Page 1

MICRSAFE

TECHNICAL REFERENCE MANUAL

Manual Part Number: 99875466-3

OCTOBER 2010

REGISTERED TO ISO 9001:2008

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

ii

Copyright© 2002-2010

Rev

Date

Notes

1.01

Mar 3, 2010

Initial Release

2.01

Aug 27, 2010

Updated images; change AC to DC; updated

command information

3.01

Oct 20, 2010

Noted configuration 8.3; In troubleshooting

Removed 08 from troubleshooting guide

MagTek® Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

REVISIONS

guide changed18 “Return MICRSAFE to

MagTek” to “Return MICRSAFE for service”;

Page 3

iii

LIMITED WARRANTY

MagTek warrants that the products sold pursuant to this Agreement will perform in accordance with MagTek’s

published specifications. This warranty shall be provided only for a period of one year from the date of the

shipment of the product from MagTek (the “Warranty Period”). This warranty shall apply only to the “Buyer”

(the original purchaser, unless that entity resells the product as authorized by MagTek, in which event this

warranty shall apply only to the first repurchaser).

During the Warranty Period, should this product fail to conform to MagTek’s specifications, MagTek will, at its

option, repair or replace this product at no additional charge except as set forth below. Repair parts and

replacement products will be furnished on an exchange basis and will be either reconditioned or new. All

replaced parts and products become the property of MagTek. This limited warranty does not include service to

repair damage to the product resulting from accident, disaster, unreasonable use, misuse, abuse, negligence, or

modification of the product not authorized by MagTek. MagTek reserves the right to examine the alleged

defective goods to determine whether the warranty is applicable.

Without limiting the generality of the foregoing, MagTek specifically disclaims any liability or warranty for

goods resold in other than MagTek’s original packages, and for goods modified, altered, or treated without

authorization by MagTek.

Service may be obtained by delivering the product during the warranty period to MagTek (1710 Apollo Court,

Seal Beach, CA 90740). If this product is delivered by mail or by an equivalent shipping carrier, the customer

agrees to insure the product or assume the risk of loss or damage in transit, to prepay shipping charges to the

warranty service location, and to use the original shipping container or equivalent. MagTek will return the

product, prepaid, via a three (3) day shipping service. A Return Material Authorization (“RMA”) number must

accompany all returns. Buyers may obtain an RMA number by contacting Technical Support at (888) 624-8350.

EACH BUYER UNDERSTANDS THAT THIS MAGTEK PRODUCT IS

OFFERED AS IS.

MAGTEK MAKES NO OTHER WARRANTY, EXPRESS OR

IMPLIED, AND MAGTEK DISCLAIMS ANY WARRANTY OF ANY OTHER

KIND, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

IF THIS PRODUCT DOES NOT CONFORM TO MAGTEK’S SPECIFICATIONS, THE SOLE REMEDY

SHALL BE REPAIR OR REPLACEMENT AS PROVIDED ABOVE. MAGTEK’S LIABILITY, IF ANY,

SHALL IN NO EVENT EXCEED THE TOTAL AMOUNT PAID TO MAGTEK UNDER THIS

AGREEMENT. IN NO EVENT WILL MAGTEK BE LIABLE TO THE BUYER FOR ANY DAMAGES,

INCLUDING ANY LOST PROFITS, LOST SAVINGS, OR OTHER INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THE USE OF, OR INABILITY TO USE, SUCH PRODUCT, EVEN IF

MAGTEK HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY

ANY OTHER PARTY.

LIMITATION ON LIABILITY

EXCEPT AS PROVIDED IN THE SECTIONS RELATING TO MAGTEK’S LIMITED WARRANTY,

MAGTEK’S LIABILITY UNDER THIS AGREEMENT IS LIMITED TO THE CONTRACT PRICE OF THIS

PRODUCT.

MAGTEK MAKES NO OTHER WARRANTIES WITH RESPECT TO THE PRODUCT, EXPRESSED OR

IMPLIED, EXCEPT AS MAY BE STATED IN THIS AGREEMENT, AND MAGTEK DISCLAIMS ANY

IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MAGTEK SHALL NOT BE LIABLE FOR CONTINGENT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES TO PERSONS OR PROPERTY. MAGTEK FURTHER LIMITS ITS LIABILITY OF ANY KIND

WITH RESPECT TO THE PRODUCT, INCLUDING ANY NEGLIGENCE ON ITS PART, TO THE

CONTRACT PRICE FOR THE GOODS.

MAGTEK’S SOLE LIABILITY AND BUYER’S EXCLUSIVE REMEDIES ARE STATED IN THIS SECTION

AND IN THE SECTION RELATING TO MAGTEK’S LIMITED WARRANTY.

Page 4

iv

FCC WARNING STATEMENT

This equipment has been tested and was found to comply with the limits for a Class B digital device pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a residential environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference with radio communications. However, there is no guarantee that interference will not occur

in a particular installation.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class B limits for radio noise from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de la classe B prescrites dans le Réglement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numériqué de la classe B est conformé à la norme NMB-003 du Canada.

CE STANDARDS

Testing for compliance with CE requirements was performed by an independent laboratory. The unit under test

was found compliant with standards established for Class B devices.

UL/CSA

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

RoHS STATEMENT

When ordered as RoHS compliant, this product meets the Electrical and Electronic Equipment (EEE) Reduction

of Hazardous Substances (RoHS) European Directive 2002/95/EC. The marking is clearly recognizable, either as

written words like “Pb-free”, “lead-free”, or as another clear symbol ( ).

Page 5

v

Contents

SECTION 1. OVERVIEW ............................................................................................................................. 1

FEATURES ............................................................................................................................................... 2

ACCESSORIES ......................................................................................................................................... 2

SOFTWARE DRIVERS REQUIRED ......................................................................................................... 2

REFERENCE DOCUMENTS .................................................................................................................... 3

SPECIFICATIONS..................................................................................................................................... 3

SECTION 2. INSTALLATION....................................................................................................................... 5

REQUIREMENTS...................................................................................................................................... 5

PROCEDURE ............................................................................................................................................ 5

USB DRIVER INSTALLATION (WINDOWS) ............................................................................................ 6

SECTION 3. OPERATION ........................................................................................................................... 7

CHECK READING PROCEDURE............................................................................................................. 7

CARD SWIPE PROCEDURE .................................................................................................................... 7

LED INDICATORS .................................................................................................................................... 8

SECTION 4. LEGACY COMMANDS ........................................................................................................... 9

INSTA-CHANGE CHECKS ....................................................................................................................... 9

MICRBASE SETUP PROGRAM FOR WINDOWS ................................................................................... 9

COMMAND FORMAT ............................................................................................................................. 10

SWB - SWITCH B COMMAND ............................................................................................................... 11

SWB PARAMETERS .............................................................................................................................. 12

Control Characters and MICR Data .................................................................................................... 12

Control Characters and Card Data...................................................................................................... 12

Communication Modes ....................................................................................................................... 12

Send Data After Error .......................................................................................................................... 13

Send Status After Data ....................................................................................................................... 13

SWC - SWITCH C COMMAND ............................................................................................................... 14

SWC PARAMETERS .............................................................................................................................. 15

CMC-7 Character Set .......................................................................................................................... 15

Invalid Command Response ............................................................................................................... 15

Data Header ........................................................................................................................................ 16

Card Data Message ............................................................................................................................ 16

HW - HARDWARE COMMAND .............................................................................................................. 16

HW PARAMETERS ................................................................................................................................. 17

Disable/Enable Tracks ........................................................................................................................ 17

ID Card Decoding ................................................................................................................................ 17

EMF Detect ......................................................................................................................................... 17

FC - FORMAT CHANGE COMMAND ..................................................................................................... 18

VR - VERSION COMMAND .................................................................................................................... 18

SA - SAVE COMMAND ........................................................................................................................... 18

RS - RESET COMMAND ........................................................................................................................ 18

DM – DISABLE MICR COMMAND .......................................................................................................... 19

EM – ENABLE MICR COMMAND ........................................................................................................... 19

KS – ENABLE KEYSTROKE COMMAND ............................................................................................... 19

SLP – SLEEP MODE COMMAND .......................................................................................................... 19

RD – ENABLE AUXILIARY PORT COMMAND ...................................................................................... 19

CHKCNT – CHECK COUNT COMMAND ............................................................................................... 20

SECTION 5. USB COMMUNICATIONS .................................................................................................... 21

HOST APPLICATIONS ........................................................................................................................... 21

CARD AND MICR DATA ......................................................................................................................... 22

PROGRAMMABLE CONFIGURATION OPTIONS ................................................................................. 22

LOW LEVEL COMMUNICATIONS ......................................................................................................... 22

HID USAGES .......................................................................................................................................... 23

REPORT DESCRIPTOR ......................................................................................................................... 23

COMMANDS ........................................................................................................................................... 24

COMMAND PROCESSING..................................................................................................................... 25

COMMAND NUMBER ............................................................................................................................. 25

DATA LENGTH ....................................................................................................................................... 25

Page 6

vi

DATA ....................................................................................................................................................... 25

RESULT CODE ....................................................................................................................................... 26

GET AND SET PROPERTY COMMANDS ............................................................................................. 26

SOFTWARE ID PROPERTY .................................................................................................................. 27

SERIAL NUM PROPERTY ...................................................................................................................... 28

POLLING INTERVAL PROPERTY ......................................................................................................... 29

TRACK DATA SEND FLAGS PROPERTY ............................................................................................. 29

ASCII TO KEYPRESS CONVERSION TYPE PROPERTY .................................................................... 30

ACTIVE KEYMAP PROPERTY ............................................................................................................... 32

CONVERT FROM CHAR A PROPERTY ................................................................................................ 33

CONVERT TO STRING A PROPERTY .................................................................................................. 34

CONVERT FROM CHAR B PROPERTY ................................................................................................ 34

CONVERT TO STRING B PROPERTY .................................................................................................. 35

RESET DEVICE COMMAND .................................................................................................................. 36

GET KEYMAP ITEM COMMAND............................................................................................................ 37

SET KEYMAP ITEM COMMAND ............................................................................................................ 38

SAVE CUSTOM KEYMAP COMMAND .................................................................................................. 40

SEND LEGACY COMMAND COMMAND ............................................................................................... 40

SECTION 6. ENCRYPTION ....................................................................................................................... 43

APPENDIX A. FORMAT LIST .................................................................................................................... 45

APPENDIX B. CHECK READING ............................................................................................................... 49

E13-B CHARACTER SET ....................................................................................................................... 49

CMC-7 CHARACTER SET ...................................................................................................................... 49

CHECK LAYOUTS .................................................................................................................................. 50

MICR FIELDS .......................................................................................................................................... 51

1-Transit Field ..................................................................................................................................... 51

2-On-Us Field ...................................................................................................................................... 51

3-Amount Field .................................................................................................................................... 52

4-Auxiliary On-Us Field ....................................................................................................................... 52

APPENDIX C. TROUBLESHOOTING GUIDE ........................................................................................... 53

REQUIREMENTS.................................................................................................................................... 53

SET-UP ................................................................................................................................................... 53

00 CHECK LED ............................................................................................................................... 53

01 CHECK THE POWER TO THE MICRSAFE .............................................................................. 54

02 READ A CHECK ......................................................................................................................... 54

03 DID PC RECEIVE DATA? .......................................................................................................... 54

04 ANALYZE DATA ......................................................................................................................... 54

05 VERIFY PARAMETERS ............................................................................................................. 55

06 READ ERROR............................................................................................................................ 55

07 MISSING CHARACTERS .......................................................................................................... 55

09 INCORRECT FORMAT .............................................................................................................. 56

10 PATH IS OBSTRUCTED ............................................................................................................ 56

11 MOTOR SENSOR IS BLOCKED ............................................................................................... 57

12 EMF NOISE/INTERFERENCE ................................................................................................... 57

13 DATA SENSOR IS BLOCKED ................................................................................................... 57

14 NO MICR DATA DETECTED ..................................................................................................... 58

15 CABLE PROBLEM ..................................................................................................................... 58

16 NO PROBLEM FOUND .............................................................................................................. 58

17 READ INSTA-CHANGE CHECK ................................................................................................ 58

18 RETURN MICRSAFE FOR SERVICE ....................................................................................... 59

APPENDIX D. ASCII CODES ..................................................................................................................... 61

APPENDIX E. USAGE ID DEFINITIONS ................................................................................................... 63

APPENDIX F. MODIFIER BYTE DEFINITIONS ........................................................................................ 71

Page 7

vii

FIGURES and TABLES

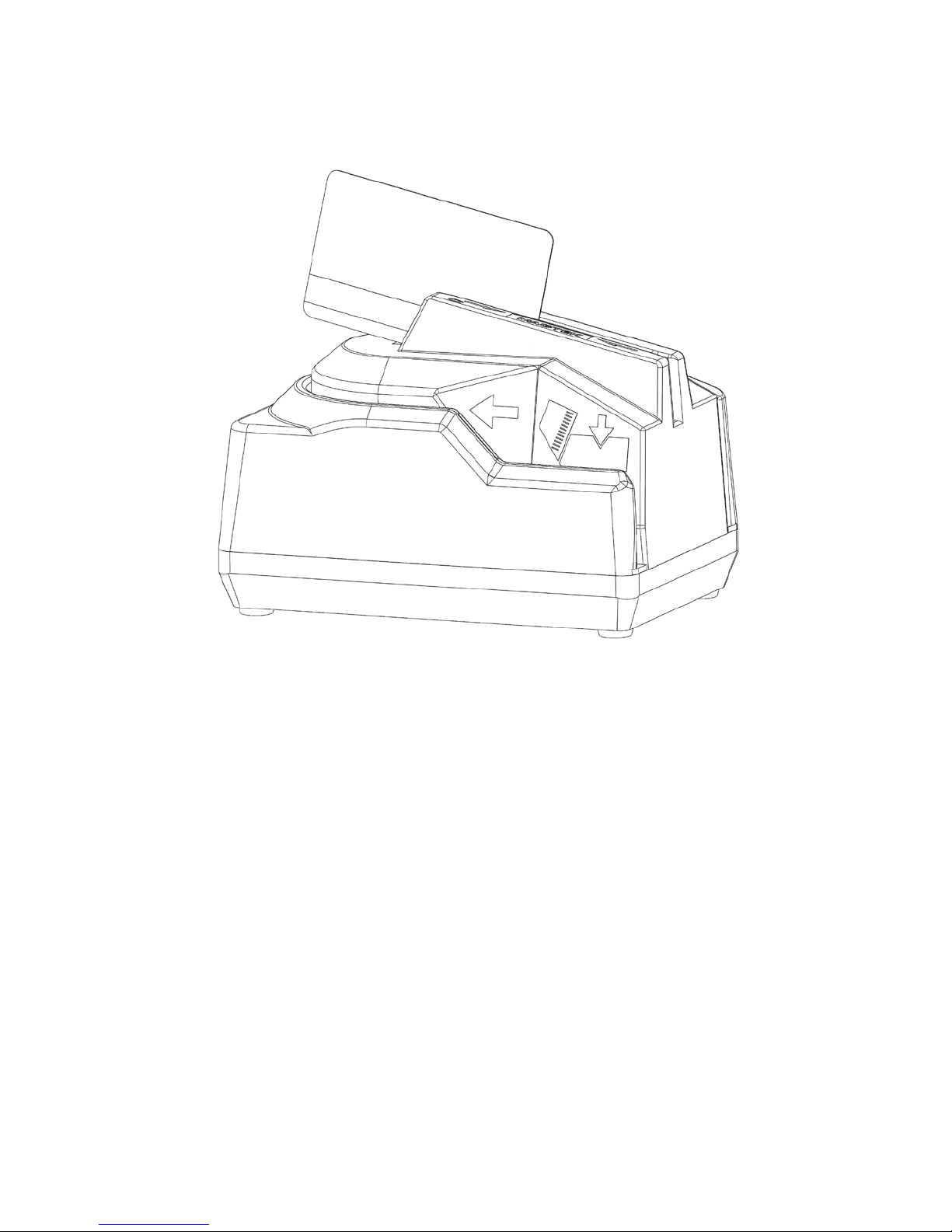

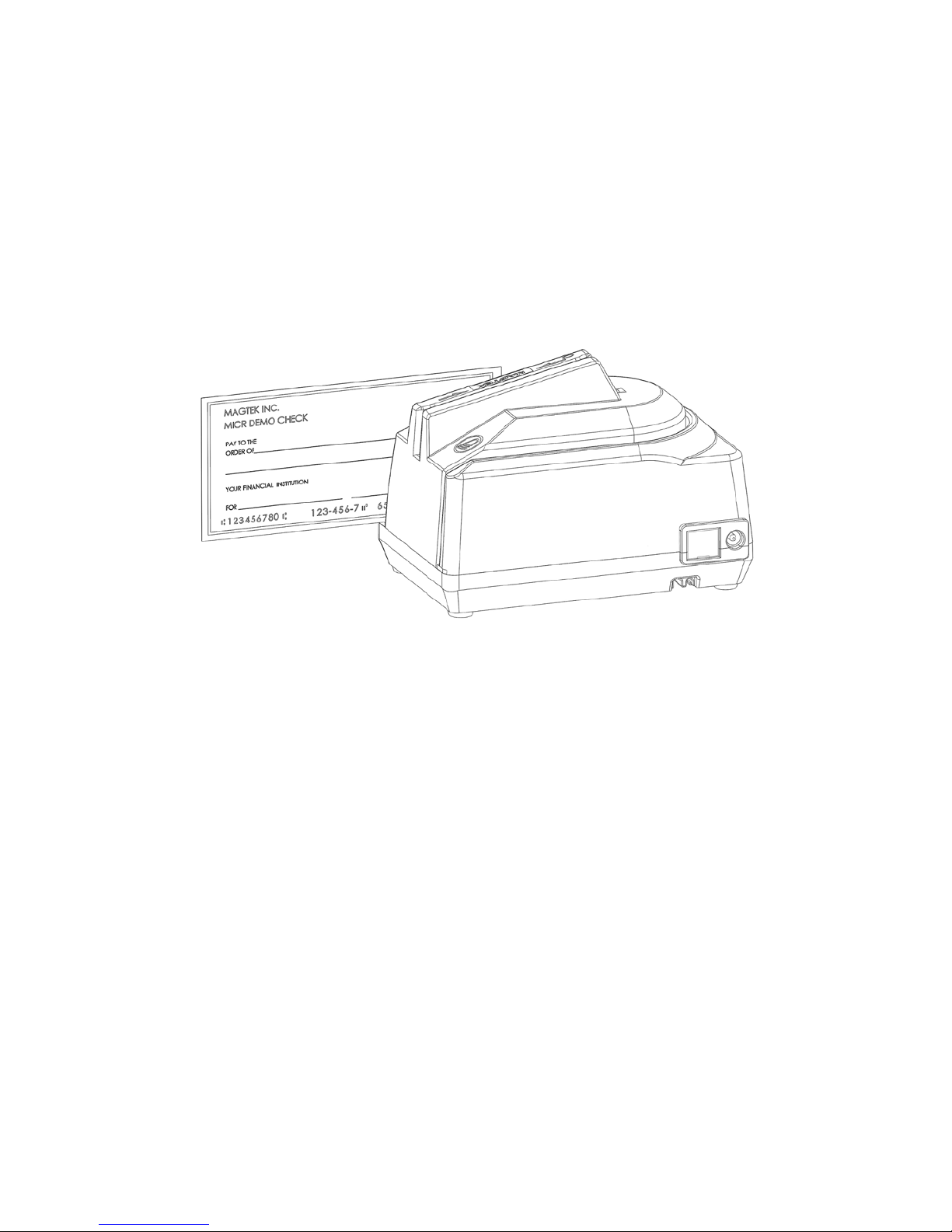

Figure 1-1. MICRSafe with 3-Track MSR ...................................................................................................viii

Table 1-1. Specifications .............................................................................................................................. 3

Figure 3-1. Check Orientation ....................................................................................................................... 7

Table 3-1. LED indicators ............................................................................................................................. 8

Table 4-2. SWB Command......................................................................................................................... 11

Table 4-3. Control Characters .................................................................................................................... 12

Table 4-4. Error and Status Codes ............................................................................................................. 13

Table 4-5. SWC Command ........................................................................................................................ 14

Table 4-6. HW Command ........................................................................................................................... 17

Table B-1. CMC-7 Nonnumeric Characters ................................................................................................ 50

Figure B-1. Personal Checks ...................................................................................................................... 50

Figure B-2. Business Checks ..................................................................................................................... 51

Figure C-1. Sensor Location ....................................................................................................................... 59

Table E-1. Keyboard/Keypad ...................................................................................................................... 63

Table F-1. Modifier Byte .............................................................................................................................. 71

Page 8

viii

Figure 1-1. MICRSafe with 3-Track MSR

Page 9

SECTION 1. OVERVIEW

The MICRSafe with 3-Track MSR is both a MICR (Magnetic Ink Character Recognition) Check

Reader and an MSR (Magnetic Stripe Reader).

The MICRSafe, in a typical application, reads the magnetic data encoded on the bottom of

checks or on magnetic stripe cards and transmits this data to a Host device. The Host device then

uses a specific authorization or verification process to validate a business transaction.

The use of the MICRSafe improves accuracy and speed because there is no manual data entry;

therefore there are no keying errors or unwanted delays.

The MICRSafe has three interface capabilities. First, the MICRSafe can communicate with the

Host system using a standard USB interface. The driver will emulate a serial port on the host

PC. All data is transmitted as ASCII characters (See Appendix D). This is MICRSafe VCOM

unit.

Second, the MICRSafe can emulate a USB keyboard. This device is compatible with PCs or

hosts that support USB keyboards. The Reader emulates a USB Human Interface Device (HID)

United States keyboard or optionally all international keyboards using ALT ASCII code keypad

key combinations or customizable key maps. This allows host applications designed to acquire

card data from keyboard input to seamlessly acquire the card data from the reader. This is

MICRSafe HID unit.

Caution

If another keyboard is connected to the same host as this device and a

key is pressed on the other keyboard while this device is transmitting,

then the data transmitted by this device may get corrupted.

Because of potential “data interleave” issues associated with the USB Keyboard interface,

MagTek recommends that this product should only be used if the application requires data to be

provided via the keyboard input.

Third, the MICRSafe can communicate with a device other than the host, for instance a POS

terminal, through an auxiliary RS-232 interface. All data is transmitted as ASCII characters (See

Appendix D). The MICRSafe has the capability of supporting some hardware handshaking

signals. (See Section 4, Legacy Commands.) Depending on POS connection port, a ‘Mini DIN 9

Pin’ or a ‘DB9’ cable can be used to connect. Communication in this mode is one-way only,

outputting data from the MICRSafe to POS terminal. Baudrate is always set to 9600 bps.

1

Page 10

MICRSafe with 3-Track MSR

2

FEATURES

• This device incorporates a MICR Reader with a 3-Track MagneSafe MSR.

• The three track MSR autodiscriminates different card formats: ISO (International Standards

Organization), CDL (California Drivers License), or AAMVA (American Association of

Motor Vehicle Administrators).

• Small footprint.

• Automatic parsing of MICR fields: transit, account, etc.

• Extensive list of formats to transmit MICR data.

• Optional error/status reporting for check reading.

• Optional TDES DUKPT encryption of MICR and Card data.

• Reads E13-B and CMC-7 MICR fonts.

• Automatically goes into sleep mode when not in use; meets EnergyStar requirements.

• EMF noise detection

• Compatible with USB specification Revisions 2.0 and 1.1

• Compatible with HID specification Versions 2.0 and 1.1

• USB communications with the host may occur via a Virtual COM port or by HID/keyboard

emulation.

• Communications with third party systems may occur via an auxiliary RS-232 interface or

using standard Windows HID drivers. No third party device driver is required.

ACCESSORIES

Accessories available for the MICRSafe are as follows:

• Standard USB cable, Part Number 22553301

• Optional auxiliary RS-232 cable, Part Number 22517584 /22517509

• DC Power Adapter with Cable, 120VAC to 12 VDC, 1 Amp, Part Number 64300118

(64300121 for international customers)

• MICR Reader Cleaning Card, Part Number 96700006

• Sample Checks, Part Number 96530005

• MICRbase Setup Program, Part Number 22000021

SOFTWARE DRIVERS REQUIRED

If you are using the HID unit, the standard HID and Keyboard drivers that come with an

operating system are usually all that is needed. For example, the Windows operating system

provides all the drivers needed to communicate to the device, unless you requested that the

factory configure your MICRSafe device(s) to use a VCOM port. In that case, you would need to

download the VCOM driver from the MagTek website. This driver allows a USB device such as

the MICRSafe to appear as an additional COM port available to the PC, enabling application

software to access the USB device as if it were connected via a standard COM (RS-232) port.

Page 11

Section 1. Overview

3

OPERATING

Reference Standards

ISO/CDL/AAMVA

Power Input

120 VAC, 50/60 Hz

Output Signal Levels

12 VDC, 200 mA (Idle), 600mA (Operating)

Check Read/Decode/Transit

Time

2 second

CMC-7

MSR supported

Tracks 1, 2, and 3

MECHANICAL

Dimensions

Length 6.25”, Width 4.0”, Height 4.25”

Weight:

3.0 lbs. MSR and Adapter included

Cable length

6’

Connectors

USB Type B connector

ENVIRONMENTAL

Temperature

Operating

0oC to 50oC (32oF to 122oF)

Storage

-30oC to 60oC (-22oF to 140oF)

Humidity

Operating

10% to 90% noncondensing

Storage

Up to 95% noncondensing

REFERENCE DOCUMENTS

Axelson, Jan. USB Complete, Everything You Need to Develop Custom USB Peripherals, 1999.

Lakeview Research, 2209 Winnebago St., Madison WI 53704, 396pp., http://www.lvr.com

MICRbase setup program for MICR readers Software and Operation P/N 99875102USB Human

Interface Device (HID) Class Specification Version 1.1

Universal Serial Bus (USB): HID Usage Tables Version 1.12 (1/21/2005)

USB (Universal Serial Bus) Specification, Version 1.1, Copyright© 1998 by Compaq Computer

Corporation, Intel Corporation, Microsoft Corporation, NEC Corporation

USB Implementers Forum, Inc., www.usb.org

ANS X9.24-2004 Retail Financial Services Symmetric Key Management Part 1: Using

Symmetric Techniques

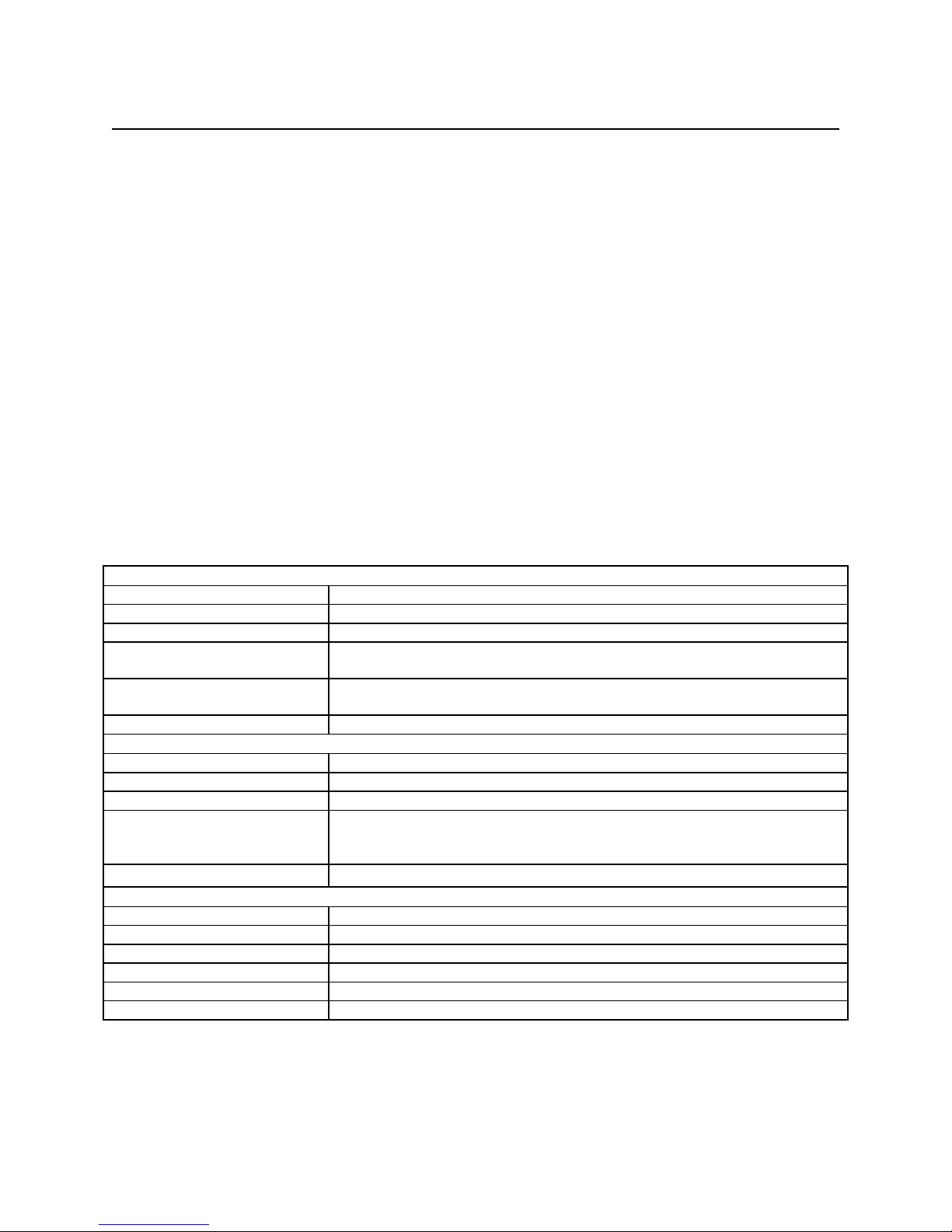

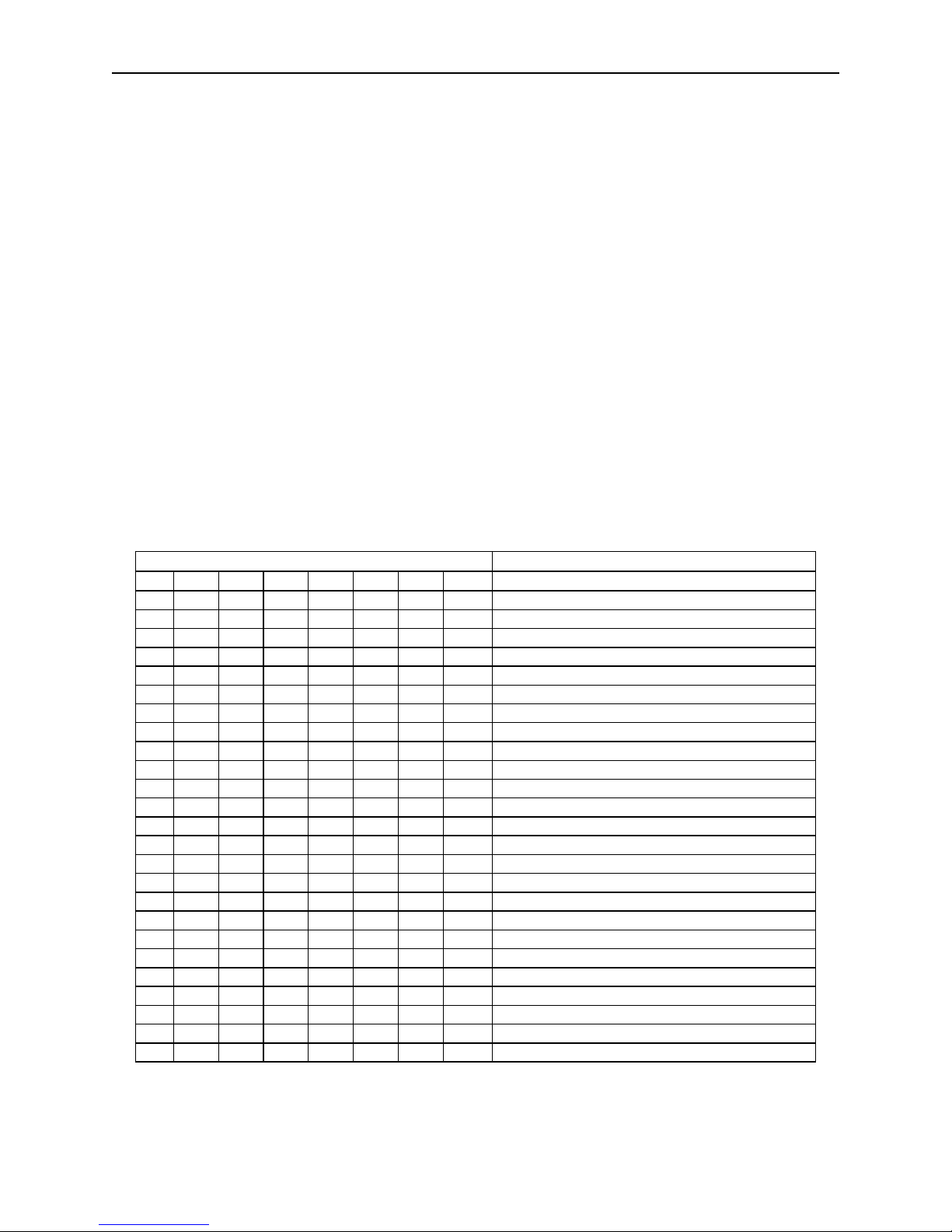

SPECIFICATIONS

Table 1-1 lists the specifications for the MICRSafe device:

Table 1-1. Specifications

MICR fonts supported E13-B

Mini Din-9 male,

Page 12

MICRSafe with 3-Track MSR

4

Page 13

SECTION 2. INSTALLATION

The installation for the MICRSafe is as follows:

REQUIREMENTS

The following is required for the Installation:

• MICRSafe Device, Part Number 22551001 (VCOM) or 22551002(HID)

• Standard USB cable, Part Number 22553301

• Optional auxiliary RS-232 cable, Part Number 22517584

• DC Power Adapter with Cable, 120VAC to 12 VDC, 1 Amp, Part Number 64300118

(64300121 for international customers)

• MICRbase software, included in the CD Package Part Number 30037855, or can be

downloaded from: http://www.magtek.com/support/software/demo_programs/ under

‘MICRbase Setup Program

• VCOM Driver for MICRSAFE, included in the CD Part Number 30037903 or can be

downloaded from: http://www.magtek.com/support/software/programming_tools/, under

‘MICRSafe VCOM’.

PROCEDURE

Perform the following steps:

1. Connect the interface cable’s USB A connector to the PC.

2. Connect the interface cable’s USB B connector to the MICRSafe.

3. Connect the DC power adapter’s jack to the plug on the MICRSafe.

4. Connect the DC power adapter’s plug to the wall outlet.

5. The first time the Reader is connected to the PC, Windows will need to install the USB

driver. See the instructions below.

6. The LED indicator on the MICRSafe should turn on to a steady green. The LED indicator is

located to the left of the slot where the check is first inserted for reading.

Do not place the MICRSafe within 6 inches of a computer

monitor or power supply. These devices may cause undesirable

interference with the check reading operation.

’

Caution

5

Page 14

MICRSafe with 3-Track MSR

6

USB DRIVER INSTALLATION (WINDOWS)

On hosts with the Windows operating system, the first time the MICRSafe is plugged into a

specific USB port, Windows will open a dialog box which will guide you through the process of

installing a driver for the device; follow the instructions given in the dialog box. Windows will

install the driver that is used for HID keyboard devices; this driver is a basic component of all

modern versions of the Windows operating system. Sometimes, Windows will find all the files it

needs. Other times, Windows will need to know the location of the files it needs. If Windows

prompts for the file locations, insert the CD that was used to install Windows on your PC and

point Windows to the CD’s root directory. Windows should find all the files it needs there.

Once completed, the driver installation process described above will not recur unless the device

is subsequently plugged into a different USB port. After this installation, the device can

communicate with user’s application programs such as MICRbase (P/N 22000021) to read

checks, credit cards and setup configurations.

Page 15

SECTION 3. OPERATION

This section contains check and card reading procedures and LED indicator states.

CHECK READING PROCEDURE

1. Orient the check so the MICR line is down and the printed side faces the center of the

MICRSafe as shown in Figure 3-1.

Figure 3-1. Check Orientation

2. Drop the check so the leading edge is in the open slot.

3. When the MICRSafe detects the presence of the check, the motor will turn on. At this

time, gently urge the check forward until the unit grabs the check. When this happens,

release the check. The check will then be transported around the check path and will exit

through the other side.

4. After the check is read, the MICRSafe will transmit the data as specified by the

parameters described in Section 4, Commands.

CARD SWIPE PROCEDURE

The card may be swiped through the MSR in either direction, but the magnetic stripe must be

oriented in only one direction as shown in Figure 1-1. The MSR will transmit raw card data (“as

is” on the card) for all tracks that have been enabled using the HW (Hardware) command

(Section 4, Legacy Commands

7

Page 16

MICRSafe with 3-Track MSR

8

LED INDICATOR

DESCRIPTION

OFF

Power off

SOLID GREEN

Ready to read check or card

OFF→ SOLID RED

Check or card read error

OFF→ SOLID GREEN

Good read

FLASH RED/GREEN

Data sensor blocked (motor does not run)*

FLASH RED

Motor sensor blocked (motor does not run)*

The MSR is capable of reading ISO, AAMVA, and CDL encoded cards. The MSR will

autodiscriminate all the card formats when the ID Card Decoding option is enabled using the HW

(Hardware) command (Section 4, Legacy Commands).

LED INDICATORS

Table 3-1 describes the LED indicator conditions for check and card reading operations. The

LED indicator for check reading is located to the left of the slot where the check is first inserted

for reading. The LED indicator for card reading is located on the upper left side of the MSR rail.

Table 3-1. LED indicators

*Refer to Appendix C. Troubleshooting Guide.

Page 17

SECTION 4. LEGACY COMMANDS

This section describes the use of commands and programmable options available for the

MICRSafe.

Note

All options described below can be factory set as specified by the

user when ordering.

You may use either of two methods to execute the MICRSafe commands: Insta-Change checks

or the MICRbase Setup Program for Windows (see *NOTE below).

INSTA-CHANGE CHECKS

The first method is the use of Insta-Change checks, which is a more practical way of setting

up the MICRSafe for most applications. The Insta-Change check is a MICR encoded

document that contains commands and options used to reset the parameters of the MICR

Reader. Multiple commands and options may be contained on one Insta-Change check.

When used, the Insta-Change checks are run through the MICRSafe the same as a standard

check, and the options to be used are automatically selected. To obtain Insta-Change checks,

notify a MagTek representative and specify what options will be used. To operate InstaChange checks, install the MICRSafe as described in Section 2 and watch the LED indicator.

When the Insta-Change check is run through the MICRSafe and read successfully, the LED

indicator will blink green. If the LED indicator turns red, the read was not successful. If the

LED is blinking red and green, the Insta-Change check contains an invalid format. Try again

or use a different Insta-Change check.

MICRBASE SETUP PROGRAM FOR WINDOWS

The MICRbase program (P/N 22000021) allows the user to control all the programmable

options available in the MICRSafe. *NOTE: MICRbase version 8.3 or newer will work

with this device in either configuration. If the MICRSafe model used is a Keyboard

Emulation HID device, you may also program the device using the USB Swipe and Insert

Reader demo (version 1.08 or newer). For details on this usage see the USB

Communications section (section 5) of this manual.

The program provides a graphical, user-friendly interface that hides the complexities

involved in manually entering MICR commands. The user is no longer required to know the

specific commands or the detailed data associated with each command. However, the

program still allows manual entry of commands for advanced users, and it also displays data

from cards and checks that are read. If your MICRSafe is using a VCOM port,; the legacy

MICR commands found in this section may be sent to the device exactly as described below.

However, if your MICRSafe is using an HID interface, you must send the legacy MICR

commands to the device using the “Send Legacy Command”, details of which can be found

in the “USB Communications” section of this manual. For details and examples of how to

use MICRbase see P/N 99875102. For more detailed information also refer to the

Readme.txt file that comes with this program. You can download the MICRbase program

from the Internet at http://www.magtek.com/support/software/demo_programs/ under

‘MICRbase Setup Program’

9

Page 18

MICRSafe with 3-Track MSR

COMMAND FORMAT

You must use the following format when entering the commands manually:

• [COMMAND][DATA]<CR>

where:

• [COMMAND] is a string of alpha characters (usually 2 or 3 bytes in length).

• [Data] is optional as described below for each command.

• <CR> is always required.

• All characters are ASCII.

• No spaces, brackets, or angle brackets required.

If your MICRSafe is using an HID Keyboard Emulation interface, then all legacy MICR

commands found in this section must be sent to the device using the “Send Legacy Command”

Command. Details of this command can be found in the “USB Communications” section of this

manual.

10

Page 19

Section 4. Legacy Commands

BIT

PARAMETERS

7

6

5

4

3

2

1

0

0

<LF>: No

1

<LF>: Yes

0 <CR>: No

1 <CR>: Yes

0

<ETX>: No

1

<ETX>: Yes

0 <ESC>: No

1 <ESC>: Yes

0

<STX>: No

1

<STX>: Yes

0 Send Data After Error?: No

1 Send Data After Error?: Yes

0

Send Status After Data?: No

1

Send Status After Data?: Yes

0 0 0 0 0 0 Comm Mode: 0 - Data Only

1 0 0 0 0 0 Comm Mode: 1 - Data<CR>

0 0 0 0 0 1 Comm Mode: 2 - Data<LF>

0 0 0 0 1 1 Comm Mode: 3 - Data<CR><LF>

0 0 1 0 0 0 Comm Mode: 4 - <ESC>Data

0 0 1 0 1 0 Comm Mode: 5 - <ESC>Data<CR>

0 1 0 1 0 0 Comm Mode: 6 - <STX>Data<ETX>

1 0 0 0 0 1 Comm Mode: 7 - <STX>Data<ETX><LRC>

0 1 1 1 1 1 Comm Mode- 8 – All controls

0 0 0 1 0 1 Comm Mode- 9- Data<ETX><LF>

0 1 0 0 1 0 Comm Mode- 10- <STX>Data<CR>

SWB - SWITCH B COMMAND

The SWB command controls the message format, shown in Table 4-2. The data for this

command consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the SWB command as follows:

SWB01010101<CR> (with data)

or

SWB<CR> (without data)

When sending data, all 8 bits must be provided. The MICRSafe will execute the

command but it will not reply. The new settings become effective immediately. To make

this command permanent, use the command SA (Save) described at the end of this

section.

If no data is sent, the MICRSafe responds with the current settings for SWB.

Table 4-2. SWB Command

11

Page 20

MICRSafe with 3-Track MSR

CHARACTER

DESCRIPTION

HEX VALUE

<STX>

Start of Text

02

<ESC>

Escape

1B

<ETX>

End of Text

03

<CR>

Carriage Return

0D

<LF>

Line Feed

0A

SWB PARAMETERS

The SWB functions are listed in Table 4-2 above and are described below:

Control Characters and MICR Data

Control Characters may be added to MICR Data messages. The MICRSafe will insert

any control characters selected using this command into outgoing formatted MICR Data

messages in the following sequence:

<STX> <ESC> data <ETX> <CR> <LF>

The control characters, descriptions, and hex values are shown in Table 4-3.

Table 4-3. Control Characters

CONTROL

For example, if the <STX> and <CR> options are set to YES, a MICR Data message

from the MICRSafe will look like this:

MICR Data: <STX>data<CR>

Control Characters and Card Data

If the card reader’s head is set to security level 2, then the same control characters may

also be added to Card Data messages, but they are applied to each track individually. For

example, if the <STX> and <ETX> options are set to YES, a Card Data message from the

MICRSafe will look like this:

Card Data: <STX>[TK1 data]<ETX><STX>[TK2 data]<ETX><STX>[TK3

data]<ETX>

Please note again that card reader heads that are set to security level 1 and 3 do not support this control

characters.

Communication Modes

The selection of Comm modes is a quick way of selecting multiple Control Characters.

For instance, to send a carriage return/line feed pair after the data, you can specify Comm

Mode 3.

12

Page 21

Section 4. Legacy Commands

PRIORITY

CODE

TYPE

DESCRIPTION

9

01

Error

No MICR data: no transit and no account found

8

09

Status

Mexican check

7

08

Status

Canadian check

6

05

Error

Transit error: No transit, bad character, bad

length, bad check digit

5

07

Error

Account error: No account, bad character

4

04

Error

Check # error: Bad character in check number

4

04

Status

No check number

3

03

Status

Low MICR signal, good read

2

10

Status

Business check

1

11

Status

Amount field present

0

00

Status

Good read

Comm Mode 7, also known as Packet Mode, calculates an LRC (Longitudinal

Redundancy Check), and appends it to the data message. Also, if a <NAK> (hex 15)

character is received in this mode, the MICRSafe will resend the last message.

Send Data After Error

The Send Data After Error option specifies whether the MICRSafe will return data to the

Host after a read error. If YES is selected and the MICRSafe detects a read error, the

MICRSafe will still send the data back to the Host. If NO is selected and the MICRSafe

finds an error, it will discard the data and nothing will be sent. The error conditions are

listed in Table 4-4.

Send Status After Data

The Send Status After Data option causes the MICRSafe to append a two-digit

error/status code to the end of the MICR data. For most formats (See Appendix A), the

error/status code will always be preceded by a forward slash (/). The error/status codes

are listed in Table 4-4.

For example, if a Canadian check (code 08) is read and has no errors, and the MICR data

is “1234567890”, then the message from the MICRSafe will look like this:

MICR Data: 1234567890/08

The status code is always at the end of the data, not the end of the message. For example,

using the above conditions, with the message format set to send <STX> and <ETX>, the

message from the MICRSafe will look like this:

MICR Data: <STX>1234567890/08<ETX>

Table 4-4. Error and Status Codes

Notes:

• The LED indicator will turn red on all error conditions.

• The absence of a check number is not considered an error.

13

Page 22

MICRSafe with 3-Track MSR

BITS

PARAMETERS

7

6

5

4

3

2

1

0

0

CMC-7 Character Set: No

1

CMC-7 Character Set: Yes

0 0 Invalid Commands: ?<CR>

0 1 Invalid Commands : No Reply (Header

Required)*

1 0 Invalid Commands: No Reply (No Header

Required)

1 1 Ignore all Commands

0 Reserved

0 Data Header: No ¹

1 Data Header: Yes ¹

0 Card Data Message: Multiple ¹

1 Card Data Message: Single ¹

included.

• If a multiple error condition occurs, the error or status code with the highest priority is

reported.

• All unreadable MICR characters are transmitted as an “?” ASCII character (hex 3F), except

for Format 00xx (See Appendix A).

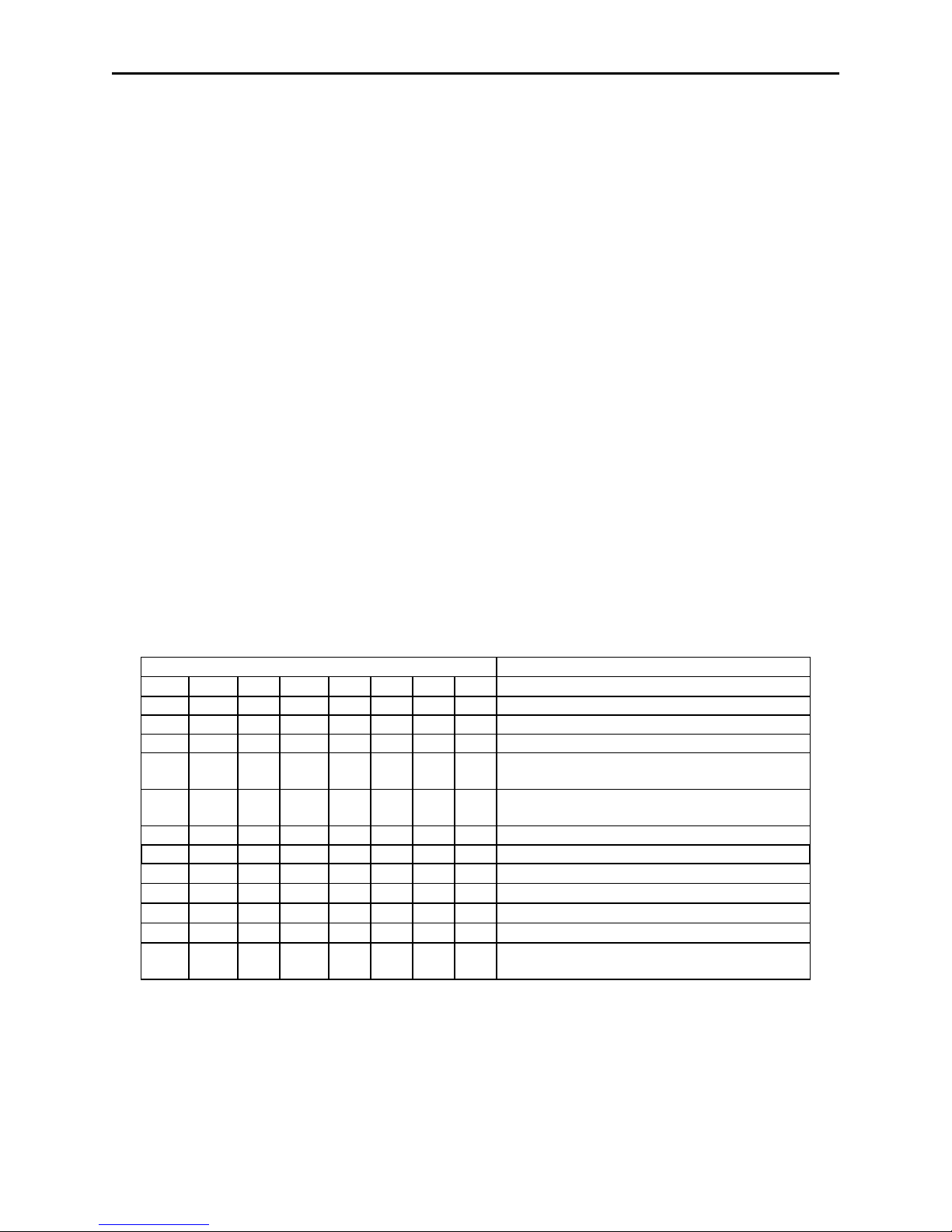

SWC - SWITCH C COMMAND

The SWC command controls miscellaneous functions, shown in Table 4-5. The data for

this command consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the SWC command as follows:

SWC01010101<CR> (with data)

or

SWC<CR> (without data)

When sending data, all 8 bits must be provided. The MICRSafe will execute the

command but it will not reply. The new settings become effective immediately. To make

this command permanent, use the SA (Save) command described at the end of this

section.

If no data is sent, the MICRSafe responds with the current settings for SWC.

Table 4-5. SWC Command

0 0 These bits are always set to 0 but must be

* ‘Header Required’ means all commands must be preceded by a GS character (Hex 1D).

¹ For the card data, this parameter does not apply to units with card reader head set to security level 1 or 3

14

Page 23

Section 4. Legacy Commands

SWC PARAMETERS

The SWC functions are listed in Table 4-5 above and are described below:

CMC-7 Character Set

If NO is selected, the MICRSafe will only read E13-B characters. When YES is selected,

the MICRSafe will read both CMC-7 and E13-B characters (see Appendix B). However,

the MICRSafe will only output raw data ("as is" on the check) for checks with CMC-7

characters.

Invalid Command Response

Invalid command response is the action the MICRSafe will take upon receipt of a

command it does not recognize. It can also be used to stop the MICRSafe from receiving

any more commands.

The first option “?<CR>” is the default. If the MICRSafe receives an unrecognized

command, it will return a question mark and carriage return to the Host. The MICRSafe

will then return to an idle state and wait for further commands or check/credit card reads.

For the second option, “no reply - header required,” the MICRSafe will only execute

commands preceded by a GS ASCII character (hex 1D). All other commands will be

ignored. Also, the MICRSafe will not reply to invalid commands.

For the third option, “no reply – no header required,” the MICRSafe will execute all valid

commands, but it will not reply to invalid commands.

The fourth option, “ignore all commands,” causes the MICRSafe to ignore any further

commands. Even the SA (Save) command is ignored and therefore this fourth option is

only temporary. To make this option permanent or to reset it, you must use an InstaChange check.

15

Page 24

MICRSafe with 3-Track MSR

Data Header

If YES is selected, a single character header precedes the data. For MICR data, the

message is transmitted as follows:

MICR data: ‘C’[data]

For card data, the header position on the message is controlled by the Card Data Message

parameter (see below). Therefore, the message may be transmitted as follows:

If Multiple Message: ‘M’[TK1]‘M’[TK2]’M’[TK3]

If Single Message: ‘M’[TK1] [TK2] [TK3]

It is important to note that the Data Header precedes the data and not the message. For

example, if <STX>, <ETX> and Data Header are set to YES, a MICR data message will

be transmitted as follows:

MICR data: <STX>‘C’[data]<ETX>

Card Data Message

This option determines the structure of the output message for the individual tracks when

a credit card is read. If Multiple is selected, the Control Characters (see SWB command,

above) and Data Header (see Data Header section, above) are added to each track

individually. On the other hand, if Single is selected, all available tracks are lumped

together into a single message. For example, if <STX>, <ETX> and Data Header are set

to YES, the output message may be transmitted as follows:

Note: This option applies only when the card reader head is set to security level 2

If Multiple Message:

<STX>‘M’[TK1]<ETX><STX>‘M’[TK2]<ETX><STX>‘M’[TK3]<ETX>

If Single Message: <STX>‘M’[TK1] [TK2] [TK3]<ETX>

HW - HARDWARE COMMAND

This command controls miscellaneous hardware options, as shown in Table 4-6. The

data for this command consists of 8 ASCII bits (“0” = hex 30 and “1” = hex 31).

To execute, send the HW command as follows:

HW 01010101<CR> (with data)

or

HW <CR> (without data)

16

Page 25

Section 4. Legacy Commands

7 6 5 4 3 2 1

0

PARAMETERS

0 Track 3: Disable*

1 Track 3: Enable*

0 Track 2: Disable*

1 Track 2: Enable*

0 Track 1: Disable*

1 Track 1: Enable*

0 ID Card decoding: Disable*

1 ID Card decoding: Enable*

0 EMF detect: Yes

1 EMF detect: No

0 0 0 These bits are always set to 0

When sending data, all 8 bits must be provided. The MICRSafe will execute the

command but it will not reply. The new settings become effective immediately. To make

this command permanent, use the SA (Save) command described at the end of this

section.

If no data is sent, the MICRSafe responds with the current settings for HW.

Table 4-6. HW Command

* Note: This option applies only when the card reader head is set to security level 2

HW PARAMETERS

Disable/Enable Tracks

Each Track can be enabled or disabled individually. The tracks are always transmitted in

ascending order: TK1, TK2, TK3. For example, if TK1 and TK3 are enabled and TK2 is

disabled, the MSR will transmit TK1, TK3.

ID Card Decoding

The MSR has two modes of operation. In the first mode, ID Card decoding disabled, the

MSR will only read ISO encoded cards. In the second mode, ID Card decoding enabled,

the MSR will read and autodiscriminate ISO, AAMVA, and CDL encoded cards. When a

card is swiped, the LED indicator will turn red and indicate an error if any of the enabled

tracks read is incompatible with the selected mode of operation. TK2 is a standard track

for all types of cards.

EMF Detect

The EMF Detect option allows the MICR Reader, when idle, to monitor EMF

interference in its immediate environment. If YES is selected, the LED indicator will

blink red/green when the MICRSafe detects a signal with amplitude large enough to

affect check reading. If NO is selected, the MICRSafe will not monitor nor indicate the

presence of EMF interference.

17

Page 26

MICRSafe with 3-Track MSR

FC - FORMAT CHANGE COMMAND

Formats are used by the MICRSafe to process and transmit the MICR fields. The format

command allows the selection of a format from the Format List (see Appendix A). The

data for this command consists of 4 digits (ASCII characters 0-9). To execute, send the

command as follows:

FCXXXX<CR> (with data)

or

FC<CR> (without data)

When sending data, all 4 digits must be provided. The MICRSafe will execute the

command but it will not reply. The new settings become effective immediately. To make

this command permanent, use the SA (Save) command described below.

If no data is sent, the MICRSafe responds with the current format number.

VR - VERSION COMMAND

The Version command gives the current software revision in the MICR Reader. To

execute, send the VR command followed by a carriage return as follows:

VR<CR>

The MICRSafe responds as follows:

MICR data: [software revision]<CR>

SA - SAVE COMMAND

All changes are considered temporary until the Save command is executed. The Save

command saves all changes to the MICRSafe memory and makes them permanent. The

MICRSafe will execute the command but it will not reply. To execute, send the SA

command followed by a carriage return as follows:

SA<CR>

RS - RESET COMMAND

The Reset command resets the MICRSafe firmware to the normal operating state of

waiting for a check or card to be read. The command also resets the serial port to the

most recently saved settings. To execute, send the RS command followed by a carriage

return as follows:

RS<CR>

18

Page 27

Section 4. Legacy Commands

DM – DISABLE MICR COMMAND

This command disables the document reading function and turns off the LED.

Communications are not affected. The motor will not turn on when a document is

inserted. To execute, send the DM command followed by a carriage return as follows:

DM<CR>

EM – ENABLE MICR COMMAND

This command enables the document reading function, and the LED will turn green. To

execute, send the EM command followed by a carriage return as follows:

EM<CR>

KS – ENABLE KEYSTROKE COMMAND

This command determines if the MICRSafe will send responses to the host via the USB

interrupt pipe or as Keystrokes (that will appear to the host application as if typed on a

keyboard). To execute, send the KS command followed by a carriage return as follows:

KS00<CR> (to send responses to the host via the USB interrupt pipe)

or

KS01<CR> (to send responses as keystrokes)

SLP – SLEEP MODE COMMAND

This command puts the MICRSafe into sleep mode for the specified time interval. While

in sleep mode, the green LED dims to half brightness. To execute, send the SLP

command followed by a carriage return as follows:

SLPB4<CR> (to put the MICRSafe in sleep mode after thirty minutes of idle state)

NOTE: The two characters following “SLP” contain the Hex value of the time before the device

goes into sleep mode, with time measured in ten-second intervals. Hex FF (numeric

255) is the maximum time you can specify; 255 ten second intervals equal 42 minutes.

RD – ENABLE AUXILIARY PORT COMMAND

This command determines if the MICRSafe will send responses to the host via the

auxiliary RS-232 port. To execute, send one of the following RD commands followed by

a carriage return:

19

Page 28

MICRSafe with 3-Track MSR

RD00<CR> (to disable the use of the auxiliary RS-232 port)

or

RD01<CR> (to enable the use of the auxiliary RS-232 port for transmitting MSR data

only)

or

RD02<CR> (to enable the use of the auxiliary RS-232 port for transmitting check data

only)

or

RD03<CR> (to enable the use of the auxiliary RS-232 port for transmitting both MSR

and check data)

If no data is sent, the MICRSafe responds with the current value of RD.

CHKCNT – CHECK COUNT COMMAND

This command returns the number of checks that have been processed by the device. To

execute, send the CHKCNT command followed by a carriage return as follows:

CHKCNT<CR>

20

Page 29

SECTION 5. USB COMMUNICATIONS

This device conforms to the USB specification revisions 2.0 and 1.1. This device also conforms

with the Human Interface Device (HID) class specification versions 2.0 and 1.1. The device

communicates to the host as a HID keyboard device. The latest versions of the Windows

operating systems come with a standard Windows USB HID keyboard driver. This section

pertains only to the HID Keyboard Emulation configuration. For character mapping and character

conversion, you may reference appendices D, E, and F for ASCII codes and USB Usage ID

definitions.

This is a full speed USB device. This device has a number of programmable configuration

properties. These properties are stored in non-volatile memory. These properties can be

configured at the factory or by the end user. The device has an adjustable endpoint descriptor

polling interval value that can be set to any value in the range of 1ms to 255ms. This property

can be used to speed up or slow down the keyboard data transfer rate. The device also has an

adjustable serial number descriptor. More details about these properties can be found later in this

document in the command section.

The device will go into suspend mode when directed to do so by the host. The device will wake

up from suspend mode when directed to do so by the host. The device does not support remote

wakeup.

This device is powered from the USB bus. The vendor ID is 0x0801 and the product ID is

0x2251.

HOST APPLICATIONS

If your MICRSafe was configured as an HID device, then it can be used with existing

applications that acquire card data via keyboard input. Also, applications that communicate with

this device can be easily developed. These applications can be developed using compilers such

as Microsoft’s Visual Basic or Visual C++. To demonstrate this device’s card reading

capabilities, any application that accepts keyboard input (for instance Windows Notepad) can be

used.

21

Page 30

MICRSafe with 3-Track MSR

CARD and MICR DATA

The card and MICR data is converted to ASCII and transmitted to the host as if it had been typed

on a keyboard.

Caution

If another keyboard is connected to the same host as this device and a

key is pressed on the other keyboard while this device is transmitting,

then the data transmitted by this device may get corrupted.

Because of potential “data interleave” issues associated with the USB Keyboard interface,

MagTek recommends that you do not depress the keyboard while swiping a card or scanning a

check. If previous applications were based upon RS-232 serial interface on a Windows operating

system, it is recommended that you use MagTek’s MINI MICR USB Virtual COM Port product.

The device’s programmable configuration options affect the format of the card and MICR data.

Refer to the legacy commands section for a description of how the card and MICR data is

formatted. Some of the properties in this section also affect the format of the card and MICR

data.

All data will be sent in upper case regardless of the state of the caps lock key on the keyboard.

PROGRAMMABLE CONFIGURATION OPTIONS

This device has a number of programmable configuration properties. These properties are stored

in non-volatile memory. These properties can be configured at the factory or by the end user

using a program supplied by MagTek. Programming these parameters requires low level

communications with the device. During normal device operation, the device acts like a

keyboard; the host operating system takes care of all low level communications with the device

so that the application developer is not burdened with these low level details. Details on how to

communicate with the device to change programmable configuration properties follows in the

next few sections. These details are included as a reference only. Most users will not need to

know these details because the device will be configured at the factory or by a program supplied

by MagTek. Most users may want to skip over the next few sections on low level

communications and continue with the details of the configuration properties.

LOW LEVEL COMMUNICATIONS

It is strongly recommended that application software developers become familiar with the HID

specification the USB specification before attempting to communicate directly with this device.

This document assumes that the reader is familiar with these specifications. These specifications

can be downloaded free from www.usb.org.

22

Page 31

Section 5. USB Communications

Usage ID

(Hex)

Usage Name

Usage

Type

Report

Type

20

Command message

Data

Feature

Item

Value(Hex)

Usage Page (Generic Desktop)

05 01

Usage (Keyboard)

09 06

Collection (Application)

A1 01

Usage Page (Key Codes)

05 07

Usage Minimum (224)

19 E0

Usage Maximum (231)

29 E7

Logical Minimum (0)

15 00

Logical Maximum (1)

25 01

Report Size (1)

75 01

Report Count (8)

95 08

Input (Data, Variable, Absolute)

81 02

Report Count (1)

95 01

Report Size (8)

75 08

Input (Constant)

81 03

Report Count (5)

95 05

Report Size (1)

75 01

Usage Page (LEDs)

05 08

Usage Minimum (1)

19 01

Usage Maximum (5)

29 05

HID USAGES

HID devices send data in reports. Elements of data in a report are identified by unique identifiers

called usages. The structure of the device’s reports and the device’s capabilities are reported to

the host in a report descriptor. The host usually gets the report descriptor only once, right after

the device is plugged in. The report descriptor usages identify the device’s capabilities and

report structures. For example, a device could be identified as a keyboard by analyzing the

device’s report descriptor. Usages are four byte integers. The most significant two bytes are

called the usage page and the least significant two bytes are called usage IDs. Usages that are

related can share a common usage page. Usages can be standardized or they can be vendordefined. Standardized usages, such as usages for mice and keyboards, can be found in the HID

Usage Tables document and can be downloaded free at www.usb.org. Vendor-defined usages

must have a usage page in the range 0xFF00 – 0xFFFF. All usages for this device use the

standard HID keyboard usages or vendor-defined magnetic stripe reader usage page 0xFF00.

The vendor-defined usage IDs for this device are defined in the following table. The usage types

are also listed. These usage types are defined in the HID Usage Tables document.

Magnetic Stripe Reader usage page 0xFF00:

REPORT DESCRIPTOR

The HID report descriptor is structured as follows:

Output (Data, Variable, Absolute) 91 02

Report Count (1) 95 01

23

Page 32

MICRSafe with 3-Track MSR

Report Size (3)

75 03

Output (Constant)

91 03

Report Count (6)

95 06

Report Size (8)

75 08

Logical Minimum (0)

15 00

Logical Maximum (101)

25 66

Usage Page (Key Codes)

05 07

Report Count

95 18

Feature (Data, Variable, Absolute, Buffered Bytes)

B2 02 01

End Collection

C0

Offset

Field Name

0

Command Number

1

Data Length

2 – 23

Data

Offset

Field Name

0

Result Code

1

Data Length

2 – 23

Data

Item Value(Hex)

Usage Minimum (0) 19 00

Usage Maximum (101) 29 66

Input (Data, Array) 81 00

Logical Maximum (255) 26 FF 00

Usage Page (vendor-defined (MSR)) 06 00 FF

Usage (command data) 09 20

COMMANDS

Command requests and responses are sent to and received from the device using feature reports.

Command requests are sent to the device using the HID class specific request Set Report. The

response to a command is retrieved from the device using the HID class specific request Get

Report. The requests are sent over the default control pipe. When a command request is sent,

the device will Nak the Status stage of the Set Report request until the command is completed.

This insures that as soon as the Set Report request is completed, the Get Report request can be

sent to get the command response. The usage ID for the command message was shown

previously in the Usage Table.

The following table shows how the feature report is structured for command requests:

The following table shows how the feature report is structured for command responses.

24

Page 33

Section 5. USB Communications

Value

Command Number

Description

0

Get Property

Gets a property from the device

1

Set Property

Sets a property in the device

2

Reset Device

Resets the device

3

Get Keymap Item

Gets a key map item

4

Set Keymap Item

Sets a key map item

5

Save Custom Keymap

Saves the custom key map

7

Send Legacy Command

Sends a legacy command

COMMAND PROCESSING

Firmware in the MSR normally handles card swipes, gets MagnePrint data, and encrypts the data;

it then passes the output to firmware in the MICRSafe for transmission to the host. Firmware in

the MICRSafe controls all functions relating to check reading and handles all communications

between the host and the device. Thus, all commands are received by the MICRSafe firmware,

which, unless instructed otherwise, will attempt to process the command. For this reason,

commands that affect card reading only (which are unknown to the MICRSafe firmware) must be

distinguished from commands which the MICRSafe firmware is equipped to handle. The

convention adopted to enable this necessary distinction is to prefix the data portion of a card

reading command with the literal “MSR”. This will cause the MICRSafe firmware not to

process a specific command. Instead, the MICRSafe firmware will pass the command through to

the MSR firmware which will process the command.

COMMAND NUMBER

This one-byte field contains the value of the requested command number. The following table

lists all the existing commands.

DATA LENGTH

This one-byte field contains the length of the valid data contained in the Data field.

DATA

This multi-byte field contains command data, if any. Note that the length of this field is fixed at

22 bytes. Valid data should be placed in the field starting at offset 2. Any remaining data after

the valid data should be set to zero. This entire field must always be set even if there is no valid

data. The HID specification requires that Reports be fixed in length. Command data may vary in

length. Therefore, the Report should be filled with zeros after the valid data.

25

Page 34

MICRSafe with 3-Track MSR

Value

Result Code

Description

0

SUCCESS

The command completed successfully.

1

FAILURE

The command failed.

2

BAD_PARAMETER

The command failed due to a bad

parameter or command syntax error.

Data Offset

Value

0

Property ID

Data Offset

Value

0 – n

Property Value

Data Offset

Value

0

Property ID

1 – n

Property Value

RESULT CODE

This one-byte field contains the value of the result code. There are two types of result codes:

generic result codes and command-specific result codes. Generic result codes always have the

most significant bit set to zero. Generic result codes have the same meaning for all commands

and can be used by any command. Command-specific result codes always have the most

significant bit set to one. Command-specific result codes are defined by the command that uses

them. The same code can have different meanings for different commands. Command-specific

result codes are defined in the documentation for the command that uses them. Generic result

codes are defined in the following table.

GET AND SET PROPERTY COMMANDS

The Get Property command gets a property from the device. The Get Property command

number is 0.

The Set Property command sets a property in the device. The Set Property command number

is 1.

The Get and Set Property command data fields for the requests and responses are structured as

follows:

Get Property Request Data:

Get Property Response Data:

Set Property Request Data:

Set Property Response Data:

None

The result codes for the Get and Set Property commands can be any of the codes listed in the

generic result code table.

26

Page 35

Section 5. USB Communications

Value

Property ID

Description

0x00 (0)

Software ID

The device’s software identifier

0x01 (1)

Serial Num

The device’s serial number

0x02 (2)

Polling Interval

The interrupt pipe’s polling interval

0x04 (4)

Track Data Send Flags

Track data send flags

0x0F (15)

ASCII To Keypress Conversion Type

Type of conversion performed when

converting ASCII data to key strokes

0x11 (17)

Active Keymap

Selects which key map to use

0x1A (26)

Selects character to use when converting to

string A

char A

0x1C (28)

Convert From Char B

Selects character to use when converting to

string B

0x1D (29)

Selects string to use when converting from

char B

Property Type

Description

Byte

This is a one-byte value. The valid values depend on the property.

String

This is a multiple byte ASCII string. Its length can range from zero to

length of the string does not include a terminating NUL character.

Cmd Num

Data Len

Prp ID

00

01

00

Result Code

Data Len

Prp Value

00

01

32 32 38 32 37 30 32 31 41 30 31

Property ID is a one-byte field that contains a value that identifies the property. The following

table lists all the current property ID values:

Convert From Char A

0x1B (27)

Convert To String A

Convert To String B

Selects string to use when converting from

Property Value is a multiple-byte field that contains the value of the property. The number of

bytes in this field depends on the type of property and the length of the property. The following

table lists all of the property types and describes them.

a maximum length that depends on the property. The value and

SOFTWARE ID PROPERTY

Property ID: 0

Property Type: String

Length: Fixed at 11 bytes

Get Property: Yes

Set Property: No

Description: This is an 11 byte read only property that identifies the software part number

and version for the device’s USB CPU. The first 8 bytes represent the part

number and the last 3 bytes represent the version. For example this string

might be “22827021A01”. Examples follow:

Example Get Software ID property Request (Hex):

Example Get Software ID property Response (Hex):

27

Page 36

MICRSafe with 3-Track MSR

Cmd Num

Data Len

Prp ID

Prp Value

01

04

01

32 32 38 32 37

31

Result Code

Data Len

Data

00

00

Cmd Num

Data Len

Prp ID

00

01

01

Result Code

Data Len

Prp Value

00

03

32 32 38 32 37 30 32 31 41

30 31

SERIAL NUM PROPERTY

Property ID: 1

Property Type: String

Length: 0 – 15 bytes

Get Property: Yes

Set Property: Yes

Default Value: The default value is no string with a length of zero.

Description: The value is an ASCII string that represents the device’s serial number. This

string can be 0 – 15 bytes long. The value of this property, if any, will be sent

to the host when the host requests the USB string descriptor.

This property is stored in non-volatile memory, so it will persist when the unit

is power cycled. When this property is changed, the unit must be reset (see

Command Number 2) or power cycled for these changes to take effect.

Example Set Serial Num property Request (Hex):

Example Set Serial Num property Response (Hex):

Example Get Serial Num property Request (Hex):

Example Get Serial Num property Response (Hex):

30 32 31 41 30

28

Page 37

Section 5. USB Communications

Cmd Num

Data Len

Prp ID

Prp Value

01

02

02

0A

Result Code

Data Len

Data

00

00

Cmd Num

Data Len

Prp ID

00

01

02

Result Code

Data Len

Prp Value

00

01

0A

POLLING INTERVAL PROPERTY

Property ID: 2

Property Type: Byte

Length: 1 byte

Get Property: Yes

Set Property: Yes

Default Value: 1

Description: The value is a byte that represents the device’s polling interval for the

Interrupt In Endpoint. The value can be set in the range of 1 – 255 and has

units of milliseconds. The polling interval tells the host how often to poll the

device for keystroke data packets. For example, if the polling interval is set to

10, the host will poll the device for keystroke data packets every 10ms. This

property can be used to speed up or slow down the time it takes to send

keystroke data to the host. The trade-off is that speeding up the card data

transfer rate increases the USB bus bandwidth used by the device, and slowing

down the card data transfer rate decreases the USB bus bandwidth used by the

device. The value of this property will be sent to the host when the host

requests the device’s USB endpoint descriptor.

This property is stored in non-volatile memory, so it will persist when the unit

is power cycled. When this property is changed, the unit must be reset (see

Command Number 2) or power cycled for these changes to take effect.

Example Set Polling Interval property Request (Hex):

Example Set Polling Interval property Response (Hex):

Example Get Polling Interval property Request (Hex):

Example Get Polling Interval property Response (Hex):

TRACK DATA SEND FLAGS PROPERTY

Property ID: 4

Property Type: Byte

Length: 1 byte

Get Property: Yes

Set Property: Yes

Default Value: 0x00

29

Page 38

MICRSafe with 3-Track MSR

Description: This property is defined as follows:

ICL 0 0 0 0 0 0 0

ICL 0 – Changing the state of the caps lock key will not affect the case of the data

1 – Changing the state of the caps lock key will affect the case of the data