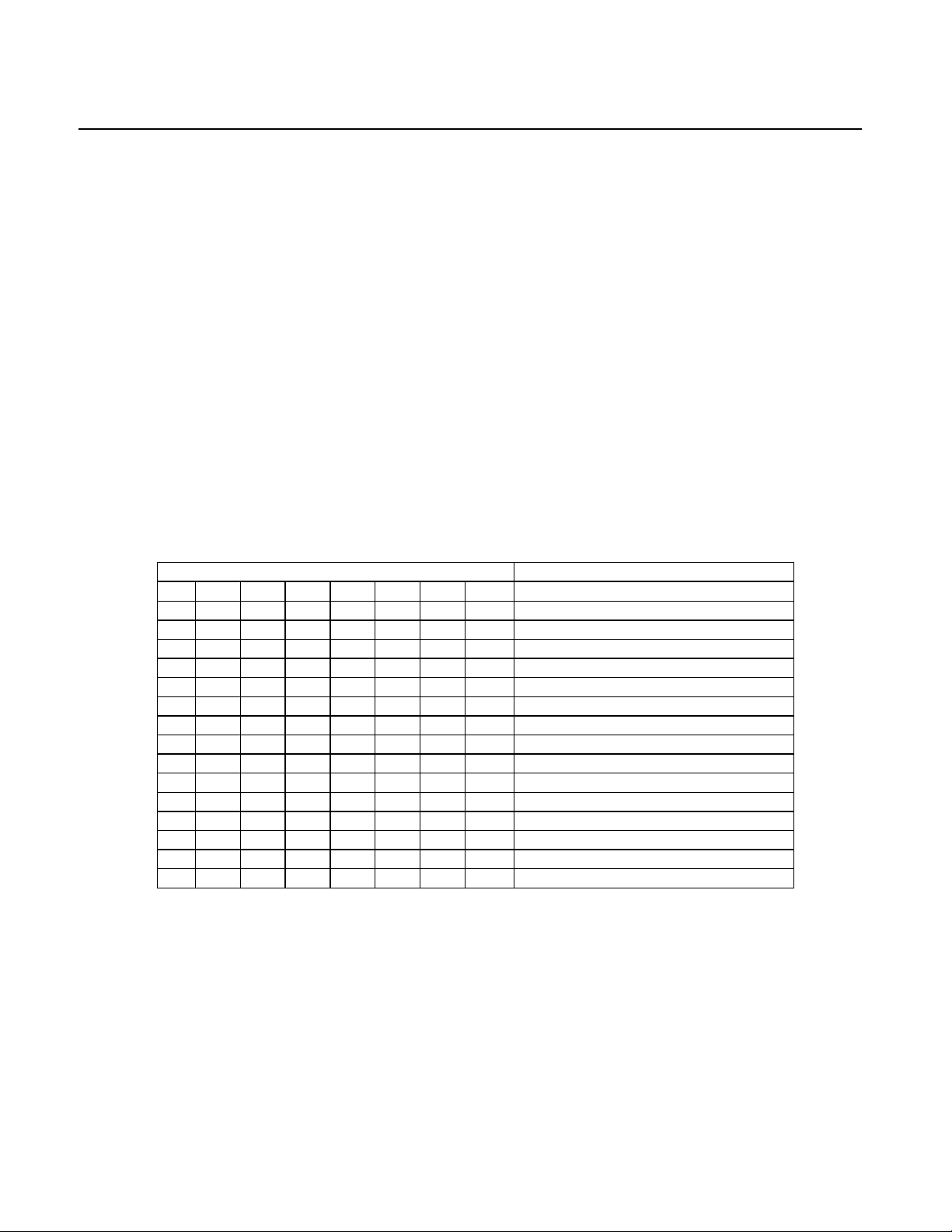

SWB - SWITCH B COMMAND

The SWB command controls the message format, shown in Table 4-3. The data for this command

consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the SWB command as follows:

SWB 01010101<ENTER> (with data)

or

SWB <ENTER> (without data)

When sending data, all 8 bits must be provided. The MICR Reader will execute the command but

it will not reply. The new settings become effective immediately. To make this command

permanent, use the SA (Save) command described at the end of this section.

If no data is sent, the MICR Reader responds with the current settings for SWB.

Table 4-3. SWB Command

BIT PARAMETERS

7 6 5 4 3 2 1 0

0 Trailing <ESC>: No

1 Trailing <ESC>: Yes

0 0 0 <ENTER> key: No - Do Not Send

0 0 1 <ENTER> key: Yes - Default single

1 0 1 <ENTER> key: Yes - Default double

0 1 1 <ENTER> key: Yes - Custom single

1 1 1 <ENTER> key: Yes - Custom double

0 <ETX>: No

1 <ETX>: Yes

0 Leading <ESC>: No

1 Leading <ESC>: Yes

0 <STX>: No

1 <STX>: Yes

0 Sent Status: No

1 Sent Status: Yes

SWB PARAMETERS

The SWB functions are listed in Table 4-3 and described below.

12

Page 21

Section 4. Commands

Control Characters and MICR Data

Control Characters may be added to the MICR data message. The characters are always in the

following locations:

<STX> <ESC> [data] <ETX> <ENTER> <ESC>

The control characters, descriptions, and hex values are shown in Table 4-4.

Table 4-4. Control Characters

CONTROL

CHARACTER

<STX> Start of Text

<ESC> Escape (Leading)

<ETX> End of Text

<ENTER> Enter

<ESC> Escape (Trailing)

DESCRIPTION

For example, if <STX> and <ENTER> are set to YES, the message from the MICR Reader will

look like this:

MICR Data: <STX>[data]<ENTER>

Control Characters and Card Data

The control characters are also available for card data but their position on the message is

controlled by the Card Data Message parameter (see SWC Command, below). For example, if the

<STX> and <ETX> options are set to YES, the message may be transmitted as follows:

If Multiple Message: <STX>[TK1]<ETX><STX>[TK2]<ETX><STX>[TK3]<ETX>

If Single Message: <STX>[TK1][TK2][TK3]<ETX>

<ENTER> Key Options

The <ENTER> key options may be required for cash registers but not for PCs. They provide

flexibility for cash register applications where the <ENTER> key may be relocated from its

original position to a new position on the keyboard. The original position is called the default

position and the new position is called is called the custom position. The MICR Reader must know

whether a default or custom position is being used to properly emulate the pressing of the

<ENTER> key after reading a check or a card.

13

Page 22

MINI MICR WEDGE with 3-Track MSR

In addition to relocating the <ENTER> key, the user may require a two-position <ENTER> key.

On the keyboard, this is accomplished by placing a plastic cap over two adjacent keys. Hence,

when the key is pressed, two signals are sent to the PC or cash register. The one-key option is

referred to as single, and the two-key option is referred to as double.

The concepts of default, custom, single, and double are illustrated in Figure 4-2.

Every key-position on a keyboard is associated with a fixed number. This number is called scan

code. When a key is pressed, the keyboard transmits the corresponding scan code. Similarly, the

MICR Reader transmits data using scan codes, effectively emulating keys being pressed on the

keyboard.

When a custom option is required, the scan code information must be determined by the customer

or with the help of MagTek. The scan code must then be programmed into the MICR Reader, and

this can be accomplished at the factory or with Insta-Change checks provided by MagTek.

Note

The default scan codes are 5A (hex) for PC/AT and 1C (hex) for

PS/2.

Move <Enter> Key to Location 16

New

(Custom)

Position

Single

Key

16

5A

Original

(Default)

Position

Double

Key

Figure 4-2. <Enter> Key Positions

14

Page 23

Section 4. Commands

Combinations of these options as shown in Table 4-3 are as follows:

Do not Send – The MICR Reader will not send the <ENTER> key to the PC.

Default Single – The MICR Reader will use the default scan code for a one-key

<ENTER>. Use this option for all PC applications.

Default Double – The MICR Reader will used two default scan codes for a two-key

<ENTER>.

Custom Single – The keyboard has a one-key <ENTER>, but it has been moved from its

default position. The scan code must be programmed into the MICR Reader.

Custom Double – The keyboard has a two-key <ENTER>, but it has been moved from its

default position. The scan codes must be programmed into the MICR Reader

Send Status After Data

The Send Status After Data option makes the MICR Reader append a two-digit error/status code

to the end of the MICR data. For most formats (See Appendix A) the error/status code will

always be preceded by a forward slash (/). The error/status codes are listed in Table 4-2.

For example, if a Canadian check (code 08) is read and had no errors, and the MICR data is

“1234567890”, then the message from the MICR Reader will look like this:

MICR Data: 1234567890/08

The status code is always at the end of the data, not the end of the message. For example, using

the above conditions, with the message format set to send <STX> and <ETX>, the message from

the MICR Reader will look like this:

MICR Data: <STX>1234567890/08<ETX>

SWC - SWITCH C COMMAND

The SWC command controls miscellaneous functions, shown in Table 4-5. The data for this

command consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the SWC command as follows:

SWC 01010101<ENTER> (with data)

or

SWC <ENTER> (without data)

15

Page 24

MINI MICR WEDGE with 3-Track MSR

When sending data, all 8 bits must be provided. The MICR Reader will execute the command but

will not reply. The new settings become effective immediately. To make this command

permanent, use the SA (Save) command described at the end of this section.

If no data is sent, the MICR Reader responds with the current settings for SWC.

Table 4-5. SWC Command

BITS PARAMETERS

7 6 5 4 3 2 1 0

0 CMC-7 Character Set: No

1 CMC-7 Character Set: Yes

0 Card Data Message: Single

1 Card Data Message: Multiple

0 0 0 0 0 0 These bits are always set to 0

SWC PARAMETERS

The SWC functions are listed in Table 4-5 and described below.

CMC-7 Character Set

If NO is selected the MICR Reader will only read E13-B characters. When YES is selected, the

MICR Reader will read both CMC-7 and E13-B characters (see Appendix B). However, the

MICR Reader will only output raw data ("as is" on the check) for checks with CMC-7 characters.

Card Data Message

This option determines the structure of the output message for the individual tracks when a credit

card is read. If Multiple is selected, the Control Characters (see SWB, below) and Data Header

(see Data Header, above) are added to each track individually. On the other hand, if Single is

selected, all available tracks are lumped together into a single message. For example, if <STX>,

and <ETX> are set to YES, the output message may be transmitted as follows:

If Multiple Message:

<STX>[TK1]<ETX><STX>[TK2]<ETX><STX>TK3]<ETX>

If Single Message:

<STX>[TK1][TK2][TK3]<ETX>

16

Page 25

Section 4. Commands

HW - HARDWARE COMMAND

This command controls miscellaneous hardware options, shown in Table 4-6. The data for this

command consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the HW command as follows:

HW 01010101<ENTER> (with data)

or

HW <ENTER> (without data)

When sending data, all 8 bits must be provided. The MICR Reader will execute the command but

it will not reply. The new settings become effective immediately. To make this command

permanent, use the SA (Save) command described at the end of this section.

If no data is sent, the MICR Reader responds with the current settings for HW.

Table 4-6. HW Command

7 6 5 4 3 2 1 0 PARAMETERS

0 Track 3: Disable

1 Track 3: Enable

0 Track 2: Disable

1 Track 2: Enable

0 Track 1: Disable

1 Track 1: Enable

0 ID Card decoding: Disable

1 ID Card decoding: Enable

0 EMF detect: Yes

1 EMF detect: No

0 0 0 These bits are always set to 0

HW PARAMETERS

Disable/Enable Tracks

Each Track can be enabled or disabled individually. The tracks are always transmitted in

ascending order: TK1, TK2, TK3. For example, if TK1 and TK3 are enabled and TK2 is disabled,

the MICR Reader will transmit TK1, TK3.

17

Page 26

MINI MICR WEDGE with 3-Track MSR

ID Card Decoding

The MSR has two modes of operation. In the first mode, ID Card decoding disabled, the MSR will

only read ISO encoded cards. In the second mode, ID Card decoding enabled, the MSR will read

and autodiscriminate ISO, AAMVA, and CDL encoded cards. When a card is swiped, the LED

indicator will turn red and indicate an error if any of the enabled tracks read is incompatible with

the selected mode of operation. TK2 is a standard track for all types of cards.

EMF Detect

The EMF Detect option allows the MICR Reader, when idle, to monitor EMF interference in its

immediate environment. If YES is selected, the LED indicator will blink red/green when the

MICR Reader detects a signal with amplitude large enough to affect check reading. If NO is

selected, the MICR Reader will not monitor nor indicate the presence of EMF interference.

FC - FORMAT CHANGE COMMAND

Formats are used by the MICR Reader to process and transmit the MICR fields. The format

command allows the selection of a format from the Format List, Appendix A. The data for this

command consists of 4 digits (ASCII characters 0-9). To execute, send the command as follows:

FC 6600<ENTER> (with data)

or

FC <ENTER> (without data)

When sending data, all 4 digits must be provided. The MICR Reader will execute the command

but it will not reply. The new settings become effective immediately. To make this command

permanent, use the SA command described at the end of this section.

If no data is provided, the MICR Reader will respond with the current format number.

VR - VERSION COMMAND

The Version command gives the current software revision in the MICR Reader. To execute, send

the VR command followed by a carriage return as follows:

VR<ENTER>

The MICR Reader responds as follows:

MICR data: [software revision]<ENTER>

18

Page 27

Section 4. Commands

SA - SAVE COMMAND

All changes are considered temporary until the Save command is executed. The Save command

saves all changes to the MICR Reader memory and makes them permanent. The MICR Reader

will execute the command but it will not reply. To execute, send the SA command followed by a

carriage return as follows:

SA<ENTER>

RS - RESET COMMAND

The Reset command resets the MICR Reader firmware to the normal operating state of waiting for

a check or card to be read. To execute, send the RS command followed by a carriage return as

follows:

RS<ENTER>

19

Page 28

MINI MICR WEDGE with 3-Track MSR

20

Page 29

APPENDIX A. FORMAT LIST

For check reading, the MICR Reader provides the flexibility to format the MICR fields and build a

specific output string that will be transmitted to the Host. These output strings are referred to as formats.

The Reader has a built-in list of formats (described below) from which the user may select one to

become the active format every time a check is read. The formats may be selected using the FC

command (Section 4, Commands) or Insta-Change checks provided by MagTek.

If none of the built-in formats meets the necessary requirements, a custom format can be created using

the Flexible Format feature. These custom formats can be easily created and downloaded using the

MICRbase Setup Program for Windows provided by MagTek (P/N 22000021). For more detailed

information refer to Section 7 in the MICRbase Reference Manual (P/N 99875102).

Each of the built-in formats is assigned a 4-digit number. The first two digits indicate the format

number, and the last two digits are specific parameters used for various functions by each format. For

example, in format “0415”, the “04” refers to format number 4 and the 15 refers the maximum number

of characters allowed for the account field.

A complete description for each format follows.

Note

The formats listed in this section apply only to U.S. and Canadian checks.

The MICR line on checks from other countries will not be broken or

parsed as described in these formats.

Fmt 00xx: Raw Data Format - sends the entire MICR line - where:

xx - specify what symbol set to use. Choose from the table

Add xx + 16 - change multiple spaces to one space

Add xx + 32 - Remove all spaces

Examples:

MICR LINE: T122000218T 1234 5678 9U 1321

FC0001 - t122000218t 1234 5678 9o 1321

(+16) FC0017 - t122000218t 1234 5678 9o 1321

(+32) FC0033 - t122000218t123456789o1321.

xx Transit On-Us Amount Dash Error

00 T U $ - ?

01 t o a d ?

02 T O A D ?

03 T U $ - *

04 T U $ 0 ?

05 T U $ 0 *

06 t o a 0 ?

07 T U $ none ?

21

Page 30

MINI MICR WEDGE with 3-Track MSR

Fmt 01xx:

FC0100 - Parsed text with dashes

FC0101 - Parsed text, replace dashes with “d”

Field Labels - TR-transit, AC-account #, CK-check #, AM-amount, TP-tpc,

EP-epc

Example: - PTTR444455556;AC 999-222-3;CK11045

Fmt 02xx:

FC0200 - Parsed text with dashes

FC0201 - Parsed text, replace dashes with “d”

Error Labels - PE-parsed error, NE-no error, TR-transit error,

CK-chk # error, TC-transit check digit error,

Examples: - PTTR444455556;AC999-222-3;CK11045/PENE

Fmt 03xx:

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- keep spaces and dashes

Fmt 04xx:

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 05xx:

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- replace spaces and dashes with zeros

Fmt 06xx:

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- replace spaces and dashes with zeros

Fmt 07xx:

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- remove spaces and dashes

Fmt 08xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Parsed Text Format

Parsed Text Format with Error Labels

AM-amount error, OU-on us/account# error,

TP-tpc error

- PTTR111?11111;AC123456/PETR (“?” = unreadable character)

[acct #]

[acct #]

[acct #]

[acct #]

[acct #]

[transit] [acct #]

22

Page 31

Appendix A. Format List

Fmt 09xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

Fmt 10xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- replace spaces and dashes with zeros

Fmt 11xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

Fmt 12xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

Fmt 13xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

[transit] [acct #]

- replace spaces and dashes with zeros

[transit] [acct #]

[transit] 'T' [acct #] 'A' [check #]

[transit] 'T' [acct #] 'A' [check #]

[transit] 'T' [acct #] 'A' [check #] '000'

23

Page 32

MINI MICR WEDGE with 3-Track MSR

Fmt 14xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

Fmt 15xx:

• [bank #]: - all characters in the field

- keep spaces and dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 16xx:

• [bank #]: - all characters in the field

- keep spaces and dashes

• [chk dgt]: - all characters (one character long)

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 17xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- keep spaces and dashes

Fmt 18xx:

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- keep spaces and dashes

• [check #]: - all characters in the field

Fmt 19xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- replace spaces and dashes with zeros

• [check #]: - all characters in the field

[transit] [acct #] [check #]

[bank #] [acct #]

[bank #] [chk dgt] [acct #]

[transit] [acct #]

[acct #] "/" [check #]

[transit] [acct #] [check #]

24

Page 33

Appendix A. Format List

Fmt 20xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- replace spaces and dashes with zeros

• [check #]: - all characters in the field

Fmt 21xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- replace spaces and dashes with zeros

• [check #]: - all characters in the field

Fmt 22xx:

• [bank #]: - all characters in the field

- keep dashes

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- replace spaces and dashes with zeros

• [check #]: - all characters in the field

Fmt 23xx:

• [error #]: - one digit, always present

- '0' read OK

- '1' read error: bad char empty field, invalid length, validation

• [transit]: - always 9 characters, zero filled

- keep dashes

• [acct #]: - always xx characters, trailing spaces;

when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

- remove spaces and dashes

[transit] [acct #] <CR> [check #]

[transit] [acct #] [check #]

[bank #] [acct #] [check #]

[error #] [transit] [acct #] [check #] 'S'

25

Page 34

MINI MICR WEDGE with 3-Track MSR

Fmt 24xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

• [amount]: - all characters in the field

Fmt 25xx:

• [transit]: - all characters in the field

- remove dashes and keep spaces (contig spcs = 1 spc)

- if the field is empty, remove 'C'

• [acct #]: - include leading characters

- maximum of xx characters; when xx=00 all characters are sent

- remove dashes and keep all spaces

- if the field is empty, remove 'D'

• [check #]: - all characters in the field

- if the field is empty, remove 'E'

Fmt 26xx:

• [acct #]: - work with characters in acct and transit fields

- a window of xx characters; xx must be greater than 00

- remove spaces and dashes

Fmt 27xx:

• [acct #]: - work with characters in the acct field only

- a window of xx characters; xx must be greater than 00

- remove spaces and dashes

Fmt 28xx:

• [acct #]: - work with characters in the acct field only

- a window of xx characters; xx must be greater than 00

- minimum of 6 digits, fill with zeros if necessary

- remove spaces and dashes

[transit] 'T' [acct #] 'A' [check #] 'C' [amount] '$'

'M' 'C' [transit] 'D' [acct #] 'E' [check #]

[acct #]

[acct #]

[acct #]

26

Page 35

Appendix A. Format List

Fmt 29xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - maximum of 6 digits

• [status]: - this is a programmable option that must be enabled (See Table 4-4).

Fmt 30xx:

• [zero fill]: - if length of (transit+account) is less than xx;

xx must be greater than 00

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - all characters in the field

- remove spaces and dashes

Fmt 31xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - maximum of 10 digits

- remove spaces and dashes

- if no check number, remove preceding slash ('/')

Fmt 3200:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - all characters in the field

- remove spaces and dashes

• [check #]: - all characters in the field

- remove spaces and dashes

• [status] : - this is a programmable option that must be enabled (See Table 4-4).

'C' '/' [transit] '/' [acct #] '/' [check #] '/' [status]

[zero fill] [transit] [acct #]

[transit] '/' [acct #] '/' [check #]

'^' [transit] '^' [acct #] '^' [check #] '^' [status]

27

Page 36

MINI MICR WEDGE with 3-Track MSR

Fmt 3300:

• [transit]: - all characters in the field

- remove dashes

• [acct #] : - maximum of 14 digits

- remove spaces and dashes

• [check #]: - maximum of 8 digits

- remove spaces and dashes

• [status]: - this is a programmable option that must be enabled (See Table 4-4.)

Fmt 34xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - all characters in the field

- remove spaces and dashes

• [zero fill]: - zero filled up to xx; xx must be greater than 00

Fmt 3500:

This format is defined specifically for Target Test Checks. A description

of the Target Test Check must be loaded in the exception table.

• [aux], [epc], [tran], [chk], [tpc], [amt]:

- all characters in the field

- keep spaces and dashes

• [acct]: - all characters in the field

- keep spaces and remove dashes

Fmt 36xx:

Read error: '0' '/'

• [transit]: - all characters in the field

- remove spaces and dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

- remove spaces and dashes

'=' [transit] '=' [acct #] '=' [check #] '=' [status]

[transit] [acct #] [zero fill]

MA [aux] B [epc] C [tran] D [acct] E [chk] F [tpc] G [amt]

Read OK : [transit] [acct #] [check #] '/'

28

Page 37

Appendix A. Format List

Fmt 37xx:

• [ABA], [chk dgt]:

- all characters in the field

- keep spaces and dashes

• [acct #]: - work with characters in the acct field only

- window of xx characters; xx must be greater than 00

- remove spaces and dashes

Fmt 38xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- include leading characters

- keep spaces and dashes

• [check #]: -all characters in the field

Fmt 39xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and keep dashes

Fmt 40xx:

• [country code]: - '1' for US checks

- '2' for Canadian checks

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 4100:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - all characters in the field

- place a slash ('/') after 10th character

- if 10 characters or less, precede with a slash ('/')

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

[ABA] [chk dgt] [acct #]

'T' [transit] 'A' [acct #] 'C' [check #]

[transit] <CR> [acct #]

[country code] [transit] [acct #]

'S' 'T' [transit] 'A' [acct #] 'C' [check #]

remove spaces and dashes

29

Page 38

MINI MICR WEDGE with 3-Track MSR

Fmt 42xx:

Can check: '9' [transit] [acct #]

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - always xx characters; zero filled;

when xx=00 all characters are sent.

- remove spaces and dashes

Fmt 43xx:

• [check #]: - maximum of 6 digits

- remove spaces and dashes

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 44xx:

• [transit]: - all characters in the field

- if Canadian check, replace dash with a space

• [acct #]: - always xx characters, trailing spaces,

when xx=00 all characters are sent

- remove spaces and dashes

Fmt 45xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces, dashes and leading zeros

• [check #]: - all characters in the field

Fmt 46xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

- remove spaces and dashes

US check : [transit] [acct #]

[check #] <CR> <CR> [transit] <CR> [acct #]

[transit] [acct #]

[transit] <CR> [acct #] <CR> [check #]

[transit] [acct #] [check #]

30

Page 39

Appendix A. Format List

Fmt 47xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

Fmt 48xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 49xx:

• [transit]: - always 9 characters, zero filled

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - maximum of 9 digits

• [check type]:- personal checks ('1'); commercial checks ('2')

Fmt 50xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

Fmt 51xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

[transit] 'T' [acct #] 'A' [check #]

[transit] 'T' [acct #] 'A'

[transit] '/' [acct #] '/' [check #] '/' [check type]

'T' [transit] 'T' 'O' [acct #] 'O' [check #]

'=' [transit] '=' [acct #] '='

31

Page 40

MINI MICR WEDGE with 3-Track MSR

Fmt 52xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

- remove dashes and spaces

Fmt 53xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

• [tpc]: - all characters in the field

• [status]: - this is a programmable option that must be enabled (See Table 4-4)

Fmt 54xx:

• [transit]: - always 12 characters, zero filled

- remove dashes

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 12 characters, zero filled

- remove dashes and spaces

• [status]: - this is a programmable option that must be enabled (See Table 4-4)

Fmt 55xx:

• [acct #]: - always xx characters, zero filled;

when xx=00 all characters are sent

- remove spaces and dashes

• [transit]: - all characters in the field

- remove dashes

• [check #]: - always 6 characters, zero filled

- remove dashes and spaces

'T' [transit] 'T' [acct #] 'A' [check #]

'/' [transit] '/' [acct #] '/' [check #] '/' [tpc] '/' [status] '/'

[transit] [acct #] [check #] [status]

'C' '/' [acct #] '/' [transit] '/' [check #] '/' 0000000000

32

Page 41

Appendix A. Format List

Fmt 56xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

- remove dashes and spaces

• [amount]: - all characters in the field

- remove dashes and spaces

Fmt 57xx:

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [amount]: - all characters in the field

- remove dashes and spaces

Fmt 58xx:

• [transit]: - 3 rightmost characters

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 59xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 9 characters, zero filled

- remove dashes and spaces

• [amount]: - all characters in the field

- remove dashes and spaces

- insert decimal point ('.') before 2nd rightmost digit

[transit] <CR> [acct #] <CR> [check #] <CR> [amount]

[acct #] <CR> [amount]

[short transit] [acct #] ':'

[transit] [acct #] <TAB> [check #] [amount]

33

Page 42

MINI MICR WEDGE with 3-Track MSR

Fmt 60xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - maximum of 10 characters

- remove spaces and dashes

- if no check #, remove preceding slash ('/')

• [check type]:- personal checks ('1'); commercial checks ('2')

Fmt 61xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces, dashes and leading zeros

• [check #]: - all characters in the field

Fmt 62xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

- remove dashes and spaces

• [status]: - this is a programmable option that must be enabled (See Table 4-4).

Fmt 63xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 4 characters, zero filled

- remove spaces and dashes

[transit] '/' [acct #] '/' [check #] '/' [check type]

[transit] <TAB> [acct #] <TAB> [check #] <TAB>

'T' [transit] 'T' [acct #] 'A' [check #] 'S' [status]

[transit] [acct #] [check #]

34

Page 43

Appendix A. Format List

Fmt 64xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - always xx characters, trailing spaces;

when xx=00 all characters are sent

- keep spaces and dashes

• [check #]: - always 6 characters (N is on quick-init check), trailing spaces

- remove spaces and dashes

• [amount]: - all characters in the field

- remove spaces and dashes

- insert decimal point ('.') before 2nd rightmost digit

Fmt 65xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

- remove dashes and spaces

• [amount]: - all characters in the field

- remove dashes and spaces

Fmt 66xx:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

Fmt 67xx:

• [check #] : - maximum of xx characters; when x=00 all characters are sent

- remove spaces and dashes

[transit] [acct #] [check #] [amount]

'!' [transit] '/' [acct #] '/' [check #] '/' [amount]

[transit] [acct #] <CR> '7' '1' <CR>

<CR> <CR> [check #]

35

Page 44

MINI MICR WEDGE with 3-Track MSR

Fmt 68xx:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - all characters in the field

- remove dashes and spaces

• [amount]: - all characters in the field

- remove dashes, spaces and leading zeros

- insert decimal point ('.') before 2nd rightmost digit

Fmt 69xx:

Read error: '0' '/'

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - always xx characters, trailing spaces;

when xx=00 all characters are sent

- remove spaces and dashes

• [check #]: - always 6 characters, zero filled

Fmt 70:

• [transit]: - all characters in the field

- keep dashes

• [acct #]: - always N characters (N is on quick-init check), space filled

- remove spaces and dashes from the account

• [check #]: - always 8 characters, zero filled

- remove dashes and spaces

• [amount]: - all characters in the field

- remove dashes and spaces

- if amount is not present, remove last ','

Fmt 71:

• [acct #]: - work with a window of N characters in the acct field

- always N characters (N is on quick-init check), zero filled

- remove spaces and dashes

• [check #]: - maximum of 4 characters

- remove spaces and dashes

[transit] <TAB> [acct #] <TAB> [check #] <TAB> [amount] <TAB>

Read OK : [transit] [acct #] [check #]

- remove dashes and spaces

[transit] ',' [acct #] ',' [check #] ',' [amount]

[acct #] '?' [check #]

36

Page 45

Appendix A. Format List

Fmt 72:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of N characters (N is on quick-init check)

- remove spaces and dashes

Fmt 73:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - maximum of N characters (N is on quick-init check)

- remove spaces and dashes

• [check #]: - all characters in the field

- remove dashes and spaces

Fmt 74:

• [transit]: - all characters in the field

- remove dashes

• [acct #]: - always N characters (N is on quick-init check), zero filled

- remove spaces and dashes

• [check #]: - always 8 characters, zero filled

- remove spaces and dashes

Fmt 75xx:

•[transit]: - always 9 characters, zero filled

•[acct #]: - maximum of xx characters; when xx=00 all characters are sent

•[check #]: - maximum of 12 characters

[transit] <TAB> [acct #]

[transit] <CR> [acct #] <CR> [check #]

[transit] [acct #] [check #]

[transit] <CR> [acct #] <CR> [check #] <CR> [status]

- keep dashes; remove spaces

- remove dashes and spaces

- remove dashes and spaces

37

Page 46

MINI MICR WEDGE with 3-Track MSR

Fmt 76xx:

• [transit]: - all characters in the field

• [acct #]: - maximum of xx characters; when xx=00 all characters are sent

• [check #]: - all characters in the field- remove dashes and spaces

• [raw data]: - translate MICR symbols to t,o,a,d

Fmt 7700: The Flexible Format

Select this format to activate a preloaded Flexible Format. The Flexible Format is

a feature that allows the user to create custom MICR formats. The Flexible formats

can be easily created and downloaded using the Windows based MICRbase program

provided by MagTek (P/N 22000021). For more detailed information refer to Section 7

in the MICRbase reference manual (P/N 99875102).

'T' [transit] 'A' [acct #] 'C' [check #] 'M' [raw data]

- remove dashes and spaces

- remove dashes and spaces

38

Page 47

APPENDIX B. CHECK READING

The characters printed on the bottom line of commercial and personal checks are special. They

are printed with magnetic ink to meet specific standards . These characters can be read by a

MICR Reader at higher speeds and with more accuracy than manual data entry. Two MICR

character sets are used world wide; they are: E13-B and CMC-7. The E13-B set is used in the

US, Canada, Australia, United Kingdom, Japan, India, Mexico, Venezuela, Colombia, and the

Far East. The CMC-7 set is used in France, Spain, other Mediterranean countries, and most

South American countries.

E13-B CHARACTER SET

The MICR font character set E13-B includes digits 0 through 9 and four symbols. The numbers

found on U.S. checks are of the E13-B character set. The numbers and symbols of E13-B are as

follows:

Transit symbol

Dash Symbol

On-Us Symbol

Amount Symbol

CMC-7 CHARACTER SET

The numbers and symbols of the CMC-7 character set are as follows:

SI SII SIII SIV SV

39

Page 48

MINI MICR WEDGE with 3-Track MSR

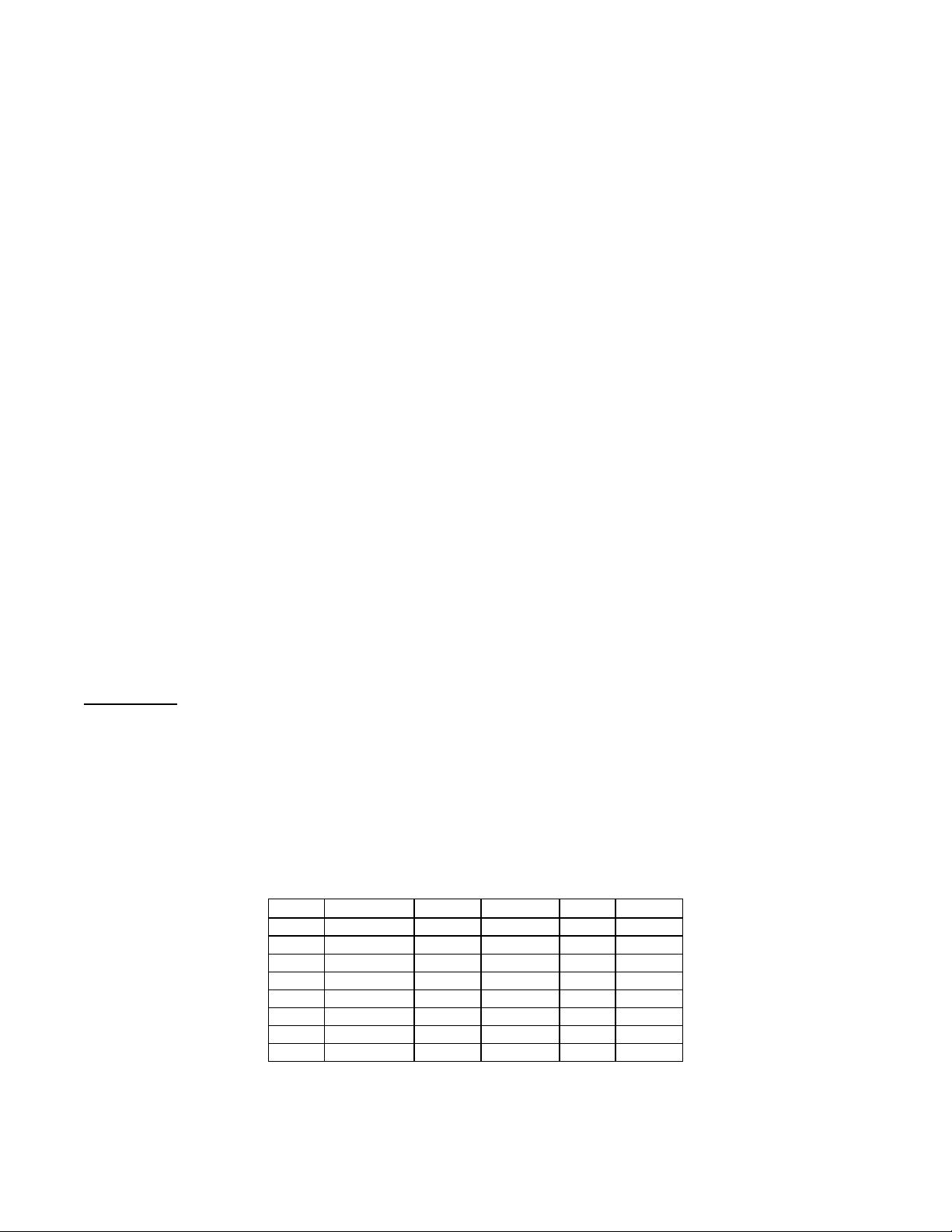

The nonnumeric CMC-7 characters are translated by the MICR Reader as shown in Table B-1.

Table B-1. CMC-7 Nonnumeric Characters

CMC-7 Character MICR Reader Output

SI

SII

SIII

SIV

SV

A

B

C

D

E

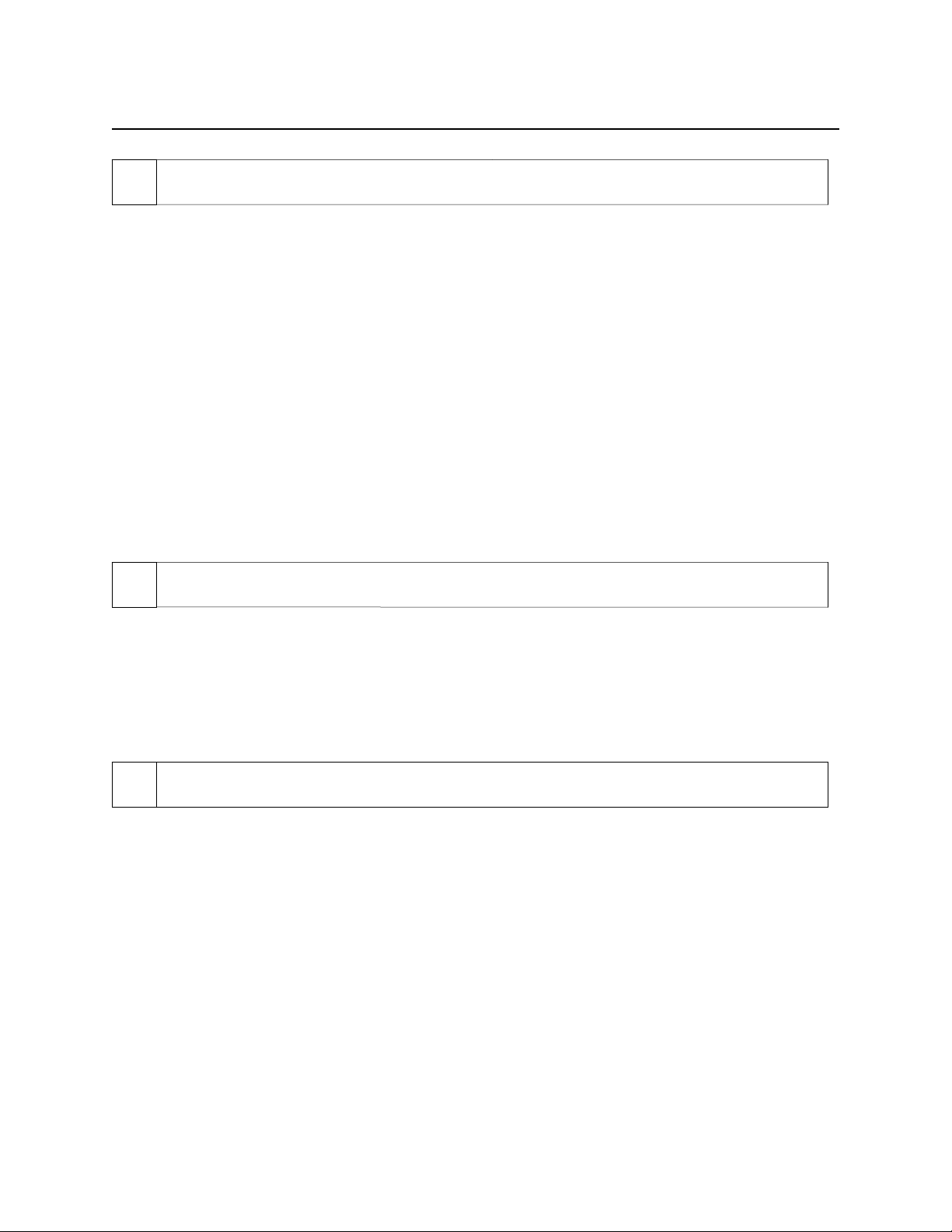

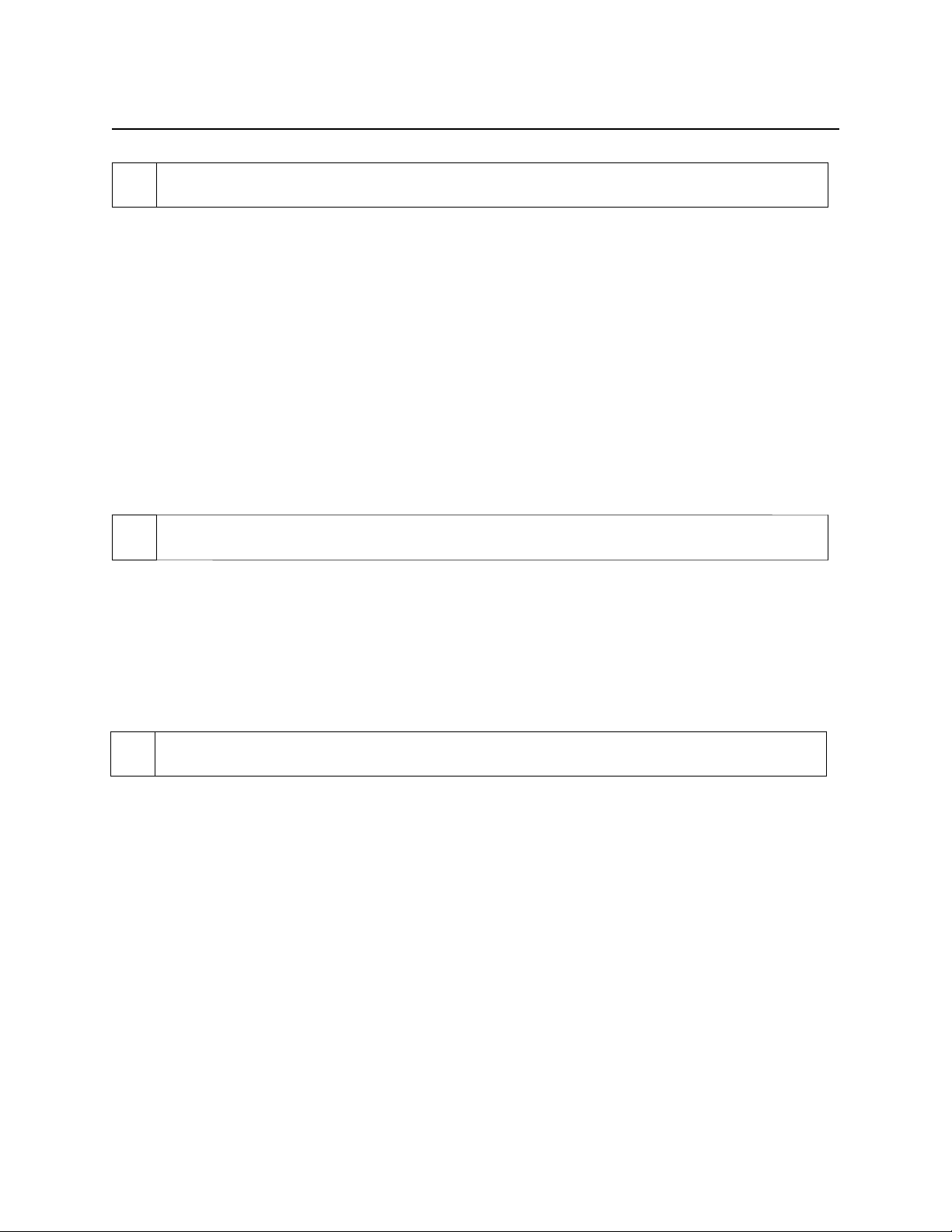

CHECK LAYOUTS

Personal checks with MICR fields are shown in Figure B-1. Business checks are shown in

Figure B-2. The digits 1 through 4 in the illustrations are described below under MICR Fields.

6.00”

2.75”

40

1

2 3

Figure B-1. Personal Checks

Page 49

Appendix B. MICR Check Reading

8.75”

3.67”

4

1

2

3

Figure B-2. Business Checks

MICR FIELDS

The numbers 1 through 4 refer to the numbers below the checks on the illustration and represent

the 4 MICR fields.

1-Transit Field

The Transit field is a 9-digit field bracketed by two Transit symbols. The field is subdivided as

follows:

• Digits 1-4 Federal Reserve Routing Number

• Digits 5-8 Bank ID Number (American Banking Association)

• Digit 9 Check Digit

2-On-Us Field

The On-Us field is variable, up to 19 characters (including symbols). Valid characters are digits,

spaces, dashes, and On-Us symbols. The On-Us field contains the account number and may also

contain a serial number (Check number) and/or a transaction code. Note that an On-Us symbol

must always appear to the right of the account number.

41

Page 50

MINI MICR WEDGE with 3-Track MSR

3-Amount Field

The Amount field is a 10-digit field bracketed by Amount symbols. The field is always zerofilled to the left.

4-Auxiliary On-Us Field

The Auxiliary On-Us field is variable, 4-10 digits, bracketed by two On-Us symbols. This field

is not present on personal checks. On business checks, this field contains the check serial

number.

42

Page 51

APPENDIX C. TROUBLESHOOTING GUIDE

REQUIREMENTS

• Personal Computer.

• Interface Cable, Mini DIN 6 pin, Part Number 22517501 or

Interface Cable, Large DIN 5 pin, Part Number 22517503

• AC adapter, P/N 64300050.

• Sample checks, P/N 96530005.

• A small bottle of compressed air.

• A cleaning card, P/N 96700006.

SET-UP