Page 1

ExpressCard 2000

Instant Issuance Card Personalization System

Hardware Service Manual

June 2014

Manual Part Number:

99875607-4.01

REGISTERED TO ISO 9001:2008

MagTek I 1710 Apollo Court I Seal Beach, CA 90740 I Phone: (562) 546-6400 I Technical Support: (888) 624-8350

www.magtek.com

Page 2

Copyright © 2006 - 2014 MagTek, Inc.

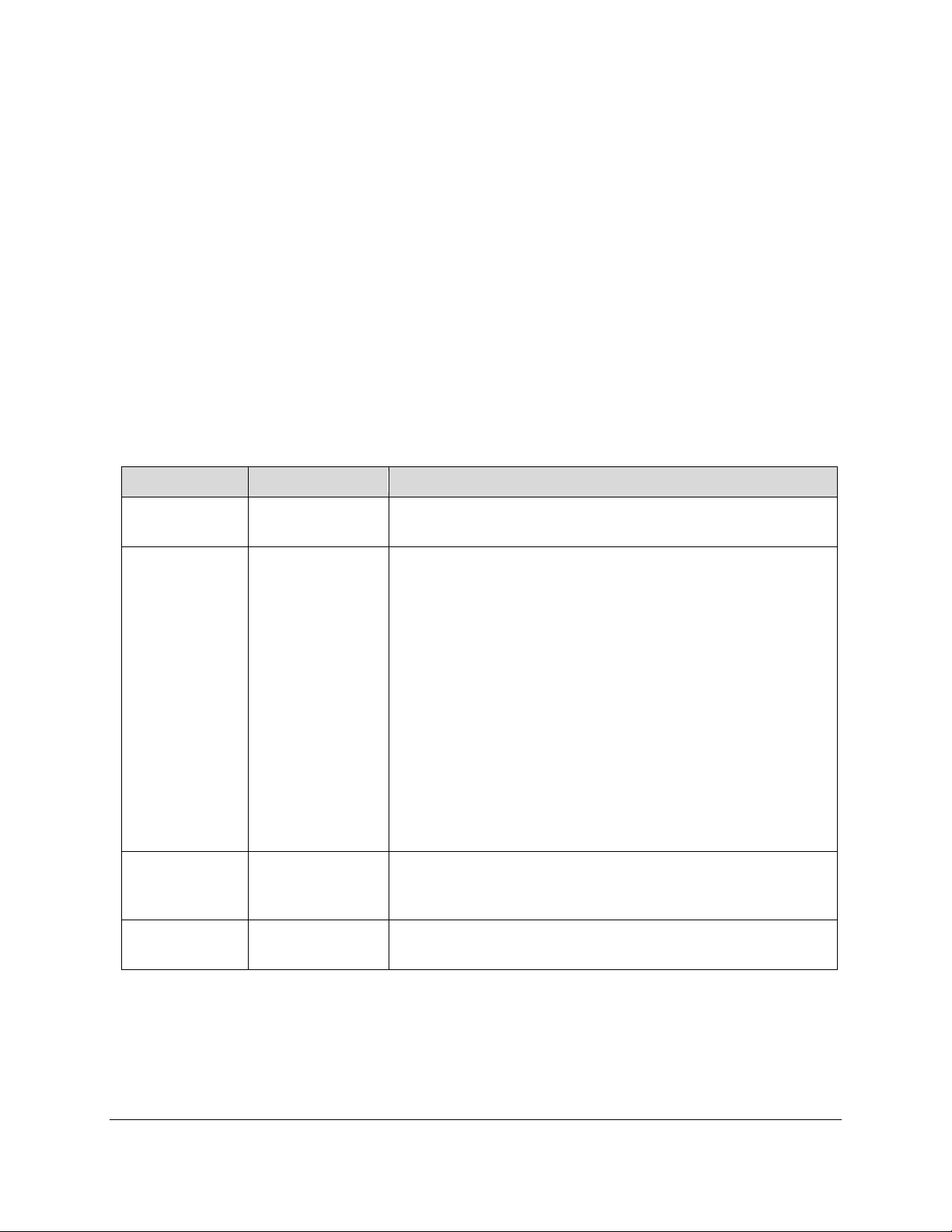

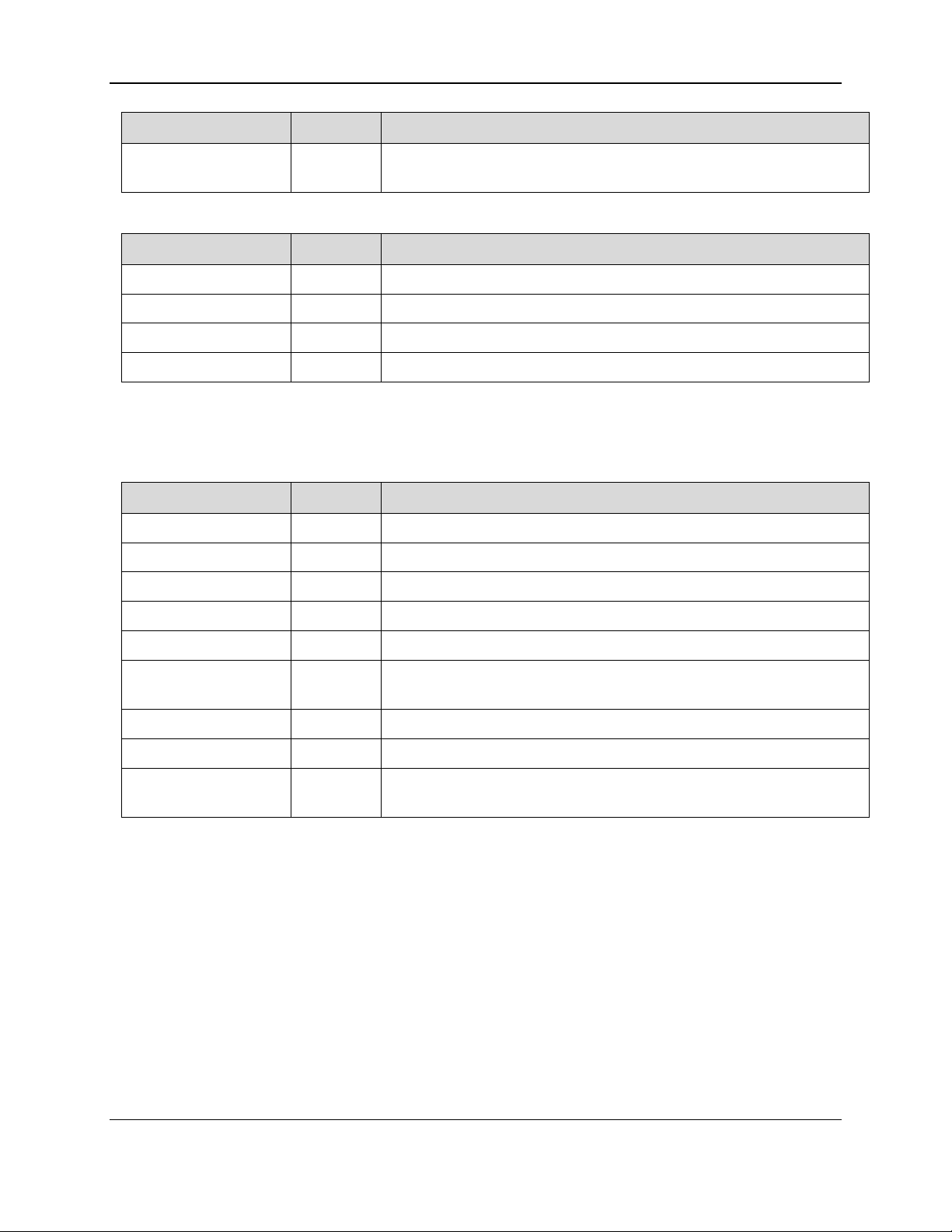

Rev Number

Date

Notes

1.01

12/11/2013

Initial release derived from 99875357-6.01, 33099078-2.01,

99875617-1.01, MagTek Support Services videos

2.01

01/14/2014

Add removal / replacement for tipper heater, hopper module,

exit transport module, exit ramp and tipper module, MLB,

power controller, embedded PC, power supply, MSR,

touchscreen. Update some figures with improved renderings.

Add orientation to cardinal directions. Incorporate warnings

and re-order to support tipper cooling time. Re-order

Replacement and Adjustments chapters for more logical crossreferences. Improve cover removal/re-install instructions.

Add time estimates for replacements. Make terminology and

order of steps more consistent. Start section for

troubleshooting service-only issues. Add introduction to

embosser alignment. Update cleaning photos. Add sensor

diagram. Improve content about security of consumables. Fix

image printer replacement structure. Add details about top

deck plate keys / slots.

3.01

05/05/2014

Fix minor formatting issues; add step to move hopper

transport before removing side access doors; add advisory to

not pinch wires when removing left side access door.

4.01

06/27/2014

Update troubleshooting information about uneven tipping;

general updates to tipper heater replacement.

Printed in the United States of America

Information in this publication is subject to change without notice and may contain technical inaccuracies

or graphical discrepancies. Changes or improvements made to this product will be updated in the next

publication release. No part of this document may be reproduced or transmitted in any form or by any

means, electronic or mechanical, for any purpose, without the express written permission of MagTek, Inc.

MagTek® is a registered trademark of MagTek, Inc.

MagnePrint® is a registered trademark of MagTek, Inc.

Magensa™ is a trademark of MagTek, Inc.

MagneSafe™ is a trademark of MagTek, Inc.

ExpressCard 2000 is a trademark of MagTek, Inc.

Microsoft® and Windows® are registered trademarks of Microsoft Corporation.

All other system names and product names are the property of their respective owners.

Table 0.1 - Revisions

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 2

Page 3

SAFETY

This product has been evaluated by multiple safety certification agencies, including

Underwriters Laboratories (UL) and the United States Federal Communications

Commission (FCC Class A and Class B), and is designed to protect both the user and the

device. This document is written specifically to work in conjunction with these safety and

integrity features to protect the user and the device. It is very important to follow all steps

in the product documentation carefully, in the order in which they are described, and at

the recommended times. Failure to do so could result in personal injury, and / or cause

damage to the device, and / or void the product warranty.

The information within this manual has been prepared for use by trained professional

service personnel and is not intended for general use. To maintain the safety and integrity

of the machine, follow the procedures described in this manual carefully.

For your personal safety and to prevent damage to the device, disconnect power from the

device before you connect or disconnect any cable, electronic board, or assembly.

SAFETY REQUIREMENTS

Caution: Never do any of the following:

DO NOT use a ground adapter plug to connect equipment to a power socket-outlet that lacks a ground

connection terminal.

DO NOT attempt any maintenance function that is not specifically described in this manual or in

other ExpressCard 2000 instructional documents published by MagTek.

DO NOT override or “cheat” electrical or mechanical interlock devices.

DO NOT use EC2000 supplies or cleaning materials for other than their intended purposes.

DO NOT operate the equipment if you or anyone else have noticed unusual noises or odors.

Consider the following before operating the ExpressCard 2000:

Connect the EC2000 to a properly grounded AC power socket-outlet. If in doubt, have the socket-

outlet checked by a qualified electrician. Improper connection of the device’s grounding conductor

creates a risk of electric shock.

Place the EC2000 on a solid surface that can safely support the device’s weight support the weight of

the EC2000 PLUS the weight of a person leaning against the device (such as a service technician).

Be careful when moving or relocating the device. Use proper lifting techniques.

Use materials and supplies specifically designed for MagTek devices. Using unsuitable materials

may result in poor performance, and in some cases may be hazardous.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 3

Page 4

0 - Table of Contents

Table of Contents

Table of Contents ............................................................................................................................... 4

1 Required Tools, Materials, and Documents ........................................................................... 7

1.1 Required Tools ..................................................................................................................... 7

1.2 Suggested Tools .................................................................................................................. 7

1.3 Required Materials ............................................................................................................. 7

1.4 Suggested Materials ........................................................................................................... 8

1.5 Required Software and Documents ................................................................................. 8

2 Introduction ................................................................................................................................. 9

2.1 Recommended Preparation for Service Appointments ................................................ 9

2.2 Important Safety Information ........................................................................................... 9

2.3 How to Handle ESD-Sensitive Parts ................................................................................. 9

2.4 Introduction to EC2000 Components ............................................................................ 10

2.5 Device Specifications ....................................................................................................... 10

2.6 About Installation & Operation ....................................................................................... 11

2.7 How to Open the Top Access Door ................................................................................. 11

2.8 How to Safely Move Transports By Hand ...................................................................... 11

2.9 How to Use Maintenance Functions On the Touchscreen .......................................... 12

3 Preventive Maintenance .......................................................................................................... 23

3.1 Prepare the Device for Preventive Maintenance ......................................................... 25

3.2 Clean the Card Path .......................................................................................................... 25

3.3 Clean All Transport Rollers .............................................................................................. 25

3.4 Update the Software ......................................................................................................... 28

3.5 Update the Firmware ........................................................................................................ 29

3.6 Service the Hopper Module ............................................................................................. 33

3.7 Service the XY Transport Module ................................................................................... 34

3.8 Service the Exit Transport Module .................................................................................. 36

3.9 Cool the Tipper Heater / Power Down the Device ....................................................... 36

3.10 Clean Inside the Device ................................................................................................ 37

3.11 Service the Image Printer Module .............................................................................. 38

3.12 Service the Embosser Module ..................................................................................... 39

3.13 Service the Electronics ................................................................................................. 42

3.14 Service the Cover ........................................................................................................... 42

3.15 Perform Final Tests ....................................................................................................... 42

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 4

Page 5

0 - Table of Contents

4 Removal and Re-installation .................................................................................................. 43

4.1 How to Prepare the Device for Removing / Re-installing Modules ........................... 43

4.2 How to Remove / Re-install the Top Access Door ....................................................... 44

4.3 How to Remove / Re-install the Side Access Doors .................................................... 48

4.4 How to Remove / Re-install the Cover .......................................................................... 50

4.5 How to Remove / Re-install the Hopper Module ......................................................... 63

4.6 How to Remove / Re-install the Image Print Head ..................................................... 76

4.7 How to Remove / Re-install the Image Printer Module .............................................. 77

4.8 How to Remove / Re-install the XY Transport Ribbon Cable ..................................... 82

4.9 How to Remove / Re-install the XY Transport Module................................................ 88

4.10 How to Remove / Re-install Embosser Fonts ........................................................... 93

4.11 How to Remove / Re-install the Embosser Module ................................................. 94

4.12 How to Remove / Re-install the Tipper Heater.......................................................101

4.13 How to Remove / Re-install the Tipper and Exit Ramp Module ..........................106

4.14 How to Remove / Re-install the Exit Transport Module ........................................111

4.15 How to Remove / Re-install the Embedded PC......................................................113

4.16 How to Remove / Re-install the Embedded PC Solid State Drive (SSD) ............119

4.17 How to Remove / Re-install the Main Logic Board (MLB) ....................................122

4.18 How to Remove / Re-install the Power Controller and Backplane .....................125

4.19 How to Remove / Re-install the Power Supply ......................................................131

4.20 How to Remove / Re-install the Magnetic Stripe Reader (MSR) Module ..........136

4.21 How to Remove / Re-install the Touchscreen ........................................................138

5 Adjustments ............................................................................................................................141

5.1 How to Calibrate the Touchscreen ...............................................................................141

5.2 How to Calibrate the Hopper Transport Module .........................................................143

5.3 How to Calibrate the XY Transport Module .................................................................145

5.4 How to Calibrate the Embosser Module ......................................................................147

5.5 How to Calibrate the Indenter Module .........................................................................164

5.6 How to Calibrate the Image Printer Module ...............................................................167

5.7 How to Minimize Image Printer Margins .....................................................................172

5.8 How to Calibrate the Tipper Module ............................................................................175

6 Diagnosis .................................................................................................................................178

6.1 Known Symptoms and Possible Causes .....................................................................178

Appendix A Technical Support ................................................................................................179

Appendix B Glossary .................................................................................................................179

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 5

Page 6

1 - Table of Contents

Appendix C Key Loading ..........................................................................................................180

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 6

Page 7

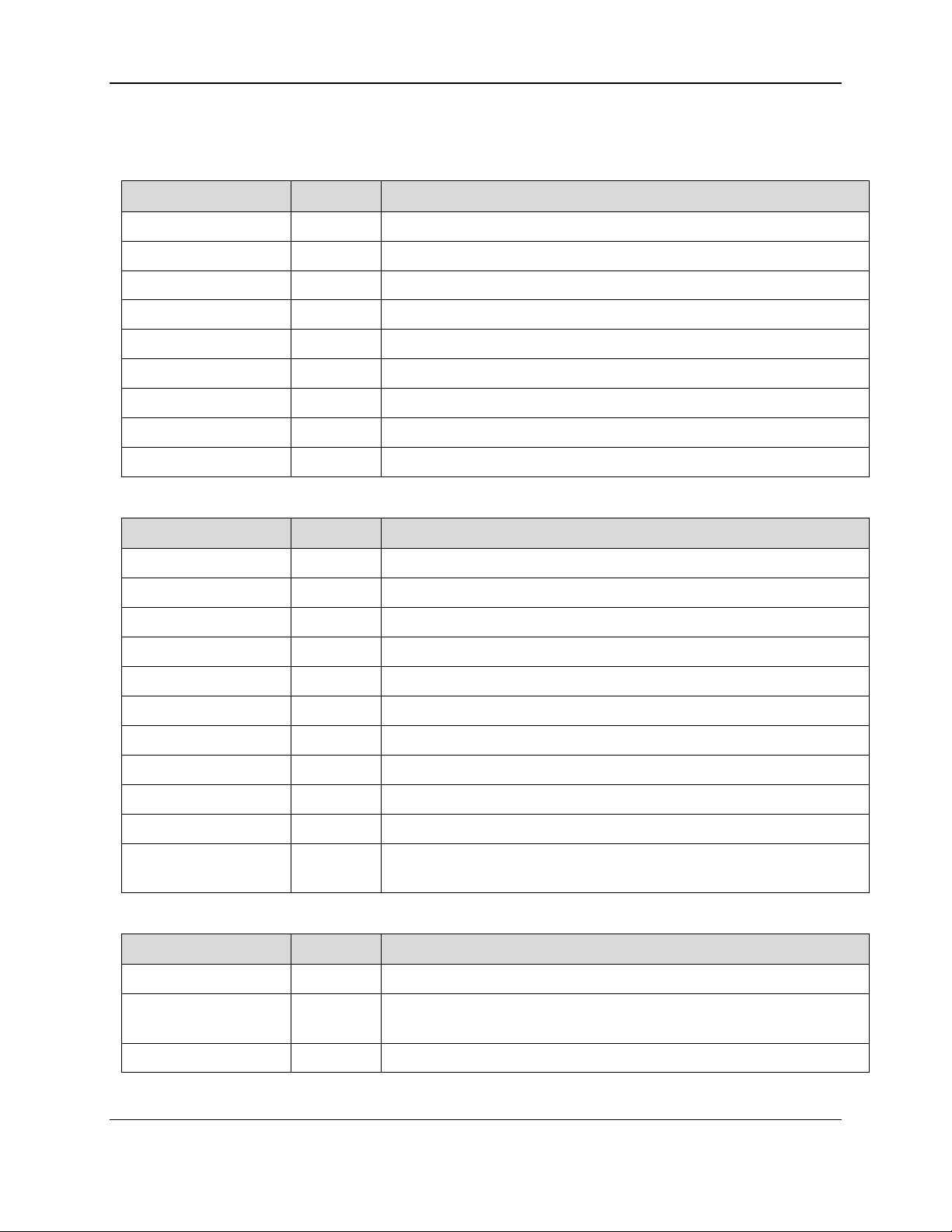

1 - Required Tools, Materials, and Documents

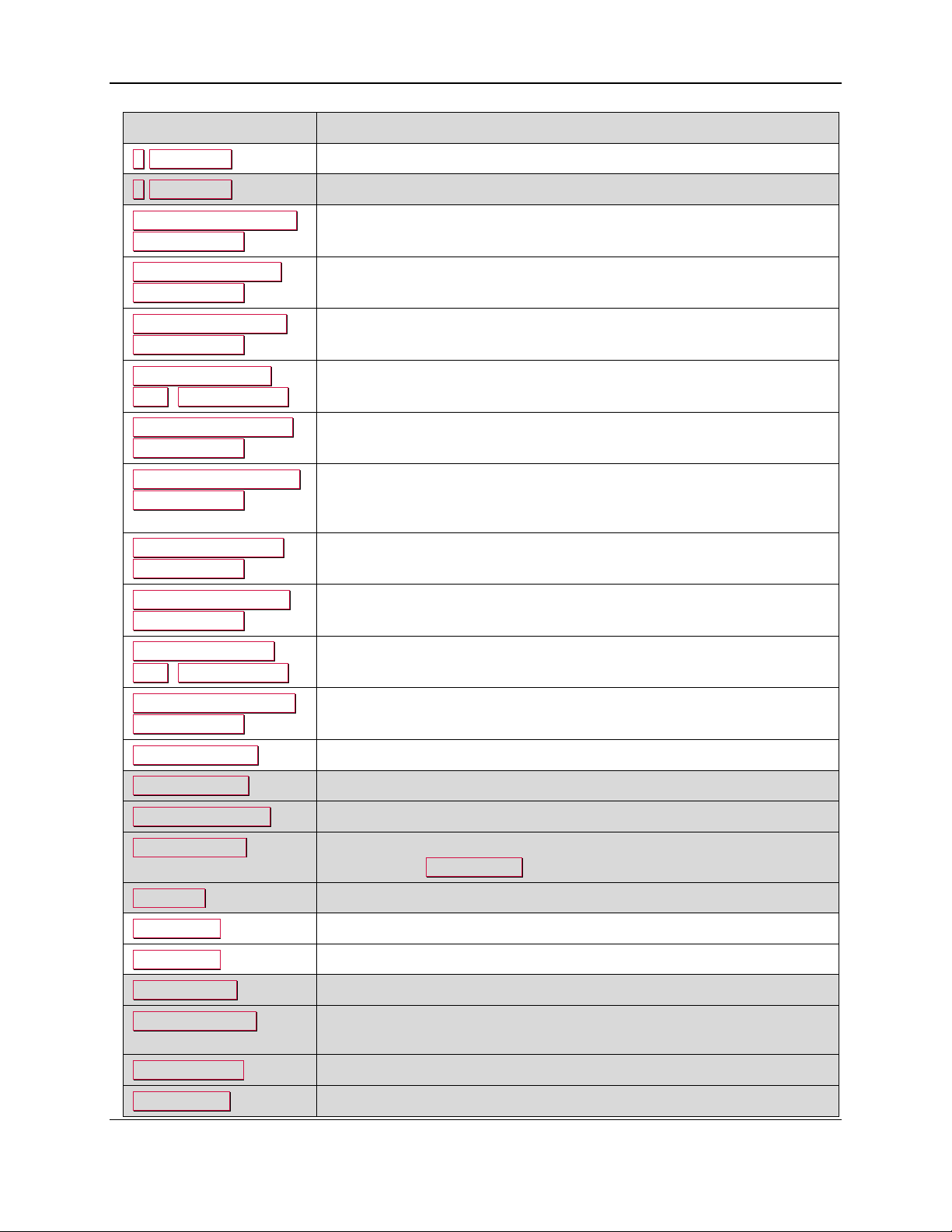

Part Number

Quantity

Description

33011008

1 ea.

ASM TOOL KIT,FIELD SERVICE,EC2000

67800019 or equiv.

1 ea.

Small USB keyboard with touchpad mouse

N/A

1 ea.

Small diagonal side cutters

N/A

1 ea.

X-Acto knife (if removing embosser characters)

N/A

1 ea.

Micrometer or digital calipers (if calibrating embosser)

N/A

1 ea.

ESD grounding wrist strap

N/A

1 ea.

ESD mat and/or ESD bags

N/A

1 ea.

USB thumb drive with required software and documentation

N/A

1 ea.

Thin-tipped permanent marker

Part Number

Quantity

Description

N/A

1 ea.

Laptop with available Ethernet port

22350302 or equiv.

1 ea.

10 ft. Ethernet cable (COM ETHERNET CAT5E BLK 10')

N/A

1 ea.

Pen or pencil

N/A

1 ea.

Paper and clipboard

N/A

1 ea.

Flashlight

N/A

1 ea.

Needle nose pliers

N/A

1 ea.

Hemostat pliers

N/A

1 ea.

Slotted screwdriver

N/A

1 ea.

Cable tie tool with adjustable tension

N/A

1 ea.

Multimeter

N/A

1 ea.

Flex Phillips screwdriver OR

Electric screwdriver with flex extension

Part Number

Quantity

Description

97200153

1 ea.

ASM KIT,PREVENTIVE MAINTENANCE,EC2000

N/A

1 ea.

Any replacement kits specified in the work order. For a list of kits,

see 33011011 REF LIST,REPLACEMENT KITS,EC2000

N/A

3 ea.

Cloth, clean and lint-free

1 Required Tools, Materials, and Documents

1.1 Required Tools

1.2 Suggested Tools

1.3 Required Materials

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 7

Page 8

1 - Required Tools, Materials, and Documents

Part Number

Quantity

Description

97200121 or equiv.

~10ml

MSP ADHESIVE,RTV SILICONE,90ML,CLEAR

If removing image printer, touchscreen, embedded PC, or MSR

Part Number

Quantity

Description

33011009

1 ea.

ASM KIT,STARTER,SPARE,FIELD SERVICE,EC2000

93400047

1 ea.

PRI RIBBON, COLOR YMCKOK EV (R3314)

33070896

1 ea.

ASM RIBBON ASSY,TIP FOIL,SILVER

33070621

1 ea.

AAY ASSY,INDENT CARTRIDGE

Part Number

Quantity

Description

99875600

1 ea.

MNL USER INSTALL & OPERATION MANUAL,EC2000

99875607

1 ea.

MNL HARDWARE SERVICE MANUAL,EC2000

99875609

1 ea.

MNL PARTS CATALOG,EC2000

99875651

1 ea.

REF PROCEDURE,PREVENTIVE MAINTENANCE,EC2000

99875646

1 ea.

REF CHECKLIST,PREVENTIVE MAINTENANCE,EC2000

N/A

1 ea.

EC2000 reference image (C:\ from a working EC2000), loaded onto

USB thumb drive or service laptop

N/A

1 ea.

Set of passwords for the device being serviced

N/A

1 ea.

Factory defaults for the device being serviced

VARIOUS

0 or more

EC2000 software patch .CAB files provided by MagTek Support

Services, loaded onto USB thumb drive or service laptop

1.4 Suggested Materials

1.5 Required Software and Documents

MagTek recommends loading the following required software and documents on the USB thumb drive or

service laptop before visiting the customer site.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 8

Page 9

2 - Introduction

2 Introduction

This document provides detailed information about maintaining the ExpressCard 2000 (EC2000). It is

part of the ExpressCard 2000 Service Library, which includes:

99875600 ExpressCard 2000 User Installation and Operation Manual

99875607 ExpressCard 2000 Hardware Service Manual

99875609 ExpressCard 2000 Parts Catalog

Documents in the service library reference each other frequently and are designed to be used together.

2.1 Recommended Preparation for Service Appointments

Before visiting a customer for a service appointment, MagTek recommends you do the following:

1) Review the documentation. For example:

a) 99875600 ExpressCard 2000 User Installation and Operation Manual contains important

information about the device, including Introduction to EC2000 Features, Introduction to

EC2000 Components, Operation, Maintenance, and Troubleshooting.

b) Section 2 Introduction, especially section 2.2 Important Safety Information and section 2.3

How to Handle ESD-Sensitive Parts.

c) All sections relevant to the service you will be performing. Depending on the service order, it

may include section 3 Preventive Maintenance, section 6 Diagnosis, section 5 Adjustments,

and section 4 Removal and Re-installation.

2) Gather and test/inspect all tools, materials, and documents, using section 1 Required Tools,

Materials, and Documents as a guide. If you are performing replacements, also gather and inspect

available replacement parts.

3) Copy software and documents you will need to a USB thumb drive.

4) Print any supporting documents you want to have available in hardcopy form.

5) Print a copy of 99875646 REF EC2000 PREVENTIVE MAINTENANCE CHECKLIST.

6) Test the field service laptop to make sure its browser and network connection are functional.

2.2 Important Safety Information

The information in this document is intended for use by trained professional service personnel only. It is

not intended for general use. To maintain the safety and integrity of the device, it is important to follow

the procedures laid out in this manual.

CAUTION: For your personal safety, and to prevent damage to the device, disconnect

power from the ExpressCard 2000 before you connect or disconnect any cable, electronic

board, or assembly.

2.3 How to Handle ESD-Sensitive Parts

To prevent electrostatic discharge (ESD) damage to electronic parts, follow the instructions below:

Keep ESD-sensitive parts in their original shipping containers until you are ready to install them.

When handling ESD sensitive parts, prevent static discharge by moving around as little as possible.

Static charges are produced by rubbing together clothing, carpets, furniture, etc.

Wear an ESD wrist strap connected to a metal part on the device’s chassis, such as the base plate.

This will discharge static electricity from your body.

Hold ESD-sensitive parts by their edges or their mounting trays. Do not touch their pins or circuitry.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 9

Page 10

2 - Introduction

Do not place an ESD-sensitive part on the device or on a metal table; put it in an ESD bag or on an

ESD mat.

Use extra caution when working under climate conditions that increase the potential for ESD, such as

cold weather or low humidity.

2.4 Introduction to EC2000 Components

For an introduction to identifying the components of the EC2000, see 99875600 EC2000 User

Installation and Operation Manual.

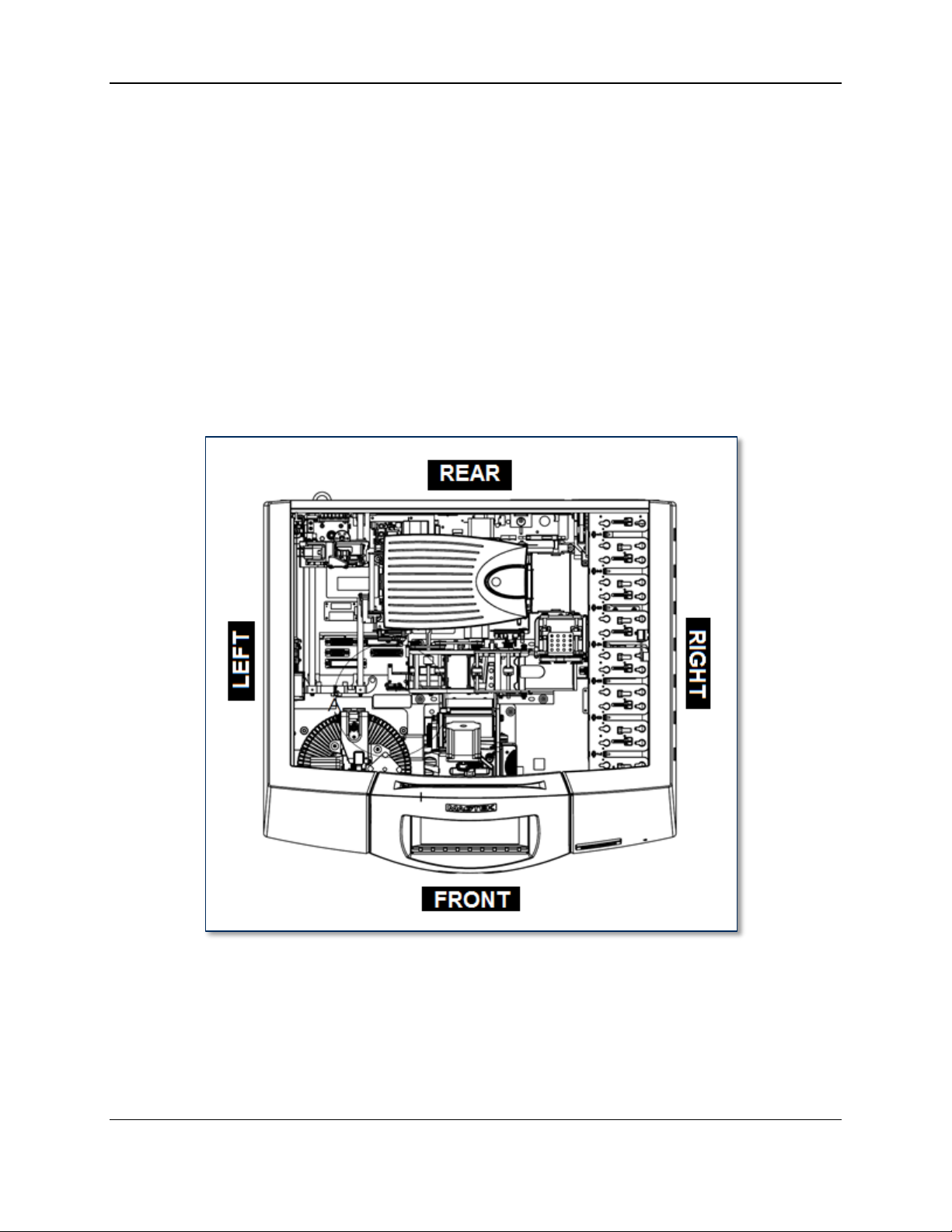

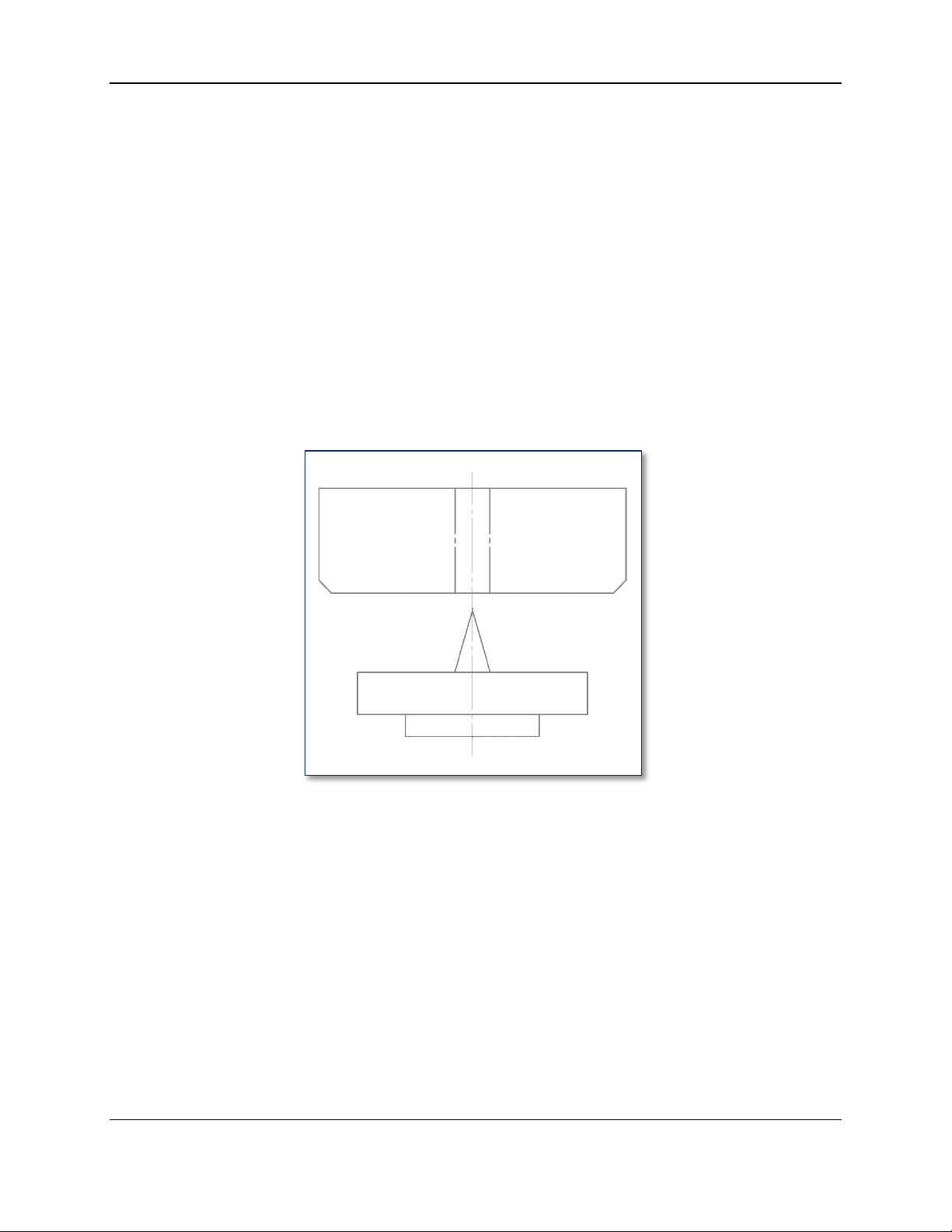

This manual uses the words “Front,” “Rear,” “Left,” and “Right” to describe where to find various parts

of the device. These terms assume the reader is standing in front of the device facing the touchscreen,

and are shown in Figure 2-1. During service, it is normal to move around the device to get easier access

to parts. In the same way, many of the photos and drawings in this manual show the device from different

angles that make key “landmarks” visible. In these cases, the caption will generally state the direction the

figure can be seen from (for example, “FRONT RIGHT VIEW”).

Figure 2-1 – Front/Rear/Left/Right Definition (TOP VIEW)

2.5 Device Specifications

For Electrical, Acoustical, Environmental, Communication, Physical, Encoding, and other detailed

specifications of the EC2000, see 99875600 EC2000 User Installation and Operation Manual.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 10

Page 11

2 - Introduction

2.6 About Installation & Operation

For detailed instructions about planning, installation, operation, and basic maintenance, see 99875600

EC2000 User Installation and Operation Manual.

2.7 How to Open the Top Access Door

For instructions to open the top access door, see 99875600 EC2000 User Installation and Operation

Manual.

Some procedures require removing the top access door completely. For removal instructions, see section

4.2 How to Remove / Re-install the Top Access Door.

2.8 How to Safely Move Transports By Hand

Although the MCP Commands page is the safest way to move parts within the EC2000 (see section

2.9.1 How to Use the MCP Commands Page), occasionally it is necessary to move parts by hand. To

prevent injury or damage to the device, follow these guidelines:

If you need to move the hopper transport or XY transport by hand, pull only on their serrated drive

belts as shown in Figure 2-2. This reduces the risk of damaging the transport.

If you need to move the XY transport along its tracks, gently pull the carriage to the left side of the

device before moving so it won’t catch on the image printer.

Figure 2-2 - Move Transports By Pulling Drive Belts

You can rotate the rollers on all transports by hand to push/pull cards to where they can be removed.

If a card is stuck in the hopper transport but has not yet gone into the image printer, one easy way to

remove the card is to remove one or two hoppers next to the hopper transport, then pull on its

triangular belt to move the card toward the hopper deck.

If a hopper transport has moved a card mostly into the image printer but the card has become stuck,

remove the card forward through the image printer (toward the XY transport). Do not try to reverse

cards from the image printer into the hopper transport.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 11

Page 12

2 - Introduction

Press This Button

Verify This Happens

Pusher Home

Hopper transport’s pusher moves into safe position for move

8 To Hopper

Hopper transport moves to (or stays at) manual feed slot, slot light

flashes

7 To Hopper

Hopper transport moves to (or stays at) hopper 1, slot light stops flashing

6 To Hopper

Hopper transport moves to (or stays at) hopper 1

5 To Hopper

Hopper transport moves to (or stays at) hopper 1

To Manual Feed

Hopper transport moves to (or stays at) manual feed slot, slot light

flashes

4 To Hopper

Hopper transport moves to (or stays at) hopper 1

3 To Hopper

Hopper transport moves to (or stays at) hopper 1

Shuttle Home

Hopper transport moves near hopper 1

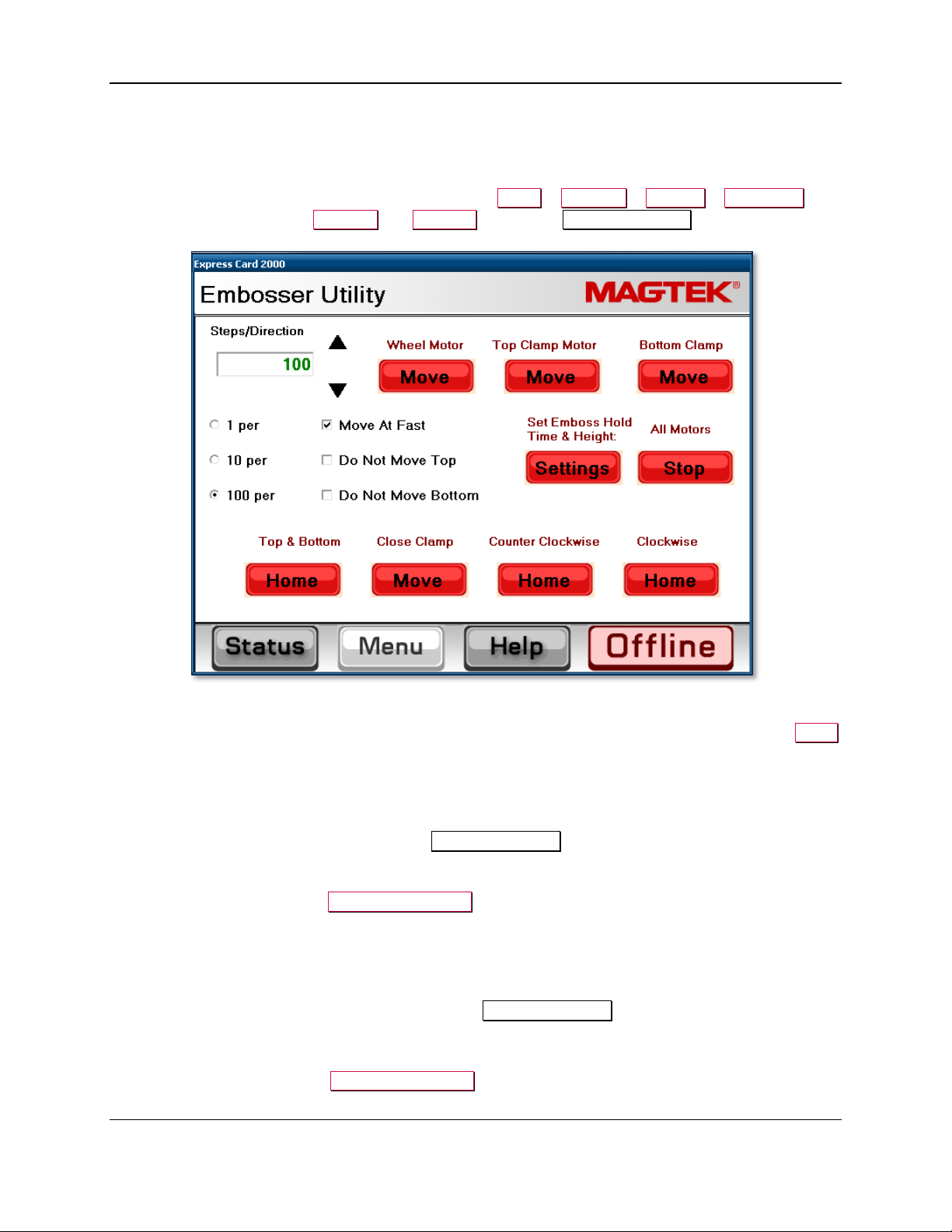

2.9 How to Use Maintenance Functions On the Touchscreen

This section explains how to use the maintenance functions on the EC2000’s touchscreen. Most of the

functions let you isolate the various subsystems during troubleshooting to determine the failure point, and

to verify repairs have corrected the problem.

To visually inspect the device while it is running, open the top access door and block the sensor mounted

to the rear left of the top access door track. For convenience, 33011008 ASM TOOL KIT,FIELD

SERVICE,EC2000 provides heat shrink tubing that fits snugly over the top access door sensor. Be sure

to put it back in your toolkit before closing the top access door.

To access most maintenance functions of the device using the touchscreen, do the following:

1) Press the Menu button to open the Main Menu page.

2) Press the Settings button to open the Settings Menu page. The Settings Menu page provides

access to user and service functions of the device, some of which require a password. If customers

have changed the passwords, request the new passwords from them. Otherwise the passwords will be

the factory defaults provided in the sections below.

3) Additional maintenance functions can be accessed from the Settings Menu page by pressing the

Service button to open the Service Menu page. For example, you can use the Sensor Utility page

to view the status of the EC2000’s sensors, or use the MCP Commands page to move the various

parts of the EC2000 individually rather than as part of a standard sequence.

2.9.1 How to Use the MCP Commands Page

The move the various parts of the EC2000 individually rather than as part of a standard sequence, use the

touchscreen to navigate to Menu > Settings > Service > MCP Commands to open the MCP

Commands page. Note that the MCP Commands page may allow you to make moves that could

damage the device -- think carefully before sending a direct move command!

Table 2.1 provides an MCP Commands sequence that tests most subsystems by moving a card from

hopper 1 to the output bin. You can test by pressing each button in the list and verifying the described

action happens correctly. The gray highlighted lines make up a shorter sequence that does the same thing.

Table 2.1 - Controller Buttons and Corresponding Movements

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 12

Page 13

2 - Introduction

Press This Button

Verify This Happens

2 To Hopper

Hopper transport moves to (or stays at) hopper 1

1 To Hopper

Hopper transport moves to (or stays at) hopper 1

Bot Cartridge Unload,

Indenter Move

Rear (black) indent cartridge moves out of embosser toward rear of

device

Bot Cartridge Load,

Indenter Move

Rear (black) indent cartridge moves back into embosser

Bot Cartridge Home,

Indenter Move

Rear (black) indent cartridge moves back into (or stays in) embosser

Bot Cart to Indent

Loc., Indenter Move

Rear (black) indent cartridge moves between letters on embosser wheel

Bot Ribbon Advance,

Indenter Move

Ribbon in rear (black) indent cartridge advances by about ¼”

Top Cartridge Unload,

Indenter Move

Only if testing EC2000 with Front Indenter installed:

Front (white) indent cartridge moves out of embosser toward rear of

device

Top Cartridge Load,

Indenter Move

Only if testing EC2000 with Front Indenter installed:

Front (white) indent cartridge moves back into embosser

Top Cartridge Home,

Indenter Move

Only if testing EC2000 with Front Indenter installed:

Front (white) indent cartridge moves back into (or stays in) embosser

Top Cart to Indent

Loc., Indenter Move

Only if testing EC2000 with Front Indenter installed:

Front (white) indent cartridge moves between letters on embosser wheel

Top Ribbon Advance,

Indenter Move

Only if testing EC2000 with Front Indenter installed:

Ribbon in front (white) indent cartridge advances by about ¼”

Roller Consume

Hopper transport’s wheels turn for a few seconds

Push To Roller

Hopper transport takes a card from current hopper

Shuttle To Printer

Hopper transport moves to image printer

Roll To Printer

Hopper transport’s wheels turn for a few seconds to feed card into image

printer. Press Printer Eject button to move card through image printer.

XY Home

XY Transport moves to rear left of device

XY Home X

XY Transport’s X carriage moves to the left

XY Home Y

XY Transport’s Y transport moves to the rear of the device

XY To Printer

XY Transport moves to image printer

XY To Printer In

XY Transport’s X carriage moves toward image printer to engage with

card

Unclamp Card

X carriage’s card clamp rotates to unclamped position

Printer Eject

Card at image printer input is ejected to image printer exit

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 13

Page 14

2 - Introduction

Press This Button

Verify This Happens

Clamp Card

X carriage clamps card at printer exit

Embosser Home

Embosser wheel moves to first character on wheel (look for empty tines

next to the tine that is currently between the hammers)

Embosser hammers open completely (not squeezing embosser tines)

Wheel Home

Embosser wheel moves to first character on wheel (look for empty tines

next to the tine that is currently between the hammers)

XY To Embosser

XY Transport moves card out of printer and to embosser

CardHomeXY

XY Transport moves card so its lower left corner is between embosser

tines

XY To Exit

XY Transport moves card to Exit Transport’s input rollers

Unclamp Card

X carriage’s clamp releases the card

Exit Reject

Exit transport raises its bottom roller, rolls for a short period of time.

Ramp fan turns on. Card goes into Card Rejection Bin.

Exit Eject

Exit Transport rolls card to exit ramp, ramp fan turns on briefly.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 14

Page 15

2 - Introduction

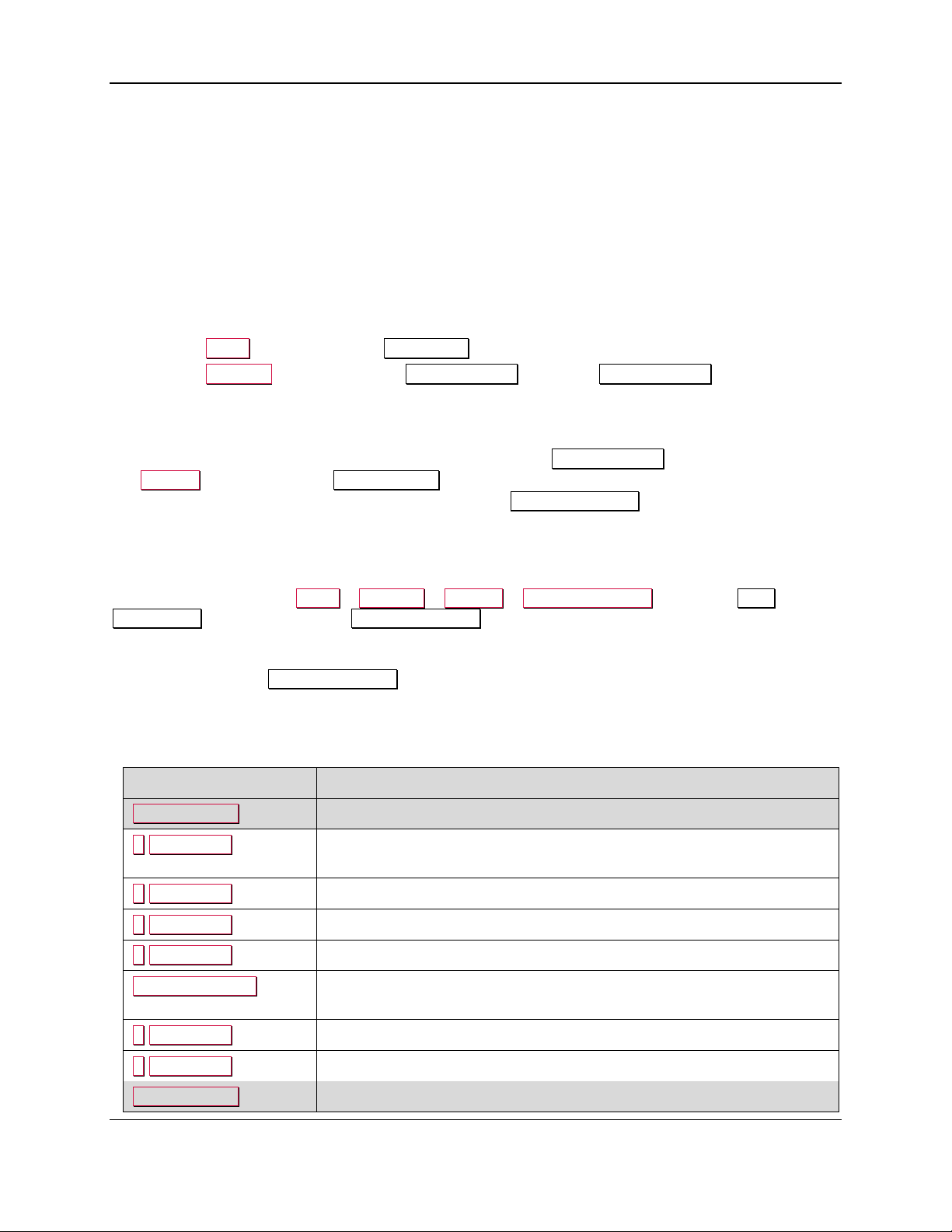

Sensor Name

Function

Printer Exit

Blocked when there is NO card in the image printer exit, and is unblocked when

there is a card in the image printer exit.

X_Home

Blocked when the X carriage on the XY transport is parked at its left edge.

Y_Home

Blocked when the XY transport is parked at the rear of the device.

Card Clamp

Blocked when the card clamp on the XY transport is closed.

Card Home XY

Blocked when the XY transport reaches the front of the device (at the embosser),

regardless of its X position.

Top Cam

Blocked during normal operation and briefly unblocks when the cam that drives

the top embosser hammer reaches specific points in its rotation.

Bottom Cam

Blocked during normal operation and briefly unblocks when the cam that drives

the bottom embosser hammer reaches specific points in its rotation.

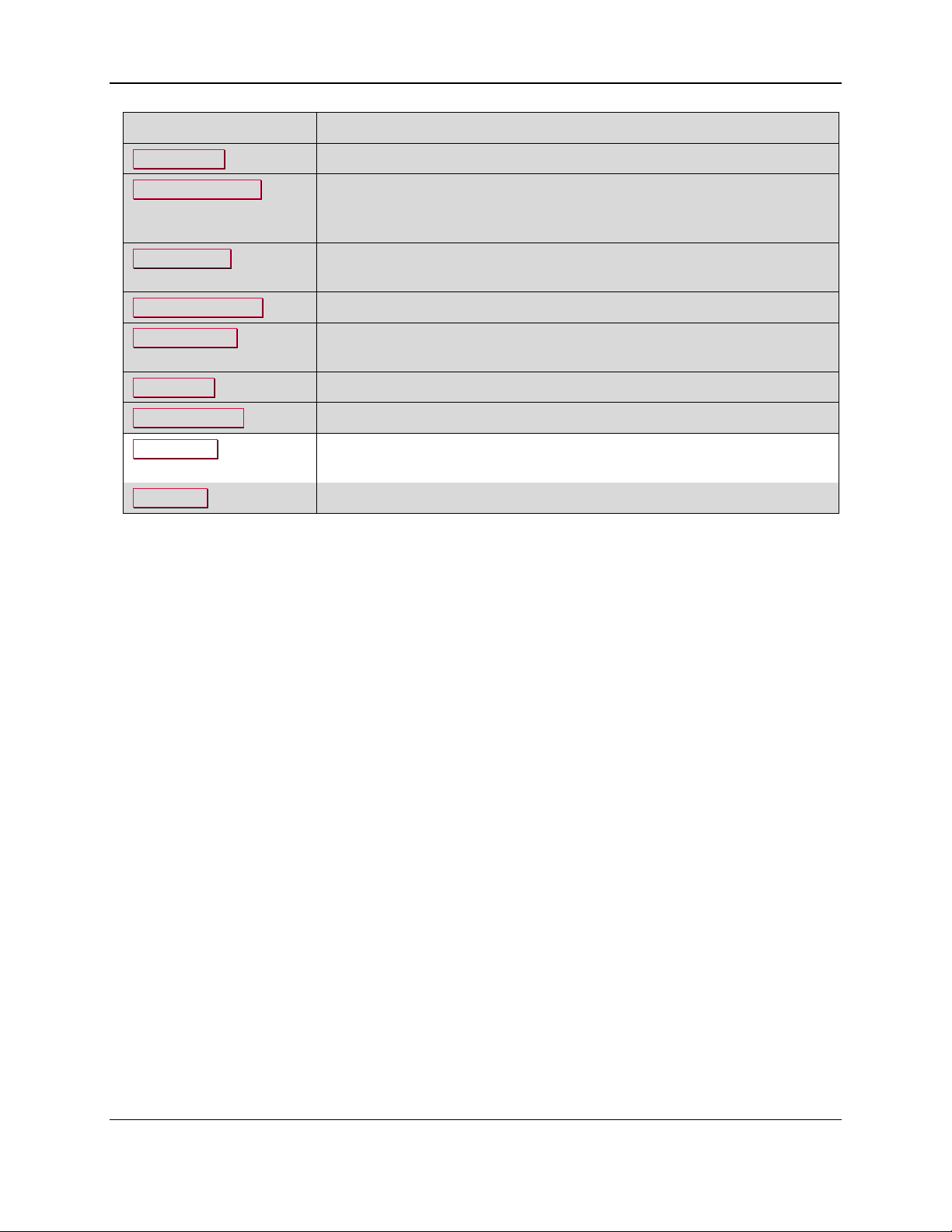

2.9.2 How to Use the Sensor Utility Page

To check the real-time status of all EC2000 sensors, use the touchscreen to navigate to Menu > Settings

> Sensors to open the Sensor Utility page. In normal operation with the top access door closed, with

all card stock hoppers inserted, and with the device just powered up and ready to process cards, the

Sensor Utility page should match Figure 2-3.

Figure 2-3 - Sensor Utility Page

To test a sensor, block or unblock it and verify its status changes. Table 2.2 provides descriptions of each

sensor and the cases where it is blocked or unblocked, and Figure 2-4 on page 17 shows where all sensors

are located in the device.

Table 2.2 - EC2000 Sensor Functions

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 15

Page 16

2 - Introduction

Sensor Name

Function

Card Edge

Blocked EITHER when the embosser daisy wheel is turned such that one of the

tines blocks the sensor, OR when a card enters the area between the embosser

wheels.

Wheel Home

Blocked when the small fin on top of the embosser daisy wheel points toward the

front of the device.

Top Case

Blocked when the top access door is closed.

Shuttle

Exception

Blocked when the hopper transport pushes far enough toward the front of the

device that it mechanically rotates to orient with the manual feed slot.

Hopper Exit

Blocked when a card reaches the point where it is fully and safely loaded from a

hopper into the hopper transport.

Eject Xport

Reserved for future use.

Eject Bin

Reserved for future use.

Exit Just Home

Reserved for future use.

RI Home

Blocked when the rear indent cartridge is in the loaded position (toward the front

of the device).

FI Home

Only used on devices that have the optional front indent module installed. Blocked

when the front indent cartridge is in the loaded position (toward the front of the

device).

Hopper Pull

Unblocked when the card puller on the hopper transport moves in to pick up a card.

Shuttle Home

Blocked when the hopper transport is parked at the rear right corner of the device.

Exception Feed

Blocked when a card just enters the manual feed slot.

RI Unload

Blocked when the rear indent cartridge is in the unload position (toward the rear of

the device).

FI Unload

Only used on devices that have the optional front indent module installed. Blocked

when the front indent cartridge is in the unload position (toward the rear of the

device).

MP Card In

Reserved for future use.

Hopper Card In

Reserved for future use.

Hopper1 Empty

- Hopper7

Empty

Unblocked when there is no hopper installed in the specified hopper slot.

Tipper Cam

Blocked when the tipper heating element is in the up/idle position.

Tipper Grip

Blocked when a card just reaches the rollers on the exit ramp.

Tipper Exit

Blocked when a card just reaches the end of the exit ramp.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 16

Page 17

2 - Introduction

Figure 2-4 - All EC2000 Sensors Shown In Red (FRONT VIEW)

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 17

Page 18

2 - Introduction

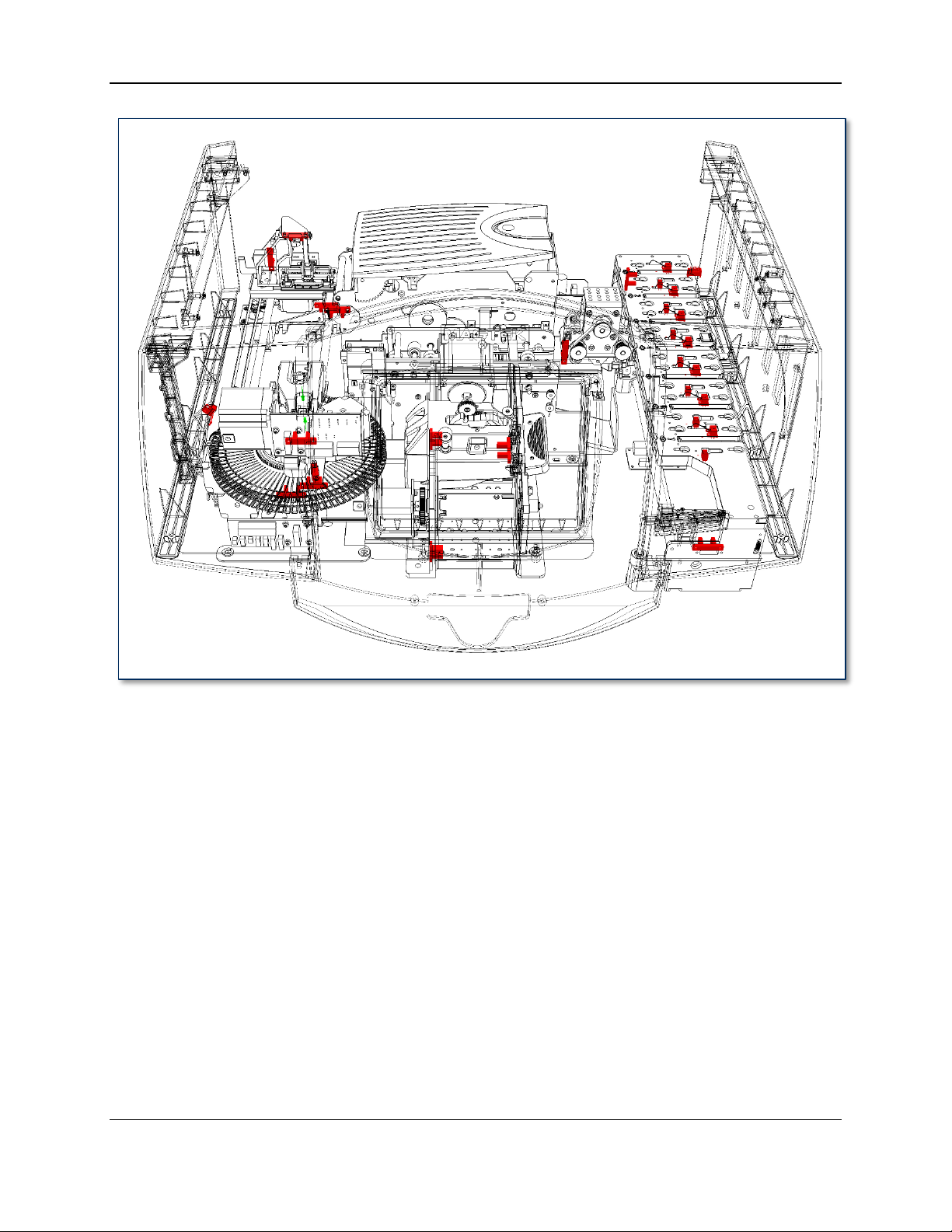

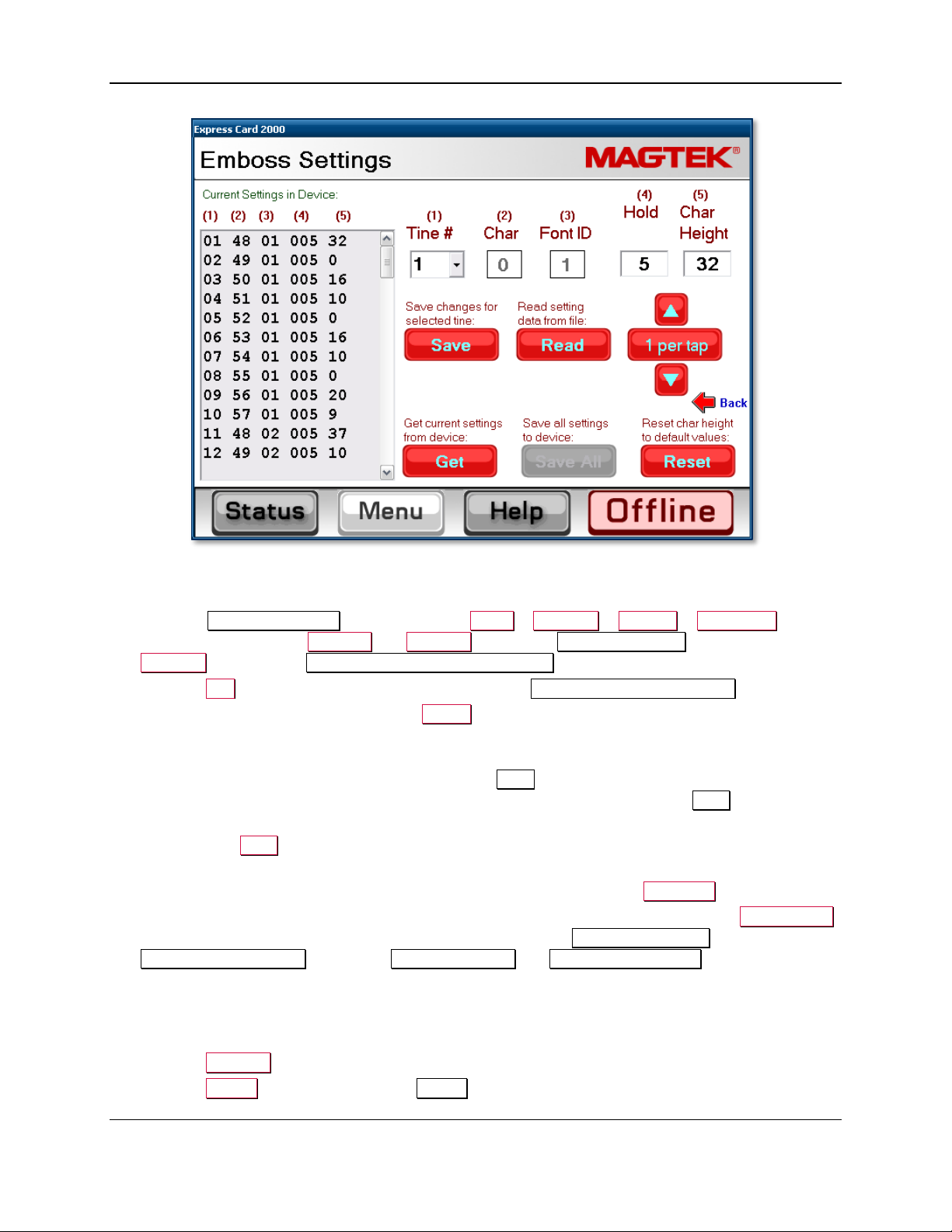

2.9.3 How to Use the Embosser Utility Page

2.9.3.1 About the Embosser Utility Page

To manually move the embosser daisy wheel or hammer cam motors, or to adjust the depth of individual

embossed characters, use the touchscreen to navigate to Menu > Settings > Service > Embosser,

then enter service passwords 4567890 and 0987654 to open the Embosser Utility page.

Figure 2-5 - Embosser Utility Page

The “Steps/Direction” box specifies how many steps the motor will take when you press any of the Move

buttons in the top row. Adjust the “Steps/Direction” value by typing a new value on the keyboard, or by

pressing the up and down arrows. Change how quickly the arrow buttons change the value by selecting

the 1 per, 10 per, or 100 per radio buttons; the default is 100 steps.

The following sections specify how to use the Embosser Utility page to perform specific operations.

2.9.3.2 How to Move the Embosser Daisy Wheel

The daisy wheel, driven by the Wheel Motor Move button, contains the set of characters the embosser

can press into cards. Each character is mounted to one of 80 tines numbered 1 through 80. The motor

takes 20 steps to advance from one tine to the next. To move the daisy wheel a full 360 degrees, move it

(80 characters) x (20 steps per character) = 1600 steps.

To move the daisy wheel, follow these steps from the Embosser Utility page:

1) Turn on the Move At Fast checkbox. The daisy wheel is designed and tested to operate at fast speed.

2) Set the number of steps you want the daisy wheel to take (see section 2.9.3.1 About the Embosser

Utility Page) and press the Wheel Motor Move button.

3) Repeat the moves as necessary to complete the test.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 18

Page 19

2 - Introduction

4) Re-home the daisy wheel by pressing either the Counter Clockwise Home or Clockwise Home

button. In normal operation, the daisy wheel homes counter-clockwise.

5) Press the All Motors Stop button to make sure the daisy wheel motor is not energized / holding still.

6) Press the Status button to return to the Status page.

2.9.3.3 How to Move the Embosser Cams (Hammers)

The top and bottom embosser cams, which can be driven by the Top Clamp Motor Move button and

Bottom Clamp Motor Move buttons, squeeze the embosser hammers to imprint raised characters on

cards. In a typical emboss cycle, each of the cam motors takes about 600 steps forward to move the cam

from its home position to press into the card, and 600 in reverse to retract back to the home position. One

step is approximately equal to 0.225 degrees of rotation, so the total emboss cycle covers about 135

degrees.

To move the top embosser cam, bottom embosser cam, or both cams, follow these steps from the

Embosser Utility page:

1) Press the All Motors Stop button to make sure no motor is applying force.

2) If there is nothing in the way of the hammers, press the Top & Bottom Home button to make sure

the cams are not closed. The “home” position is the standard starting position for an emboss cycle.

3) Press either the Counter Clockwise Home button or the Clockwise Home button to make sure the

daisy wheel has a character positioned between the embosser hammers. If the daisy wheel is offcenter, the hammers could damage it.

4) You may encounter a situation during testing where you want to close the hammers to their calibrated

close position, but prevent one embosser hammer from moving during testing; for example, to

prevent damage if something is jammed in the device, or if moving a specific cam would be a safety

hazard. In that type of situation, you can prevent one or both of the cams from moving in the next

step by checking the Do Not Move Top and / or Do Not Move Bottom checkbox. Note: This

feature only locks out movement when pressing the Close Clamp button and will not prevent

clamp movement for any other buttons on the page or during normal device operation.

7) Set the number of steps you want the cam(s) to move (see section 2.9.3.1 About the Embosser

Utility Page) and press the Top Clamp Motor Move or Bottom Clamp Move button, OR press the

Close Clamp button, OR press the All Motors Stop button if you find you have moved too far and

need to release the cams immediately.

8) Repeat the moves as necessary to complete the test.

9) Press the Top & Bottom Home button to make sure the cams are not left closed.

10) Press the All Motors Stop button to make sure no motor is applying force.

11) Press the Status button to return to the Status page.

2.9.3.4 How to Change the Embosser Character Depth and Dwell Time

Over time or after embosser service, an individual embossed character’s height may change to the point

that it doesn’t match other characters. The Emboss Settings page provides access to settings for each

tine on the embosser daisy wheel, which affect the pressing force and hold time for that one character.

The Emboss Settings page provides two ways to change these settings: You can import settings for all

tines from a file on the EC2000’s solid state drive or a USB thumb drive using the Read button, or you

can change each tine’s settings individually. The page also provides a Reset button that will reset all

tine settings to factory defaults.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 19

Page 20

2 - Introduction

Figure 2-6 - Emboss Settings Page

To adjust a single character’s pressing force or hold time, do the following:

1) Open the Emboss Settings page: Navigate to Menu > Settings > Service > Embosser and

enter service passwords 4567890 and 0987654 to open the Embosser Utility page, then press the

Settings button below Set Emboss Hold Time & Height.

2) Press the Get button to refresh the settings shown in the Current Settings in Device list box.

3) Select the tine you want to change in the Tine # drop-down menu. The touchscreen will display the

current settings for that tine in the top row of the page.

4) To adjust how long the embosser hammer will press that specific character into the card before lifting

back off to the embosser home position, change the Hold setting. The setting is in increments of 10

milliseconds, so a value of 5 equals a hold time of 50 ms. In most cases, setting Hold to 0 should

produce acceptable results:

a) Select the Hold field.

b) Enter a new value using the keyboard, or use the up and down arrows to adjust the value. You

can set how quickly the arrows will change the value by pressing the N per tap button.

5) To adjust the depth the hammer will press that specific character into cards, change the Char Height

setting. The EC2000 will add this value to the device’s global EmbossAngleTop and

EmbossAngleBottom settings, or IndentAngleTop and IndentAngleBottom settings, as

appropriate (see section 5.4 How to Calibrate the Embosser). To increase the embossed depth of

that specific character, increase the value; to decrease the embossed depth of a given character,

decrease the value. The valid range is from -127 to +127, but typical values are in the -20 to +40

range.

6) Press the Save All button to save the settings for all tines

7) Press the Status button to return to the Status page.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 20

Page 21

2 - Introduction

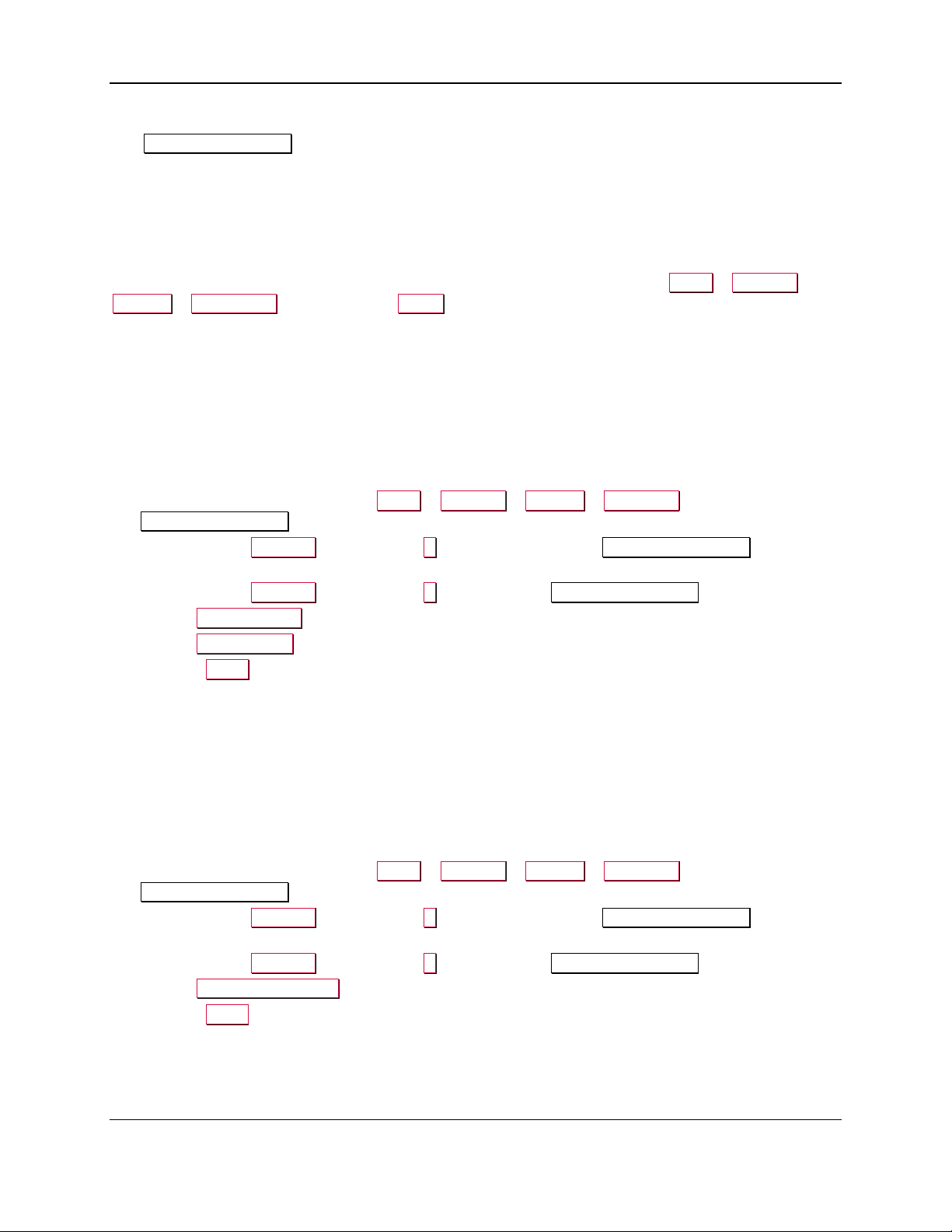

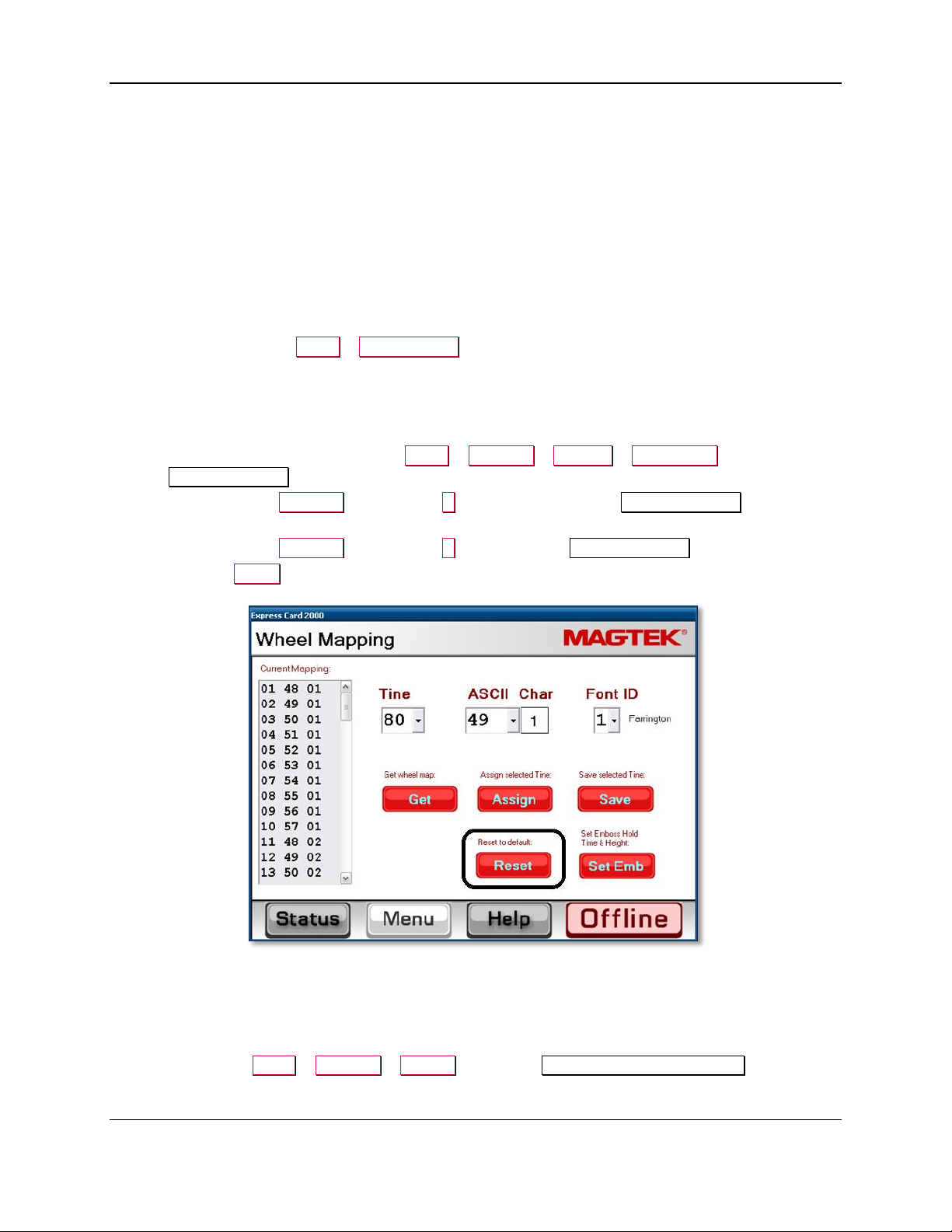

2.9.4 How to Use the Character Mapping Page

The Character Mapping page provides support for changing the configuration of characters on the

EC2000 embosser’s daisy wheel, and will most commonly be used in conjunction with the steps in

section 4.10 How to Remove / Re-install Embosser Fonts and in section 4.11 How to Remove / Re-

install the Embosser. Functions include adding new fonts, moving an existing character to a different

tine, and removing a character from a tine.

At any time (such as if you make a mistake that you discover later in testing), you can reset the changes

you made to the daisy wheel and return them to factory defaults by navigating to Menu > Settings >

Service > Wheel Map and pressing the Reset button.

To move a character from one daisy wheel tine to another, follow these steps:

1) Look at the numbers stamped on each daisy wheel tine to determine which tine the character was (or

is) originally on, and which tine you will move it to.

2) If the character is still on the old tine, uninstall it. Every character has a piece on the top daisy wheel

and a second piece on the bottom daisy wheel, so make sure to uninstall both, and to note which piece

belongs on the top and which piece belongs on the bottom.

3) Install both halves of the character on the new tine.

4) From the touchscreen, navigate to Menu > Settings > Service > Char Map to open the first

Character Mapping password page.

5) Enter password 4567890, then press the E key to open the second Character Mapping password

page.

6) Enter password 0987654, then press the E key to open the Character Mapping page.

7) Use the From Current dropdown list to select the old tine where the character was installed.

8) Use the To New Tine dropdown list to select the new tine where the character is now installed.

9) Press the Move button.

10) Repeat the above steps for any additional characters you need to move.

11) Test your changes by creating a sample card or an embosser tuning card.

To remove a character from a daisy wheel tine, follow these steps:

1) Look at the numbers stamped on each daisy wheel tine to determine which tine you want to remove

the character from.

2) If the character is still on the old tine, uninstall it. Every character has a piece on the top daisy wheel

and a second piece on the bottom daisy wheel, so make sure to uninstall both.

3) From the touchscreen, navigate to Menu > Settings > Service > Char Map to open the first

Character Mapping password page.

4) Enter password 4567890, then press the E key to open the second Character Mapping password

page.

5) Enter password 0987654, then press the E key to open the Character Mapping page.

6) Use the From Current Tine dropdown list to select the tine where the character was installed.

7) Press the Clear button.

8) Repeat the above steps for any additional characters you need to remove.

9) Test your changes by creating a sample card or an embosser tuning card.

To add a new character to a daisy wheel tine, follow these steps:

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 21

Page 22

2 - Introduction

1) Verify the EC2000 software supports the character(s) you are going to install.

2) Look at the numbers stamped on each daisy wheel tine to find the number of the tine where you will

install the new character.

3) Install the character on the tine. Every character has a piece on the top daisy wheel and a second

piece on the bottom daisy wheel, so make sure to install both, and to put each piece on the correct

half: For embossing fonts and rear indent fonts (FontID1, FontID2, and FontID4), the “punch”

(positive) side goes on the bottom; for front indent fonts (FontID3), the “punch” side goes on the top.

Indent fonts have a “blank” flat side that goes opposite the punch side.

4) Install both halves of the character on the new tine.

5) From the touchscreen, navigate to Menu > Settings > Service > Char Map to open the first

Character Mapping password page.

6) Enter password 4567890, then press the E key to open the second Character Mapping password

page.

7) Enter password 0987654, then press the E key to open the Character Mapping page.

8) Use the Add Char. dropdown list to select what character you are installing (for example, if you are

installing a capital ‘A,’ select 65). Verify you have selected the character you expected to select by

looking at the ASCII Char box next to the dropdown list.

9) Use the Font dropdown list to indicate the type of font you have installed (FontID1-4).

10) Use the To dropdown list to select which tine you have installed the characters on.

11) Press the Add button.

12) Repeat the above steps for any additional characters you need to add.

13) Test your changes by creating a sample card or an embosser tuning card.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 22

Page 23

3 - Preventive Maintenance

3 Preventive Maintenance

The EC2000 requires regular preventive maintenance to maintain image quality and reliability. Follow

the steps in each section below to perform preventive maintenance.

Before starting, ask the EC2000 user or customer if they have had any specific problems with the device.

If you need to troubleshoot a specific problem, address that before performing preventive maintenance.

See section 6 Diagnosis for assistance troubleshooting reported issues.

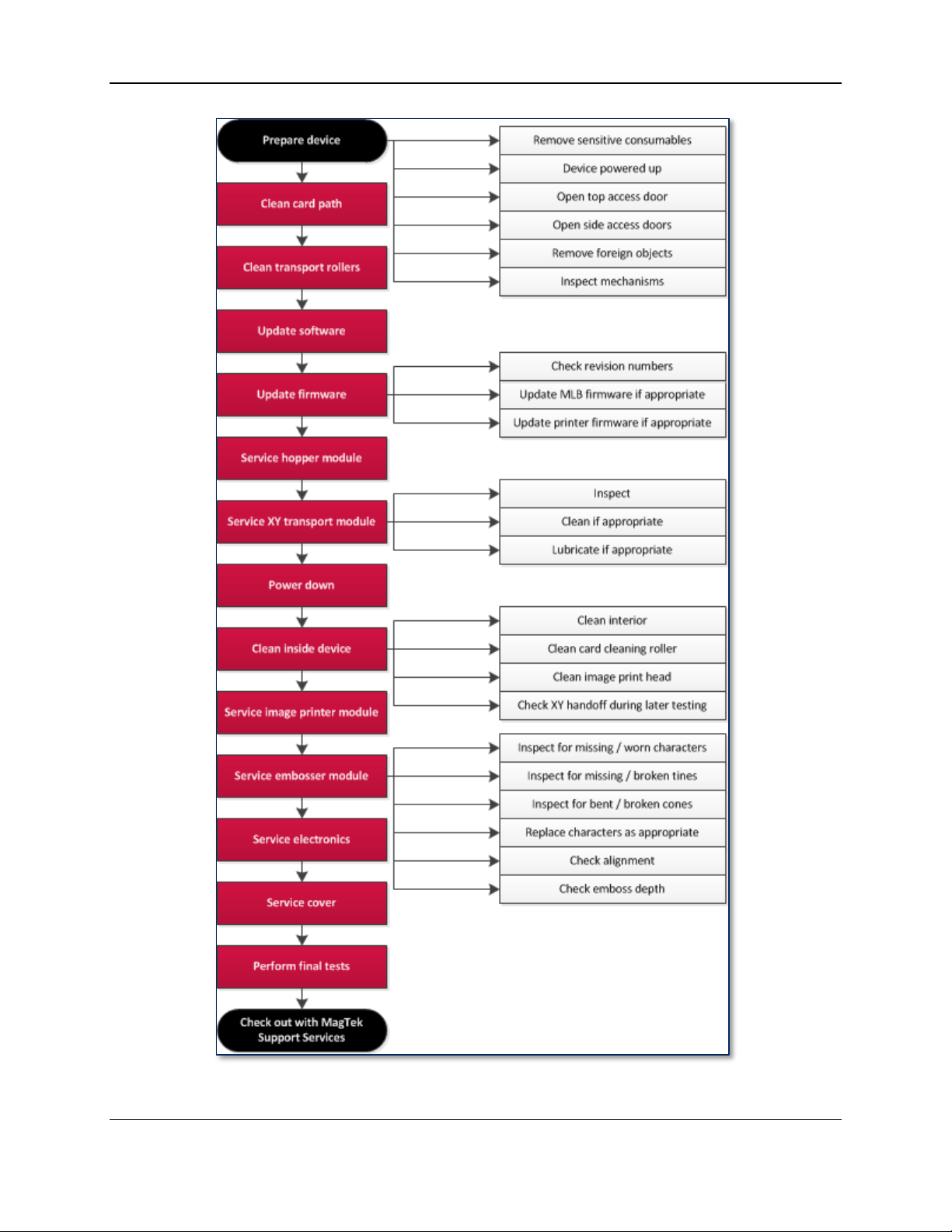

The following page shows a flowchart that gives a brief overview of the preventive maintenance

procedure. It should only be used as a guide, not as a substitute for following the detailed steps provided.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 23

Page 24

3 - Preventive Maintenance

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 24

Page 25

3 - Preventive Maintenance

3.1 Prepare the Device for Preventive Maintenance

To prepare the device for service, follow these steps:

1) Offer the customer the opportunity to remove any proprietary or security-sensitive consumables from

the device, including card stock, image printer ribbons, indent cartridges, and tipper foils. Some

consumables contain negative imprints of cardholder data and must be handled securely.

2) Make sure the device is powered up and connected to the network.

3) Open the top access door (see 99875600 EC2000 User Installation and Operation Manual).

4) Open the two side access doors (see section 4.3 How to Remove / Re-install the Side Access

Doors).

5) Inspect the device for any items that do not belong inside the cover, and remove them (examples

include loose mechanical parts, cards, insect or animal leavings, or jewelry).

6) Inspect the mechanical parts inside the device and inside the image printer, paying special attention to

belts, cables, and plastic gears to see if there are signs of wear or damage.

3.2 Clean the Card Path

Clean the card path per the steps in the Maintenance section of 99875600 EC2000 User Installation

and Operation Manual.

3.3 Clean All Transport Rollers

Follow these steps to clean the rollers on the hopper transport, XY transport, and exit transport. Use the

white cleaning cards:

1) Remove hoppers 1 and 2.

2) Remove the tipper foil cartridge (see 99875600 ExpressCard 2000 User Installation and

Operation Manual for detailed instructions) and set it aside in a secure location, or offer it to the

customer for temporary storage or secure disposal.

3) On the touchscreen, navigate to Menu > Settings > Service > MCP Cmds to open the

Controller Commands page.

4) Use the white cleaning card and do not let the rollers take it out of your hand as you clean each set

of rollers as follows:

a) Feed the card partly into the hopper transport and press the Roller Consume button. Hold the

card there until the rollers stop moving.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 25

Page 26

3 - Preventive Maintenance

Figure 3-1 - Cleaning the Hopper Transport Rollers (TOP VIEW FROM FRONT)

b) Feed the card partly into the left side of the exit transport and press the Exit Eject button. Hold

the card there until the rollers stop moving.

Figure 3-2 - Cleaning the Left Side of the Exit Transport (TOP VIEW FROM FRONT)

c) Feed the card partly into the right side of the exit transport and press the Exit Reject button.

Push inward to keep the card from being pushed out until the rollers stop moving.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 26

Page 27

3 - Preventive Maintenance

Figure 3-3 - Cleaning the Right Side of the Exit Transport (TOP VIEW FROM FRONT)

d) Feed the card partly under the exit ramp rollers and press the Exit Eject button. Hold the card

there until the rollers stop moving.

Figure 3-4 - Cleaning the Exit Ramp Rollers (TOP VIEW FROM FRONT)

5) Press the Status button to return to the Status page.

6) Re-install the tipper foil spool assembly with the original tipper foil roll, or obtain and install a new

one from the customer.

7) Re-install hoppers 1 and 2.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 27

Page 28

3 - Preventive Maintenance

3.4 Update the Software

If MagTek Support Services has supplied .CAB files to apply EC2000 software patches, follow these

steps to install them:

1) Use the Ethernet cable to connect the service laptop to the EC2000. If necessary, you may instead

use the customer’s instant issuance workstation, provided it has Microsoft Internet Explorer and a

USB port with security settings that allow you to read from the USB thumb drive.

2) Launch the Internet Explorer web browser and navigate to https://ec-xxxxxxx, where xxxxxxx is the

device’s serial number. The browser should show an ExpressCard 2000 web interface page.

3) Open the Software Upload link on the left side of the page to display a File to Upload page.

4) Press the Browse… button to launch the Choose File to Upload dialog box.

5) Navigate to the folder that contains the .CAB files you want to apply (such as the field service

laptop’s hard drive or the USB thumb drive).

6) Select the .CAB file you want to apply, and press the Open button to return to the File to Upload

page.

7) Press the Send button to upload the .CAB file to the device. The browser will display a status

message telling you when the patch will be applied (for example, “File Copied Successfully. Update

will be performed during next reboot.”). The device’s touchscreen may also go blank.

8) Restart the device by powering it off, then powering it on. Wait until the touchscreen once again

displays the ExpressCard 2000 Status page.

9) In the web browser, open the Upload Status link on the left side of the page. If the browser reports

“SUCCESS,” repeat these steps for any additional patch .CAB files you need to apply, or continue to

the next section.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 28

Page 29

3 - Preventive Maintenance

3.5 Update the Firmware

Follow the steps in this section to determine whether the EC2000 firmware needs to be updated, and to

update it if necessary.

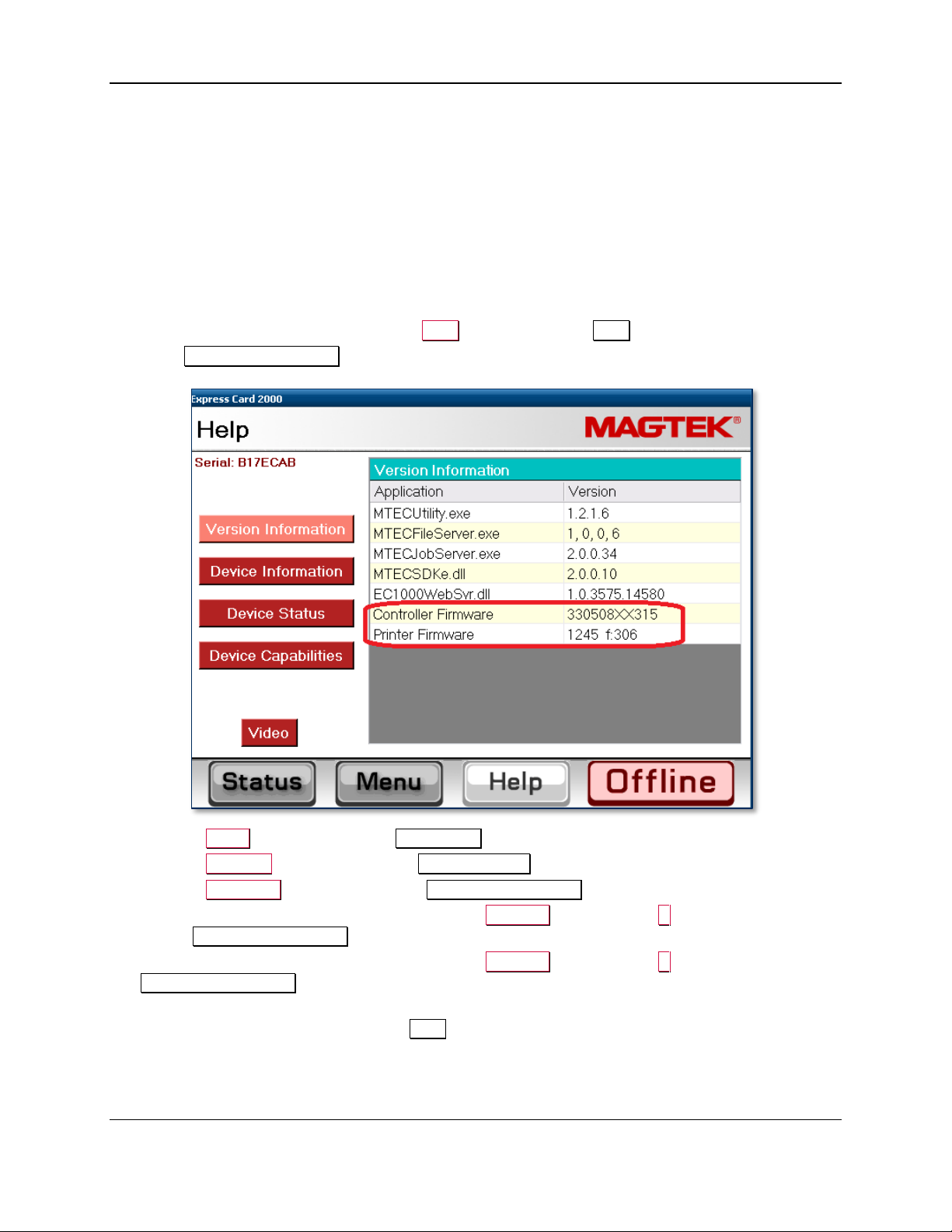

3.5.1 Check Firmware Revision Numbers

To check whether the EC2000 has the latest main logic board (MLB) and image printer firmware

installed, follow these steps:

1) Install any software updates MagTek Support Services has provided, using the instructions in section

3.4 Update the Software. This is a very important first step, because new revisions of firmware files

are distributed to the EC2000 via software updates.

2) From the EC2000 touchscreen, press the Help button to open the Help page.

3) In the Version Information list, note the Controller Firmware and Printer Firmware entries.

4) Press the Menu button to launch the Main Menu page.

5) Press the Settings button to launch the Settings Menu page.

6) Press the Load F/W button to launch the Firmware Download password page.

7) Use the on-screen keyboard to enter the password 1234567, then press the E key to launch the

second Firmware Download password page.

8) Use the on-screen keyboard to enter the password 7654321, then press the E key to launch the

Firmware Download page.

9) Note the revision numbers listed for each .hex file in the list. If any revision number does not match

the revision numbers you found on the Help page, update the firmware for that component using the

steps in the following sections.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 29

Page 30

3 - Preventive Maintenance

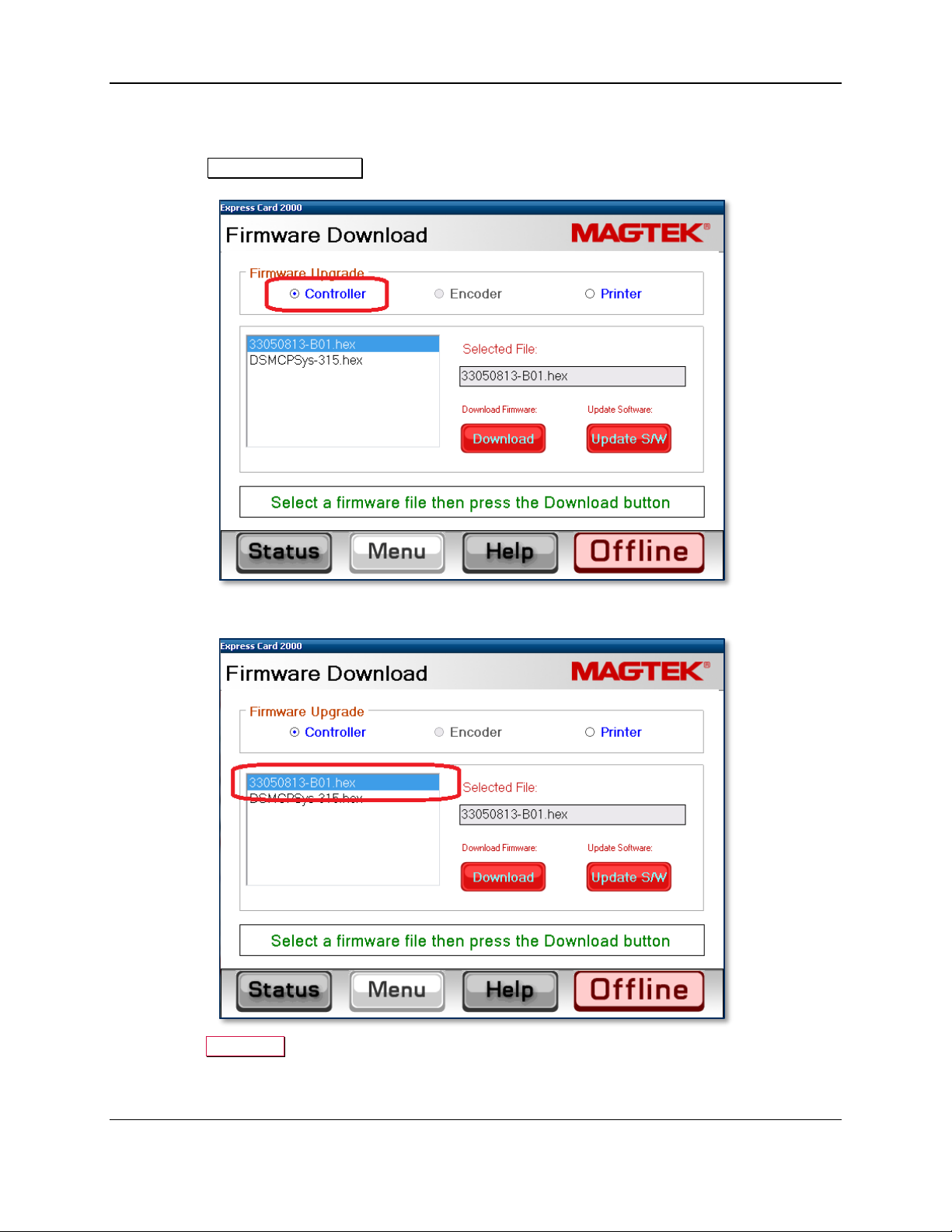

3.5.2 Update the Main Logic Board (Controller) Firmware

To update the controller (main logic board / MLB) firmware, follow these steps:

1) From the Firmware Download page, select the Controller radio button.

2) In the list of .hex files, select the file that corresponds to the new revision.

3) Press the Download button to download the .hex file to the controller. The system will report

“Loading the firmware. Please wait….”

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 30

Page 31

3 - Preventive Maintenance

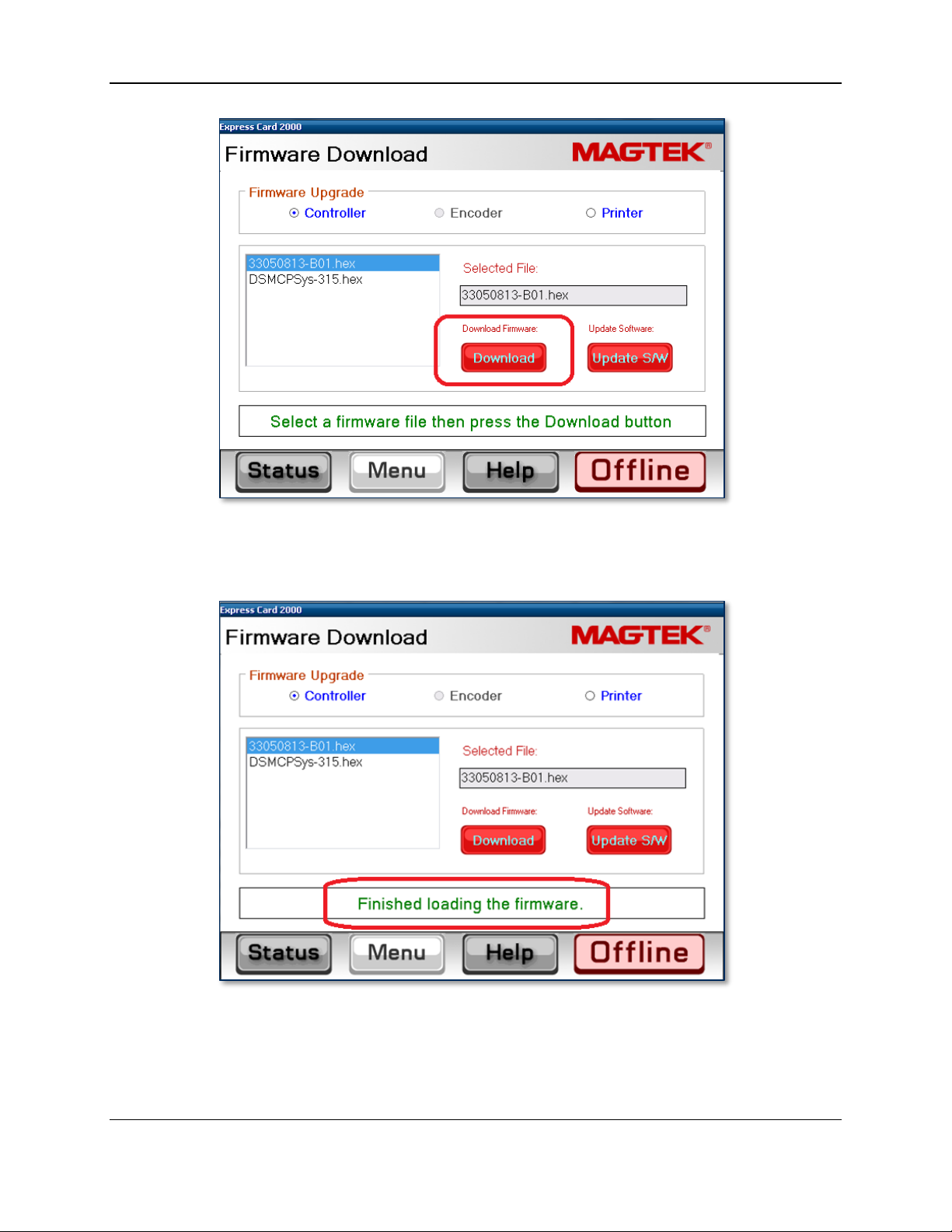

4) Wait about 5 minutes for the firmware to finish downloading. Do not power off the device.

5) After the firmware update is complete, the device will make sounds as the MLB resets. Wait until the

sounds stop and the touchscreen reports “Finished loading the firmware.”

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 31

Page 32

3 - Preventive Maintenance

3.5.3 Update the Printer Firmware

To update the printer firmware, follow the steps from section 3.5.2, but select the Printer radio button

and select the .hex file appropriate to the revision of the image printer firmware you want to install, before

pressing the Download button.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 32

Page 33

3 - Preventive Maintenance

3.6 Service the Hopper Module

Follow these steps to service the hopper transport:

1) Use the MCP Commands page (see section 2.9 How to Use Maintenance Functions On the

Touchscreen) to move the hopper transport from the front to the rear of the device to verify the

movement is smooth and there is no belt slippage.

2) Only if the hopper transport rods are dirty, wipe off the dirt with a soft, lint-free cloth.

3) Check the hopper transport drive belt for signs of damage. If it is damaged, contact MagTek Support

Services for a replacement.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 33

Page 34

3 - Preventive Maintenance

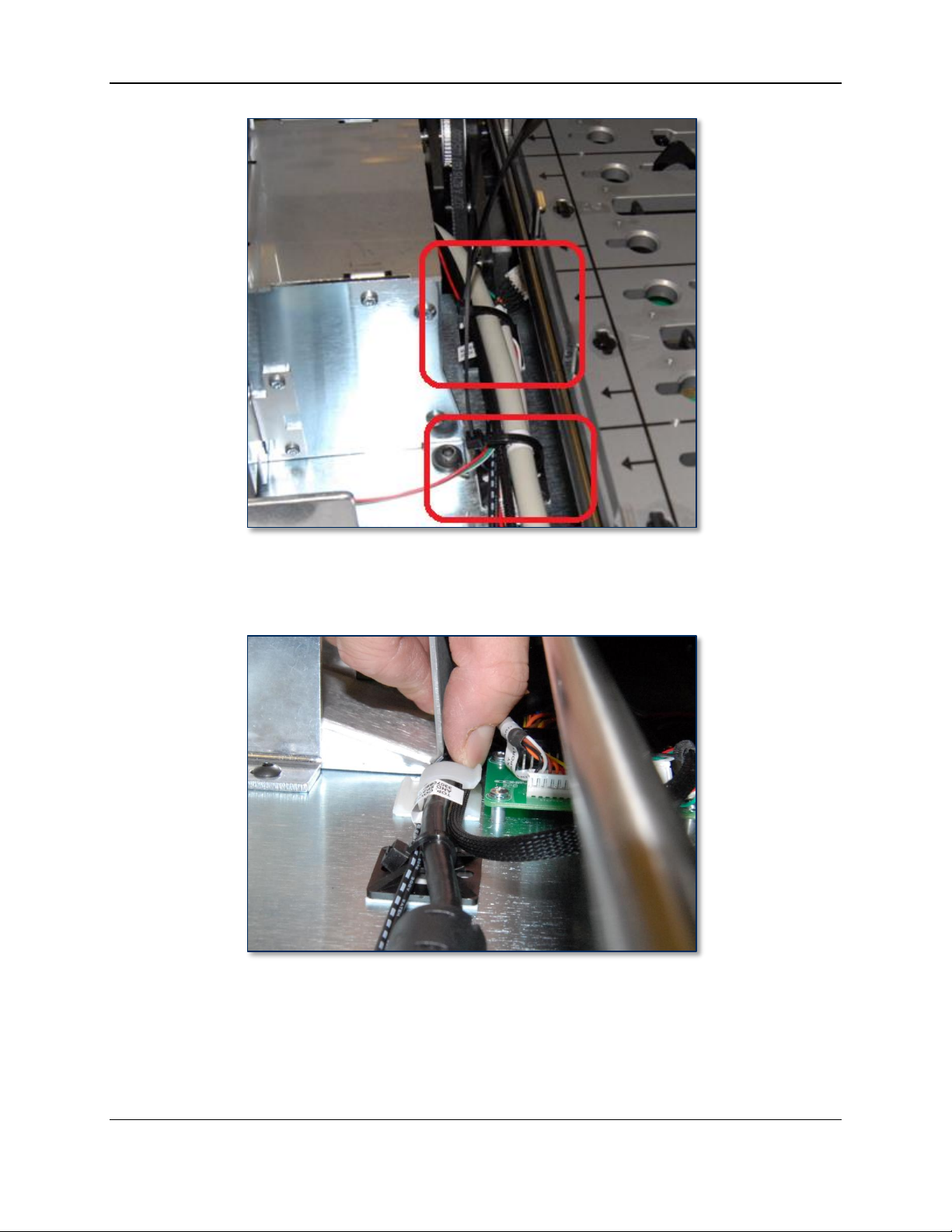

3.7 Service the XY Transport Module

Do not lubricate the EC2000’s gears or bearings. They are made of self-lubricating powder

metal, and lubricants can damage their surfaces.

Follow these steps to lubricate the one shaft that requires lubrication. Do not use Tri-Flow lubricant on

any shaft other than the one shown below.

1) If there is dirt, dust, or debris on the XY transport rods, wipe it off using a soft, lint-free cloth.

2) Use the MCP Commands page (see section 2.9.1 How to Use the MCP Commands Page) to move

the XY transport from the front to the rear of the device to verify the movement is smooth and there is

no belt slippage. Leave the transport at the rear of the device.

3) Check the XY transport drive belt for any signs of damage. If it is damaged, contact MagTek Support

Services for a replacement.

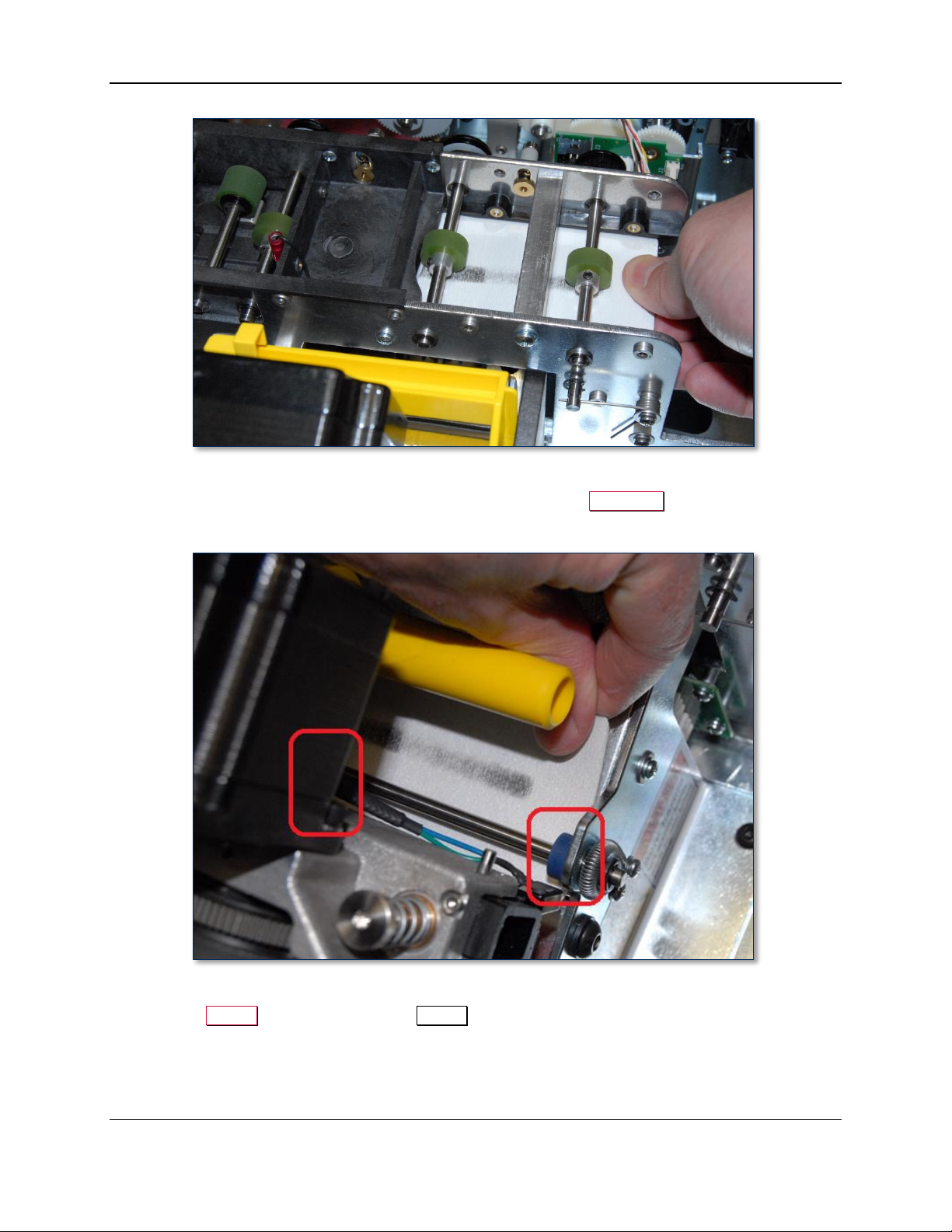

4) Stand at the front of the device and locate the XY transport shaft closest to the image printer. It is the

only shaft that has a blue bearing around it (see Figure 3-5).

Figure 3-5 - Blue Bearing On XY Transport (FRONT LEFT VIEW)

5) Shake the bottle of Tri-Flow lubricant and remove the cap.

6) Run a thin 3-4 inch long bead of Tri-Flow along the top of that one shaft.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 34

Page 35

3 - Preventive Maintenance

Figure 3-6 - Run a Thin Bead of Tri-Flow Along the Top of the Shaft (TOP LEFT VIEW)

7) Use the drive belt to move the XY transport to the front of the device, then to the rear again to spread

the Tri-Flow along the length of the shaft (see section 2.8 How to Safely Move Transports By

Hand).

8) If you have applied too much Tri-Flow to the shaft, some may drip off the shaft. If this happens, dab

off the excess with a clean, lint free cloth.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 35

Page 36

3 - Preventive Maintenance

3.8 Service the Exit Transport Module

No additional service is necessary for the Exit Transport, other than the roller cleaning described in

section 3.3 Clean All Transport Rollers.

3.9 Cool the Tipper Heater / Power Down the Device

1) Navigate to Menu > Settings > Tipper to open the Tipper page.

2) Press the Set Heater OFF button to turn off the tipper heater.

3) Note the value under Current Tipper Temp. If the tipper temperature is 50°C or hotter, the tipper

heater is not safe to touch.

4) Take note of the current time, and plan your work to allow enough time for the tipper heater to cool,

which can take up to 15 minutes. You may be able to use compressed air to cool it more quickly.

5) Power down the device.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 36

Page 37

3 - Preventive Maintenance

3.10 Clean Inside the Device

Caution: Do not use alcohol wipes, liquids, or chemicals on the touchscreen.

Clean the device in phases to avoid blowing dirt, dust, or debris into sensitive components:

1) Remove all remaining consumables from the device (stock cards, image printer ribbon, indent

cartridge[s], tipper foil, etc.) and set them aside in a secure location or give them to the customer for

temporary storage or secure disposal.

2) If there is a large, visible amount of dirt, dust, or debris in the device, wipe the worst of it out with a

clean, dry cloth.

3) Wipe remaining dirt, dust, and debris off the base plate and main components with alcohol wipes.

4) Used compressed air to blow out any remaining dirt, dust, or debris from between components and re-

wipe as necessary.

5) Use compressed air to clean each of the sensors (see section 2.9.2 How to Use the Sensor Utility

Page for an inventory of all sensors in the device).

6) Use compressed air to clean out the electronics in the bottom between the side access doors, with

special attention paid to the power supply in the rear left corner.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 37

Page 38

3 - Preventive Maintenance

3.11 Service the Image Printer Module

Follow these steps to service the image printer:

1) Make sure the interior of the EC2000 is clean (see section 3.10 Clean Inside the Device).

Performing image printer maintenance with dirt or debris inside the cover may damage the printer.

2) Open the image printer and clean its interior if necessary. Dust and other particles are attracted to the

image printer ribbon or card stock by static produced during image printing, and can contaminate

image-printed cards, causing spots or speckles.

3) Clean the card cleaning roller and replace it if necessary (see 99875600 ExpressCard 2000 User

Installation and Operation Manual for details).

4) Clean the image print head with head cleaning pen (see 99875600 ExpressCard 2000 User

Installation and Operation Manual for details).

5) Check handoff from image printer to XY transport. Adjust if needed (see section 5.3.2 How to

Calibrate Printer to XY Transport Handoff).

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 38

Page 39

3 - Preventive Maintenance

3.12 Service the Embosser Module

3.12.1 About Servicing the Embosser Module

The embosser module presses characters into card stock by squeezing the card between a raised metal

letter, called a punch, and an indented letter of the same shape, called a die, installed on the embosser’s

top and bottom daisy wheels. For indented characters, the die is replaced with a flat metal plate so the

card stock is only altered on the character side. Worn out punches or dies can produce characters of poor

quality, or characters that are raised/indented less than the required depth.

The top and bottom embosser motors each drive a hammer that applies force to the punches and dies on

the daisy wheel. Both hammers have a small round plate with a hole that lines up with a cone on each

character. The cone on each character should be sharp and unbent, and must line up properly with the

hole in the hammer. Figure 3-7 shows a magnified view of a properly aligned hammer (above) and die

(below), viewed from the front of the embosser. Because it can be difficult to see the front of the

embosser module with the EC2000’s cover and other modules installed, it is best to inspect the cones with

an inspection mirror. Section 3.12.2 provides further detail.

Figure 3-7 - Embosser Hammer and Character (FRONT VIEW)

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 39

Page 40

3 - Preventive Maintenance

3.12.2 How to Service the Embosser Module

Service the embosser by following these steps. If you discover any issues you can not resolve, contact

MagTek Support Services to procure a replacement embosser module.

1) Use compressed air to clean the embosser bridge (the metal block between the daisy wheels that

supports the indent cartridge ribbon).

2) Inspect the top and bottom embosser daisy wheels for missing or worn characters and replace them if

possible (see section 4.10 How to Remove / Re-install Embosser Fonts). After installing, make

sure the tine is still intact and holds the character tightly.

3) Inspect the top and bottom embosser daisy wheels for missing, bent, or broken tines. Install any

missing characters on other tines and re-map them after preventive maintenance is complete and the

device is powered up (see section 4.10 How to Remove / Re-install Embosser Fonts and section

2.9.4 How to Use the Character Mapping Page).

4) Inspect the characters on the top embosser wheel to identify any broken or bent cones. Top-side

replacement font sets include:

a) 33070077 FUN TYPE,FARRINGTON F7B,EMBOSS DIE

b) 33070079 FUN TYPE,GOTHIC,ALPHA,EMBOSS DIE,ZERO/OH

c) 33070181 FUN TYPE,GOTHIC,NUMBER,EMBOSS DIE

d) 33070183 FUN TYPE,GOTHIC,SPECIAL CHARACTERS,EMBOSS DIE

e) 33070516 FUN TYPE, FRONT INDENT SANS SERIF, 12PT

f) 33070524 FUN TYPE, INDENT, HELVETICA 8PT

g) 33070546 FUN TYPE, FRONT INDENT SANS SERIF, 14PT

h) 33070581 FUN TYPE, TURKISH EMBOSS DIE

i) 33070075 FUN ANVIL, REAR INDENT.

5) Use the inspection mirror and a flashlight to inspect the characters on the bottom embosser wheel to

identify any broken or bent cones (see Figure 3-8 and Figure 3-9). Bottom-side replacement font

sets include:

a) 33070078 FUN TYPE,FARRINGTON F7B,EMBOSS PUNCH

b) 33070080 FUN TYPE,GOTHIC,ALPHA,EMBOSS PUNCH, ZERO/OH

c) 33070081 FUN TYPE,REAR,INDENT,MC,ZERO

d) 33070182 FUN TYPE,GOTHIC,NUMBER,EMBOSS PUNCH

e) 33070184 FUN TYPE,GOTHIC,SPECIAL CHARACTERS,EMBOSS PUNCH

f) 33070582 FUN TYPE, TURKISH EMBOSS PUNCH

g) 33070608 FUN TYPE FRONT INDENT BANK ID NUMBER

h) 33070074 FUN ANVIL,FRONT INDENT

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 40

Page 41

3 - Preventive Maintenance

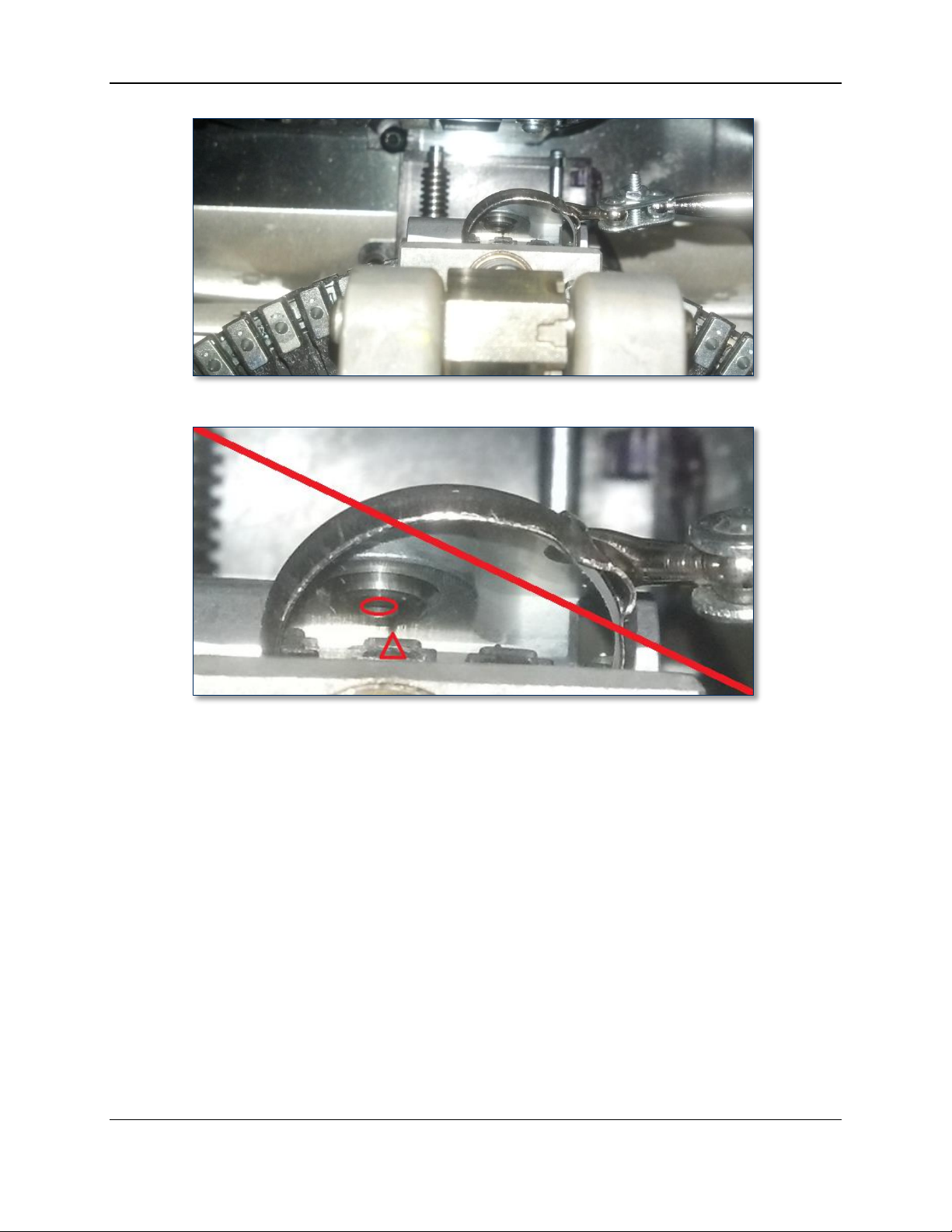

Figure 3-8 - Using Inspection Mirror to Check Tine / Hammer Alignment (TOP VIEW FROM FRONT)

Figure 3-9 - Bad Embosser Wheel Alignment (Figure 3-8 MAGNIFIED)

6) If any cones are broken or bent, replace the characters in the same location if possible. If replacement

is not feasible, cut off the top and bottom tines using the diagonal side cutters, remove the character

from the tines, and install it to another set of tines, and re-map the character to another tine after

preventive maintenance is complete and the device is powered up (see section 4.10 How to Remove /

Re-install Embosser Fonts and section 2.9.4 How to Use the Character Mapping Page).

7) Check the daisy wheel alignment by standing in front of the device and looking straight down at the

embosser. Use an inspection mirror as shown in Figure 3-8 so you can see the cone on the bottom of

the current character and the hole in the embosser hammer. Figure 3-9 shows a cone and hole that

are not properly aligned.

8) Check embossed character heights using the steps in section 5.4 How to Calibrate the Embosser,

and adjust them if necessary to account for normal wear. Pay special attention to any characters you

have replaced or re-mapped.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 41

Page 42

3 - Preventive Maintenance

3.13 Service the Electronics

Visually inspect all wires and cables, checking for insulation breakage or wear on moving cables.

3.14 Service the Cover

After completing all other service, service the cover as follows:

1) Inspect the cover for damage.

2) Clean the black and gray portions of the outside of the cover with alcohol wipes.

3) Clean fingerprints off the touchscreen with a soft, clean, dry cloth.

3.15 Perform Final Tests

After completing preventive maintenance, follow these steps to test the device and restore it to its original

state:

1) Re-connect the power and network cables.

2) Re-attach any security hardware.

3) Re-install consumables.

4) Close all open doors.

5) Power up the device.

6) Re-synchronize the image printer ribbon.

7) Create a sample card using customer card stock.

8) Check image print quality and embosser alignment, and adjust components as necessary using the

information in section 5 Adjustments.

9) Fill out the checklist included with the preventive maintenance kit, and return it to MagTek.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 42

Page 43

4 - Removal and Re-installation

4 Removal and Re-installation

This section describes how to remove and re-install the major assemblies within the EC2000. To avoid

personal injury or damage to the device, be sure to follow ESD procedures (see section 2.3 How to

Handle ESD-Sensitive Parts) and use standard safety practices.

4.1 How to Prepare the Device for Removing / Re-installing Modules

To prepare the device for removing / re-installing modules, follow these steps in accordance with standard

safety practices:

1) Offer the customer the opportunity to remove any proprietary or security-sensitive consumables from

the device, including card stock, image printer ribbons, indent cartridges, and tipper foils. Some

consumables contain negative imprints of cardholder data and must be handled securely.

2) Make sure you have adequate lighting around the device, or plan to use a flashlight.

3) Make sure you have a safe location to place removed parts and replacement parts.

4) If the relevant replacement procedure requires you to use the touchscreen user interface, perform

those steps while the device is still powered up and connected to the network.

5) Power down the device.

6) Disconnect the device’s power cable from the AC socket-outlet, then disconnect the power cable and

network cable from the rear of the device.

7) If necessary, unlock or disconnect any security hardware from the device.

8) If the replacement procedure requires you to remove the device’s top access door or the entire cover,

or requires rear access to the device, make sure you have adequate clearance around the device.

Depending on the installation location, you may need to move the device to a service location.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 43

Page 44

4 - Removal and Re-installation

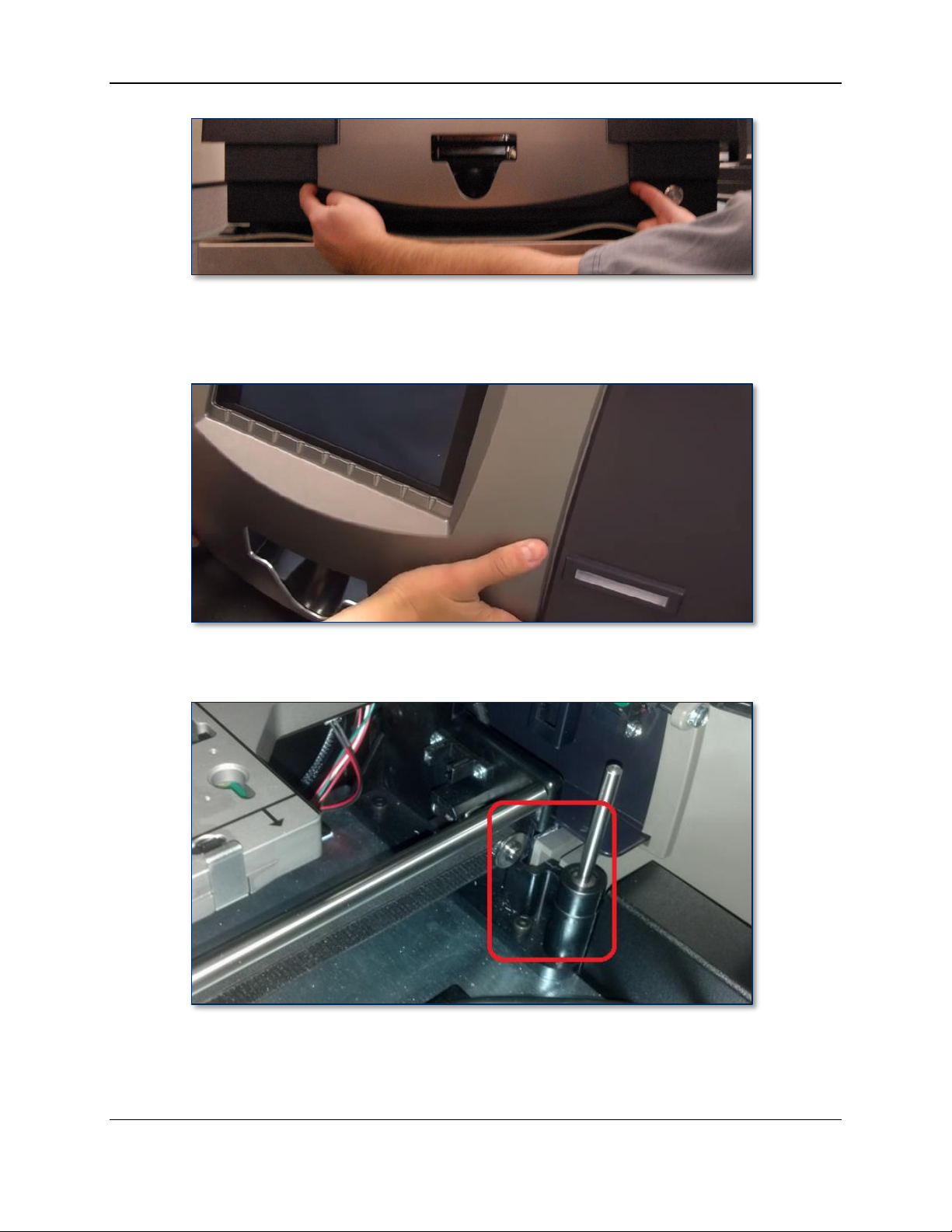

Approximate time to remove: 5 minutes plus any sub-procedures

Approximate time to re-install: 5 minutes plus any sub-procedures

4.2 How to Remove / Re-install the Top Access Door

The top access door is the large lockable door in the top of the cover that secures the user-serviceable

areas inside the device, while allowing users to access and replace consumable items like image printer

ribbons and card stock. Some service procedures require removing the top access door to give

unobstructed access to certain components.

Figure 4-1 - Top Access Door (REAR VIEW)

To remove the top access door, follow these steps:

1) Unlock the top access door (see section 2.7 How to Open the Top Access Door).

2) Open the top access door halfway (just past the latches on either side of the cover).

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 44

Page 45

4 - Removal and Re-installation

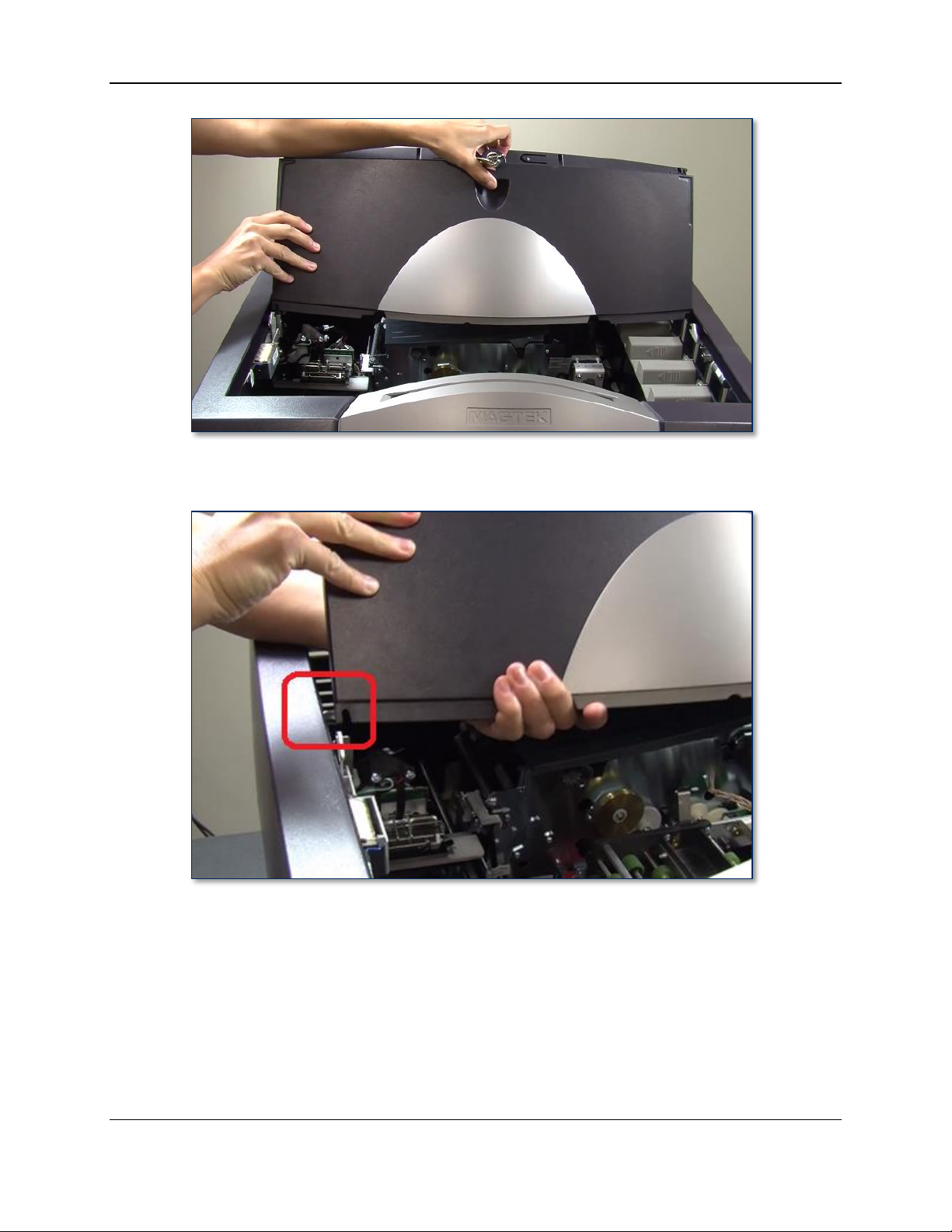

3) Using both hands, gently pull the top cover to the right, then slightly upward to free it from its left

track as shown in Figure 4-2.

Figure 4-2 - Pulling the Left Side of the Top Access Door Out of Its Track (FRONT VIEW)

4) Repeat the process, pulling it to the left and slightly upward, to free it from its right track.

5) Lean the top access door out toward the rear of the device as shown.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 45

Page 46

4 - Removal and Re-installation

Figure 4-3 - Top Access Door Leaning Up and Back (FRONT VIEW)

6) Move the hopper transport toward the front of the device, around hopper 6 (see section 2.8 How to

Safely Move Transports By Hand).

7) Remove card stock hoppers 1 and 2.

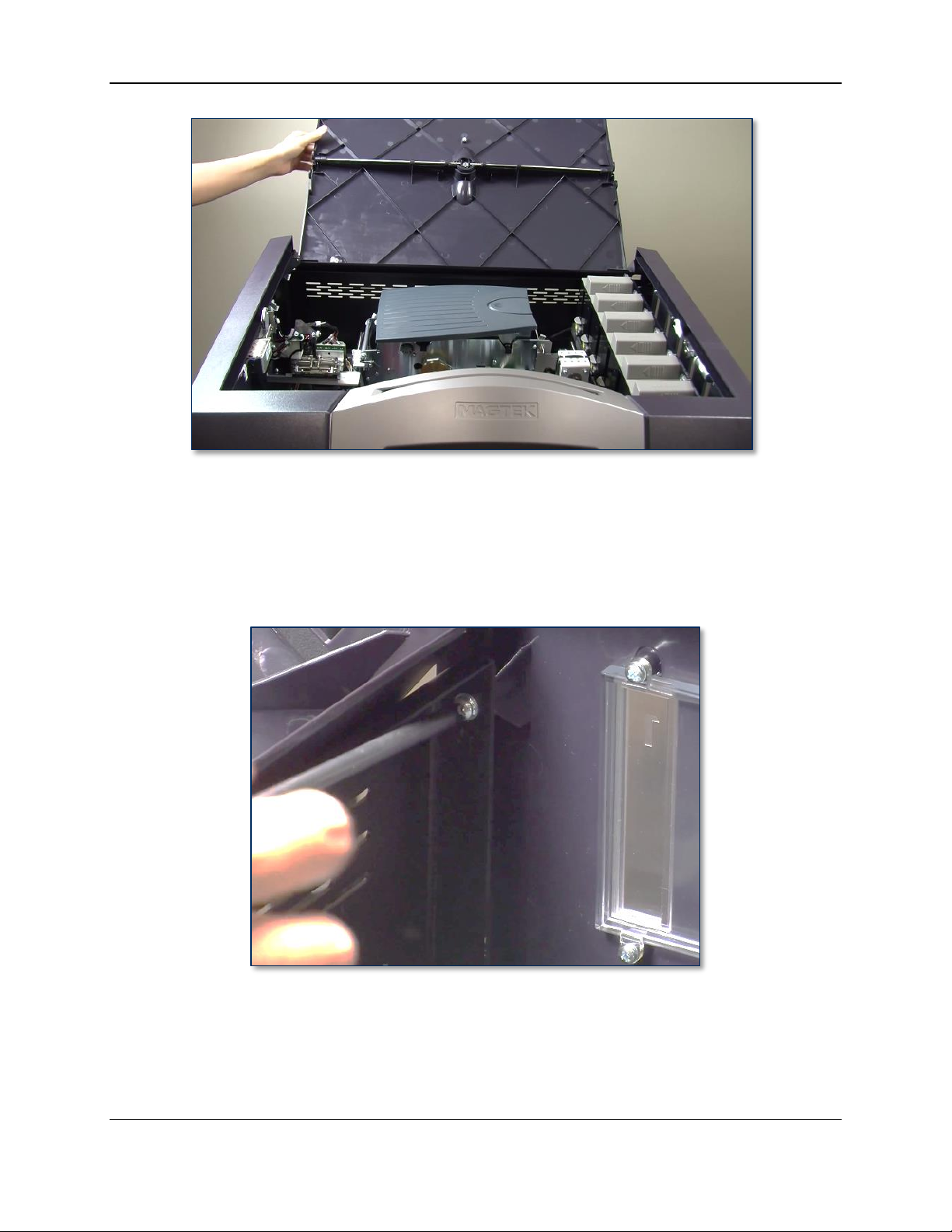

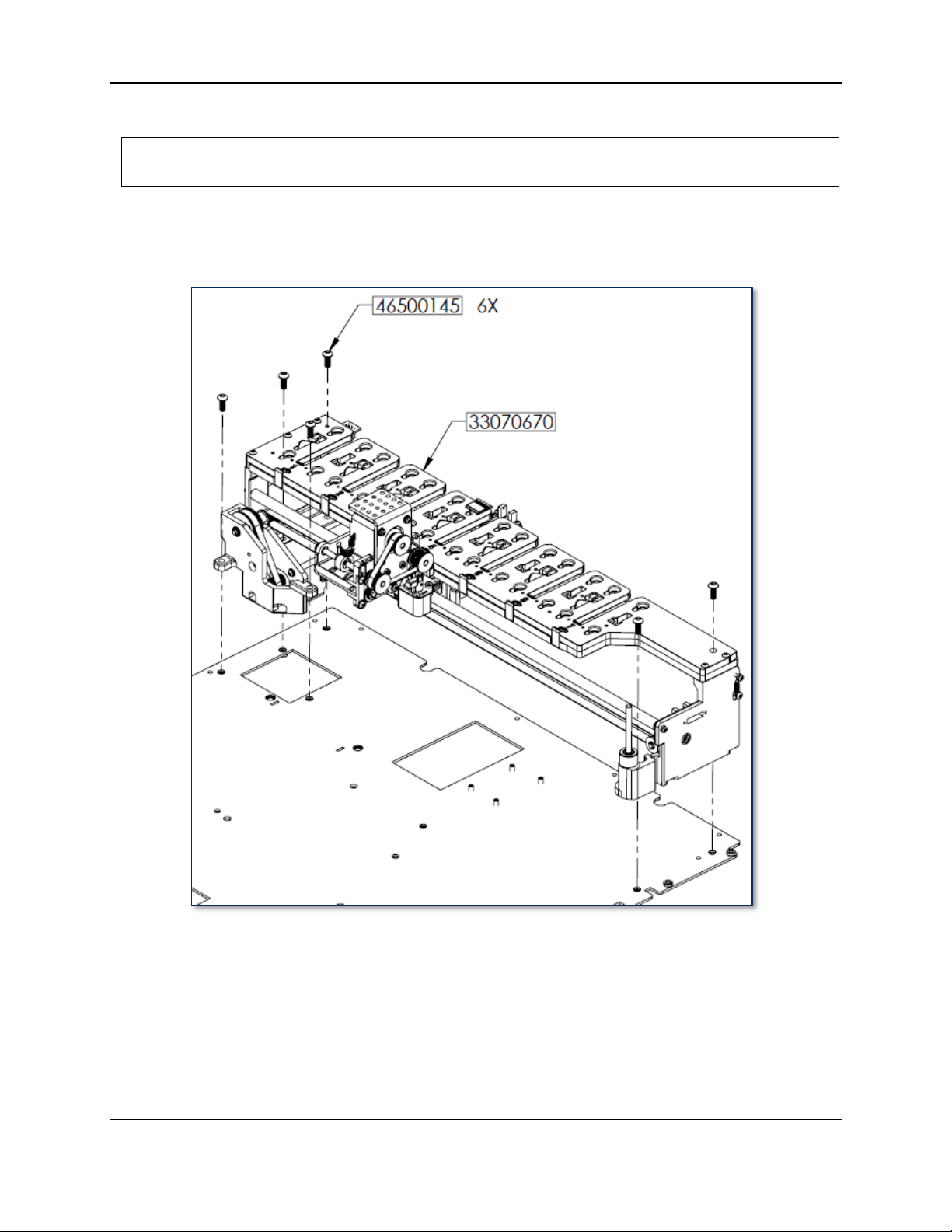

8) Locate the screw and washer that fasten the cover to the metal plate on the rear of the base. The

fastener can be found in the rear upper right of the device behind hopper 1, as shown in Figure 4-4.

Figure 4-4 - Removing the Right Side Cover Screw Near Top Access Door Hinge (FRONT LEFT VIEW)

9) During the next step, hold the top access door with one hand or it may fall or break.

10) Use the No. 2 Philips screwdriver to loosen the fastener.

11) Remove the top access door and set it aside with the two screws and washers (if necessary, move the

XY transport out of the way per section 2.8 How to Safely Move Transports By Hand).

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 46

Page 47

4 - Removal and Re-installation

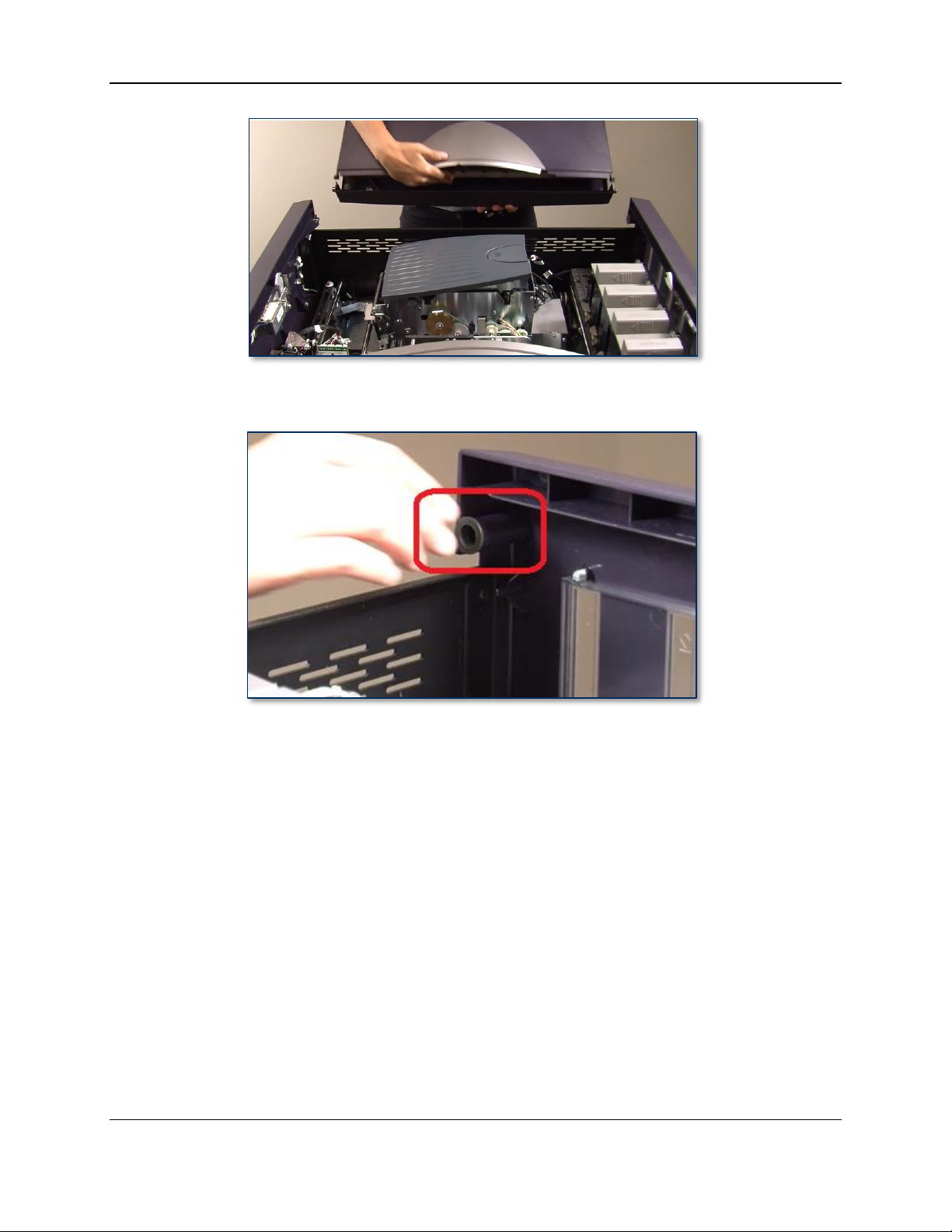

12) Remove the bushings from the top cover’s two hinges (one on each side) and set them aside with the

cover and the two screws and washers.

Figure 4-5 - Top Access Door Hinge Bushings (FRONT LEFT VIEW)

To re-install the top access door, reverse the steps for removing it. Be careful not to lose the door’s

bushings, which are not secured to the cover or to the top access door’s hinges.

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 47

Page 48

4 - Removal and Re-installation

Approximate time to remove: 5 minutes plus any sub-procedures

Approximate time to re-install: 5 minutes plus any sub-procedures

4.3 How to Remove / Re-install the Side Access Doors

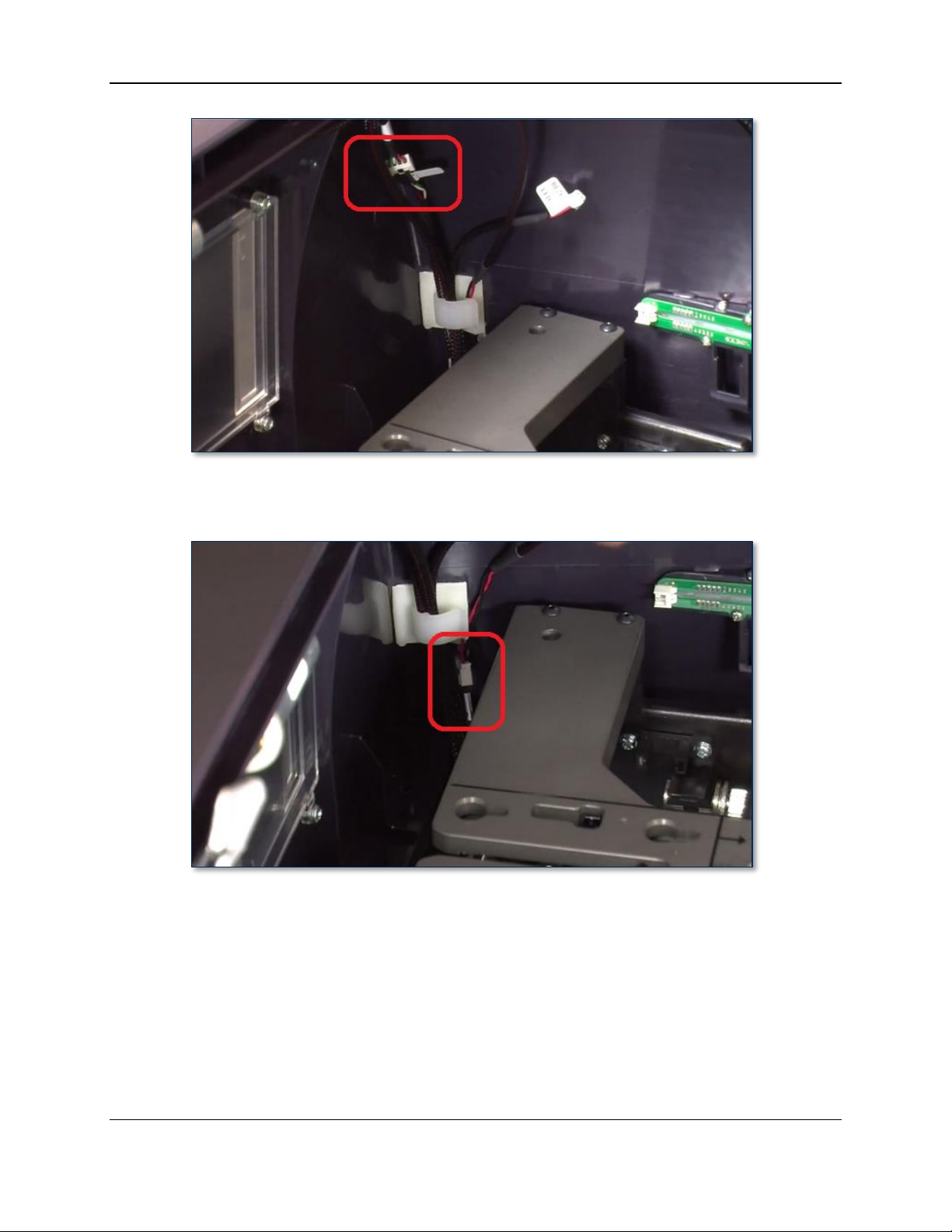

The side access doors secure the control electronics (embedded PC, power supply, power controller, and

main logic board) inside the device:

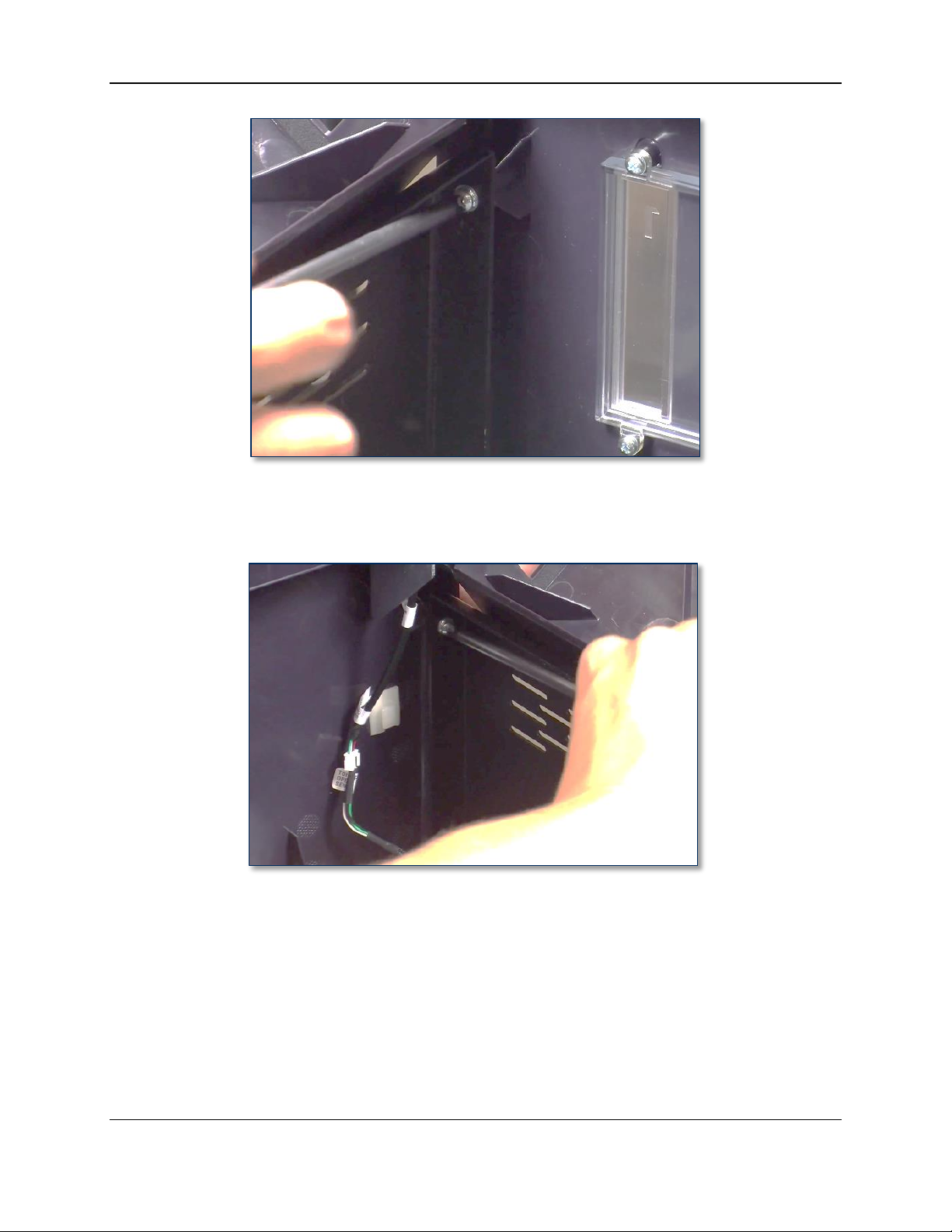

The right side access door gives easy access to the embedded PC’s connectors, including Ethernet

and USB ports (for example, to plug in a keyboard/mouse or USB thumb drive), and also provides

access to examine or replace the Main Logic Board (MLB).

The left side access door provides access to the power supply and the power controller board

(sometimes referred to as the “Green controller”). It is less common to need to open the left side

access door.

Figure 4-6 – Left and Right Side Access Doors (REAR VIEW)