Page 1

High Volume

Modular System

MAGNUM VENUS PRODUCTS Part No. 90079-1

Operations Manual

Page 2

This page intentionally blank

Page 1 of 25

Page 3

Table of Contents

High Volume Modular System Manual

CHAPTER 1 - OPERATIONAL DATA

CHAPTER 2 - MATERIALS

Resin

Catalyst

Glass-Fiber Roving

Solvent

Air

CHAPTER 3 - START-UP, RUNNING AND SHUT-DOWN PROCEDURE

Start-Up

Priming Procedure (Resin)

Priming Procedure (Catalyst)

Shut-down Procedure

Removing Materials from System

CHAPTER 4 - PARTS DRAWINGS

Page 2 of 25

Page 4

CHAPTER 1

OPERATIONAL DATA

In order to function at maximum performance level, the High Volume Modular system requires

an air source capable of providing 35 CFM of clean, dry air, at 100 PSI. The air supply hose to

the unit must be kept as short as practical and be no less than ½” inner diameter to assure an

adequate air supply. Clean, dry air is essential to give the best service life of the power head

and chopper motor. Consult your local representative or Magnum Venus Products directly for

air requirements if you feel your operation may need more detailed information.

Page 3 of 25

Page 5

CHAPTER 2

MATERIALS

Selection of proper materials and the use of them can make the difference between success

and failure, with this or any other equipment. Your local distributor can assist in proper

selection for the best results. The following generalities should be followed.

RESIN should be formulated for gun use with proper promoters for MEKP. Also, with

Thixotropic characteristics and relatively low viscosity for fast impregnating. Resin should be

stored at about 70 to 75 degrees Fahrenheit (21 – 30 degrees C) before using. Resin at 85

degrees F (30 deg. C) will allow the equipment to perform better, minimize the variations and

control problems, speed up impregnation, and improve quality of products. Solid additives

which are introduced into resin for any purpose (such as flame retardation or thixotropic

properties) invariably increase the wear factor on internal moving parts in the resin pump.

More frequent replacement of these parts must be considered as part of the cost of using such

additives. It may be necessary to use special parts in the system such as carbide needles and

seats or heat-treated pump cylinders with modifications of the piston area to help lengthen the

life of the parts.

CATALYST should be Methyl Ethyl Keytone Peroxide of strength to give proper gel times for

products made with percentages of ¾ to 3% on standard equipment. This range is ½ to 1 ¼ %

on high volume units. A factory-tinted catalyst, for visual control purposes, is recommended.

This can be obtained from the peroxide manufacturer. Failure of the equipment (unless other

problems) is generally the result of trying to add tinting materials. Never use solvents to

clean the catalyst system as it forms unstable peroxides. Use only clear water.

GLASS FIBER ROVING should be made for spray-up roving cutters and with a soft, non-static

treatment. The Magnum Venus Hydraulic systems do not have a high pressure air blast that

causes the fibers to tumble and float all over, as with air aspirated guns, hence the softer the

treatment, the better the glass pattern. If treatment is too hard, fibers lay in clumps, the pattern

is narrow and it is difficult to attain uniformity and good impregnation.

SOLVENT The High Volume Modular unit is composed of parts and material lines compatible

to Acetone and solvent replacements . NOTE: Certain reclaimed solvents could affect

systems in such a way as to nullify the warranty.

AIR must be clean and dry. Moisture or oils in air supply may damage various components of

this system as they would any other machinery.

Page 4 of 25

Page 6

CHAPTER 3

START-UP, RUNNING AND SHUT DOWN PROCEDURE

The Magnum Venus Products High Volume Modular System is the ultimate in spray-up

equipment. This instruction manual, the Trouble-Shooting guide and the Parts Drawing

Package should be read thoroughly and used as a reference when working with your Magnum

Venus System. We have tried to note when differences occur, but suggest you contact

Magnum Venus Products or it’s nearest representative if performance of your particular

Magnum Venus Products system is not satisfactory following these instructions.

START-UP

These steps should be followed when unit is new, recently repaired, or has no material in

system:

1. Read and become familiar with Manual, Trouble-shooting Guide and drawings for

your particular unit, and all other operational aids provided with unit.

2. Check all fittings for proper connection.

3. Fill resin pump cavity (center section) approximately 1/3 full using Throat

Seal/Lubricant (TSL-XX).

4. Turn all regulators counter-clockwise so gauges will read 0 (zero) when air is

connected to system.

5. Open catalyst Recirculation valve on the Catalyst Manifold.

6. Pull bottom quick pin from Pivot Link Assembly (part number UPS-3104-01).

NOTE: This will allow resin pump to stroke but prevent catalyst pump from pumping

during start-up procedure. It should be general procedure to never have the catalyst

pump connected except when spraying a laminate.

7. Attach air source to manifold fitting. Open main air inlet ball valve.

NOTE: ½” diameter (minimum) air hose should be used for maximum efficiency.

8. Remove top from flush tank and fill with clean suitable solvent. Replace tank top.

9. Slowly bring flush regulator up to 40 PSI (turn clockwise).

NOTE: Flush tank pressure should never be higher than 60 PSI.

10. Open flush air control valve.

11. Remove nozzle, nozzle cap, turbulent mixer and mix chamber from gun.

12. Push solvent button on gun until solvent exits gun nozzle.

13. Open gun by pulling gun trigger. Aim gun into suitable container and keep gun open

during priming procedure.

PRIMING PROCEDURE (RESIN)

NOTE: The High Volume system should be connected to a Bulk Feed Resin System. MVP

Recommends a 2” Y-filter and ball valve on the Resin Inlet.

1. Open resin pump air valve and slowly turn resin pump regulator clockwise until resin

pump is stroking slow, even strokes (approximately 1 to 10 PSI). On systems with

Page 5 of 25

Page 7

air supply override valves you must press and hold the priming button before the

pump will move.

NOTE: as resin enters pump you may have to increase PSI slightly in order to maintain

even pump stroke. Observe gun to make sure resin is exiting evenly with no air

inclusion.

2. Shut off air to resin pump by either turning regulator to zero or turning pump air

control valve to off position.

3. Close gun and flush into appropriate container for approximately 2 seconds.

NOTE: Flush by pushing solvent button on side of gun.

4. Repeat opening of gun and aim into appropriate container for catalyst priming. Keep

gun open during priming procedure.

PRIMING PROCEDURE (CATALYST)

1. Slowly fill 2-gallon catalyst jug with MEKP (never dilute catalyst for Magnum Venus

system).

NOTE: See catalyst manufacturer for proper MEKP formulation for your particular

operation.

2. Check to make sure catalyst recirculation valve is open. Open if needed.

3. Remove quick pin from pivot link assembly.

4. Loosen catalyst packing nut slightly to hand prime.

5. Slowly with steady, even strokes, hand pump catalyst pump using rail assembly.

Stop hand priming when steady stream of catalyst exits gun. Close gun and flush

for approximately 2 seconds.

6. Reinstall quick pin into pivot link assembly.

7. Close catalyst recirculation valve on the catalyst manifold.

8. Retighten packing nut. Snug tight only.

9. Slowly open resin pump air valve and slowly turn pump regulator to 15-20 PSI.

Resin and catalyst pump will stroke until system is full. On systems with air supply

override valves you must press and hold the priming button before the pump will

move. Check all fittings for leaks.

10. System is ready for use.

NOTE: Always remember to turn off regulator and slowly open gun trigger to bleed

system fluid pressure before any disassembly or repair takes place.

SHUTDOWN PROCEDURE

1. Turn resin pump and chopper regulators to zero. Turn resin pump air valve to off

position.

2. Open catalyst recirculation valve on the catalyst manifold.

3. Pull quick pin from pivot link assembly.

4. Remove nozzle, nozzle cap, turbulent mixer and mix housing and injector assembly

from gun head. Clean parts and set aside. Inspect for wear.

5. Aim gun into container and pull trigger until flow of material becomes small trickle.

Release trigger.

6. Push flush button to flush gun head.

7. Check water trap.

8. Check pump packings for leaks. Resin leaking into oil reservoir in center section

cavity indicates packings need tightening or replacement.

Page 6 of 25

Page 8

9. Turn main air valve off.

10. Relieve flush tank pressure until all air has exhausted from flush tank.

REMOVING MATERIALS FROM SYSTEM

NOTE: Remove fluid pressure before performing maintenance or disassembly.

1. Disconnect resin pump from bulk resin system and allow to drain. Place inlet in

solvent or fill bulk system with solvent.

2. Aim gun into container and open gun by pulling trigger. Keep trigger open.

3. Open resin pump air valve and turn regulator until pump begins to stroke even, slow

strokes.

4. When clean solvent exits gun, shut off regulator.

5. Place container under resin pump accumulator and slowly unscrew the accumulator.

6. Clean resin accumulator with solvent.

7. Reinstall accumulator.

8. Resin system can now be broken down for maintenance. Refer to Manual, Troubleshooting Guide and Parts Drawings for proper maintenance. Refer to page 30 of

Trouble Shooting Guide for filled system procedure and pages13 & 14 for long

period shutdown procedure.

Page 7 of 25

Page 9

CHAPTER 6

PARTS DRAWINGS

Page 8 of 25

Page 10

1

35

38

33

3

32

55

6

34

35

5

10

30

8

46

13

31

44

45

7

12

2

34

9

28

30

22

28

45

37

31

46

8

44

13

30

12

11

30

9

15

30

29

56

28

14

29

30

42

28

56

19

57

58

58

21

21

L

59

USE REMOVABLE LOCTITE ON THESE THREADS AT ASSEMBLY

L

TM

61

60

37

11

62

26

3

57

65

66

63

G = ADDED ITEMS FOR MPH-2542 RESET ASSY 3/25/03 JEM

63

H = REMOVED APP-9096, APP-9109, & APP-9102 FROM ASSY 6/10/03 JEM

L

L

23

18

23

J = ITEM 18 WAS 3 PIECES, (2) MPH-2519, & MPH2408 11/24/03 JEM

L

L

SHOWS ORIENTATION OF ITEM 11, (MPH-2512), SEAL GUIDE.

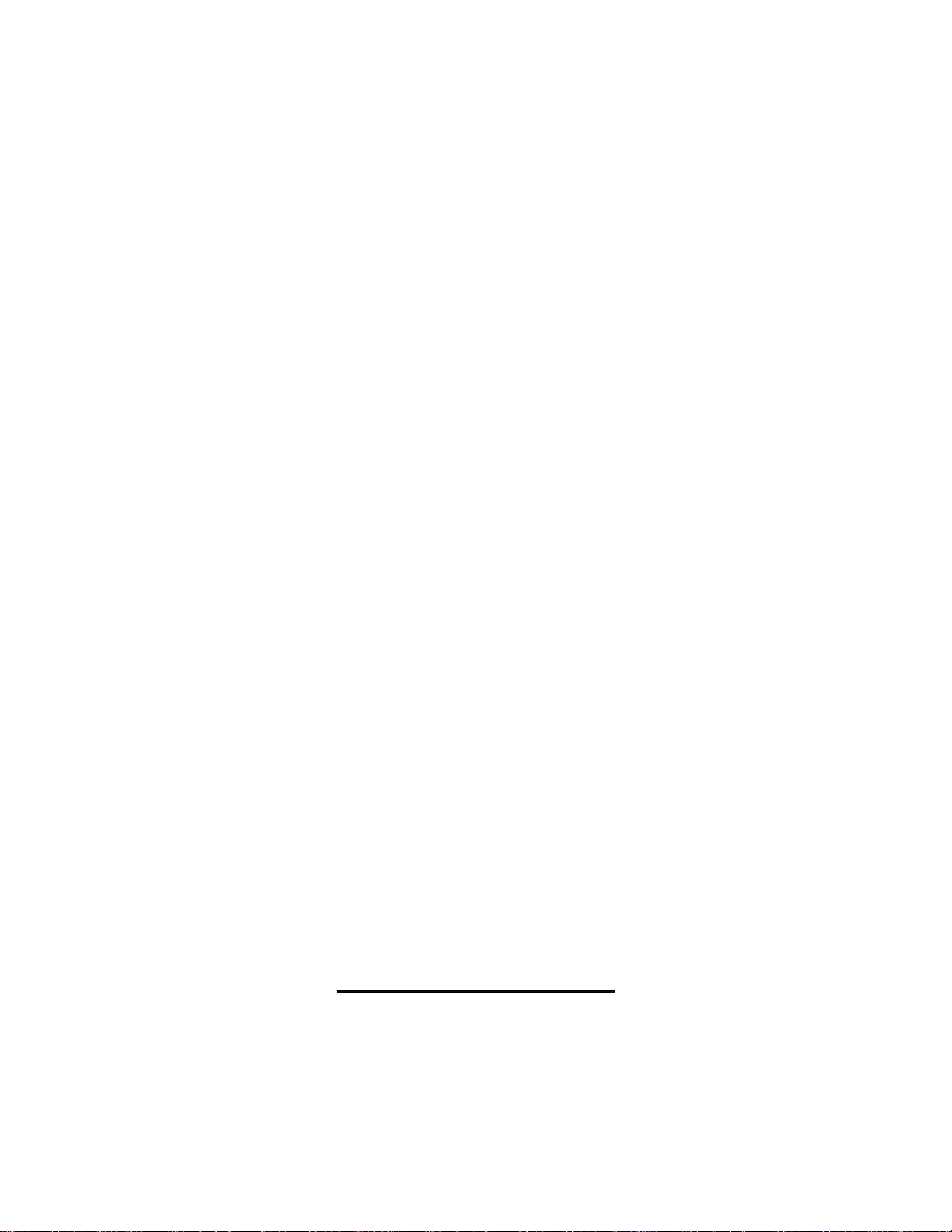

Assembly - 7" Power Head 4" Stroke

MAGNUM VENUS PRODUCTS

REV.

VPH-7000

41

4

41

26

16

24

19

39

40

20

47

43

24

16

42

62

27

39

47

25

20

40

25

42

48

51

49

50

36

36

Page 9 of 25

Page 11

56

O-B-011 2

O-RING

57

PF-AP-02-SS 2

PIPE PLUG

58

F-FW-04 2

FLAT WASHER

MPH-7000-SK

REPAIR KITS

PART NO.

*

SEAL KIT

DESCRIPTION

*

COMPONENTS INCLUDED WITH SEAL KIT.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

59

PF-HN-08-08S

1

ADAPTER

62

MPH-3262 2

PISTON STOP

60

2104-4-1

4

TIE ROD

61

F-HB-06C-24-GR8

4

GR 8 HEX BOLT

PARTS LIST

ITEM

PART NO. QTY

DESCRIPTION

63

00276 1

TEE FITTING

64

MPH-2546-01

1

VALVE STEM ASSY

65

MPH-2545 1

SEAL

66

MPH-2542 1

RESET BUTTON ASSY

OPTIONAL PARTS AND ASSEMBLIES

PARTS LIST

ITEM

PART NO. QTY

DESCRIPTION

DESCRIPTION

PART NO.

ITEM

PARTS LIST

QTY

Assembly - 7" Power Head 4" Stroke VPH-7000

FIGURE 1-1

1

MPH-7004 1

PISTON - 7" PUMP

2

VPH-7001 1

CYLINDER - 7" PUMP X 4" STROKE

3

VPH-4259 1

PISTON ROD

4

VPH-5004-01

1

MUFFLER ASSY - 4" STROKE PUMP

5

VPH-4254 1

PISTON ROD BUSHING

6

MPH-7002

1

LOWER ENDCAP - 7" PUMP

7

MPH-7001

1

UPPER ENDCAP - 7" PUMP

8

MPH-2541

2

INLET SPRING HOUSING - PILOT VALVE

9

MPH-2511-01

2

ASSY - STEM SEAL

10

O-B-121 1

O-RING

11

MPH-2512 2 SEAL GUIDE

12

MPH-2513 2

VALVE STEM - PILOT VALVE

13

MPH-2540 2 INLET ROD - PILOT VALVE

14

VPH-5001 1

UPPER VALVE BLOCK - 4" STROKE PUMP

15

MPH-5001 1

LOWER VALVE BLOCK

16

MPH-2517 2

VALVE PISTON

18

MPH-5005

1

VALVE POPPET

19

MPH-2521

2

VALVE END CAP

20

MPH-5009

2

VALVE EXHAUST

21

O-B-019

2

O-RING

22

VPH-5003 5 TIE ROD 4" STROKE PUMP

23

O-U-206-90

2

O-RING

24

O-B-116 2

O-RING

25

O-B-026 2 O-RING

26

O-D-010-90 2

O-RING

27

O-B-125 1

O-RING

28

O-B-008 4

O-RING

29

O-B-O14 4

O-RING

30

O-B-012

6

O-RING

31

O-U-006 2

O-RING

32

O-B-118

1

O-RING

33

O-B-439 1 O-RING

34

O-B-167

2

O-RING

35

O-B-431 2 O-RING

36

F-HB-04C-56-SS 2 HEX HEAD CAP SCREW

37

F-HN-06F 10 HEX NUT

38

F-HBFT-08C-20-GR5 1

HEX HEAD CAP SCREW

39

F-CS-04C-40-SS 4 SOCKET HEAD CAP SCREW

40

F-CS-04C-08-SS 4

SOCKET HEAD CAP SCREW

41

F-SW-04-SS 2

LOCK WASHER

42

F-SS-832-02-SS 4

CUP POINT SET SCREW

43

F-BHCS-04C-16-SS

1

BUTTON HEAD CAP SCREW

44

MPH-2526 2

SPRING

45

MPH-2528

2

SPRING

46

MPH-2533

2

SPRING

47

MPH-5010 2 DIAPHRAM

48

PF-AP-04-SS

1

PIPE PLUG

49

MPH-2539 1

PUSH POLY FITTING - MALE ELBOW

50

MPH-2538 1 PUSH POLY FITTING - MALE TEE

51

01417 .56ft

Ø1/4 x 6-3/4 POLY TUBING - NATURAL

55

MPH-3261 1

SNAP - RING

Page 10 of 25

Page 12

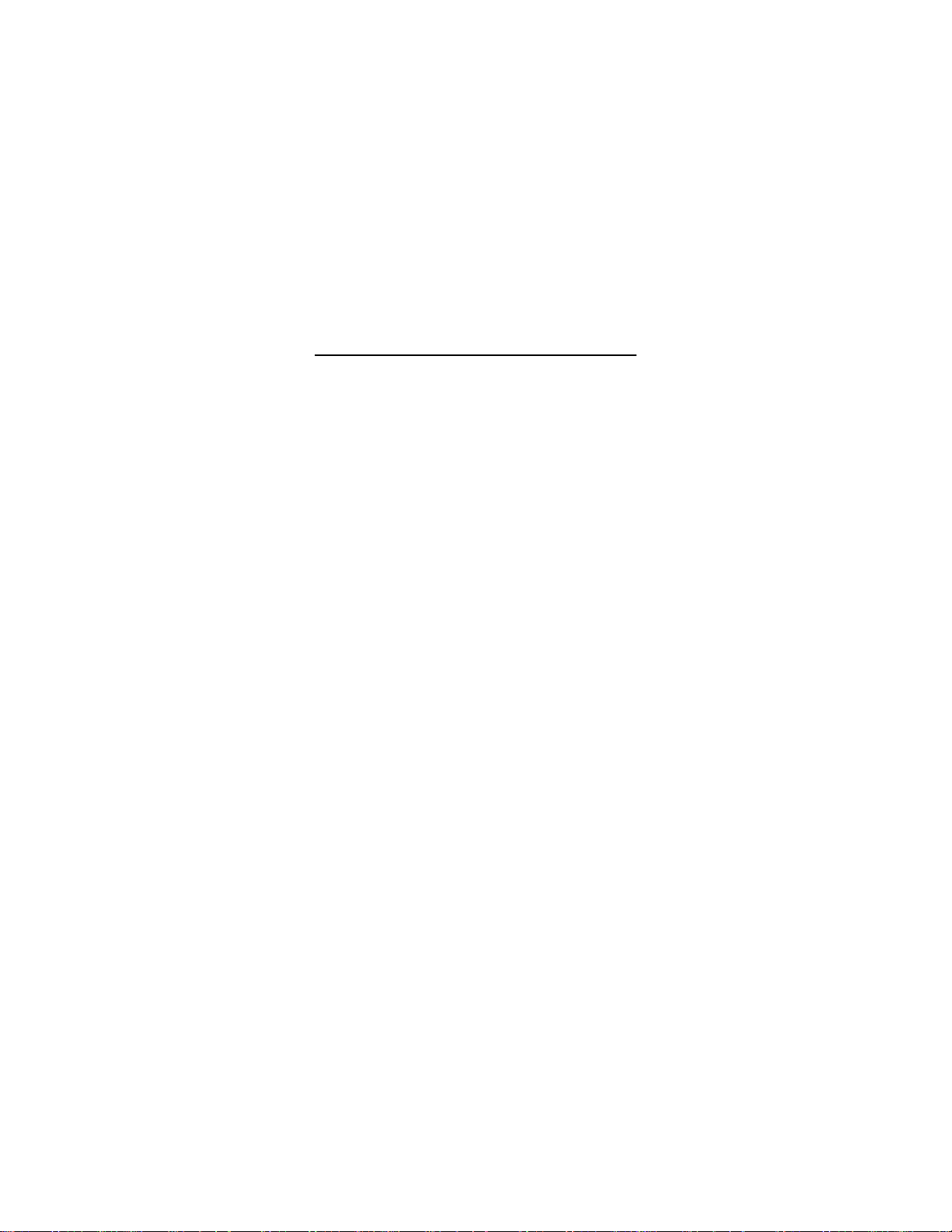

Modular HV Fluid Section Assy

MAGNUM VENUS PRODUCTS

REV. A = ITEM 21 WAS 68310-1, ITEM 27 WAS 86520-1 5/2/03 JEM

HVLS-1000

2

1

3

12

5

6

7

8

10 (REQ)

10

9

9

9

9

25

24

11

11

17

16

15

23

29

29

29

29

4

26

15

22

14

21

27

14

28

20

13

30

19

19

19

18

B = ADDED OPTIONSL ITEMS AND SEAL KIT 7/3/03 JEM

Page 11 of 25

Page 13

86530-1

28

PISTON NUT

1

86520-3

27

SPACER RING

1

86510-1

26

PISTON ADAPTER

1

86420-1

25

FOOT VALVE COLLAR

1

86400-1

24

CYLINDER

1

86390-1

23

PISTON BODY

1

68310-3

22

BACK UP RING

1

67110-1

21

FEMALE PACKING RING

1

7101-2-12

20

HEX CAP SCREW

4

3101-8-1

19

PISTON ROD ADAPTER

1

04309-1

18

BALL STOP

1

04072-1

17

PISTON BALL SPRING

1

03604

16

BALL

2

02181-1

15

PISTON CUP

2

02158-4

14

PACKING SET

1

01621

13

O-RING

1

01611

12

O-RING

2

00714

11

ELBOW

1

7201-6-8

10

HEX NUT

4

HVLS-1009

9

WAVE SPRING

10

8

HVLS-1007

7

BALL GUIDE

1

HVLS-1006

6

GUIDE BEARING

1

HVLS-1005

5

SPRING SUPPORT RING

1

HVLS-1004

4

DISPLACEMENT ROD

1

HVLS-1003

3

PACKING NUT

1

HVLS-1002

2

PUMP MOUNT PLATE

1

HVLS-1001

1

OUTLET BODY

1

DESCRIPTION

PART NO.

ITEM

PARTS LIST

QTY

Modular HV Fluid Section Assy HVLS-1000

TIE ROD

86540-1

29

4

MALE PACKING RING

1

87090-1

86370-1

1

FOOT VALVE BODY

30

21A

68310-1

1

HARDENED BACK-UP RING

OPTIONAL PARTS AND ASSEMBLIES

PART NO.

ITEM

DESCRIPTION

QTY

HVLS-1000-SK

SEAL KIT

DESCRIPTION

REPAIR KITS

PART NO.

*

*

*

*

*

ITEMS INCLUDED IN SEAL KIT

24A

86401-1 1

HARDENED CYLINDER

27A

86520-1 1

HARDENED SPACER RING

Page 12 of 25

Page 14

Page 13 of 25

Page 15

Page 14 of 25

Page 16

MAGNUM VENUS PRODUCTS

A = CHECK VALVE ASSY WAS OMITTED FROM DWG, VHPC-4200 & VHPC-4200-RV 8/14/02 JEMREV.

2

3

5

6

7

8

9

8

11

12

13

14

15

16

17

1

18

17

10

4

Assy - C42 Catalyst Pump

VHPC-4200-C-3J

19

21

22

23

17

11

20

24

Page 15 of 25

Page 17

ASSY - C42 CATALYST PUMP VHPC-4200-C-3J

Note:

figure 1-1

one flat on hex as shown in

Offset intake and outlet ports

FIGURE 1-1

VHPC-4200-SK

PART NO.

COMMON ASSY PARTS LIST

DESCRIPTION

PART NO.

ITEM

QTY

DESCRIPTION

SEAL KIT

REPAIR KITS

INLET TUBE FITTING

PACKING SET ASSY

PISTON ROD SLEEVE

PISTON ROD SPRING

10

18

16

17

13

14

15

12

11

7

9

8

6

5

2

4

3

104013-1

6701-24-EN

O-S-013

4101-8-1

51050-1

1

1

3

1

9201-1-7

02014

50530-1

03072

50440-1

1

1

1

2

1

INLET BODY

O-RING

SEAL RETAINER

PISTON SEAL

PISTON BODY

7/32" SS BALL

9/16" SS BALL

7301-9-016

50820-1

50940-1

50730-1

02022-5

1

1

2

1

1

50360-1

50591-3

50630-1

1

1

1

CYLINDER

O-RING

LOCK NUT

OUTLET BODY

PISTON ROD

PACKING NUT

PUMP SEAL WARNING DECAL (NOT SHOWN)

CLEVIS

1VHPC-4201

19

9202-1-1

1

1

SPHERICAL BEARING

JAM NUT

SPRING RETAINER

CHECK VALVE BODY

COMPRESSION SPRING

4101-18-1

4101-17-1

4101-15-1

4101-16-1

24

20

23

22

21

1

1

2

1

25

VHPC-1001-3J 1

OUTLET FITTING

Page 16 of 25

Page 18

MAGNUM VENUS PRODUCTS

Ultra - Proportioner System

REV.

UPS-3100

2

RESIN

FLUID

SECTION

(REF)

4

7

10

11

12

14

15

17

18

19

20

20

21

22

26

24

25

25

27

28

28

29

29

30

31

32

33

34

35

35

35

36

37

36

38

23

16

B = ITEM 37 WAS F-BHCS-1024-06 11/18/02 JEM

C = ITEM 30 WAS F-LN-04C LOCK NUT 6/3/023 JEM

39

D = REPLACED 7203-8-1 QUICK PIN WITH NUT AND BOLT 10/28/03 JEM

Page 17 of 25

Page 19

OPTIONAL PARTS AND ASSEMBLIES

PART NO.

ITEM

DESCRIPTION

QTY

PARTS LIST

Ultra - Proportioner System UPS-3100

PART NO.

ITEM

QTY

DESCRIPTION

2

UPS-3102

1

MOUNT BAR

4

UPS-3103-01 1

CLEVIS BLOCK ASSY

7

UPS-3104-01 1

PIVOT LINK ASSY

14

UPS-3108 1

SPACER

11

UPS-3106-01 1

RH SIDE RAIL ASSY

17

UPS-3110 1

BACK END PIECE

15

UPS-3109-01 1

FRONT END PIECE ASSY

12

UPS-3106-02 1

LH SIDE RAIL ASSY

10

UPS-3105 1

CATALYST STUD BOLT

24

7203-1-1 1 HAIRPIN COTTER

23

9202-1-1 1

SPHERICAL BEARING

22

DUAL-2012 1 ADJUSTMENT KNOB

21

UPS-3114 1 TOP PLATE

20

UPS-3113 1 ADJUSTMENT SCREW

19

UPS-3112 1 ADJUSTMENT NUT

18

UPS-3111-01 1 PIN ASSY

25

APS-1016 2 QUICK PIN

26

UPS-3115 1

HAIRPIN COTTER

27

F-SB-08-20 1

SHOULDER BOLT

28

APS-1015 2

EXTERNAL SNAP RING

29

F-LN-06C 2 NYLOCK NUT

30

F-HN-04C 1 HEX NUT

31

F-CS-1024-06 1 SOCKET HEAD CAP SCREW

32

7101-2-12

2

HEX CAP SCREW

33

02885-12

1

SPRING PIN

34

F-CS-04C-32

1

SOCKET HEAD CAP SCREW

35

F-BHCS-04C-12

8

BUTTON HEAD CAP SCREW

36

F-BHCS-04C-06

2

BUTTON HEAD CAP SCREW

37

01218-4

1

BUTTON HEAD CAP SCREW

38

F-CS-06C-40

2

SOCKET HEAD CAP SCREW

16

F-AB-04F-19 1

AIRCRAFT BOLT

39 F-LN-04F

1

LOCK NUT

24

UPS-3101

1

RESIN DECAL

25

UPS-3116

1

GELCOAT DECAL

26

UPS-3117 1 HV DECAL

Page 18 of 25

Page 20

Page 19 of 25

Page 21

Page 20 of 25

Page 22

MAGNUM VENUS PRODUCTS

HV CHOPPER MANIFOLD ASSY

87014-1

1

2

3

4

5

6

8 9

8

9

10

11

12

12 12

12

13

13

22

22

15

23

16

24

24

17

18

21

26

14

14

REV. A = UPDATED FORM, ADDED ITEM 1, REMOVED ONE ITEM 17

AIR IN

12

14

16

16

7

19

20

25

27

24

B = REMOVED ON ITEM 14 1/28/05 JEM

Page 21 of 25

Page 23

23

8405-2-1 1 MINI REGULATOR

22

8405-1-1

2

REGULATOR

21

8404-1-1 1

FILTER

17

7701-3-12 1

NIPPLE

14

PF-HN-04-04S 2 ADAPTER

12

7701-3-1 5

HEX NIPPLE

4

6302-1-1 1

MANIFOLD BLOCK

3

09350 1 BALL VALVLE

1

00817

1

PIPE NIPPLE

8

7101-1-16 2 HEX CAP SCREW

7

6504-17-03.3

1

AIR HOSE ASSY

6

6504-16-04 1

AIR HOSE ASSY

5

6504-1-05 1

AIR HOSE ASSY

19

7701-7-1 1

FEMALE QUICK CONNECT

20

7702-2-2 1

BALL VALVE

13

7701-3-2

2

BUSHING

16

7701-3-7

3

ADAPTER

18

7701-4-3 1

PLUG

15

7701-3-5 1

BUSHING

24

8702-2-1 3 PRESSURE GAUGE

10

7701-1-1 1

ELBOW

PARTS LIST

HV CHOPPER MANIFOLD ASSY 87014-1

9

7201-6-4 2 HEX NUT

2

05819 1

BALL VALVE

11

7701-1-9 1

ELBOW

25

6701-7-EN 1

PUMP GAUGE DECAL

26

6701-8-EN 1

GUN GAUGE DECAL

27

6701-9-EN 1

FLUSH GAUGE DECAL

Page 22 of 25

Page 24

Page 23 of 25

Page 25

Page 24 of 25

Page 26

This page intentionally blank.

Page 25 of 25

Page 27

E-mail: info@mvpind.com Web: www.mvpind.com

Corporate Headquarters/Manufacturing

5148 113th Ave.

Clearwater, FL 33760 USA

Ph: (727) 573-2955

Fax: (727) 571-3636

Manufacturing/Sales

1862 Ives Ave.

Kent, WA 98032 USA

Ph: (253) 854-2660

Fax: (253) 854-1666

Page 26 of 25

Loading...

Loading...