Page 1

PVSensor

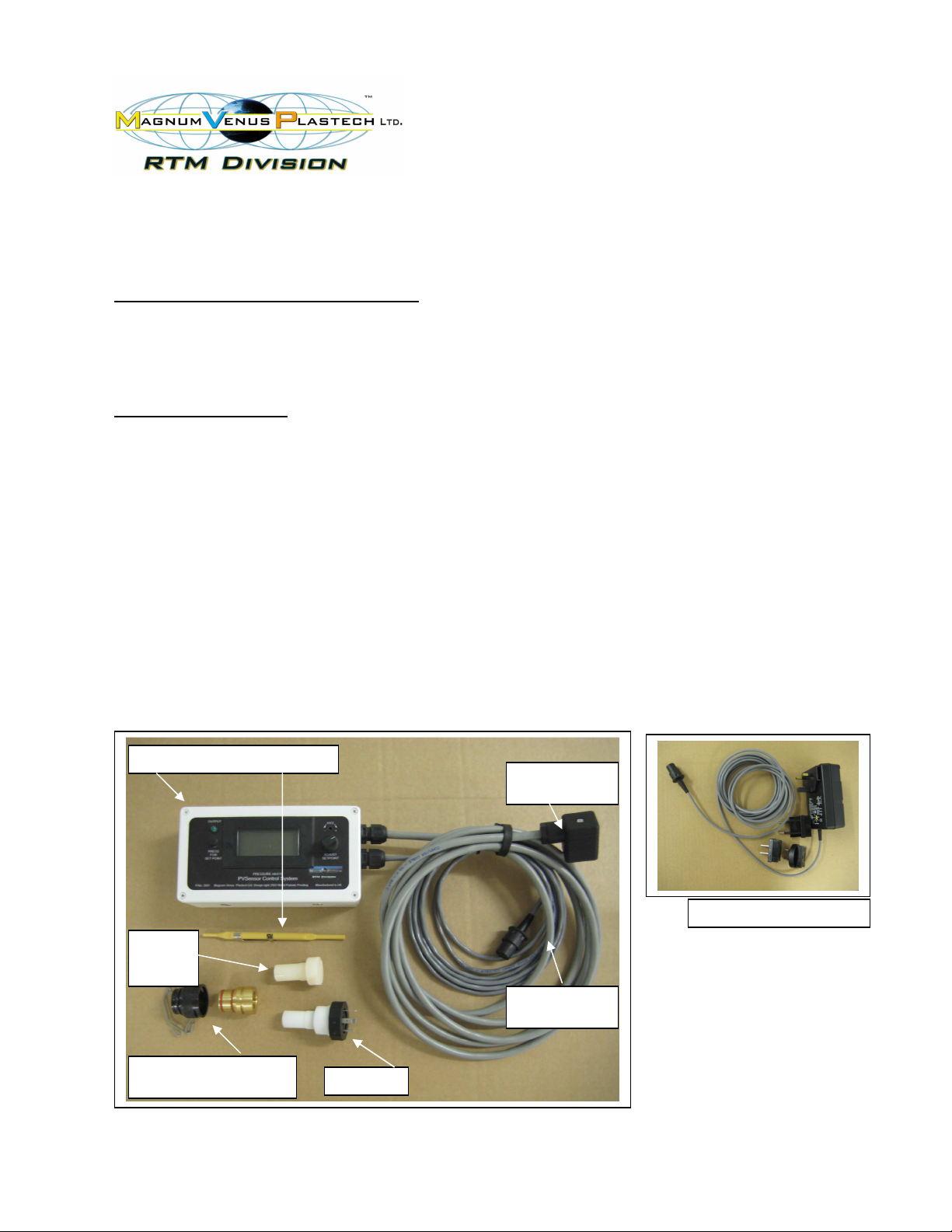

Complete System # 5801

Procedure for Installation and Use

The PVSensor (PVS) system is designed to safely optimise LRTM or RTM mould fill. It is now possible to

monitor and control the in-mould pressure from 800mb to 2000mb. (The short term, safe over-pressure is

rated at 3 bar).

The system comprises:

• Electronic Display Module # 5798 – Operator controls and status LED

• Power Supply Unit # 5799 - 240/110vAC input, 12vDC output

• PVSensor # 5797 - A PTFE bodied precision electronic pressure sensor to fit a mould insert.

• Machine Control # 5789 - Output solenoid to control the resin flow of meter mix machinery.

Kit contains complete mounting bracket set and conversion fittings for Patriot SSB and

Megaject MkIV / MkV machines.

• Universal Insert with spring Clip # 6316, and Adapter # 6317

ELECTRONIC DISPLAY MODULE AND POWER PACK:

The Electronic Module houses the circuitry that manages the signal from the PVSensor and allows the

setting of the required mould pressure set-point and hysterisis. It also provides Actual Pressure readings

from the sensor in the mb range. The scale is x 10, as individual millibar changes would be too rapid and

confusing to read. Therefore a reading of 101 is actually 1010 mb (101 x 10).

Electronic Module & Trimmer tool

PVSensor

Socket

Power Supply Unit ( PSU )

PVS

Dummy

Plug

Machine control

lead

Universal Mould Insert,

Spring Clip and adapter

PVSensor

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 1 of 8

Page 2

RETRO FITTING THE ELECTRONIC MODULE TO YOUR MACHINE:

1.

2.

-

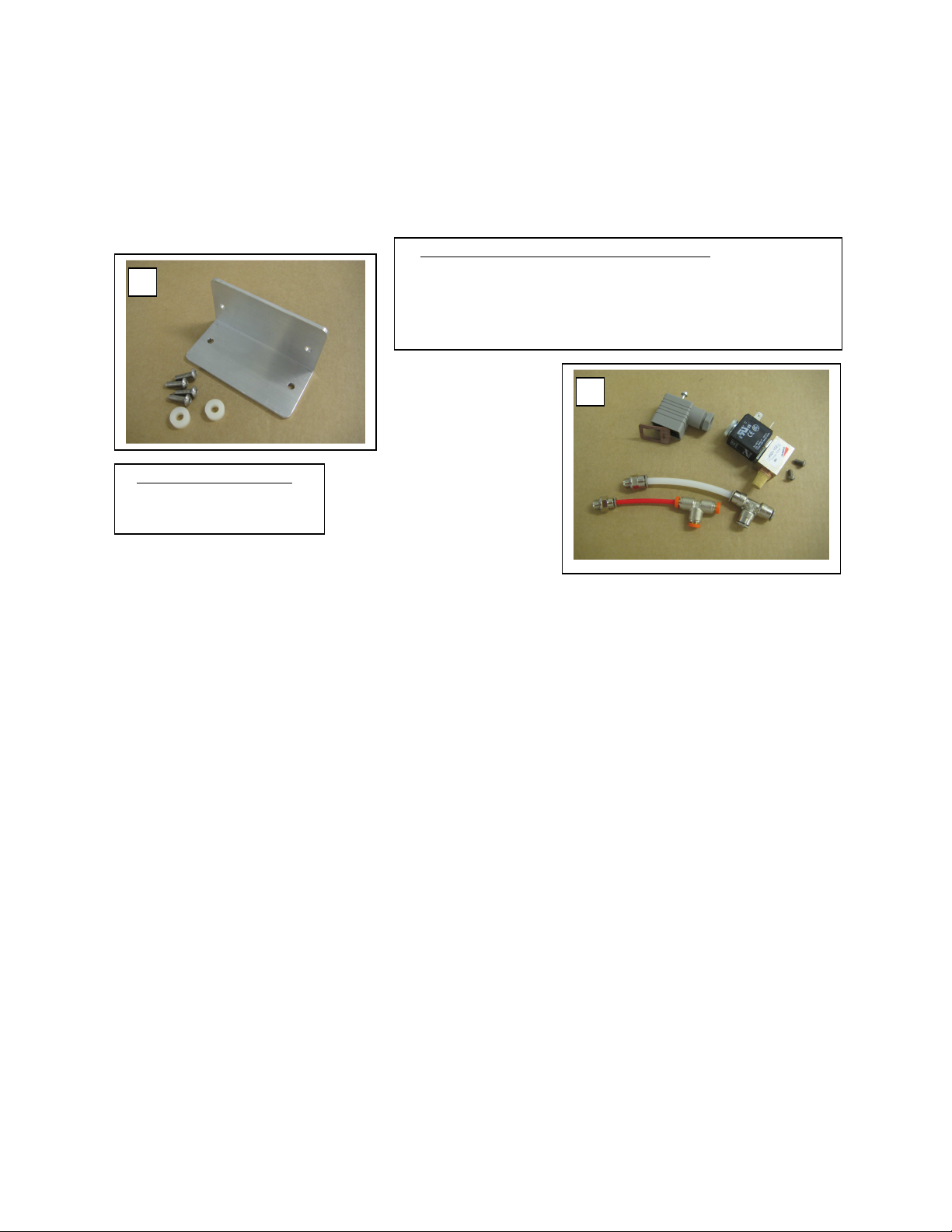

Retro Mounting Kit

.

1

2

If your PVSensor system was not factory fitted you will need to fit the mounting bracket and make some

minor changes to the machine’s air circuit. The PVSensor is supplied complete with, Machine Control

Solenoid Valve assembly # 5789, and fixing bracket, spacers and screws to mount the Electronic Module

to the SSB chassis, or the Megaject Cabinet. See Appendix A.1, A.2 and A.3 for full instructions.

Machine Control solenoid assembly # 5789 includes:

- Solenoid Socket.

- Solenoid Valve & silencer with mounting screws to SSB or MkIV / MkV.

- 6mm clear nylon pipe with Tee and stud fittings for SSB connection.

- 4mm red nylon pipe with Tee and stud fittings for MkIV & MkV connection.

Retro Mounting Kit includes:

Mounting Bracket, 4 x Bolts and

2 x Spacers.

CONNECTING THE ELECTRONIC MODULE TO THE MACHINE:

With the power switched OFF, connect the 12vDC PSU to the socket on the left hand end of the

Electronic Module.

Connect the 3 way, black socket to the injection machine plug now fitted as standard on all

standard Magnum Venus Plastech meter mix machines.

This plug can be found flush mounted on the side of older Megaject SSB model chassis, on the

rear of Patriot SSB chassis, or on the back of the yellow Megaject MkIV and MkV machine

cabinets.

Switch the power ON, and assuming the mould is not under vacuum supply, the atmospheric

pressure on the electronic display screen should read between 95 and 105 (950 to 1050 mb),

dependent upon weather conditions.

SETTING UP THE ELECTRONIC MODULE:

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 2 of 8

For the PVSensor system to operate, the Electronic Module must be connected to the machine via

the Machine Control Solenoid Valve assembly.

Whilst pressing, and holding in the left hand button on the Electronic Module, adjust the right hand

knob to select the desired set-point value (at which the operator is to be warned that the maximum

set pressure has been reached). This should be about 10-20 mb BELOW atmospheric pressure.

E.g. If atmospheric pressure reads 100 on the digital display (1000 mb) then set the control unit

pressure (when pressing the left hand button) to read 99 or 98. (990 or 980 mb). If this pressure

setting in the mould is reached during injection the system will send a signal to the machine to

slow down the injection rate or stop the machine.

The PVSensor set-point cannot be adjusted when the output solenoid is energized. (LED is on).

Page 3

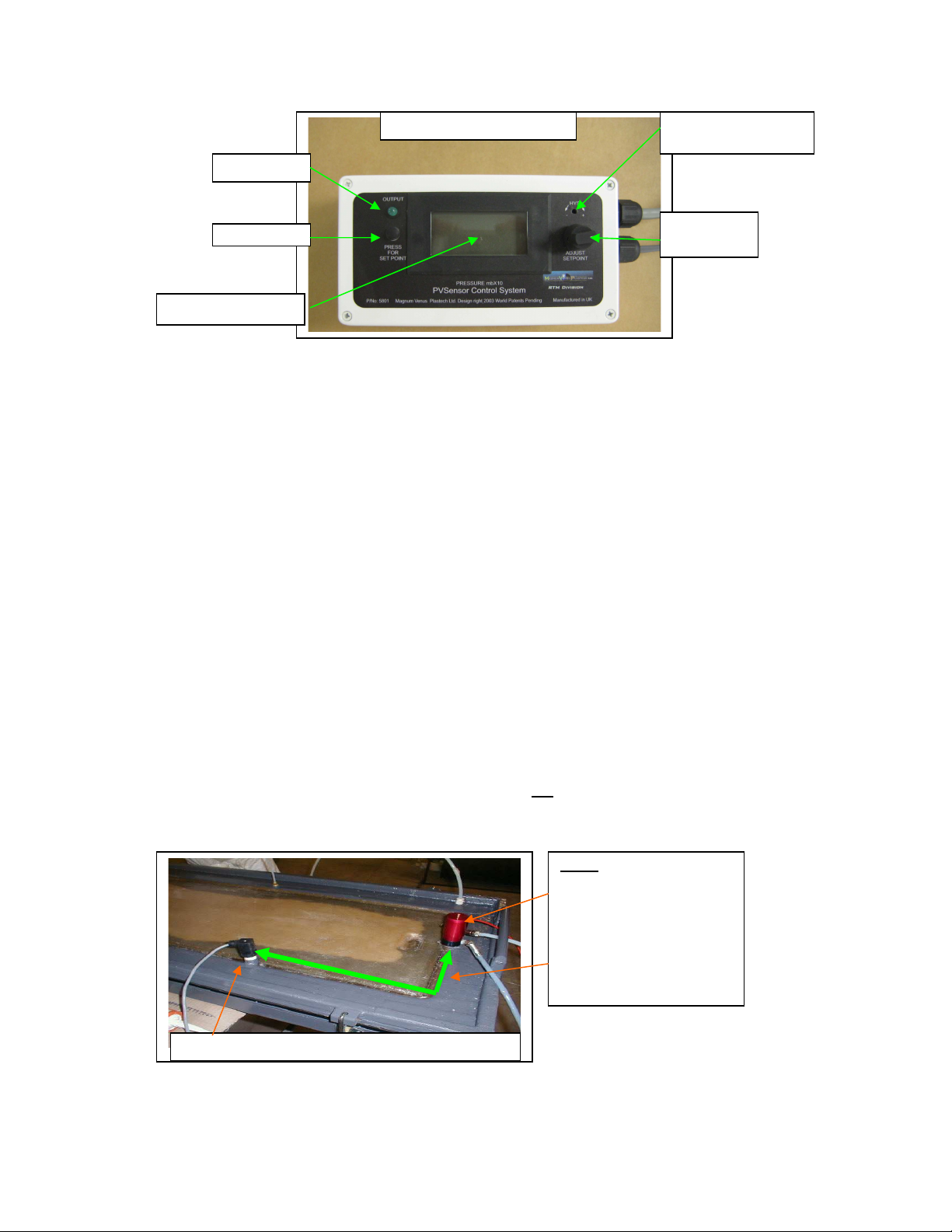

Green LED

Electronic Module Controls

Hysterisis Adjustment

– use Trimmer tool

Set-point

adjustment

LCD Display x 10mb

OPERATING THE PVSENSOR:

The resin pressure within the mould will be continuously monitored and once the set-point has

been reached a green LED will illuminate on the left hand side of the unit. This also provides a

signal to the Machine Control solenoid valve mounted within the machine.

This signal will reduce the flow of resin to the mould by slowing the machine, or stopping it all

together, so that the mould’s internal pressure does not exceed the set-point. Once the pressure

drops back the machine will automatically speed up, or start again.

Once the set-point has been reached and the solenoid energized to stop the machine (LED on),

the pressure must fall by a given amount (Hysterisis) before the unit restarts the machine. This

prevents the system from continuously starting and stopping the machine as the mould pressure

moves around the set-point (hunting). The Hysterisis is factory set and should not be adjusted

under normal circumstances.

POSITIONING AND FITTING THE SENSOR IN THE MOULD:

In LRTM moulds, the Sensor should be positioned in the resin feed channel using a mould insert

that is positioned between 300mm and 600mm from the resin input point.

For infusion applications this should be between 100mm and 200mm. If the PVS unit is to be

used solely to sense the mould pressure and not to control the machine, then the Sensor can be

sited anywhere in the mould using the Film Infusion Extension option # 5885.

It is important that the Sensor’s mould insert is installed in a vertical, or near to vertical position on

the mould’s upper (back) tool. NOTE: The Sensor is not designed to work if it is installed off

vertical by more than 30º and must not be installed, or used, inverted.

NOTE:

Injection Autosprue positioned

in the peripheral resin feed

channel.

The PVSensor positioned no

more than 600mm away from

the injection point.

PVSensor mounted vertically on upper (back) LRTM tool.

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 3 of 8

Page 4

With the now standard Universal Insert laminated into the rear face of the LRTM tool, screw the

PVSensor

Complete System

# 5801

–

Parts supplied.

PVSensor clockwise into the Universal Mould insert Adapter supplied in the kit. It is important that

the PVS is screwed tightly down on the adapter so that it seals cleanly on the O ring; therefore

ensure that the top surface of the adapter is clean and smooth. - A little silicon grease smeared

onto this surface and the Sensor’s PTFE threads will help to achieve a good vacuum seal. DO

NOT OVERTIGHTEN as the PTFE Threads could become stripped.

Push the adapter firmly into the Universal mould insert and use the spring clip to retain the

adapter in the mould insert. (If desired, the old style PVS Insert # 1772 can still be used in place

of the Universal insert and adapter.)

Connect the four way PVSensor socket to the Sensor’s four pin, top plug and secure firmly in

position using the central retaining screw.

If the Sensor is not required to be used in the mould, then the Dummy Plug supplied can be used

to blank off the PVS adapter, and the Sensor can be moved to another mould.

NOTE: - For a long Sensor service life:

•

•

•

DO NOT

DO NOT

DO NOT

- Operate in an inverted position, or at an angle greater than 30º off vertical.

- Push any implement / tool into the Sensor’s PTFE cone.

- Allow release agents to flood the Sensor cone. NOTE: It may be necessary to protect

the open end of the Sensor during mould preparation and release coat application.

•

DO NOT

- Operate on automatic machine control without first confirming the safe set-point

pressure. (Simply check the set-point by pressing the left hand button on the unit and adjust

accordingly).

•

DO NOT

- Change the set-point when the Green LED is illuminated, as it will NOT provide an

accurate setting, therefore only change this setting when the Green LED is OFF

•

ALWAYS - E

nsure that the Sensor socket is firmly screwed to the Sensor during production use.

1 x Electronic Module # 5798

1 x Trim Tool # 3139

1 x Power Supply Unit # 5799

1 x PVSensor with O Ring # 5797

1 x PVS Dummy Plug with O Ring # 5785

1 x Machine Control – Solenoid Assembly # 5789

1 x Solenoid valve # 1160

1 x Silencer # 0882

1 x Coil # 1158

1 x Solenoid Socket # 5809

FITTINGS FOR RETROFIT TO PATRIOT SSB & MEGAJECT SSB

1 x 6mm Pushfit Tee # 0637

1 x 6mm Pushfit 1/8” Stud # 0620

300mm x Clear 6mm Nylon Pipe # 0208

1 x M4 x 20 Button Head Screws # 0309

FITTINGS FOR RETROFIT TO MEGAJECT MK4 & MK5

1 x 4mm Pushfit Tee # 0636

1 x 4mm Pushfit 1/8” Stud # 0619

300mm x Red 4mm Nylon Pipe # 0207

2 x M4 x 8 Button Head Screws # 0301

1 x Mounting Bracket # 6250

4 x M5 x 16 Button Head Screws # 1694

2 x M5 Nuts # 0320

2 x Nylon Spacers # 4336

1 x Universal mould Insert & Spring Clip # 6316 ( Insert # 6300) ( Spring Clip # 5834 )

1 x Universal Insert Adapter with 2 x o rings # 6317 ( O ring # 3265 ) ( Adapter # 6301)

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 4 of 8

Page 5

APPENDIX A.1 - Retro-fit to Megaject MkIV and MkV machines.

other o

ption

s

.

Connecting the PVS to the

Electrical connection

Factory cut hole.

IF NOT drill 19mm hole

for Solenoid plug

Rear view of cabinet.

Internal view of PVSensor plug

MPG Regulator

Machine Control solenoid

assembly #5789

Tee in to 4mm red nylon

pipe between MPG and

MPG Regulator

Fix the Solenoid Valve through the 4.5mm hole at this point.

The exact position is NOT critical.

Megaject MkIV & MkV

PVSensor Plug inside the cabinet with

grey feed wire leading to the Solenoid

valve.

Note – The other 2 wires shown refer to

Power feed wires

to the solenoid

socket

Earth wire

1. Ensure machine is isolated from air and electrical supply before carrying out any modification or

maintenance.

2. Connect the Feed Wires (leading from the PVS plug mounted on the chassis), to the Solenoid Socket as

shown and making sure that the gasket is in place, replace the socket cover using the central retaining

screw.

3. Screw the Machine Control solenoid assembly on to the base of the yellow cabinet as per photo, using the

M4 x 12 button head screws provided.

4. Using the 4mm red nylon pipe, 4mm Tee and the 4mm stud provided, cut the 4mm red pipe leading from the

MPG block to the MPG regulator as per the photo. Insert the Tee and connect to the solenoid assembly

using the 4mm stud fitting.

5. Connect the Mounting Bracket on to the rear of the cabinet using the 2 qty M5 x 16 button head screws and

nuts provided.

6. Screw the PVS Electronic Module on to the top of the mounting bracket and connect the Module socket to

the machine mounted plug.

7. The PVSensor is now ready to set and connect to the mould.

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 5 of 8

Page 6

APPENDIX A.2 - Retro-fit to Patriot SSB machines.

Connecting the PVS to the

Electrica

l connection

Soleniod Socket

and Feed Wire

2 x M5 Threaded

Mounting Inserts

Reset

Button

Sensor Plug

Machine Control

Solenoid Assembly

Tee into

6mm MPG

line

Patriot SSB

Power feed wires

to the solenoid

socket

Earth wire

1. Connect the Feed Wires (leading from the PVS plug mounted on the chassis), to the Solenoid Socket as

shown, and making sure that the gasket is in place replace the socket cover using the central retaining

screw.

2. Screw the Machine Control solenoid assembly on to the underside of the Reset Button mounted on the side

of the chassis as per photo, using the M4 x 20 button head screw provided.

3. Using the 6mm clear nylon pipe, 6mm Tee and the 6mm stud provided, cut the 6mm pipe leading from the

MPG block to the MPG regulator as per the photo, insert the Tee and connect to the solenoid assembly

using the 6mm stud fitting.

4. Connect the Mounting Bracket on to the rear of the chassis, - making sure that the 2 x spacers are

positioned in between, and fix to the chassis using the 2 qty M5 x 16 button head screws provided.

5. Screw the PVS Electronic Module on to the top of the mounting bracket and connect the Module socket to

the machine mounted plug.

6. The PVSensor is now ready to set and connect to the mould.

APPENDIX A.3 - Retro-fit to Megaject SSB machines.

1. Follow the retro-fit instructions described for the Patriot SSB. You may find that the PVSensor plug was not

factory fitted on earlier machines, or the hole drilled. If this is the case then a PVSensor Plug # 5788 suitable

for a Megaject SSB will need to be ordered from your local Magnum Venus Plastech distributor to complete

the installation, and ask for further instructions if required.

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 6 of 8

Page 7

APPENDIX B

SENSOR REPAIR / CLEANING

The PVSensor measures pressures between 0 and 2000mb absolute. It is designed to work upright

and NOT inverted. This is in order that resin does not enter the small 1mm diameter hole leading to the

sensitive electronic chip placed within the Sensor’s top body.

Operated correctly in this upright position, no resin should accumulate within the cone entrance,

however when cleaning, releasing or polishing the mould, the Sensor is left in the mould in the inverted

position. - In these circumstances we recommend that the upturned cone is covered with a small foam

plug, such as PE foam or anything which protects the 1mm hole against ingress of dirt, cleaning fluid or

new release agent.

If it is found that the cone becomes contaminated, or partially blocked with resin or build up of debris

and ceases to sense the pressures we recommend the following cleaning process.

See attached diagram of cross section of Sensor

1.

Obtain a 1mm drill.

2.

Mark a drilling depth of 37mm on the drill bit, measured from the tip.

3.

Hold the drill between thumb and index finger and start to rotate the drill clockwise.

NOTE

: It is important not to simply push the drill bit into the 1mm hole at the top of the Sensor

without a drilling action, as any debris could be pushed forward damaging the Sensor’s

sensitive diaphragm.

4.

After drilling in a couple of millimetres remove the drill and tap out the debris. Continue this

action in small drilling depths and continue to tap out debris often until it is possible to read

pressure changes on the digital meter by blowing into the Sensor’s open cone end.

5.

NEVER drill deeper than 37mm.

6.

Damage to the PVSensor electronics could cause permanent damage to the PVSensor

system.

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 7 of 8

Page 8

APPENDIX C

Sensor Specification Sheet

-

PARAMETER

Pressure range

Maximum overpressure

Sensitivity

Full scale span

Operating temperature

Linearity, Hysteresis Error

Type/Model; PV Sensor 0 -2bar ABSOLUTE

TYPICAL MEASUREMENT

2-30

90.0

3

90

-25 to +85

+/- 0.25% typ, +/-0.5% max. Span

UNIT

Psi(abs)

psi

m V/psi

M V

Deg C

PVSensor Instruction Manual. Issue-08 25/06/2008 Page 8 of 8

Loading...

Loading...