Page 1

Megaject MKIV

Manufacturing Technology Centre,

Chilsworthy Beam,

Gunnislake,Cornwall,PL18 9AT, UK

Tel: +44(0)1822 832621 Fax: +44(0)1822 833999

e-mail: rtm@plastech.co.uk

http://www.plastech.co.uk

Instruction Manual

Revision 1_2

Machine Serial Number: KO30141

Megaject MK IV Issue 1_2 25/11/2003 Page 1 of 31

Page 2

Contents

1. Megaject MK IV Overview

Introduction

Injection Head

Machine Front Guard

Catalyst System

Solvent Tank

2. Operating Controls

3. Commissioning and Set-up Procedures

4. Filling/Refilling Solvent Tank

5. Setting Catalyst Percentage

6. Recirculating & Repriming

Recirculating

Repriming

7. Injecting & Flushing

Before Injection

Injection

Flushing

8. Optimising Output

9. Shutdown Instructions

10. Maintenance

Maintenance Schedule

Replacing Resin Pump Seals

Replacing Catalyst Pump Seals

Servicing Injection Head

Mixer Tubes

Resin & Catalyst Pipework

Catalyst Overpressure Valve

Machine Air Circuit

Solvent Pump

11. Appendices

Mould Pressure Guard

CATAL catalyst monitoring system

Resin Heaters

Revision History

Megaject MK IV Issue 1_2 25/11/2003 Page 2 of 31

Page 3

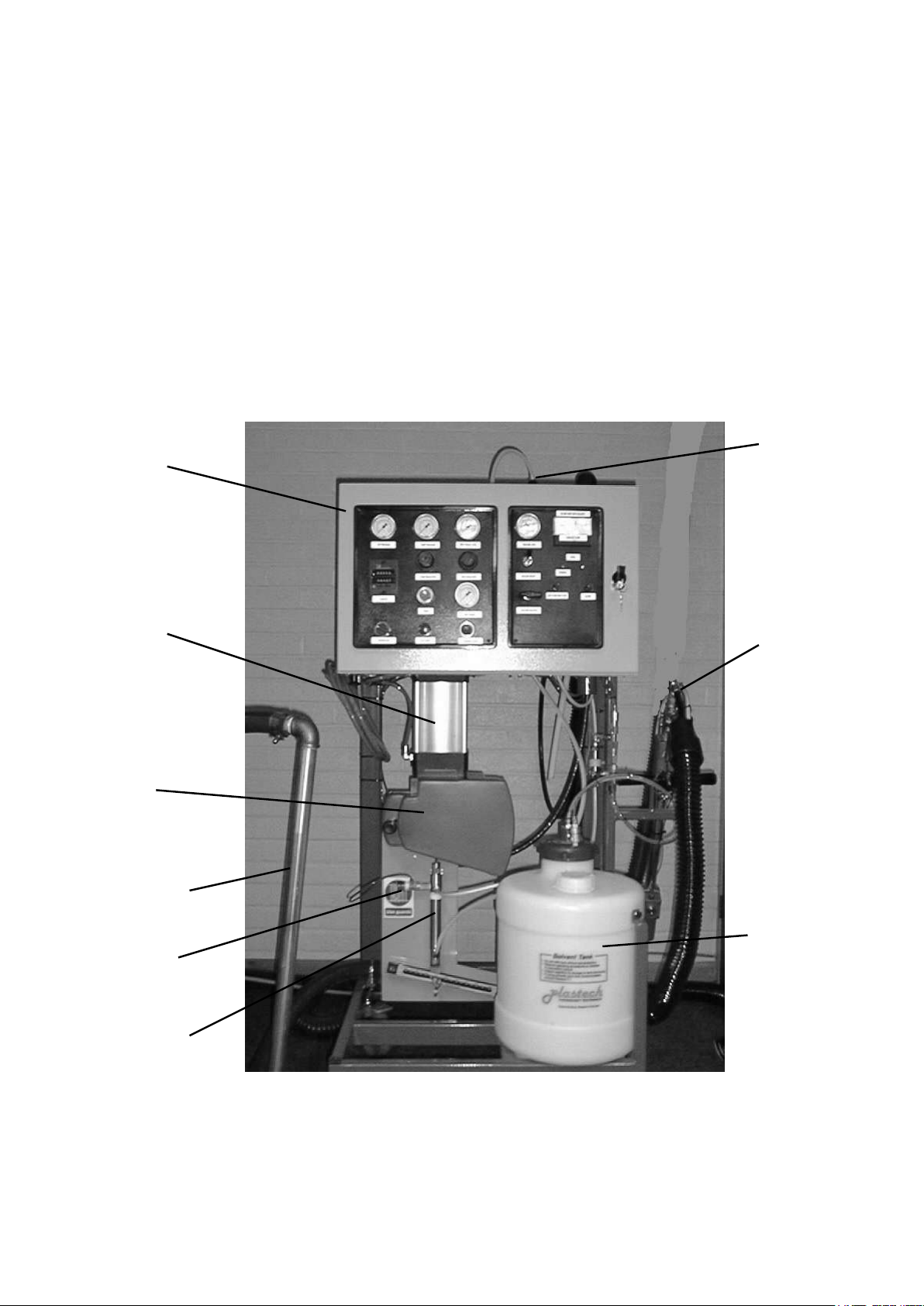

Catalyst Bottle

(behind)

Control

Cabinet

Pick up pipe

Injection

Head

Main Air

Cylinder

Catalyst Pump

Solvent Tank

Front

Guard

Catalyst Overpressure valve

Megaject Mk IV Overview

Introduction

This manual covers the operating and maintenance instructions of your particular model and

also includes details of options which may not be present on your machine. This will be

indicated at the relevant points.

This chapter shows the main machine components.

Megaject MK IV Issue 1_2 25/11/2003 Page 3 of 31

Page 4

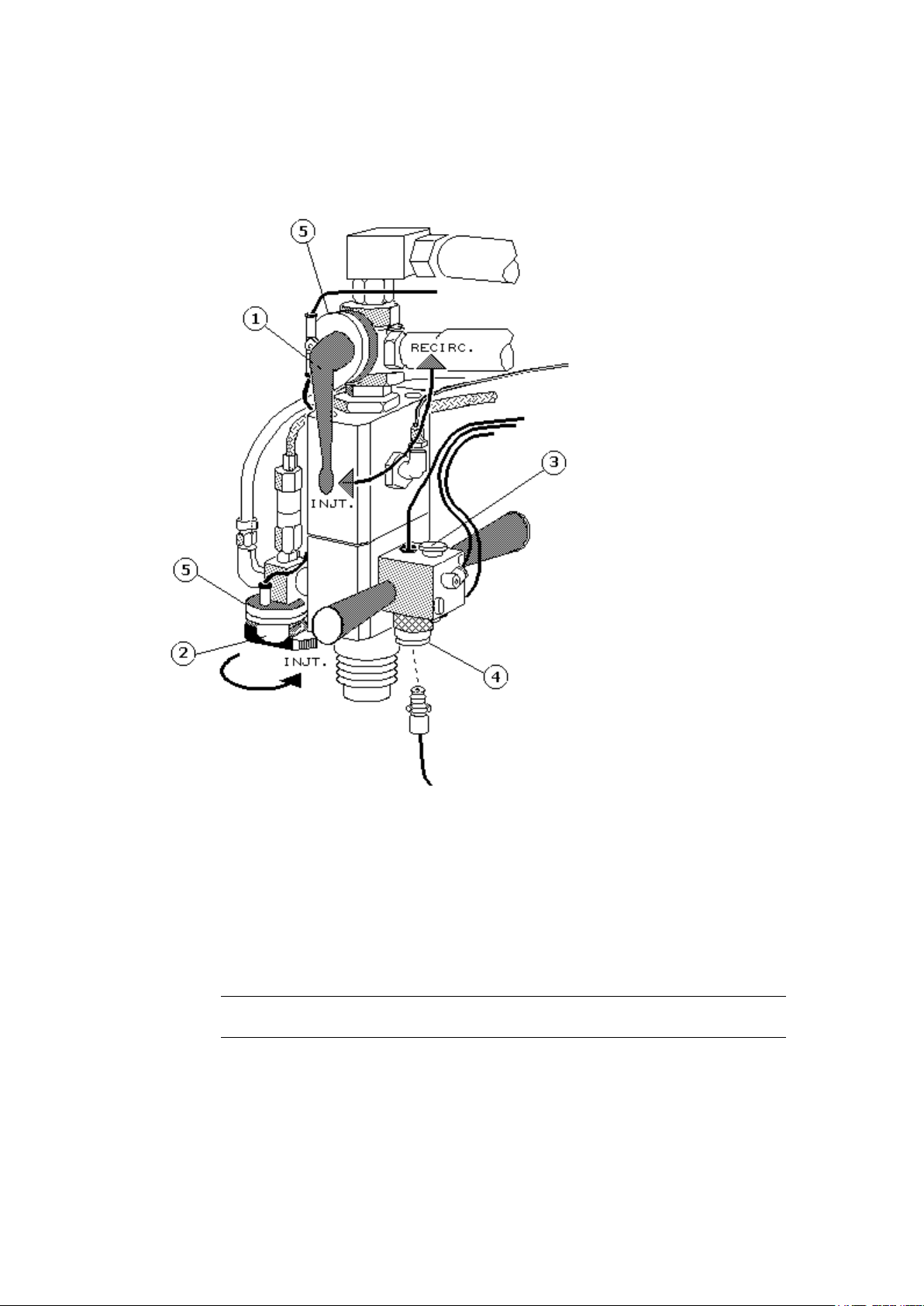

Injection Head

1. Resin recirculation valve. Swaps the resin stream between the injection and

the recirculation position. (90° movement)

2. Catalyst recirculation valve. Swaps the catalyst stream between the injection

and recirculation positions. (180° movement)

Note: Recirculation valves must be turned to their full extent for correct

operation i.e. 90° for resin and 180° for catalyst

3. Thumb Start Switch. Used to start machine for injection. Will only operate

when recirculation valves are in the injection position.

4. Autosprue Connector (for use with Autosprue option only)

5. Resin and Catalyst Interlock Switches. Check that both resin and catalyst

recirculation valves are in the inject position.

Megaject MK IV Issue 1_2 25/11/2003 Page 4 of 31

Page 5

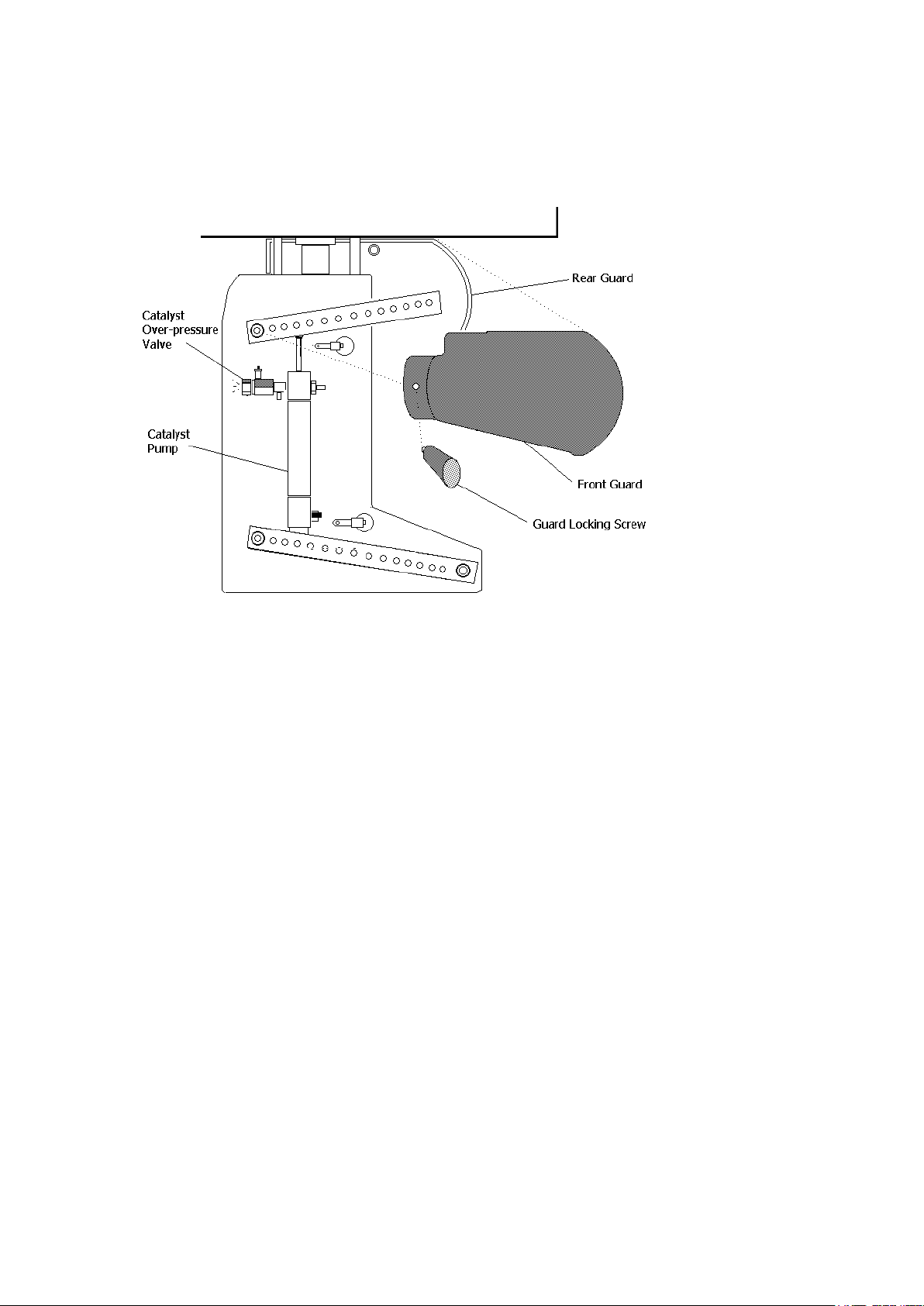

Machine Front Guard

1. Pump Front Guard. The linkage between the resin pump, catalyst pump and

the catalyst ratio arm is guarded to prevent any injury from moving machine

parts during the operation of the machine. The guard locking screw holds the

front guard in position. Removal of the guard will stop the machine.

Catalyst System

1. Catalyst Pump. Operated by the main resin pump. Catalyst ratio is indicated on

the ratio arms. On Megaject PF machines for use with phenolic resins (000067/68), two 316 stainless steel slave pumps are provided, with the catalyst ratio

determined by adding the two ratios.

2. Catalyst Overpressure Valve. If during the operation of the machine, the

catalyst system becomes blocked for any reason causing the catalyst to exceed a

pre-set pressure, the catalyst overpressure valve will activate and stop the

machine. Refer to Megaject Doctor for fault finding.

3. Catalyst Container. Catalyst store with feed and return pipes attached.

Megaject MK IV Issue 1_2 25/11/2003 Page 5 of 31

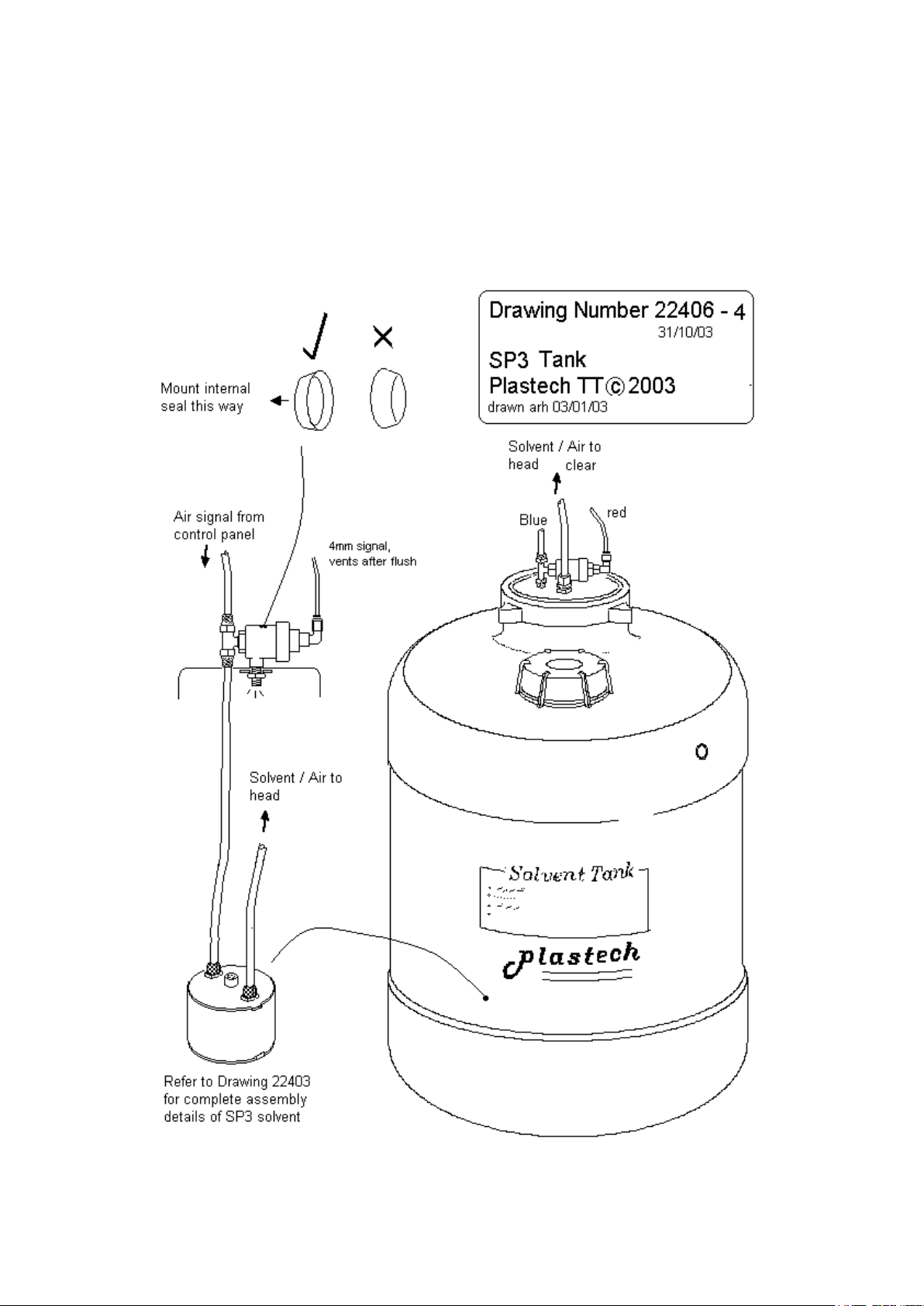

Page 6

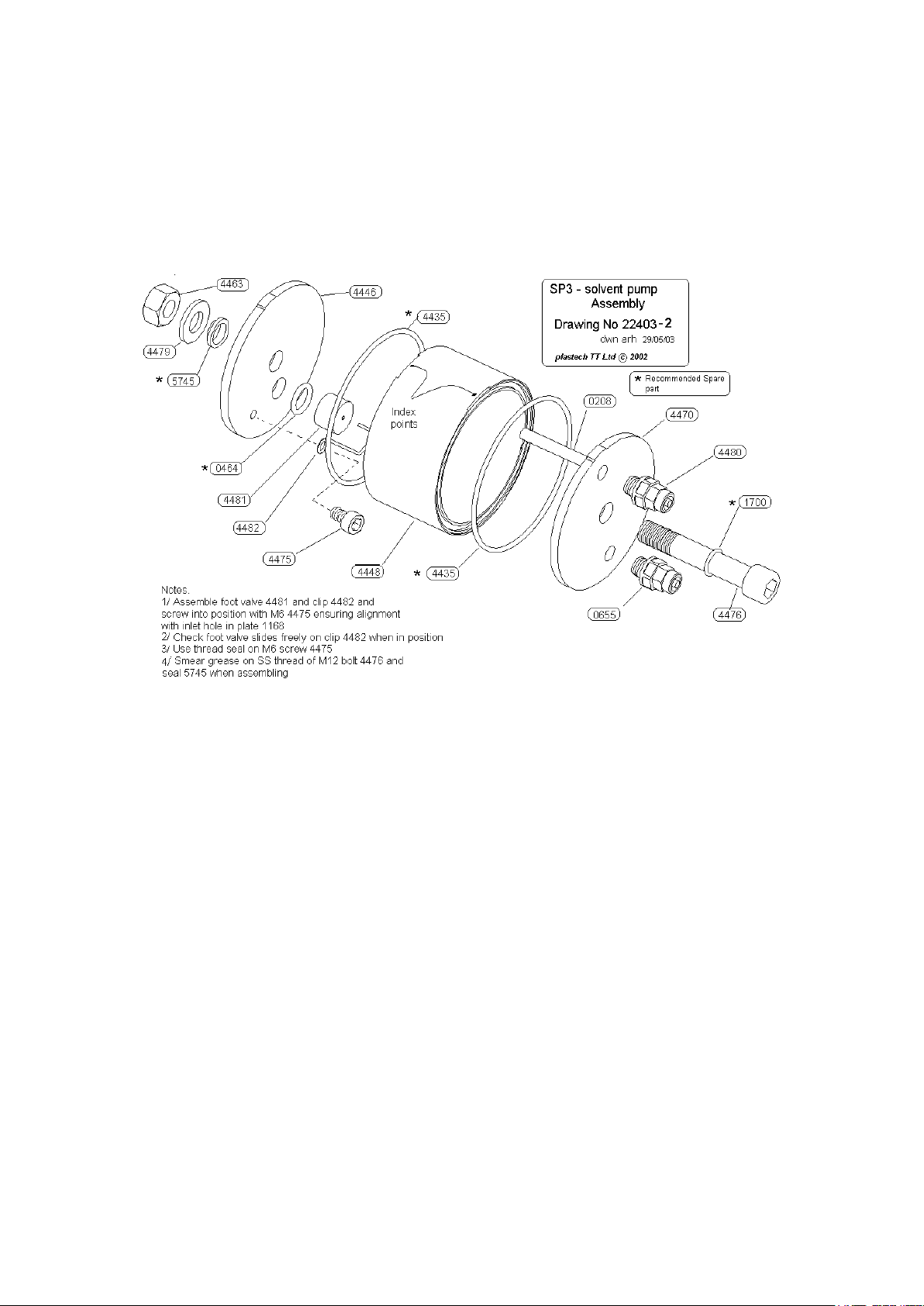

Solvent Pump NEW SP3

Note. With the introduction of the new Stainless Steel SP3 Solvent Pump System on

models supplied from January 2003 it is possible to upgrade previous machine models

with this unit. It is a simpler design over the former SP2 system and has greater

cleaning efficiency as there is greater throughput of air to the pump and thus to the

mixing head.

Megaject MK IV Issue 1_2 25/11/2003 Page 6 of 31

Page 7

SP3 Assembly

Megaject MK IV Issue 1_2 25/11/2003 Page 7 of 31

Page 8

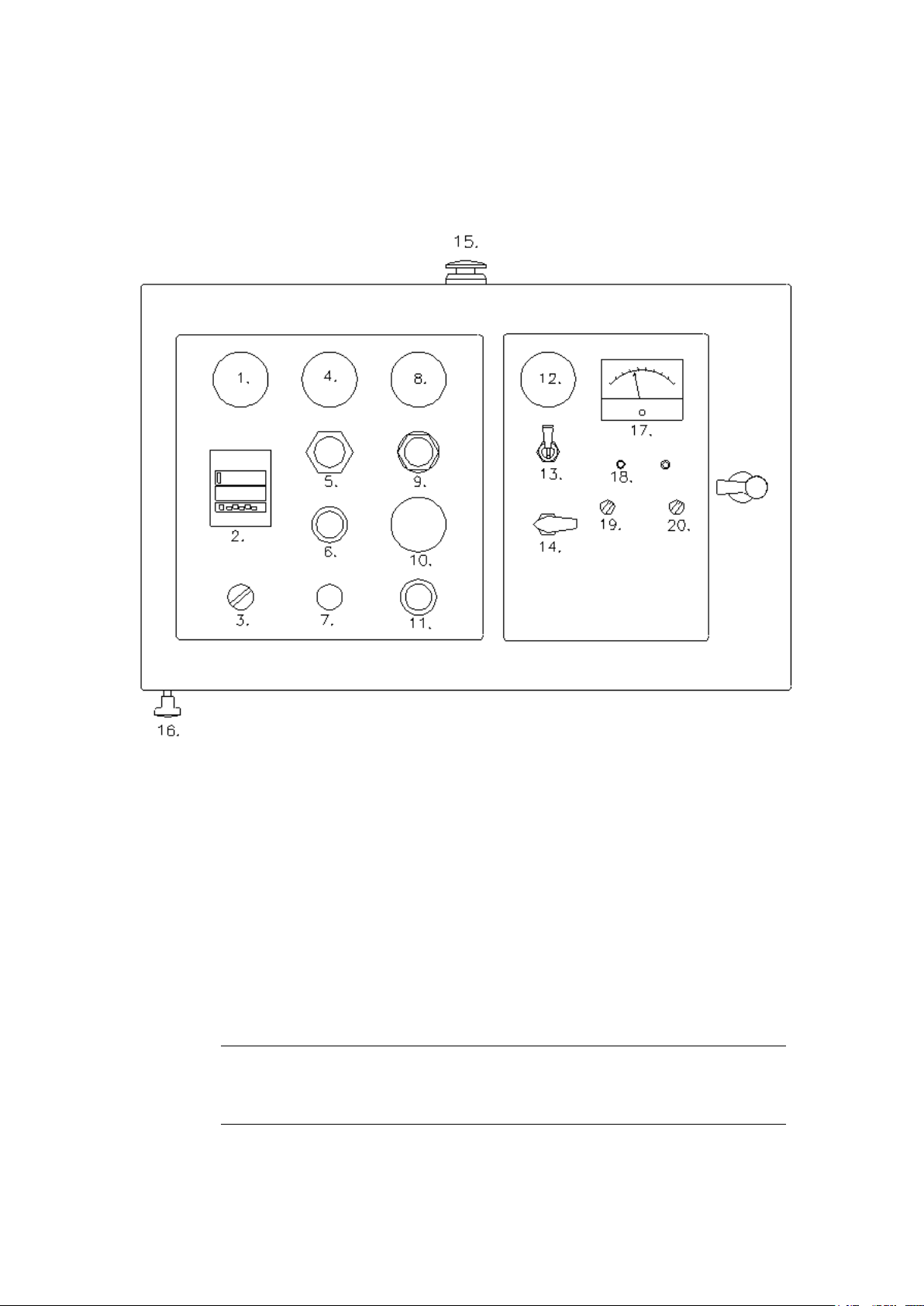

Operating Controls

Note: Some options may not appear on your machine

1. Incoming Air Pressure Gauge.

Indicates incoming air pressure to the machine.

2. Counters.

i) standard counter

Records the number of pump strokes of the machine. Each digit represents 100

cc’s (0.1 litres) of resin displaced.

ii) Pre-Determined Counter (PDC)

The pre-determining counter contains two readouts. The upper readout displays

the machine output count during injection. The lower readout displays the preset

count entered by the operator. Each digit represents 100 cc's (0.1 litres) of resin

displaced.

Megaject MK IV Issue 1_2 25/11/2003 Page 8 of 31

Page 9

To preset the counter, push white arrow lever on counter down and whilst

holding down - set the predetermined amount of strokes required with the

individual digit buttons and then release the white arrow lever. (Range 0-99.9

litres)

3. Recirculation Switch.

Turn to right to run the machine in recirculation mode (‘on’). Turn to left to stop

machine running in recirculation mode. (‘off’)

4. Pump Speed Pressure Gauge

Measures air pressure being sent to the resin pump air motor.

5. Pump Speed Pressure Regulator

Adjusts air pressure fed to the resin pump air motor, with reading shown on pump

speed pressure gauge.

6. Start Button (PDC machines only)

Begins machine operation. Will only operate when resin and catalyst recirculation

valves are in the inject position.

7. Air Purge Switch. (pull to operate)

Air purges excess resin\solvent from the injection head. Operates until pushed back

to stop.

OPTION: MPG Control Unit (automatically controls pump speed –

see Appendices)

8. MPG Preset Level Gauge

Indicates the maximum injection pressure selected by the operator

9. MPG Preset Regulator

Adjusts maximum injection pressure, with reading shown on MPG preset level

gauge.

10. Pump Signal gauge

Indicates pressure signal being sent to resin pump auto regulator. The lower

the pressure, the slower the pump speed.

11. Solvent Flush Button.

Activates the machine solvent flush cycle for approximately 30 seconds.

12. Mould Vacuum Level Gauge

Indicates level of vacuum achieved by the internal vacuum generator. With perfect

sealing of vacuum cavity, levels of -0.8 to -0.9 bar can be achieved.

13. Mould Vacuum On/Off.

Switches vacuum on/off. (Switch down for ON). Vacuum connection point is located

on rear of cabinet.

14. Mould Vacuum Isolator.

Isolates the vacuum generator from the remainder of the machine enabling air tight

vacuums to be held and read with the vacuum generator switched on or off. ( Switch

horizontal for isolate.)

15. Emergency Stop Button.

Removes all air pressure from the machine and deactivates the pull ‘on’ switch.

Megaject MK IV Issue 1_2 25/11/2003 Page 9 of 31

Page 10

16. Machine Pull ‘On’ Switch

Activates the machine. Deactivates in the event of either the emergency stop button

being pressed or if air supply falls below 1 bar.

OPTION: CATAL Catalyst Flow Monitor (see Appendices)

17. Analogue Flow Meter

Indicates level of catalyst flow in recirculation and injection modes

18. Green ‘ON’ LED

Indicates when the CATAL unit is operating. This will only occur when power

is supplied and the main pump is in motion.

19. Low\High Range Switch.

Adjusts scale resolution for differing catalyst flow rates.

20. Alarm Set Level

Adjusts the catalyst flow level at which an alarm will sound.

(on back of cabinet)

External power supply socket. (+/- 9V)

Remote LED large/small repeater socket (repeaters optional)

Whistle - not shown

Sounds when machine requires flushing (1 minute after end of injection). Operating solvent

flush button cancels whistle and resets timer.

Megaject MK IV Issue 1_2 25/11/2003 Page 10 of 31

Page 11

Commissioning & Set Up Procedures

CAUTION

Overalls and eye protection must be worn at all times during operation of the

machine.

CAUTION

Do not adjust the catalyst overpressure valve. If in any doubt about operation or

adjustment of any part of this machine please contact Plastech TT.

IMPORTANT NOTE

The resin pump upper collar must be filled with Plastech Pump Lubricant (supplied) to

clean and lubricate pump seals. Remove rear guard window and fill to approximately

10mm below top lip.

An oiler/lubricator must NOT be used in the air supply to the machine. Air must be

filterd and dry at 6-8 bar (85-115 psi).

The Megaject MK IV is tested and secured against leaks prior to despatch. It is

essential that the inlet tube connected to the resin pick up pipe and filter remain tight

and sealed at all times to prevent air ingress into the resin system.

We recommend the use of Acetone as the primary choice of cleaning solvent. If a

different solvent system is to be used please contact Plastech for details of changes

required.

Procedure

1. Connect earth lead from solvent tank to a suitable earth point. Ensure recirculation

switch is off. Connect 10mm air line (supplied) to workshop air supply. Pull the ON

switch down to the ON position. Observe incoming air pressure gauge reads a

minimum 6 bar at all times.

2. Place resin pick up pipe and resin recirculation pipe in resin container. Securely

anchor both pipes.

Note: If the machine is to be fed directly from a resin tank it may not be possible to use

the resin pick up pipe and filter supplied. A suitable in-line filtering system is

available from Plastech TT

3. Using the funnel provided, fill catalyst container to approx 3/4 full. For polyester

resin systems we recommend Acetyl Acetone Peroxide (AAP) catalyst (e.g.

Luperox 224).

Note: The use of MEKP is not recommended for RTM as product de-mould time is

significantly longer than with AAP. MEKP may also cause ‘gassing’ in the catalyst

system resulting in inaccurate catalyst flow and potential ‘wet spots’ in the

moulded part.

Megaject MK IV Issue 1_2 25/11/2003 Page 11 of 31

Page 12

Disclaimer: Plastech do not accept responsibility for the performance of Megaject

machines when using non recommended materials. For further information

contact Plastech TT.

4. Fill solvent tank following ‘Filling/Refilling Solvent Tank’ procedure.

5. Remove front guard and catalyst slave pump from the backplate. (DO NOT

remove any catalyst pump pipework.) Operate pump by hand until even resistance

is felt on both strokes and the lines are free of air. If difficulty is encountered

removing all air invert pump and continue operating by hand. Replace pump at

required percentage and refit guard.

6. Adjust pump output regulator to read 2 bar on the pump pressure gauge.

7. If MPG system is fitted, adjust preset regulator until preset level gauge reads 2

bar.

8. Ensure both resin and catalyst recirculation valves are in the recirculation position.

Turn recirculation switch ‘on’. Recirculate until a bubble free fluid flow is observed

at both the resin and catalyst containers and pump output is even on both

strokes. If air in the catalyst system persists turn the recirculation switch ‘off’ and

repeat procedure 6

Note: The recirculation switch should be used for recirculation only and must be turned

‘off’ when priming is complete.

9. Turn resin and catalyst recirculation valves to inject position.

10. Using either the start button (Predetermined counter machines only) or the thumb

start switch, pump 300cc’s (3 counts) into a waste container.

11. Pump 200 cc’s (2 counts) into a cup. DO NOT STIR.

12. The injection head must be flushed. Return resin and catalyst recirculation valves

to recirculate position. Place injection nozzle in a waste container. Operate the air

purge button to expel waste resin. Press the solvent flush button. This will reset

after approximately 30 seconds. Operate the air purge button to dry out the head

and mixer tube.

13. Check that resin in cup gels evenly and fully. If not, return to procedure 6.

Note: We strongly recommend that after injection, the recirculation valves are always

placed back into the recirculation position. This ensures that small amounts of

resin and/or catalyst do not leak forward into the head chambers. Major

movement of the pipes and/or day and night workshop temperature variations

could cause slight weeping into the head if the machine is idle and the

recirculation valves are not left in the recirculation position.

Megaject MK IV Issue 1_2 25/11/2003 Page 12 of 31

Page 13

Filling/Refilling Solvent Tank

Sufficient solvent levels are essential for the correct flushing of the machine. The solvent level

must not be allowed to fall below 5 litres as this may cause inefficient flushing.

Safety Note: Solvents are flammable. Care must be taken when handling solvents. Avoid

naked flames and sparks. Do not smoke in any area containing solvents.

When refilling solvent tank ensure earth clip is connected to dispensing container

Procedure

1. Remove small white filler cap from solvent tank. Refill tank to approx. 4/5 full.

Solvent level must always be high enough to cover top of pump chamber inside

the tank.

2. Replace cap

Megaject MK IV Issue 1_2 25/11/2003 Page 13 of 31

Page 14

Setting Catalyst Percentage

Megaject catalyst levels can be adjusted in the range 0.5% to 4.5% to suit differing resin

systems. This is achieved by movement of the catalyst slave pump along ratio arms directly

connected to the main resin pump.

Safety Note: Before altering catalyst percentage ensure that the resin and catalyst

recirculation valves are in the recirculation position. REMOVE air/power supply to the

machine. Any guards removed MUST be replaced before operation.

Procedure

1. Remove front guard where applicable

2. Remove ratio locking pins from the top and bottom joints of the catalyst slave

pump to the ratio arms by depressing the top of the pin, and then withdrawing.

3. Set catalyst slave pump to new required percentage on ratio arms and replace

top and bottom ratio locking pins.

4. Recirculate machine to ensure pump is correctly primed

5. If required, carry out a timed gel test, injecting approx 200 cc’s of resin into a

cup.

Megaject MK IV Issue 1_2 25/11/2003 Page 14 of 31

Page 15

Recirculating & Repriming

Recirculating

Recirculation of the machine should be carried out on a regular basis to ensure resin and

catalyst flows are even, free of air bubbles (observed through recirculation returns) and to

prevent sedimentation of any fillers/additives in the resin system.

Recirculation should be carried out at the start of each shift or if new material has been

added to either the resin or catalyst containers.

Procedure

1. Ensure both resin and catalyst recirculation valves are in the recirculate position.

2. Adjust pump pressure regulator until the pump pressure gauge reads approx. 2

bar. If MPG is fitted, adjust MPG preset level to approx. 1 bar.

3. Turn the recirculation switch to the ‘on’ position.

4. Allow machine to recirculate for required period. Ensure recirculating materials are

free of air bubbles and even on both pump strokes.

5. Turn recirculation switch to ‘off’ position.

Repriming

To be carried out when the operator wishes to change the resin/catalyst in a machine which

has already been commissioned.

Procedure

1. Remove pick up filter from fluid. Recirculate machine to empty fluid lines

2. To clean the lines and pump, place pick pipe in solvent container and recirculate

until clean solvent is observed at the recirculation pipe.

3. Place the recirculation pipe in a waste container. Place pick up pipe in new fluid.

Recirculate machine until all solvent is discharged and new fluid is observed at

the recirculation pipe.

4. Place recirculation pipe in fluid container with pick up pipe.

5. Continue recirculating until material is free of all air bubbles.

Note: If the new material is of a similar chemical type to the existing material,

then it may not be necessary to clean the system with solvent before loading the

new material.

Megaject MK IV Issue 1_2 25/11/2003 Page 15 of 31

Page 16

Injecting and Flushing

This procedure should be followed each time an injection or series of injections are carried

out.

Before Injection

Procedure

1. Check the pull ‘ON’ valve is on and the incoming air pressure gauge reads at least

6 bar.

2. Check recirculation switch is ‘off’.

3. Ensure there is sufficient resin, catalyst and solvent.

4. Check catalyst percentage is set to required level.

5. Adjust the pump pressure regulator to the required setting. (Suggested initial

setting – 1 bar)

Note: If MPG system is fitted, adjust the MPG preset regulator until the required

maximum injection pressure is indicated on the MPG preset level gauge.

(Suggested initial setting – 2 bar)

6. (PDC machines only) Set predetermined count to required count number. Press

counter reset button to set output count to zero.

Injection

Procedure

1. Place the injection nozzle into the mould injection port and hold.

2. Turn resin and catalyst recirculation valves to injection position.

3. Standard machine

press and hold thumb start button machine will inject until thumb start button is released.

OR

4. PDC machine

either:

i) press green start button machine will inject until predetermined count is reached.

or

ii) press and hold thumb start button machine will inject until thumb start button is released.

Megaject MK IV Issue 1_2 25/11/2003 Page 16 of 31

Page 17

Note: Pump pressure and MPG preset level (if fitted) can be adjusted during injection to

optimise the injection speed. DO NOT exceed the maximum safe injection

pressure for the selected mould.

5. Turn resin and catalyst recirculation valves to recirculation position.

6. Remove injection nozzle from mould

7. Place sprue plug in mould injection port.

Flushing

Procedure

1. Hold injection nozzle in waste container

2. Pull air purge button until excess resin is expelled.

3. Push solvent flush button. After approximately 30 seconds this button will reset.

The solvent flush button may be used a second time if necessary.

Note: If two or more injections are to be carried out consecutively, it may not be

necessary to flush the mixing head between shots. Approximately 1 minute after

the end of an injection, the whistle will sound indicating that the machine must be

flushed. Operating the solvent flush or continuing with the injection will cancel the

alarm.

Injection & Flushing when using an Autosprue™

When carrying out an injection through an Autosprue™, it is essential that the both the

Autosprue™ resin and signal pipes are connected to the injection head before starting

injection. The Autosprue™ MUST REMAIN CONNECTED to the injection head for the

flushing cycle. Only when flushing is complete may the Autosprue™ be disconnected.

Refer to Autosprue™ instructions for further details.

Megaject MK IV Issue 1_2 25/11/2003 Page 17 of 31

Page 18

Optimising output

Maximum output rate is dependant on various factors when pumping resin systems. The

following factors should be taken into account in order to achieve maximum mixed output.

1. Supply of air to the machine.

An air supply of sufficient pressure and volume flow rate must be supplied to the machine. To

check supply is sufficient, ensure that incoming air flow is at least 1200 litres/min at 8 bar

2. Resin viscosity.

High viscosity resins will reduce the potential output of any metering machine for a given

power input. Viscosity of the resin can be decreased by a) increasing the temperature. b)

Reducing filler loadings. c) Using viscosity modifiers

3. Pipe work restriction from pump to mixing head.

Fitting larger bore output hoses, or reducing the hose length can improve output of the

machine. This is an important criteria if long hoses (> 4 metres) or higher viscosity resins are

used.

4. Fillers

When using fillers, it is essential that the filler is well mixed and not allowed to settle out over

a period of time. A tank agitator may be used. Alternatively regularly recirculate the resin.

This may however reduce pump seal life. Filler particle sizes of 5m or less should be used. If

filter blockage is occurring, a larger mesh size should be used. Contact Plastech for further

details.

Megaject MK IV Issue 1_2 25/11/2003 Page 18 of 31

Page 19

Shutdown Instructions

Procedure

1. At the end of the day/shift switch off the machine air. Leave resin and catalyst

recirculation valves in the recirculation position.

2. The resin pump piston shaft should be parked at the bottom of its stroke. This ensures

any smears of resin on the pump shaft do not dry out causing excess seal wear

3. For shutdown periods, if any doubts exist about the stability of the resin system, it

should be reprimed with an unfilled, unaccelerated resin system. Once the system is full

of unaccelerated resin, pump approx 300cc’s (3 counts) of resin through the injection

head then flush. Do not leave the Megaject either empty or with a cleaning solvent in the

resin system. Under normal circumstances, catalyst may be left in the system for

extended periods.

4. If filled resin systems have been used filler may sediment at the bottom of the pump and

pipework. Under these circumstances a higher pump pressure may be required to start

the pump recirculating. If filler has formed a sediment around the bottom inlet ball valve

of the pump it may momentarily stick. In such circumstances continue to pump on

recirculation for 3 minutes which should ‘unstick’ the valve. The resulting flow will quickly

wash away sediment, allowing the pump to operate correctly. Should the problem

continue, the bottom resin pump ball valve must be serviced. (refer to service

instructions).

5. After a shutdown period, it is expedient to ensure the resin and catalyst systems are fully

primed. See commissioning instructions for details.

Megaject MK IV Issue 1_2 25/11/2003 Page 19 of 31

Page 20

Maintenance

The Megaject RTM Machine range has proved to be extremely reliable in service. To

maximise service life, it is important to keep the machine free from dirt and contamination

and follow correct procedures for use and maintenance as instructed in this manual.

Spares Ordering

To order spare parts for your machine, please indicate the relevant drawing ident number for

the part required.

Important Note: Read this section before attempting any maintenance of your

machine.

1. Eye Protection and protective clothing and gloves MUST be worn for all maintenance

operations.

2. Before carrying out any maintenance on this equipment, Remove air supply from machine.

3. Be aware that small residual pressures may exist in fluid lines even when the machine is

isolated from the air supply. Take care when removing fittings.

4. We recommend that if any work is to be carried out on the fluid sections (i.e. resin,

catalyst or solvent) that they are pumped empty prior to maintenance.

Maintenence Schedule.

(based on experience with standard recommended materials)

Every 1 tonne of resin pumped

1. Check general cleanliness of machine and ensure there are no leaks.

2. Check resin pump lubricant level

3. Clean resin filter. (Remove, clean with acetone, dry and replace).

4. Remove mixer shroud and check cleanliness of mixer tube.

Every 5 tonnes of resin pumped

1. Split injection mixing head. Examine internals for gelled resin or foreign objects. It

is not necessary to dismantle head Non Return Valves if the head appears to be in

good condition.

2. If MPG block is fitted, remove 4 M5 cap screws and examine parts. It is not

necessary to remove MPG diaphragm.

3. Remove catalyst filter. Clean with acetone, dry and replace.

Every 100 tonnes of resin pumped

1. Replace main resin pump seals

2. Replace mixer tube and mixer tube O ring.

3. Empty solvent tank, clean tank and filter.

Replacing Resin Pump Seals

Megaject MK IV Issue 1_2 25/11/2003 Page 20 of 31

Page 21

Important Safety Note All maintenance work on the machine must be carried out with the air supply

to the machine disconnected and due caution must be observed when opening all fluid and pneumatic

connections by using personal protection against possible internal residual pressures.

The following sections describe seal and internal fluid section maintenance procedures accompanied by

assembly and parts drawings.

Resin pump

Megaject MK IV Issue 1_2 25/11/2003 Page 21 of 31

Page 22

Resin pump service.

In order to service internal resin pump seals first pump out any resin from internals by placing system on

recirculation. It is also advisable to clean internals with solvent after resin removal before service. Do this

by recirculating 5 litres solvent through resin pump and finally pumping the solvent out of system.

Isolate machine from air supply

4.3.2 Piston Seal (0555) and Shaft seal (0549)

To access Piston seal (part 0555) remove 4 x M8 securing bolts (Part 0559). Slide Pump cylinder (0548)

and lower gold block assembly (0558) from piston.

The piston seal may now be removed by unscrewing seal retainer nut (0556). Replace seal observing that

the seal lip must face UP and valve ball (0554) is placed back into cage (0551)

NOTE If the shaft seal (0549) is to be replaced proceed further without re assembling the Piston and seal

The piston is re assembled in reverse order to the above. Observe that medium strength thread lock

should be used on piston bolt (0342)

To replace the shaft seal (0549) it is necessary to remove the top block (0546) from the machine. To do this

first remove the four M8 retaining bolts accessed from the underside of top block.. This will allow the top

block to be drawn down shaft away from the four square air motor pillars.

Using circlip pliers remove large circlip (0544). Remove washer (0545). Remove old seal (0549) and

discard. Install new seal and re assemble pump in reverse order. Note- O ring top and bottom seals (0547)

may be replaced during these service operations if found to be damaged.

Ensure pump assembly is evenly retightened with M8 tie bolts (0559)

When Pump is reinstalled in machine, renew pump seal lubricant in top seal block (0546)

Megaject MK IV Issue 1_2 25/11/2003 Page 22 of 31

Page 23

Replacing Catalyst Pump Seals

See drawings 22022/22042

Procedure

1. Remove catalyst pump from ratio arms. Disconnect inlet and outlet hoses at

swivel fittings

2. Unscrew bottom and top blocks from outer tube. Examine bottom block ball

bearing for pitting/damage. Replace if necessary.

3. Slide pump bore out of top block and remove from piston shaft

4. Replace pump bore outer tube O rings and lubricate using silicone grease.

5. Unscrew piston seal body from shaft. Examine piston ball and spring. Replace if

necessary.

6. Unscrew piston seal retainer. Remove and replace piston seal.

7. Remove top block from piston shaft. Unscrew top seal block from top block.

Remove shaft seals from top seal block and replace.

8. Remove felt washers and replace.

9. Reassembly is a reversal of the above procedure. When refitting the piston seal

retainer (part 0531) clean threads thoroughly. Place a small amount of Loctite

243 threadlock on the threads and screw in finger tight only.

Megaject MK IV Issue 1_2 25/11/2003 Page 23 of 31

Page 24

Servicing Injection Head

See drawing 22015

Note: During maintenance ensure resin and catalyst recirculation valves are in the

recirculate position. Avoid any cross contact of resin and catalyst.

Procedure

1. Remove air signal and solvent lines from the head. Using a 5mm allen key,

remove head block bolts. Split head into two sections. Remove head block O ring.

To remove NRV 3, first remove spring retaining pin at top of valve. Screw M8 bolt

partially into the valve and pull to remove from head.

2. NRV 2 may be unscrewed from the side port.

3. To remove NRV 1 unscrew from resin recirculation valve swivel fitting and then

remove from top head block.

4. To remove NRV 4, undo catalyst pipe swage fittings. Unscrew 3 way ball valve

from NRV 4. Unscrew NRV 4 from bottom head block.

5. Inspect all head block and NRV galleries. If hardened resin is evident, remove or

replace parts as necessary.

6. To disassemble all NRV’s, remove spring retaining pin. PTFE cone can be

replaced by removing spring from seat retainer.

7. When using a new PTFE cone, grind into NRV seat using thumb pressure only to

ensure a good seal. On reassembly a suitable hook must be used to stretch the

spring sufficiently to enable the retaining pin to be replaced.

8. Reassembly is a reversal of above procedures. Inspect head block O ring and

replace if necessary using a small amount of silicon grease to lubricate.

9. After reconnection of hoses and pipes, machine must be recirculated to expel air.

Note: We highly recommend catalyst and resin pipes are not removed from the recirculation

valves as leakage is inevitable.

Megaject MK IV Issue 1_2 25/11/2003 Page 24 of 31

Page 25

Mixer Tubes

See drawing 22020

Mixer tubes will only require replacement if partial or full gellation/sedimentation has

occurred in the injection head. They cannot be repaired and must be replaced.

To replace, remove mixer shroud from head. (If MPG option is fitted, signal pipes

must be removed first.) Remove mixer tube from shroud. Lightly grease new mixer

tube/shroud threads with silicon grease, ensure O ring is in position and replace in

mixer shroud.

Re-attach to mixer head and reconnect MPG pipes if applicable. (Blue pipe nearest to

mixer tube)

Resin and Catalyst Pipework

See drawing 22022/22028

If air is being drawn into the system, check integrity of all joints and connections

shown.

Joints should be tight and sealed correctly using a proprietary thread sealant. Do not

use sealant on cone and seat type joints.

Megaject MK IV Issue 1_2 25/11/2003 Page 25 of 31

Page 26

Catalyst Overpressure Valve

See drawing 22021

Under normal operational circumstances the catalyst overpressure valve is

maintenance free.

If catalyst leaks constantly from fitting (4), O rings (2) must be replaced

Important Note: It is essential that the internal spring tension is not disturbed in the event

of servicing this unit.

Procedure

To renew front O rings

1. Disconnect red signal pipe and clear overflow pipe. Unscrew whole assembly

from catalyst pump using 19 AF spanner on the forward stainless steel body

taking care of any small residual pressurised catalyst as thread seal is broken. DO

NOT disturb the spring tension end cap (0671).

2. Hold brass body (1035) and unscrew stainless steel body (1032). Pull shaft

(1034), and collar (1033) from body, replace O rings (0750) and reassemble.

Ensure shaft is reinserted with rounded end into the body.

3. Reassemble observing order illustrated in dwg. 22021. Ensure bodies (1032) and

(1035) are correctly screwed together using PTFE tape or similar thread sealant.

4. Reattach valve to catalyst pump using thread sealant.

5. Reprime catalyst system to remove any air from the system.

Machine Air Circuit

In case of problems, follow enclosed schematic diagrams to check the machine air circuits.

This circuit is specific to your machine. When contacting Plastech, please quote machine

serial number. (see front cover)

Megaject MK IV Issue 1_2 25/11/2003 Page 26 of 31

Page 27

Solvent Pump

See drawing 22036

Warning: Before commencing any work on the solvent system, ensure that the working

area is free from any sources of ignition.

To Test:

Turn on air supply to machine. Place injection nozzle in a waste container. Press solvent flush

button. Check solvent output from injection nozzle. Check inside tank during the flush cycle.

If air bubbles appear from the bottom of the solvent pump, either the foot valve or the

threaded joints in the solvent pump will require servicing.

To service solvent pump foot valve:

Procedure

1. Remove air supply from machine.

2. Remove 6mm blue air supply pipe. Mark position of 6mm clear solvent feed pipe

with tape. Unscrew fitting and remove pipe from top of solvent pump complete

with fitting cap and PTFE olive

3. Unscrew M8 cap screw holding tank to machine frame and remove tank.

4. Unscrew red solvent cap. Remove whole pump assembly. Solvent will drain from

the pump assembly as it is lifted. To completely empty solvent pump, turn upside

down and allow remaining solvent to pour out of solvent pipe fitting.

5. Secure pump body and unscrew solvent pump foot valve.

6. Examine filter for blockage and replace as necessary.

7. Using correct size drift, remove roll pin from foot valve.

8. Remove foot valve plunger. Replace O ring. Ensure correct size and grade O ring

is used.

9. Re-assemble foot valve using PTFE tape and/or silicone sealant on threads.

10. Replace pump assembly in tank and refit to machine frame.

11. Refit air supply and solvent feed pipes. Ensure that solvent feed pipe is pushed

through the fitting to the marked position and fitting olive is in the correct

position before tightening. Do not overtighten.

Megaject MK IV Issue 1_2 25/11/2003 Page 27 of 31

Page 28

Appendices

Mould Pressure Guard (MPG)

A fluid pump driven by a piston type air motor will deliver an amplified injection pressure.

For example; a standard machine uses an 11:1 air motor/pump ratio. This could result in the

actual pump pressure being amplified eleven times, thus 3 bar could become 33 bar when

the mould cavity becomes hydraulically full.

The MPG is designed to control the Megaject pump speed, and thus injection pressure, to

prevent injection pressure exceeding an adjustable preset limit.

Operation

Set the maximum injection pressure on the MPG preset level gauge using the MPG

regulator. (Suggested initial setting – 2 bar)

If the resin pressure is below the preset pressure, then the automatic regulator will

remain fully open allowing full mains pressure to the resin pump regulator.

If the resin pressure exceeds the preset level, the ‘MPG signal pressure’ will reduce

proportionally closing the automatic regulator and limit air pressure to the resin pump

regulator. This slows or stops the resin pump, reducing resin pressure until it

matches the preset level. During operation, a small leak of air will occur from the

MPG sensor block. This is normal.

The MPG preset level may be adjusted during an injection to achieve optimum pump

output speed at the safest injection pressure.

Several factors will affect the optimum setting of the MPG regulator, e.g. fibre volume

fraction, mould size and rigidity, resin viscosity, required resin delivery rate etc.

Megaject MK IV Issue 1_2 25/11/2003 Page 28 of 31

Page 29

CATAL Catalyst Monitoring System

The CATAL catalyst monitoring system provides a visual and audible indication of catalyst flow during

injection and recirculation.

Operation

Connect the Catal Power Supply to the Megaject. The connection is via the 5 pin DIN

socket located on the back of the Megaject control cabinet.

The Catal power supply is rated at 110 or 240v input, +/- 9V output. If you have the

incorrectly rated unit for your supply, please contact Plastech TT.

The catalyst flow monitor will operate only whilst the machine is pumping

Catalyst flow is indicated on the analogue gauge.

The sensor has been factory set to catalyst flow ranges typical in normal RTM

application i.e. 5kg/minute resin mix at 2% cat. ratio. When the flow range switch is

switched to ‘LOW FLOW’ position the system will indicate a catalyst flow as low as

6ml/minute (e.g. resin mix output of 1kg/minute at 0.5% catalyst). If indicating

towards the maximum level, move the range switch to ‘HIGH FLOW’. If meter

reading reaches top of meter, the sensor element may be moved upwards to

accommodate the higher flow. (see diagram).

It is not necessary to keep readjusting the sensor element. It is simply a coarse

adjustment setting depending on your normal output levels.

The operator can observe the flow rate of catalyst over a wide range of pump speeds

and percentage settings. The audible alarm can be set by turning the alarm setting

control clockwise from zero to a point just below the ‘running level’ (e.g. giving an

alarm when the catalyst flow drops below this setting).

Megaject MK IV Issue 1_2 25/11/2003 Page 29 of 31

Page 30

Resin Heaters

Important Note

It is essential that resin heaters are not left turned on with stationary resin in the system.

Uncatalysed resin will eventually cure at elevated temperatures and block the heater

channels..

Whilst the resin heater is on, the machine MUST be either recirculating or injecting.

At the end of a shift, turn off the resin heater and continue to recirculate the machine until

the resin has cooled to room temperature. It is then safe to turn off the machine.

Megaject MK IV Issue 1_2 25/11/2003 Page 30 of 31

Page 31

Revision History

Manual

Date

Revision

Code

Revised Content

MKIV

23/2/00

1_0

New Manual – revision from previous sections

MKIV Doctor

23/2/00

1_0

Revision code changed

Drawing Number

Revision

22001

3

22041

4

22042

7

22022

9

22015

11

22020

10

22021

3

22028

6

22036

9

22034

3

22039

2

Air Circuit

S/N

Revision codes appear on the front page of the manual.

e.g. Sprint1_0

Sprint = Machine Name

1 = major revision 1

0 = minor revision 0

Drawings included in this manual

Megaject MK IV Issue 1_2 25/11/2003 Page 31 of 31

Loading...

Loading...