Page 1

This Magswitch MagSquare is designed to hold steel plate, pipe, bar and rod stock, flat stock or angle iron.

Using Patented Technology, this device has tremendous holding power as well as

a great amount of Shear Force Holding Strength to prevent sideways movement.

Read all instructions! Failure to follow all instructions listed below may result in an unsafe or dangerous condition.

MagSquare

Operation and

Instruction Manual

Magswitch Technology Inc.

621 Southpark Dr. #1800

Littleton, CO 80120

www.Magswitch.com.au

General Information

o All Magnets need to be kept at a safe distance from all Magnetic storage devices, electronics and credit cards etc…

o Ensure that the MagSquare is stored in the “OFF” position when not in contact with Ferromagnetic metals. The MagSquare can be left ON or OFF indefinitely without

harm. When ON and near Ferromagnetic metals there will be a sudden and powerful attraction.

o Never use a MagSquare to lift any materials, although it is ideal for debris cleanup, nuts and bolts, metal shavings, etc…

o DO NOT attempt to disassemble or alter the Magswitch MagSquare; there are no user serviceable parts inside the device.

o All Magswitch products are designed for normal work/jobsite conditions, do not use underwater or in a hazardous environment unless specifically designed for that

purpose.

o DO NOT use the MagSquare if it is damaged or is not working properly. Severe injury can occur if this device is not used properly and safely.

o DO NOT expose the Magswitch Magnets to temperatures above 176 deg Fahrenheit (80 Celsius). High temperatures will permanently degrade the Magnet’s

effectiveness and may result in an unsafe condition.

o Never use a MagSquare for OVERHEAD LIFTING or to transport any materials.

o Not recommended for painted or finish coated surfaces as these will reduce the magnetic bond and the finish may be damaged.

o This product contains PTFE lubricant. For MSDS information contact Magswitch.

o Always keep the bottom of the magnet clean and free of debris and rust. If needed wipe with WD40 or light oil

To Use the MagSquare

o Always test the connection before attempting to use the MagSquare to ensure that it is capable of holding the material securely.

o Numerous factors can negatively affect the strength of the Magnetic bond, dirt, debris, oils and grease, painted surfaces and any gap between the Magnet and the metal

surface will decrease the bond. Ensure that the connection point is clean and free of these factors.

o Thicker metals will be held more strongly than thinner metals. E.g.: 1/4" steel will be held more strongly than thin gauge metals.

o Never exceed the rated capacity of the MagSquare. 30mm MagSquares have up to 150 lbs of Break-Away Force. 50mm MagSquares have up to 550 lbs of Break-

Away Force and 70mm MagSquares have up to 1000 lbs of Break-Away force under ideal conditions. Tested in accordance with International Magnetics Association

testing methods and represents a straight Break-Away pull. Actual in-use results will vary greatly and user must test every bond to determine the suitability of the

magnet to hold the material.

o Avoid sudden jerking or Shock force as this will cause the MagSquare to lose its hold.

o Threaded Holes are provided in this MagSquare to mount accessories to it or to mount the square into a fixture. For best results do not attach Ferromagnetic Metals to

the MagSquare, unless using spacers as described below. This will keep the magnetic grip at its most powerful.

o Magswitch recommends that Stainless Steel screws be used to attach non-Ferromagnetic materials to the sides when used as a holder for your Jig or Fixture. Wood,

Plastics and Aluminum are all non-Ferromagnetic materials that make for excellent attachments. Alternatively non-Ferromagnetic spacers can be placed between the

MagSquare and the jig/fixture

o This MagSquare is not designed to be used as a welding ground clamp or as part of an electrical circuit.

o For safe operation, the bottom surface of the Magnet must always be Flat and Smooth. If necessary, it is possible to sand the Magnet face smooth using 400 grit

sandpaper and a flat surface. Always file any burrs that would interfere with full contact.

o As with all precision devices, damage can occur from dropping, bumping and impact. Magswitch recommends periodic inspection by the user to ensure that the 90

degree angles are still accurate and the MagSquare still fits their needs.

MagSquare Operation

o The handle on this MagSquare must be turned clockwise 180 degrees until it stops in order to be turned “ON”. It is not possible to hold the Magnet in place unless

fully turned “ON”.

o DO NOT turn ON unless in contact with Ferromagnetic Metal

o To release the MagSquare push the handle down and turn the handle in the counter clockwise direction until it stops. The MagSquare will turn off and release

Immediately upon turning the handle, Use Caution to ensure that it is safe to release the MagSquare and that nothing will fall or become dangerous.

o Always turn off power tools before turning the MagSquare ON or OFF to avoid injury.

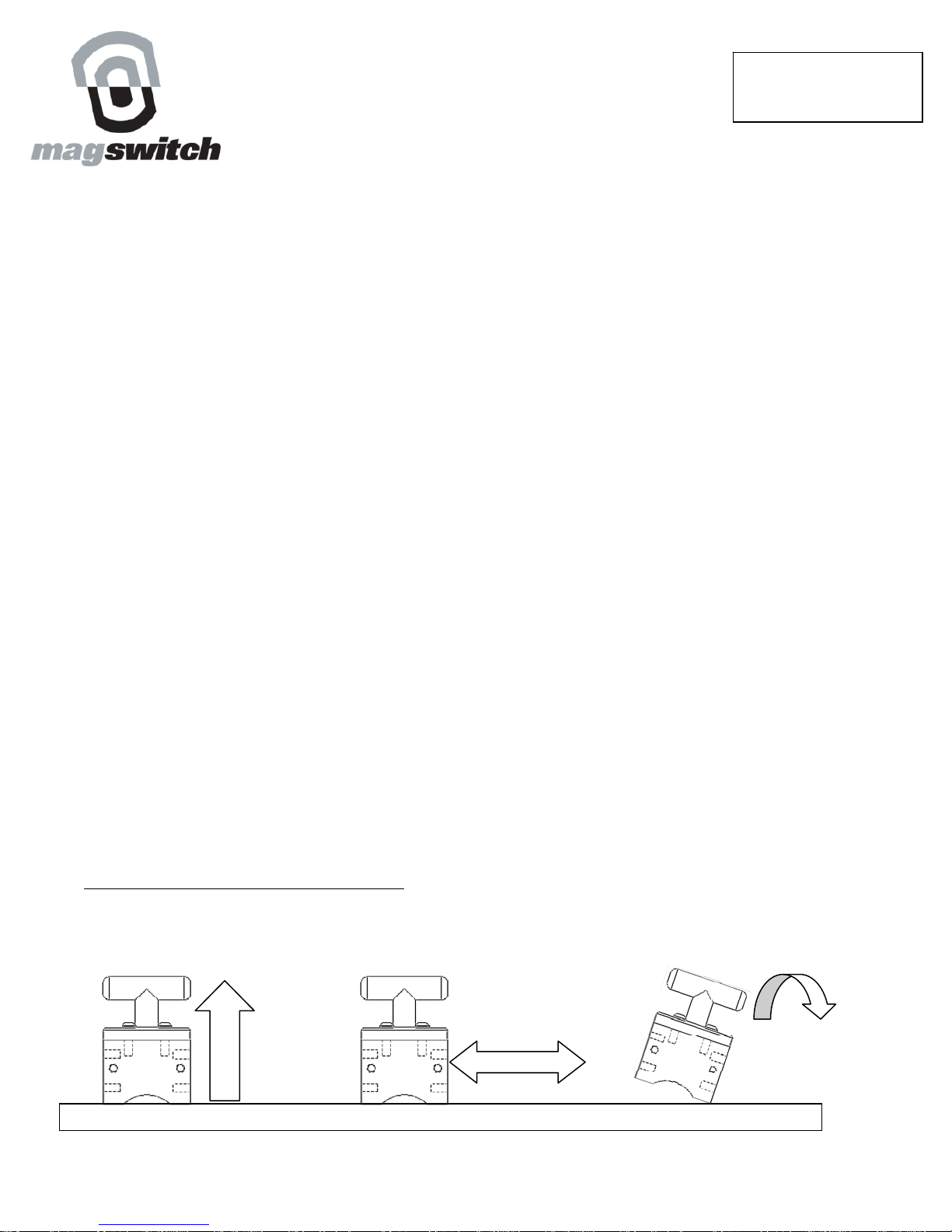

o This MagSquare is capable of exceptional Break-Away force holding power; MagSquares are exceptionally strong in Shear Force as well. Prying force is the least

powerful of the holding capabilities and great care must be used when attempting to use this device with Pry force. See illustrations below.

Pull Up-Most

Part Number 110174

Revision Date, July 7, 2008

Table Surface

Slide-less

Pry

ForceLeast!

Page 2

MagSquare Usage Manual

Never before have such versatile and powerful magnets had ON/OFF control with such ease. MagSquare is a multi-purpose

Workholding/Clamping tool with uses limited only by your imagination. Whether using it as a positioning aide, mounting tools to the

magnet, or installing the magnet into a fixture, you now have a versatile Workholding tool that will last for many years.

Ideal for holding material in place when on any cast iron or steel surface including;

9 Table Saw

9 Planer

9 Jointer

9 Shaper

9 Steel Router Table top

9 Band Saws

¾ MagSquares are precision machined to hold Ferromagnetic material at 90 angles. They are perfectly suited to work-holding applications when you are

holding any Ferro-Magnetic substance such as steel plate, angle iron, pipe, and rod and bar stock.

¾ While the greatest holding power is straight down to the table, the two sides of the MagSquare that have arches in the bottom have very powerful magnetic

attraction forces as well. This allows for Multi-Plane work holding for fit-up at precise 90 degree angles. See Illustration on last page.

¾ Ferromagnetic Metals will be lightly held on the two non-arched sides as well.

¾ When used for material holding for metals that are to be welded, be careful not to overheat the magnets. Temperatures above 176 degrees internal will

permanently degrade the magnetic power and holding strength. Magswitch recommends a tack weld only to keep the heat transfer to a minimum. To help

reduce heat buildup, keep the MagSquare at least 3 inches from the welding point and remove after the tack weld.

¾ Attaching Ferromagnetic metals to the sides of the MagSquare will reduce the magnetic hold of the bottom as this force is now shared among more than one

direction.

¾ The holes are approximately ¼ inch deep, please add this amount to the thickness of your attached material to determine the fas

9 Drill Presses

9 Steel Fit-Up Table

9 Welding Table

9 Steel Pipe

9 Flat Stock

9 Bar Stock

Industrial/Fabrication Applications:

MagSquares are ideal for replacing many types of clamps in a repetitive assembly or fabrication shop

application.

9 Cost Savings. Green. Requiring no electricity to turn on and OFF, they save money and are not affected by power loss.

9 Enduring. MagSquares can be left on indefinitely for long working times.

9 Ergonomics and Safety. Unlike standard hand clamps, MagSquares are easily positioned precisely as needed, and require little effort to turn on/OFF.

Reduce chances of repetitive stress and hand injuries from clamping.

9 Precise Positioning. Varying hold force throughout the actuation cycle from OFF to ON, Precise positioning is achieved through adjusting the hold force

while moving your material.

9 Non Marring Unlike traditional clamps, MagSquares will hold materials at any angle without damaging or marring the surfaces.

9 When attached to a Ferromagnetic repetitive assembly fixture for permanent or semi-permanent mounting, insert a non-Ferromagnetic spacer between the

MagSquare and the Ferromagnetic metal frame. This will ensure that maximum magnetic energy is directed into the bottom of the housing.

9 MagSquares can easily be mounted or used lying on their sides, either on a steel fit-up table or in an assembly fixture. This allows for maximum magnetic

hold to be in a direction of your choosing.

9 MagSquares are ideal for clean up after work. Picks up nuts, bolts, screws, scrap metal and shavings. Turn the MagSquare OFF to instantly release the

material, wipe off any remaining shavings and it is ready for use again.

9 Makes a perfect repetitive work stop when attached to any Ferromagnetic table top or vise.

Automotive and Body Shop Applications:

9 Quick, Strong Workholding. Ideal for holding and aligning parts when assembling a frame or chassis. Anytime a quick weld or precise assembly is

Part Number 110174

Revision Date, July 7, 2008

required- MagSquare is the answer!

9 Support Large Awkward Parts. Use one or more MagSquares to create a powerful support hold when working underneath a vehicle. Perfect for

Mufflers, CV Axles, calipers and more. Always attach to clean metal and test to ensure holding strength.

9 Perfect as a third hand when installing lines, exhaust pipes, mufflers, axles etc… Attach a chain or hook to the sides for added support opportunities.

9 Attach a hook or chain material to the sides to hang parts or larger items during install and repair.

9 Precision. Precisely positioned on metal surfaces, perfect for use to align and weld on parts. With multi-plane work holding capability, the MagSquare will

hold most weld on parts securely to the side, while remaining positioned on the frame. Magswitch recommends that a tack weld be used to avoid

overheating the MagSquare.

9 Ideal for holding small tools, fasteners and Ferromagnetic parts when working under a hood or vehicle. Two sides are magnetic!

9 Perfect for clean up after the job is done. Turn the MagSquare OFF to release all of the scrap, parts and shavings, wipe clean and it is ready for use.

Magswitch products are covered by a One Year Limited Warranty on M aterial and Workmanship. Warranty is Non-Transferable. Magswitch reserves the right to

inspect all product claims under warranty. Any alteration of the device voids this warranty.

User assumes all risk for the proper use of this device and for ensuring product suitability for intended application.

This warranty shall not cover any incidental or consequential damages due to the improper use or failure of this device.

All Magswitch products are covered under International and U.S. Patents 6,707,360 & 7,012,495. Add’l patents pending.

Magswitch Limited Warranty

9 Angle Iron

9 Structural Steel

9 Vehicle Frame/Chassis

9 Shop Machinery

9 And more!

tener length required.

Loading...

Loading...