Magnuson Products GTO LS2 User Manual

89-89-60-014 Rev B

Installation Instructions for:

INTERCOOLED SUPERCHARGER SYSTEM

2005-2006 PONTIAC GTO LS2

Step-by-step instructions for installing the best in

supercharger systems.

Magnuson Products Inc

1990 Knoll Drive, Ventura, CA 93003

(805) 642-8833 * (805) 677-4897 fax

magnusonproducts.com * magnacharger.com

Use distilled or

de-ionized water only.

INSTALLATION MANUAL

12/05

Page 2

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

Magna Charger

GM 6.0 LS2 Liter Engines,

2005 and later Pontiac GTO

Please take a few moments to review this manual thoroughly before you begin work, as there are special steps for both the LS1

(2004) and LS2 (2005-on) equipped vehicles: Μake quick parts check to make certain your kit is complete (see shipper parts

list in this package). If you discover shipping damage or shortage, please call our offi ce immediately. Take a look at exactly

what you are going to need in terms of tools, time, and experience. Review our limited warranty with care. When unpacking the

supercharger kit DO NOT lift the supercharger assembly by the black plastic bypass actuator. This is pre-set from the factory and

can be altered if used as a lifting point!

Caution: Relieve the fuel system pressure before servicing fuel system components in order to reduce the risk of fi re and

personal injury. After relieving the system pressure, a small amount of fuel may be released when servicing the fuel lines or

connections. In order to reduce the risk of personal injury, cover the regulator and fuel line fi ttings with a shop towel before

disconnecting. This will catch any fuel that may leak out. Place the towel in an approved container when the job is complete.

Use only premium fuel, 91 octane or better.

Magna Charger systems are manufactured to produce about 20 RWHP per pound of boost at sea level. High altitudes will

produce different numbers.

Our Magna Charger kits are designed for engines in good mechanical condition only. Installation on high mileage or damaged

engines is not recommended and may result in engine failure, for which we are not responsible. Magna Charger is not responsible

for the engine or consequential damages.

Aftermarket engine recalibration devices that modify fuel and spark curve (including, but not limited to programmers) are

not recommended and may cause engine damage or failure. Use of non-Magna Charger approved programming will void all

warranties. If you have any questions, call us.

After you fi nish your installation and road test your vehicle, please fi ll out and mail in the limited warranty card, so we can add

you to our fi les (this is important for your protection).

A new GM fuel fi lter is recommended at the time of supercharger installation.

Stock spark plugs and stock plug gap is recommended

Drive belt = Gates# K061010

Air Filter = K&N# 33-2289

Tools Required:

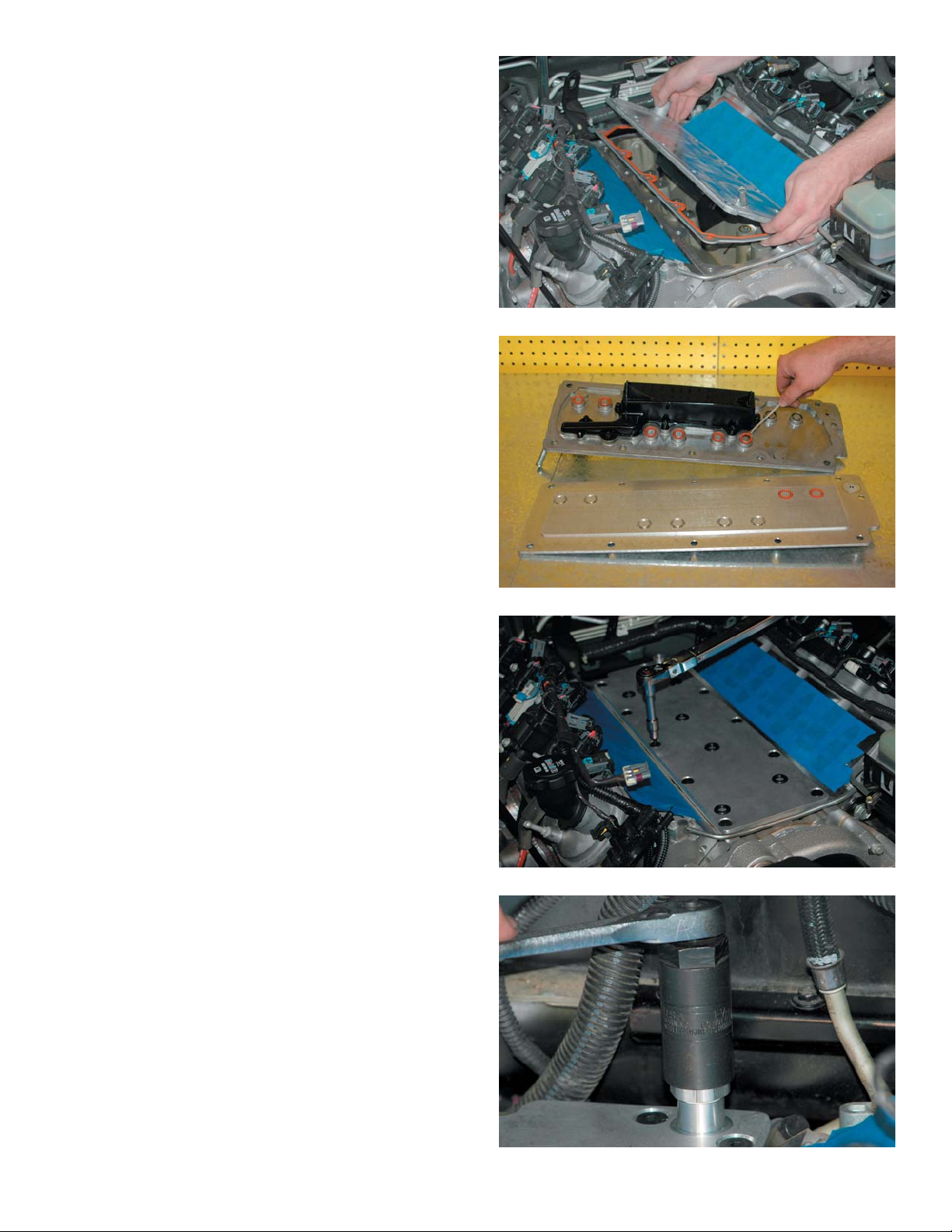

Metric wrench set

1/4” - 3/8” and 1/2” drive metric socket set (Standard & Deep)

3/8”and 1/2” drive Foot pound and inch pound torque wrenches

Phillips and fl at head screwdrivers

Fuel line quick disconnect tools (included in kit)

Small or angled 3/8 drill motor

Drain pan

Hose cutters

Hose clamp pliers

Safety glasses

Metric Allen socket set 3/8 drive

Shop vacuum cleaner

Contact information:

Magnuson Products Inc

Magna Charger Division

1990 Knoll Drive

Ventura, CA 93003

Sales/Tech support 805-289-0044

Websites:

www.magnusonproducts.com

www.magnacharger.com

Email:

info@magnacharger.com

1. Open the hood and remove the under hood

Latch closed

Latch open

Cover

12/05

Page 3

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

insulation by prying out the seven plastic buttons that

retain it. The insulation will not be reused.

2. Disconnecting the negative (-) and then the positive

(+) battery clamps with a 13mm wrench. Next,

remove the the battery anchor and the battery itself.

3. Locate the vehicles computer on the front surfase

of the driver side wheel well.

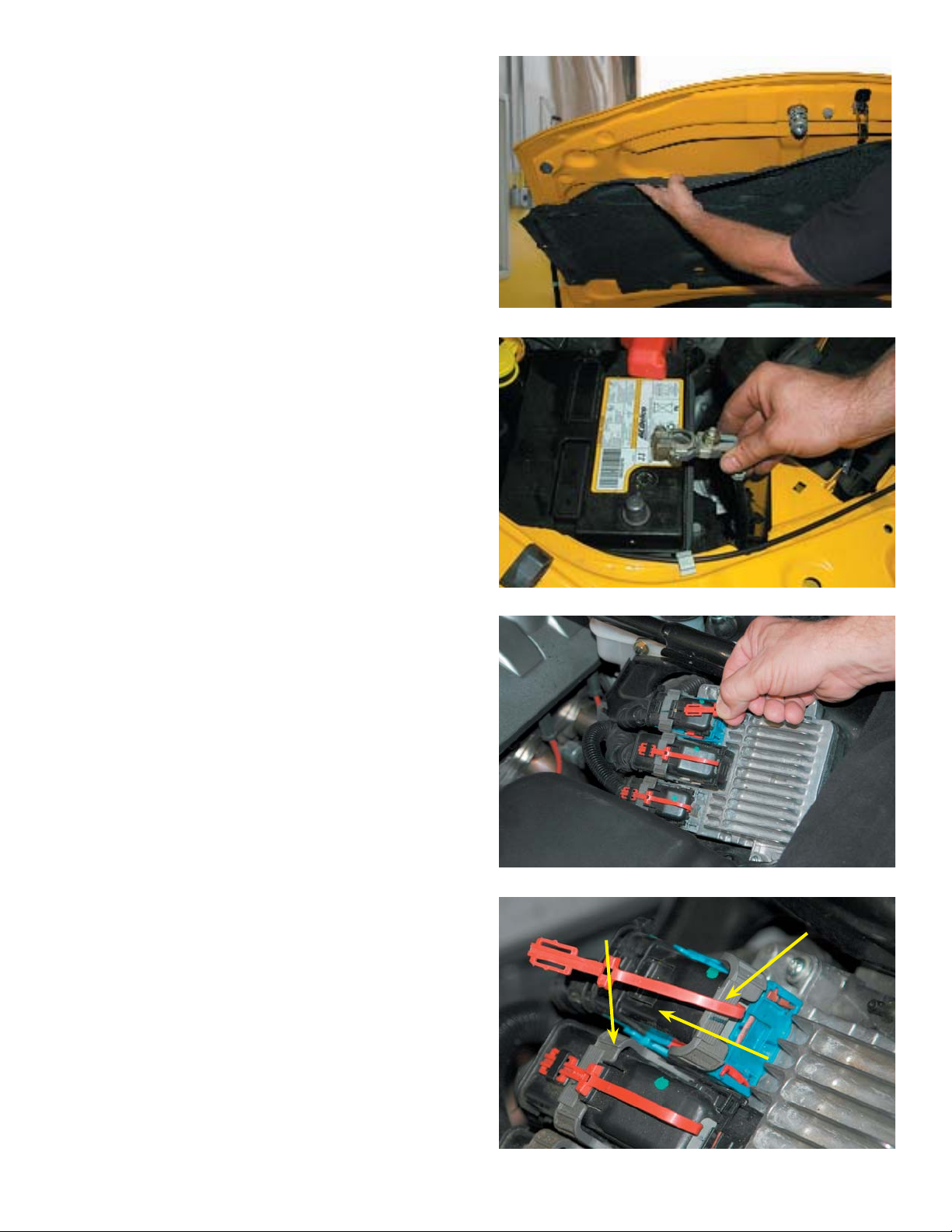

4. There are three computer connectors, Grey, Black

and Blue. Remove the connectors by fi rst removing

the Red locking key, then pushing in on the Black

cover and pushing the Grey latch down to open it.

Latch closed

Latch open

Cover

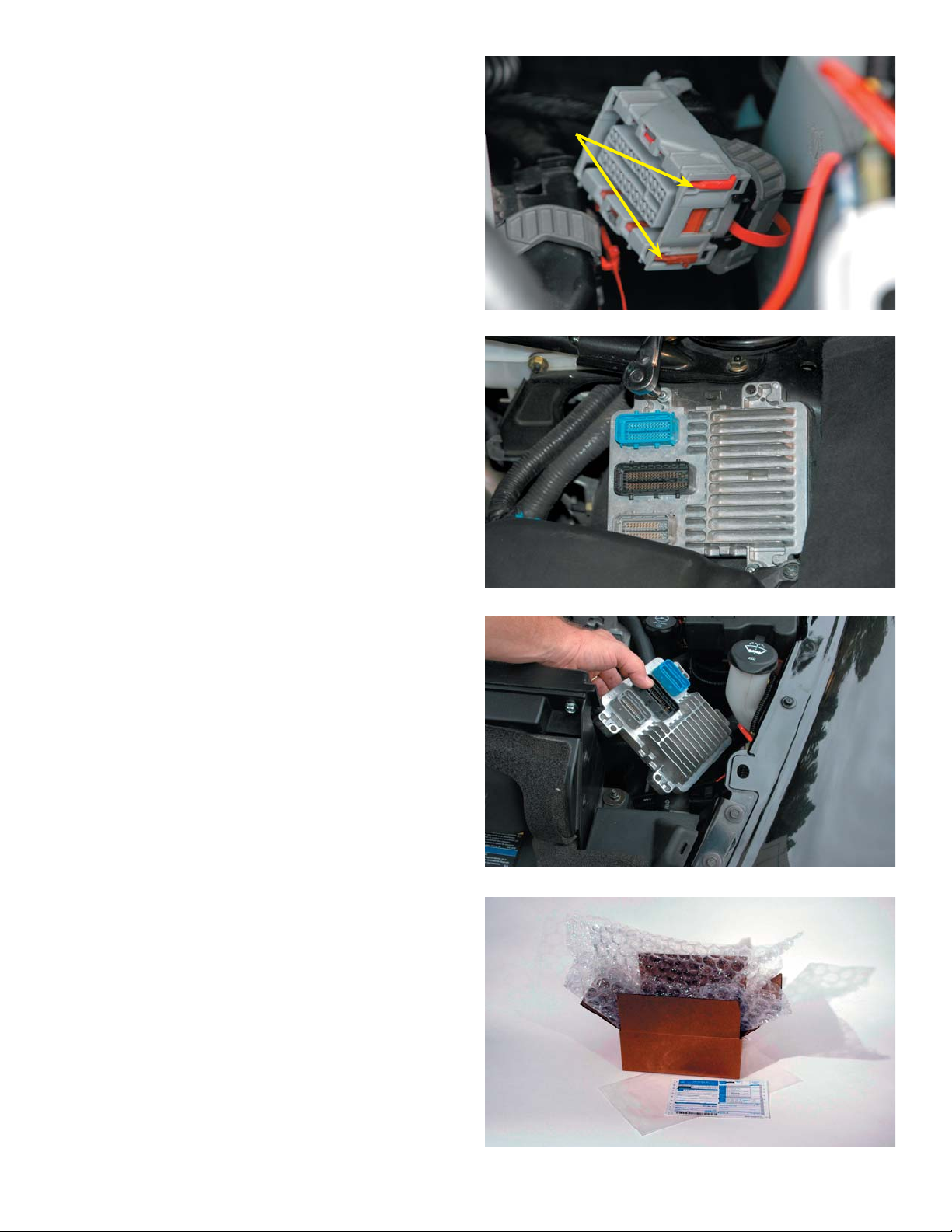

5. The computer connectors can be removed when

Latch tail

12/05

Page 4

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

the latch is pushed down and the red tail of the latch is

visible on the end of the connector.

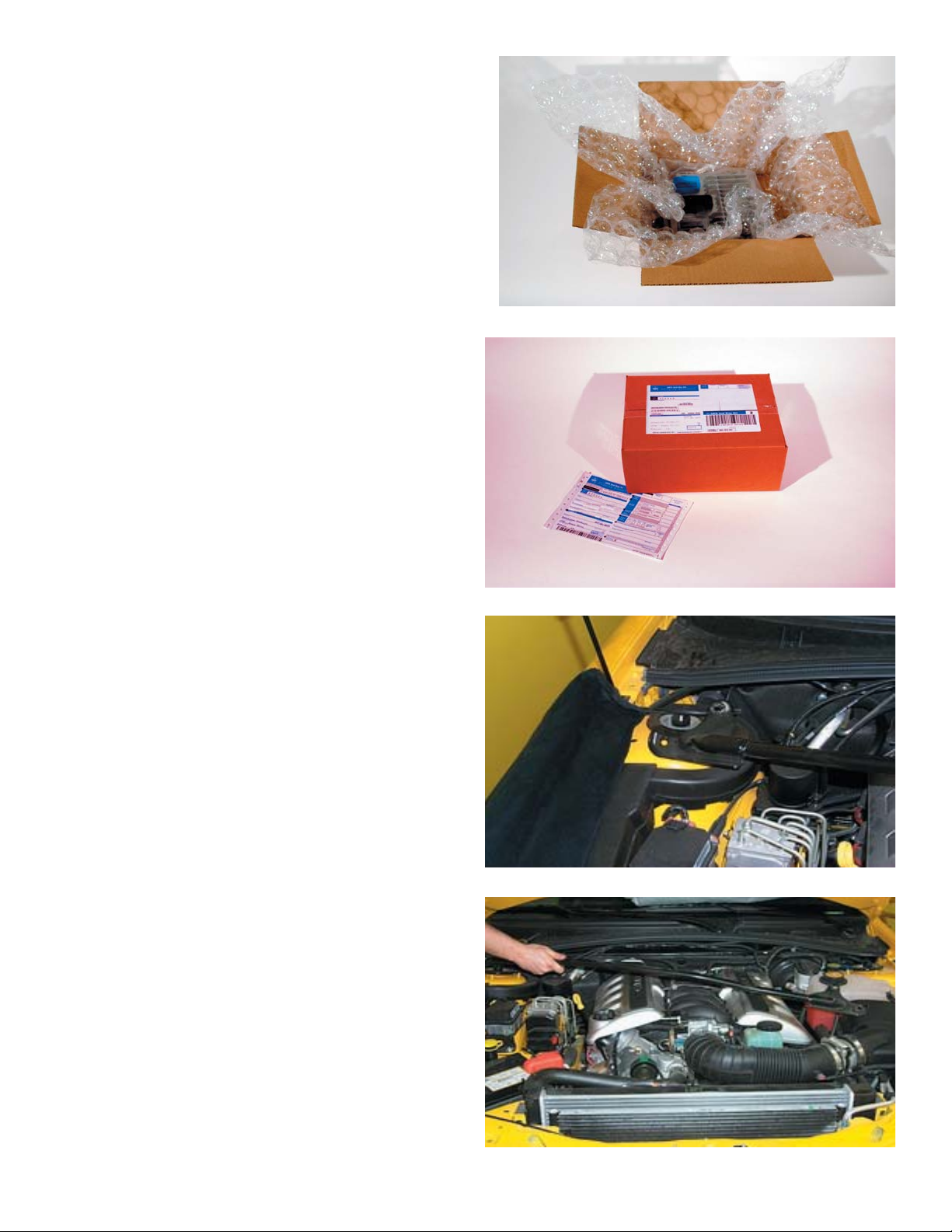

6. Remove the two T20 TORX screws that secure the

computer to its mounting bracket.

Latch tail

7. Remove the computer carefully from the vehicle.

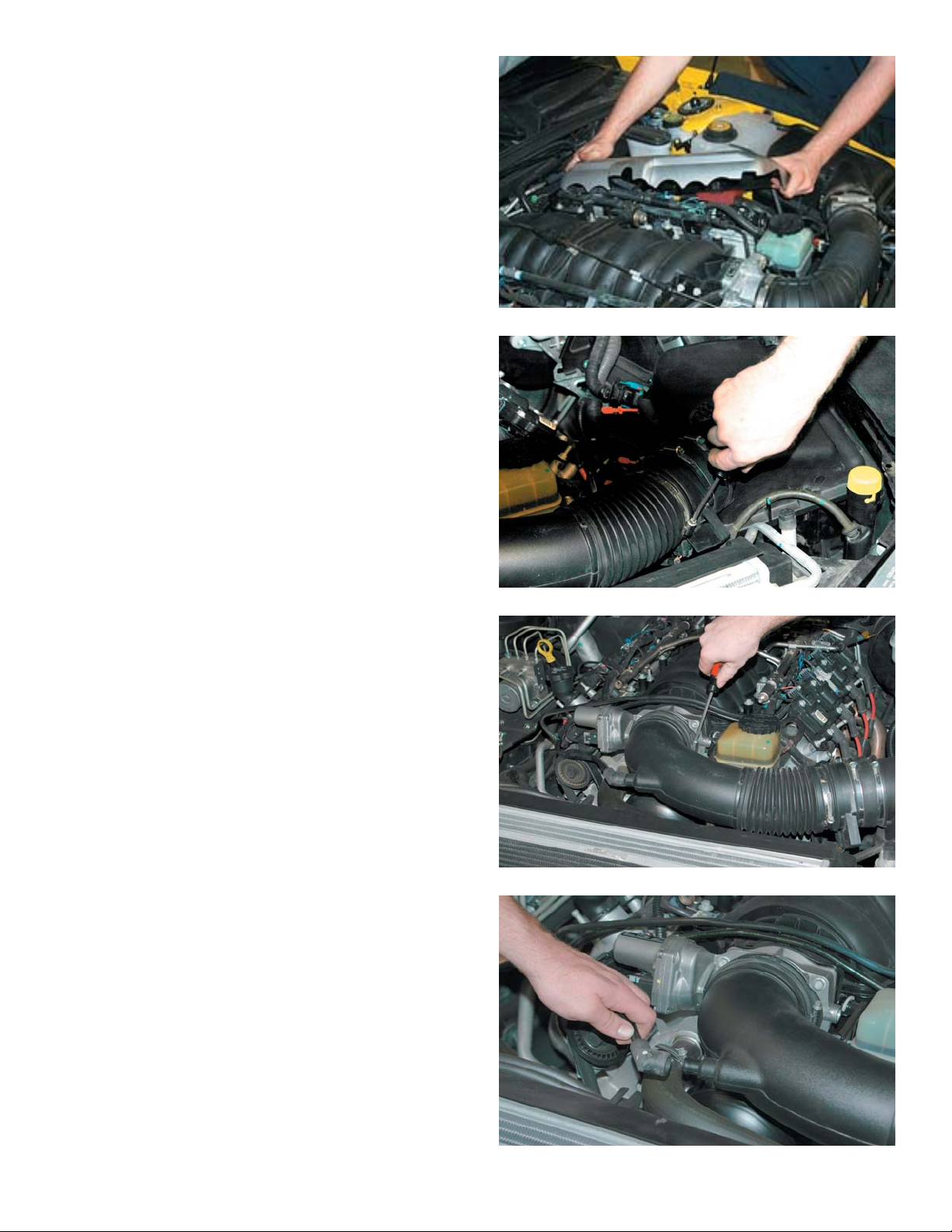

8. Here are the shipping materials supplied to quick-

ley return the vehicle computer to Magnuson Products

Inc.

9. Place the computer into the plastic bag supplied

12/05

Page 5

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

and then wrap it in the bubble-pack sheet and seal the

box.

10. Completely fi ll out the pre-paid shipping form

supplied and then remove the adhesive label on the

third page, placing it on the top of the box. Take the

box to your nearest UPS offi ce to be returned to Mag-

nuson Products Inc. Magnuson will then re-program

the computer and quickly return it to you via UPS.

11. On top of each shock tower remove the two nuts

that secure the strut tower brace with a 13mm socket

wrench.

12. Remove the strut tower brace and fasteners from

the vehicle, the brace can be reinstalled after the

supercharger installation.

13. Remove the two engine covers by pulling up

12/05

Page 6

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

fi rmly along the edges.

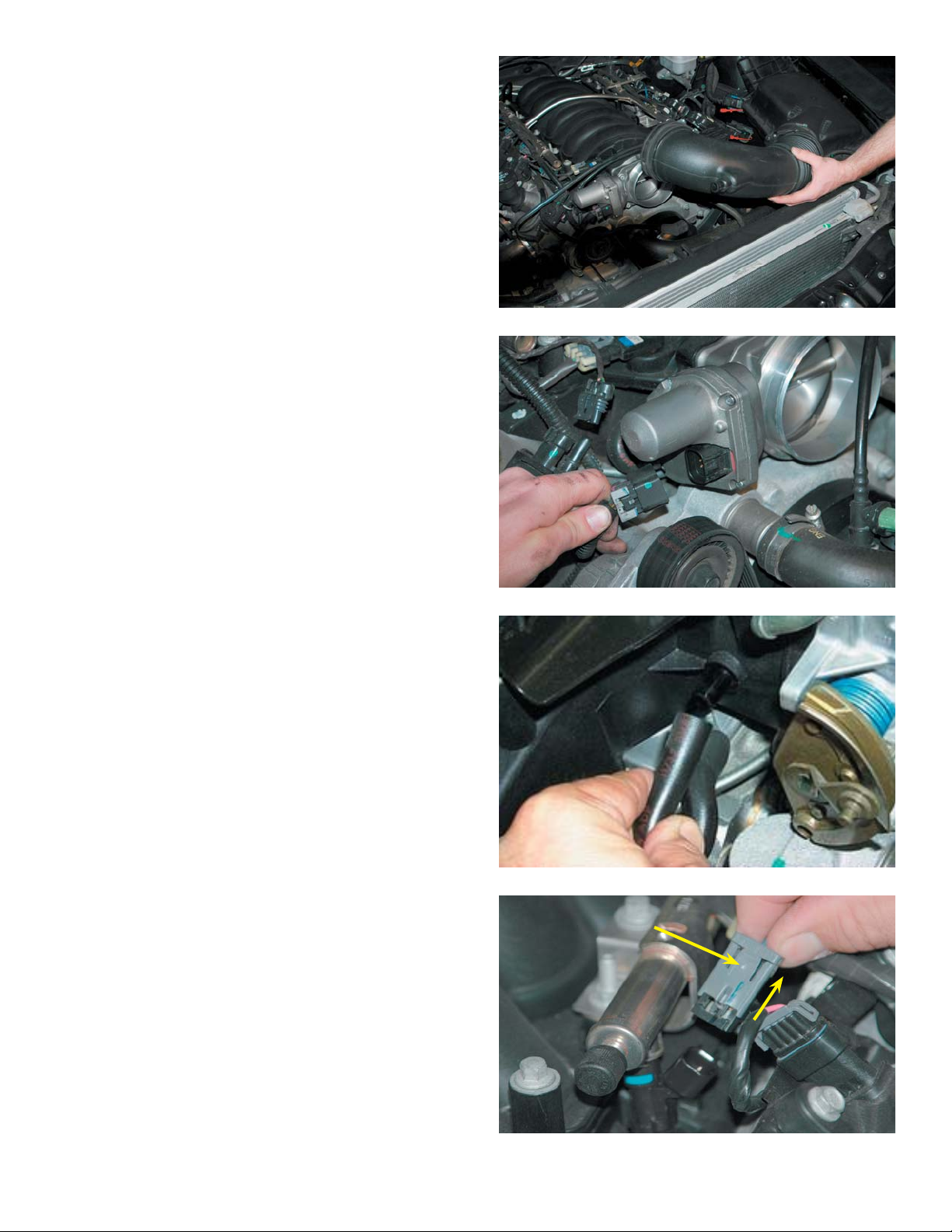

14. Loosen the Air Tube clamp at the Mass Air Flow

meter (MAF).

15. Loosen the Air Tube clamp at the throttle body.

16. Remove the PCV tube from the air tube and from

where it connects to the valve cover barb.

17. Remove the air tube completely, it will not be re-

Pull up

Squeeze here

12/05

Page 7

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

used.

18. Disconnect the Electronic Throttle Control (ETC)

connector on the right side.

19. Remove the PCV hose that connects the intake

manifold to the engine valley cover vent.

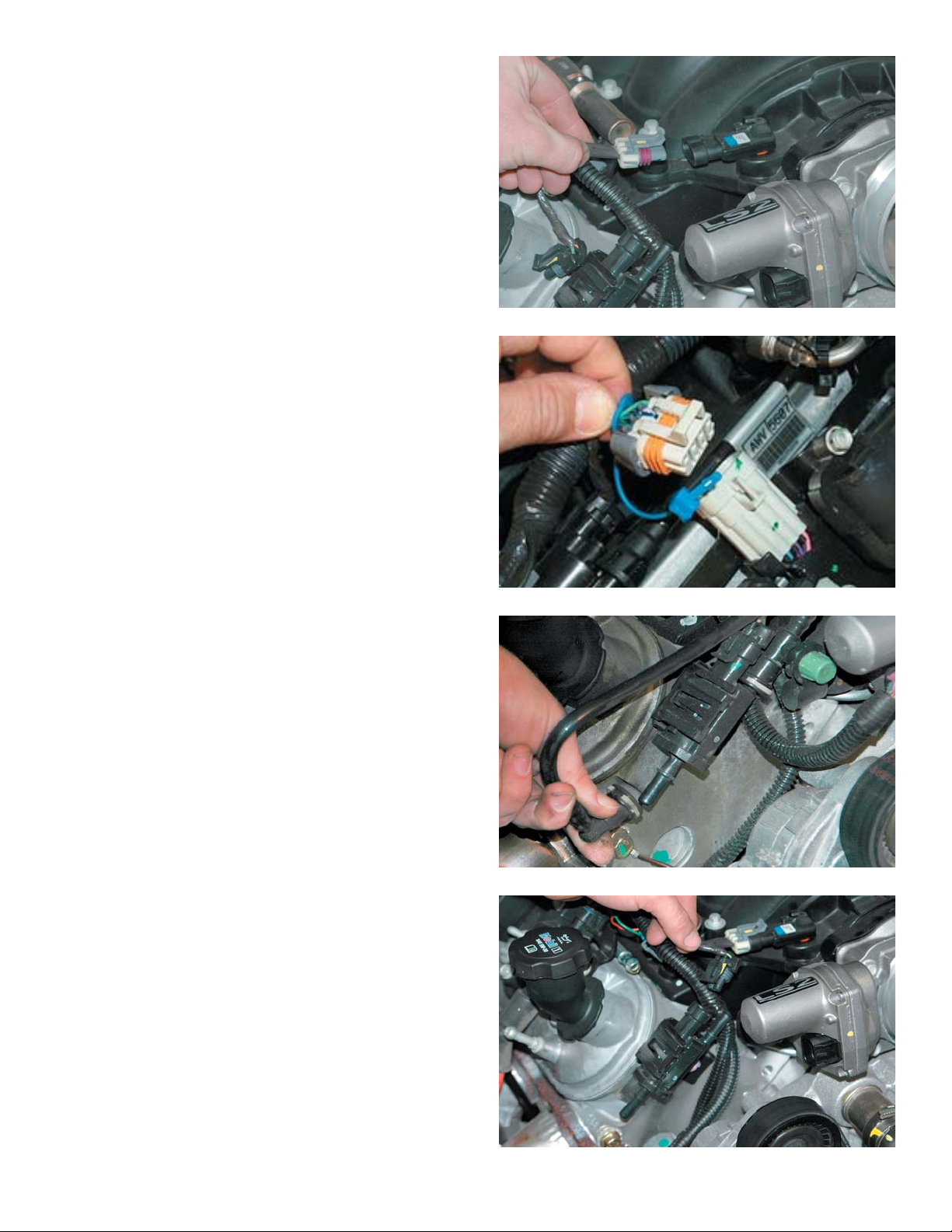

20. Disconnect the eight fuel injector connectors

by pulling up on the grey release latches and the

squeezing them at the top. Remove the injector

harness clips from the intake manifold.

Squeeze here

Pull up

21. At the front of the intake manifold locate the

12/05

Page 8

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

Manifold Absolute Pressure (MAP) sensor and

disconnect the electrical connector.

22. On both sides of the engine disconnect the

ignition coil pack connectors fron the coil packs by

fi rst removing the blue lock key.

23. The EVAP is located at the front of the passenger

(Right) cylinder head.

24. Disconnect the Evaporative Purge Solenoid

(EVAP) electrical connector.

25. Remove the EVAP line at the fi rewall by squeez-

12/05

Page 9

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

ing on the connector and pulling it free.

26. Remove the EVAP tube connector from the intake

manifold by pushing in on the white release trigger

and pulling fi rmly.

27. Remove the vacuum acessory hose and connector

from the rear of the manifold.

28. On the left side of the intake manifold, locate the

fuel pressure test port.

CAUTION! The fuel in the system is under pressure!

Relieve the pressure in the fuel system by removing

the cap and depressing the check valve with a screwdriver and collecting the fuel with a shop towel.

Vacuum

accessory

hose

29. Remove the fuel line from the fuel rail by fi rst

12/05

Page 10

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

prying the lock clip free with a small screwdriver. Use

the supplied removal tool to remove the fuel line connector.

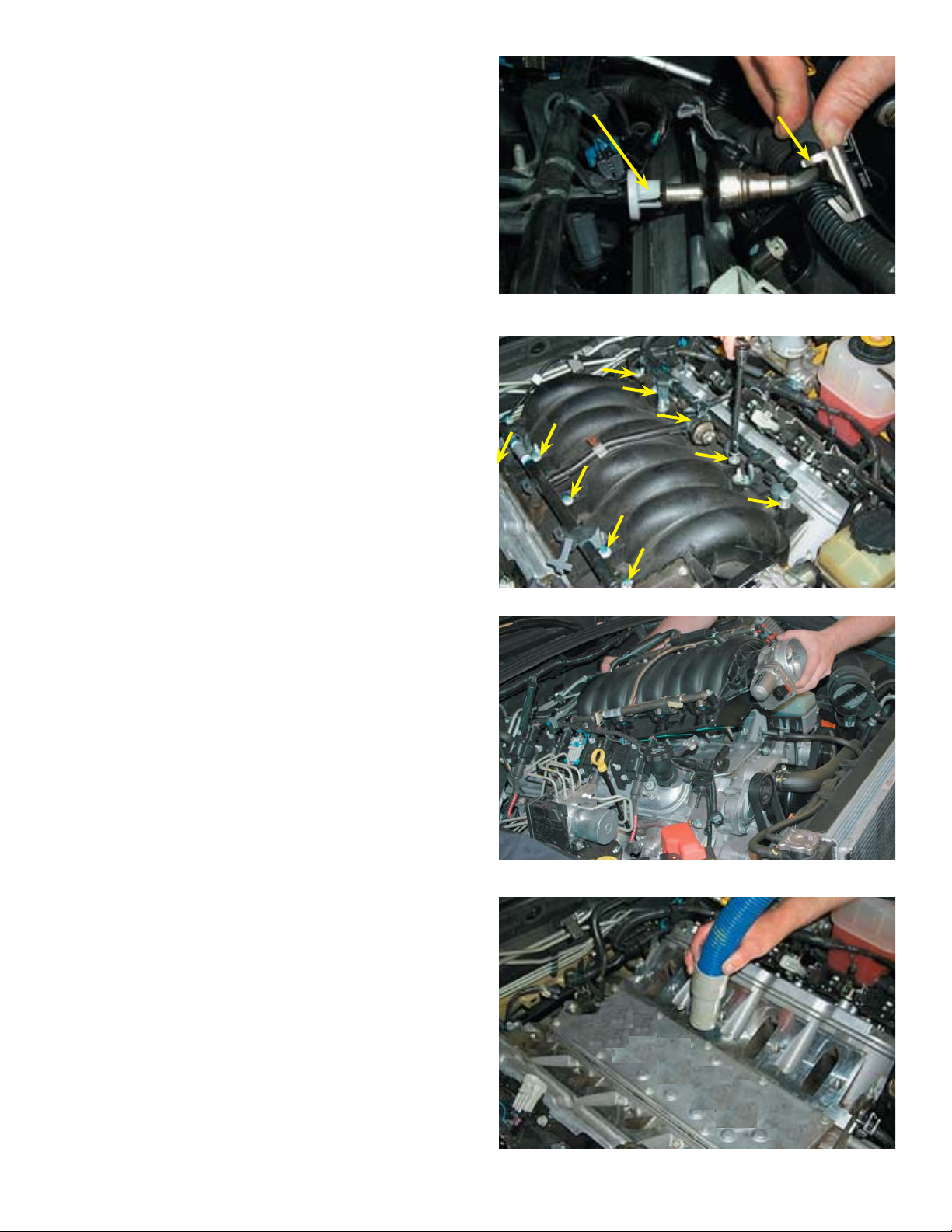

30. Remove the intake manifold by loosening the

ten manifold bolts with a socket wrench and a 8mm

socket.

Tool

Lock clip

Manifold

bolts

31. Remove the intake manifold, fuel system and

throttle body assembly.

32. Use a shop vacuum cleaner to remove any debris

or dirt from the intake port area and engine valley

cover.

33. Cover the intake ports with tape or clean rags to

12/05

Page 11

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

keep dirt and debris from entering the engine.

34. Reove the coolant vent hose from the vent pipe.

35. Remove the coolant vent pipe by removing the

attachment bolts with a 10mm socket wrench.

Coolant vent

hose

36. Remove the coolant vent pipe. Ensure that the O-

ring gaskets under the vent pipe blocks do not stick to

the cylinder heads. If so, remove them as new gaskets

are supplied.

37. Install the new vent pipe O-ring gaskets using the

12/05

Page 12

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

supplied grease to hold them in place.

38. Install the new vent pipe with the supplied bolts

and torque them with a torque wrench and 10mm

socket to 106 in-lbs.

39. Remove the accessory serpentine belt by rotating

the tensioner bolt with a 15mm wrench. Release the

slack and then pull the belt off the tensioner pulley.

40. Remove the stock belt tensioner assembly by

removing the two mounting bolts with a 15mm socket

wrench.

41. Install the new tensioner assembly in place of the

12/05

Page 13

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

stock unit with the supplied bolts and torque them to

40 ft-lbs.

42. Remove the engine oil pressure sensor connector

from the pressure sensor located at the rear of the valley cover.

43. Remove the engine oil pressure sensor from the

valley cover with a 28mm wrench.

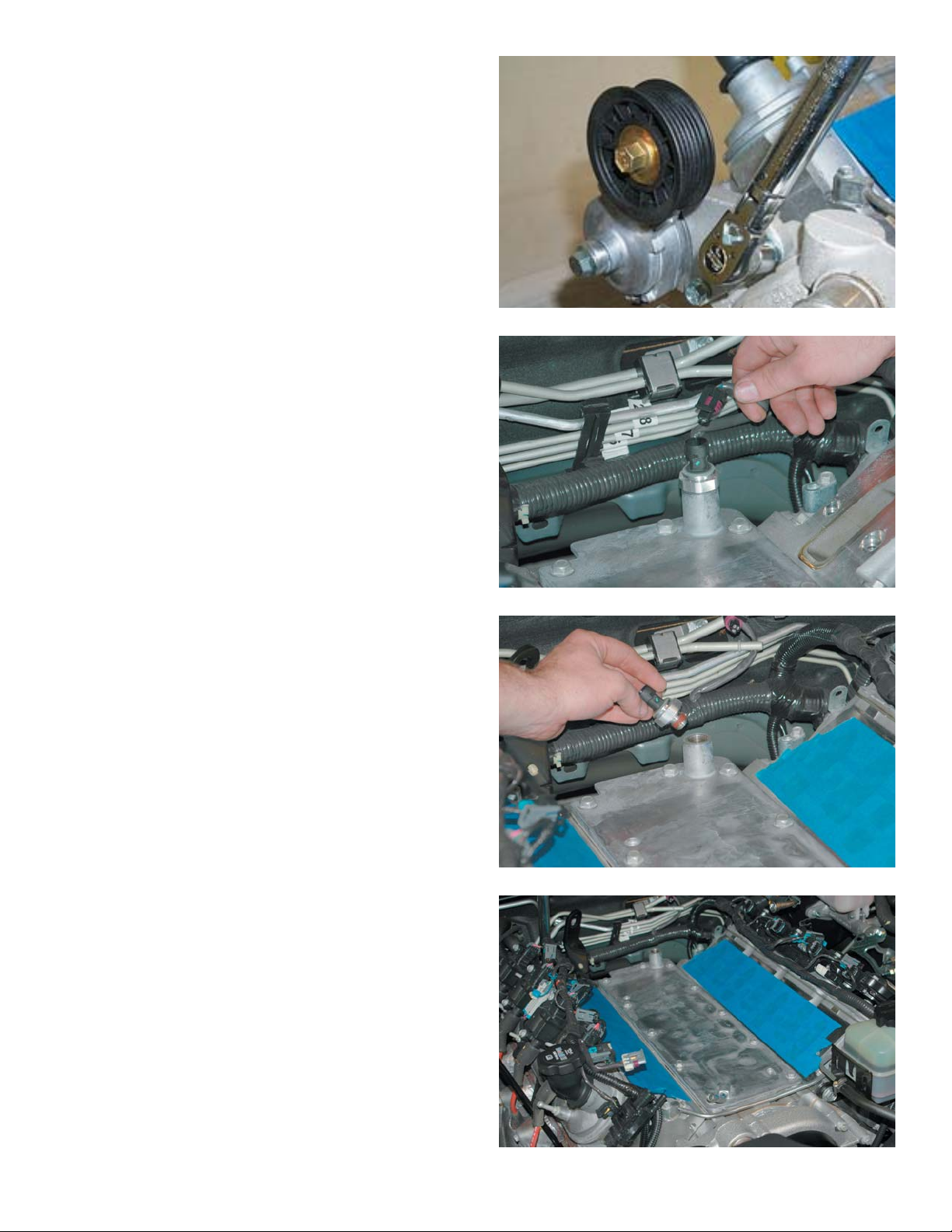

44. Remove the engine valley cover and gasket by re-

moving the ten bolts with a ratchet and 13mm socket.

45. The gasket will be reused, the original valley

12/05

Page 14

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

cover and bolts will not. Inspect the gasket for any

damage and then reinstall, note that it will only fi t cor-

rectly in one position.

46. Using a small straight blade screwdriver, remove

the 8 O-rings from the underside of the engine valley

cover and transfer them to the grooves in the bottom

of the new cover.

47. Install the new engine valley cover and fl athead

bolts supplied with a 5mm Allen socket and torque the

bolts to 18 lb-ft. Insert the six O-rings in the recesses

in the new valley cover.

48. Install the Oil Pressure Transmitter in the new val-

ley cover with a 26mm socket and torque it to 18 lb-ft.

49. Re-connect the oil pressure transmitter electrical

12/05

Page 15

2005-2006 Pontiac GTO LS2 Supercharger Installation Instructions magnacharger.com

connector.

50. Re-install the oil pressure sensor and torque it to

15 ft-lbs. Re-attach the sensor electrical connector.

51. Remove the engine lift bracket from the rear of

the right cylinder head by removing its two mounting

bolts with a 15mm wrench.

52. The automatic transmission fi ll tube will need to

be moved slighly outward to avoid contact with the

supercharger fuel cross-over pipe.

Loading...

Loading...