Page 1

InSpec 9000 TM

ENCODED CARD TESTER

INSTALLATION AND OPERATION MANUAL

Manual Part Number 99875049 Rev 12

AUGUST 2004

REGISTERED TO ISO 9001:2000

1710 Apollo Court

Seal Beach, CA 90740

Phone: (562) 546-6400

FAX: (562) 546-6301

Technical Support: (651) 415-6800

or: (562) 546- 6803

www.magtek.com

i

Page 2

Copyright© 1996-2005

MagTek®, Inc.

Printed in the United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of MagTek, Inc.

MagTek and InSpec 9000 are registered trademarks of MagTek, Inc.

Microsoft, MS, and MS-DOS are registered trademarks, and Windows is a trademark of Microsoft

Corporation.

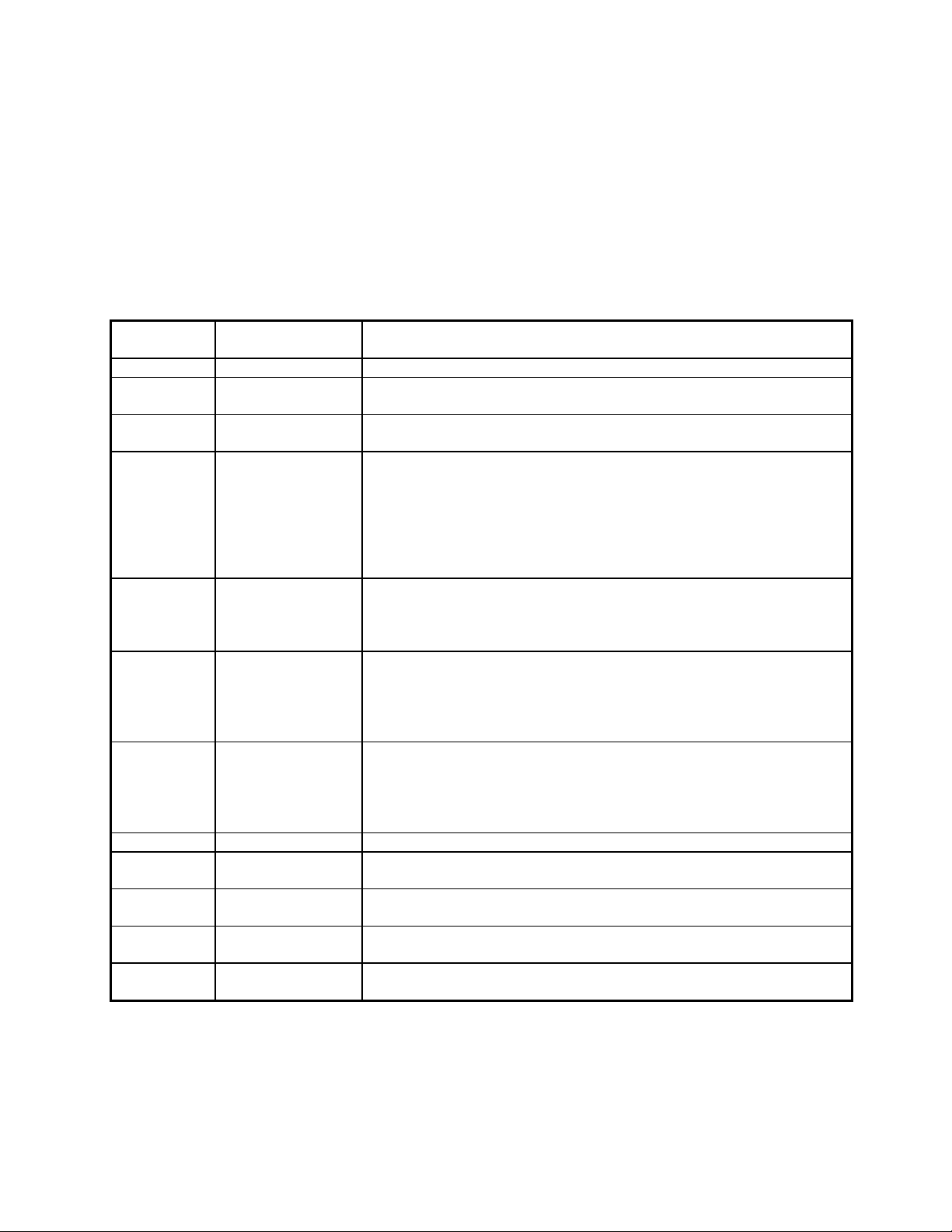

REVISIONS

Rev

Number

1 9/27/96 Release for Pre-Production Beta Units

2 12/18/96 Deleted Calibration, added Setup, and complete revision except for

3 1/16/97 Changed Setup screen to add “Cleaning Cycles” and “Total Setup”

4 2/24/98 Updated all screen captures to Windows 95; Changed

5 4/2/98 Added Product Information to front matter. Changed analysis area in

6 8/4/98 Added phone number on title page. Section 1: added part numbers.

7 4/21/99 Sec 1. Clarified note to state that cards within ISO 7810 spec can be

8 9/6/01 Front Matter: Updated agency approval status and Safety page.

9 4/15/03 Front Matter: added ISO line to logo, changed Tech Support phone

10 7/13/04 Sec 1, Requirements, MagTek Supplied: Test Cards (2) Changed

11 8/5/04 Sec 1, Requirements, MagTek Supplied: Deleted 3 ½ “ disk and

12 8/24/04 Throughout: Deleted references to Windows 95. Sec 2: Replaced

Date Notes

Appendices

in Section 2. Spec change, Card Parameters, Section 1

Requirements and Specs Sec 1; Added Roller Cleaning, added

Security to Main Screen Fig 3-2, Sec 3; Added Card Failures and

Noise Detection and Security to Sec 3, Figs 3-4, -5, -6, -7, -8; Added

Calibration and Verification Procedure, and Fig 3-11 to Sec 3;

Added new Figs 4-2, -5, Sec 4; Added message to troubleshooting

table Sec 5; Added Appendix D, Error Messages; Added Index.

Spec, Sec 1. Changed cleaning procedure, Sec 2. Added Noise

Detection description, and changed Figs 3-2, 3-7, and 3-11, Sec 3.

Changed Figs 4-4, 4-5, 4-6, and 4-8, Sec 4.

Section 2: added installation disks; added cleaning, test card, and

head polishing procedures. Section 3: added 'password' to index.

Section 4, Figure 4-2 and 4-3: changed illustration and related text

to update.

read. Added card-cleaning precaution. Sec 2. Combined Head and

Roller cleaning procedure to reflect software change which adds

second cycle to cleaning; Added caution note for letting unit dry

before inserting a card.

number, added new warranty statement.

P/N 96700033 to 96600033.

added CD P/N 39810316.

Software Section.

ii

Page 3

LIMITED WARRANTY

MagTek warrants that the products sold to Reseller pursuant to this Agreement will perform in accordance with

MagTek’s published specifications. This warranty shall be provided only for a period of one year from the date

of the shipment of the product from MagTek (the “Warranty Period”). This warranty shall apply only to the

original purchaser unless the buyer is authorized by MagTek to resell the products, in which event, this warranty

shall apply only to the first repurchase.

During the Warranty Period, should this product fail to conform to MagTek’s specifications, MagTek will, at its

option, repair or replace this product at no additional charge except as set forth below. Repair parts and

replacement products will be furnished on an exchange basis and will be either reconditioned or new. All replaced

parts and products become the property of MagTek. This limited warranty does not include service to repair

damage to the product resulting from accident, disaster, unreasonable use, misuse, abuse, customer’s negligence,

Reseller’s negligence, or non-MagTek modification of the product. MagTek reserves the right to examine the

alleged defective goods to determine whether the warranty is applicable.

Without limiting the generality of the foregoing, MagTek specifically disclaims any liability or warranty for

goods resold in other than MagTek’s original packages, and for goods modified, altered, or treated by customers.

Service may be obtained by delivering the product during the warranty period to MagTek (1710 Apollo Court,

Seal Beach, CA 90740). If this product is delivered by mail or by an equivalent shipping carrier, the customer

agrees to insure the product or assume the risk of loss or damage in transit, to prepay shipping charges to the

warranty service location and to use the original shipping container or equivalent. MagTek will return the product,

prepaid, via a three (3) day shipping service. A Return Material Authorization (RMA) number must accompany

all returns.

MAGTEK MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAGTEK DISCLAIMS ANY

WARRANTY OF ANY OTHER KIND, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

EACH PURCHASER UNDERSTANDS THAT THE MAGTEK PRODUCT IS OFFERED AS IS. IF THIS

PRODUCT DOES NOT CONFORM TO MAGTEK’S SPECIFICATIONS, THE SOLE REMEDY SHALL BE

REPAIR OR REPLACEMENT AS PROVIDED ABOVE. MAGTEK’S LIABILITY, IF ANY, TO RESELLER

OR TO RESELLER’S CUSTOMERS, SHALL IN NO EVENT EXCEED THE TOTAL AMOUNT PAID TO

MAGTEK BY RESELLER UNDER THIS AGREEMENT. IN NO EVENT WILL MAGTEK BE LIABLE TO

THE RESELLER OR THE RESELLER’S CUSTOMER FOR ANY DAMAGES, INCLUDING ANY LOST

PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OF OR INABILITY TO USE SUCH PRODUCT, EVEN IF MAGTEK HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

LIMITATION ON LIABILITY

EXCEPT AS PROVIDED IN THE SECTIONS RELATING TO MAGTEK’S LIMITED WARRANTY,

MAGTEK’S LIABILITY UNDER THIS AGREEMENT IS LIMITED TO THE CONTRACT PRICE OF THE

PRODUCTS.

MAGTEK MAKES NO OTHER WARRANTIES WITH RESPECT TO THE PRODUCTS, EXPRESSED OR

IMPLIED, EXCEPT AS MAY BE STATED IN THIS AGREEMENT, AND MAGTEK DISCLAIMS ANY

IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

MAGTEK SHALL NOT BE LIABLE FOR CONTINGENT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES TO PERSONS OR PROPERTY. MAGTEK FURTHER LIMITS ITS LIABILITY OF ANY KIND

WITH RESPECT TO THE PRODUCTS, INCLUDING ANY NEGLIGENCE ON ITS PART, TO THE

CONTRACT PRICE FOR THE GOODS.

MAGTEK’S SOLE LIABILITY AND BUYER’S EXCLUSIVE REMEDIES ARE STATED IN THIS SECTION

AND IN THE SECTION RELATING TO MAGTEK’S LIMITED WARRANTY.

iii

Page 4

This product has been evaluated, tested, and certified by the Canadian Standards Association (CSA 22.2), No.

950, and Underwriters Laboratories (UL1950). In order to insure that it maintains the safety integrity that was

designed into the product, and for which it has been evaluated by the Safety Certification Agencies, compliance

with all Installation Instructions and Safety Requirements is essential.

SAFETY REQUIREMENTS

Never do any of the following:

• Use a ground adapter plug to connect equipment to a power source receptacle that lacks a ground connection

terminal.

• Attempt any maintenance function that is not specifically described in this Manual or any other MagTek

InSpec 9000 Manual.

• Remove any of the covers or guards that are fastened with screws. There are not operator-serviceable areas

within these covers.

• Override or “cheat” electrical or mechanical interlock devices.

• Use supplies or cleaning materials for other than their intended purposes.

• Operate the equipment if unusual noises or odors are noticed.

Consider the following before operating the InSpec 9000:

• Connect equipment to a properly grounded power source receptacle. If in doubt, have the receptacle checked

by a qualified electrician.

• Improper connection of the equipment grounding conductor can result in risk of electrical shock.

• Locate equipment on a solid support surface with adequate strength for the weight of the machine.

• Be careful in moving or relocating the equipment. Use the proper lifting techniques.

• Use materials and supplies specifically designed for MagTek equipment. Use of unsuitable materials may

result in poor performance and can possibly create a hazardous situation.

iv

Page 5

FCC WARNING STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

FCC COMPLIANCE STATEMENT

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following two

conditions: (1) This device may not cause harmful interference. And (2) this device must accept any interference

received, including interference that may cause undesired operation.

CANADIAN DOC STATEMENT

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de las classe A prescrites dans le Réglement sur le brouillage radioélectrique édicté par les

ministère des Communications du Canada.

CE STANDARDS

Testing for compliance to CE was performed by an independent laboratory. The unit under test was found compliant

to Class A.

UL/CSA

This product is listed per Underwriter Laboratories and Canadian Underwriter Laboratories 1950.

v

Page 6

Product Information

The InSpec 9000 Encoded Card Tester is a real-time, continuous feedback, production line card tester.

Because the parameters that appear on the screen are color coded, and warning screens advise when a

card “MAY NOT BE READABLE IN THE FIELD,” the tester is relatively easy to operate. The Tester

is intended to be a reliable instrument of in-line testing that does not require a technician or an engineer

to operate; nor does it require extensive technical knowledge of magnetics to operate and to interpret the

parameters on the screen. The InSpec 9000 Tester is designed to complement the more expensive,

highly complex, precision, laboratory test equipment. MagTek recommends that out-of-spec cards

from the Tester should be confirmed periodically by an independent laboratory.

Because the InSpec 9000 is a cost-effective tradeoff compared with a precision laboratory test unit,

some policy judgment is required to interpret ISO limits and the machine tolerances or “measurement

uncertainty.” ISO limits and measurement uncertainties are listed in Section 3, Figure 3-11, and

examples are shown in Section 4, Figures 4-2 and 4-3. Measurement uncertainty for average amplitude,

average bit size, and start sentinel are concerns of management for acceptance or rejection of cards. If

these parameters are centered on the screen between minimum and maximum limits (centered in the

green), the card will be acceptable even if the measurement uncertainty is worst case. If these

parameters are near maximum or minimum limits when worst case measurement uncertainty is

projected, the following precautions should be considered: the Tester should be checked; the sample

may need to be expanded; or the cards may need to be physically checked to ensure they are clean and

flat. Ultimately, judgment is required, and a policy decision should be in place for the operator.

The screen may also warn of two other parameters that concern noise detection: Added Pulse Detection

and Wave Form Distortion. Tests of these parameters are critical in HiCo material testing. Exceeding

the ISO limit by even a small percentage may affect read reliability. Since these two parameters are

characteristic of the magnetic stripe and not encoding, issuers who have prequalified their stripes at a

testing laboratory will rarely see this warning. If the warning appears frequently, sample cards should

be sent to a testing laboratory for investigation and confirmation of the absolute values for the added

pulse and waveform conditions.

For accurate card reading, normal preventive maintenance is the guideline. Consult the following:

Card size and thickness (Section 1, Specifications)

Card and Tester Cleaning (Section 2, Cleaning)

Calibration (Section 3, Calibration and Verification)

For corrective maintenance, consult Section 5, Troubleshooting and Appendix D, Error Messages.

vi

Page 7

vii

Page 8

TABLE OF CONTENTS

SECTION 1. FEATURES AND SPECIFICATIONS.....................................................................................1

FEATURES...............................................................................................................................................1

REQUIREMENTS.....................................................................................................................................1

MagTek supplied ..................................................................................................................................1

User supplied........................................................................................................................................2

SPECIFICATIONS....................................................................................................................................2

SECTION 2. INSTALLATION......................................................................................................................3

UNPACKING.............................................................................................................................................3

HARDWARE.............................................................................................................................................3

SOFTWARE..............................................................................................................................................4

SETUP......................................................................................................................................................5

Keyboard Protocol................................................................................................................................6

Taskbar Removal .................................................................................................................................7

CLEANING................................................................................................................................................7

Card Cleaning.......................................................................................................................................8

Head and Roller Cleaning - Standard Card, P/N 96700004................................................................8

TEST CARDS ...........................................................................................................................................9

Head Polishing - 0.5-micron (Abrasive Card), P/N 96700014 ...........................................................10

SAMPLING TECHNIQUES.....................................................................................................................10

SECTION 3. OPERATION.........................................................................................................................13

OPENING THE TESTER PROGRAM....................................................................................................13

MAIN SCREEN.................................................................................................................... ...................14

Windows Screen.................................................................................................................................14

CARD STOCK, SYSTEM, SHIFT...................................................................................................... .....17

SECURITY..............................................................................................................................................18

READING A CARD.................................................................................................................................19

CARD FAILURES...................................................................................................................................19

PARAMETERS .......................................................................................................................................21

ISO Limits and Measurement Uncertainty..........................................................................................23

Amplitude............................................................................................................................................24

Bit Size................................................................................................................................................25

Sub. Int. ..............................................................................................................................................25

Adj. Bit ................................................................................................................................................26

Adj. Sub..............................................................................................................................................26

Start Sent............................................................................................................................................26

CALIBRATION.................................................................................................................... ....................27

CALIBRATION VERIFICATION..............................................................................................................28

SECTION 4. GRAPHICS PRESENTATIONS ...........................................................................................29

ISO PARAMETERS................................................................................................................................30

CARD PROFILES...................................................................................................................................31

PERFORMANCE CHARTS............................................................................................................. .......36

INTERPRETING PERFORMANCE CHARTS........................................................................................36

DATABASE.............................................................................................................................................40

SECTION 5. TROUBLESHOOTING..........................................................................................................43

TROUBLESHOOTING TABLE ...............................................................................................................43

CARD EXTRACTION..............................................................................................................................44

APPENDIX A. MAGNETIC ENCODING....................................................................................................47

HISTORICAL BACKGROUND ...............................................................................................................47

BASICS OF MAGNETIC RECORDING..................................................................................................48

Magnetic Tape....................................................................................................................................48

Modern Magnetic Tape.......................................................................................................................50

Encoding Process...............................................................................................................................50

Magnetic Tape Characteristics...........................................................................................................52

DIGITAL MAGNETIC RECORDING.......................................................................................................54

F2F Encoding .....................................................................................................................................54

APPENDIX B. GLOSSARY.......................................................................................................................61

APPENDIX C. CARD STANDARDS.........................................................................................................65

ISO PARAMETERS................................................................................................................................65

HIGH COERCIVITY MAGNETIC MEDIA ...............................................................................................69

viii

Page 9

CARD STANDARDS LISTING ...............................................................................................................69

APPENDIX D. ERROR MESSAGES.........................................................................................................73

INDEX..........................................................................................................................................................79

ILLUSTRATIONS

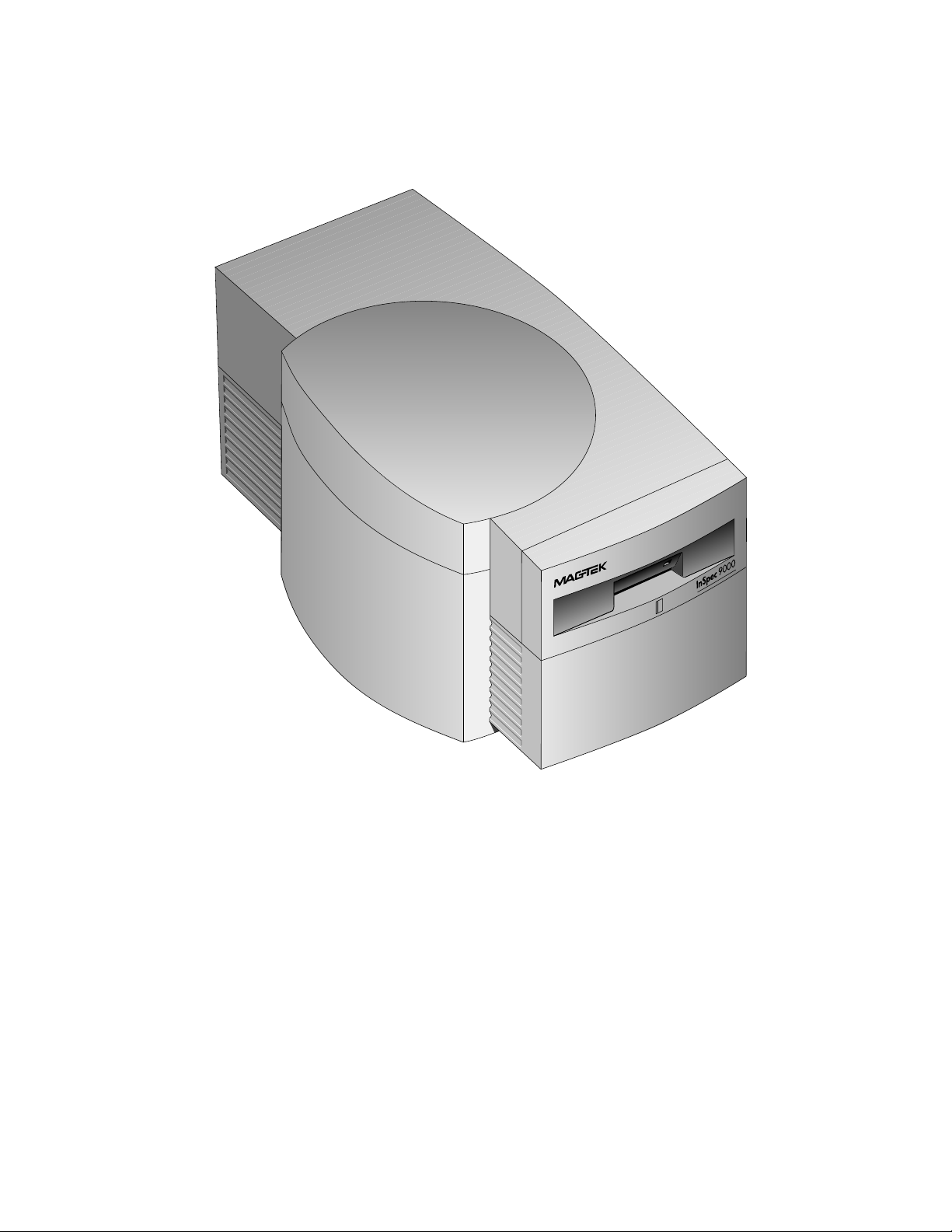

Figure 1-1. InSpec 9000 Card Tester ..........................................................................................................x

Figure 2-1. Fuse Holder ...............................................................................................................................4

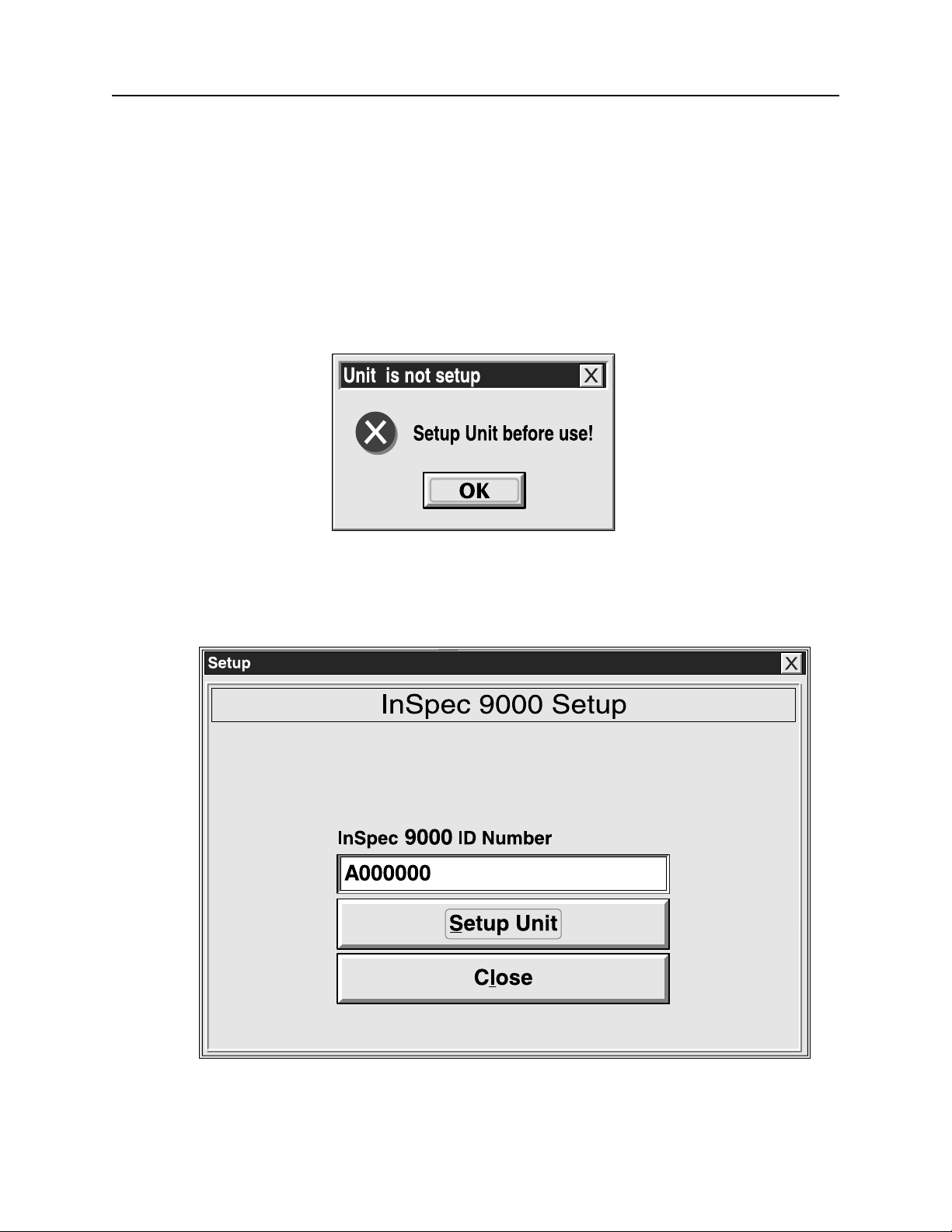

Figure 2-2. Unit Not Set Up..........................................................................................................................5

Figure 2-3. Setup Screen.............................................................................................................................5

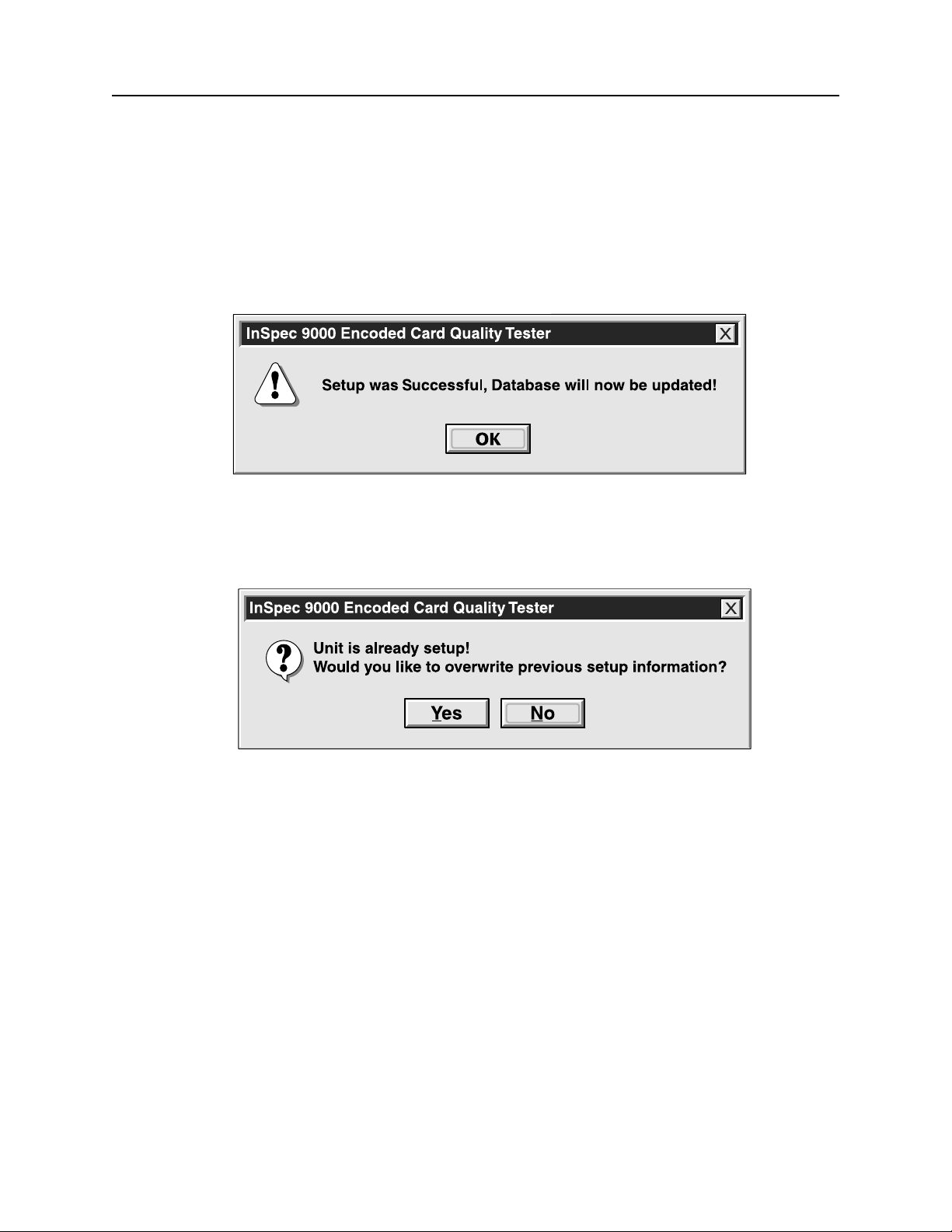

Figure 2-4. Successful Setup.......................................................................................................................6

Figure 2-5. Setup Previously Performed......................................................................................................6

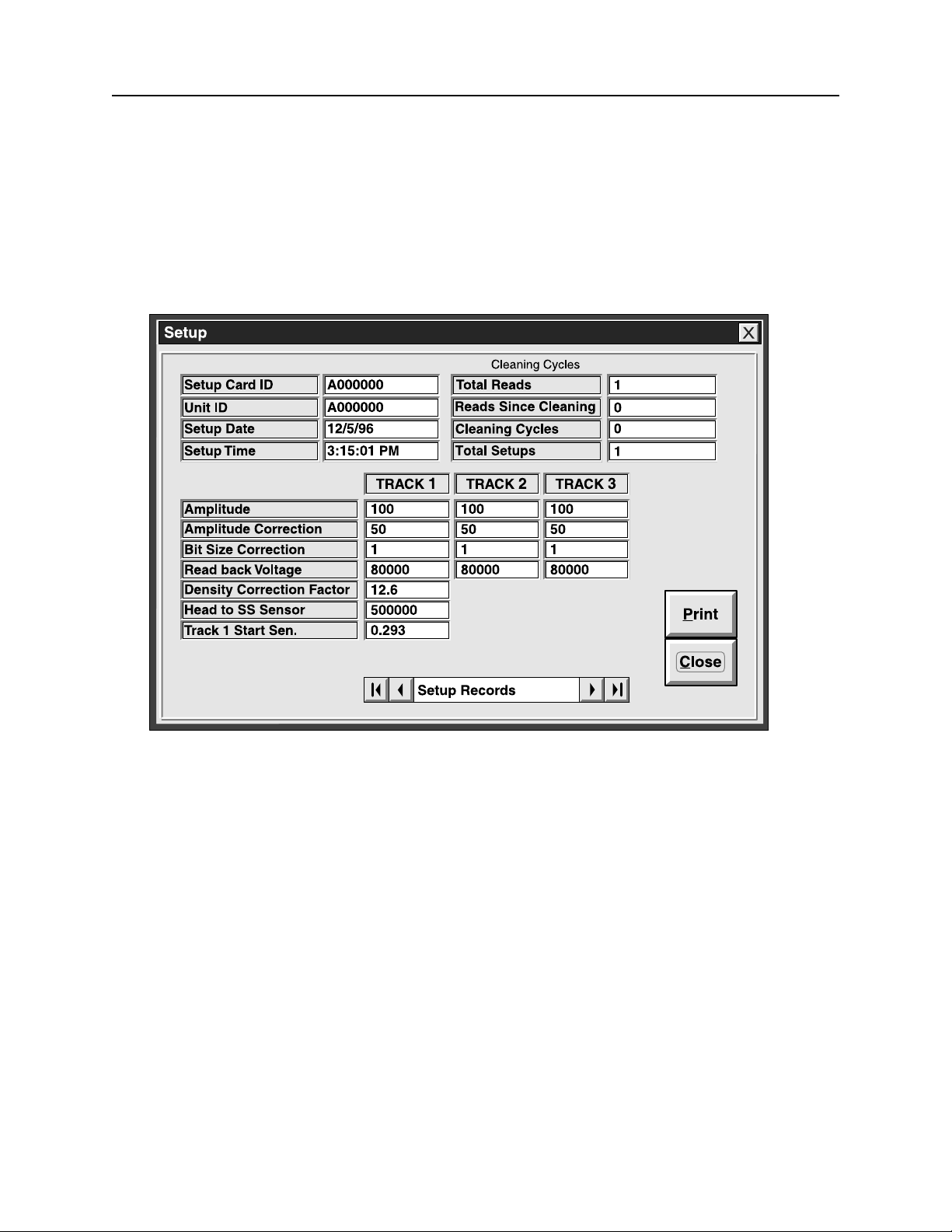

Figure 2-6. Setup Database.........................................................................................................................7

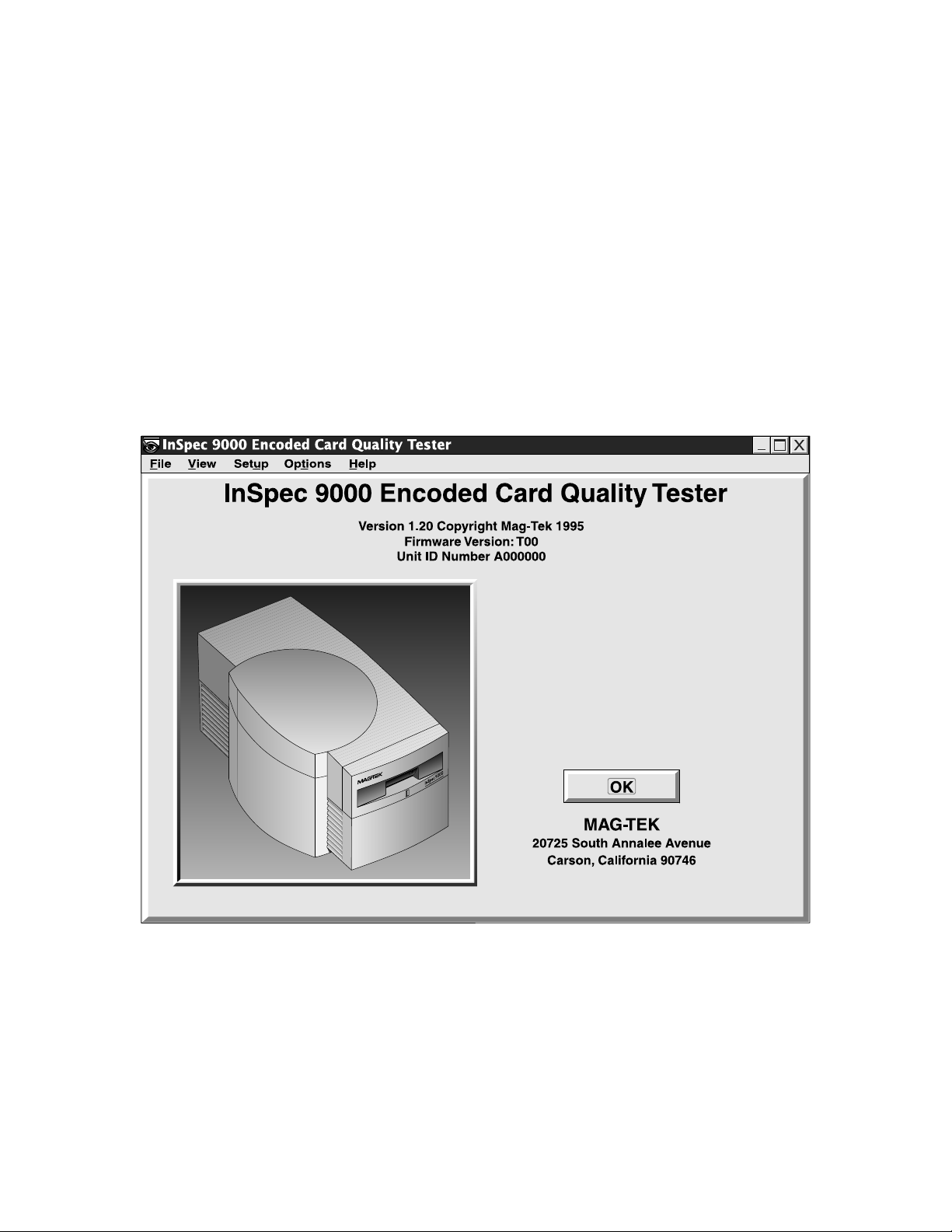

Figure 3-1. Opening Display ......................................................................................................................13

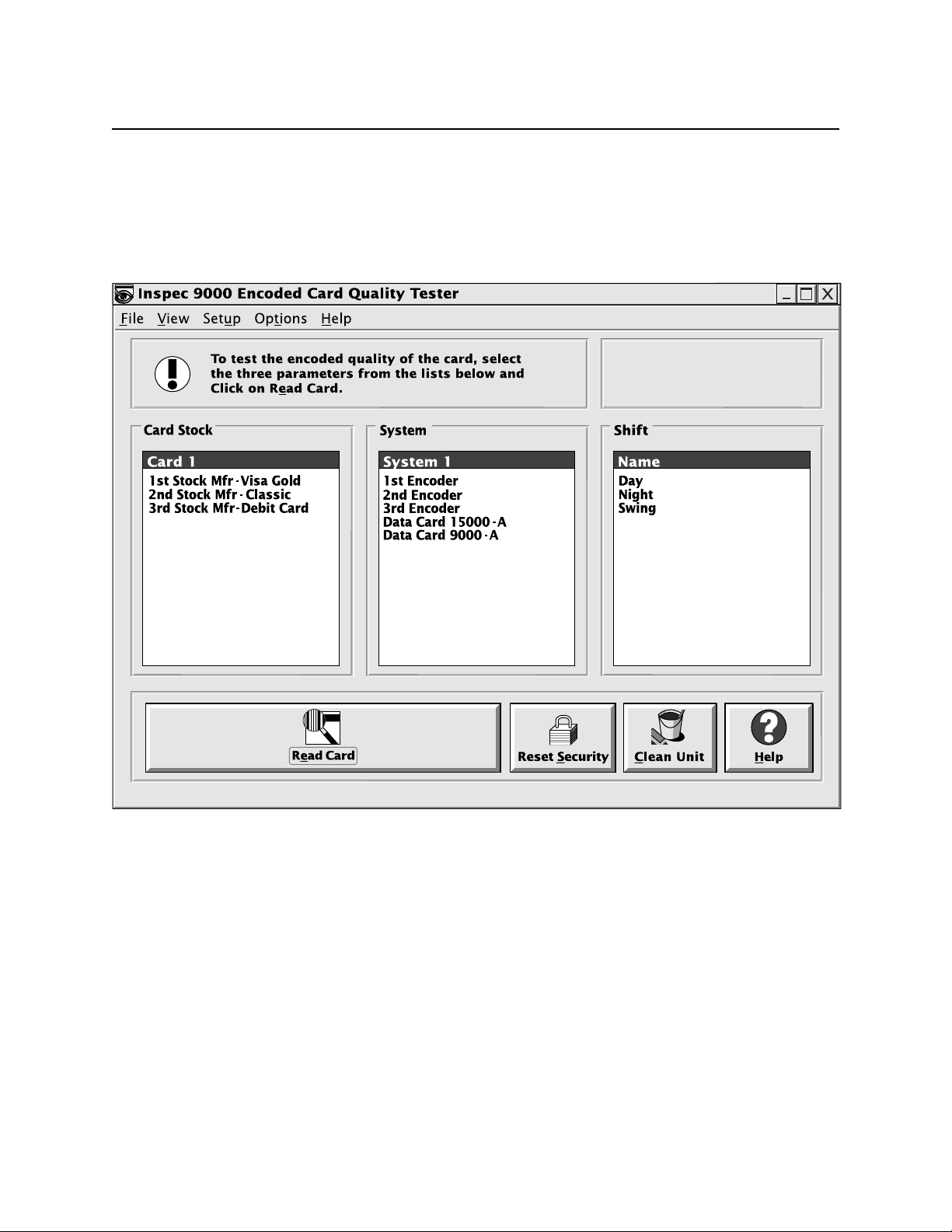

Figure 3-2. Main Screen.............................................................................................................................14

Figure 3-3. Archive Database ....................................................................................................................15

Figure 3-4. Security Screen .......................................................................................................................18

Figure 3-5. LRC Failure..............................................................................................................................20

Figure 3-6. LRC or Parity Check Failure....................................................................................................20

Figure 3-7. Start Sentinel Not Found .........................................................................................................20

Figure 3-8. Added Pulse Detected.............................................................................................................21

Figure 3-9. Max/Min ISO Parameters ........................................................................................................22

Figure 3-10. Average ISO Parameters.......................................................................................................23

Figure 3-11. ISO Limits ..............................................................................................................................24

Figure 3-12. Reference Amplitude.............................................................................................................25

Figure 3-13. Bit Size...................................................................................................................................26

Figure 4-1. ISO Parameters.......................................................................................................................30

Figure 4-2. Numerical Parameters.............................................................................................................32

Figure 4-3. Numerical Printout...................................................................................................................33

Figure 4-4. Amplitude Graph......................................................................................................................34

Figure 4-5. Start Sentinel ...........................................................................................................................35

Figure 4-6. Performance - Amplitude.........................................................................................................37

Figure 4-7. Performance - Bit Size.............................................................................................................38

Figure 4-8. Performance - Start Sentinel ...................................................................................................39

Figure 4-9. Card Database Search............................................................................................................40

Figure 4-10 Card Database Records.........................................................................................................41

Figure 5-1. CET Orientation.......................................................................................................................44

Figure 5-2. CET Insertion...........................................................................................................................44

Figure 5-3. CET Rotation ...........................................................................................................................45

Figure 5-4. CET Extraction.........................................................................................................................45

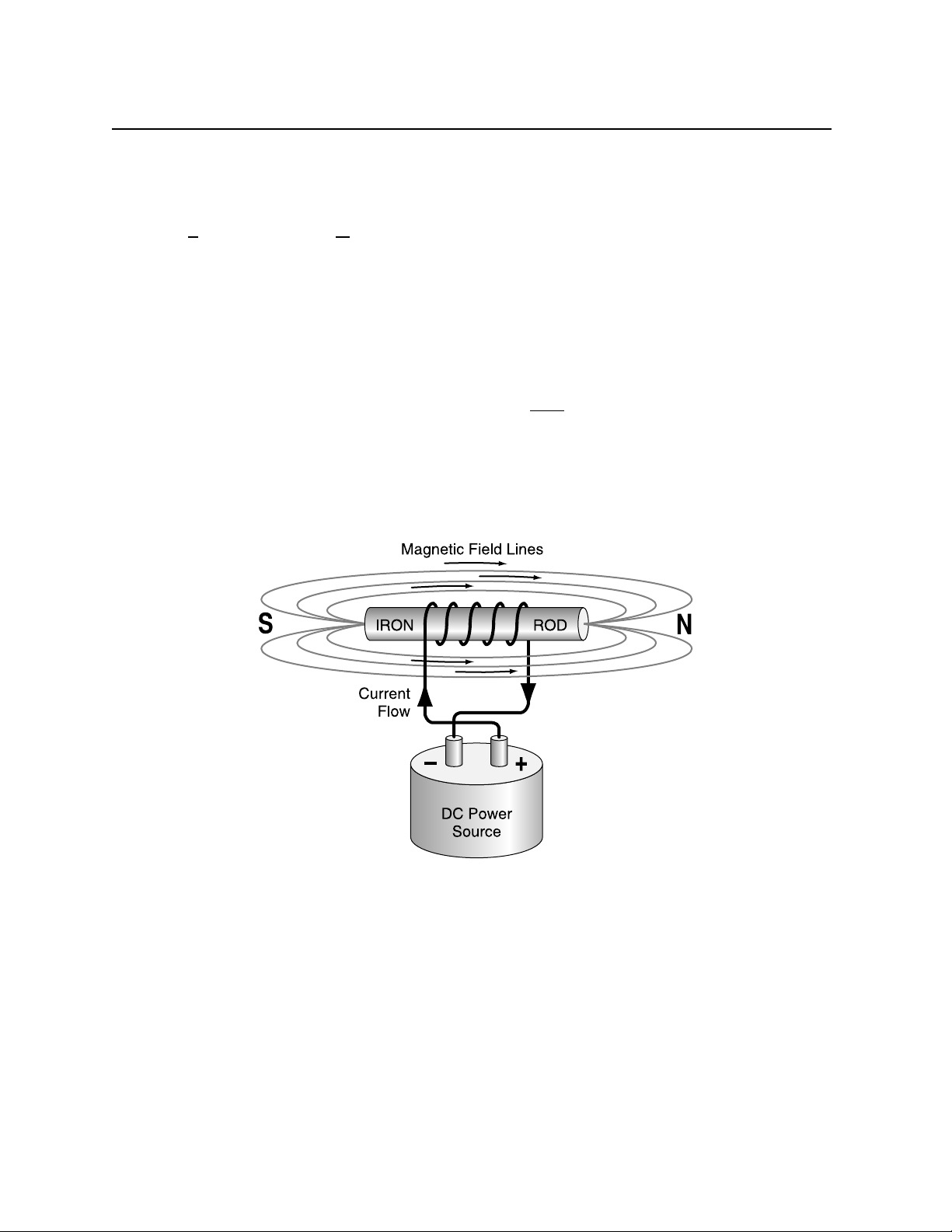

Figure A-1. Magnetic Field.........................................................................................................................48

Figure A-2. Reverse Polarity......................................................................................................................49

Figure A-3. Encoding Head Model.............................................................................................................50

Figure A-4. Magnetic Tape Model..............................................................................................................51

Figure A-5. Flux Transitions.......................................................................................................................52

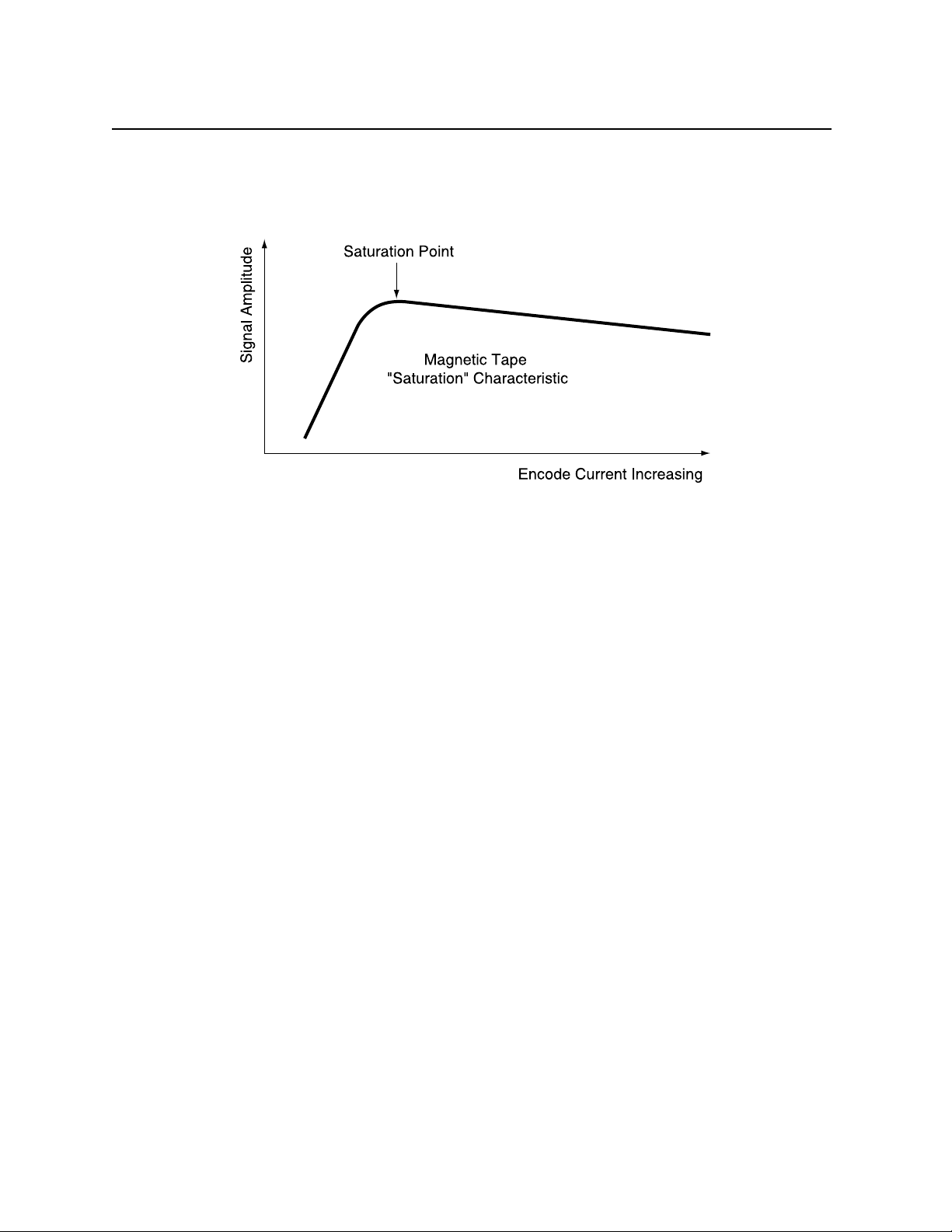

Figure A-6. Encode Current Level..............................................................................................................52

Figure A-7. Signal Amplitude .....................................................................................................................53

Figure A-8. Bit Cell - Flux Transition..........................................................................................................55

Figure A-9. Card Coding ............................................................................................................................56

Figure A-10. Bit Cells for 0 and 1 Bits........................................................................................................58

ix

Page 10

x

Figure 1-1. InSpec 9000 Card Tester

Page 11

SECTION 1. FEATURES AND SPECIFICATIONS

The InSpec 9000 Encoded Card Tester measures parameters of magnetic stripe encoding. The

parameters are shown on a computer screen and compared with ISO (International Standards

Organization) standards. Because the parameters are presented as graphic illustrations, they are

easy to read and easy to understand. The Tester also provides performance trends based on a

database of test results.

FEATURES

• Measures amplitude, bit size, and start sentinel, and compares results with ISO standards and

presents data in various graphs, charts and tables

• Provides previous measurements of individual cards or daily summaries to establish trends

• Presents card profile graphs of each measured parameter

• Easily installed and easy to use Windows-based software

• Uses specially provided cards for easy head cleaning

• Maintains database files

• On-site calibration from user collected data on a test card compared to a factory-provided

card

• Security password to restrict access or permit controlled use access to certain data

REQUIREMENTS

Equipment needed to operate the Tester is either supplied by MagTek or the customer. These

items are listed below.

MagTek supplied

• InSpec 9000 Card Tester hardware, P/N 39810003; Software-CD, Noise Detect, P/N

39810316

• Cable, 9 pin male Tester to 9-pin female PC Adapter, P/N 21015823

• Cable, power from Tester to wall receptacle, P/N 71100001

• Cleaning Cards, P/N 96700004

• Polishing Card, 0.5 micron (1), P/N 96700014

• Test Cards (2), P/N 96600033

• Setup Cards (2) - InSpec 9000, unit specified, P/N 96600036

• Card Extraction Kit, P/N 39814801

1

Page 12

InSpec 9000 Encoded Card Tester

User supplied

The recommended minimum requirements are as follows:

• Pentium Computer System

• VGA color monitor (resolution 800 x 600 pixels or higher)

• 8MB RAM (recommended 16MB)

• 10MB of hard disk space

• 1 Serial Port

• Windows 98, ME, NT, or 2000

• Color Printer

SPECIFICATIONS

Operational

Operating Voltage: 100 – 240 VAC

Operating Current 1.0 amp

Operating Temperature: 50oF to 122oF (+10oC to +50oC)

Humidity: 10% to 90% without condensing

Card Speed: 8 inches per second, typical

Resolution 10µ inches

Analysis Area All three data tracks excluding 0.130 inch at each end

Measure Limits Conform to ISO 7811 within Analysis Area

Mechanical

Depth: 13.3 inches

Width: 7.5 inches

Height: 7.1 inches

Weight: 8 lbs.

Card Parameters

Width and Length: Per ISO/IEC Specification 7810:1995(E)

Thickness: 0.030 in ± 0.003 in (0.76 mm ± 0.08 mm)

Note

The InSpec 9000 may not accurately read cards whose thickness and/or warpage

exceed the ISO 7810 specification. In addition, cards that are not properly

cleaned may give poor results along with contamination of the card path and

head face.

2

Page 13

SECTION 2. INSTALLATION

This section provides instructions for installing the Tester. There are five parts to the installation

of the InSpec 9000 Tester: unpacking, hardware installation, software installation, setup, and

cleaning. Because card sampling is required for production, some examples are referenced in this

section.

UNPACKING

Remove all material from the shipping carton and check the material with the shipping invoice

to ensure everything on the invoice is contained in the carton. If there is damage to the unit or

material on the invoice is missing, notify MagTek and the carrier.

Note

Retain the shipping carton and all packing material. The Tester

may be packed and shipped back to the factory periodically for

calibration or warranty service .

HARDWARE

Install the hardware as follows:

1. Place the Tester near the PC and a wall receptacle so that the cables can be installed.

Caution

Ensure power is off before plugging in cables, or

damage to equipment or the program may result.

2. Plug the cable with the 9-pin connector into the Tester and the other end to the PC Com

Port. It may be necessary to use a DB9 to DB25 adapter for the Com port.

3. Plug the power cord into the Tester and the wall receptacle.

4. Power up the computer and press the power on (I) switch on the rear panel of the Tester.

5. The LED on the front of the Tester should be green. If the LED does not come on,

check to ensure the cables are properly connected.

6. If the LED still does not light, press the power switch off, remove the cables, and check

the fuse, located next to the power switch as shown in Figure 2-1.

7. Replace the fuse if necessary, reconnect the cables, and power up. If the LED still does

not light, call for technical or supervisory personnel.

3

Page 14

InSpec 9000 Encoded Card Tester

Figure 2-1. Fuse Holder

SOFTWARE

To begin the installation, insert the CD into the appropriate drive. The installation program will

automatically start. If the installation program does not start automatically, select Run from the

Start menu. Within the open field, type x:\setuup, where x: is the drive letter of your CD ROM

drive. Click OK to begin the installation. The installation program will guide you through the

setup process.

Note for International Users

The Inspec 9000 software requires regional settings be set to

English (United States). Some features may not work correctly if

other settings are used.

4

Page 15

Section 2. Installation

SETUP

To setup the unit for operation, perform the following steps:

1. From the Windows Program Manager, open the InSpec 9000 program. (If more details

are required for opening the program, refer to the next section, Operation.)

2. After the opening screen briefly flashes on the screen and the main menu appears, click

on the Read Card button. If the unit is not set up, the dialog box shown in Figure 2-2 will

appear. Error messages are listed in Appendix D.

Figure 2-2. Unit Not Set Up

3. From the Main Menu select Setup, select Hardware, then Setup and the following screen

will appear:

Figure 2-3. Setup Screen

5

Page 16

InSpec 9000 Encoded Card Tester

The ID number is a unique number for that unit that also identifies the firmware. If a problem

exists with the unit, this number will be needed by technical support personnel.

4. Click on Setup unit. The dialog box to appear will request the Setup Card: Insert

Setup Card No: A000000. The number that appears on the box will be the

number on the Setup Card that was shipped with the unit.

5. Insert the Setup Card, and the next dialog box to appear is shown in Figure 2-4

Figure 2-4. Successful Setup

If the unit has been previously set up, the screen shown in Figure 2-5 will appear:

Figure 2-5. Setup Previously Performed

To obtain information about the database setup, select View from the Main Menu, then Setup

Database. Figure 2-6 shows the Setup Database screen. The screen lists the identification

numbers, the date and time of setup, the total number of cards read, and the number of reads

since the last cleaning. Information at the bottom of the screen is for maintenance personnel.

Keyboard Protocol

The keyboard protocol of the InSpec 9000 follows the protocol of Windows; for example, if a

keyboard is to be used instead of a mouse, the underlined letter in the dialog box can be typed

instead of clicking on it with a mouse. In Figure 2-5, if the previous setup is to be overwritten,

instead of clicking on Yes with the mouse, type Y. Sometimes the keys Ctrl or Alt are used with

the underlined letter. Check the Windows documentation for details.

6

Page 17

Section 2. Installation

Taskbar Removal

If the taskbar at the bottom of the screen is in the way of viewing the screen, it may be necessary

to remove it. Click on Start, then Settings and Taskbar. When Taskbar Properties appears,

click on Taskbar Options, then Auto hide, then OK. The Taskbar will then go below the

bottom of the screen. To reposition the taskbar, move the cursor to the bottom of the screen, and

the taskbar will reappear.

Figure 2-6. Setup Database

CLEANING

Accurate signal amplitude measurements (described in Section 3) depend on high quality contact

between the Tester’s magnetic head and the magnetic stripe under test. If the head does not

make good contact by even a small amount, the resulting signal amplitude measurement value

will be lower than it would have been with proper contact. A separation between the head and

stripe of only 0.0005 inches (13µm) can lower the signal amplitude result by 50%.

Aside from surface distortions on the magnetic stripe or card, contamination is primarily

responsible for poor head to stripe contact.

7

Page 18

InSpec 9000 Encoded Card Tester

Offset powder sometimes used in card manufacture to prevent blocking (powder can cause a

significant decrease in amplitude and can contaminate the read head giving false readings for

many cards.)

• Packing materials; fibers from containers

• Hologram/Signature, Panel/Magnetic media particles “flash” not adhering to the card as

intended

• Cards can also become statically charged making them attract airborne dust.

Card Cleaning

To optimize test results, MagTek recommends cleaning the magnetic stripe cards with ammoniabased glass cleaner before testing.

Caution

Do not clean magnetic stripe cards with alcohol or damage to the

magnetic stripe may occur.

Head and Roller Cleaning - Standard Card, P/N 96700004

The Tester can only provide reliable results if it is clean. As a result, the Tester will issue a

warning after 50 card read cycles. When the warning is received, the cleaning procedure should

be performed. The warning will appear for each card tested until the cleaning procedure is

performed.

Caution

Do not run the 0.5-micron card (abrasive stripe) for this procedure

or damage to the cleaning card and the Tester may result.

Use the cleaning card and clean the head as follows:

1. From the Main Menu, select Options and select Clean Unit.

Note

Ensure the cleaning card is flat. If it is not flat, straighten it as

required before using.

2. When the following prompt appears,

Insert Card Fabric Side UP!

8

Page 19

Section 2. Installation

Insert the cleaning card into the Tester with the fabric side up (shiny side down) and

press Clean Unit.

3. The cleaning card will move in and out of the Tester three times. When completed,

follow the prompt:

Remove card and press OK to continue.

4. The next prompt will be:

Insert Card Fabric Side DOWN!

Turn the cleaning card over and insert it into the Tester with the fabric side down (shiny

side up).

5. The cleaning card will move in and out of the Tester three times.

6. Remove and discard the card.

Caution

Wait approximately 2 minutes before performing card analysis.

This will allow the unit to dry and thereby prevent damage to the

magnetic stripe to the next cards to be analyzed.

TEST CARDS

Two test cards are shipped with each unit for the purpose of verifying that the Tester is within

tolerance. Each card has a serial number on the face. The values that should appear when a test

card is inserted into the Tester are also listed on the InSpec 9000 Test Card Report that is

shipped with each unit. The cards are listed on the Report by serial number. Use the cards as

follows:

1. Insert a sample production card that is out of ISO specifications; that is, a card that shows

yellow or red bars on the ISO Parameters screen when it is inserted into the Tester. (See

Section 3, Operation and Section 4, Graphics Presentations.)

2. Insert a MagTek test card into the Tester, and check the ISO Parameters screen. All the

bars on the screen should be green for the test card. If there is any doubt about the

validity of the test, check the values of the test card on the screen against the InSpec 9000

Test Card Report. The values should be approximately the same*. Both should be

within tolerance. Compare the production card with the Test Card.

*Tolerances for the test cards are as follows:

• Average Amplitude = ± 15%

• Start Sentinel = ± 0.007 inch

• Average Bit Size = ± 2%

9

Page 20

InSpec 9000 Encoded Card Tester

3. If there is still some doubt about the accuracy of the Tester, run the other test card and

check the values as described in step 2. If necessary, perform the 0.5-micron head

polishing procedure below.

Head Polishing - 0.5-micron (Abrasive Card), P/N 96700014

If the Tester shows a change in amplitude of approximately 15% to 20% after the Test Card

Procedure is run, use the 0.5 micron (abrasive) head-polishing card, P/N 96700014, and clean the

head as follows:

1. With the abrasive stripe up and to the left, insert the card and click on Clean Unit.

2. The card will move in and out of the Tester three times.

Caution

Do not run the head-polishing card with abrasive stripe down, or

damage to the roller surface and the Tester may result.

3. Remove the head-polishing card from the Tester, and run the cleaning card.

Note

Do not discard the head-polishing card after one use; this card is

for multiple use.

4. Perform the Test Card procedure to ensure the Tester is within tolerance. If the results

are not within spec, call service personnel.

SAMPLING TECHNIQUES

The InSpec 9000 Encoded Card Tester is designed for a production environment; that is, samples

are taken from a large production run and tested on the InSpec 9000. The samples tested

represent a lot or batch. The lot or batch is accepted or rejected on the basis of these samples.

More than sampling lots for acceptance or rejection, the Tester also reveals problem trends with

the processes of producing, encoding, or testing cards. Because of the graphics presentations

and database in the Tester, problem trends are easier to identify. (See Section 4, Graphics

Presentations, Interpreting Performance Charts.)

There are many techniques for sampling, and the example below is commonly used in industry.

The example is taken from the following publication:

ANSI/ASQC Z1.4 - 1993, American National Standard, Sampling Procedures and Tables for

Inspection by Attributes, American Society for Quality Control.

10

Page 21

Section 2. Installation

In the following table, the "Single Normal Plan, General Inspection Level I, AQL .010"

designates the criteria used in sampling. In the Table, the Lot Size is equivalent to the card

production run; the Sample Size is the number of randomly selected cards to be run on the

Tester; the Accept and Reject columns are the number of samples for rejecting or accepting the

Lot. If, for example, Accept is 1 and Reject is 2, the Lot will be accepted if there is 1 card out of

spec, but rejected if there are 2 cards out of spec. If the Lot is rejected, the process is repeated.

If rejected again, 100% evaluation is required.

Example of Single Normal Plan, General Inspection Level I, AQL .010

Lot or Batch Size Sample Size Accept Reject

2 to 8 All 0 1

9 to 15 All 0 1

16 to 25 All 0 1

.

.

.

151 to 280 13 0 1

281 to 500 20 0 1

501 to 1200 32 0 1

The following procedure is only an example using ANSI/ASQC Z1.4 - 1993 as a guideline for

sampling:

1. Determine the Lot size, and remove the number of samples listed in the table.

2. For a Lot size of 501 to 1200, remove 32 samples and run them on the

Tester.

3. If all 32 cards are within spec, accept the Lot.

4. If 1 card is out of spec, repeat steps 2 and 3.

5. If 1 card is out of spec, test the entire Lot.

Consult ANSI/ASQC Z1.4 - 1993, for actual techniques and values for sampling.

11

Page 22

InSpec 9000 Encoded Card Tester

12

Page 23

SECTION 3. OPERATION

The operation of the Tester includes opening the tester program, cleaning, reading cards and

interpreting the results, obtaining performance charts and interpreting trends. Also included in

this section are descriptions of Windows-style buttons and Tester icons on the main screen.

OPENING THE TESTER PROGRAM

After the InSpec Tester program is opened from Windows, a picture of the Tester with the

version number will appear as shown in Figure 3-1. In this example the unit is installed, and the

firmware version number and the Unit ID are listed. When the unit is not properly installed, the

message “Unit Not Installed...” appears where the firmware and ID numbers are.

Figure 3-1. Opening Display

This screen will disappear in a few seconds leaving the main screen showing.

13

Page 24

InSpec 9000 Encoded Card Tester

MAIN SCREEN

At the top of the main screen, shown in Figure 3-2, the buttons are similar to Windows buttons

but are specific to the Tester. The screens selected from the main screen are shown in this

section and in “Section 4. Graphics Presentations”.

Figure 3-2. Main Screen

Windows Screen

Brief descriptions of the routines that are presented by the Windows menu bar are as follows:

14

Page 25

Section 3. Operation

File

Open Card - The Open button is for a unique card-specific file used for previous card reads that

have been saved on an individual basis. Card profile charts, which are normally used by

technical personnel, are not saved in the database but may be accessed by using this button when

saved with the save button.

Save Card - The Save Card button is for a unique card-specific file used for saving a card, bar

chart, and card profile information for future reference. This does not save the card in the

database. See Section 4, “Graphics Presentations”, for a description of card profiles.

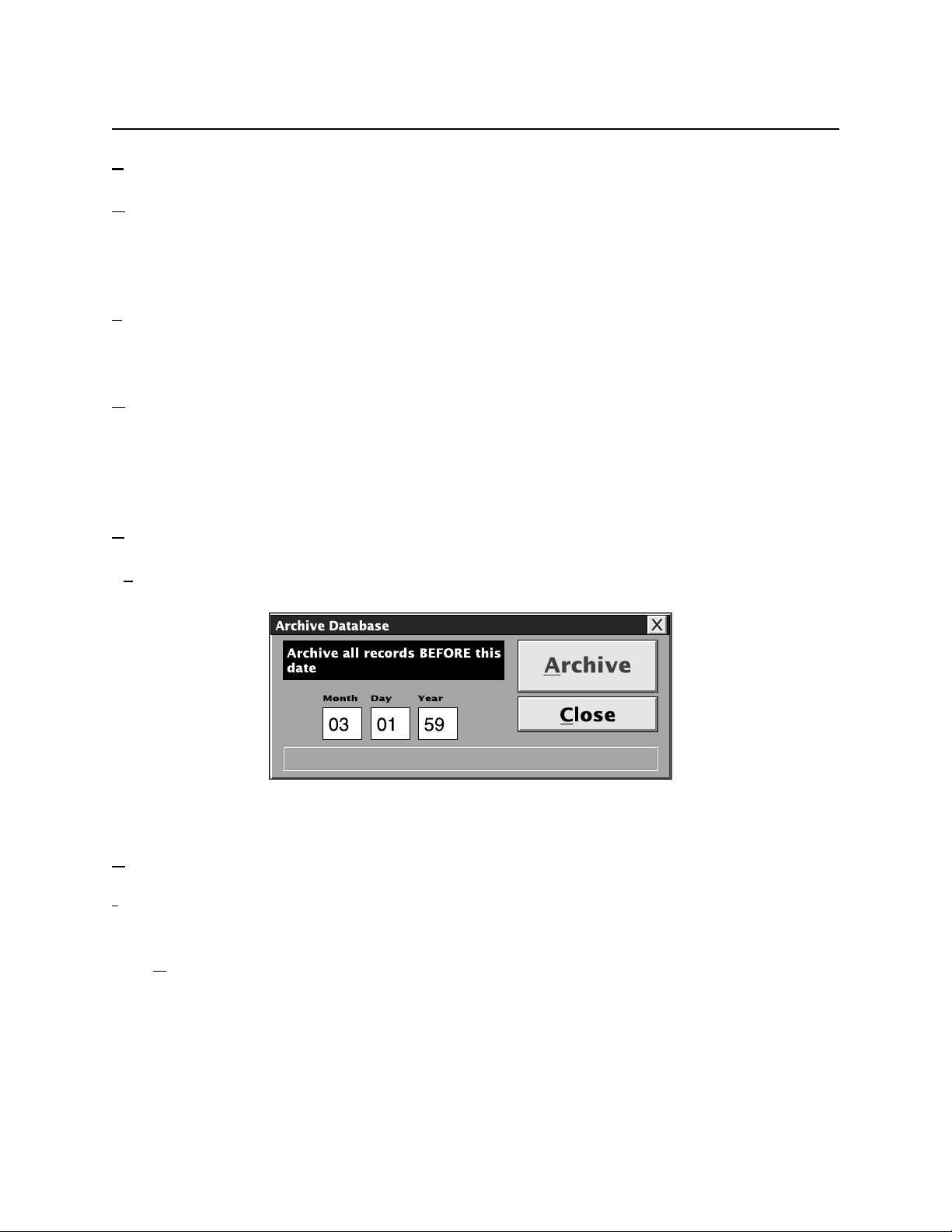

Archive Database - Allows the operator to move all data before a selected date from the database

to an archive file. If the size of the database is reduced, working with performance charts is

faster. The screen is shown in Figure 3-3. An example of the date for 2 Jan 99 is written as 01

02 99. Any year less than 90 will be considered to be after 2000; for example, 59 will be 2059;

the year 98 will be 1998. MagTek recommends the database should be archived monthly.

Reset Security – See Reset Security below.

Exit - Standard Windows exit from this program.

Figure 3-3. Archive Database

iew

V

ISO Compliance - The bar chart that appears represents the most recent card that was read. After

a graph or chart has been canceled, this button will retrieve only the most recent card viewed.

Card DataBase - The screen Card Database Search Parameters permits search of data base by

time and date, card stock, system type, and shift. When the parameters are selected, the screen

Card Database Records gives results for amplitude, bit size, adjacent bit, start sentinel, and track,

all of which are listed in Section 4 under Database.

15

Page 26

InSpec 9000 Encoded Card Tester

Setup Database - Refer to Setup in Section 2 and see below.

erformance Charts - Presents individual card or daily summary of amplitude, bit characteristics,

P

start sentinel and specified time period. This is used to obtain Performance Trend Charts which

alert the operator to take action when parameters begin to drift out of specification. The user

may also specify a printout of numerical data with all ISO parameters, or for a single Track, a

graph, a print out of the screen, or exit from the screen. For the numerical data screen, as the

cursor is positioned on each parameter, ISO specifications for that parameter appear at the

bottom of the screen.

Archived Data Charts -Permits viewing of archived data (See Archived Database above).

ISO Limits - Lists ISO limits for new cards (also called unused encoded cards) and used cards

(also called returned cards, which are cards that have been issued and returned for evaluation).

Error Log - Lists Date, Time, Error Code, Error Description, and Error Location. Used by

technical personnel for troubleshooting.

Setup

Presents screen for Software and Hardware Setup. Software includes Parameters and Security.

Parameters is for adding or removing card stock, system type, and shift as described below.

Security restricts access to certain data and is also described below. Hardware lists and permits

selection of PC Com Ports 1 through 4. If a Com Port is not selected, a dialog box will appear:

“Com port not selected. Please select a com port from the Options menu!” Refer to Section 2,

Installation, Hardware Setup for further installation setup information.

Options

Allows operator to select the functions of Clean Unit or Eject Card. When Clean Unit is

selected, a prompt appears for cleaning. When Eject Card is selected, the unit should eject the

card. If the card does not eject, see Section 5, Troubleshooting, for removing the card.

Help

Contents gives extensive on-line “How to” presentations and other operational

descriptions. About shows opening screen which lists the firmware and unit ID numbers

Read Card

Before “Read Card” is selected, selections from “Card Stock”, “System”, and “Shift” selections

must be highlighted. When the ISO screen appears, the operator may add to the

database or cancel (not add to the database). See the subsection “Reading a Card”

below.

16

Page 27

Section 3. Operation

Clean Unit

When Clean Unit is selected, the program will prompt to insert the cleaning card. Insert the card

with the soft side up (shiny side down). The unit will then move the card in and out

three times, and the head will be cleaned. To clean the rollers, turn the card over and

insert it with the soft side down (shiny side up). The unit will move the card as

previously described to clean the rollers.

Reset Security

When the software starts up, or when Reset Security is clicked, the standard restriction is

activated. The standard restriction may be changed or modified as described below

under Security.

CARD STOCK, SYSTEM, SHIFT

Before a card can be read and the information stored in the database, the card stock, system type

and shift must be highlighted. The titles “Card Stock, System, Shift” may be changed by the

user as required. To change the entries, select Setup and Software Setup from the main menu,

double click on the entry to be changed, and when the dialog box appears type in the new title

and click on OK.

To Setup the database, perform the following steps:

1. From the main screen select the Setup button then Software.

2. Under Card Stock type in the name of the card manufacturer and the batch number of the

cards, or equivalent for identification. (MagTek recommends this information. The user

may require more or less.) An example is: 1st Stock Mfr -Visa Gold.

3. Press the Add button.

4. Under System, enter the name of the encoder. MagTek also recommends the model, and

the serial number. An Example is: 1st Encoder, Mod 1, SN 12345678.

5. Press the Add button.

6. Under Shift, enter the name of the shift when the tests are performed (another entry may

be Employee).

7. Press the Add button.

8. Press the OK button.

17

Page 28

InSpec 9000 Encoded Card Tester

SECURITY

The security features in the InSpec 9000 are used to restrict access to certain data. These

features are accessed by selecting Setup from the main screen, then Software, then Security. The

current password must be entered to access the security form. The default password is

“password”. Passwords are case sensitive; p is not the same as P. The Security screen is shown

in Figure 3-4.

Figure 3-4. Security Screen

To change the current password, type the new password in the test boxes labeled New and

Confirm. Click on the OK button to change the password.

As shown above, the security features have two states, standard restriction and Administrative

Override. The standard restriction is the security level that is used when the software starts up or

the Security Reset (on the Main Screen) has been clicked. Administrative Override is to allow a

supervisor to enable the visibility of certain data for a limited time.

18

Page 29

Section 3. Operation

Once the Administrative Override has been enabled, it determines what data is visible until the

software is shut down or the Reset Security button or menu item on the Main Screen is clicked.

Display Card Data will restrict the visibility of the data encoded on the card being tested. This

data normally is displayed on the ISO compliance bar graph (Figure 3-9) and numerical

parameters (Figure 4-2). Also, the card data will not be saved in the saved file when the card

data is restricted.

Save Card to File will restrict the user’s ability to save the card read to a file. The encodingquality results of the read will still be saved into the database for statistical evaluation.

View Profile Graphs will restrict the user’s ability to view the profile graphs from the ISO

compliance (Figures 4-4 and 4-5).

Security Option is a reserved slot for future security features. It has no use at this time.

READING A CARD

On the main screen perform the following steps for the Tester to read a card:

1. Ensure selections from “Card Stock”, “System”, and “Shift” are selected by highlighting.

2. Click on the “Read Card” icon.

3. When the Insert Card! prompt appears, insert the card.

4. If the card is to be saved in the database, when the ISO screen appears, click on the Add

button. (The ISO parameters screen is shown below.)

5. If a card is blank or inserted incorrectly, a dialog box will appear: “Blank card or card

inserted Incorrectly!”. Insert the card with the magnetic stripe up and to the left, or insert

a new card.

CARD FAILURES

If the Tester does not receive the correct LRC (Longitudinal Redundancy Check) an indication

as shown in Figure 3-5 will appear on the screen. If the Parity is not correct or if both LRC and

parity are incorrect, an indication as shown in Figure 3-6 will appear on the screen. These

checks are to ensure the data on the card is decoded correctly.

19

Page 30

InSpec 9000 Encoded Card Tester

Figure 3-5. LRC Failure

Figure 3-6. LRC or Parity Check Failure

If the Start Sentinel character on a card is not found by the Tester, an indication as shown in

Figure 3-7 will appear on the screen. Although the Start Sentinel Location graph, shown in

Section 4, may indicate a position of the start sentinel, the value in the graph is the distance

calculated to the first “1” bit on the card and not the Start Sentinel character.

Figure 3-7. Start Sentinel Not Found

The Noise Detection window is shown in Figure 3-8.

20

Page 31

Section 3. Operation

Figure 3-8. Added Pulse Detected

The Noise Detection window will appear if the threshold for either “added pulse detected” or

“waveform distortion” is exceeded. This window will also appear if the threshold is exceeded

because of the combination of effects from both added pulse and waveform. This test is critical

in HiCo material testing. Exceeding this ISO limit by even a small percentage may affect read

reliability.

The ISO standards identify these two parameters, added pulse and waveform, associated with the

magnetic stripe. ISO standards 7811-2 and 7811-6 describe limits for added pulse while only

7811-6 (the HiCo document) describes waveform. Since added pulse and waveform are

characteristics of the magnetic stripe and not encoding, issuers who have prequalified their

stripes at a testing laboratory will see this window very rarely.

Note

False Added Pulses may be caused by physical damage to the

card, such as a scratch.

If this window occurs frequently, sample cards should be sent to an independent testing

laboratory requesting the absolute value of the added pulse and waveform conditions.

PARAMETERS

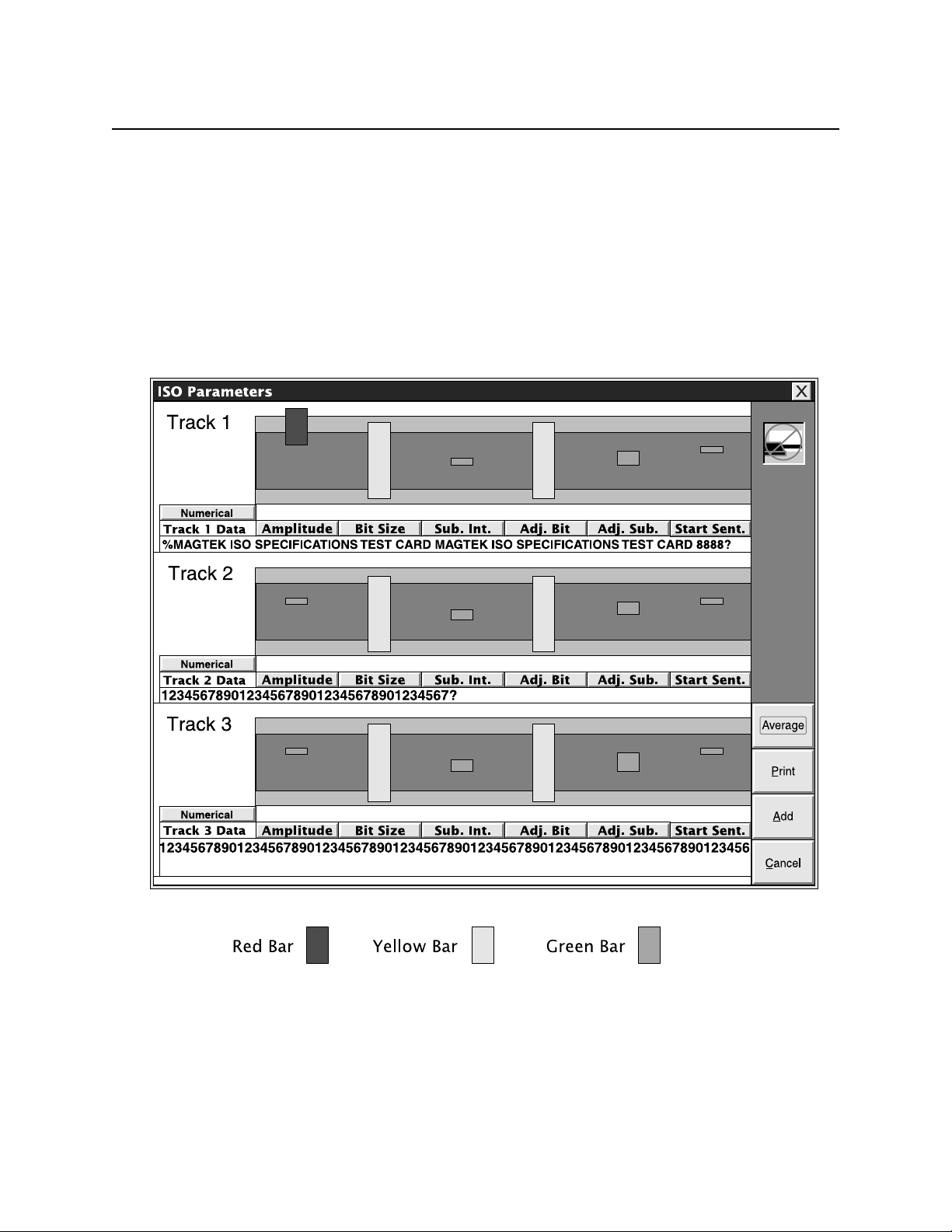

When a card is read, the Tester checks six important ISO parameters, which are presented

graphically, and color coded as green, yellow, and red. Figure 3-9 illustrates this concept. There

are parameters for two types of cards: one for new cards and one for used cards. New cards are

cards that have been encoded but have not been used. Used cards are cards that have been

encoded and issued, and usually used in practical applications, and returned for testing.

As shown in the illustration, the parameters are tested for Tracks 1, 2, and 3 of the magnetic

stripe. Notice that the amplitude in Track 1 is a red bar (simulated here, but red on the screen).

This indicates to the operator that the card is out of spec for both new and used cards. In all

three tracks the bit size and the adjacent bits are yellow. This indicates that the card is out of

spec for new cards but in spec for used cards. All other bars on the illustration are green, in spec

for both new and used cards.

21

Page 32

InSpec 9000 Encoded Card Tester

Figure 3-9. Max/Min ISO Parameters

The bars shown in the illustration represent maximum and minimum ISO parameter values. To

obtain the average values, click on the “Average” button. When the screen projects the average

values, shown in Figure 3-10, the button changes to Max/Min. Click on the button and the

screen changes back to the original.

The icon in the upper right corner of the screen indicates that the card may not be readable in the

field based on error messages displayed previously.

22

Page 33

Section 3. Operation

Figure 3-10. Average ISO Parameters

To select further information in the form of charts and graphs for each of the parameters, select

the buttons below the bar charts for each track. These parameters are described below and

illustrated in Section 4, Graphic Presentations. The parameters are also discussed in Appendices

A and C of this manual.

ISO Limits and Measurement Uncertainty

The ISO Limits specified under the View menu are a composite of two ISO specifications: 78112 and 7811-6. These values are the widest ISO limits of both specifications. They were selected

because LoCo and HiCo values are different, and Readers in the field read reliably with cards

encoded within these combined limits.

23

Page 34

InSpec 9000 Encoded Card Tester

As with any machine, there are also tolerances, or measurement uncertainties, ascribed to the

Tester. Measurement uncertainty limits may be found on the “ISO Limits” screen that is

accessed from the View Menu, and shown in Figure 3-11. The measurement uncertainty is at the

bottom of the screen.

Figure 3-11. ISO Limits

Amplitude

The signal amplitude is the resulting voltage as the read head passes over the flux transitions on

a track. The measure of signal amplitude is stated as a percentage of the Reference Signal

Amplitude.

24

Page 35

Section 3. Operation

The value of the reference signal amplitude is traceable to the Primary Standard as established

by the United States National Institute for Standards and Technology (NITS), formerly the

National Bureau of Standards. Figure 3-12 shows the reference amplitude and the related

boundaries for within spec, marginal, or out of spec. These values as well as the values for the

other parameters below are listed in Appendix C (from 7811). Composite values (from 7811-2

and 7811-6) are listed in the ISO Limits under the View Menu.

Figure 3-12. Reference Amplitude

Bit Size

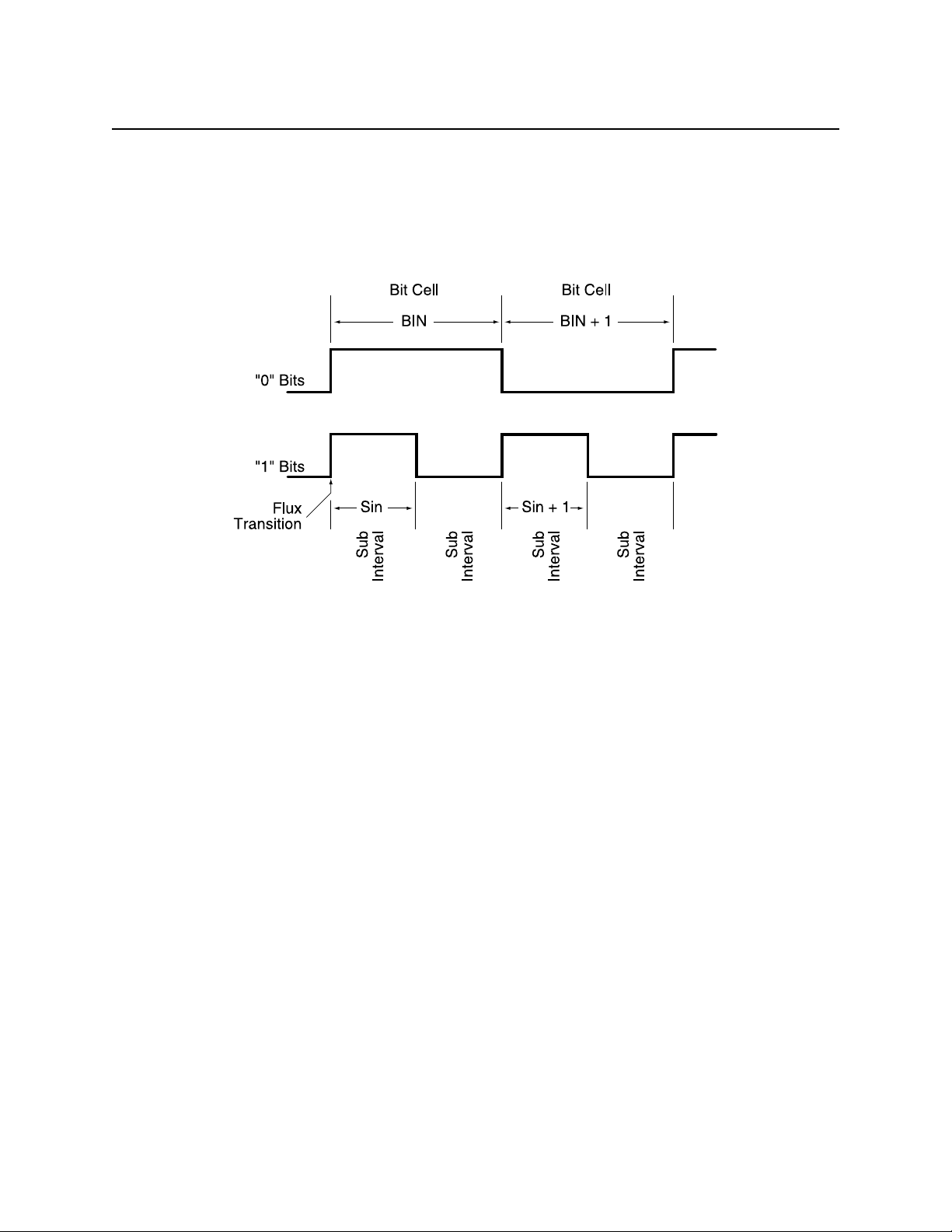

The bit size, or bit cell, is the distance between two clocking flux transitions. This distance is the

“zero” bit. The ISO standard abbreviates the bit size as Bin and calls it Individual Flux

Transitions Spacing Variation. Figure 3-13 shows the bit size, the subinterval, the adjacent bit

and the adjacent subinterval.

Sub. Int.

The Sub Int., or subinterval, is simply the distance of the bit cell divided by two. Two

subintervals form a “one” bit, shown in Figure 3-13 as Sin. The ISO standard abbreviates the

subinterval as Sin and calls it Subinterval Spacing Variation.

25

Page 36

InSpec 9000 Encoded Card Tester

Adj. Bit

The Adj. Bit, or adjacent bit, is the distance between the “zero” bit flux transition and the

previous bit cell, shown in Figure 3-13 as Bin + 1. The ISO standard abbreviates the adjacent bit

as Bin + 1 and calls it Adjacent Bit Cell Spacing Variation.

Figure 3-13. Bit Size

Adj. Sub.

The Adj. Sub., or adjacent subinterval, is the distance between a subinterval transition and the

previous subinterval, shown in Figure 3-13 as Sin + 1. The ISO abbreviates the adjacent

subinterval as Sin + 1 and calls it Adjacent Subinterval Spacing Variation.

Start Sent.

Start Sent., or Start Sentinel, is the distance from the edge of the card to the first subinterval flux

transition (the first one bit) encountered for each track.

26

Page 37

Section 3. Operation

CALIBRATION

The InSpec 9000 is calibrated at the factory. This calibration should last several months with

normal use. The data on the setup card that was received with the unit transfers the calibration

information to the InSpec calibration database. However, the calibration of the unit should be

periodically verified. See “Calibration Verification” below for the procedure. If calibration is

required, then a new setup card will be sent to the user by MagTek based on information

provided by the user. The procedure to obtain the required information is as follows:

1. From the Main Screen select from the following headers: Card Stock, System, Shift.

These headers have been preset at the factory for use with the “test card”.

Note

The names Card Stock, System, and Shift may have been changed

to suit the institution’s requirements (See “Card Stock, System,

Shift” above).

2. Click on the read button to read the “test card”.

3. From the ISO Parameters bar chart screen, click on “Numerical” to obtain the numerical

screen, then click on “Print”. If a printer is not available, the Average Amplitude,

Average Bit Size, and Start Sentinel values must be manually transcribed for the three

tracks. Close the numerical screen, then click on “Add” to exit from the “ISO

Parameters” bar chart screen.

4. Repeat the above until 10 reads of the “test card” are completed.

5. From the “View” menu, click on “setup database”. Click on “Print”, then click on

“Close”. Again, if a printer is not available, transcribe the information manually.

6. Copy (either manually or from a copier) the test card serial number and the data from the

form supplied with the card.

Send the printed (or written) results and the card from the above procedure to the following

address:

MagTek Technical Support

3550 Labore Rd, Suite 9

Vadnais Heights, MN 55110-5126

Ph (888) 624-8350

Fax (612) 486-8760

27

Page 38

InSpec 9000 Encoded Card Tester

MagTek will use the information to either produce a new setup card or to recommend service.

CALIBRATION VERIFICATION

Calibration may be verified by using the “test card” Supplied with the InSpec 9000. This may be

done as follows:

1. From the Main Screen select the following: Card Stock: Test Card; System: InSpec;

Shift: Test.

2. Click on the read button to read the “test card”.

3. From the ISO Parameters bar chart screen, click on “Numerical”, then compare the

average amplitude, average bit size and start sentinel values from the numerical screen to

the values for all three tracks on the form included with the cards. Check to see if the

readings are within the measurement uncertainty found at the bottom of the screen on

Figure 3-11.

28

Page 39

SECTION 4. GRAPHICS PRESENTATIONS

The charts and graphs shown in this section represent only a part of all the charts and graphs that

can be produced by the program; however, these graphs are representative of the others.

The charts and graphs are organized in the order in which they are most likely to appear. The

first bar chart, “ISO Parameters” is the first chart to appear after a card is inserted in the Tester.

From this chart the operator may select the graph or “Card Profiles” from the buttons under the

bars, such as Bit Size under Track 2. When any of the numerical buttons are pressed, the

numerical values of the bars will be shown for all three tracks. If the cursor is pointed to any

value on the numerical screen, the ISO limits for that value will appear at the bottom of the

screen. The information encoded on all three tracks will also appear on the screen. If print is

selected, all of the values will be printed out with all the ISO limits and the measurement

uncertainty of the Tester. The Start Sentinel Location screen lists values in inches and

millimeters.

The next three bar graphs are performance charts used to view trends on an individual card basis

or a daily basis.

The last charts are Card Database Search Parameters and Card Database Records. Much of the

information in these charts will be used by maintenance personnel.

29

Page 40

InSpec 9000 Encoded Card Tester

ISO PARAMETERS

The ISO Parameter chart, shown earlier, is repeated here for convenience. In Figure 4-1, the

parameters in Track 1 illustrate all three conditions: The amplitude is out of spec for both used

and new cards. The bit size and adjacent bit are within spec for used cards but out of spec for

unused cards. The subinterval, adjacent subinterval, and start sentinel are within spec for both

used and new cards.

In Tracks 2 and 3 the bit and subinterval sizes are out of spec for new cards but within spec for

used cards. Other values in Tracks 2 and 3 are within spec for both used and new cards.

30

Figure 4-1. ISO Parameters

Page 41

Section 4. Graphics Presentations

CARD PROFILES

The illustrations that follow are obtained from the ISO Parameters bar graph in Figure 4-1. To

obtain a graph of each parameter, press the button under the bar; for example, under Track 1,

press the Amplitude button under the red bar, and a screen showing the Track 1 Amplitude graph

will appear.

When the Add button is pressed, the card read is saved in the Database. If information is not to

be saved in the Database, do not press this button; press Cancel. The screen can be retrieved by

selecting View from the Main Menu and ISO Compliance.

Caution

If the information is to be saved, it is VERY important that correct

“Card Stock”, “Encoding System”, and “Shift” selections be

made BEFORE a card is entered into the reader. If this is not

done, the database and performance charts will not be meaningful.

To obtain numerical data of the entire graph, click on the button marked “Numerical”, and a

screen similar to Figure 4-2 will appear.

31

Page 42

InSpec 9000 Encoded Card Tester

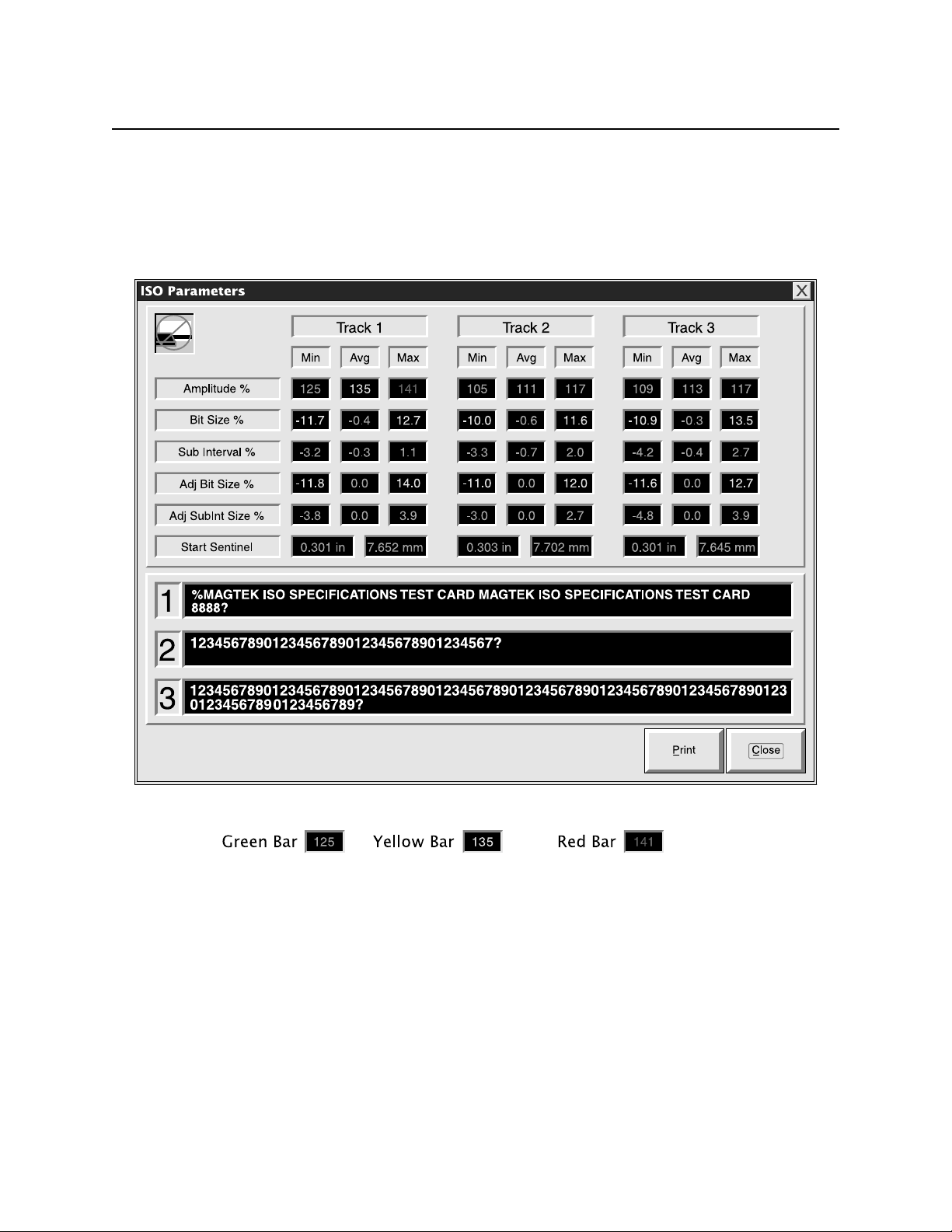

These numbers are the actual values of the bar charts, and they are color coded on the screen

accordingly (simulated here by shading). As the cursor is placed on any parameter number, the

actual ISO limits will appear at the bottom of the screen. The examples at the bottom of the

illustration (Green Text 125 Yellow Text 135, and Red Text 141) are shown near the top of the

illustration under Track 1 as Amplitude Min, Amplitude Avg, and Amplitude Max respectively.

Figure 4-2. Numerical Parameters

If a print is required, click on the Print button, and the results will be formatted as shown in

Figure 4-3. The screen will appear with a place for a description; this may be filled in or left

blank. The date and time will be printed. The values of the card read and ISO limits for new

cards and returned cards will be listed along with a measurement uncertainty statement that gives

the parameters (in percentage) for the Tester. The lower half of Figure 4-3 shows all limits for

cards with the colors (at the top of the columns) indicating the range of the limits; for example,

the Amplitude for Track 1 shows Red-52-Yellow-64-Green-126-Yellow-136-Red. Green falls

within 64 and 126. Red is under 52 and over 136.

32

Page 43

Section 4. Graphics Presentations

InSpec 9000 numerical test results

Description:

Date and Time Printed: 1/29/98 10:41:18 AM

Track No.: 1 2 3

Min Avg Max Min Avg Max Min Avg Max

Amplitude%: 125 135 141 105 111 117 109 113 117

Bit Size%: -11.7

Sub Interval%: 3.2 3.0 1.1 -3.3 -0.7 2.0 4.2 -0.4 2.7

Adj. Bit Size%: -11.8

Adj. Sub Bit Size%:-3.8 0.0 3.9 -3.0 0.0 2.7 -4.8 0.0 3.9

Start Sentinel (in): 0.301 in 0.303 in 0.301 in

Start Sentinel (mm) 7.652 mm 7.702 mm 7.645 mm

Green - Within ISO Limits for New Card.

Yellow - Within ISO Limits for Returned Card.

Red - Exceeds All ISO Limits

Limits

Track No.: 1 2 3

Red Green Red Red Green Red Red Green Red

Yellow Yellow Yellow Yellow Yellow Yellow

Amplitude%: 52 64 126 136 52 64 126 136 52 64 126 136

Bit Size%: -15 -10 10 15 -15 -7 7 15 -15 -10 10 15

Sub Interval%: -20 -12 12 20 -20 -10 10 20 20 -12 12 20

Adj. Bit Size%: -15 -10 10 15 -15 -10 10 15 -15 -10 10 15

Adj. Sub Bit Size%: -30 -12 12 30 -30 -12 12 30 -30 -12 12 30

Start Sentinel (in): 0.123 0.273 0.313 0.493 0.223 0.273 0.313 0.493 0.123 0.253 0.333 0.493

Start Sentinel (mm): 3.12 6.93 7.95 0.693 5.66 6.93 7.95 12.52 3.12 6.43 8.46 12.52

Measurement uncertainty of the InSpec 9000 System: Average amplitude +/-15%; Average bit size +/-2%; Start Sentinel +/-.007 inches.

To maintain the range of measurement uncertainty, the tester and card must be clean.

The card must also be flat and within ISO size specifications.

This product tests Amplitude, Jitter, Start Sentinel, and Baseline Integrity. There are other parameters that may influence read

Before testing for limits, the program removes 0.130 inch from each end of the data.

-0.4 12.7 -10.0 -0.6 11.6 -10.9 -0.3 13.5

0.0 14.0 -11.0 0.0 12.0 -11.6 0.0 12.7

reliability.

Figure 4-3. Numerical Printout

33

Page 44

InSpec 9000 Encoded Card Tester

To obtain a plot of the ISO parameters against the length of the card (in inches), click on the

Amplitude button (for example) on the ISO Parameters screen. Figure 4-4 shows the plot with

the amplitude points at distances from the beginning of the card. When the Print button is

activated, the printout will show the graph and list the minimum and maximum values for new

and used cards.

34

Figure 4-4. Amplitude Graph

Page 45

Section 4. Graphics Presentations

To obtain an illustration of the Start Sentinel location, click on the “Start Sent.” button on the

ISO Parameters screen. The location and the numerical data will be shown on the screen as

illustrated in Figure 4-5, but the screen cannot be printed.

Figure 4-5. Start Sentinel

The ISO range of the start sentinel for Tracks 1 and 2 is 0.293 ± 0.020 inch. For Track 3 the

range is 0.293 ± 0.040 inch. The vertical line through the bar illustrates where the sentinel starts

in relation to the ISO standard. If the vertical line is within the green range, it is within spec.

The yellow range indicates that the start sentinel is out of range but will still be readable in most

applications.

35

Page 46

InSpec 9000 Encoded Card Tester

PERFORMANCE CHARTS

To select and interpret a Performance Chart perform the following steps:

1. From the main screen, select View then Performance Charts.

2. From the display, select the first of the three bars (each bar will display “all”) which will

be card stock. From the list, select the stock or “All”.

3. Select the second bar and the Encoding System (the Tester) or “All”.

4. Select the third bar and the shift or “All”. The fourth bar is for status.

5. Select Daily Summary or Individual Cards.

6. Select Amplitude, Bit Size, Sub Size, or Start Sentinel.

7. Select Track 1, 2, or 3.

8. Select the Start and End Dates and Times. (Select and type in new dates or times.)

9. Select Graph.

10. After a short pause, the performance bar chart should appear on the screen.

11. If a printout is desired, press the Print button. A dialog box appears with “Use Screen

Layout” and “Layout for Printer”. If the “Screen” is chosen, the printout will contain the

same information but usually be smaller than if “Layout” is chosen. Screen is the factory

default. The default printouts will both be landscape; that is, the wide part of the page

will be horizontal.

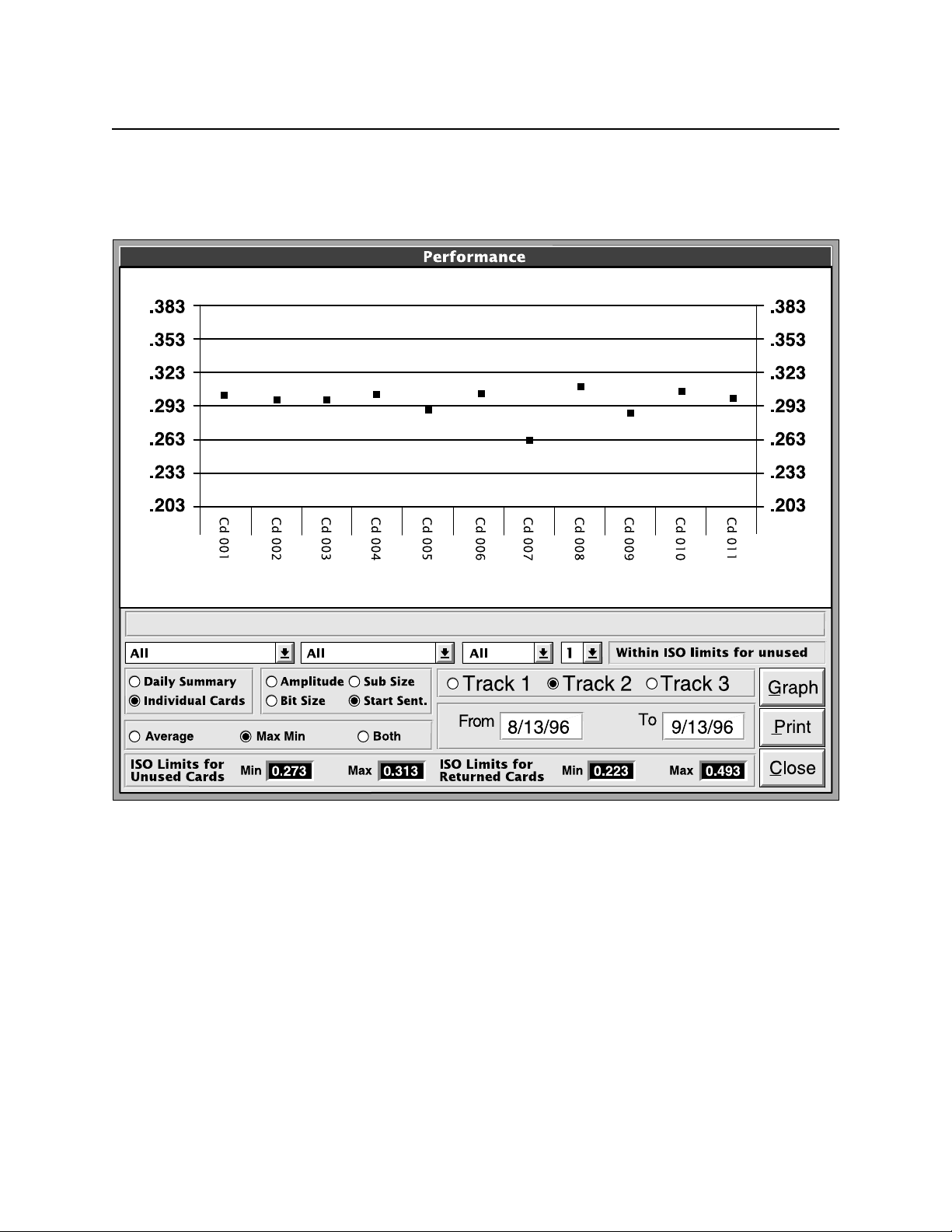

INTERPRETING PERFORMANCE CHARTS

When interpreting performance charts, the observer looks for trends. Compilations of daily

summaries or individual cards may reveal problems with the process of producing cards, or

encoding them, or the card stock, or the encoder, or even the Tester itself (cleaning for example).

The operator should report these trends to the supervisor, the technician or other appropriate

personnel. It may be helpful to print the screen to illustrate the trend.

36

Page 47

Section 4. Graphics Presentations

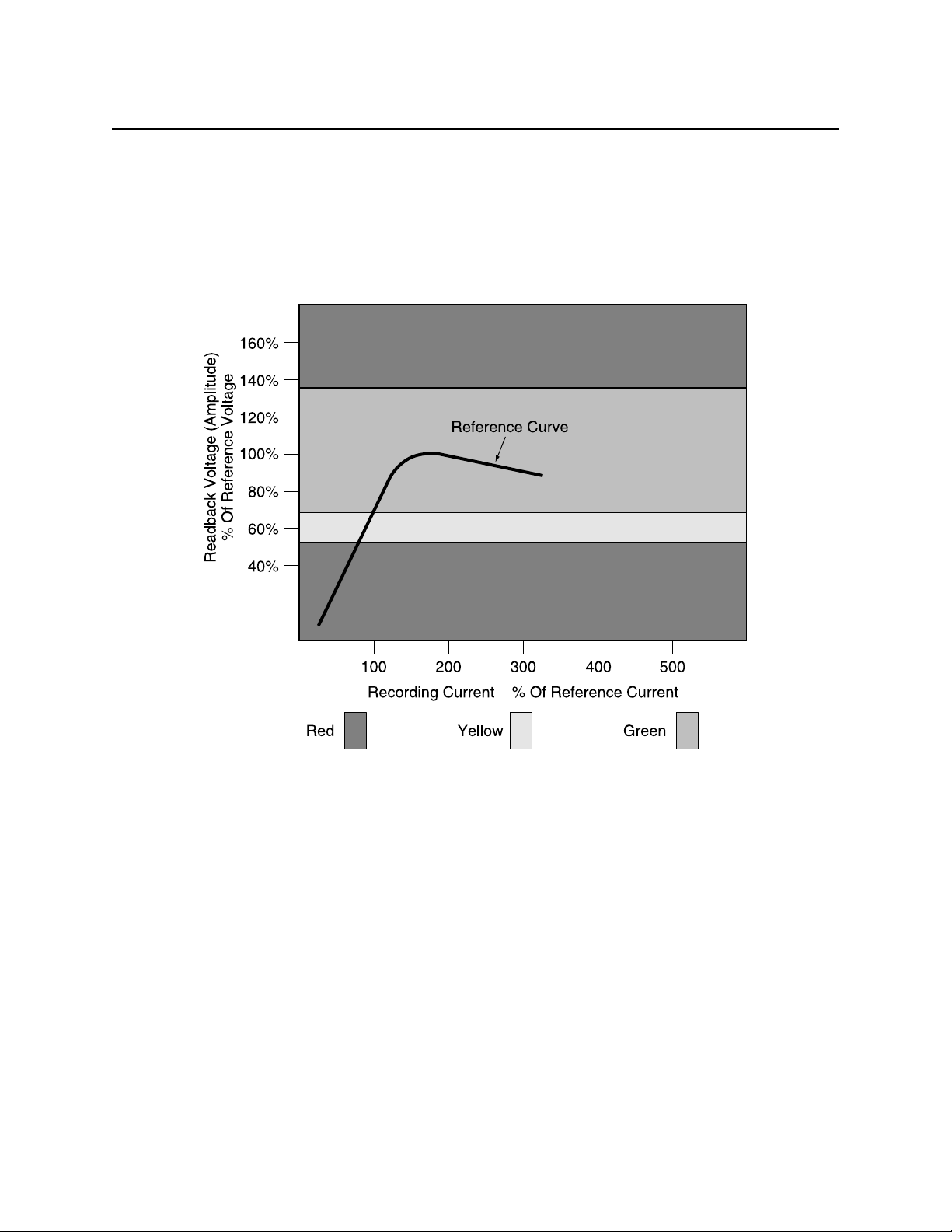

Trends to observe and report are when the bars begin to drift up or down. When this occurs, the

technician may want to investigate the process for encoding the card stock, the encoder, or may

send the card or cards to a test laboratory for analysis. Cleaning and calibration of the Tester

may be in order. Figure 4-6 shows an example of card amplitude drifting up and down. Note

that the last few bars extend above the 136% maximum. This shows that some of the cards are

out of the ISO limits for new (Unused) and used (Returned) cards, but most are within limits for

both.

Figure 4-6. Performance - Amplitude

The operator should report this trend before the card extends to the limit for new cards. A graph

and print should be made of this trend. Some variations in amplitude are to be expected.

Another indication of problems is erratic changes in parameters, where a bar may be at or close

to the upper limit, and the next bar may be at or close to the lower limit. This may indicate

problems with card stock or the Encoder.

37

Page 48

InSpec 9000 Encoded Card Tester

A rising pattern for bit size is shown in Figure 4-7. The maximum limit of bit size for new

(Unused) cards is exceeded at R14 and again at R25. Technical personnel should be notified in

both instances as both limits are exceeded for new cards. At R27 the card exceeds the maximum

for used (Returned) cards. The operator should graph and print this trend.

38