Page 1

MICRImage

CHECK READER

TECHNICAL REFERENCE MANUAL

Manual Part Number: 99875173 Rev 8

OCTOBER 2008

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

Copyright© 2000-2009

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

MICRImage is a trademark of MagTek, Inc.

REVISIONS

Rev Number Date Notes

1 20 Oct 00 Initial Release

2 27 Jun 01 Front Matter: Changed Limited Warranty to exclude

Scan Bar. Sec 2: Added two cabling diagrams, Terminal

and Auxiliary Device and PC and Net Connection.

Moved Check Path Cleaning to Sec 3.

3 2 Aug 01 Front Matter, Agency page: Editorial changes to CE and

UL/CUL.

4 12 Oct 01 Front Matter: New Figure 1-1, added MSR.

Section 1: Added description and P/N of MSR. New

Table 1-1, added list of cables. Table 1-2 changed

document size from 9” to 8.5” max.. Editorial Changes.

Section 2: New Figure 2-1, added MSR and editorial

changes.

Section 3: New Figure 3-2, added MSR orientation

Modified Figures 3-3 and 3-4, added new procedure for

opening and closing unit for imaging bar. New Figures 35 and 3-6 for new cleaning procedures. Modified Figure

3-7 for closing.

5 9 May 02 Sec 1: Added 2 more Configurations and clarified

features; added 1 more Cable; clarified Spec for

interface option. Sec 2: changed Fig 2-4 and 2-5 for

clarification. Sec 3: Clarified Card Reading Procedure.

6 16 Jul 02 Front Matter: Added FCC, Part 68 Notice. Changed

MagTek to MagTek throughout. Sec 2: Changed title of

Fig 2-5 from “Net” to “Ethernet or Modem.”

7 27 May 03 Front Matter: added ISO line to logo, changed Tech

Support phone number, added new warranty statement

8 18 Aug 03 Sec 1, Features: Deleted “Horseshoe design….” Added

“Horseshoe check path…” and “Configurable Enhanced

Reading (ER) …”

ii

Page 3

LIMITED WARRANTY

MagTek warrants that the products sold to Reseller pursuant to this Agreement will perform in accordance with

MagTek’s published specifications. This warranty shall be provided only for a period of one year from the date

of the shipment of the product from MagTek (the “Warranty Period”). This warranty shall apply only to the

original purchaser unless the buyer is authorized by MagTek to resell the products, in which event, this warranty

shall apply only to the first repurchase.

During the Warranty Period, should this product fail to conform to MagTek’s specifications, MagTek will, at its

option, repair or replace this product at no additional charge except as set forth below. Repair parts and

replacement products will be furnished on an exchange basis and will be either reconditioned or new. All replaced

parts and products become the property of MagTek. This limited warranty does not include service to repair

damage to the product resulting from accident, disaster, unreasonable use, misuse, abuse, customer’s negligence,

Reseller’s negligence, or non-MagTek modification of the product. MagTek reserves the right to examine the

alleged defective goods to determine whether the warranty is applicable.

Without limiting the generality of the foregoing, MagTek specifically disclaims any liability or warranty for

goods resold in other than MagTek’s original packages, and for goods modified, altered, or treated by customers.

Service may be obtained by delivering the product during the warranty period to MagTek (1710 Apollo Court,

Seal Beach, CA 90740). If this product is delivered by mail or by an equivalent shipping carrier, the customer

agrees to insure the product or assume the risk of loss or damage in transit, to prepay shipping charges to the

warranty service location and to use the original shipping container or equivalent. MagTek will return the product,

prepaid, via a three (3) day shipping service. A Return Material Authorization (RMA) number must accompany

all returns.

MAGTEK MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAGTEK DISCLAIMS ANY

WARRANTY OF ANY OTHER KIND, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

EACH PURCHASER UNDERSTANDS THAT THE MAGTEK PRODUCT IS OFFERED AS IS. IF THIS

PRODUCT DOES NOT CONFORM TO MAGTEK’S SPECIFICATIONS, THE SOLE REMEDY SHALL BE

REPAIR OR REPLACEMENT AS PROVIDED ABOVE. MAGTEK’S LIABILITY, IF ANY, TO RESELLER

OR TO RESELLER’S CUSTOMERS, SHALL IN NO EVENT EXCEED THE TOTAL AMOUNT PAID TO

MAGTEK BY RESELLER UNDER THIS AGREEMENT. IN NO EVENT WILL MAGTEK BE LIABLE TO

THE RESELLER OR THE RESELLER’S CUSTOMER FOR ANY DAMAGES, INCLUDING ANY LOST

PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OF OR INABILITY TO USE SUCH PRODUCT, EVEN IF MAGTEK HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

LIMITATION ON LIABILITY

EXCEPT AS PROVIDED IN THE SECTIONS RELATING TO MAGTEK’S LIMITED WARRANTY,

MAGTEK’S LIABILITY UNDER THIS AGREEMENT IS LIMITED TO THE CONTRACT PRICE OF THE

PRODUCTS.

MAGTEK MAKES NO OTHER WARRANTIES WITH RESPECT TO THE PRODUCTS, EXPRESSED OR

IMPLIED, EXCEPT AS MAY BE STATED IN THIS AGREEMENT, AND MAGTEK DISCLAIMS ANY

IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MAGTEK SHALL NOT BE LIABLE FOR CONTINGENT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES TO PERSONS OR PROPERTY. MAGTEK FURTHER LIMITS ITS LIABILITY OF ANY KIND

WITH RESPECT TO THE PRODUCTS, INCLUDING ANY NEGLIGENCE ON ITS PART, TO THE

CONTRACT PRICE FOR THE GOODS.

MAGTEK’S SOLE LIABILITY AND BUYER’S EXCLUSIVE REMEDIES ARE STATED IN THIS SECTION

AND IN THE SECTION RELATING TO MAGTEK’S LIMITED WARRANTY.

iii

Page 4

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 Of The FCC Rules. Operation of this device is subject to the following two

conditions: (1) This device may not cause harmful interference. And (2) This device must accept any interference

received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de las classe A prescrites dans le Réglement sur le brouillage radioélectrique édicté par les

ministère des Communications du Canada.

CE STANDARDS

Testing for compliance to CE requirements was performed by an independent laboratory. The unit under test was

found compliant to Class A.

UL/CSA

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

iv

Page 5

FCC PART 68 NOTICE

The following refers to MICRImage readers with internal modem only:

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the ACTA. On the

bottom cover of this equipment is a label that contains, among other information, a product identifier in the format

US:AAAEQ##TXXXX. If requested, this number must be provided to the telephone company.

The registration jack Universal Service Order Code (USOC) used by this equipment is RJ-11C. A plug and jack

used to connect this equipment to the premises wiring and telephone network must comply with the applicable

FCC Part 68 rules and requirements adopted by the ACTA. A compliant modular plug is provided with this

product. This equipment is designed to be connected to a compatible modular jack using a telephone cord that is

also compliant. See installation instructions for details.

The REN is used to determine the number of devices that may be connected to a telephone line. Excessive RENs

on a telephone line may result in the devices not ringing in response to an incoming call. In most but not all areas,

the sum of RENs should not exceed five (5.0). To be certain of the number of devices that may be connected to a

line, as determined by the total RENs, contact the local telephone company. The REN for this product is part of

the product identifier that has the format US:AAAEQ##TXXXX. The digits represented by ## are the REN

without a decimal point (e.g., 03 is a REN of 0.3).

If the MICRImage with internal modem equipment causes harm to the telephone network, the telephone company

will notify you in advance that temporary discontinuance of service may be required. But if advance notice isn't

practical, the telephone company will notify the customer as soon as possible. Also, you will be advised of your

right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations or procedures that could affect

the operation of the equipment. If this happens the telephone company will provide advance notice in order for

you to make necessary modifications to maintain uninterrupted service.

If you experience trouble with this equipment, refer to the page titled Limited Warranty near the front of this

manual for contact, repair or warranty information. If the equipment is causing harm to the telephone network,

the telephone company may request that you disconnect the equipment until the problem is resolved.

There are no user serviceable parts on the modem contained inside this equipment.

Connection to party line service is subject to state tariffs. Contact the state public utility commission, public

service commission or corporation commission for information.

If your business has specially wired alarm equipment connected to the telephone line, ensure the installation of

the MICRImage with internal modem does not disable your alarm equipment. If you have questions about what

will disable alarm equipment, consult your telephone company or a qualified installer.

v

Page 6

TABLE OF CONTENTS

SECTION 1. OVERVIEW............................................................................................................................. 1

CONFIGURATION ...................................................................................................................................1

FEATURES .............................................................................................................................................. 1

ACCESSORIES........................................................................................................................................ 2

SPECIFICATIONS.................................................................................................................................... 2

SECTION 2. INSTALLATION ..................................................................................................................... 5

REQUIREMENTS..................................................................................................................................... 5

CABLING PROCEDURE.......................................................................................................................... 6

SECTION 3. OPERATION........................................................................................................................... 9

CHECK READING PROCEDURE ........................................................................................................... 9

CARD READING PROCEDURE............................................................................................................ 10

LED INDICATORS .................................................................................................................................11

CLEANING.............................................................................................................................................11

Opening the Unit ................................................................................................................................11

MSR Cleaning Card...........................................................................................................................11

Cleaning Check Path and Imager...................................................................................................... 12

Closing the Unit..................................................................................................................................14

SECTION 4. TROUBLESHOOTING GUIDE............................................................................................. 15

REQUIREMENTS................................................................................................................................... 15

SET-UP...................................................................................................................................................15

APPENDIX A. INTERFACE CABLE PIN LISTS ...................................................................................... 23

APPENDIX B. ASCII CODES ................................................................................................................... 25

APPENDIX C. CHECK READING ............................................................................................................ 27

E13-B CHARACTER SET...................................................................................................................... 27

CMC-7 CHARACTER SET..................................................................................................................... 27

CHECK LAYOUTS.................................................................................................................................28

MICR FIELDS.........................................................................................................................................29

1-Transit Field ....................................................................................................................................29

2-On-Us Field.....................................................................................................................................30

3-Amount Field...................................................................................................................................30

4-Auxiliary On-Us Field......................................................................................................................30

vi

Page 7

FIGURES

Figure 1-1. MICRImage Check Reader with MSR.....................................................................................viii

Figure 2-1. MICRImage with MSR...............................................................................................................5

Figure 2-2. DB25 Connection.......................................................................................................................6

Figure 2-3. Cabling – Single PC...................................................................................................................7

Figure 2-4. Cabling –Terminal and Auxiliary Device....................................................................................8

Figure 2-5. Cabling – PC and Ethernet or Modem Connection...................................................................8

Figure 3-1. Check Orientation - Insertion.....................................................................................................9

Figure 3-2. Optional Magnetic Swipe Reader Orientation .........................................................................10

Figure 3-3. Opening the Unit......................................................................................................................12

Figure 3-4. Cleaning Check Path and Imager............................................................................................12

Figure 3-5. Activating the Cleaning Swab..................................................................................................13

Figure 3-6. Cleaning the Imager ................................................................................................................13

Figure 3-7. Closing the Unit .......................................................................................................................14

Figure 4-1. Sensor Location.......................................................................................................................21

Figure C-1. Personal Checks....................................................................................................................28

Figure C-2. Business Checks.....................................................................................................................29

TABLES

Table 1-1. MICRImage Cables.....................................................................................................................2

Table 1-2. Specifications..............................................................................................................................3

Table 3-1. LED indicators...........................................................................................................................11

Table A-1. DB9, DB25 Interface Connector Pin List (P/N 22410302) .....................................................23

Table C-1. CMC-7 Nonnumeric Characters...............................................................................................28

vii

Page 8

Figure 1-1. MICRImage Check Reader with MSR

viii

Page 9

SECTION 1. OVERVIEW

TM

The MICRImage

Check Reader is both a MICR Reader (Magnetic Ink Character Recognition)

and a check-imaging device. The MICRImage reads the MICR character set at the bottom of a

check, and the Imager produces a digitized image of the entire check. The characters and the

image can be transmitted to a Host device. The Host device then uses a specific authorization or

verification process to validate a business transaction.

The MICRImage Reader improves accuracy and speed because there is no manual data entry;

therefore there are no keying errors or unwanted delays.

Both the MICR Reader and the Imaging device will communicate with the Host system using a

standard RS-232 interface (contact the factory for other interfaces). MICR data is transmitted as

ASCII characters (See Appendix B). The MICRImage Reader has the capability of supporting

some hardware handshaking signals.

An optional three-track MSR autodiscriminates different card formats: ISO (International

Standards Organization), CDL (California Drivers License), or AAMVA (American Association

of Motor Vehicle Administrators).

CONFIGURATION

Configurations are as follows:

Part Number Description

22410002 MICRImage, RS-232

22410003 MICRImage, RS-232, with 3-Track MSR

22410004 MICRImage, RS-232, with Ethernet

22410005 MICRImage, RS-232, with Ethernet, 3-Track MSR

22410006 MICRImage, RS-232, with V. 34 Modem

22410007 MICRImage, RS-232, with V. 34 Modem, 3-Track MSR

FEATURES

The following is a list of features of the MICRImage Reader:

• Full MICR check reader compatible with existing applications

• Horseshoe check path design allows capture of MICR data and check image in a single pass

• Configurable Enhanced Reading (ER) feature allows for automated confirmation of MICR

data by comparing the results of multiple MICR reads (up to 3 reads).

• Automatic parsing of MICR fields: transit, account, etc.

1

Page 10

MICRImage Check Reader

• Extensive list of formats to transmit MICR data.

• Capable of scanning 200 dpi image of entire front of check

• CCITT G4 Image Compression

• Ability to send complete image or user-specified portions

• Supports dual interface paths, one for MICR, one for image data

• Dual RS-232 Interface Support

• Models available with Ethernet or V. 34 Modem

• Optional 3-track MSR (Magnetic Stripe Reader)

• Reads E13-B and CMC-7 MICR fonts

• Dynamic Thresholding for image background removal

ACCESSORIES

Accessories available for the MICRImage Reader include:

• Host Interface Cables (See Table 1-1)

• AC Power Adapter with Cable, 120VAC to 12 VDC, 1.5 Amp, Part Number 64300090

• MICRbase Program, Part Number 22000021

• Sample Checks, Part Number 96530005

• Cleaning Cards P/N 96700004

• Cleaning Swabs P/N 97200078

Table 1-1. MICRImage Cables

SPECIFICATIONS

Table 1-2 lists the specifications for the MICRImage Reader.

Part Number Description

22410302 RS232, DB9F, gray, 8 ft.

22410306 RS232, DB9F + RS232, DB9F, gray, 8 ft.

22410307 RS232, DB9F + Ethernet, RJ8 socket, gray, 8 ft.

22410308 RS232, PC-DB9F + RS-232-DB25M, gray

22410309 RS232, PC-DB9F + RS-232-DB9M, gray

22410310 RS232, PC-DB9F + Modem RJ-11 Socket

2

Page 11

Section 1. Overview

Table 1-2. Specifications

OPERATING

Reference Standards ANSI X9.27

Power Input 12VDC regulated, 1.5 Amp

Current (Idle)

(Operating)

MTBF Electronics: 125,000 hours

Document Speed 10 ips

Document Size 4"x 8.5" Maximum

Image Resolution 200 dpi

MICR fonts supported E13-B

Interface Options Primary: RS-232, RS-485, IBM 4683

Dimensions Length 9.0”, Width 3.9”, Height 6.0”

Weight: 2.5 lbs. Adapter included

Connector: Power and

Communication

Temperature

Operating 0oC to 50oC (32oF to 122oF)

Storage -30oC to 70oC (-22oF to 158oF)

Humidity

Operating 10% to 90% noncondensing

Storage Up to 100% noncondensing

Altitude

Operating

Storage

300 mA

1.5 A Max

Check Read Head: 1,000,000 passes

MSR Read head: 1,000,000 passes

CMC-7

Secondary: RS-232, Ethernet 10 Base-T, V.34 Modem

MECHANICAL

DB25 female

ENVIRONMENTAL

0 -10,000 ft (0 - 3,048m)

0 - 50,000 ft (0 - 15240m)

3

Page 12

MICRImage Check Reader

4

Page 13

SECTION 2. INSTALLATION

The installation for the MICRImage Check Reader is described below. Figure 2-1 shows the

unit with the MSR.

Card Path

Easy-Access

Latch

Figure 2-1. MICRImage with MSR

REQUIREMENTS

The following is required for the Installation:

• MICRImage

• Interface Cable,

• Power Adapter 12 VDC, 1.5 Amp

LED

Check Path

5

Page 14

MICRImage Check Reader

CABLING PROCEDURE

The pin lists for all connections are shown in Appendix A. Perform the following steps:

1. Connect the male DB25 connector to the MICRImage as shown in Figure 2-2.

Easy-Access Latch

LED

Pin 1

Pin 14

Pin 13

Pin 25

Pin 13

Pin 25

Pin 14

Pin 1

Figure 2-2. DB25 Connection

2. Connect the DB9 connector to the PC as shown in Figure 2-3, 2-4, and 2-5.

3. Connect RJ45 Jack to the network connection as indicated in Figure 2-5.

4. On the AC power adapter, connect the jack to the plug on the cable.

5. On the AC power adapter, connect the plug to the wall outlet.

6. The LED indicator on the MICRImage Reader should turn on to a steady green. The LED

indicator is located on the slot where the check is first inserted for reading (see Figure 2-1).

6

Page 15

Section 2. Installation

Caution

Do not place the MICRImage Reader within 6 inches of a

computer monitor or power supply. These devices may cause

undesirable interference with the check reading operation.

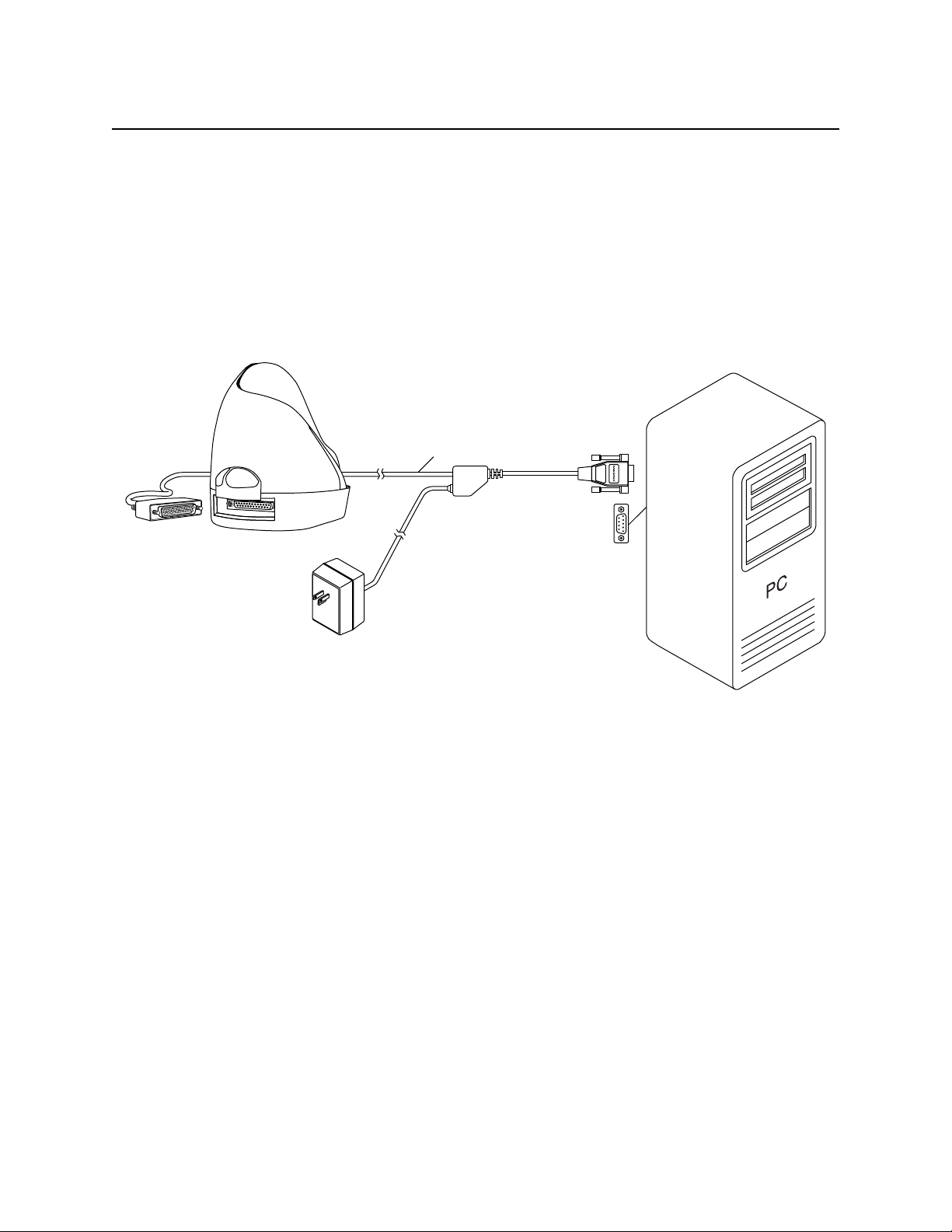

For a single PC, install the MICRImage cables as shown in Figure 2-3.

P/N 22410302

MICRImage

12 VDC

Power

Adapter

Figure 2-3. Cabling – Single PC

7

Page 16

MICRImage Check Reader

For a Terminal and Auxiliary Device, install the MICRImage cables as shown in Figure 2-4.

12 VDC

Power

Adapter

P/N 22410306

Terminal

MICRImage

RS-232 Peripheral

Figure 2-4. Cabling –Terminal and Auxiliary Device

For a PC and Network connection, install the MICRImage cables as indicated in Figure 2-5.

12 VDC

Power

Adapter

P/N 22410307

(Ethernet)

MICRImage

or

22410310

(Modem)

To Network

Connection

or

Phone Jack

Figure 2-5. Cabling – PC and Ethernet or Modem Connection

8

Page 17

SECTION 3. OPERATION

This section contains check and card reading and cleaning procedures and LED indicator states.

CHECK READING PROCEDURE

1. Orient the check so the MICR line is down and the printed side faces the center of the

MICRImage as indicated in Figure 3-1.

2. Drop the check so the leading edge is in the open slot. Slide the check forward.

3. When the MICRImage detects the presence of the check, the motor will turn on. At this

time gently urge the check forward until the unit grabs the check. When this happens,

release the check. The check will then be transported around the check path and will exit

through the other side.

4. After the check is read, the MICRImage will transmit the data as specified by the

parameters.

5. Remove the check.

Slowly Slide Check Forward

Until Reader Pulls Check In

2

Place Check Flush

1

Onto Entry Slot

Figure 3-1. Check Orientation - Insertion

9

Page 18

MICRImage Check Reader

CARD READING PROCEDURE

1. Orient the card so that the magnetic stripe is down and facing away from the logo on the

unit and toward the wide color stripe on the MRS, as indicated in Figure 3-2.

2. Slide the card in one motion from the top of the unit down through the slot as indicated in

the illustration.

3. After the card is read, the MICRImage will transmit the data as specified by the

parameters.

10

Figure 3-2. Optional Magnetic Swipe Reader Orientation

Page 19

Section 3. Operation

LED INDICATORS

Table 3-1 describes the LED indicator conditions for check and card reading operations. The

LED indicator is located below the slot where the check is first inserted for reading.

Table 3-1. LED indicators

LED INDICATOR DESCRIPTION

OFF Power off

SOLID GREEN Ready to read check or card

OFF→ SOLID RED

OFF→ SOLID GREEN

FLASH GREEN Needs initialization*

FLASH RED/GREEN Magnetic Interference Detected

FLASH RED/GREEN Data sensor blocked (motor does not run)*

FLASH RED Motor sensor blocked (motor does not run)*

*Refer to “Section 4. Troubleshooting Guide.”

Check read error

Good read

CLEANING

Clean the outside of the MICRImage unit with a soft, damp cloth and wipe with a dry cloth.

Caution

To avoid damaging the read head, do not get the inside of the

check or card paths wet.

Use the Cleaning Card, P/N 96700004, on the MSR as described below. Use the Cleaning Swab,

P/N 97200078, to clean the Imager Scan Bar as shown and described below.

Opening the Unit

To open the check path and Imager, grip the access latch, and pull up and then back as shown in

Figure 3-3.

MSR Cleaning Card

Orient the cleaning card similar to Figure 3-2. Swipe the card two or three times to clean the

head.

11

Page 20

MICRImage Check Reader

Pull Latch Up Then Back

Easy-Access Latch

Figure 3-3. Opening the Unit

Cleaning Check Path and Imager

1. When the unit is open, as shown in Figure 3-4, check the path for debris. To clean, turn

the unit over and tap gently on the bottom.

Imager

Alignment

Pin

Alignment

Hole

Easy-Access

Latch

Figure 3-4. Cleaning Check Path and Imager

2. Check the Imager to ensure there is no build-up of ink or paper debris.

12

Page 21

Section 3. Operation

3. To clean the Imager, use the cleaning swab, shown in Figure 3-5. Activate the swab by

bending the plastic tube until you hear a snap.

Figure 3-5. Activating the Cleaning Swab

4. Wait until the liquid moves into the sponge tip. It should be damp when touched.

5. When the tip of the swab is damp, clean the Imager by wiping the swab up and down the

Imager as indicated in Figure 3-6.

Figure 3-6. Cleaning the Imager

13

Page 22

MICRImage Check Reader

Closing the Unit

1. Hold the unit as shown in Figure 3-7. Push the covers together while ensuring

alignment of the pin and hole.

2. The unit is properly closed when the two panels are flush and the latch has "clicked"

into position.

Pin

Imager

Alignment

Hole

To Close:

Push Panel Back And

Ensure Alignment Pin

And Hole Match.

Alignment

14

Easy-Access

Latch

Figure 3-7. Closing the Unit

Page 23

SECTION 4. TROUBLESHOOTING GUIDE

REQUIREMENTS

• Personal Computer.

• Interface Cable, Host End = DB9 female, Part Number 22410302.

• AC adapter, P/N 64300090.

• MICRbase Program, P/N 22000021

• Sample checks, P/N 96530005.

• A small bottle of compressed air.

SET-UP

1. Plug DB25connector of the RS232 cable into the MICRImage Reader.

2. Plug the DB9 connector of the RS232 cable into the PC.

3. Power on the MICRImage Reader.

4. Run the MICRbase program on the PC.

5. Start trouble-shooting procedure at Step 00.

00 Check LED

Check the status of the LED indicator:

◊ off, continue to step 01.

◊ green, continue to step 02.

◊ blinking red, continue to step 11.

◊ blinking green, continue to step 16.

◊ blinking red/green, continue to 12.

◊ red or orange, continue to step 17.

15

Page 24

MICRImage Check Reader

01 Check the Power to the MICRImage Reader

Possible causes for this problem are:

• AC adapter connection to outlet - make sure the AC adapter is securely connected to outlet

on the wall or power strip.

• AC adapter connection to MICRImage Reader - make sure the AC adapter is securely

connected to the power jack on the Cable.

• Power strip - if using a power strip, make sure the strip is connected to outlet on the wall and

the switch on the strip is turned on.

• AC adapter is defective - replace the AC adapter.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 00.

◊ If no, continue to step 17.

02 Read a check

Read a check through the MICRImage Reader:

◊ If the check is transported all the way around the check path, continue to step 03.

◊ If the check gets "stuck" in the check path, continue to step 10.

◊ If the motor does not turn on, continue to step 17.

03 Did PC receive data?

After the check is read, did the PC receive any data?

◊ If yes, continue to step 04.

◊ If no, continue to step 05

16

Page 25

Section 4. Troubleshooting Guide

04 Analyze data

Analyze the data received by the PC:

◊ If the data is good, continue to step 15.

◊ If the data contains one or more '?', continue to step 06.

◊ If the data is missing characters, continue to step 07.

◊ If the data is garbled, continue to step 08.

◊ If the data is good but not what is expected, continue to step 09.

05 Verify parameters

Use MICRbase to verify the following parameters:

• "Send Data After Error" - if this option is set to NO, the MICRImage Reader will not send

any data after a read error. Use SET-MICR to change this option to YES.

• "Use CTS/DSR" - if this option is set to USE, the MICRImage Reader will not send any data

unless the CTS and DSR signals are enabled. Use SET-MICR to change this option to

IGNORE.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 13.

06 Read error

Possible causes for this problem are:

• Interference - the MICRImage Reader may be too close to a monitor, AC adapter or

magnetic device. Move the MICRImage Reader away from the source of interference.

• Printing problem - the check being read may not meet the requirements of the ANSI

Standards. Use one the sample checks provided by MagTek .

• Feeding the check - do not hold on to the check as it goes around the path. Release the check

immediately after the MICRImage Reader "grabs" it. Also, make sure that the front end is

not tilted up while the check is being read.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 10.

17

Page 26

MICRImage Check Reader

07 Missing characters

Possible causes for this problem are:

• Character rate - the character rate at which the MICRImage Reader is transmitting data may

be too fast for the PC. Use MICRbase to set the "Inter-character Delay" option to YES.

• Feeding the check - When feeding the check, make sure that the MICR line is at the bottom

and the printed side of the check is facing the MagTek logo on the MICRImage Reader.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 08.

08 Communication parameters do not match

Verify that the communication parameters of the MICRImage Reader match the parameters of

the PC. Use MICRbase to verify/change the communication parameters.

Determine if the condition described above is true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 14.

09 Incorrect Format

Possible causes for this problem are:

• Incorrect Format Number - the current Check data format in the MICRImage Reader is not

the desired format. Use MICRbase to verify/change the format.

• Incorrect Message Format - the current Message format in the MICRImage Reader is not the

desired format. Use MICRbase to verify/change the Message format.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 17.

18

Page 27

Section 4. Troubleshooting Guide

10 Path is obstructed

Foreign debris is obstructing the check path:

• Loose debris - power off the MICRImage Reader and refer to Section 3, Check Path

Cleaning.

• Wedged debris - the debris is wedged in and cannot be removed with the procedure described

above.

Is the foreign debris removable?

◊ if yes, remove and continue to step 02.

◊ If no, continue to step 17.

11 Motor sensor is blocked

The Motor sensor may be blocked by dust build-up or foreign debris (see Figure 5-1). Use forced

air to clean the sensor.

Power off the MICRImage Reader and then power on again, observe the LED indicator:

◊ If the LED indicator blinks red, continue to step 17.

◊ Any other LED indicator status, continue to step 00.

12 Data sensor is blocked

The data sensor may be blocked (see Figure 4-1). Refer to Section 3 for access and use forced air

to clean the sensor.

Power off the MICRImage Reader and then power on again, observe the LED indicator:

◊ If the LED indicator blinks red/green, continue to step 17.

◊ Any other LED indicator status, continue to step 00.

19

Page 28

MICRImage Check Reader

13 No MICR data detected

Possible causes for this problem are:

• No MICR characters - the ink used to print the MICR characters does not have magnetic

properties. Try one of the sample checks provided by MagTek.

• Feeding the check - When feeding the check, make sure that the MICR line is at the bottom

and the printed side of the check is facing the MagTek logo on the MICRImage Reader.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 14.

14 Cable problem

Possible causes for this problem are:

• Loose connection - the cable connector on the PC or the MICRImage Reader may be loose.

Make sure that both connectors are tightly connected.

• Damaged cable - the connectors, pins or wires in the cable may be damaged. Replace cable.

Determine if any of the conditions described above are true:

◊ If yes, rectify and continue to step 02.

◊ If no, continue to step 17.

15 No problem found

The MICRImage Reader is operating properly. If you have additional concerns or requirements

please contact your MagTek representative.

16 Read Insta-Change check

Read Insta-Change check with the appropriate settings. Return to step 00. If condition persists,

continue to step 17.

17 Return MICRImage Reader to MagTek

20

Page 29

Section 4. Troubleshooting Guide

The MICRImage Reader has a problem that needs further analysis, testing, and possibly repair.

Please contact the MagTek Help Desk at (888) 624-8350, and make arrangements to send the

unit back to MagTek. Include a detailed description of the problem.

↑

Motor Sensor Data Sensor →

Exit Sensor

↓

Figure 4-1. Sensor Location

21

Page 30

MICRImage Check Reader

22

Page 31

APPENDIX A. INTERFACE CABLE PIN LISTS

The pin list for the DB9 and DB25 Interface Connectors are shown in Table A-1.

Table A-1. DB9, DB25 Interface Connector Pin List (P/N 22410302)

P1 PIN

NUMBER

DB-9

2 RXD Received Data. Receives data

P1 SIGNAL

(Host as

Reference)

DESCRIPTION P2 PIN

NUMBER

11 TXD

from the MICRImage Reader to

the Host.

P2 DB-25

SIGNAL

3 TXD Transmitted Data. Transmits

data from the Host to the

MICRImage Reader.

5 GND Ground 16 GND

7 RTS Request to Send. Sends a

signal to the MICRImage Reader

to indicate that the Host is ready

to receive data.

8 CTS Clear to Send. Receives a signal

from the MICRImage Reader to

indicate that the MICRImage

Reader is ready to send data.

6 DSR Data Set Ready.

4 DTR Data Terminal Ready.

13 12V

25 12V

12 GND

24 GND

22

21 RXD

10 CTS

23 RTS

DTR

SHELL

(DRAIN

WIRE)

9

SHELL

DSR

(DRAIN WIRE)

23

Page 32

MICRImage Check Reader

24

Page 33

APPENDIX B. ASCII CODES

The following is a listing of the ASCII (American Standard Code for Information Interchange)

codes. ASCII is a 7-bit code, which is represented here with a pair of hexadecimal digits.

ASCII Hex value ASCII Hex Value ASCII Hex Value ASCII Hex Value

NUL 00 SP 20 @ 40 ` 60

SOH 01 ! 21 A 41 a 61

STX 02 " 22 B 42 b 62

ETX 03 # 23 C 43 c 63

EOT 04 $ 24 D 44 d 64

ENQ 05 % 25 E 45 e 65

ACK 06 & 26 F 46 f 66

BEL 07 ' 27 G 47 g 67

BS 08 ( 28 H 48 h 68

HT 09 ) 29 I 49 i 69

LF 0A * 2A J 4A j 6A

VT 0B + 2B K 4B k 6B

FF 0C , 2C L 4C l 6C

CR 0D - 2D M 4D m 6D

SO 0E . 2E N 4E n 6E

SI 0F / 2F O 4F o 6F

DLE 10 0 30 P 50 p 70

DC1 11 1 31 Q 51 q 71

DC2 12 2 32 R 52 r 72

DC3 13 3 33 S 53 s 73

DC4 14 4 34 T 54 t 74

NAK 15 5 35 U 55 u 75

SYN 16 6 36 V 56 v 76

ETB 17 7 37 W 57 w 77

CAN 18 8 38 X 58 x 78

EM 19 9 39 Y 59 y 79

SUB 1A : 3A Z 5A z 7A

ESC 1B ; 3B [ 5B { 7B

FS 1C < 3C \ 5C | 7C

GS 1D = 3D ] 5D } 7D

RS 1E > 3E ^ 5E ~ 7E

US 1F ? 3F _ 5F DEL 7F

25

Page 34

MICRImage Check Reader

26

Page 35

APPENDIX C. CHECK READING

The characters printed on the bottom line of commercial and personal checks are special. They

are printed with magnetic ink to meet specific standards . These characters can be read by a

MICRImage Reader at higher speeds and with more accuracy than manual data entry. Two

MICR character sets are used world wide; they are: E13-B and CMC-7. The E13-B set is used

in the US, Canada, Australia, United Kingdom, Japan, India, Mexico, Venezuela, Colombia, and

the Far East. The CMC-7 set is used in France, Spain, other Mediterranean countries, and most

South American countries.

E13-B CHARACTER SET

The MICR font character set E13-B includes digits 0 through 9 and four symbols. The numbers

found on U.S. checks are of the E13-B character set. The numbers and symbols of E13-B are as

follows:

Transit symbol

Dash Symbol

On-Us Symbol

Amount Symbol

CMC-7 CHARACTER SET

The numbers and symbols of the CMC-7 character set are as follows:

SI SII SIII SIV S5

27

Page 36

MICRImage Check Reader

The nonnumeric CMC-7 characters are translated by the MICRImage Reader as shown in Table

C-1.

Table C-1. CMC-7 Nonnumeric Characters

CMC-7 Character MICRImage Reader

Output

SI A

SII B

SIII C

SIV D

SV E

CHECK LAYOUTS

Personal checks with MICR fields are shown in Figure C-1. Business checks are shown in

Figure C-2. The digits 1 through 4 in the illustrations are described below under MICR Fields.

6.00”

2.75”

28

1 2 3

Figure C-1. Personal Checks

Page 37

Appendix C. Check Reading

8.75”

3.67”

4

1

2

3

Figure C-2. Business Checks

MICR FIELDS

The numbers 1 through 4 refer to the numbers below the checks on the illustration and represent

the 4 MICR fields.

1-Transit Field

The Transit field is a 9-digit field bracketed by two Transit symbols. The field is subdivided as

follows:

• Digits 1-4 Federal Reserve Routing Number

• Digits 5-8 Bank ID Number (American Banking Association)

• Digit 9 Check Digit

29

Page 38

MICRImage Check Reader

2-On-Us Field

The On-Us field is variable, up to 19 characters (including symbols). Valid characters are digits,

spaces, dashes, and On-Us symbols. The On-Us field contains the account number and may also

contain a serial number (Check number) and/or a transaction code. Note that an On-Us symbol

must always appear to the right of the account number.

3-Amount Field

The Amount field is a 10-digit field bracketed by Amount symbols. The field is always zerofilled to the left.

4-Auxiliary On-Us Field

The Auxiliary On-Us field is variable, 4-10 digits, bracketed by two On-Us symbols. This field

is not present on personal checks. On business checks, this field contains the check serial

number.

30

Loading...

Loading...