Page 1

Patriot SSB Auto

Commissioning and instruction and maintenance manual

Issue 05

CONTENTS

Section Description Page

1.0 Machine Overview 2

1.1 Health & Safety General Overview 3

2.0 Instrumentation and Control Familiarisation 4-7

3.0 Priming SSB Fluid Sections 7-9

4.0 Machine Operation 9-11

5.0 Shut down 11

6.0 Routine Maintenance 11

7.0 Maintenance 12

8.0 Patriot Resin Pump 16

9.0 Catalyst Pump, CAV,OP valve and ratio system 22

10.0 Injection Head & Mixer Assembly 32

11.0 Solvent Pump 33

11.2 Solvent automatic head valve 34

12.0 RGA Resin Gel Alarm 36

13.0 SSB Auto Machine Doctor 38

14.0 Additional Machine Connections 41

15.0 Machine Air Circuit 42

Revision history 43

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 1 of 43

Page 2

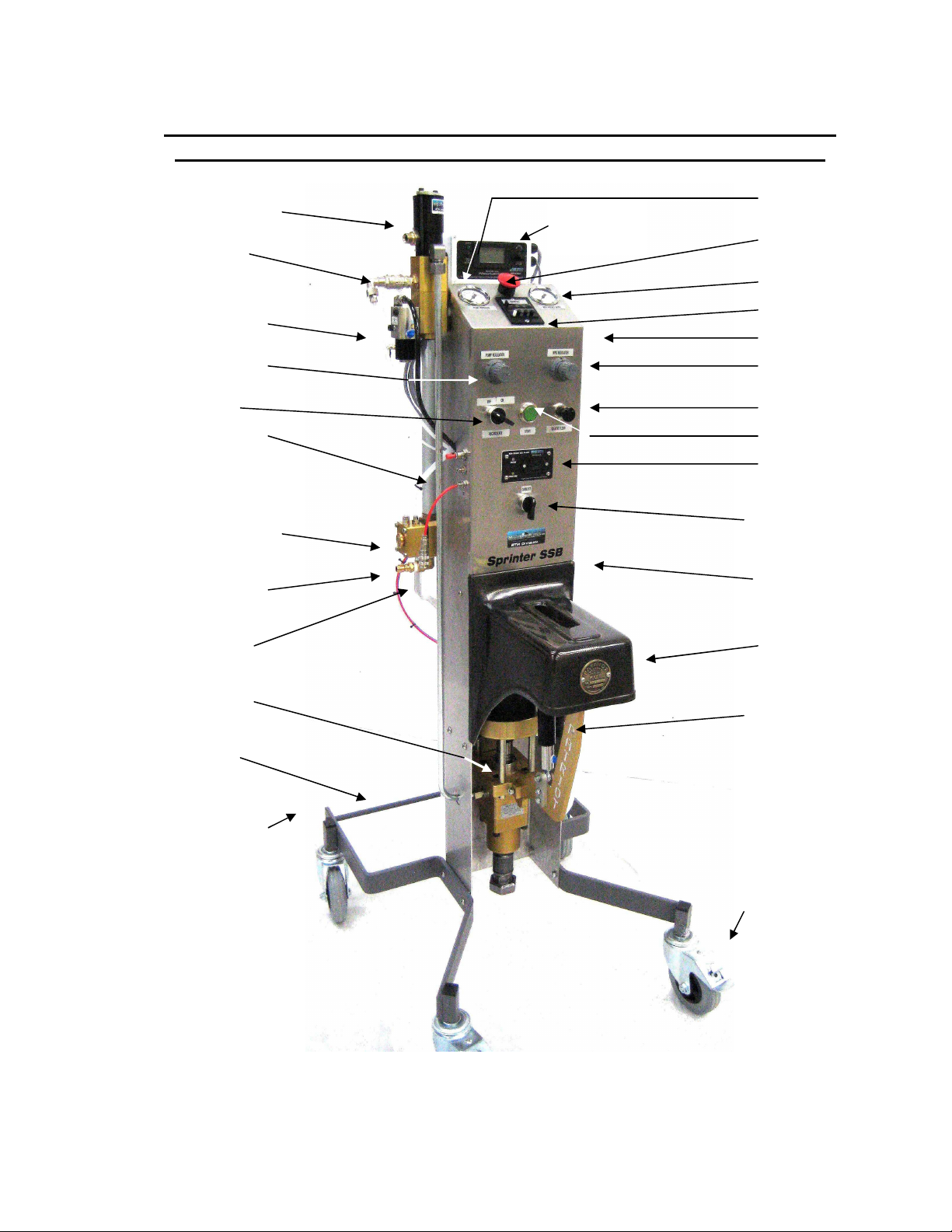

1.0 To enable understanding of machine controls please read the

following descriptions referenced to the general machine view

Resin automatic valve

Solvent automatic

valve

Catalyst automatic

valve

Pump speed regulator

Pump Start/Stop

recirculation

Static Mixer

Mould Pressure

injection hose pressure

Guard

Mixer outlet point

Catalyst Bottle 5L

Mount

Patriot Resin Pump

Solvent tank 20L

Mount

Optional Drum Trolley

fixing points

Optional PV

Sensor

system

Pump Speed air

pressure

Emergency stop/

Power ON/OFF

Mix resin pressure

Counter

Reset (Side mounted)

Mix Resin Pressure

Regulator

Solvent/Air Flush

Pump Start /Stop

Resin Gel Alarm (RGA)

MotoCat Ratio Control

Internal Lever enables

unlock of fluid section

for easy maintenance

Ratio arm Cover

Catalyst pump

Lockable Castor

wheels

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 2 of 43

Page 3

1.1 Health & Safety - General over view of important health and safety

issues relating to this machine

The following instruction manual contains a number of references to controls and

procedures that will ensure safe operation of the machinery. The machines are designed

to process substances that are hazardous to health and therefore it is vital that any

materials that are introduced to the machinery have valid MSDS (material safety data

sheets) in place and that machine operators and maintenance staff are fully informed and

trained in the use of the materials and of the potential hazards.

Users are also advised to ensure that these operator instructions are correctly and

adequately made available to machine operators and maintenance staff.

Machine Guard

The Machine guard, which is supplied with this machine, must be correctly fitted at all

times during operation. Also during servicing, maintenance staff must ensure due care is

taken if it is found necessary to conduct any operational tests whilst the machine guard is

removed.

Residual Pressure

Due care should be exercised by maintenance staff to protect against any residual

pressures that may be present in the machine as discussed in the maintenance sections

Organic Peroxides

Particular note should be taken that materials utilised for the various fluid parts of the

machine are specifically selected and designed for use with Organic Peroxides and resins

The nature of organic peroxide catalysts can be reactive with certain metals and plastics.

It is therefore imperative that when renewing parts during maintenance, only genuine

MVP Ltd component parts and spare parts be fitted to the machine.

Leaks & Seals

Any leaks that become evident either compressed air or fluid from machine piping or

fittings must be investigated and corrected as soon as they become evident. Any fluid

leaks or spillages of resin, catalyst or solvent must be immediately cleaned from machine

parts or surrounding area. Cleaning materials used must be safely disposed of in

accordance with recommendations as described on the appropriate MSDS

Safety Notices

All safety use recommendation and warning labels displayed upon the machine cover and

chassis must be maintained clean and visible to the operator.

Cleaning external surfaces

Do not use solvent based cleaners on the counter or the Resin Gel Alarm (RGA) system.

All metal parts including the entire Stainless steel chassis and facia may be cleaned with

solvent cleaners.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 3 of 43

Page 4

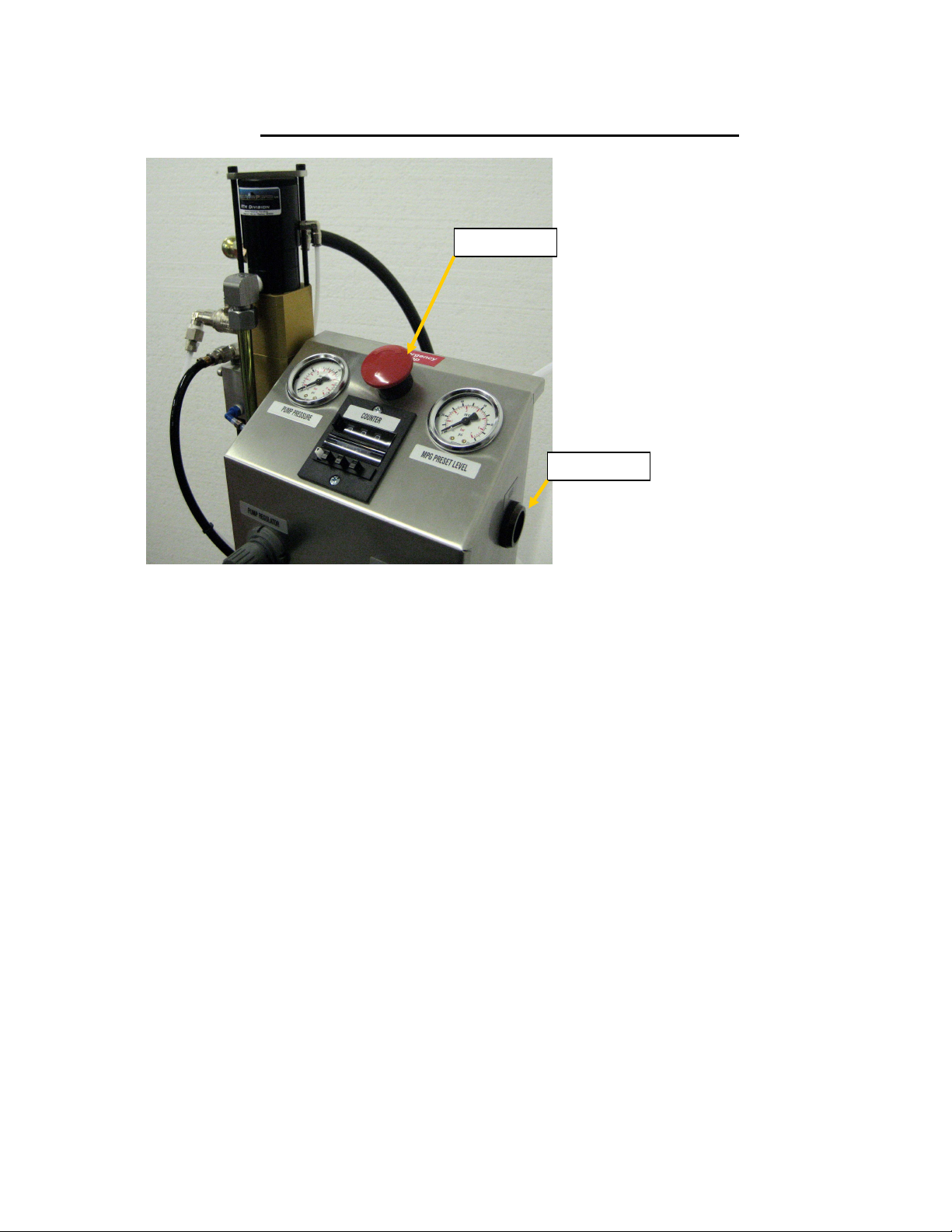

2.0 Instrumentation and control familiarisation

To switch Air supply

ON to machine.

E Stop Button

Reset Button

1. Release E

stop - Turn

counter

clockwise to

allow spring

up action

2. Press Blue

reset button

on side

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 4 of 43

Page 5

To set resin outlet line

install 9 vdc

→

+

ess

Counter reset

Count set

Note the PDC Counter can

only be adjusted when PDC

white button is continuously

pressed whilst pressing each

counter button to select

predetermined count number.

Note. If counter is set to zero

then it is NOT possible to pr

green start

Adjust air pressure

to pump motor to at

least 1 bar (15 psi)

To recirculate the

operate this control

to ON ( turn

clockwise ¼ turn)

To inject Press this

button IN

To adjust Catalyst

ratio turn to right to

increase ratio. Turn

to left to decrease

ratio

pressure limit, adjust

to at least 0.5 bar

(7 psi)

To flush head, Pull

OUT for at least 30

seconds.

Resin Gel Alarm. To

activate –

battery. See

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 5 of 43

Page 6

during recirculation. It should be adjusted

downwards) during pump movement.

Catalyst

flow

The Catalyst Bottle mounted at the rear

of the machine is fitted with a glass tube

to allow observation of catalyst flow

to remain visible by tightening in position

Above is a typical view of the catalyst

flowing down the glass tube during

re-circulation. This flow should be

seen for each stroke (upwards or

Before proceeding to connect air supply to the machine ensure for safety reasons the

following steps are taken. Refer also to image files in Last section of this manual

• Emergency Stop/ ON/OFF button is pushed down and locked - Machine OFF.

• Solvent/Air flush switch is off (Pushed in)

• Pump Start/Stop recirculation Control is switched to OFF as marked (90º turn)

• PDC counter is set to zero 0000 counts and reset is pressed once firmly

• Catalyst Ratio arm guard is screwed into position.

2.1 Connect shop air supply to machine located at rear top of machine chassis (8mm

Push fit connector) Yellow 8mm pipe supplied

2.2 Switch on air by partially rotating anticlockwise RED Emergency Stop/ON/OFF button.

This will enable it to turn the air ON by spring UP action.

2.3 Press blue pushbutton marked “RESET”

2.4 Check machine pump operation by first clockwise increasing the Pump speed

regulator control to preset to 2 bar shown on Pump speed Pressure gauge.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 6 of 43

Page 7

2.5 Check Mix resin pressure regulator is preset at 1 bar shown on Mix resin pressure

gauge by clockwise increasing Mix resin regulator control.

2.6 Rotate to recirculation switch Pump control clockwise (90º)

2.7 The pump will now operate.

2.8. Turn Pump recirculation switch counter clockwise to OFF position

3.0 Priming SSB fluid sections. Catalyst, Resin, Solvent and pump

Lubrication.

NOTE - For safety reasons it is essential when carrying out any manual activity on the

lower guarded machine pump section that the machine is switched OFF.

3.1 Switch Machine OFF and for security isolate air by depressing E stop red button which

will lock down in OFF position

3.2 Fill Solvent cleaning tank with at least 5 litres of Acetone (see caution note below)

Maximum 20 litres. Use smaller white filler cap opening to do this. Replace cap (Do not fill

solvent tank through the large RED cap.)

Caution Note- DO NOT FILL the cleaning tank with solvent when the machine is fitted

with the SP3-NSH non solvent water based cleaner system tank. Use only water based

cleaner in these circumstances. E.g. RST-5 and HtwoO proprietary liquid cleaning

systems

The SP3 NSH tank is marked as such and is distinguished by external electrical heater

attached.

3.3 To enable access to fill the Catalyst bottle, first the black plastic catalyst feed pipe

bottle top union must be loosened to release the grip on the catalyst feed pipe. With this

done, unscrew the white bottle cap and fill bottle with the appropriate catalyst for

Polyester resin to be used. Replace cap and finger tighten the catalyst feed pipe once the

filter end is immersed and is touching the bottom of the catalyst bottle.

3.4 Place resin pickup pipe into suitable drum of pre accelerated polyester resin. Secure

pipe so that as resin container becomes empty (Lighter) the resin feed pipe does not pull

the container over causing a spillage. Also place resin recirculation pipe end securely

into resin container.

3.6 Set Catalyst ratio to Maximum Ratio by switching the MotoCat control to move the

Catalyst pump to the rear max. ratio. Note the motor will automatically stop when this

point has been reached.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 7 of 43

Page 8

3.7 Operate recirculation to ON position and observe Catalyst and Resin pipes prime with

their materials. Continue until recirculation both resin and catalyst recirculation pipes

indicate flow back into the resin tank and the Catalyst bottle to ensure full priming of all

fluid sections.

NOTE.

If the catalyst does not prime easily it is possible to loosen the catalyst pipe union at the

head catalyst inlet. (See Catalyst Auto Valve drawing 22422-8 pipe union part number

0153). By loosening this union the down stream air can easily escape during initial priming

of the pump. Once the catalyst fluid has reached the pump, stop priming and re tighten

this union 0153 before continuing thus preventing Catalyst spillage

This initial priming method is only used for initial priming of a new machine from empty. It

is NOT necessary to use this method again once the machine has been in use.

3.8. Stop pump and prepare to prime head block and mixer for the first time.

3.9 IMPORTANT. Attach the 1 metre priming Pipe securely with quick release connection

to Mixer outlet point. Secure the other end in a waste container. Alternatively the Turbo

Autosprue (TAS) may be connected but so that it does not open during this initial priming

exercise simply do not connect the 4 mm TAS red signal line. However do secure the

clear 10mm drain pipe safely to a waste container.

3.10. Set pre determining counter to at least 10 counts and press counter reset button

3.11 Press inject green button. The pump will start and then stop after the predetermined

volume of resin mix has been dispensed into the container.

3.12 The RGA Resin Gel Alarm will sound within n30 seconds (see separate section on

RGA at the end of this section 3.)

3.13 Operate (Pull) solvent Air flush control. Allow machine head and mixer to flush clean

and dry out with air flow for about 35 seconds. Return solvent /air flush control to off

position. (PUSH IN)

b/ The machine design has build in safety preventing inadvertent operation of the flush if

the operator attempts to flush during injection. The flush control will only be active when

the machine is NOT injecting

The machine is now fully primed and ready for first mix and gel test before production

operation.

3.14 Resin Mix gel time test

It is important that the mixed resin reactivity (gel time) needs to be checked before

injecting a mould. It is wise therefore to make a test mixture from the machine mix head in

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 8 of 43

Page 9

order to determine this gel time exactly at the ambient temperature and for selected

catalyst ratio.

To carry out a mix and gel test set the desired catalyst ratio and then simply follow the

same procedure from stages 3.9 to 3.13 above but direct the mixed resin safely into a gel

test container. Once the resin mix sample has been dispensed and the machine has

stopped, place the resin outlet pipe securely into the waste container before flushing the

head and pipe.

3.15 General notes on gel time.

a/ It is wise to set and confirm gel times at least 30% longer than mould fill time

b/ Remember that UP resin will gel twice as fast for a 10°C increase in resin temperature.

c/ Be aware that cool resin is significantly more viscous than when at normal room

temperature. In these circumstances allow more time to fill the mould and thus more time

for gel time is needed to ensure mould fill without pre gel condition.

d/ As a guide, MVP’s experience has shown a general UP low viscosity resin suitable for

injection has given the following general specifications on gel time

Using 6% strength Cobalt Naphthalate ( 6% CN) as the primary accelerator and AAP

catalyst

0.1% CN = 1 hour gel time with 1% AAP catalyst

0.2% CN = 20-30 minutes gel time at 1 % AAP catalyst

0.3% CN = 15-25 minutes gel time at 1% AAP catalyst

A typical 20 minute gel time would be formulated with 0.2% CN with 2 % AAP catalyst

ratio setting.

These figures are given as a guide and must be checked for your chosen UP resin

system. Some resins are supplied already accelerated however users often add more CN

accelerator to speed u the resin gel time if found too slow.

4.0 Machine Operation

4.1 RTM or Light RTM operation

4.2 Adjust Catalyst ratio to required setting

4.3 Attach Mould to Mixer output point using 10 mm nylon pipe or via Autosprue® or

Turbo Autosprue brass quick connect. IMPORTANT –Ensure this is locked into position.

Notes a/ Additional lengths of 10mm pipe are available from MVP Ltd.

b/ The TAS 4mm red signal pipe is connected to the SSB chassis connection on

the left hand side 4mm central connector marked Autosprue signal.

Note- do not mistakenly connect to the lower 4 mm chassis connector as this

is a remote start optional connection and if connected to the Turbo AS it will

actually start the machine.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 9 of 43

Page 10

These are marked and located on the LH side of the chassis next to the Mixer

output point. see diagram illustration at end of this manual referring to additional

connections.

Note – The 6 mm Autosprue connection at this location is no longer required

for the latest Turbo Autosprue (TAS) and should remain plugged. However

this point can be utilised by the user as an air gun pressure connection point

or to the Vacuminder.

4.4. Injection operation start and stop

Injection is carried out by setting the Pre determining counter (PDC) lower number set to

the expected volume of resin required. Each digit count represents a volume of resin

approximately equal to 38 cc. To determine exactly the volume collect 10 strokes of resin

accurately from the recirculation resin hose end and observe how much it weighs or

volume for the 10 strokes. If 10 strokes measure 380 ml (0.38 Litres) then each stroke

(numeric count on the counter will give a volume of 38cc. .

Be aware that a count of ten should only be made once the mixed resin has filled the

mixer and pipe

Once the predetermined counter has been set and the PDC counter top LH reset button

has been pressed firmly and the outlet pipes are connected to the mould simply press in

the green start injection button. The machine will now open both the head resin valve and

catalyst valve and internally provide the machine control with a confirmation signal to

start. The machine will dispense/inject the PDC volume of catalysed resin. Speed of

injection can be adjusted by the pump speed regulator. Upon reaching the PDC set count

the machine will stop automatically and the head valves and Autosprue will close safely.

4.5. Once the machines stops, the Resin gel alarm (RGA) will sound after 30 seconds (if

flush is not operated) to warn that the head needs to be flushed. Operate the Flush pull

switch for a minimum of 30 seconds. As soon as this switch is activated to flush the alarm

(if sounding) will cease but the red flashing warning will only extinguish after 30 seconds

confirming that sufficient air drying time has elapsed.

Note if the flush control is pushed in, to stop flushing sooner than 30 seconds the RGA

alarm will sound once more warning that not sufficient time has been allowed for the

recommended air dry out time. If this happens simply operate the flush pull switch once

again and only push back in to stop after 30 seconds has elapsed which is confirmed by

the RGA red flashing light ceasing and the RGA going back into sleep mode (No lights

and no alarm.)

Note if a count of resin is set greater than required it is necessary to stop the machine

manually. To stop the machine under this circumstance simply hit the E stop followed by

unlocking the E stop and pressing the blue reset button. .For security reasons the

machine systems will not allow flush if the green start button is depressed ON. Only the

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 10 of 43

Page 11

count reaching the pre determined count or hitting E Stop and resetting the machine to

ON will allow flush to take place.

Finally if a count on the PDC was set too little and more resin is required to fill the mould

simply press the PDC rest button followed by pressing the green start button once again.

As this selects the original count set, the machine will now continue to pump until the full

reset count is achieved. Stop the machine as described above in these circumstances

and record the number of extra counts the mould needed. This will allow a more accurate

count to be set for the next injection cycle on the same mould.

5.0 Shut down

5.1 Operate the pump to the down stroke limit by using of the recirculation switch. This

ensures that the resin pump piston shaft remains unexposed to air during shutdown and

thus lengthens the life of the shaft seal.

5.2 Turn off machine air supply by pushing the emergency stop button to OFF locked

position.

6.0 Routine Maintenance

General.

Ensure working parts of machine are kept clean. Also ensure all controls and indicators

remain clean. The gauges are glass faced and can be cleaned with solvent however all

other plastic controls should be cleaned with non solvent based cleaners. Remove all

spillages from machine. Immediately correct any air leaks or seepage of any fluid from

machine.

6.1 Resin pump. During normal use the resin pump lubrication cup needs to be topped up

with pump lube. This should be checked at least once a week during normal daily

production use. See separate sheet on internal part maintenance in section 9.0

6.2 Catalyst pump and feed and recirculation pipes. The catalyst pump needs no regular

maintenance however any seepage producing catalyst spillage from the machine from

catalyst pump top seal indicates catalyst pump top seal replacement. See separate sheet

on internal part maintenance in section 10.0.

Please note seepage of catalyst NOT producing leakage onto the workshop floor

from this point on the catalyst pump is acceptable.

Visually check security and condition of catalyst feed pipe from Catalyst bottle and smaller

recirculation pipe and all associated fittings. If any show signs of wear, seepage or

damage, replace with new parts immediately. Ensure Catalyst feed pipe is routed from

catalyst bottle to pump lower fitting around the right hand outside of the machine chassis

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 11 of 43

Page 12

The catalyst inlet filter located within the catalyst bottle should be removed and cleaned in

solvent and water at least every 4 months.

The Catalyst bottle internals must remain clean. If catalyst appears to be discoloured or

any form of sediment is observed within the catalyst bottle remove and clean as

necessary and dry out before replacing with fresh catalyst and placing back into service.

Use only water through the catalyst system if cleaning is necessary. Do not use or pump

solvent based cleaners in the catalyst fluid section

6.3 Solvent Pump system. The Solvent tank requires no routine maintenance however if

dirt particles as sediment accumulate within solvent tank base remove and clean and refill

with fresh solvent.

The remaining solvent system should only be routinely maintained by weekly checks to

locate any leaks or damaged pipes which should be repaired immediately.

See separate sheet on internal part maintenance in section 12.0

6.4 Mixing head assembly. The Resin mix pressure sensor (Mould Pressure Guard MPG) has an internal diaphragm which should be renewed periodically. A renewal rate

after every 10,000 Kg mix usage is recommended. See sections 11.0 and 11.1

7.0 Maintenance

Important Safety Note All maintenance work on the machine must be carried out with the

air supply to the machine disconnected and due caution must be observed when opening

all fluid and pneumatic connections by using personal protection against possible

internal residue pressures.

The following sections describe seal and internal fluid section maintenance procedures

accompanied by assembly and parts drawings.

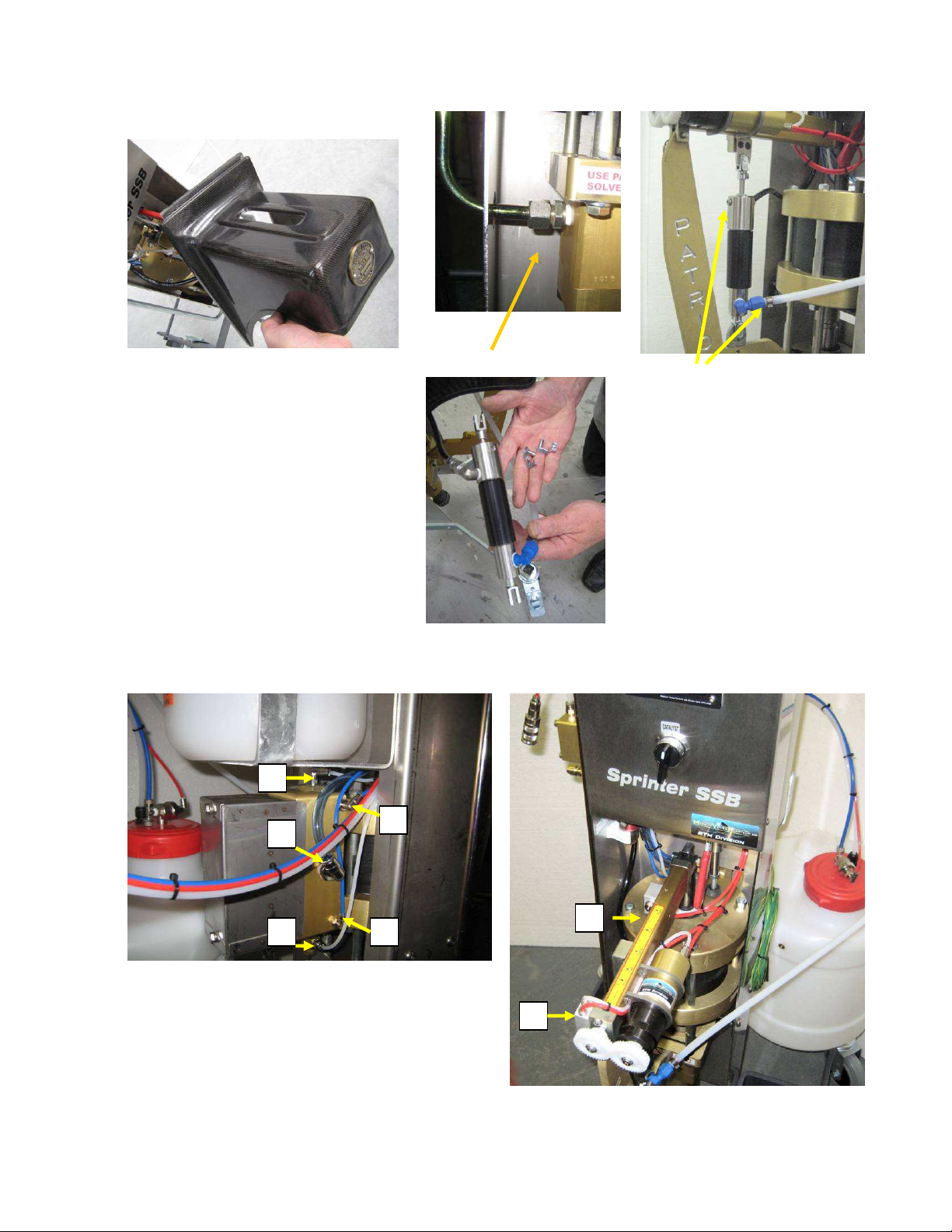

Maintenance feature for ease of access.

It is now possible to remove the entire Patriot fluid section once the air pipes and fluid

pipes have been disconnected. There are NO bolts holding this section in the machine.

Instead the unit is locked into position with an over centre lever lock.

It is a simple and rapid procedure to remove the pump and is recommended if any main

maintenance operations are to be carried out on this section.

Proceed as follows.

1. Lift catalyst and resin intake wands above fluid levels and recirculate to empty both fluid

section.

2. Remove pump guard and the resin outlet and catalyst outlet pipes. Take care to mob

up slight fluid seepage from these unions as they will still have a small residue of fluid

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 12 of 43

Page 13

1

2

3

4

5

1

2

Remove guard Disconnect resin outlet Disconnect Catalyst

inlet and outlet

3. Disconnect 5 pneumatic pipe connection at rear of pump air motor and 2 at front on

MotoCat .

Disconnect 5 pipes to pump air motor ↑

Disconnect 2 red MotoCat feed pipes

→

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 13 of 43

Page 14

pe

ease of access.

1/ Red lever up

to unlock.

2/ The pump assembly can now be eased from

the machine. In the picture the catalyst pump has

already been unclipped. Note the resin intake pi

can remain connected to prevent residue fluid

spillage

The entire fluid

section may now

be bench

mounted for

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 14 of 43

Page 15

The resin pump can be disengaged from the air motor by releasing the circlip (APP-9102)

and lifting the shell retainer (PAT-PA-9109) upwards. This allows removal of the two half

shell connectors (APP-9096). Remove the 4x bolts (F-HB-06C-24-GR8). The resin intake

pipe, if removed, should be disconnected at swivel fitting (4233)

The Patriot resin pump may now be removed for service

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 15 of 43

Page 16

8.0 Patriot Resin Pump

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 16 of 43

Page 17

General Note When rebuilding pump assemblies use

and component mating surfaces

Red

Grease (6706-2-1 1 oz) on seals

Seal replacement. – Piston shaft seals (PAT-LS -1016)

1. To replace piston shaft seals (PAT-LS -1016) first remove four bolts (CS-06C-32) from

lower inlet body (PAT-LS-1002)

2. Secure the upper outlet body (PAT-LS-1001) and push the piston shaft (PAT-LS-1008)

downwards. This will force the lower inlet body and upper body apart. Put the lower body

aside complete with the piston shaft assembly.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 17 of 43

Page 18

3. The one piston rod seal can be removed after first unscrewing the Packing nut (PATLS-1006).

4. Before replacing the new seals ensure that the entire housing is clean. Lightly grease

the seal housing and packing nut thread section. Check also the rod bushing (PAT-LS-

1005) for wear and damage and replace as necessary.

5. The seals must be pushed into the housing evenly. A simple way by which the new

seals can be installed is by first placing one seal (Lip down) into the outlet body so that it

rests horizontal. Now the packing nut can be screwed down upon the seal by hand which

will progressively push the first seal down with an even parallel force. Once screwed by

hand as far as possible, unscrew the packing nut and repeat this exercise with the second

seal (lip down).

6. Finally back off and retighten the packing nut so that it just makes contact with the

seals which are now firmly in their housing bottom position.

Seal replacement. – Piston seal (PAT-LS-1014)

7. Withdraw the piston assembly from the lower intake body and place aside taking care

not to drop or damage the high tolerance surfaces of the rod or larger piston diameter.

8. The piston seal (PAT-LS-1014) can be removed after lifting out the bush (PAT-LS -

1013).

9. Ensure the new seal is placed inside the lower intake body with the O ring lip seal

upper most as indicated. Also note the bush must be placed on top of the seal with the

wider edge down as indicated. Fit the O ring (0-E-035) over the bush before inserting the

piston and re assembling the upper outlet body.

Inlet Valve (PAT-LS-1015) Disassembly

1. Using a pair of Pliers squeeze the Ball Stop (VLS-2420) and remove it from the Inlet Valve (PATLS-1015).

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 18 of 43

Page 19

2. Remove the Foot Valve Spring (3102-16-1) and Ball (PAT-LS-1017) from the Inlet Valve.

NOTE: Use care not to drop the hard chrome balls in the Inlet and Piston Bodies as they will

be damaged. Replace all parts provided in the repair kit. Use only original MVP parts.

•

Inlet Valve Assembly

1. Properly clean Inlet Valve (PAT-LS-1015) checking the ball seat area.

2. Install a new O-Ring (O-E-3-920) on the Inlet Valve, lubricate O-Ring and threads with Red Grease

(6706-2-1 1 oz).

3. Lightly grease the Inlet Ball (PAT-LS-1017) with Red Grease and place in the Inlet Valve.

NOTE: Use care not to drop the Inlet ball as it will be damaged.

4. Install the Foot Valve Spring (3102-16-1) onto the Inlet Ball, narrow side against the Ball.

5. Place the back of the Ball Stop (3102-16-1) on top of the Foot Valve Spring and into the grove in the

Inlet Valve, using a pair of Pliers squeeze the Ball Stop (VLS-2420) and push the front into the

grove. Set it aside for now.

•

Inlet Body Assembly –

6. Properly clean Inlet Body (PAT-LS-1002), lightly lubricate the threads and seal area with Red

Grease (6706-2-1 1 oz).

7. Screw the assembled Inlet Valve Assembly into the bottom of the Inlet Body (PAT-LS-1002),

lightly tighten.

8. Mount the Inlet Body into a vice by the flats on the Inlet Valve.

NOTE: Secure the pump vertically in

the vice by the flats on the Inlet Valve

or the Inlet Body. Use care not to

damage the pump when clamping it

into a vice. Use a soft jawed vise or a

towel or rag between the vise and

pump.

•

Fluid Rod & Piston Assembly –

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 19 of 43

Page 20

9. Properly clean Piston (PAT-LS-1007), Fluid Rod (PAT-LS-1008) and Piston Valve (PAT-LS-1009),

check ball seat area of the Piston Valve for damage or debris.

10. Install a new O-Ring (O-E-3-916) on the Piston Valve, lubricate O-Ring and threads with Red

Grease (6706-2-1 1 oz).

11. Lightly grease the Piston Ball (VLS-2427 and place in the Piston Valve.

NOTE: Use care not to drop the Piston Ball as it will be damaged.

12. Install the Spring (PAT-LS-1010) onto the Piston Ball, narrow side against the Ball.

13. Place the back of the Spring Retainer (PAT-LS-1011) on top of the Spring and into the grove in the

Piston Valve, using a pair of Pliers squeeze the Spring Retainer (PAT-LS-1011) and push the front

into the grove.

14. Screw the Piston Valve Assembly into the bottom of the Piston and tighten firmly. Check that the

Fluid Rod (PAT-LS-1008) is tightened onto the Piston (PAT-LS-1007).

•

Pump Assembly –

1. With the assembled Inlet Body mounted

in the vise slowly and firmly push the

Piston and Fluid Rod assembly all the

way down into the Inlet Body.

2. Carefully and firmly

push the assembled

Outlet Body onto the

Inlet Body until the

Fluid Rod extends

though the Packing

Nut.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 20 of 43

Page 21

3. Align the Inlet and Outlet Bodies and install the four Socket Headed Cap Screws (CS-06C-32).

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 21 of 43

Page 22

9.0 Catalyst Pump - Catalyst pump parts drawing

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 22 of 43

Page 23

9.1 Catalyst pump piston seal.

The Patriot SSB model is designed with a new type of internal Piston valve. This new

design has dispensed with the conventional small ball and spring metal to metal types

formally common in the industry.

In the new design the valve action is generated by the fact that the piston assembly has a

very small amount of “slop” or lost motion.

It is essential therefore that during any maintenance on the piston seal the correct

lost motion is set as detailed below and is observed before re assembly after

service of this section.

To access the pump piston seal or any other internal pump parts proceed as follows.

1 Adjust ratio to maximum

2/ Lift the filter end of the catalyst feed above the catalyst bottle fluid level, operate

recirculation to pump out catalyst from system. Continue to pump until air bubbles appear

in the return flow sight glass.

3/ Remove catalyst feed pipe from the inlet (assy. 0099) and the outlet pipe connection

(6150). The inlet fitting should only be hand tight. Take care to collect or wipe away any

residual catalyst as the fitting is opened

4/ Unclip top and bottom clevis pins to allow pump removal (4279)

5/ Unscrew by hand the lower catalyst block (PS 4282) from pump body.

6/ Unscrew outer tube (PS 0526). The pump cylinder (PS 0525) is now exposed.

Remove this by pulling and sliding off the pump shaft and piston assembly.

7/ Loosen locking nut 6256 and unscrew the piston retainer M4 screw (5692) using 2.5 AF

Allen key The piston assembly will remain upon the screw as it is removed.

8/ Remove the Piston assembly from the screw and unscrew the piston (4234) from the

retainer bush (4235). Withdraw the piston seal (1712).

9/ Replace with new seal. Observe the correct” lip up” orientation of the seal as detailed

on figure 33 below. Do not force seal onto piston (4234) unevenly. Best results are

obtained by placing seal in position (lip upper most) and hand tightening piston and bush

back together. Do ensure assembly is fully retightened. It should measure 13.5 mm

(0.524”) when tightened. Piston valve seal O ring (5684) may be renewed at this time.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 23 of 43

Page 24

Figure 33. Catalyst piston assembly lost motion setting (assy 0100)

Warning Notes.

If the piston seal assembly is not assembled as per the instructions concerning the lost

motion tolerance the following will occur.

a)

If there is no gap then the pump will seize solid on the down stroke when filled with

catalyst.

b)

If the gap is too great poor catalysation will be evident in the mix.

Important. Ensure the piston bush (4235) is screwed onto the piston the correct way up.

The four small V grooves on the bush MUST be uppermost as shown

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 24 of 43

Page 25

The reassembly of the piston assembly using the piston retaining screw must only be

done when the Piston shaft is mounted back through the top block.

The screw should be set at the right position to set the desired 0.5 to 1.0 mm (0.020” to

0,040” ) lost motion gap and locked in position with locking nut 6256 however we

recommend medium thread locking solution is used to secure its correct position as an

additional security measure. (I.e. Loctite® 243)

Do not attempt to remove the top piston rod clevis (4278) from the shaft as this is

permanently thread locked together.

The remaining parts are reassembled in the reverse order

9.2 Catalyst pump Piston shaft seal

The top seal (0535) can be removed and replaced by following the above description to

remove the pump and disassemble. The piston assembly must be removed so that the

piston rod can be withdrawn and top seal housing (4236) and spacer (4237) can be

pushed forward from the top of the top block to remove and gain access to piston rod seal

(0535).

9.3 Catalyst Over pressure Valve (O/P valve)

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 25 of 43

Page 26

The Catalyst Over pressure valve (OPV) is a pressure switch designed to stop the

machine pumping in the unlikely event of catalyst fluid section blockage causing high

pressure. This unit has been factory set and tested by MVP. It will trigger the machine

pump OFF for pressures higher than 24 bar (350 psi)

The OPV is mounted inside the machine covered chassis on the left hand side and

secured on a robust nylon clip.

If for any reason the user needs to install new O ring seals (0750) then only the front

Stainless steel body (1032) should be unscrewed from the pressure switch brass body.

Do not disturb the Brass body end cap setting as this will invalidate the factory pressure

setting.

9.4 Catalyst Ratio arm - MotoCat

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 26 of 43

Page 27

There are no serviceable parts associated with the above assembly and no lubrication is

necessary. Periodically check for and tighten any loose screws and fittings if noted.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 27 of 43

Page 28

10.0 Injection Head and Mixer assemblies

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 28 of 43

Page 29

10.1 Catalyst Auto valve assembly. – CAV

Servicing notes.

The catalyst auto valve needs little servicing as all components are suitable for both MEKP

and recommended AAP catalysts

The movement of the spool as indicated from the aluminium air cylinder end should be

between 4 and 5 mm. Any less or greater can cause Catalyst to flow incorrectly so ensure

this movement is observed to be correct by measurement using callipers after service and

before using the machine in production.

Take care not to damage or scratch the spool internal body 6369 when O ring 3316 needs

replacing.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 29 of 43

Page 30

The valve should only need servicing if air or catalyst is noted to weep from between the air

cylinder 6078 and Stainless steel body 6067. In this case the O ring 3316 should be

renewed.

If catalyst appears to weep back to the catalyst bottle during injection mode then the internal

spool O rings (6004) need replacing.

If catalyst is observed to weep from the injection nozzle during recirculation mode then the

small front O ring (6079) needs replacing. .

Injection Recirculation

Illustration of Catalyst

Auto valve cross

section showing

catalyst flow and

correct position of air

actuator for

A. injection flow

And

B. recirculation flow

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 30 of 43

Page 31

10.2 Auto Resin Valve assembly - RAV

Caution Note. For safety reasons - Always ensure that the Resin Auto valve above is

locked into the head top position with the two securing lock M5 screws 4081

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 31 of 43

Page 32

10.3 Head Mixer and Mould pressure Guard (MPG)

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 32 of 43

Page 33

11.0 Solvent pump NEW SP3 (Jan 2003 onwards)

Note. With the introduction of the new Stainless Steel SP3 Solvent pump system on models

supplied from January 2003 it is possible to upgrade previous machine models with this unit.

It is a simpler design over the former SP2 system and has greater cleaning efficiency as

there is greater throughput of air to the pump and thus to the mixing head.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 33 of 43

Page 34

11.1 SP3 assembly

11.2 Solvent valve Assembly 58742-PLAS

. The automatic solvent head valve may be serviced. However note the important use of

thread locker solution (recommend Loctite 242 between parts 3 and 6. This needs to be

disassembled if the main solvent seal 19 needs renewing.

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 34 of 43

Page 35

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 35 of 43

Page 36

12.0 Resin Gel Alarm – RGA

Start – Green

Alarm

- Red

flashing

Power on

Injecting

- Yellow

Battery low

-Yellow flashing

The RGA unit is set to operate only when injection takes place. On injection start both the

green light and yellow light illuminate.

If injection is either stopped or the machine stops pumping (stalled) for more than 60 -120

seconds the Top green light will change colour to Red flashing mode and an audible alarm

will sound.

If injection is restarted then the Red light changes back to Green and the alarm warning

stops.

At the end of injection when the counter or the operator stops the injection and proceeds to

flush the machine head the Red light will continue to flash for 30 seconds (without the

audible warning) and the RGA unit will then revert to sleep mode.

If the operator switches off the flush command earlier than 30 seconds the audible warning

will start again with the red light still on demanding that a full 30 seconds of flush and head

mixer air dry out is commanded.

Low battery.

9 VDC

battery (PP3

type)

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 36 of 43

Page 37

The internal 9 vdc battery is accessed by sliding out the front battery draw. Under normal

use the standard PP3 9vdc battery should last for more than two weeks. If the battery has

insufficient volts the lower yellow light will flash. If this condition is observed immediately

renew the battery.

Gel time Changes

If the gel time is to be reset to another time interval it is necessary to access the rear of the

RGA enclosure. Here will be found a small blue adjuster wheel on the box rear face. By

rotational switching clockwise the time will be increased and decreased if rotated anti

clockwise

RGA Alarm time set switch.

Use small screwdriver to

adjust. DO NOT force beyond

stops

As previously stated, the time before the alarm is activated can be selected by the user,

based on the resin system being utilised. On the SSB machine model it is necessary to open

the control fascia to access this RGA rear position. This is achieved by setting the rotary

switch, located on the rear of the RGA, to the position for the required time as specified in

the following table.

SWITCH SETTING Pump inactivity time (minutes)

0 0.25

1 0.5

2 1

3 2

4 3

5 4

6 5

7 6

8 7

9 8

A 9

B 10

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 37 of 43

Page 38

C 12

D 15

E 20

F 25

13.0 SSB Auto Machine Doctor

This table provides typical fault conditions their possible causes and remedies

Fault

symptom

Machine fails to

start on

recirculation or

injection

command

2. Pump speed set too

3. MPG set too low Set MPG pressure higher

ON injection

command

( when green

button is

pressed)

5. PDC Counter not

6. Catalyst over

5. Catalyst head valve

Possible cause Remedies

1. Air supply too low Ensure air supply at least 6 bar

(90psi)

Set at least to 1 bar and above

low

4. Auto head valves

NOT reached open

inject position and thus

not providing start signal

to machine

reset correctly or set at

zero

pressure valve operated

- Either the NRV4 has a

blockage OR the head

mixer is blocked.

has not fully opened

when commanded by

injection command

Check both Resin and catalyst head

valve have moved to open position.

Observe Metal pin at pneumatic

actuator has moved out.. Approx 8

mm for Resin valve and 5 mm for

catalyst valve. If not then increase

shop air pressure or service the

valve at fault.

Press reset firmly or set at least a

count of 5

Check Catalyst Over pressure valve

is NOT leaking small air volume

from brass body end cap

If this valve has an air leak then it

has triggered the machine to stop.

Investigate why the valve has

triggered as it indicates the catalyst

has found significant blockage.

Inspect NRV8 for signs of blockage

Check both the resin auto valve and

the catalyst auto valve have opened

.The Resin valve must fully open to

signal the catalyst valve to open.

Both should indicate their

respective open positions by the

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 38 of 43

Page 39

Resin valve brass pin raised above

the black valve top by at least 7

mm. (0.276”)

The catalyst auto valve (CAV)

should show the movement open by

the aluminium pin raised by at least

5 mm (0.200”) from the closed

position.

Service the valve which is showing

signs of not fully opening.

6. Resin head valve

blocked .This condition

could happen if the

machine has been left

with resin in the system

for extended times

without use.

Internally clean and if necessary

renew internal parts.

Caution NOTE. Always replace the

resin valve locking M5 screws

securely after servicing the Resin

auto valve.

Catalyst flow

appears erratic

1. Air in catalyst feed

pipe or Fluid section

Re purge catalyst system.

Contaminated catalyst also causes

bubbles in system. To remedy

empty entire catalyst system

including catalyst bottle. Wash out

with clean water. Dry, and Refill

with fresh Catalyst

2. Catalyst Gassing -Clean catalyst system of

contamination.

- Preferably use AAP catalyst

system as MEKP has a greater

tendency to produce gas bubbles

more readily than the more stable

AAP systems

Resin flow has

bubbles or

appears erratic

1. Air leaks in the resin

feed intake system.

1.Check all joints for leaks in intake

pipe work and fittings on the resin

pickup fluid section

2. Resin filter blocked Clean resin intake filter

3. Resin Filler loading

too high

Lower viscosity of resin OR lower

pump speed until even flow on up

and down pump strokes is observed

Flush does not

clean efficiently

1.Low air supply

pressure

Ensure supply pressure between 6

to 8 bar (90 – 120 psi)

or appears

weak

2.solvent valve assy

blocked or broken

Check assy 58742-PLAS internal

seat and spring

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 39 of 43

Page 40

3.Mixer partially blocked Check mixer and renew if

necessary

Catalyst pump

1. Worn top seal Renew seal

top seal

leakage

beyond top of

pump

2. Catalyst pump piston

Renew seal and pump shaft.

shaft

damaged/scratched

Resin pump top

1. worn top seal Renew seal

seal leaking

beyond pump

lube zone

2. Top seal worn quickly

due to non lube renewal

Observe recommended pump lube

renewal

3.resin pump left for

extended times in UP

Observe recommended service

notes on pump parking position

position causing shaft to

become dry

4.Filled resin use A shorter service life will be

expected if highly filled resin is

used. Service life depends on filler

type and filler micron size. Use only

coated fillers with 5 micron filler

particle size

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 40 of 43

Page 41

Additional SSB

Connections

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 41 of 43

Page 42

Machine air circuit

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 42 of 43

Page 43

Issue record – Revision history

Issue 05 dated 30/06/08 arh

– All reference to hand operated head solvent valve deleted .Also NRV2 deleted. Now using automatic air

operated solvent valve assy 58742-PLAS

Patriot SSB Auto Instructions Issue 05 30/06//08

Page 43 of 43

Loading...

Loading...