Page 1

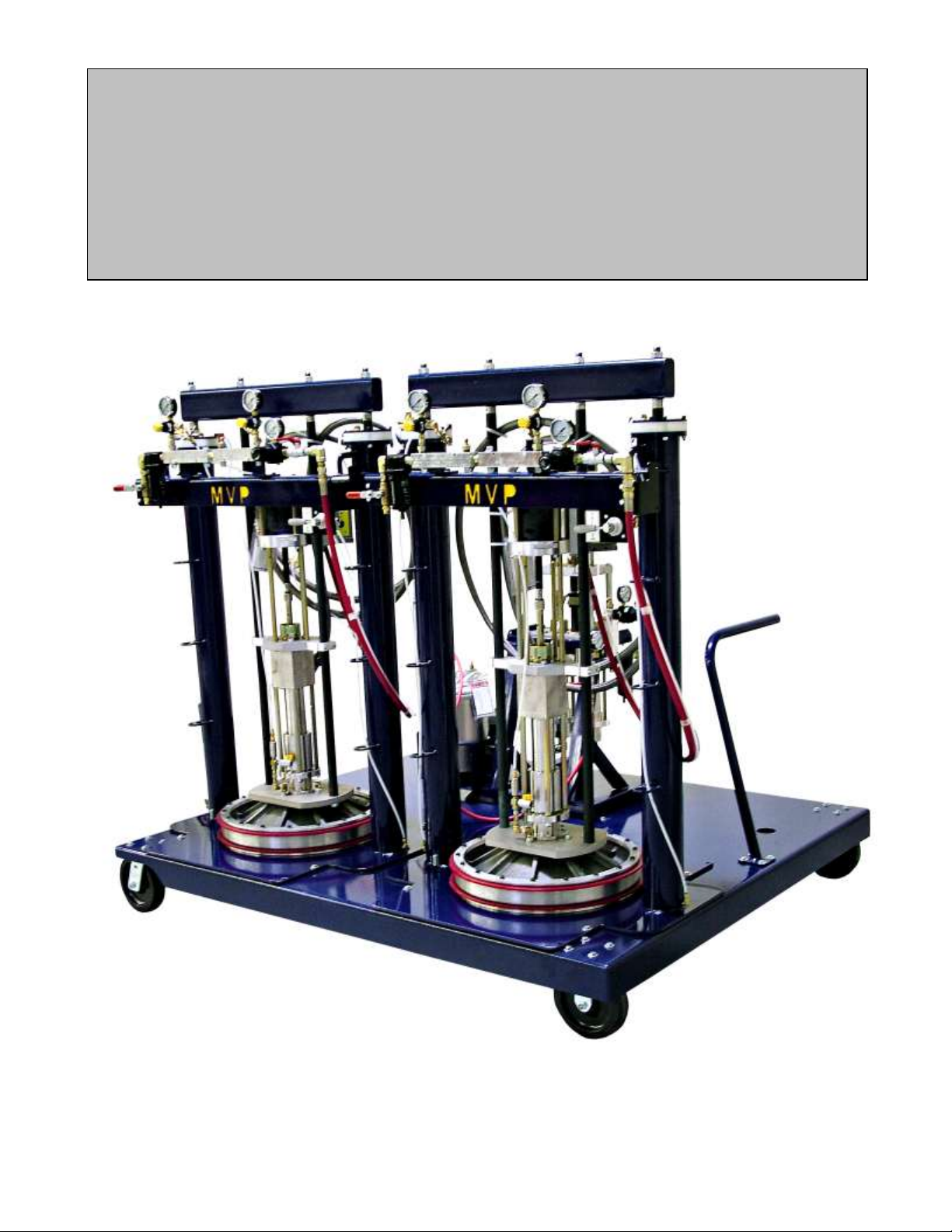

ULTRABOND

Methacrylate Adhesive Dispensing unit

IMP-DUO-54646

Start-Up Instructions

MAGNUM VENUS PLASTECH

UltraBond Start-Up Instructions Rev. 5/07

Page 2

Page 3

START-UP INSTRUCTIONS

1. Attach main air supply to the air manifold on both systems.

NOTE: The regulators marked pump, air lift and ram extraction should be set at zero on all

systems.

2. On the Duo Link unit fill solvent tank with solvent. Turn the air supply to the flush system to

60psi (4 bar). Check for solvent leaks and test flush system by flushing the dispensing head.

3. Located on the Ram units check and adjust the Ram Lower Limit. By adjusting the APD-1011

bracket the pump piston stop height can be adjusted in the drum. (see drawings below)

PRIMING ADHESIVE TO GUN

4. Move the rotary valve handle (06275) to the up position.

NOTE: Do not install static mixer tube to gun at this time.

5. Open the ball valve located off of the regulator and gauge marked airlift cylinder. To raise the

ram and barrel piston, slowly increase air regulator (marked AIRLIFT) to 15 to 20 psi.

6. While the barrel piston is going up, check that no hoses are kinking.

7. Once ram is to maximum up position, tape the Piston Boot (60531-1) the round piece of

plastic (use plastic boot as a template to make more before installing) to the top of the barrel

piston. Make sure that the round hole in the center of the plastic piston boot is centered with

the opening at the bottom of the barrel piston.

NOTE: If the 55-gallon drum has a plastic liner it is helpful to prevent the liner from being

pushed down into the drum. Use the ring from the drum top to hold the liner in place or

tape the liner to the outside of the drum. Inspect the drum for dents and damage, using

a dented or damaged drum can damage the piston seals and cause leaking.

8. Slide 55-gallon drum of adhesive onto the unit and center drum to the barrel piston.

9. Open ball valve (06276)) located at the top of the barrel piston; this will allow air trapped

between the barrel piston and the putty to escape.

10. To lower barrel piston down into the drum, push rotary valve (06275) handle to down position.

11. Once barrel piston has started into adhesive drum, slowly increase airlift regulator pressure 80

to 100 psi.

NOTE: Allow time for air to be pushed out of the ball valve (06276) at the top of the barrel

piston.

12. Once barrel piston has come to a complete stop, close ball valve (06276) at the top of the

barrel piston.

13. Remove the night cap or mixer assembly from the front of the dispensing block.

14. Pull the manual gun handle back to the open position, and leave in the open position.

Page 4

15. At the air manifold, slowly increase regulator marked pump. Do this for both of the ram

adhesive pumps.

16. Adjust pump regulators as needed to maintain a slow uniform movement of the adhesive

pumps.

NOTE: It may take more pressure for one drum of material than another as the viscosity may

be different.

17. At the Duo Link unit slowly increase the pump pressure as needed to maintain a slow uniform

movement of the Duo Link adhesive pumps.

18. Allow units to run until a steady flow of adhesive material is being dispensed out both sides of

the dispensing block with no air pockets.

19. Push the dispensing head handle to the close position.

20. Flush both sides of the dispensing head.

21. To build fluid pressure, push the priming button (09188) located on the Duo Link air manifold

that is labeled prime.

22. While pushing the priming button in, slowly increase the pump regulator, 80 to 90 psi for

maximum flow rates. Once pump has come to a stop, release priming button.

NOTE: For best results perform a ratio check at the dispensing head. The pump pressure on

the ram adhesive units should be kept as low as possible to prevent over riding the

inlet balls in the Duo Link unit. The pressure may need to be adjusted differently on two

ram units because of viscosity differences and to reach a 1:1 ratio.

NOTE: Apply a small amount of red grease on the dispensing head threads before installing

mix tube to gun.

23. Install mixing tube (05260) onto gun head, making sure there is a seal (02029-1) between the

mix housing and the adapter union fitting (54861-1). The static mixers (05271) have a notch

on one end that inner lock the four mixers together.

NOTE: The notch should face up when installing into the mix tube (05260).

Page 5

Daily - Startup & Shut-Down UltraBond Adhesive Unit

DAILY STARTUP

1. Check and refill all components and materials.

2. On the Duo Link unit close the relief valve on the flush tank lid.

3. On the ram adhesive pumps open the lockout ball valve (7702-2-2) to pressure up the system.

4. On the ram adhesive pumps slowly open the air ball valve (09350) to the pump.

5 On the Duo Link unit open the main air supply to pressure up the system.

6. On the Duo Link unit push and hold the priming button while slowly opening the air ball valve

to the pump.

7. Remove the night cap plug (HOD-1002).

8. Apply a small amount of red grease (7607-2-1) to the threads of the dispensing head.

8. Reassemble and attach static mixer assembly.

9. Check flush system for proper operation.

DAILY SHUT-DOWN

1. Drain water trap filter (06989) daily.

2. Thoroughly flush the dispensing head.

3. Remove static mixer tube and push the four static mixers (05271) out of tube.

4. Thoroughly clean mixers and mix tube with solvent.

5. On the ram adhesive units close the air ball valve (09350) to the pump.

6. On the ram adhesive units close the lockout ball valve (7702-2-2) to relieve air pressure from

the system.

7. On the Duo Link unit close the air ball valve to the pump

8. On the Duo Link unit close the lockout ball valve (7702-2-2) to relieve air pressure from the

system

9. Lift the relief valve on the flush tank lid to release flush tank pressure.

10. Install night cap plug (HOD-1002) to the front of the dispensing head.

NOTE: Do not leave barrel piston in 55-gallon drum if the system will be idle for more then two

weeks.

Page 6

Parts Drawing Section:

APD-1010 Assembly – Frame Work Ram Cylinder

APD-1000-ADH Frame Work Ram Cylinder assembly

Page 7

MAGNUM VENUS PRODUCTS

ASSY - FRAME WORK RAM CYL.

APD-1010

REV - 09/08/05 BT2

EXISTING RAM

POST

3

1

2

4

5

6

7

7

8

Page 8

ASSY - FRAME WORK RAM CYL. APD-1010

ITEM

PART NO. QTY

DESCRIPTION

PARTS LIST

6

09068 1

VALVE BRACKET

3

09343 1

BALL OPERATOR

2

09321 1

NORMALLY OPEN VALVE

1

APD-1009

1

MOUNT BRACKET

7

MPH-2534

2

POLY ELBOW

5

F-CS-832-04

2

CAP SCREW

4

F-CS-05C-20 2

CAP SCREW

8

APD-1011 1 SHAFT COLLAR

Page 9

5

43

36

21

39

44

41

41

33

RESIN PUMP (REF)

46

59

60

616263

6163 62

58

57

REV. A= ITEM 8 WAS 02805-16, ITEM 46 WAS 00404, DELETED ITEMS 42 (PF-HP-04) AND ITEM 51 (F-CS-05C-20) 4/23/07 JEM

48

49

50

53

47

52

54

38

55

56

4

6

39

31

12

39

36

31

31

43

45

40

28

29

26

29

27

7

30

1

2

39

24

35

38

5

2

23

22

3

MAGNUM VENUS PRODUCTS

ASSY - FRAME WORK RAM CYL.

- 09/07/05 BT2REV.

20

11

DETAIL

& RAM EXTRACTION

BLEED OFF VALVE

APD-1000-ADH

BARREL PISTON (REF)

8

32

2011

16

18

17

38

5

14

13

43

Page 10

2

O-B-342 4

O-RING

3

02005

2

CYLINDER ROD SEAL

4

02007 2

CYLINDER ROD WIPER

5

02576 10 WASHER

6

02668-18

8

SOCKET HEAD CAP SCREW

7

02685-24

18

SHOULDER BOLT

8

F-PH-832-28 2

PAN HEAD SCREW

11

06270

2

BARREL HOD DOWN KNOB

12

06271 2 CYLINDER ROD CLAMP COLLAR

13

06274 1

CHECK VALVE

14

CM-1005

1

BALL VALVE

16

PF-SW-04-04J-SS

1

SWIVEL ADAPTER

17

PF-HN-04-04J-SS 1

MALE CONNECTOR

18

PF-PT-04MMF-SS

1

FEMALE RUN TEE

20

APD-1005 2 BARREL CLAMP

21

APD-1003 2

SUPPORT ROD

22

60514-1

2

SUPPORT RING

23

60515-3 2

CYLINDER CAP

24

60517-1

2

LIFT CYLINDER PISTON

26

60519-11

1

BARREL PISTON

27

60519-13 1 TOP RING - BARREL PISTON

28

60519-5 1

BOTTOM RING - BARREL PISTON

29

60520-1

2

SEAL - BARREL PISTON

30

60521-1 18

SPACER - BARREL PISTON

31

APD-1004

2

CYLINDER ROD

32

APD-1001

1

FRAMEWORK LIFT CYLINDER

33

60533-1 1

SUPPORT PANEL

35

60539-1 2

MOUNT BRACKET - MANIFOLD

36

APD-1002

1

WELDMENT - SUPPORT BAR

38

F-HB-04C-12 8

HEX CAP SCREW

39

7201-1-12

8

HEX NUT

40

F-HN-832

2

HEX NUT

43

7701-6-2 5

POLY ELBOW

44

PF-HN-04TS-04 3

POLY CONNECTOR

45

06275

1

ROTARY VALVE

46

MPM-2568

1

BREATHER VENT

47

APD-1009

1

MOUNT BRACKET

48

APD-1011 1

SHAFT COLLAR

49

09321 1

NORMALLY OPEN VALVE

50

09343 1

BALL OPERATOR

52

F-CS-832-04

2

CAP SCREW

53

09068

1

VALVE BRACKET

54

MPH-2534 2

POLY ELBOW

55

60534-1 1

SUPPORT HOOK

58

PF-SE-04-SS

1

STREET ELBOW

59

APD-1007

1

MOUNTING BRACKET

60

6101-4-01

1

FLUSH TANK BRACKET

61

F-HB-06C-16 4

HEX BOLT

62

F-SW-06 4

LOCK WASHER

63

F-HN-06C 4 HEX NUT

57

MPM-2052-1 20 FT. TUBE

41

F-HN-04C-12 8

HEX NUT

56

APD-1010 1

RAM LIMIT VALVE ASSY

ITEM

PART NO. QTY

DESCRIPTION

OPTIONAL PARTS & ASSEMBLIES

ASSY - FRAME WORK RAM CYL. APD-1000-ADH

1

F-LN-05C

8

LOCK NUT

ITEM

PART NO. QTY

DESCRIPTION

PARTS LIST

Page 11

Corporate Headquarters/Manufacturing

5148 113th Ave.

Clearwater, FL 33760 USA

Ph: (727) 573-2955

Fax: (727) 571-3636

MVP Technology Center

1862 Ives Ave.

Kent, WA 98032 USA

Ph: (253) 854-2660

Fax: (253) 854-1666

E-mail: info@mvpind.com · Web: www.mvpind.com

MAGNUM VENUS PLASTECH

Loading...

Loading...