Page 1

HALF CARD PORT POWERED

INSERTION READER

TECHNICAL REFERENCE MANUAL

Manual Part Number 99875234-7

FEBRUARY 2007

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

www.magtek.com

Page 2

Copyright© 2002-2007

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may

be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of MagTek, Inc.

MagTek is a registered trademark of MagTek, Inc.

REVISIONS

Rev Number Date Notes

1 21 Jun 02 Initial Release

2 09 Sep 02 Editorial comments throughout. Sec 1: Buffered Mode, clarified data

and error status, clarified output when sensor is blocked or card

withdrawn, Related Documents, added source of ISO specs, Specs:

added cmps for card speed, added 6’ cable, corrected storage temp

to 176 degrees, modified Related Documents to qualify characters in

Tk 1 and Tk 2, corrected Fig 1-2 side view dimension. Sec 2:

corrected Table 2-1 and added Molex connectors, corrected Table 22 by adding P designations. Sec 3: Table 3-2: added red and green

LED status and to note “LED controlled by Host”, added Watchdog

LED paragraph, added optional statement to card insertion block,

clarified Tables 3-3 and 3-4.

3 13 Jun 03 Front Matter: added ISO line to logo, changed Tech Support phone

number, added new warranty statement.

4 26 Jun 03 Sec 1: added part number to Table 1-1; Specifications: changed

operating temperature to before (32

shipping date.

5 30 Aug 04 Sec 3, Table 3-2: changed To Set Option L(0x52) to L(0x4C); Table

3-3: added Card Inserted line and Card Removed line at the end of

the table, added “data buffer is cleared” to “Sends card data…” line.

6 15 Nov 04 Sec 1, Table 1-1: Added P/N 21066020, 215232 Insertion Reader

TK1,2 1Head Right, Half Card Port Powered, Black.

7 9 Feb 07 Added new model 21066000; updated throughout to include printed

circuit board 21067505; added ability to configure the communication

parameters; added configuration commands

o

F) and after (-4 oF) 1 Nov 03

ii

Page 3

Limited Warranty

MagTek, Inc. warrants that the Product described in this document is free of defects in materials and

workmanship for a period of one year from the date of purchase where the date of purchase is defined as

the date of shipment from MagTek. During this warranty period, MagTek shall, at their option, repair or

replace without charge for either parts or labor, any failure, malfunction, defect or nonconformity which

prevents the product from performing in accordance with MagTek’s published technical specifications

and manuals.

This warranty does not apply to wear of the magnetic read head. This warranty shall not apply if the

product is modified, tampered with, or subject to abnormal working conditions. This warranty does not

apply when the malfunction results from the use of the Product in conjunction with ancillary or peripheral

equipment where it is determined by MagTek that there is no fault in the Product itself.

Notification by the Customer to MagTek of any condition described above should be directed to the

Customer’s MagTek Sales Representative or to MagTek’s Help Desk at (651) 415-6800. If the Product is

to be returned from the Customer to MagTek, a returned material authorization (RMA) will be issued by

MagTek. The Customer shall be responsible for shipping charges to MagTek, (1710 Apollo Court, Seal

Beach, CA 90740). MagTek shall be responsible for shipping charges back to the Customer.

Repair or replacement as provided under this warranty is the exclusive remedy. This warranty is in lieu

of all other warranties, express or implied.

iii

Page 4

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for Class B digital device, pursuant to

Part 15 of FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following

two conditions: (1) This device may not cause harmful interference. And (2) This device must accept any

interference received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class B limits for radio noise for digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de las classe B prescrites dans le Réglement sur le brouillage radioélectrique

édicté par les ministère des Communications du Canada.

CE STANDARDS

Testing for compliance to CE requirements was performed by an independent laboratory. The unit under

test was found compliant to Class B.

UL/CUL

This product is recognized per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

iv

Page 5

TABLE OF CONTENTS

SECTION 1. FEATURES AND SPECIFICATIONS.....................................................................................1

FEATURES...............................................................................................................................................1

CONFIGURATIONS.................................................................................................................................2

MODES OF OPERATION ........................................................................................................................3

Unbuffered Mode..................................................................................................................................3

Buffered Mode...................................................................................................................................... 3

RELATED DOCUMENTS.........................................................................................................................4

SPECIFICATIONS....................................................................................................................................4

DIMENSIONS...........................................................................................................................................7

SECTION 2. INSTALLATION...................................................................................................................... 9

CONNECTORS........................................................................................................................................9

PC Connector.......................................................................................................................................9

MOUNTING............................................................................................................................................10

Orientation..........................................................................................................................................11

SECTION 3. COMMANDS, FORMATS, TIMING......................................................................................13

HOST TO READER COMMANDS.........................................................................................................13

WATCHDOG LED ..................................................................................................................................14

READER TO HOST FORMATS.............................................................................................................15

TIMING FOR ID SIGN-ON AND TRANSMISSION BURSTS.................................................................17

TRANSMISSIONS EXAMPLES .............................................................................................................18

PROGRAM MODE .................................................................................................................................20

Sending Program Mode Commands..................................................................................................20

PROGRAM MODE COMMAND SET.....................................................................................................21

Exit Program Mode.............................................................................................................................21

Reset Device ...................................................................................................................................... 21

Version Request.................................................................................................................................21

Upload Command...............................................................................................................................21

Configuration Commands................................................................................................................... 22

Switch A..............................................................................................................................................23

Switch B..............................................................................................................................................24

Switch C..............................................................................................................................................25

Sentinel Definitions.............................................................................................................................26

v

Page 6

FIGURES and TABLES

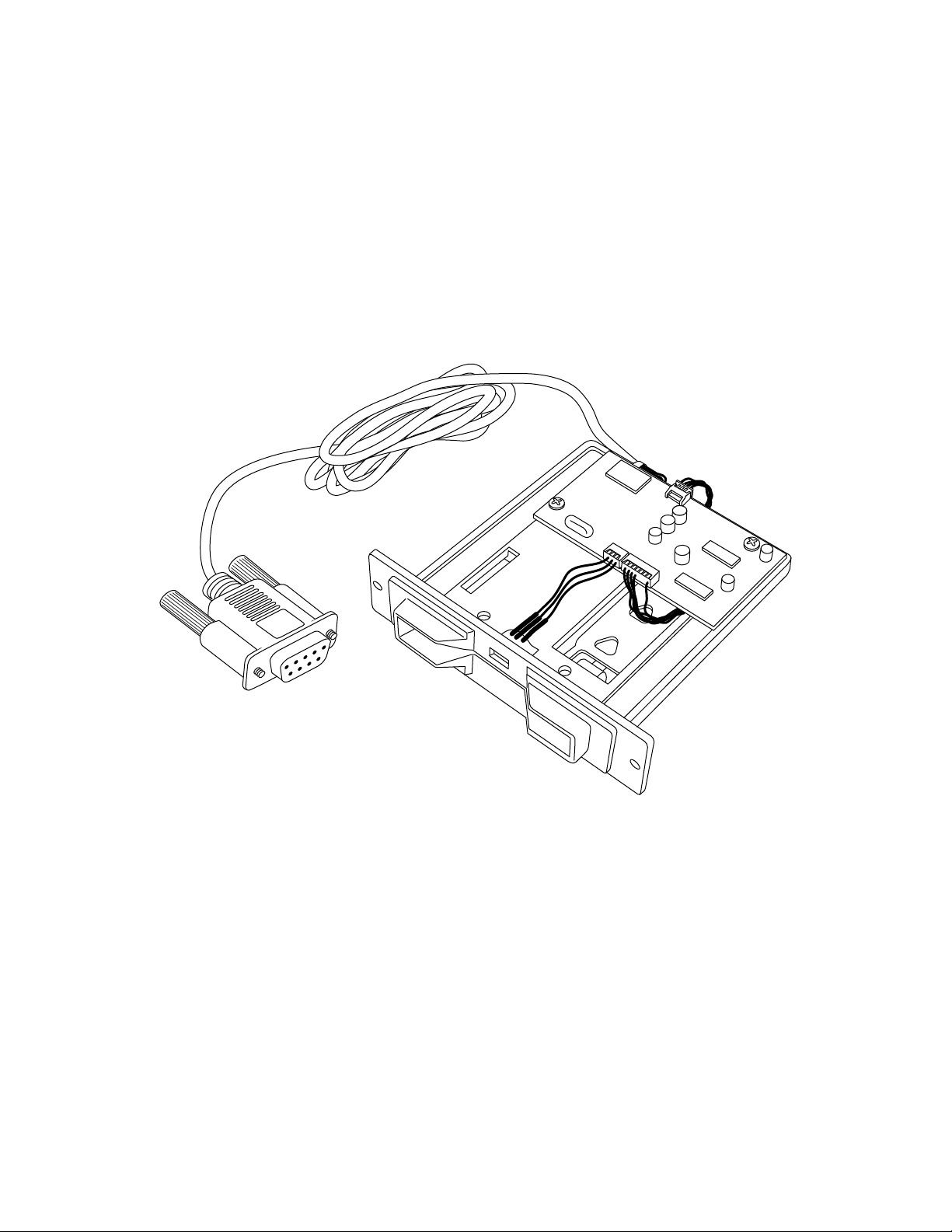

Figure 1-1. Half Card Port Powered Insertion Reader................................................................................vii

Table 1-1. Configuration...............................................................................................................................2

Table 1-2. Specifications..............................................................................................................................5

Figure 1-2. Half Card Reader Dimensions...................................................................................................7

Table 2-1. J1 Connector - RS232................................................................................................................9

Table 2-2. P2 Connector and Cable ............................................................................................................9

Figure 2-1. Reader Layout - Top................................................................................................................10

Figure 2-2. Reader Layout -Bottom ...........................................................................................................11

Table 3-1. Commands and Responses .....................................................................................................13

Table 3-2. Options and Reader Responses...............................................................................................14

Figure 3-1. Timing For ID Sign-on and Transmission Bursts.....................................................................17

Table 3-3. Transmission Data Examples Not in Buffered Mode................................................................ 18

Table 3-4. Transmission Data Examples in Buffered Mode With STX and ETX Included........................19

Table 3-5. Switch A....................................................................................................................................23

Table 3-6. Switch B....................................................................................................................................24

Table 3-7. Switch C....................................................................................................................................25

Table 3-8. Start and End Sentinels............................................................................................................26

vi

Page 7

Figure 1-1. Half Card Port Powered Insertion Reader

vii

Page 8

Page 9

SECTION 1. FEATURES AND SPECIFICATIONS

The Half Card Port Powered Insertion Reader is a single-head, dual-track configuration (Tracks

1 and 2). The magnetic stripe is down and to the right as viewed from the front of the Reader.

The single head configuration can read the card on insertion and removal.

FEATURES

Features of the Reader are as follows:

• Port Powered RS-232 Interface – No power pack required, powered from PC port with

computers having an RS-232 interface

• Card Present Opto-sensor – Detects if card is fully inserted in Reader

• Dual-Color LED – Red/Green colors provide visual cues to the card holder

• Watchdog LED – Provides visual cues to service personnel to verify Reader electronics are

operational

• Open Chassis design – Provides superior debris clearing capability

• Isolated PCB – Isolates electronics from debris and liquids

• Beam-mounted Read-head – Provides superior tracking of bowed or warped cards

• Mag-Stripe reading during insertion and removal of card – For reliable card reading

• AGC F2F ASIC – Provides improved ability to read cards (Automatic Gain Control, Two

Phase Frequency, and Application Specific Integrated Circuit)

• Command Selectable Buffered or Unbuffered Modes – Provides greater versatility of

operating modes

• Command Selectable Framing Characters – Provides selection of STX, ETX, ESC, and CR.

• ASCII Message Format at 9600, also 19.2k, 38.4k, 57.6k, or 115.2k bps for new reader (33%

duty cycle)

1

Page 10

Half Card Port Powered Insertion Reader

CONFIGURATIONS

Table 1-1 lists the part number, single or dual head, head positions, tracks, and cable type.

Note

Additional features have been incorporated into the new version of

the Half Card Insert Reader (generally available after December

2006). In the new version, the firmware part number will be

reported as 21088842. This new reader was designed to be a drop

in replacement for the old reader. However, there are some slight

behavior differences mentioned throughout this manual. This new

reader also added a number of features that are mentioned

throughout this manual. The part number of the readers did not

change for the new readers, however the revisions did change.

The enhancements included in this new version are identified

within this document with the word “new”.

Table 1-1. Configuration

Part Number Heads Head Position* Track Bezel Cable Type

21066000 Single Head Down/Right 1-2 Black No Cable

21066008 Single Head Down/Right 1-2 White 6’ Cable

21066019 Single Head Down/Right 1-2 White No Cable

21066020 Single Head Down/Right 1-2 Black 6’ Cable

21166021 Single Head Down/Right 1-2 White No electronics,

no cable

* The magnetic stripe is inserted in the same orientation as the head position; for example,

head down/right means magnetic stripe down or to the right.

2

Page 11

Section 1. Features and Specifications

MODES OF OPERATION

The Reader can operate in either unbuffered or buffered mode. The modes are described below.

The note that follows applies to both modes.

Note

The insertion and removal of the card must be done in a

continuous motion. If not, the Reader may not read the encoded

data properly. In that case, the Reader responds by either

transmitting the ASCII character “E” representing an error, or by

not transmitting any character, which indicates that the Reader

has not detected data and the card was not completely inserted.

Unbuffered Mode

When a card is inserted and removed, a read attempt is made during both insertion and removal.

If the read is successful, data (including the two sentinel characters) is sent to the PC. The data

is transmitted immediately after removing the card and not re tained in the Reader.

When operating in the unbuffered mode, the Reader does not need to receive commands from the

host in order to transmit data or status characters, and data, if available; however, the Reader

does respond to an “Inquiry Command” by sending status characters. The inquiry command that

requests the transmission is the ESCAPE (ESC) character followed by “I” (0x49).

In the unbuffered mode, data can be retrieved from the card after the card has been inserted and

while it is blocking the rear sensor. Issuing an “Inquiry Command” (see Section 3) will retrieve

data from the card.

Buffered Mode

When a card is inserted and removed, a read attempt is made during both insertion and removal.

Upon removal of the card if the read is successful, data (including the two sentinel characters) is

stored in a memory buffer on the Reader and is not transmitted until the Reader receives an

“Inquiry Command” from the host. This command is the ESCAPE character followed by “I”.

The data or error status is available when the back sensor is blocked, however the Release

Command will not clear the buffer. The Reader cannot read another card until the buffer is

cleared. To clear the buffer, the Host must transmit the ESCAPE character followed by “R”.

The unit will always output a 1 and enabled optional characters when the back sensor is first

blocked. It will output a 0 and enabled optional characters when the card has been withdrawn.

See Section 3, Table 3-4 for detailed examples.

3

Page 12

Half Card Port Powered Insertion Reader

RELATED DOCUMENTS

MagTek 99875125 The MagTek Device Drivers for Windows, Part Number

30037385, may be used with the Port Powered Insertion Reader.

The title of the manual is MagTek Device Drivers For Windows

Programming Reference Manual.

The Port Powered Insertion Reader will read cards that meet the standards defined by ISO

(International Standards Organization) with the exception that track 1 can only contain up to 51

characters and track 2 up to 25 characters:

ISO 7811 Identification Cards - Mag-stripe Cards, Tracks 1-3

ISO 7810 Identification Cards - Physical Specifications (ID-1 Cards)

Available from ANSI Phone 212-642-4900, www.ansi.org

SPECIFICATIONS

The Specifications are listed in Table 1-2.

4

Page 13

Section 1. Features and Specifications

Table 1-2. Specifications

OPERATING

Reference Standards ISO7810 and 7811;

51 Characters on Track 1, 25 on Track 2

Power Input From RS-232 Interface or Auxiliary Power Input (some units)

Interface Signal RS-232 compatible

Message Format ASCII

Track Card Speed 3 to 50 IPS (7,6 to 127 cm/sec)

Head Life 500,000 Insertion Cycles (1,000,000 head passes)

ELECTRICAL

DTR Voltage (Input)

V

DTR

Transmit Data (TXD) +/-5 VDC minimum +/-(V

Receive Data (RXD) +/-15 VDC op erating

Communication

(bursts of 5 ms transmit with

10 ms idle between bursts)

DTR Current

Or Auxiliary Supply Current

(Positive supply to unit)

Power On 12 mA Max (and practically

Transmitting 11 mA typical, 5 ms duration See above.

Quiescent 6 mA typical, continuous See above.

RXD Current Within RS-232 specified limits

Output Cable Not Specified See note “*” below.

Dimensions

Length

Width

Height

Weight 4.1 oz (115 g) including 6’ cable

Printed Circuit Assembly

21067502 (discontinued)

+5 to +15 VDC operating

+16 VDC absolute maximum

-25 VDC absolute maximum

Printed Circuit Assembly

21067505 (new unit)

+5 to +15 VDC operating

+/-20 VDC absolute maximum

– 0.4 V) VDC

DTR

minimum

+/-15 VDC operating

+/-25 VDC absolute maximum

Transfer Rate: 9600 bps, 33%

duty cycle; 8 data bits, no

parity, 1 stop bit

+/-20 VDC absolute maximum

Transfer Rate: Selectable

9600, 19.2k, 38.4k, 57.6k,

115.2k bps, all at 33% duty

cycle; 8 data bits, no parity, 1

stop bit or configurable

See below

* 2.7 mA minimum required

under all operating conditions

with cable capacitance limited

to 1000pF (and practically

unlimited inrush current)

See above.

unlimited inrush current)

Average current approximates

(does not function as a

negative supply to unit)

that of a normal RS-232 load.

(Negative supply to unit)

MECHANICAL

3.86 in (98.0 mm) – Allow 0.30 in (7.6 mm) for cable thickness

and tie wrap at the rear of the unit

4.00 in (101.6 mm)

1.00 in (25.4 mm)

5

Page 14

Half Card Port Powered Insertion Reader

ENVIRONMENTAL

Temperature

Operating

Storage

Humidity

Operating

Storage

Printed Circuit Assembly

21067502 (discontinued)

o

F to 158oF (-20oC to 70oC)

4

o

F to 176oF (-40oC to 80oC)

-40

10% to 90% noncondensing

10% to 90% noncondensing

Printed Circuit Assembly

21067505 (new unit)

-40°F to 158°F (-40°C to 70°C)

o

F to 176oF (-40oC to 80oC)

-40

* The 2.7 mA figure is for continuous data transmission at 33% duty cycle while

reading a card. Typical capacitance from TXD is about 1000 pF for our standard 2 m

cable. Minimum DTR current ‘IT’ required for continuous transmission at 33% duty

cycle, while reading a card, with cable capacitance ‘C’ and arbitrary baud rate is

approximately:

IT = (2.5 mA) + (10 V) * 33% *(baud rate in Hz) / 2 * C.

Maximum transmission burst time ‘T’ at 33% duty cycle for RS-232 compatibility is

approximately:

T = (64 μF) * (5 V - 3.4 V) / (IT - IS), where IS is the current supplied by the DTR

line (T is unlimited for IS > IT)

A note about “port-powered” readers: These readers operate off some combination of otherwise

unused RS-232 lines, DTR and TXD from the host in this case. Per the RS-232 specification,

these lines are only required to drive a 3 kΩ load at +/-5 V. This is a current of merely 5 V / 3

kΩ=1.67 mA per line. All “port-powered” readers fundamentally require more current than 1.67

mA (consider that at least 1.67 mA must be supplied to a 3 kΩ load, and some extra current is

needed for the circuit that does so). Thus these readers are not technically guaranteed to work

unless multiple unused lines are used for power and/or some duty cycle limit is imposed on

transmitting while employing an energy storage device (a capacitor). In practice, however most

ports can easily supply the 2.7 mA at +5 V required by this new reader on DTR and the nearspecification average TXD (from host) current at -5 V. This new reader is MagTek’s lowest

current “port-powered” reader to date. Strictly speaking, some RS-232 ports may not supply the

required current, and this is the reason for including a current consumption specification for a

“port-powered” device. The current drive capability of an RS-232 port is not typically specified,

so experimentation may be required in a particular application. If more current is needed for the

positive supply, RTS may be paralleled with DTR (both host-referenced) in the cabling to the

unit. If this is done, the host must of course hold RTS high.

6

Page 15

Section 1. Features and Specifications

DIMENSIONS

The dimensions and tolerances for the Reader are shown in Figure 1-2.

1.000

± .015

0.75

± .01

3.740 ± .01

3.247 ± .015

2.135 +.003 –.001

4.000 ± .015

R .06 ±.01

(4 places)

Ø .140 ±.01

(2 places)

3.856 ± .015

.300

±.015

.75

±.015

.230

Ref.

4.000 ± .015

Figure 1-2. Half Card Reader Dimensions

7

Page 16

Half Card Port Powered Insertion Reader

8

Page 17

SECTION 2. INSTALLATION

This section describes Connectors, cabling information, mounting, and card orientation.

CONNECTORS

The connector pin list is shown in Table 2-1. The mating connector manufactured by Molex is

51021-0400. The Molex Terminal is 50058-8000.

Table 2-1. J1 Connector - RS232

PIN NUMBER SIGNAL (HOST AS REFERENCE)

J1-1 RXD (To PC)

J1-2 TXD (From PC)

J1-3 DTR (From PC)

J1-4 GND

All pins must be connected as shown.

PC Connector

The serial cable is shown in Figure 2-1. One end connects to J1 and the other end is a DE-9

female. The pin list for the cable connectors is shown in Table 2-2.

Table 2-2. P2 Connector and Cable

P2 SIGNAL COLOR P1

1 NC* -- -2 RXD YELLOW 1

3 TXD GREEN 2

4 DTR ORANGE 3

5 GND BROWN 4

6-9 NC* -- -*NC = No connection

All pins (except NC) must be connected as shown.

9

Page 18

Half Card Port Powered Insertion Reader

MOUNTING

Figure 2-1 shows the board layout orientation as viewed from the top. The Reader is attached to

the customer plate with two mounting screws. There are three levels on the front face: the

bracket with the mounting holes; the beveled race above the mounting bracket; and the card

guide brackets. The unit is mounted to the inside of the user’s surface. The mounting bracket is

not seen by the customer, and the beveled race and area above it and the card guide brackets are

visible to the customer.

Dimensions and tolerances are shown in Section 1, Figure 1-2.

Tie Wrap

Pin 1

J1

PCB

J4

Mounting

Hole

Pin 1

Pin 1

J3

PC Connector

Pin 5

Pin 9

Card With

Stripe Down

Pin 6

Pin 1

LED

Card Slot

Mounting

Hole

Read Head

Figure 2-1. Reader Layout - Top

For the LED shown in the illustration refer to Section 3, Table 3-2, for setting the color options.

10

Page 19

Section 2. Installation

Orientation

The Reader is mounted as oriented in Figure 2-1, or it may be rotated 90o counterclockwise from

that orientation. In the latter position, debris and foreign objects can clear the unit without

damaging head or card stop areas, shown in Figure 2-2.

Card Stop

Card-Seated Sensor

Beam-Mounted

Read Head

Figure 2-2. Reader Layout -Bottom

The Reader should be mounted only in the two orientations describe above, so that the magnetic

stripe is facing down and to the right or up and to the right

11

Page 20

Half Card Port Powered Insertion Reader

12

Page 21

SECTION 3. COMMANDS, FORMATS, TIMING

This section includes commands, message formats, and transmission timing.

The MagTek Device Drivers for Windows, part number 30037385, may be used with the Half

Card, Port Powered Insertion Reader. When these drivers are used, refer to MagTek Device

Driver for Windows, Programming Reference Manual, Part Number 99875125.

When power is applied, the Reader transmits a sign-on ID message. About 150 (500 for the new

reader) milliseconds after DTR is applied, the Reader sends the part number of the firmware in

the following form: 21088828A01 (21088842A01 for the new reader). The first 8 characters

indicate the firmware number; the letter is the revision, which is followed by a revision sublevel

of 01 to 99.

Since the input voltage is supplied by a relatively low source of power, the Reader depends on its

input capacitor to maintain proper charge during all operations. In order to reduce the drain on

this internal power source during data transmission, the output data is transmitted in 5 to 6

millisecond bursts with a 10-millisecond gap between bursts1 to allow the capacitor to recharge.

The PC software should be able to tolerate this 10-millisecond space between characters.

HOST TO READER COMMANDS

All commands transmitted from the Host to the Reader must be preceded by the ASCII

“ESCAPE” character (0x1B). These command messages may contain other framing characters

that are ignored by the Reader. Table 3-1 describes the commands and responses. Table 3-2 lists

setting and clearing options and the responses.

Table 3-1. Commands and Responses

HOST COMMANDS READER RESPONSES

COMMAND PREFIX USE EITHER CHARACTER

<ESC> (0X1B) I (0x49) + (0x2B) Inquiry command causes the Reader to

transmit data, error, or status message.

This command works in both the

buffered and unbuffered modes.

<ESC> (0X1B) R (0x52) - (0x2D) Release command causes the Reader

to clear its memory buffer of any data

present. This command works only in

the Buffered mode.

The Inquiry command (I/+) will transmit data after the card has been inserted even if not in the

buffered mode. This allows a card to remain in the slot during the transaction. If not in the

buffered mode, the card data will also be transmitted when the card is removed. (Refer to Tables

3-3 and 3-4 for examples.)

1

For the 21067505 printed circuit assembly, the transmission is strictly in 5 ms bursts with 10 ms between.

13

Page 22

Half Card Port Powered Insertion Reader

Table 3-2. Options and Reader Responses

COMMAND

PREFIX

<ESC> (0x1B) S (0x53) s (0x73) Send STX

<ESC> (0x1B) E (0x45) e (0x65) Send ETX

<ESC> (0x1B) C (0x43) c (0x63) Send CR

<ESC> (0x1B) P (0x50) p (0x70) Send ESC

<ESC> (0x1B) B (0x42) b (0x62) Buffered Mode

<ESC> (0x1B) G (0x47) - Green LED On, Red LED off

<ESC> (0x1B) L (0x4C) - Red LED On, Green LED off

<ESC> (0x1B) O (0x4F) Both LEDs Off (default)

<ESC> (0x1B) Q (0x51) q (0x71) Quiet Mode; Buffered Mode (reader

<ESC> (0x1B) V (0x56)

<ESC> (0x1B) X (0x58)

TO SET OPTION TO CLEAR OPTION

(DEFAULT)

- Version request. Same as the

New reader only

See the exit program

New reader only

mode command in the

program mode

command set section.

READER FUNCTION

does not send status)

program mode version request

command except the reader does

not send an ACK character in the

response.

Enter program mode. See program

mode section for a full description.

The device will only respond to the

program mode command set when

in program mode.

Note

If DTR is dropped and restored, the setup options are returned to

the default state. Some default states can be modified by the

program mode command set in the new reader. The LED is

controlled by the Host.

WATCHDOG LED

A watchdog LED provides a visual clue to service personnel that the Reader electronics are

operational. This LED is located on the PCB and is designated D1. If power is applied and the

CPU is in its normal idle loop, the LED will continually blink green, on for approximately one

second, off for one second. If an encoded card is withdrawn from the Reader at the beginning of

the on cycle, the LED should give an extra short blink. For the new reader, the watchdog LED

remains off when the dual color LED is on.

14

Page 23

Section 3. Commands, Formats, Timing

READER TO HOST FORMATS

The following diagram represents the format of the data transmitted to the Host:

STX ESC % Track 1 Data ? ; Track 2 Data ? Sensor CR ETX

Optional

Where optional characters

STX (0x02) = Start of text character

ESC (0x1B) = Escape character

CR (0x0D) = Carriage return character

ETX (0x03) = End of Text

are used to frame data.

These sentinel characters can be changed in the new reader by using the program mode

command set.

% = Start Sentinel Track 1

; = Start Sentinel Track 2

? = End Sentinel

The LRC character is not transmitted.

Track data may be represented as follows:

SS Track Data ES Card Sensor Status

Where

SS = Start Sentinel: "%" for Track 1; ";" for Track 2

Data = Track Data in track order that is, Track 1 then Track 2

ES = End Sentinel: "?"

Sensor = "0" no card in reader

"1" card present in reader (rear sensor blocked)

If there is an error in one of the tracks, the "Track Data" field will be replaced with "E" (0x45).

15

Page 24

Half Card Port Powered Insertion Reader

An example of a card insertion or removal is as follows when the Back Sensor is first blocked by

the card:

STX ESC 1 CR ETX

Optional

Where 1 indicates Sensor blocked; 0 indicates the sensor became unblocked.

The following is an example of a good read on withdrawal of a card:

STX ESC % Track 1 Data ? ; Track 2 Data ? 0 CR ETX

Optional

Where 0 indicates the sensor unblocked.

The following is an example of a bad read on Track 1 and a good read on Track 2 on withdrawal

of a card:

STX ESC % E ? ; Track 2 Data ? 0 CR ETX

Optional

Where

E (0x45) = Error

Track 2 Data = Good read Track 2 Data

0 = Sensor unblocked

16

Page 25

Section 3. Commands, Formats, Timing

TIMING FOR ID SIGN-ON AND TRANSMISSION BURSTS

Timing for the ID Sign-on and transmission bursts (5 ms with 10 ms between bursts) is shown in

Figure 3-1.

MCU*

150 ms (500 ms for the new reader)

Sign-on ID

Transmission

Burst

5 ms

10 ms

NOT TO SCALE

* Up to 1.5 seconds are required from DTR rising until the MCU comes out of reset.

Figure 3-1. Timing For ID Sign-on and Transmission Bursts.

The firmware controls the operation of ID Sign-on and Transmission bursts. The ID sign-on is

21088828A04 (21088842A01 in the new reader)

Where:

21088828 is the firmware part number,

A is the alpha revision, and

04 is the number sub-revision.

17

Page 26

Half Card Port Powered Insertion Reader

TRANSMISSIONS EXAMPLES

Table 3-3 shows transmission examples not in the buffered mode:

Table 3-3. Transmission Data Examples Not in Buffered Mode

Action Port Powered Insert Reader Data PC Data

Card Inserted 1 (0x31)

PC Sends Inquiry (if the application needs

data before card removed)

Bad read on insert so reader sends error

plus card status

Card removed %<track 1 data>?;<track 2 data>?0

Card Inserted 1 (0x31)

PC Sends Inquiry (if the application needs

data before card removed)

Sends card data plus card status; data

buffer is cleared

Card removed (card data is always

transmitted when the card is removed if not

in buffered mode)

Card Inserted 1 (0x31)

Card removed (card data is always

transmitted when the card is removed if not

in buffered mode)

<ESC> I

(0x1B, 0x49)

%E?;E?1 (0x25, 0x45, 0x3F, 0x3B,

0x45, 0x3F, 0x31)

<ESC> I

%<track 1 data>?;<track 2 data>?1

%<track 1 data>?;<track 2 data>?0

%<track 1 data>?;<track 2 data>?0

(0x1B, 0x49)

18

Page 27

Section 3. Commands, Formats, Timing

Table 3-4 shows transmission examples in the buffered mode with STX and ETX included:

Table 3-4. Transmission Data Examples in Buffered Mode With STX and ETX Included

Action Port Powered Insert Reader Data PC Data

PC Sets Buffered Mode <ESC>B

(0x1B, 0x42)

PC Sets STX <ESC>S

(0x1B, 0x53)

PC Sets ETX <ESC>E

(0x1B, 0x45)

Card Inserted <STX>1<ETX> (0x02, 0x31, 0x03)

PC Sends Inquiry <ESC>I

(0x1B, 0x49)

If bad read on insert, reader sends error

status

If good read on insert, sends card data <STX>%<track 1 data>?;<track 2

Card removed <STX>0<ETX> (0x02, 0x30, 0x03)

PC Sends Inquiry <ESC>I

Sends card data <STX>%<track 1 data>?;<track 2

PC Sends Inquiry <ESC>I

Sends card data (data remains in buffer

until a release command has been

received)

Buffer cleared (released) <ESC>R

PC Sends Inquiry <ESC>I

Sends status <STX>0<ETX> (0x02, 0x30, 0x03)

<STX>%E?;E?1<ETX>(0x02,0x25,

0x45,0x3F,0x3D,0x45,0x3F,0x31,0x03)

data>?1<ETX>

data>?0<ETX>

<STX>%<track 1 data>?;<trac k 2

data>?0<ETX>

(0x1B, 0x49)

(0x1B, 0x49)

(0x1B, 0x52)

(0x1B, 0x49)

19

Page 28

Half Card Port Powered Insertion Reader

PROGRAM MODE

The new reader has a number of non-volatile properties. Once these properties are changed and

saved in non-volatile memory, the changes will take affect after a power cycle or reset. These

properties are usually only modified once prior to installing the device. These properties can

only be modified when in program mode. See the enter program mode command in the regular

command set for a description of how to enter program mode. Once in program mode, the

reader will only respond to the program mode command set until the device is power cycled,

reset or the exit program mode command is received. This section describes the program mode

commands set.

Sending Program Mode Commands

The Reader will operate from 2400 to 115200 bps but each command sent to the Reader must

match the communication parameters of the Reader. The default communication parameters are

9600 bps with 8 bits, no parity and 1 stop bit (8N1). If the Reader fails to respond after a

command has been transmitted, the application should modify the transmission parameters until

a response is received.

Commands, as described below, must be preceded by an Escape (<ESC> – 0x1B) character and

be terminated by a Carriage Return (<CR> – 0x0D). All commands are case sensitive—that is,

they must all use upper case characters.

After a valid command has been received, the Reader will respond with an Acknowledge

(<ACK> – 0x06) within one character time. If a message is started but not completed within 2

seconds, a No-acknowledge (<NAK> – 0x15) will be transmitted; also, if the baud rate or other

communication settings are incorrect, the Reader will transmit a NAK using its current

communication parameters. An unrecognized command will also return a NAK.

20

Page 29

Section 3. Commands, Formats, Timing

PROGRAM MODE COMMAND SET

The reader must be in program mode for the device to respond to this command set.

Exit Program Mode

This command can be used to exit program mode; however changes made while in program

mode will not take affect unit the device is reset or power cycled:

<ESC>x<CR>

Once program mode is exited, the device will only respond to the regular command set and not

the program mode command set.

Reset Device

The Reader will always be reset when power (DTR) is applied (hardware reset). It can also be

reset programmatically with a Reset (RS) command. This command can be used after changing

the setting to activate the new values:

<ESC>RS<CR>

After sending the <ACK>, the Reader will perform a soft reset and, if the function is enabled

(SA-6), will transmit the sign-on ID message:

<ACK>21088842A01<CR>

Version Request

In order to determine which device is connected, the application can send a Version Request

(VR) command to the Reader:

<ESC>VR<CR>

The Reader will respond with an ACK and then will transmit the firmware part number and the

corresponding version in a format like this:

<ACK>21088838A00<CR> or

<ACK>21088842A01<CR> for the new reader

Upload Command

The Upload (UP) command is used to move any modified properties from temporary storage into

the flash memory. This only needs to be done once after all changes have been made.

This method of updating the programmable settings allows all parameters to be modified in

anticipation of the next reset. Thus, a series of switch commands (including the sentinel values

described below) can be sent to the Reader without affecting any operation. The set of

configuration commands should be followed by an Upload (UP) command to transfer all settings

21

Page 30

Half Card Port Powered Insertion Reader

into flash. Finally, the Reset (RS) command can be sent to validate that all changes have taken

place. After the RS command, any changes to communication parameters will be effective.

Configuration Commands

The configuration properties are stored in three separate bytes (referred to as switches). The

switch settings are modified with three separate commands, one for each switch. The switch

names, bits and corresponding properties are shown in the tables below.

The command to interrogate or modify a switch is of the form:

<ESC>Sn<CR>

where “n” is “A”, “B” or “C”.

For example, to interrogate the values of switch B, send the command:

<ESC>SB<CR>

The response will look like this:

<ACK><ESC>SB00000001<CR>

Note that changes made to the switch settings with the switch commands can not be read back

until they are activated. Also note that certain volatile commands from the regular command set

affect the active switch settings. For example, the <ESC> S and <ESC> s commands affect the

value read back from the <ESC>SB<CR> command in byte position 1.

In order to change any switch settings, send a command like this:

<ESC>SA11100010<CR>

which will set switch A to the default value. The Reader will respond with an ACK if the

command is formatted properly. The change in settings will NOT take place until after the

Upload and Reset commands have been sent:

<ESC>UP<CR>

<ESC>RS<CR>

The Upload (UP) command moves the new setting(s) into flash memory. The new setting(s),

however, will not be used until the device has been reset—either with a power reset or with the

soft Reset (RS) command.

22

Page 31

Section 3. Commands, Formats, Timing

Switch A

Switch A, Table 3-5, is primarily used to define the communication settings. The default for

Switch A is:

11100010 9600, no parity, 8 bits, send ID at power on, transmit SS & ES

Table 3-5. Switch A

Command position

Byte Position

1 2 345678

7 6 5 4 3 2 1 0 Description

Baud rate 2400 (This setting may

draw too much power from the host

000

001

0 1 0 Baud rate 9600

0 1 1 Baud rate 14400

1 0 0 Baud rate 19200

1 0 1 Baud rate 38400

1 1 0 Baud rate 57600

111

0 0 No parity

0 1 Even parity

1 0 Odd parity

1 1 Mark (Parity = 1 all the time)

0 7 bits data length

1 8 bits data length

0 Send ID at power on: No

1 Send ID at power on: Yes

0 Transmit SS and ES: No

1 Transmit SS and ES: Yes

so it should be avoided if possible.)

Baud rate 4800 (This setting may

draw too much power from the host

so it should be avoided if possible.)

Baud rate 115200 (If the device is

put into this setting, it will no longer

be able to receive commands

unless the characters sent to the

device are spaced apart such that

there is at least 100µs of idle time

between each character. For this

reason, this setting should be

avoided if possible.)

23

Page 32

Half Card Port Powered Insertion Reader

Switch B

Switch B, Table 3-6, is used to define the bracketing characters that are used in the messages.

The default for Switch B is:

00000000 Don’t send CR, STX, ETX, ESC, LRC

Table 3-6. Switch B

Command position

Byte Position

1 2 3 4 5 6 7 8

7 6 5 4 3 2 1 0 Description

0 Send CR after messages: No

1 Send CR after messages : Yes

0 Send STX before data: No

1 Send STX before data: Yes

0 Send ETX before data: No

1 Send ETX before data: Yes

0 Send ESC before data: No

1 Send ESC before data: Yes

0 Send LRC with track data: No

1 Send LRC with track data: Yes

X Reserved

X Reserved

X Reserved

24

Page 33

Section 3. Commands, Formats, Timing

Switch C

Switch C, Table 3-7, is used to define the way a card is read. The default for Switch C is:

00010101 Enable (but don’t require) tracks 1, 2 & 3; decode ISO/ABA tracks only

Table 3-7. Switch C

Command position

Byte Position

1 2 3 4 5 6 7 8

7 6 5 4 3 2 1 0 Description

0 0 Track 1 Disabled

0 1 Track 1 Enabled

1 1 Track 1 is required*

0 0 Track 2 Disabled

0 1 Track 2 Enabled

1 1 Track 2 is required*

0 0 Track 3 Disabled

0 1 Track 3 Enabled

1 1 Track 3 is required*

0 Decode ISO/ABA tracks only

1 Decode ISO/ABA & custom tracks

X Reserved

* If a track is required but does not exist, the Reader will indicate an error for that track.

25

Page 34

Half Card Port Powered Insertion Reader

Sentinel Definitions

The start and end sentinels values can individually be specified by commands. The default

settings are shown in the Table 3-8.

Note

Changing the value of any of the sentinels does not actually

change the encoded value on the magnetic track; it merely

represents the sentinel in a unique way to help distinguish

differently formatted tracks.

Table 3-8. Start and End Sentinels

Value

Name

S1 25

S2 3B

S3 2B

S4 40

S5 26

S6 23

SE 3F

Default

(hex)

Default

(ASCII)

%

;

+

@

&

#

?

Definition

Start Sentinel ISO/ABA Track 1

Start Sentinel ISO/ABA Track 2

Start Sentinel ISO/ABA Track 3

SS Non-standard (7bits) Track 2

SS Non-standard (7bits) Track 3

SS AAMVA track 3

End Sentinel for all tracks all type

As with the switch settings, the sentinel parameters can be discovered by sending the

corresponding command for that value immediately followed by a CR. For instance, in order to

determine the present setting of the 7-bit track 3 start sentinel, send the following command:

<ESC>S5<CR>

The Reader will respond with the value, in nibbles:

<ACK><ESC>S526<CR>

Any ASCII character from 0x00 to 0x7F can be used as a sentinel. To change the value of the 7bit track 3 start sentinel to “!” (0x21), send the following command:

<ESC>S521<CR>

Again, as with the switch commands described above, send the Upload (UP) command followed

by the Reset (RS) command to complete the transaction.

26

Loading...

Loading...