Page 1

11:1 PRO PUMP ASSEMBLY

MAINTENANCE AND REPAIR MANUAL

VPRO-45110

MAGNUM VENUS PRODUCTS

MAINTENANCE & REPAIR MANUAL - VPRO-45110

Rev. 8/2006

Page 2

2

Page 3

3

PRO PUMP MAINTENANCE & REPAIR MANUAL

Warranty Information

DANGER DANGER DANGER DANGER DANGER

This equipment operates under pressure and can inject chemicals under the skin if triggered

near the skin. Any injury caused by high pressure liquid can be serious. If you are injured,

or even suspect an injury:

1. Take this page and go to the hospital emergency room NOW!

2. Tell the doctor you suspect an injection injury.

3. Show the doctor this page.

4. Tell him what kind of material you were spraying.

Note to physician:

Injection in the skin is a serious traumatic injury. TREAT THE INJURY SURGICALLY AS

SOON AS POSSIBLE. Do not delay treatment to research toxicity. Toxicity is a concern

with some exotic coatings injected directly into the bloodstream.

NOTE: Consultation with a plastic surgeon or a reconstructive hand surgeon may be

advisable.

The seriousness of the wound depends on where on the body the injury occurred, whether

the substance hit something on its way in and deflected causing more damage, and other

variables. If injected material contains acrylic latex and titanium dioxide it may damage the

tissue’s resistance to infection, and bacterial growth will flourish.

The treatment that doctors recommend for an injection injury to the hand includes:

immediate decompression of the closed vascular compartments of the hand to

release the underlying tissue distended by the injected material, judicious would

debridement and immediate antibiotic treatment.

Reprinted and adapted from a warning issued by: National Spray Equipment Manufacturers

Association.

IMPORTANT WARRANTY INFORMATION

Please note that components used on this equipment are made of specially developed,

high-strength material.

Only authentic Magnum Venus Products replacement parts are acceptable

for use with this equipment.

Use of unacceptable replacement parts will void our liability and warranty of

this equipment.

Please contact your Magnum Venus Products distributor for more information.

Page 4

4

TABLE OF CONTENTS

Chapters

1. INTRODUCTION

2. REQUIREMENTS

3. MAINTENANCE

4. PRO PUMP

5. ACCUMULATOR & FILTER

6. OPERATOR VALVE.

7. TROUBLE SHOOTING CHART

Appendix

1. AIR LOCK IN THE CATALYST PUMP

Drawings

1. VPRO-45110 11:1 PRO PUMP ASSEMBLY

2. FF-5000-XXX FILTER ASSEMBLY

3. VPRO-2000 SHIFT BLOCK ASSEMBLY

4. VPRO-1000 SLAVE ARM ASSEMBLY

5. VPRO-45110-SK SEAL KIT

Page 5

5

CHAPTER

1

Introduction

This manual, the PRO PUMP MAINTENANCE & REPAIR MANUAL, provides information

you need to perform simple maintenance and repair on your equipment.

Step-by-step assembly and disassembly procedures are included for each

component.

A troubleshooting guide helps you diagnose and perform common repair

situations.

A comprehensive maintenance schedule provides a detailed list for

performing daily, weekly, monthly, three-month and annual maintenance.

Please read the manual carefully. Follow the steps in the order given, otherwise you may

damage the equipment or injure yourself.

DANGER: Always wear proper safety equipment, including eye protection and gloves

when performing service and repair on this equipment.

During Disassembly:

As you disassemble the equipment, lay out the components in the correct order and

direction. This will help you to reassemble them.

Especially note the order of the piston cup (3101-12-1), piston cup spacer ring (3101-13-1),

piston cup backup ring (3101-14-1) and compression ring (15936-1) and the directions they

face. These directions are critical to proper functioning of this equipment.

Lubrication:

Throughout this manual, directions are given for lubricating various parts of the Pro Pump.

There are three types of lubricant used:

If the part contacts resin, use MVP Red Grease (6706-2-1).

If the part is located where it will contact air, use Lubriplate

®

(08465).

DANGER: FIRE AND EXPLOSION HAZARD. Never use any lubrication on the

components of the catalyst system. Contact your catalyst manufacturer for

additional material handing information.

Throat Seal Oil (TSL-3200) used in the oil reservoir of the pump.

Page 6

6

Major Components:

Your Pro Pump consists of the following major components:

Resin pump Fluid section.

Resin pump Air motor.

Shift Block Assembly.

Description of Controls for Spray unit:

Familiarize yourself with the manifold controls, which consist of the following regulators and

gauges:

PUMP PRESSURE gauge and regulator. These control main air pressure to

the resin pump.

ATOMIZING-AIR gauge and regulator. This controls the air pressure to the

catalyst nozzle on the gun.

Hazard Information:

Please note the following safety and informational designations used throughout this manual:

DANGER: Indicates hazards or unsafe practices that are likely to result in severe

personal injury or death.

WARNING: Indicates hazards or unsafe practices which could result in severe

personal injury or extensive equipment damage.

CAUTION: Indicates hazards or unsafe practices which could result in minor injury or

damage to equipment.

NOTE: Indicates additional information including explanations of certain procedures

or helpful suggestions. Notes do not contain safety information.

Page 7

7

CHAPTER

2

REQUIREMENTS:

Air Requirements:

Clean, dry compressed air must be available at up to 90 psi (6.3 kg/cm2) and a minimum

volume of 12 CFM (340 l / min.). Air must be provided through an air hose with a diameter

of 0.5 inch (1.3 cm) or greater.

Tool and Supplies Requirements:

When performing service and repair on the Pro Pump, you should have the following tools,

spare parts and supplies available before beginning.

NOTE: Items followed by a * may be purchased from Magnum Venus Products.

One table vise

Loctite™ (removable)

One small hammer

Needle-nose pliers

Solvent or emulsifier for cleaning

One clean work table

Anti-seize thread sealant

Set of hex wrenches * (08469)

One 5/8-inch wrench * (08474)

One 9/16-inch wrench * (08476)

One 5/16-inch wrench * (08477)

Empty buckets for cleaning

Clean ¼-inch plastic dowel or rod

One 8-inch adjustable wrench * (08467)

Page 8

8

One 12-inch adjustable wrench * (08468)

One 7/16-inch open-end wrench

One ½-inch socket wrench

One 7/16-inch socket wrench * (08472)

Wooden sticks or tongue depressors (for testing)

Labels and pens (for marking pneumatic lines)

Clean rags and paint brushes for cleaning equipment

One tube of medium-weight lithium grease (such as Lubriplate

Large (approximately 3 feet by 10 feet or 1 meter by 3 meters) strips of paper for

performing spray tests.

One pin wrench * (45031-1) (comes with catalyst jug)

One scribe * (08126)

Red Grease * (6706-2-1)

Seal Kit * (VPRO-45110-SK)

NOTE: Lubriplate® is a registered trademark of the Lubriplate division of Fiske

Brothers Refining Company.

NOTE: Loctite™ is a trademark of the Loctite Corporation.

NOTE: Teflon® is a registered trademark of E.I. DuPont de Nemours and Co.

®

lubricant * (08465))

Page 9

9

CHAPTER

3

MAINTENANCE:

DANGER: Contaminated catalyst may cause FIRE or EXPLOSION. Before working on

the catalyst pump or catalyst accumulator, wash hands and tools thoroughly. Be

sure work area is free of dirt, grease or resin. Clean catalyst system components with

clean water only.

DANGER: FLUIDS UNDER HIGH PRESSURE. Before performing any service and

repair on this equipment, be sure to relieve air and fluid pressure.

DANGER: Always wear appropriate eye protection when working with this

equipment.

WARNING: When removing hoses, place a rag over the hose before loosening it.

Performing proper maintenance at the recommended time intervals maximizes your

equipment’s productivity and efficiency. This section describes recommended maintenance

procedures to be performed daily, weekly, monthly, every three months, twice per year and

once per year.

Please follow the maintenance schedules recommended in this manual. This schedule is

based on a one-shift, 5-day work week, using standard general purpose resin. An idle unit

left with resin in it requires more frequent parts replacement.

DAILY MAINTENANCE CHECKLIST

PART PROCEDURE

Air Filter (“Water Trap”) Drain the air filter by holding a container under the filter

Hoses Check for kinks or leaks.

Pro Pump Check the oil reservoir and add oil if needed.

Nozzle Cap Coat nozzle cap and threads with Red Grease.

Materials Check and fill catalyst jug and gel coat / resin. Never

and turning the valve at the bottom.

run out

Page 10

10

WEEKLY MAINTENANCE CHECKLIST

PART PROCEDURE

Air Filter (“Water Trap”) Drain

Hoses Check for kinks or leaks.

Gauges and Regulators Check for damage and proper operation.

Accumulator Remove and clean inside. Danger: Never attempt to

remove an accumulator until you have relieved

pressure. See Chapter 5: Accumulator & Filter.

Filter Clean and inspect filter screen for plugging. Note:

Clean the screen weekly and when changing from

one material to another. Use proper screen mesh

size according to the material being used.

Pro Pump Check the oil reservoir and add oil if needed. If

necessary, clean and dry the silencers.

Pro Pump Lower Assembly Check the pickup hose and wand for leaks and

damage. Check for packing leaks.

Air Lines Check for leaks, wear and kinks. Replace if necessary.

MONTHLY MAINTENANCE CHECKLIST

PART PROCEDURE

Air Filter (“Water Trap”) Drain.

Hoses Check for kinks or leaks.

Gauges and Regulators Check for damage and proper operation.

Accumulator Remove and clean inside. Danger: Never attempt to

remove an accumulator until you have relieved pressure.

See Chapter 5: Accumulator & Filter.

Filter Clean and inspect filter screen for plugging. Note: Clean the

screen weekly and when changing from one material to

another. Use proper screen mesh size according to the

material being used.

Pro Pump Check the oil reservoir and add oil if needed. If necessary,

clean and dry the silencers.

Pro Pump Lower Assembly Check the pickup hose and wand for leaks and damage.

Check for packing leaks.

Catalyst Jug Check and clean tubes and filter screens if necessary.

Danger: Fire and explosion hazard. Never allow solvent

or grease to contact any part of the catalyst system.

Air Lines Check for leaks, wear and kinks. Replace if necessary.

Page 11

11

SIX MONTH MAINTENANCE CHECKLIST

PART PROCEDURE

Air Filter (“Water Trap”) Drain.

Hoses Check for kinks or leaks.

Gauges and Regulators Check for damage and proper operation.

Accumulator Remove and clean inside. Replace the O-Rings.

Danger: Never attempt to remove an accumulator

until you have relieved pressure. See Chapter 5:

Accumulator & Filter.

Filter Clean and inspect filter screen for plugging. Note:

Clean the screen weekly and when changing from

one material to another. Use proper screen mesh

size according to the material being used.

Pro Pump Replace the oil in the oil reservoir. If necessary, clean

and dry the silencers. Check piston rod, cylinder head,

piston and trip sleeve for wear and damage, replace as

needed. Replace O-Rings, cups, and packing set.

Pro Pump Lower Assembly Check the pickup hose and wand for leaks and

damage. Check for packing leaks. Check piston rod

and pump cylinder for wear, replace as needed.

Replace the packing set, piston cups and O-Rings.

Catalyst Jug Check and clean tubes and filter screens if necessary.

Danger: Fire and explosion hazard. Never allow

solvent or grease to contact any part of the catalyst

system.

Air Lines Check for leaks, wear and kinks. Replace if necessary.

Catalyst Pump Replace all soft parts of the catalyst pump. Be sure to:

check bushings and pump cylinder and replace S.S.

balls, O-Rings, springs, piston seal and packing set.

Page 12

12

ANNUAL MAINTENANCE CHECKLIST

PART PROCEDURE

Air Filter (“Water Trap”) Drain. Repair any leaks or damage.

Gauges and Regulators Check for damage and proper operation.

Accumulator Remove and clean inside. Replace the O-Rings.

Danger: Never attempt to remove an accumulator

until you have relieved pressure. See Chapter 5:

Accumulator & Filter.

Filter Clean and inspect filter screen for plugging. Note:

Clean the screen weekly and when changing from

one material to another. Use proper screen mesh

size according to the material being used.

Pro Pump Replace the oil in the oil reservoir. Clean and dry the

silencers. Check piston rod, trip sleeve, cylinder head

and piston for wear or damage, replace as required.

Replace the O-Rings, piston cups and packing set.

Pro Pump Lower Assembly Rebuild lower assembly. See Chapter 4: Pro Pump.

Page 13

13

CHAPTER

4

Pro Pump

NOTE: Flushing the pump fluid section with solvent will make it easier to clean and

rebuild.

CAUTION: There are two (2) hard chrome balls in the Pro 11:1 pump assembly. If a

ball drops to the floor, it will be damaged. (Even if it appears undamaged, it will

contain dents and scratches that will create problems.) Damaged balls must be

replaced or the pump will not work properly.

NOTE: When disassembling the Pro pump assembly, replace any O-Rings that you

expose.

Maintenance:

1. For a complete maintenance schedule, please refer to Chapter 3: Maintenance.

Troubleshooting:

1. For a complete troubleshooting schedule, please refer to Chapter 7:

Troubleshooting Chart.

Parts Drawings:

1. To perform service and repair on the Pro pump assembly, please follow the

procedures below. Please refer to:

Drawing VPRO-45110 – Pro Pump Assembly

Drawing VPRO-2000 – Shift Block Assembly

Drawing 85805-1 – Pro Series Resin Pump Assembly

Page 14

14

Turn Off Pressure:

1. Be sure all fluid pressure and air pressure is relieved from the Pro Pump assembly.

DANGER: To avoid serious injury or equipment damage, do not proceed unless the

system has been completely depressurized.

Remove Catalyst Pump:

1. Be sure the catalyst pump has been removed from the slave arms.

Remove Pro Pump:

1. Remove the air hose connected to the fitting (PF-HN-06S-04) on the Shift Block

assembly.

2. Remove the pick-up wand hose (VHSA-1000) from the elbow (PF-ME-12-12J) at the

bottom of the pump.

3. Remove the resin hose from the fitting (PF-ME-08-06) on the resin filter assembly

(FF-5000-100).

4. Remove the air supply from the tee (MPM-2584) on the shift block assembly.

5. Remove the two screws (7101-7-6) holding the pump to the pump mount.

Remove Foot Valve Assembly:

1. Mount the Pro pump in a vise.

CAUTION: Before proceeding, note the original position of the elbow (PF-ME-12-12J)

on the foot valve body (3101-19-1). When you reinstall the foot valve body, the elbow

must be oriented in the same position.

CAUTION: As you disassemble the equipment, lay out the components in the correct

order and direction. This will help you to reassemble them. Especially note the order

of the piston cup (3101-12-1), piston cup spacer (3101-13-1), and compression ring

(15936-1), and the directions they face. These directions are critical to proper

functioning of this equipment.

2. Use a wrench to remove the two hex cap screws (02681-38) which secure the

cylinder (15986-1) and foot valve body (3101-18-1) to the center section of the pump

(85729-3).

NOTE: Loosen the hex screws alternately to prevent distorting them.

3. Remove the foot valve body (3101-18-1) and the cylinder (15986-1) from the pump.

Page 15

15

Disassemble Foot Valve Assembly:

1. Separate the cylinder from the foot valve assembly by pulling them apart. Inspect

the cylinder for damage or wear.

2. Remove built-up material from the interior.

NOTE: The two O-Rings (7301-1-137) on the cylinder will need to be replaced during

reassembly.

3. Use needle-nose pliers to remove the ball stop (3101-17-1) from the interior of the

foot valve.

4. Remove the spring (3101-18-1) and the ball (9201-2-36).

NOTE: The ball may need to be replaced during reassembly.

5. Check the interior of the foot valve body for material buildup or damage.

Assemble Foot Valve Assembly:

1. Lubricate the new foot valve ball (9201-2-36) with a light film of Red Grease (6706-2-1).

2. Roll the ball into the foot valve body.

NOTE: Handle the foot valve ball carefully. If it is damaged, it must be replaced.

3. Insert the spring (3101-18-1) on top of the ball.

4. Use the ball stop (3101-17-1) to secure the foot valve spring and the foot valve ball in

the foot valve body.

NOTE: The ball stop (3101-17-1) should be in the groove in the foot valve body, with

the ball stop on top of the spring.

5. Place the new O-Rings (7301-1-137) on the cylinder (15986-1) and lubricate them

with Red Grease (6706-2-1).

6. Insert the cylinder into the foot valve body.

7. Use the palm of your hand to press the cylinder securely into the foot valve until the

cylinder seats.

8. The foot valve will be installed on the pump later.

Page 16

16

Remove Piston Body Assembly:

1. Remove the piston body (15939-1).

CAUTION: Hold your hand under the pump as you loosen the piston body to prevent

the ball (ALS-1018) and piston ball spring (3102-8-1) from falling out.

2. If the ball falls, it must be replaced. Inspect the ball and spring to be sure that there

is no damage.

3. Remove the spring retainer (86800-1) and lower packing spring (04305-1).

Disassemble Piston Body Assembly:

1. Separate the piston cup backup ring (VLS-4617), the two piston cups (VLS-4615),

the piston cup spacer ring (VLS-4616) and the compression ring (15936-1). Inspect

these components for wear and replace if necessary.

NOTE: The piston cups will have to be replaced during reassembly.

Assemble Piston Body Assembly:

1. Lubricate the two piston cups (VLS-4615) with Red Grease (6706-2-1).

2. Assemble the piston body components onto the piston body (15939-1) in the order

they were removed. Be sure to assemble the components with the correct sides

facing each other. See below

a. The piston cup backup ring (VLS-4617) should have its grooved side facing

up toward the pump.

b. The piston cup (VLS-4615) should have its “cup” facing up.

c. The piston cup spacer ring (VLS-4616) (which separates the piston cups)

should have its grooved side facing up.

d. The second piston cup (VLS-4615) should have its “cup” facing up.

e. The compression ring (15936-1) should have its beveled side facing down

toward the bottom of the pump. Newer versions of the compression ring are

universal, both sides are the same.

Piston Cup – VLS-4615

Piston Cup Spacer Ring – Ridges Up

Piston Cup – VLS-4615

Piston Cup Backup Ring – Ridges Up

3. Keep the ball (ALS-1018) and piston ball spring (VLS-2414) with this assembly, but

do not assemble them onto the pump yet.

NOTE: Be sure the compression ring is positioned down over the shoulder of the

piston body or the piston cups will not tighten properly.

Page 17

17

Remove Packing Set:

1. Place the pump in a vise by clamping onto the bottom slave arm. Be sure the

opening at the bottom of the center section is clear of the vise.

NOTE: To remove packing set you will use one set of the packing removal tools

(“clamshells”) (45051-1). Each set of clamshells consists of two pieces of metal bent

in a U-shape.

2. Remove the black plastic plugs (15515) on the side of the pump body.

3. Be sure the pump is set to mid-stroke.

NOTE: You should be able to access the hex screw (F-HB-04C-24) and hex nut (F-LN-04C)

through the holes in the pump head. If the pump is not at mid-stroke, connect and slowly

increase air to the pump until the pump is at mid-stroke. Be sure you have a second air

hose connected to the tee (MPM-2584) on the shift block assembly (VPRO-2000). Then

disconnect the air.

WARNING: Always disconnect the air when instructed to do so to prevent injuring

yourself and damaging the equipment.

4. Remove the upper slave arm (VPRO-1001 or 85717-1) from the pump by removing

the hex cap screw (F-HB-04C-24) which secures the slave arm to the pump’s center

section. Use two socket wrenches to remove the hex screw. Use one wrench to

hold the lock nut (F-LN-04C) in position while using the other wrench to remove the

hex screw.

5. Move the pump to the top of the stroke by hand or reconnect the air to the pump. Be

sure you have a second air hose connected to the tee on the shift block assembly.

DANGER: Never insert fingers or tools into the pump cavity when air is connected to

the pump. Serious injury or amputations may occur.

6. Slowly increase the air pressure until the pump reaches the top of the stroke, and

then shut off the air.

7. Disconnect the air.

WARNING: For your protection, always disconnect the air when instructed to do so.

8. Insert the clamshells (45051-1) around the piston rod (85810-1). Insert the bottoms

of the clamshells between the piston rod and the center section. Center the tops

under the hex screw (F-HB-04C-24) on either side of the piston rod.

9. Reconnect the air to the pump.

DANGER: Never insert fingers or tools into the pump cavity when air is connected to

the pump. Serious injury or amputation may occur.

10. Slowly increase the air pressure until the hole for the hex screw (F-HB-04C-24)

appears then shut off the air.

11. Disconnect the air.

Page 18

18

Connect the Upper Slave Arm:

1. Coat the hex screw (F-HB-04C-24) with Lubriplate® grease.

2. Connect the upper slave arm (VPRO-1001 or 85717-1) to the pump by using the two

wrenches to install the hex screw and the lock nut (F-LN-04C).

3. Install the plastic plug (15515) over the hole on the side of the pump’s center section.

DANGER: Serious injury or amputation. Never operate the pump unless the plastic

plugs are installed on the pump. Serious injury or amputation may occur.

DANGER: Never insert fingers or tools into the pump cavity during operation.

Serious injury or amputation may occur.

4. Push down on the slave arms and clamshells to remove the packing set from the

bottom the pump. If you are unable to do this by hand, reconnect the air and slowly

increase air pressure until the pump reaches the bottom of the stroke, then shut off

the air.

5. Disconnect the air.

NOTE: If the packing set have not come down far enough, gently insert a blunt tool

into the pump cavity and use it to drive the clamshells farther down.

6. Remove the following components from the bottom of the pump

a. The male compression ring (87060-1).

b. The piston rod packing set (VLS-4605).

c. The female compression ring (VLS-4604).

NOTE: The piston rod packing set (VLS-4605) will need to be replaced during

reassembly.

7. Remove the clamshells through the bottom of the center section.

8. Inspect the inside of the packing cavity. It should be clean and free of material.

Remove Cylinder Head:

NOTE: Use drawing VPRO-45110 Pro Pump Assembly and VPRO-2000.

1. Remove the air tube (MPM-2583-1) from the top of the Pro pump air motor.

2. Use a wrench to unscrew the cylinder head (15983-1).

3. Inspect the inside of the cylinder head (15983-1) for wear or damage.

4. Remove O-Ring (O-B-242) from the air motor piston (15888-1).

5. Remove O-Ring (O-B-157) from the top of the center section casting (85729-3).

6. Remove hex nut (F-JN-07C) from the top of the air motor piston.

7. Unscrew the air motor piston (15888-1) from the piston rod (85810-1).

Page 19

19

Remove Shift Block Assembly:

NOTE: Use drawing VPRO-45110 Pro Pump Assembly and VPRO-2000 Shift Block

Assembly.

NOTE: The shift block assembly does not need to be completely disassembled for

routine inspection and maintenance. If troubleshooting indicates that you need to

disassemble the shift block, please see Section 6: Shift Block for complete

instructions.

1. To remove the shift block assembly from the pump, remove the three hex screws (FHB-04C-20). As you remove hex screws, hold onto the shift valve assembly with

one hand to prevent it from falling.

2. Set aside for now.

NOTE: Do not remove machine screws (F-MS-832-24), which holds the valve (VPRO-

2003) in place.

NOTE: The O-Ring (O-S-012) at the top of the shift block assembly will need to be

replaced during reassembly.

Remove The Piston Rod:

1. Remove the socket head cap screw (F-CS-04C-24-SS) and trip sleeve (85806-1)

from the piston rod (85810-1).

2. Check the socket head cap screw (F-CS-04C-24-SS) to make sure it is not bent.

3. Remove the upper slave arm (VPRO-1001 or 85717-1) from the pump by removing

the hex cap screw (F-HB-04C-24) which secures the slave arm to the pump’s center

section. Use two socket wrenches to remove the hex screw. Use one wrench to

hold the lock nut (F-LN-04C) in position while using the other wrench to remove the

hex screw (F-HB-04C-24). Use caution not to drop the piston rod as the hex cap

screw is removed.

4. Remove the piston rod (85810-1) and inspect for damage and wear.

5. Remove o-ring (O-B0112) from the bushing in the top of the center section (85729-3).

CAUTION: Use only genuine Magnum Venus Products replacement parts to replace

components of this system. Using other parts could result in injury to personnel and

damage to equipment. Clean & inspect all components for wear and damage, and

replace them as needed. Replace all the used components in the pump with the ones

supplied with the Seal Kit (VPRO-45110-SK)

Page 20

20

Piston Rod Installation:

1. Coat o-ring (O-B-112) with Lubriplate® grease (08465) and install it into the bushing

on top of the center section.

2. Coat the top portion of the piston rod (85810-1) with Lubriplate® grease (08465), and

install up thru the center section into o-ring (O-B-112). Use caution not to damage

the o-ring.

3. Coat the hex screw (F-HB-04C-24) with Lubriplate® grease.

4. Connect the upper slave arm (VPRO-1001) to the piston rod by using the two

wrenches to install the hex screw (F-HB-04C-24) and the lock nut (F-LN-04C).

5. Install the trip sleeve (85806-1) onto the socket head cap screw (F-CS-04C-24-SS).

6. Put a drop of Loctite™ onto the threads of the socket head cap screw (F-CS-04C-24-SS)

extending thru the trip sleeve and thread it into the piston rod (85810-1).

Install Cylinder Head:

1. Be sure the pump is in the center stroke position.

2. Lubricate the following items with Lubriplate® grease (08465):

a. O-Ring (O-B-242) on the piston

b. Piston Rod (85810-1) above the center section (85729-3)

c. Threads on the center section where the cylinder head fits

d. O-Ring (O-B-157) on the top of the center section.

e. Inside of the cylinder head (15983-1)

3. Install the o-ring (O-B-242) on to the air motor piston

4. Install the o-ring (O-B-157) onto the top of the center section (85728-3)

5. Screw the cylinder head (15983-1) onto center section (85729-3) and tighten.

Page 21

21

Install Packing Set:

1. Lay the pump on its side to make it easier to insert the balls and springs.

2. Lubricate – Fill each packing and the female compression ring with MVP Red Grease

(6706-2-1) and assemble them in the following order.

a. Female compression ring (top of stack) (VLS-4604). The flat side should be

toward the top of the pump and the concave side should face the packing set.

Fill the concave side full of Red Grease (6706-2-1)

b. Piston rod packing set (VLS-4605). Fill the inside of each packing with Red

Grease (6706-2-1), and be sure to install them in the order in which they were

removed. The concave side of the packing should face toward the bottom of

the pump. See below

c. Male compression ring (bottom of stack) (87060-1). The lip of the male

compression ring should face away from the packing set and toward the

spring.

d. Lower packing spring (04305-1). The smaller coil of the spring fits over the

lip of the male compression ring.

e. Spring retainer (86800-1). The lip of the spring retainer fits into the larger coil

of the spring.

Female Compression Ring (VLS-4604)

Piston Rod Packing Set (VLS-4605)

Male Compression Ring (87060-1)

3. Push the packing set, the spring and the spring retainer onto the piston rod and up

into the packing cavity.

Page 22

22

Install Piston Body Assembly:

1. Insert the piston ball spring (VLS-2414) into the piston rod (85810-1), being sure that

the spring goes onto the end of the dowel pin (located on the bottom of the piston rod).

2. Take the piston body assembly (consisting of the ball, compression ring, piston cup,

spacer ring, piston cup, backup ring, and piston body), and thread it into the end of

the piston rod (85810-1).

CAUTION: If the piston body is screwed tightly against the piston rod, but the

packing cups still rotate easily, the top of the compression ring is not aligned

correctly. Disassemble the piston body and reinstall it.

Install Foot Valve Assembly:

1. Insert the cylinder (15986-1) and foot valve body (VLS-4602) onto the piston rod

(85810-1).

2. Coat the threads of the two hex screws (F-HB-06C-76-GR5) with a thin layer of

Lubriplate® grease. Then gently hand-tighten the screws to secure the foot valve collar

(VLS-2424), foot valve body and cylinder to the pump’s center section (85729-3). Do

not completely tighten the assembly yet.

3. Check the orientation of the elbow (PF-ME-12-12J) and reinstall as noted earlier.

4. When the foot valve body is oriented correctly, tighten the hex screws to 13 ft.-lb (18

N-M, 1.6 KP-M).

NOTE: Tighten the hex screws in an alternating pattern to ensure a good seal.

WARNING: Do not over tighten the hex screws on the foot valve collar. Damage to

the center section will occur.

Install Shift Block Assembly:

1. Place the new O-Ring (O-S-012) on top of the shift block assembly and lubricate it

with Lubriplate® grease (6706-2-1).

WARNING: Before attempting to connect the shift valve assembly to the pump, be

sure the socket cap screw (00260) is in the center stroke position. If the screw is not

in the center stroke position, you will damage the equipment.

2. Coat the three hex screws (02650-18) with a thin film of Lubriplate

hold the shift block assembly against the pump’s center section and slightly finger-

tighten each screw.

3. Use one hand to press the shift block assembly upward while tightening the hex

screws in an alternating pattern.

®

grease. Then

NOTE: This secures the O-Ring (O-S-012) on top of the shift block assembly against

the underside of the cylinder head. If the O-Ring is not positioned properly, the pump

will lose air pressure during operation.

4. Install the air tube (MPM-2583-1) between the shift block and the top of the Pro pump.

Page 23

23

Install Pro Pump:

1. Remove the pump from the vise and install on the unit with hex cap screws

(F-HB-05C-12).

2. Connect all hoses to the pump.

Set The Packing Set:

1. Prime the Pro pump fluid section.

2. Close the gun-head.

3. SLOWLY increase the pump pressure to 60 psi.

4. Keep the pump stalled for 5 to 15 minutes to allow the packing set to set.

5. Decrease the pump pressure to the desired operating pressure. Now you are ready

to connect, prime and pressurize the catalyst pump for operation.

Page 24

24

CHAPTER

5

ACCUMULATOR & FILTER: FF-5000-100

Maintenance:

The accumulator & filter should be disassembled and cleaned approximately once per week

(more often if the weather is hot).

Troubleshooting:

If you must keep increasing pressure to maintain an adequate spray fan, the filter may be

clogged with debris. If the spray is pulsing, the accumulator is probably blocked. When

dealing with system blockages, follow the safety instructions below.

DANGER: Before disassembling accumulator, relieve fluid pressure and air pressure.

If material is plugging the system, some parts of the system may still contain fluids

under high pressure, even after you have followed normal procedures to relieve the

pressure.

WARNING: To prevent injury, hold a large rag or shop towel around the wrench and

fitting as you remove the fitting. Remove the fitting slowly to allow fluid pressure to

escape into the rag or towel.

WARNING: Always wear appropriate eye protection and other protective clothing

when performing service and repair on the accumulator & filter.

Parts Drawings:

To service the accumulator, please follow the procedures below, using drawing FF-5000-XX

Accumulator & Filter Assembly.

Relieve Air and Pump Pressure:

1. Turn pump pressure off.

2. Hold the gun over an appropriate empty container and lock the gun in an open position.

DANGER: Never attempt to remove, repair or clean an accumulator until you have

relieved pressure.

3. Disconnect air from the system.

4. Place an empty container under the filter/accumulator; slowly open the ball valve at

the bottom of the filter cap.

Page 25

25

Remove and Disassemble Filter:

1. Unscrew the filter cap (FF-5002) from the filter body (FF-5001).

NOTE: The components of the resin accumulator and filter should not be over

tightened.

2. Remove the screen (FF-5099-100) from the filter body (FF-5001).

3. Inspect the screen and clean with solvent.

NOTE: Typically, the screen is a 100-mesh. Mesh size depends on the resin type and

the size of the nozzle tip used on the gun. If you change resin types, you may want to

experiment with a different nozzle tip and/or a different size mesh in your filter screen.

4. Inspect the interior of the filter body and clean with solvent.

5. Check the O-Ring (O-V-022) on the filter cap for wear or damage. Replace if

necessary.

NOTE: If resin is leaking down the side of the filter cap, the O-Ring (O-V-022) is worn

and should be replaced.

Assemble and Install Filter Body:

1. Lubricate the threads of the filter cap (FF-5002) and o-ring (O-V-022) with red grease

(6706-2-1).

2. Place the screen (FF-5099-100) onto the filter cap (FF-5002).

3. Screw the filter cap into the filter body (FF-5001).

Remove Accumulator Bottle:

DANGER: Before disassembling accumulator, relieve fluid pressure and air pressure.

If material is plugging the system, some parts of the system may still contain fluids

under high pressure, even after you have followed normal procedures to relieve the

pressure.

1. Unscrew the surge chamber (SC-2510) from the nipple (PF-HN-08-06).

2. Inspect the interior of the accumulator bottle. Clean with solvent and blow dry with

air if needed.

Install Accumulator Bottle:

1. Screw the nipple (PF-HN-08-06) and surge chamber (SC-2510) into the top of the

filter body (FF-5001).

2. Check for leaks

Page 26

26

CHAPTER

6

SHIFT BLOCK ASSEMBLY:

Maintenance:

Usually, the shift block assembly on the Pro pump needs to be completely disassembled

only once per year for maintenance.

Troubleshooting:

If the Pro pump stalls Check for resin blockage Check and clean resin filter.

Flush resin hose, if blocked

replace.

Check air supply to pump Connect air line to shift block.

Air motor malfunction Remove air motor cylinder head

Shift Block Malfunction Replace valve or actuator valve

If the stroke “stutters” Shift Block malfunction Check and clean the actuator

Check air line for kinks or

blockage.

and inspect piston and o-ring.

as needed on the shift block.

valve or replace the actuator valve.

Page 27

27

Parts Drawings:

To disassemble the shift valve, please follow the procedures below. Please refer to drawing

VPRO-2000 Shift Block Assembly and drawing VPRO-45110 Pro Pump Assembly.

DANGER: Before performing service or repair on this equipment, be sure to

disconnect all air to the system.

WARNING: Be sure to wear appropriate safety equipment, including gloves and eye

protection.

Check Socket Cap Screw Position:

Before performing service and repair on the shift block, be sure the socket cap screw

(F-CS-04C-24-SS) and trip sleeve (85806-1) is in the center position of the pump.

NOTE: The socket cap screw and trip sleeve is shown on drawing VPRO-45110 Pro

Pump Assembly.

Remove Operator Valve Assembly From Pump:

DANGER: Before performing service or repair on this equipment, be sure to

disconnect all air to the system.

1. Be sure all fluid pressure and air pressure is relieved from the system.

2. Remove the red air hose and the clear tube from the shift block assembly.

3. Remove the air tube (MPM-2583-1) from the top of the air motor cylinder head.

4. Remove the three screws (F-HB-04C-20) from the front of the shift block

5. Remove the shift block assembly from the pump.

NOTE: The O-Ring (O-S-012) at the top of the shift block assembly needs to be

inspected and replaced if needed.

Remove Valve from Shift Block:

1. Remove the urethane tubes (MPM-2052-5.5) from the valve body (VPRO-2003).

2. Remove the two mufflers (VPRO-2004) from the valve body.

3. Unscrew the nipple (PF-HN-06S-04) and reducer (PF-RA-04-02) from the valve

body.

4. Unscrew the two tube fittings (7701-6-4) from the valve body.

5. Remove the two machine screws (F-MS-832-24) from the valve body (VPRO-2003).

Note: The guard (VPRO-2002) will also come loose when you remove the machine screws.

6. Remove the valve and guard from the actuator body.

Page 28

28

Install Valve onto Shift Block:

1. Install the nipple (PF-HN-06S-04) and reducer (PF-RA-04-02) onto the valve.

2. Install the mufflers (VPRO-2004) onto the valve.

3. Screw the two tube fittings (7701-6-4) into the valve body.

4. Hold the guard (VPRO-2002) and valve (VPRO-2003) up to the actuator body

(VPRO-2003) and attach with machine screws (F-MS-832-24).

5. Attach tube (MPM-2052-5.5) to the valve.

Remove Actuator Valve from Shift Block:

1. Remove the urethane tube (MPM-2052-5.5) from the valve body (VPRO-2003).

2. Unscrew the elbow (TRU-1021) from the end of the actuator (MPM-2598).

3. Remove the nut (MPM-2587) holding the actuator (MPM-2598) in place and pull the

actuator free.

4. Repeat the process for the other end if necessary.

Install Actuator Valve onto Shift Block:

1. Install the actuator (MPM-2598) into the actuator body (VPRO-2001) and install nut

(MPM-2587).

2. Thread the elbow (TRU-1021) into the end the actuator (MPM-2598).

3. Install the urethane tube (MPM-2052-5.5) onto the actuator (MPM-2598).

4. Install the urethane tube (MPM-2052-5) onto the elbow (TRU-1021).

5. Repeat process on the other end if necessary.

Page 29

29

Connect Shift Block Assembly to Pump:

WARNING: Be sure the socket cap screw (00260) and trip sleeve (85806-1) is in the

center stroke position or you will damage the equipment.

1. If you need to install the socket cap screw and trip sleeve, refer to drawing (VPRO-

45110) Pro Pump Assembly and do the following:

a. Install the trip sleeve onto the socket cap screw (F-CS-04C-24-SS) and put

medium-strength Loctite™ on the threads of the socket cap screw (F-CS04C-24-SS).

b. Thread the socket cap screw and trip sleeve into the piston rod until it is tight

against the trip sleeve.

2. Apply a light film of Lubriplate® to o-ring (O-S-012) and install onto the top of the

actuator body.

3. Hold the shift block assembly against the pro pump’s center section. Slightly finger-

tighten the three hex screws (F-HB-04C-20) into the center section.

4. Use one hand to press the shift block assembly upward while tightening the hex

screws in an alternating pattern.

NOTE: This secures the O-Ring (O-S-012) on top of the shift block assembly against

the underside of the cylinder head. If the O-Ring is not positioned properly, the pump

will lose air pressure during operation.

5. Install the air tube between the top of the pump and the shift block.

6. Connect the air hose and the clear tube to the shift block assembly.

Test Operator Valve:

1. Test the valve to ensure that there is proper air flow intake and output.

2. Increase the pump pressure.

3. Open the gun over an appropriate container.

4. If the pump operates, the shift block works.

Page 30

30

CHAPTER

7

TROUBLESHOOTING CHART

DANGER: Contaminated catalyst may cause Fire or Explosion. Before working on

the catalyst pump or catalyst accumulator, wash hands and tools thoroughly. Be

sure work area is free of dirt, grease or resin. Clean catalyst system components with

clean water only.

DANGER: Fluids under high pressure. Before performing any service and repair on

this equipment, be sure to relieve air and fluid pressure.

DANGER: Always wear appropriate eye protection when working with this

equipment.

WARNING: When removing hoses, place a rag over the hose before loosening it.

DIAGNOSING PROBLEMS:

The most common problems with the equipment are diagnosed by analyzing the cured part.

NOTE: Many problems are the direct result of a failure to maintain the equipment

according to the maintenance schedules given. Please follow your maintenance

chart.

CURE PROBLEM CAUSE SOLUTION

Slow cure during upstroke S.S. Ball in catalyst pump Clean ball and inspect seat.

piston body not seating. Replace ball, piston seal check

or piston body if questionable. cylinder.

Slow cure during down stroke S.S. Ball in catalyst pump Clean ball and inspect seat.

inlet body not seating. Replace ball or have seat

repaired if questionable.

No cure or slow over-all cure Catalyst pump at too low or Move catalyst pump to a higher

too high of a percentage. (Setting closer

to the gel coat pump). Be sure to

attach the catalyst pump in a

vertical position.

Catalyst supply below outlet Fill catalyst jug 2/3 full.

fitting on jug.

Page 31

31

Quick pin not attached to pump Install quick pin. Be sure to

Danger: In the next steps you will be dealing with fluids

under high pressure. Catalyst will be sprayed from the hose

fitting when the fitting is loosened. Follow safety

instructions below. Danger: Wear eye and skin protection.

Fluids in the system are under pressure and can cause

severe injury, including skin punctures.

Danger: Medical emergency. If skin is punctured by highpressure fluids, or if material gets in eyes, seek immediate

emergency medial attention.

Note: You may need to cut off 2” of hose to reinstall the

fitting properly. If your hose is less than 30 feet long and

you cut off 2” of hose, you should also cut off 2” of the

core. If the hose is longer than 30 feet, you do not need to

cut the core.

or slave arm. attach the catalyst pump vertically.

Fluid leak. Check all fittings. The system

must be fluid tight.

Catalyst relief valve on catalyst Relieve pressure from Pro pump.

pump is leaking. Clean inside of relief valve body

or repair.

Catalyst suction screen in Clean catalyst suction screen

catalyst jug clogged and ensure that catalyst supply is

not contaminated.

Air lock in catalyst pump. Remove air lock. See Appendix:

Air Lock in the Catalyst Pump.

Catalyst pump piston seal Replace piston seal. During

worn or damaged reassembly, be sure spring seal

faces top of pump.

Catalyst pump outlet body Replace catalyst pump outlet

damaged. body and ball.

Catalyst pump check valve Disassemble check valve and

blocked remove blockage.

Catalyst hose plugged. Relieve pressure from the

system. Disconnect the catalyst

hose from the gun. Hang the

catalyst hose over an empty

container and try to hand-pump

catalyst through the hose. If no

catalyst flows from the hose,

place a clean rag over the hose

fitting and nipple on the

accumulator. Holding the rag in

place, use a wrench to remove

the hose fitting from the nipple.

Remove the catalyst hose fitting

from the gun end of the hose.

Remove the solid core from

inside the catalyst hose. Run

clean water through the hose. If

the hose fitting on the

accumulator end of the hose will

not accept fluid, remove and

examine the fitting. Clean the

core with a clean rag then insert

the core back into the hose.

Inspect the fitting on the gun end

of the hose. If the fitting is clear

and clean, reassemble it onto

Page 32

32

Danger: To prevent injury, always relieve pressure before attempting to remove components.

the catalyst hose. Check the

hose to be sure air flows freely

through it before reassembling it

back onto the unit. If it requires

more than 60 psi to remove

blockage, remove the hose and

replace it with a new one. When

water flows freely through the

hose, blow air through the hose

to dry it.

Resin or gel coat too cold. Consult your materials supplier

for proper temperature. Maintain

a draft-free environment of about

70 degrees F. An auxiliary heat

source may be required to

reduce gel time.

Low output on upstroke of Piston cups, piston ball, or Inspect the piston cups, piston

Pro pump pump cylinder worn. ball, and pump cylinder. Clean

and replace any damaged

components. See Chapter 6:

Pro Pump.

No fan, constant low output, Screen of pump pick-up wand Unscrew screen from hose and

or fast cure blocked. clean.

Resin filter blocked. Disassemble and clean filter

body and screen, with solvent

Resin hose plugged. Flush hose with solvent. If

material is hard, replace hose.

Pick-up wand assembly leaking. Tighten assembly fittings.

Resin filter clogged. Disassemble and clean the resin

filter. See Chapter 5:

Accumulator & Filter.

Material too cold or air pressure Heat material or increase pump

low. pressure.

Narrow Fan Material too cold, nozzle too Heat Material, use smaller

large or air pressure low. nozzle, or as a last resort

increase pump pressure.

Resin filter clogged. Disassemble and clean the resin

filter.

Page 33

33

Danger: To prevent injury, always relieve pressure before attempting to remove components.

Wide Fan Air pressure too high. Lower pressure then increase

pressure to the desired fan.

Nozzle too small or too wide. Change nozzle.

Round fan Orifice in nozzle worn, clogged, Push fine wire through orifice

or damaged. from back side. Use fingernail to

clean material form “V” shaped

notch in front. Soak hardened

material in solvent. If notch is

rough or worn, replace nozzle.

Air-assist pressure too high. Decrease air-assist pressure.

Excessive misting Air pressure too high. Reduce air pressure to gel coat

pump.

Heavy pulsation Resin accumulator plugged. Disassemble accumulator and

clean.

.

Pump jumps on upstroke Piston ball worn or not seating Replace piston ball and piston

properly. cups. Be sure to lubricate ball

and cups thoroughly with Red

Grease. See Chapter 4: Pro

Pump.

Pump dives on down stroke Foot valve, spring retainer, or Clean or replace foot valve,

foot valve ball damaged or retainer and foot valve ball. Be

spring dirty. sure to lubricate ball thoroughly

with Red Grease. See Chapter 4:

Pro Pump.

Pick-up wand assembly not tight. Tighten or seal joints of pick-up

wand.

Air in material. Agitate material to remove air.

Low output on upstroke Piston cups, piston ball, or Inspect the piston cups, piston

pump cylinder worn. ball, and pump cylinder. Clean

and replace any damaged

components. See Chapter 4:

Pro Pump.

Pump does not run Silencers on valve block Turn off air to pump and unscrew

plugged. silencers. Clean silencers and

re-install.

Page 34

34

Danger: To prevent injury, always relieve pressure before attempting to remove components.

Danger: To prevent injury, always relieve pressure before attempting to remove components.

Danger: To prevent injury, always relieve pressure before attempting to remove components.

Actuator valve or socket cap Replace the broken cartridge

screw at shift block broken. valve or socket cap screw. See

Chapter 6: Pro Pump.

Pro pump or hose plugged. Disassemble and clean Pro

pump. Replace any worn parts.

Replace hose as required.

Air not connected. Check that air hose is connected

at manifold, and regulator is at

20psi or more.

Air restricted. Straighten any kinks in air hoses.

Pro pump not primed. Check all connections between

pump and end of pick-up wand

for leaks. Prime resin system.

Material in oil well Packing worn. Replace packing set in lower

part of the pump. See Chapter

4: Pro Pump.

Piston rod worn or scored. Replace piston rod. See

Chapter 4: Pro Pump.

No resin or gel coat delivery Foot valve, spring retainer, or Clean or replace foot valve,

on down stroke foot valve ball damaged or dirty. spring retainer, and foot valve

ball. Be sure to lubricate ball

thoroughly with Red Grease.

See Chapter 4: Pro Pump.

Hose leaks at fittings Fitting loose. Tighten fitting. Check all fittings

for leaks before operating.

Fitting or nipple damaged. Replace damaged parts.

Crimped hose. If the hose has been sharply

bent, the plastic liner may be

ruptured. Remove and replace

hose.

Danger: To prevent injury, always wear eye protection and follow safety guidelines provided

by your materials manufacturer.

Page 35

35

APPENDIX

AIR LOCK IN THE CATALYST PUMP:

DANGER: Fluids Under High Pressure. Before performing any service and repair on

this equipment, be sure to relieve air and fluid pressure.

DANGER: Always wear appropriate eye protection when working with this

equipment.

WARNING: When removing hoses, place a rag over the hose before loosening it.

What is an Air Lock?

An air lock is an air bubble in the catalyst pump that blocks catalyst. The piston body moves

inside the bubble of air instead of pumping catalyst.

If you have determined that there is an air lock in your catalyst pump, follow the procedures

in this section.

1. Relieve line pressure from the catalyst pump by locking the gun open over an empty

bucket. Leave the gun in this position.

WARNING: Relieve pressure from the catalyst pump before continuing.

2. Remove the catalyst hose from the nipple on the catalyst accumulator.

WARNING: When removing hose, place a rag over the hose and fitting before

loosening it.

3. Remove the quick pin from the catalyst bearing block and upper slave arm.

4. Tilt the pump back toward the resin pump to release the bubble.

NOTE: If the bubble does not appear in the inlet tube, remove the lower quick pin and

turn the pump upside-down.

5. Slowly hand-pump the catalyst into a suitable container until catalyst spurts from the

nipple an equal amount on both the upstroke and down stroke.

6. Reconnect the catalyst hose to the nipple.

7. Hand-pump the catalyst pump until catalyst comes out through the gun.

8. Install the pump and quick pin into the slave arm.

9. Close the gun

Page 36

36

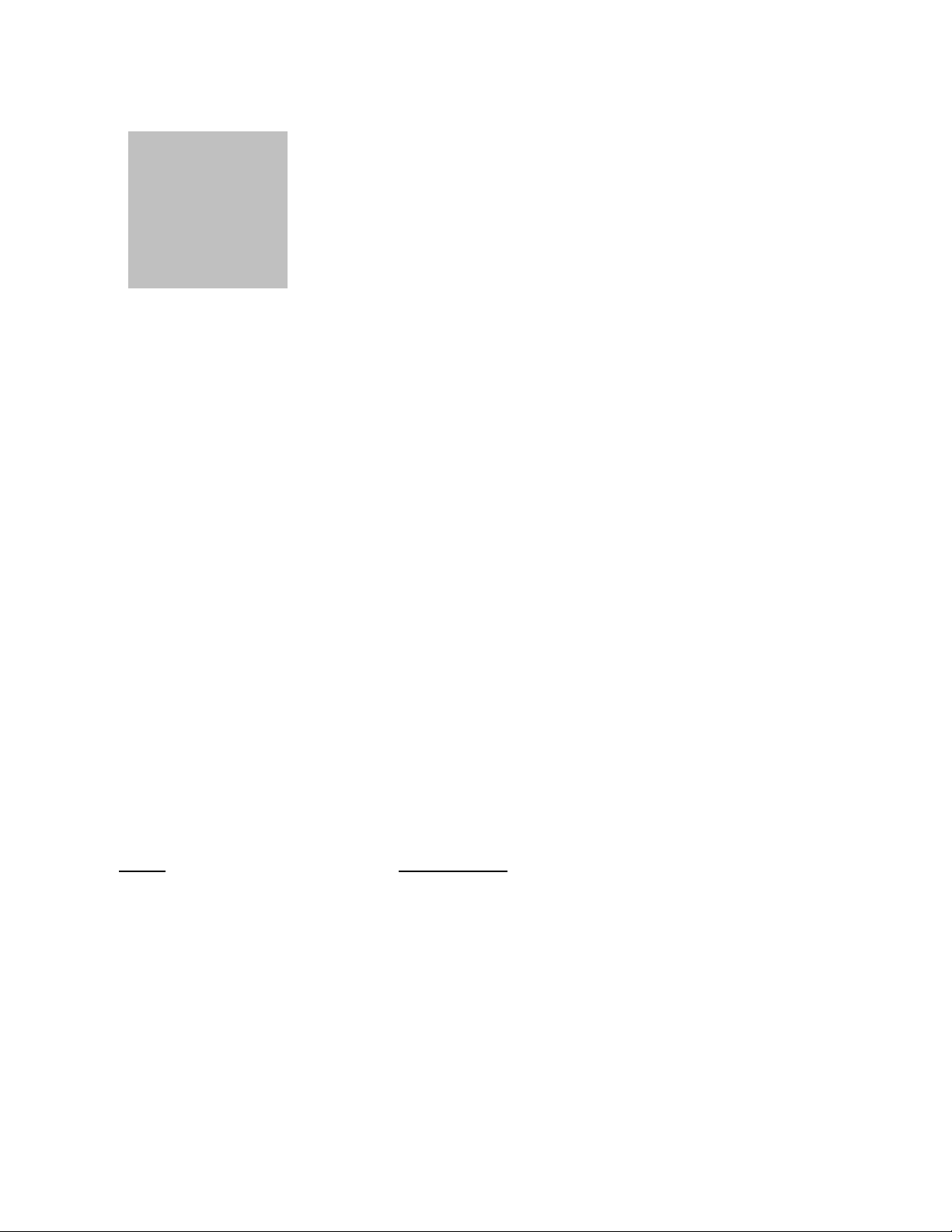

PARTS DRAWINGS

VPRO-45110 11:1 PRO PUMP ASSEMBLY

VPRO-2000 SHIFT BLOCK

VPRO-1000 SLAVE ARM ASSEMBLY

FF-5000-XXX FILTER ASSEMBLY

VPRO-45110-SK SEAL KIT

Page 37

37

33

4

THIS PUMP ASSY IS FOR EXTERNAL MIX ONLY

MAGNUM VENUS PRODUCTS

NOTE:

ASSY - 11 : 1 PRO PUMP

17

50

29

4

44

ABRASIVE KIT

VPRO-45110

B21

38

B23

B24

39

8

30

11

9

45

28

48

47

3

4

34

32

4

43

1

6

33

36

12

56

15

9

44

19

42

9

24

22

27

52

26

25

18

5

22

23

2

51

31

37

21

37

20

48

49

41

7

REV. A VPRO-1007 WAS VPRO-1004, VPRO-1005 QTY OF 3 WAS 4

7/22/02

REV. B VPRO-1003-01 WAS VPRO-1003

46

17

16

PUMP SUPPLY AIR IN

LINE AIR IN

REV. C = REPLACED 85774-1 WITH VPRO-2000 7/16/03 JEM

40

Page 38

38

56

VLS-2425 1

BALL STOP PIN

1

F-LN-04C 1

LOCK NUT

21B

15986-3 1

HARDENED CYLINDER

23B

3101-13-2 1

HARDENED PISTON CUP SPACER

24B

3101-14-2

1

HARDENED PISTON CUP BACKUP

OPTIONAL PARTS AND ASSEMBLIES

ASSY - 11 : 1 PRO PUMP VPRO-45110

PARTS LIST

ITEM

PART NO. QTY

ITEM

QTY

PART NO.

DESCRIPTION

VPRO-45110-SK

SEAL KIT

REPAIR KITS

DESCRIPTION

PART NO.

DESCRIPTION

2

F-JN-07C 1

HEX NUT

4

F-LN-04F 6 LOCK NUT

3

F-CS-04C-24-SS

1

SOCKET HEAD CAP SCREW

7

F-HB-05C-32

2

HEX BOLT

8

F-HB-06C-76-GR5

2

HEX BOLT

6

F-HB-04C-24

1

HEX BOLT

5

O-B-242 1

O-RING

15

15888-1 1

AIR MOTOR PISTON

17

04305-1

1

SPRING

16

O-B-112 1

O-RING

11

PF-SW-06

1

SWIVEL FITTING

12

15515

1

PLUG

10

O-B-157

1

O-RING

9

02966 6

AIRCRAFT BOLT

23

VLS-4616

1

PISTON CUP SPACER

26

VLS-4621 1

FOOT VALVE SPRING

27

VLS-4602

1

FOOT VAVLE BODY

29

VLS-4605 1 PISTON ROD PACKING SPA

28

VLS-4604

1

FEMALE COMPRESSION RING

30

VLS-2424 1

FOOT VALVE COLLAR

32

52106-3

1

QUICK PIN CABLE ASSY.

33

VPRO-1006 6

SLAVE ARM BUSHING

31

VLS-2414

1

PISTON BALL SPRING

25

VLS-4620

1

BALL STOP

24

VLS-4617 1

PISTON CUP BACKUP

22

VLS-4615 2

PISTON CUP

20

15983-1

1

CYLINDER HEAD

21

15986-1 1 CYLINDER

19

15939-1 1

PISTON BODY

18

15936-1 1

COMPRESSION RING

42

VPRO-1003-01

1

LINK BAR

41

VPRO-1007

1

MOUNT BLOCK

40

7701-4-5 1

PLASTIC PLUG

39

PF-RB-16-12

1

REDUCER BUSHING

38

PF-ME-12-12J 1

MALE ELBOW

37

O-V-137-90 2

O-RING

36

F-HB-05C-12

2

HEX BOLT

34

VPRO-1005 3

SLAVE ARM SPACER

43

VPRO-1001

2

UPPER SLAVE ARM

50

87060-1 1

MALE COMPRESSION RING

49

86800-1 1

SPRING RETAINER

48

85810-1 1 PISTON ROD

47

85806-1

1

TRIP SLEEVE

46

VPRO-2000 1

SHIFT BLOCK ASSY.

45

85729-3 1 CENTER SECTION ASSY.

44

VPRO-1002

2

LOWER SLAVE ARM

55

95084-EN 1

AIR SHUT OFF CAUTION LABEL (NOT SHOWN)

54

95081-3

1

SLAVE ARM DECAL (NOT SHOWN)

53

95033-EN 1

PUMP PRIME CAUTION LABEL (NOT SHOWN)

52

VLS-4622 1

CHROME BALL

51

ALS-1018

1

CHROME BALL

Page 39

39

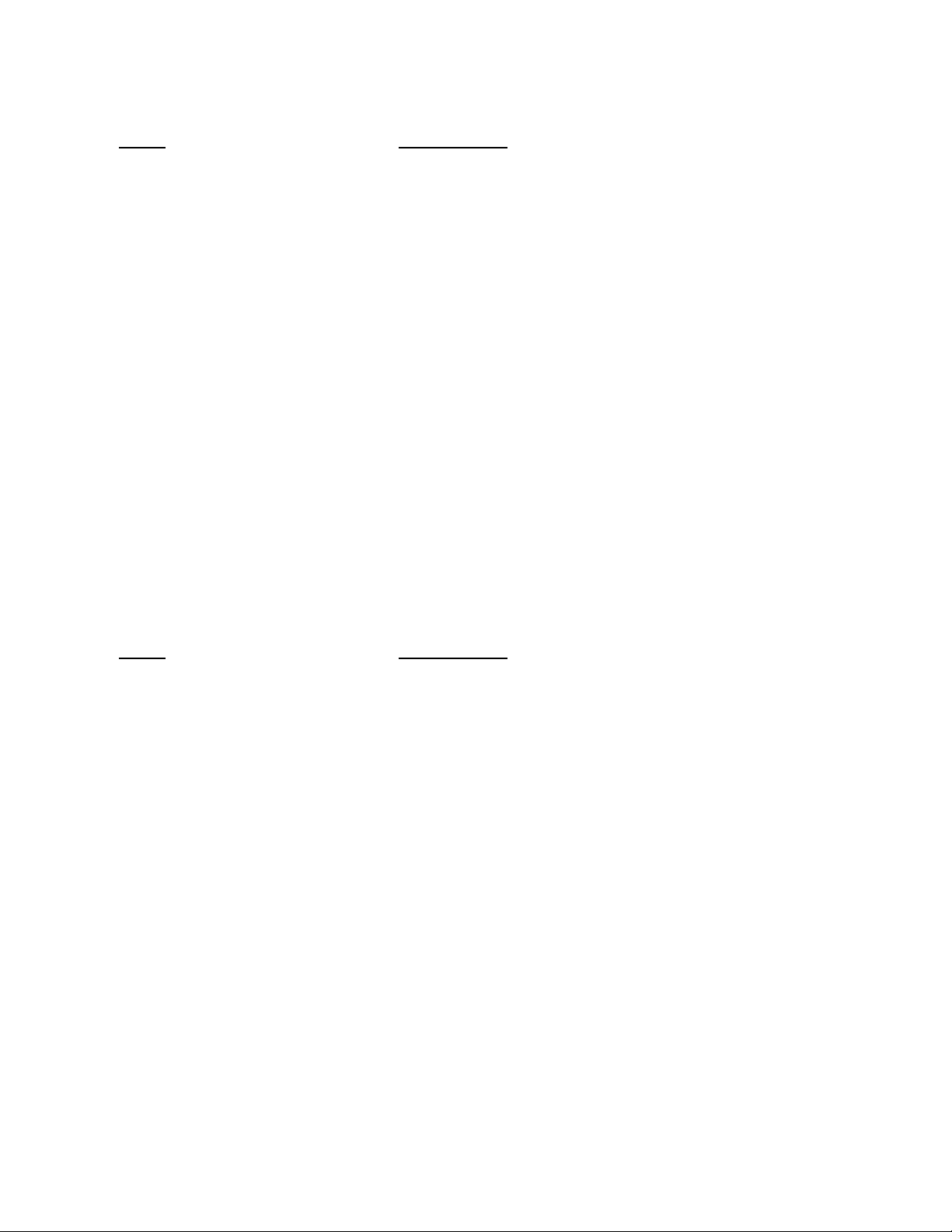

Assembly - Shift Block

REV. - 7/15/03 JEM

VPRO-2000

1

11

11

3

4

5

5

6

7

22

10

8

9

9

12

12

12

13

14

16

17

18

19

19

20

21

2

TO TOP OF POWER HEAD

14

15

Page 40

40

1

F-HB-04C-20

3

HEX BOLT

PARTS LIST

Assembly - Shift Block VPRO-2000

PART NO.

ITEM

QTY DESCRIPTION

2

7701-6-17 2 ELBOW

3

PF-HN-06S-04 1 NIPPLE

4

PF-RA-04-02

1

REDUCER

5

VPRO-2004

2

MUFFLER

6

VPRO-2002

1

GUARD

7

VPRO-2001 1 ACTUATOR

8

7701-6-4 2

TUBE FITTING

9

MPM-2598 2

ACTUATOR

10

O-S-012 1 O-RING

11

TRU-1021 2 ELBOW

12

TRU-1022 4 BARB FITTING

13

MPM-2052-5.5" 2

TUBE

14

MPM-2052-5" 2

TUBE

15

MPM-2584 1

TEE

16

MPM-2587 2

NUT

17

MPM-2583-1 1

TUBE

18

MPM-2583-16"

1

TUBE

19

MPM-2565 2

BARB FITTING

20

VPRO-2003 1

VALVE

21

F-MS-832-24 2

MACHINE SCREW

22

7701-6-18 1

POLY ELBOW

Page 41

41

ASSY - SLAVE ARM

MAGNUM VENUS PRODUCTS

REV. A = VPRO-1007 MNT BLK REPLACED VPRO-1004 MNT PLATE 7/18/02 JEM

VPRO-1000

9

10

6

6

5

8

8

4

5

5

7

7

7

8

8

11

6

6

3

1

1

2

2

REV. B = VPRO-1003-01 WAS VPRO-1003

Page 42

42

6

VPRO-1006 6

BUSHING

10

00130 1

NYLOCK NUT

9

02650-12 1

HEX CAP SCREW

8

00600 6 LOCK NUT

7

02966

6

BOLT

5

VPRO-1005 3

SLAVE ARM SPACER

4

VPRO-1007

1

MOUNT BLOCK

3

VPRO-1003-01

1

LINK BAR

2

VPRO-1002 2

LOWER SLAVE ARM BAR

1

VPRO-1001 2

UPPER SLAVE ARM BAR

ASSY - SLAVE ARM VPRO-1000

DESCRIPTION

PARTS LIST

PART NO.

ITEM

QTY

11

02666-20 2

HEX CAP SCREW

Page 43

43 44

Page 44

Page 45

45

MAGNUM VENUS PRODUCTS

ASSY - PRO SERIES RESIN PUMP

REV.

D85805-1 WAS 12182-1

A =

17

7

51

29

7

32

55

9

44

34

7/30/01

85805-1

ABRASIVE KIT

B21

38

B23

B24

33

4

39

8

30

42

46

28

49

48

11

3

55

9

57

32

43

1

41

6

36

12

17

57

15

45

33

19

4

24

22

27

53

26

25

18

5

22

23

2

52

31

37

21

37

20

49

50

LINE AIR IN

47

16

REPLACED 85774-1 WITH VPRO-2000 7/16/03 JEM

B =

PUMP SUPPLY LINE

40

Page 46

46

58

15923-3

2

SLAVE ARM BUSHING

48

85806-1 1

TRIP SLEEVE

56

95084-EN 1

AIR SHUT OFF CAUTION LABEL (NOT SHOWN)

55

95081-3 1

SLAVE ARM DECAL

54

95033-EN 1 PUMP PRIME CAUTION LABEL (NOT SHOWN)

53

9201-2-36

1

1-1/4" CHROME BALL

52

ALS-1018 1

7/8" CHROME BALL

29

3101-4-01

1

PISTON ROD PACKING SPA

28

3101-3-1 1

FEMALE COMPRESSION RING

20

15983-1 1

CYLINDER HEAD

19

15939-1 1

PISTON BODY

10

04305-1 1

LOWER PACKING SPRING

2

00252

1

HEX NUT

57

7203-2-10 1 DOWEL PIN

56

15911 1 BALL STOP PIN

49

85810-1 1

PISTON ROD

46

85729-3

1

CENTER SECTION ASSY

38

7701-1-4

1

SWIVEL ELBOW

39

7701-3-16

1

REDUCER BUSHING

41

85712-1

1

FLOW CONTROL BODY

40

7701-4-5 1

PLASTIC PLUG

43

85717-1 1 UPPER SLAVE ARM

42

85713-1 1

FLOW CONTROL ORIFICE

47

VPRO-2000 1 SHIFT BLOCK ASSY

51

87060-1 1

MALE COMPRESSION RING

50

86800-1

1

SPRING RETAINER

44

85718-1 1

LOWER SLAVE ARM

45

85719-1

1

CONNECTING ARM

30

3102-18-1 1

FOOT VALVE COLLAR

31

3102-8-1

1

PISTON BALL SPRING

33

58739-1 2

SLAVE ARM BUSHING

32

52106-3

1

QUICK PIN CABLE ASSY

36

7101-7-6

2

HEX CAP SCREW

37

7301-1-137

2

O-RING

34

58739-3

2

SLAVE ARM WASHER

25

3101-17-1 1

BALL STOP

27

3101-19-1 1 FOOT VALVE BODY

26

3101-18-1 1

FOOT VALVE SPRING

23

3101-13-1 1

PISTON CUP SPACER

24

3101-14-1 1 PISTON CUP BACKUP

22

3101-12-1 2

PISTON CUP

1

00130 1 NYLOCK HEX NUT

21

15986-1

1

CYLINDER

3

00260 1

SOCKET HEAD CAP SCREW

18

15936-1

1

COMPRESSION RING

8

02681-38 2 HEX CAP SCREW

21B

15986-3 1

HARDENED CYLINDER

23B

3101-13-2 1

HARDENED PISTON CUP SPACER

24B

3101-14-2

1

HARDENED PISTON CUP BACKUP

OPTIONAL PARTS AND ASSEMBLIES

12

15515 1

PLUG

17

04305-1

1

COMPRESSION SPRING

4

00600 2

LOCK NUT

16

15890

1

O-RING

15

15888-1

1

AIR MOTOR PISTON

11

05502 1

PIPE THREAD SEAL

9

02966 2

AIRCRAFT BOLT

7

02666-12 2

HEX CAP SCREW

6

02650-12

2

HEX CAP SCREW

5

02220

1

O-RING

ASSY - PRO SERIES RESIN PUMP 85805-1

PARTS LIST

ITEM

PART NO.

ITEM

PART NO.

DESCRIPTION

QTY

QTY

DESCRIPTION

Page 47

47

MAGNUM VENUS PRODUCTS

ASSY - QUICKSHOT DESPENSER RESIN PUMP

REV.

D85675-1-1 WAS 12550-1

A =

10

50

29

32

85675-1

ABRASIVE KIT

B21

38

B23

B24

8

40

30

11

45

28

48

47

3

41

32

39

36

12

16

56

15

20

A

24

22

27

52

26

25

19

A

5

22

23

2

51

31

37

A

21

37

56

48

49

LINE AIR IN

46

PUMP SUPPLY LINE

REPLACED 85774-1 WITH VPRO-2000 7/17/03 JEM

B =

1

54

54

ITEM 1 WAS 00130, REPLACED ITES 4, 6, 7, 9, 18, 33, 34, 42, 43, & 44 WITH VPRO-1000 12/17/04 JEM

C =

17

Page 48

48

40

7701-3-16 1 REDUCER BUSHING

11

PF-HN-04-04S 1

HOSE FITTING

47

85806-1 1 TRIP SLEEVE

55

95084-EN 1

AIR SHUT OFF CAUTION LABEL (NOT SHOWN)

54

95081-3 1

SLAVE ARM DECAL

53

95033-EN 1

PUMP PRIME CAUTION LABEL (NOT SHOWN)

52

9201-2-36 1 1-1/4" CHROME BALL

51

ALS-1018

1

7/8" CHROME BALL

29

3101-4-01

1

PISTON ROD PACKING SPA

28

3101-3-1

1

FEMALE COMPRESSION RING

20

15939-1 1

PISTON BODY

19

15936-1

1

COMPRESSION RING

10

04305-1

1

LOWER PACKIND SPRING

2

00252

1

7/16-14 UNC HEX NUT

56

15911

1

BALL STOP PIN

48

85810-1

1

PISTON ROD

45

85729-3 1

ASSY - CENTER SECTION

38

7701-1-4

1

SWIVEL ELBOW

39

7701-3-14 1

BUSHING

41

7701-4-5 1 PLASTIC PLUG

46

VPRO-2000

1

SHIFT BLOCK

50

87060-1

1

MALE COMPRESSION RING

49

86800-1

1

SPRING RETAINER

30

3102-18-1 1

FOOT VAVLE COLLAR

31

3102-8-1

1

PISTON BALL SPRING

32

52106-3 1

ASSY - QUICK PIN CABLE

36

7101-7-6

2

HEX CAP SCREW - GRADE 5

37

7301-1-137

2

O - RING

35

7101-1-18 3

HEX CAP SCREW

25

3101-17-1 1

BALL STOP

27

3101-19-1

1

FOOT VAVLE BODY

26

3101-18-1 1

FOOT VALVE SPRING

23A

3101-13-1

1

PISTON CUP SPACER

24A

3101-14-1

1

PISTON CUP BACKUP

22

3101-12-1 2

PISTON CUP

1

VPRO-1000 1

SLAVE ARM ASSEMBLY

21A

15986-1 1 CYLINDER

3

00260

1

SOCKET HEAD CAP SCREW

21B

15986-3

1

HARDENED CYLINDER

23B

3101-13-2

1

HARDENED PISTON CUP SPACER

24B

3101-14-2

1

HARDENED PISTON CUP BACKUP

QTY

OPTIONAL PARTS AND ASSEMBLIES

12

15515 1 PLUG

17

15891 1

O - RING

16

15890 1

O - RING

15

15888-1 1

AIR MOTOR PISTON

8

02681-38 2 HEX CAP SCREW

5

02220 1

O - RING

ASSY - QUICKSHOT DESPENSER RESIN PUMP 85675-1

QTY

PARTS LIST

ITEM

PART NO.

ITEM

PART NO.

DESCRIPTION

DESCRIPTION

56

15983-1

1

CYLINDER HEAD

Page 49

49

Page 50

50

MAGNUM VENUS PRODUCTS

CORPORATE HEADQUARTERS and MANUFACTURING

5148 113th Ave. N. *Clearwater, FL 33760 * Tel 727-573-2955 * Fax 727-571-3636

WEST COAST MANUFACTURING

1862 Ives Ave. * Kent, WA 98032 * Tel 253-854-2660 * Fax 253-854-1666

www.mvpind.com

Loading...

Loading...